Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

649 results about "Pyromellitic dianhydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyromellitic dianhydride (PMDA) is an organic compound with the formula C₆H₂(C₂O₃)₂. It is the double carboxylic acid anhydride that is used in the preparation of polyimide polymers such as Kapton. It is a white solid.

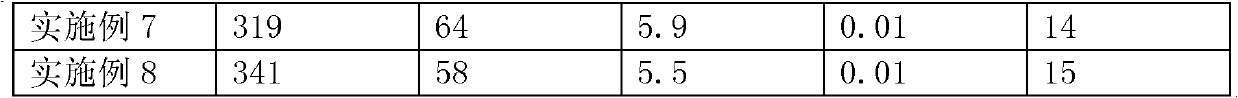

Pyromellitic dianhydride catalyst and preparation method thereof

InactiveCN102008971ASolve the problem of selectivityPhysical/chemical process catalystsOrganic chemistryAlkali metal oxideSlurry

The invention provides a pyromellitic dianhydride catalyst and a preparation method thereof, relates to a catalyst and the preparation method and solves the problems of low catalyst yield and low selectivity of the conventional gaseous oxidation method for preparing pyromellitic dianhydride. The catalyst consists of an active ingredients and a carrier, wherein the active ingredients consist of V2O5, TiO2, P2O5, Sb2O3 and alkali metal oxides. The method comprises the following steps of: 1, weighing; 2, adding an antimony source and a vanadium source into oxalic acid solution with stirring to obtain vanadyl oxalate solution; 3, adding a phosphorus source, the antimony source and alkali metal salt into the vanadyl oxalate solution, uniformly mixing, then adding a titanium source, adding polyvinyl acetate emulsion and then pulping and grinding to obtain size; and 4, adding the carrier into a revolving drum of spray painting equipment, heating and spraying the size on the carrier, putting into a Muffle furnace to carry out air purge and cooling to obtain the catalyst. The catalyst is used for catalysis and preparation of pyromellitic dianhydride.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

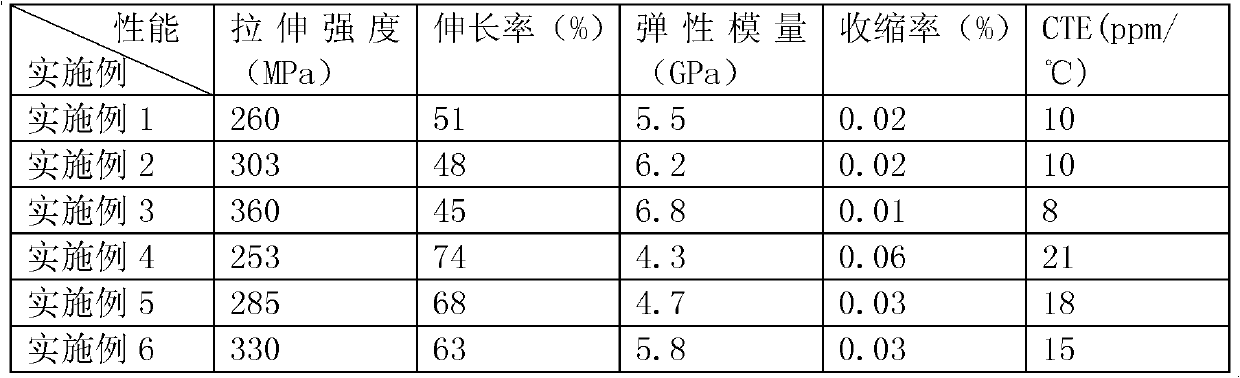

Dimensionally-stable polyimide film and preparation method thereof

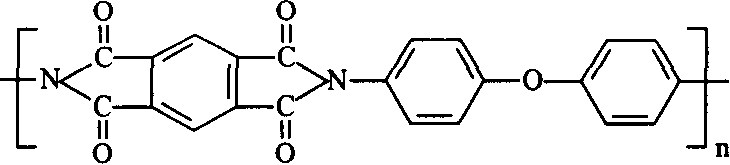

ActiveCN102558860ALow heat shrinkageSmall coefficient of thermal expansionDiaminodiphenyl etherPolymer science

The invention discloses a dimensionally-stable polyimide film and a preparation method thereof. According to the weight percentage, the polyimide film is manufactured by evenly mixing 40 to 80 percent of component A, 0 to 60 percent of component B and 0 to 60 percent of component C and then conducting slobbering and imidization according to a conventional process, wherein the component A is polyamide acid resin solutions obtained after 2-(4-aminophenyl)-5-amido-benzimidazole reacts with pyromellitic dianhydride (PMDA) or biphenyltetracarboxylic acid dianhydride (BPDA); the component B is polyamide acid resin solutions obtained after p-phenylenediamine (PDA) reacts with the PMDA; and the component C is polyamide acid resin solutions obtained after 4,4'-diaminodiphenyl ether (ODA) reacts with the BPDA and the PMDA. The polyimide film provided by the invention has the advantages of lower thermal shrinkage rate, lower thermal expansion coefficient, higher elastic modulus and higher tensile strength and reflects better dimensional stability. The whole preparation method is simple and is easy to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

Graphene modified polyimide-based composite and preparation method thereof

ActiveCN102911360AImprove conductivityImprove mechanical propertiesDiaminodiphenyl etherComposite film

The invention discloses a graphene modified polyimide-based composite which is characterized in that the graphene modified polyimide-based composite comprises the following components in parts by weight: 95-105 parts of 4,4'-diaminodiphenyl ether, 110-120 parts of pyromellitic dianhydride and 1-25 parts of graphene. A preparation method comprises the steps of weighing ODA (octyl decyl adipate) and the graphene in proportion, measuring a DMAC (dimethylacetamide) solvent, adding the ODA, the graphene and the DMAC solvent to a reaction vessel, using ultrasonic till the ODA is dissolved sufficiently and the graphene is dispersed completely in the DMAC to obtain a graphene suspension, adding PMDA (pyromellitic dianhydride) in batches under high-speed stirring conditions till weak pole climbing appears, continuing to stir to allow diamine to react with dianhydride completely, and flattening an obtained graphene / PAA (poly acrylic acid) complex to obtain a composite film with uniform thickness so as to obtain a graphene polyimide composite film. The composite is 0.5 g / cm<3>-1.5 g / cm<3> in density and 60-170 KJ / m<2> in tensile strength.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Production technique of benzenetetracarboxylic dianhydride by catalyzing carrier-type polyoxometalates

InactiveCN101037439AOvercome the difficulties, high production costs and other shortcomingsEasy to recycleOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsFixed bedIndustrial equipment

The invention discloses a craft for producing pyromellitic dianhydride catalyzed by a carrier-type poly-oxometalate, including melting the pyromellitic dianhydride by the groove, feeding to the mixing machine for evapouration after pre-heating with a feed concentration of 15.0-19.5g / m3, mixing with the air, entering into the fixed bed reactor for a oxidation, oxidating with an airspeed of 4500-6500 h-1, cooling the produced air, then condensing in the collector, getting coarse pyromellitic dianhydride. At 300-340 DEG C, the catalyzer is mostly poly-oxometalate which is fixed on the catalyst bed after loading. The mass ratio of the catalyzer to pyromellitic dianhydride is 0.2-1%. The invention has the durene in the C10 heavy aromatics as raw material, produces the pyromellitic dianhydride by oxidation in air, makes the C10 heavy aromatics be with a higher added value, uses the current resource and industrial equipments as more as possible, exploits the catalysis and synthesis path of the pyromellitic dianhydride. The invention has a low pollution and production cost, a wide development prospect and is suitable for commercial process.

Owner:NORTHEAST NORMAL UNIVERSITY

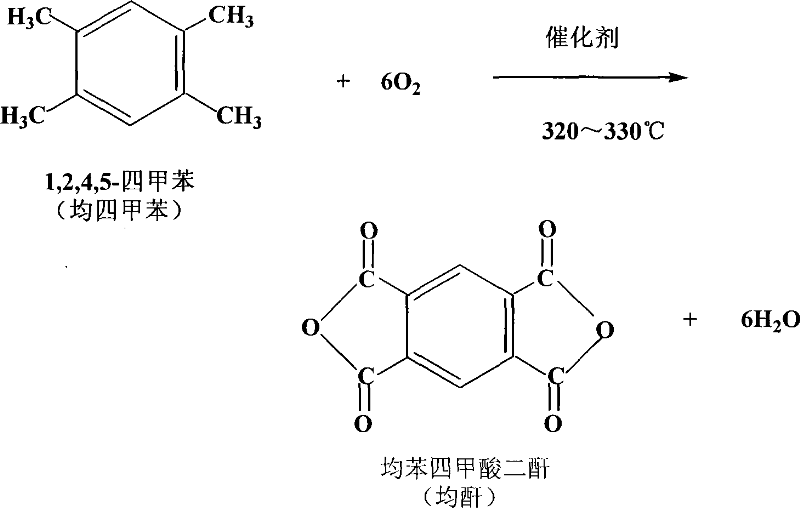

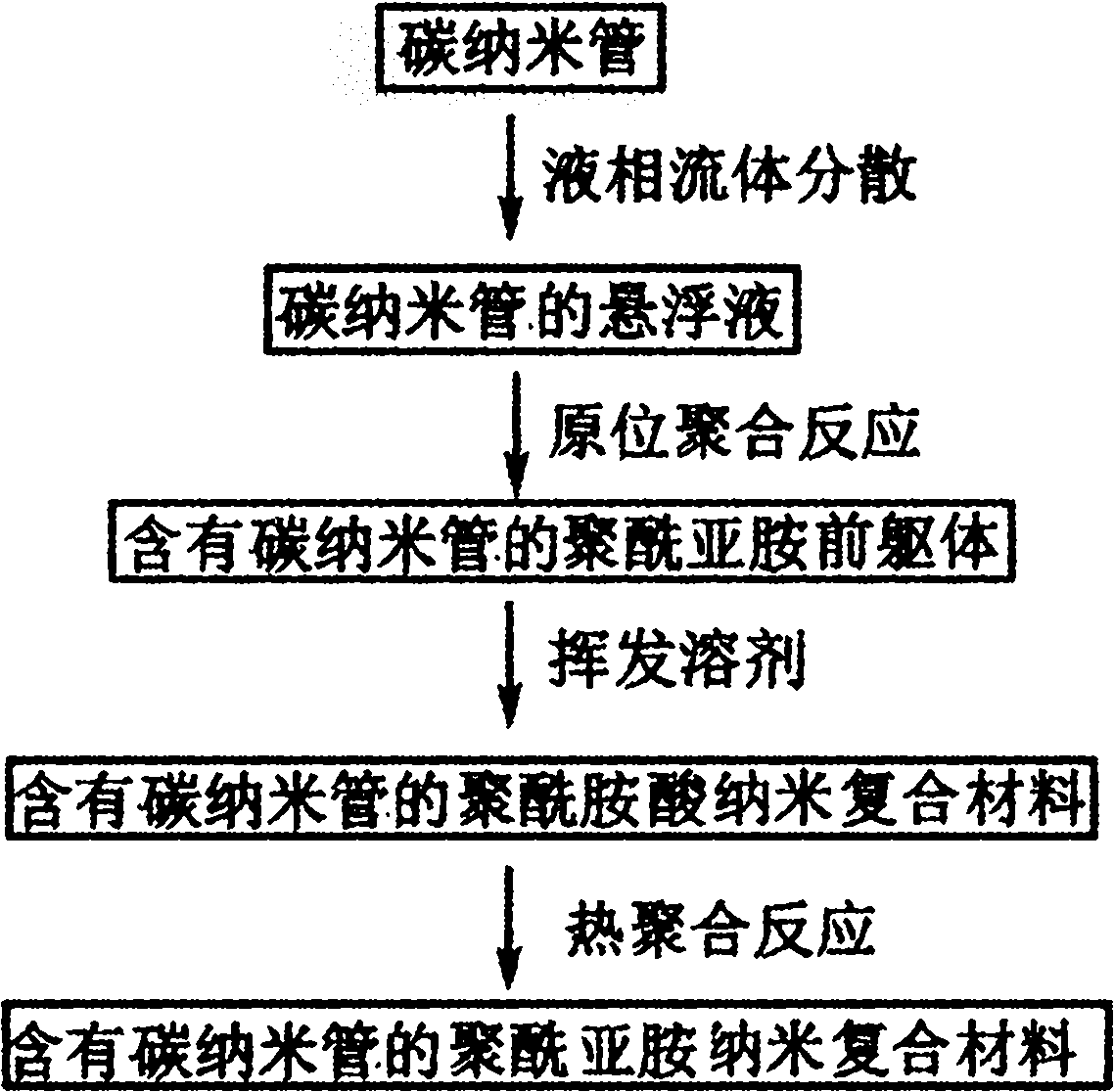

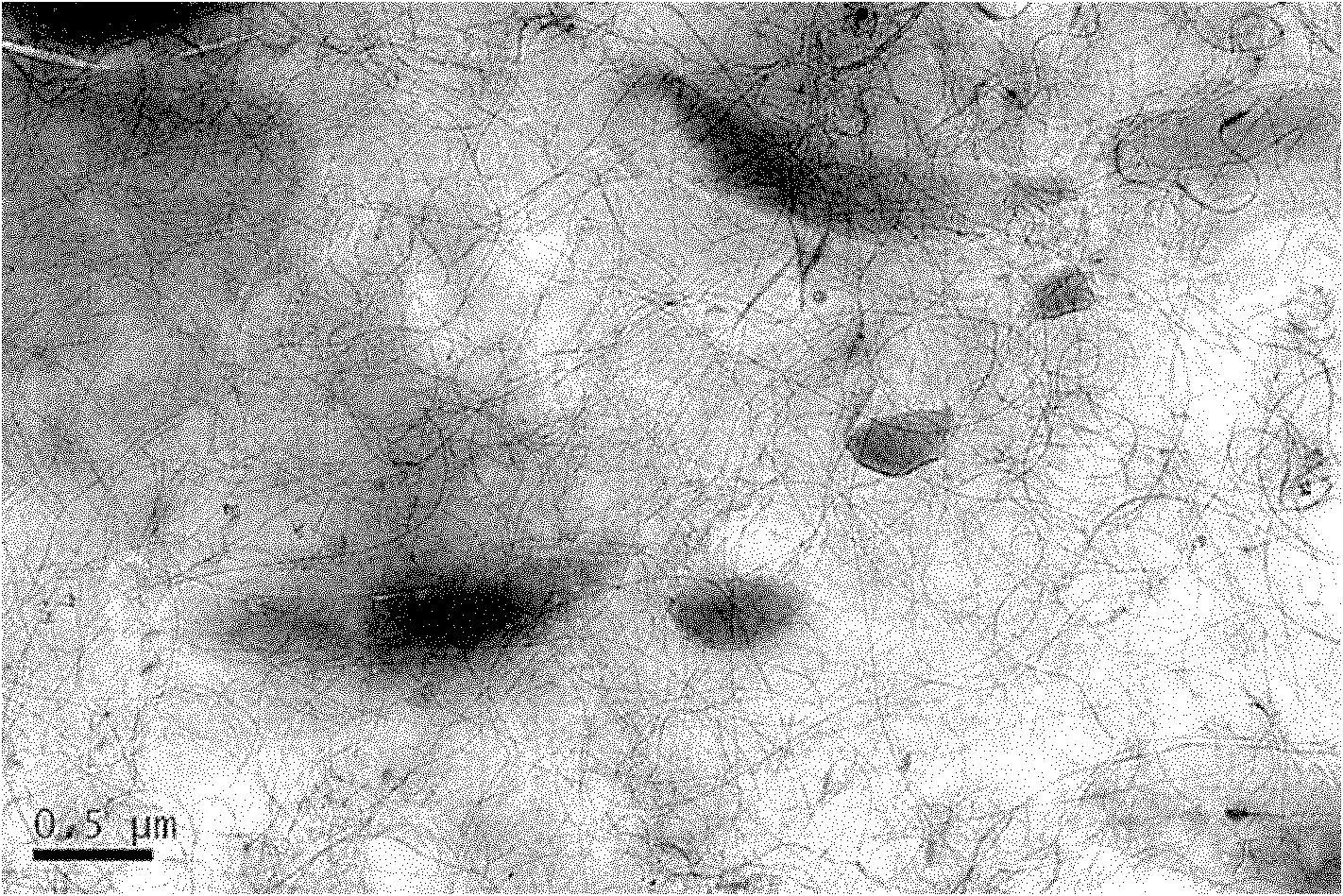

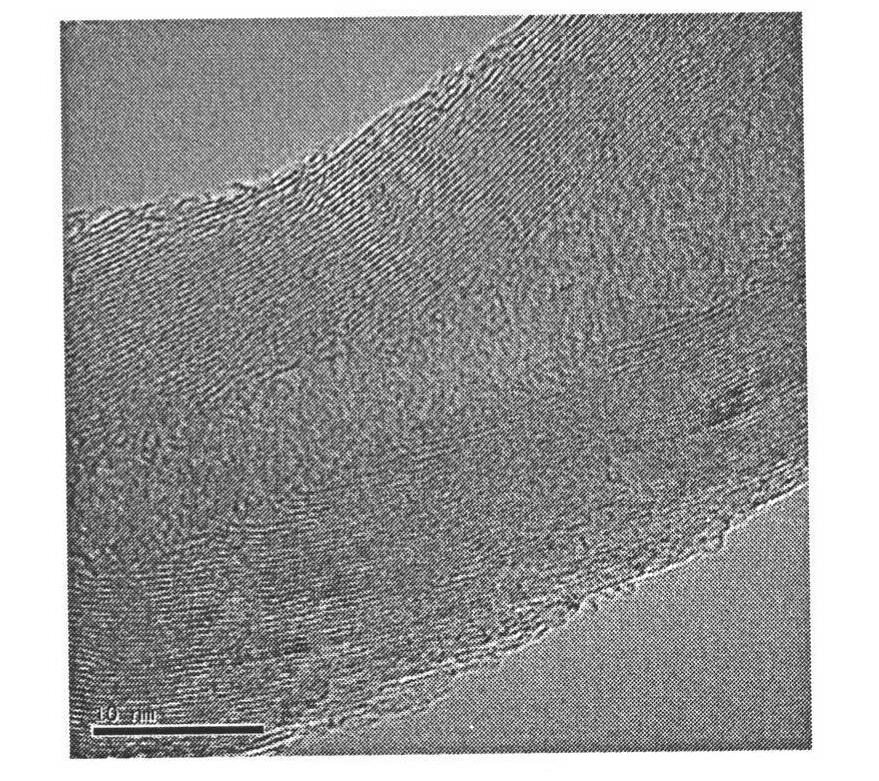

Preparation method of carbon nanotube reinforced polyimide nano composite material

ActiveCN102093715AImprove thermal stabilityIncrease contentMonocomponent synthetic polymer artificial filamentFiberImide

The invention relates to a preparation method of a carbon nanotube reinforced polyimide nano composite material, which comprises the following steps: carrying out liquid-phase shearing dispersion on 10-10000 micrometer long carbon nanotubes in an organic solvent; adding 4,4-diaminodiphenyl ether and pyromellitic dianhydride into the dispersed carbon nanotube slurry to carry out an in-situ polymerization reaction; and carrying out vacuum degasification to obtain a thin film or fibers, volatilizing the solvent, and carrying out heat treatment to obtain the carbon nanotube / polyimide nano composite material. By using the high-length-diameter ratio carbon nanotubes to provide interfaces for adequate slip of polyimide molecules and favorable interface combination, the composite material has excellent mechanical properties, thereby being hopefully applied to fields such as aerospace, automobiles, flexible substrates and the like.

Owner:TSINGHUA UNIV

Catalyst for preparation of pyromellitic dianhydride through durene oxidation

ActiveCN107866241AHigh activityImprove stabilityOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsLow activityActive component

The invention relates to a catalyst for preparation of pyromellitic dianhydride through durene oxidation. The catalyst mainly solves the problem that the existing pyromellitic dianhydride production catalyst has low activity, produces more by-products and leads product yield reduction. An oxide catalyst utilizes alpha-Al2O3, silicon carbide, a porcelain ring or a mixture thereof as a carrier, andan active component comprises at least one of a vanadium element, a titanium element, a group VA element and an alkali metal element. The catalyst solves the technical problem and greatly improves theyield of pyromellitic dianhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyimide fiber and its preparing method

InactiveCN1821457AOptimize synthesis conditionsGood mechanical propertiesMonocomponent synthetic polymer artificial filamentDiphenyl etherFiber

The present invention discloses a kind of polyimide fiber and its preparation process. The preparation process includes the following steps: 1. reacting 4, 4í»-diamino diphenyl ether and pyromellitic dianhydride in the weight ratio of 1 to 1.02 with N, N-dimethyl acetylamide solution of 15-20 % concentration at 0-5 deg.c to obtain polyamic acid solution; 2. wet spinning the polyamic acid solution and imidation reaction of the polyamic acid fiber to obtain polyimide fiber through dewatering and cyclization; and 3. mixing the polyimide fiber with acetic anhydride and triethylamide, flushing with acetone, soaking and drying to obtain the polyimide fiber. The present invention has positive effects of optimized synthesis condition of spinning solution, prolonged solidification period of initially formed fiber in the solidification bath, and fiber with ideal mechanical performance.

Owner:DONGHUA UNIV

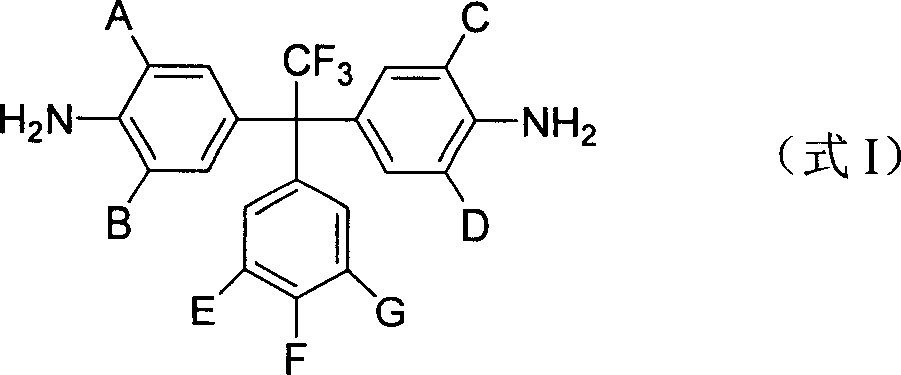

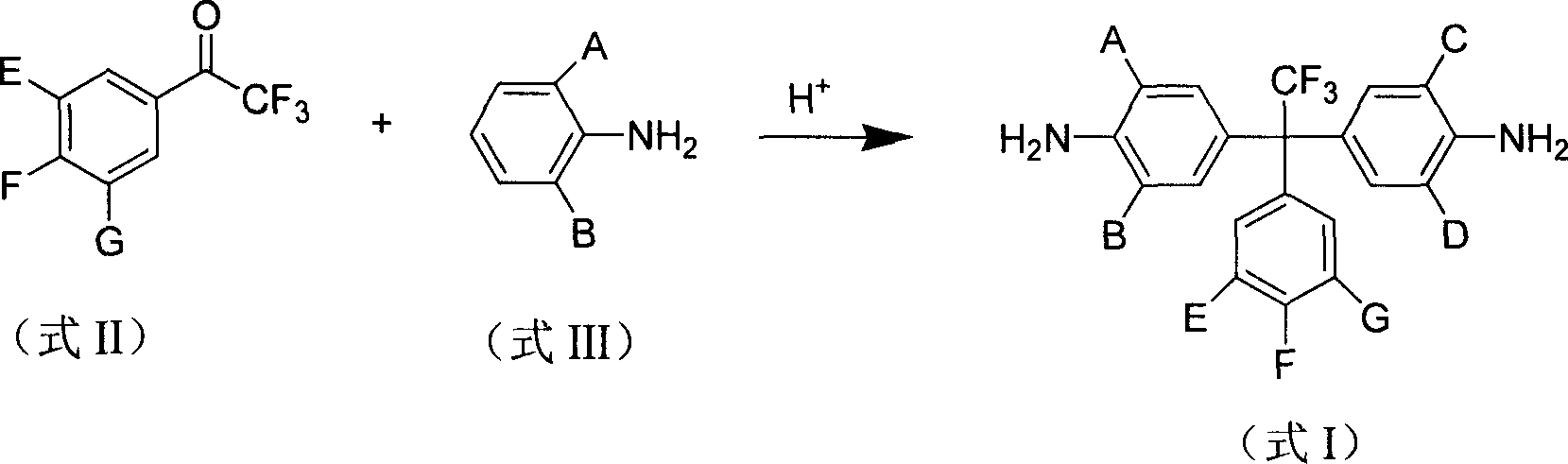

Intrinsical fluorinated photosensitive polyimide resin and its preparation method

The invention discloses an intrinsic-typed photoactive polyimide resin and making method, which is polycondensated by 3,3',4,4' -benzophenone pyromellitic dianhydride 40 with polyalkyl substituted aromatic methane diamine 20-42 as fluorine aromatic lateral group, wherein the carbon atom number of A, B, C and D in the formula I is 1-10; E, F, G is H atom or trifluoromethyl. The invention possesses superior solubility, which can be reserved for half year under indoor temperature and 18 months under 4 deg.c.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Corona-resistant polyimide film and preparing method thereof

ActiveCN101323672AImprove corona resistanceSimple preparation processDiphenyl etherPyromellitic dianhydride

The invention relates to a polyimide film with corona resistance, which essentially comprises pyromellitic dianhydride, 4.4' diamido-diphenyl ether and nanoscale metallic oxide; wherein, the particle size of the nanoscale metallic oxide is less than or equal to 50 nanometers. By adopting the technical proposal, the invention has the advantages as follows: as nanophase materials are adopted by the invention and the nanoscale metallic oxide and N, N' dimethylacetamide are prepared into stable and uniform suspended substance in a high-speed cutting and scatter, the product adopting the polyimide film with corona resistance produced in the invention has excellent performance of corona resistance, good production technology and high rate of finished products.

Owner:JIANGSU ICE CITY INSULATION MATERIALS STOCK

Method for preparing polyimide multilayer complex films containing inorganic nanometer powder

InactiveCN101812183AImprove mechanical propertiesSolve the shortcomings of insufficient mechanical propertiesDiaminodiphenyl etherPolyamic acid

The invention relates to a method for preparing polyimide multilayer complex films containing inorganic nanometer powder. Polyimide multilayer complex materials containing inorganic nanometer powder often reduce the mechanical property of films, and obviously reduce the property of the films especially when the nanometer powder is unevenly distributed. The method comprises the following steps of: (1) pre-processing the inorganic nanometer powder; (2) dissolving 4, 4'- diaminodiphenyl ether and pyromellitic dianhydride as raw material monomers into a solvent, and polymerizing to generate polyamic acid solution; (3) dispersing the pre-processed inorganic nanometer powder to the solvent through an ultrasound, and adding the solvent to the polyamic acid solution to prepare the polyamic acid solution containing the inorganic nanometer powder; (4) sequentially paving films on the polyamic acid solution containing the inorganic nanometer powder and the pure polyamic acid solution; and (5) putting the films in an oven for hot-imidization treatment at the temperature of 50 to 400 DEG C to obtain the polyimide hybrid multilayer complex films containing the inorganic nanometer powder. The invention is used for preparing the polyimide multilayer complex films containing the inorganic nanometer powder.

Owner:HARBIN UNIV OF SCI & TECH +1

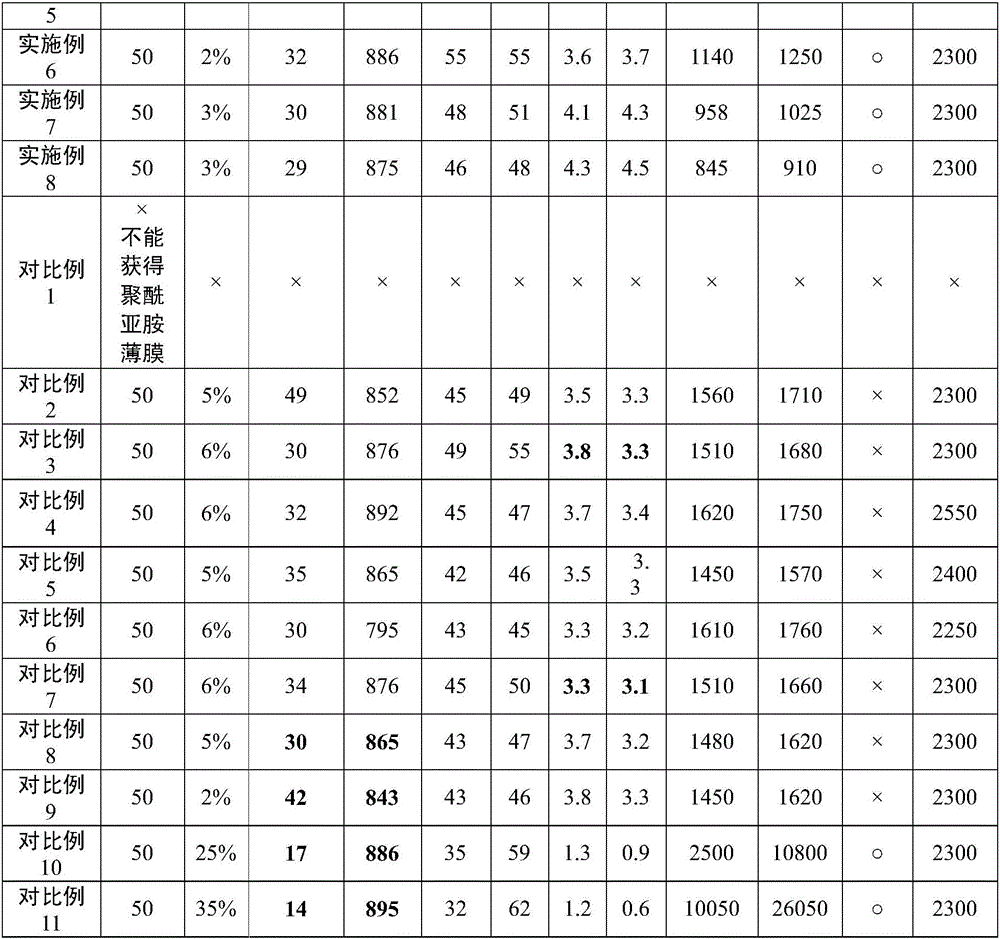

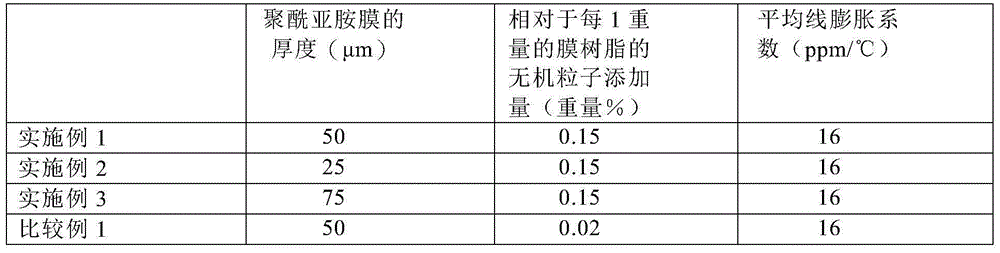

Polyimide thin film for preparing artificial graphite film and preparation method of polyimide thin film

The invention provides a polyimide thin film for preparing an artificial graphite film with excellent mechanical properties and a preparation method of the polyimide thin film. The polyimide thin film is prepared from a raw material diamine monomer which comprises 0 to 75 mol ratio of p-phenylenediamine; the raw material dianhydride monomer, comprises 40 percent to 100 mol ratio of of pyromellitic dianhydride; two types of inorganic fillers, including a calcium-containing compound and transition metal oxide, are uniformly dispersed in the polyimide thin film. The polyimide thin film provided by the invention is applicable to a graphitization process of single-sheet, multilayered stacking and continuous coiled materials and can be used for carrying out graphitization at temperature of 2300 DEG C; the crystallization degree is less than 10 percent. The graphite film prepared from the polyimide thin film has an excellent heat conducting property and has excellent mechanical properties in longitudinal and lateral directions of the thin film; the modulus is less than or equal to 2000MPa, the elongation at break is more than or equal to 3 percent, the tensile strength is more than or equal to 40MPa and the difference of the longitudinal and lateral directions is less than 15 percent.

Owner:RAYITEK HI TECH FILM CO LTD

Polyimide film for graphite sheet and manufacture method thereof

The invention provides a polyimide film. The film which is graphitized through heat treatment has good foaming. A sheet after graphitization has good thermal conductivity, softness and bend resistance. The polyimide film with a linear expansion coefficient less than 20ppm / DEG C is characterized in the polyimide film is made of raw materials containing p-phenylenediamine, or p-phenylenediamine and 4, 4'-diamino diphenyl ether, and at least one anhydride selected from pyromellitic dianhydride and 3,3',4,4'-biphenyltetracarboxylic anhydride. The graphite sheet is manufactured through thermal treatment of the polyimide film in which inorganic particles at the temperature more than 2000 DEG C.

Owner:DUPONT TORAY CO LTD

Polyimide film, method of manufacture, and metal interconnect board with polyimide film substrate

InactiveUS6908685B2Synthetic resin layered productsWood working apparatusMetal interconnectFlexible circuits

The invention provides a polyimide film manufactured from a polyamic acid prepared from pyromellitic dianhydride in combination with 10 to 60 mol % of phenylenediamine and 40 to 90 mol % of 3,4′-oxydianiline, based on the overall diamine. The polyimide film, when used as a metal interconnect board substrate in flexible circuits, chip scale packages (CSP), ball grid arrays (BGA) or tape-automated bonding (TAB) tape by providing metal interconnects on the surface thereof, achieves a good balance between a high elastic modulus, a low thermal expansion coefficient, alkali etchability and film formability.

Owner:DUPONT TORAY CO LTD +1

Double-layer catalyst and preparation thereof, and application of catalyst in preparation of pyromellitic dianhydride

ActiveCN102658188AProduction of homoanhydrideLess impuritiesOrganic chemistryPhysical/chemical process catalystsActive componentSlurry

The invention belongs to preparation and application of a catalyst, and particularly relates to a double-layer catalyst and preparation thereof, and application of the catalyst in preparation of pyromellitic dianhydride. The preparation method comprises the following steps: respectively weighing effective quantities of active components (V2O5, TiO2, P2O5, Na2O, MoO3 and Sb2O3), compounds of other metals and whiskers, preparing solutions, preparing spraying slurry, spraying the slurry on a support, roasting, cooling and carrying out other technical steps to obtain catalysts E and G; respectively putting the catalysts G and E at a raw material gas mixture inlet end and a reaction gas outlet end; and preparing the pyromellitic dianhydride under the conditions of low air speed, low temperature and the like. The invention solves the problems of high operating condition requirements, massive product impurities, heavy color, low purity and the like, and has the advantages of low operating condition requirements, high product purity, fewer impurities and the like.

Owner:SHIJIAZHUANG HAOPU CHEM

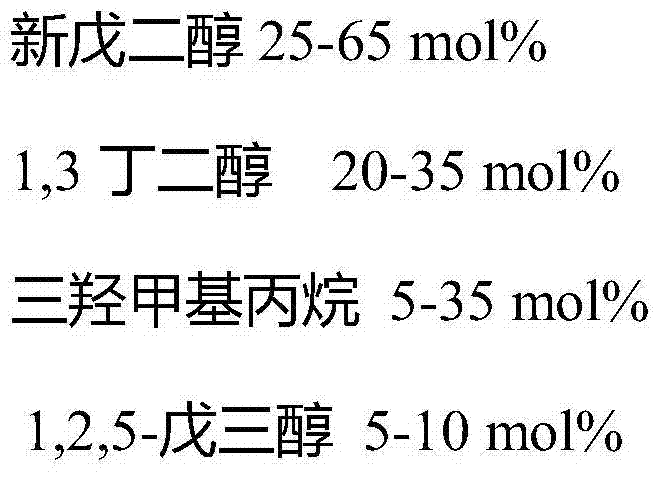

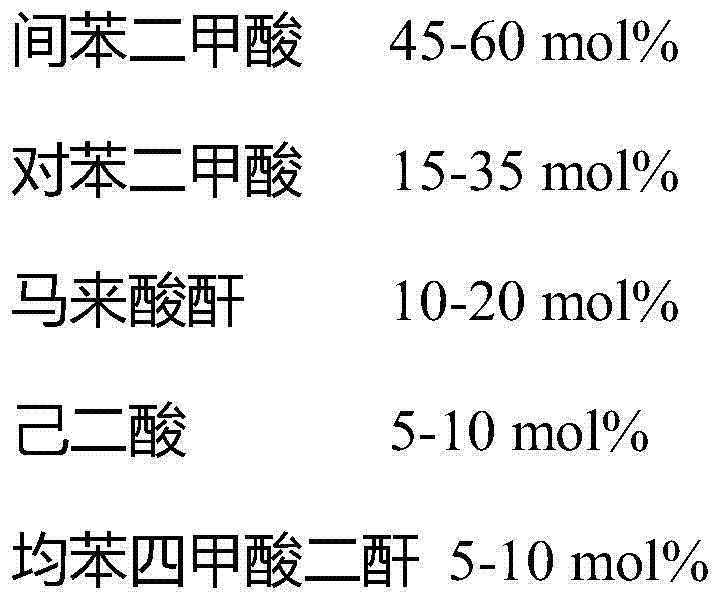

Low-temperature-curing polyester resin for powder paints, powder paint using resin and preparation method thereof

ActiveCN104497289AEasy curingReduce consumptionPowdery paintsPolyester coatingsLow temperature curingAdipic acid

The invention relates to a low-temperature-curing polyester resin for powder paints. According to the polyester resin, the varieties and quantity of high-branching-degree tribasic alcohols in polyalcohols are increased; and in the aspect of polybasic acid raw material selection, the quantity of the high-activity polybasic acid m-phthalic acid is increased, maleic anhydride and adipic acid are compounded, and high-activity pyromellitic dianhydride is used. The powder paint prepared from the polyester resin can be cured at the low temperature of 140-160 DEG C, and has the advantages of favorable curing film-forming property and favorable leveling property.

Owner:黄山市向荣新材料有限公司

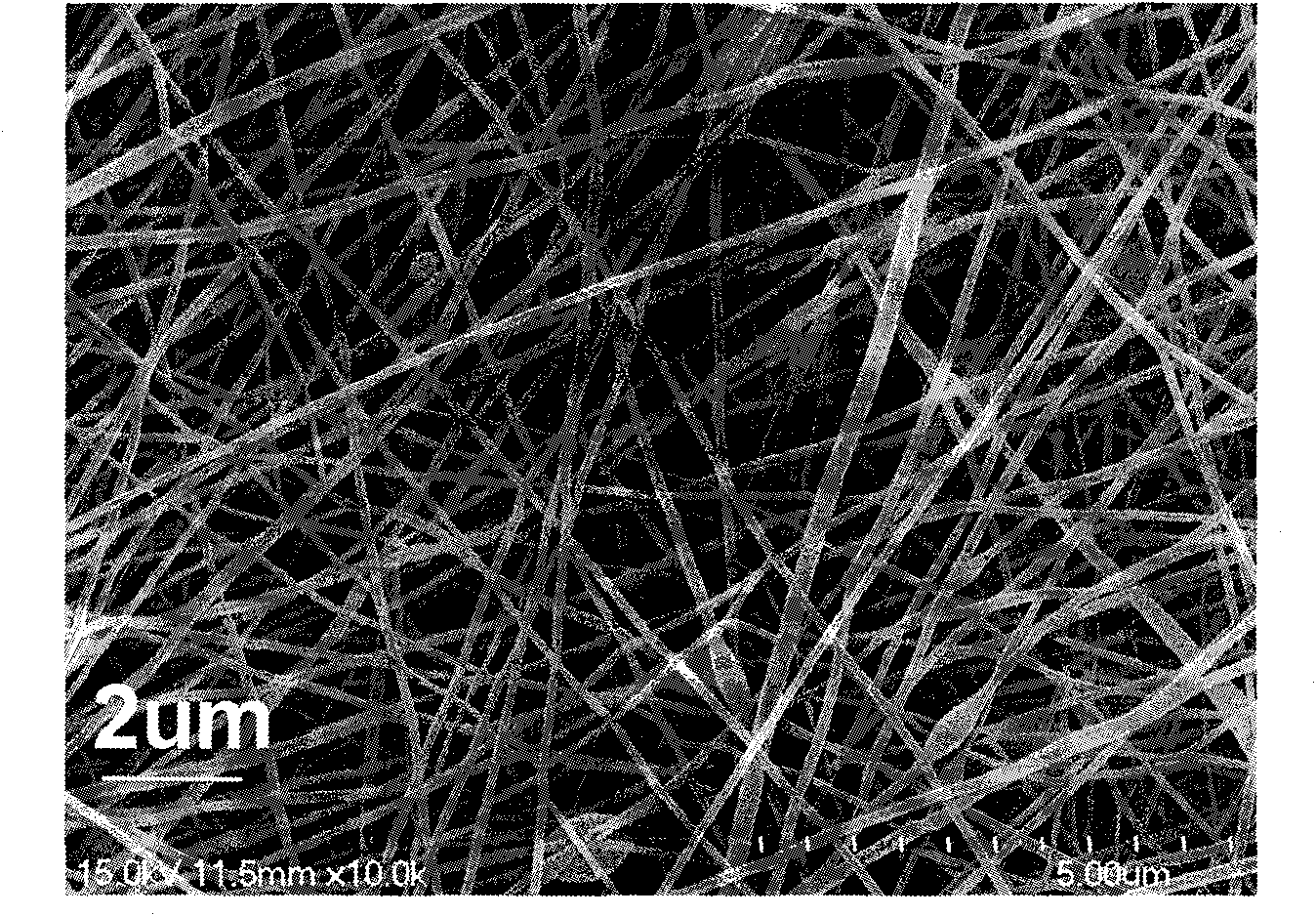

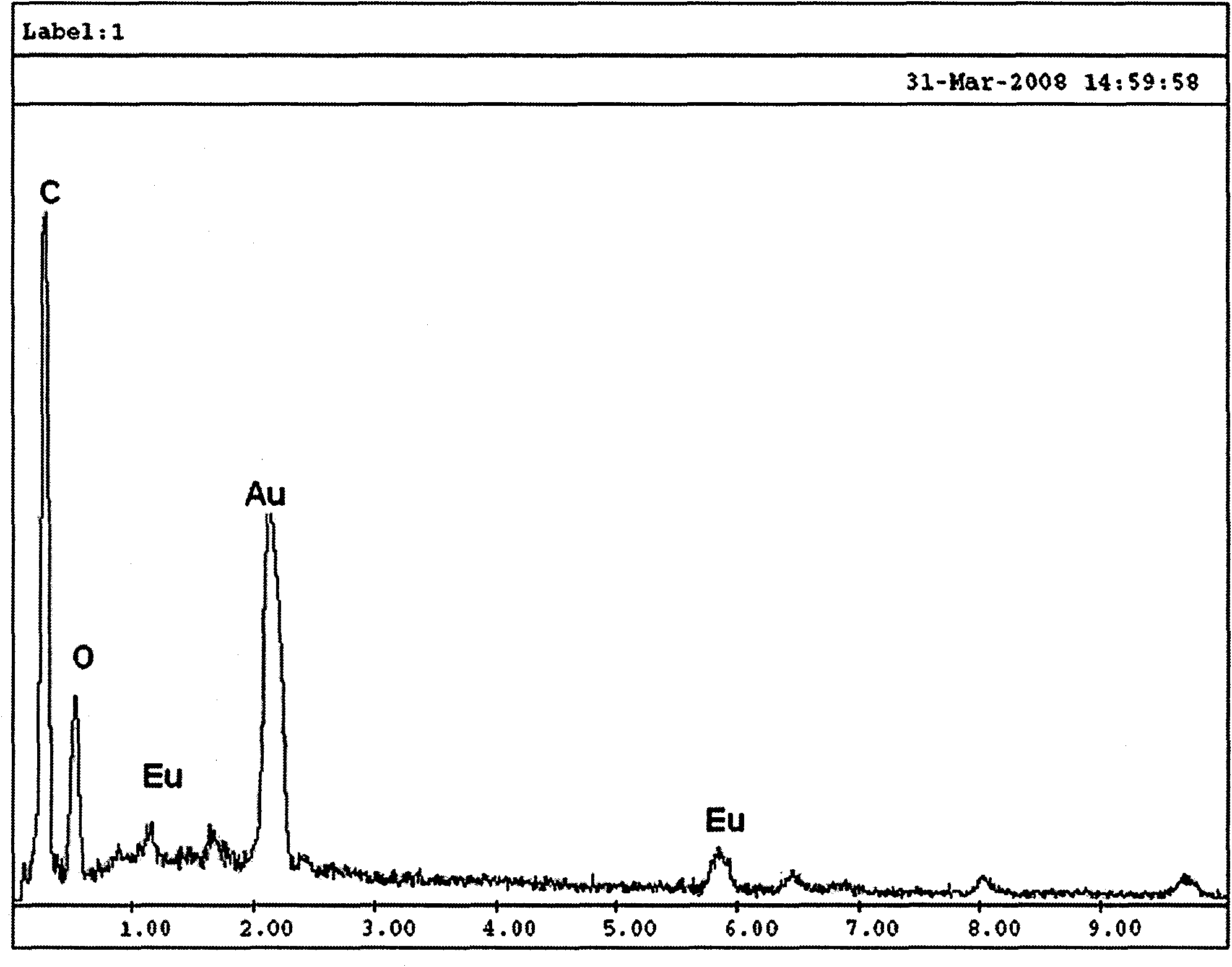

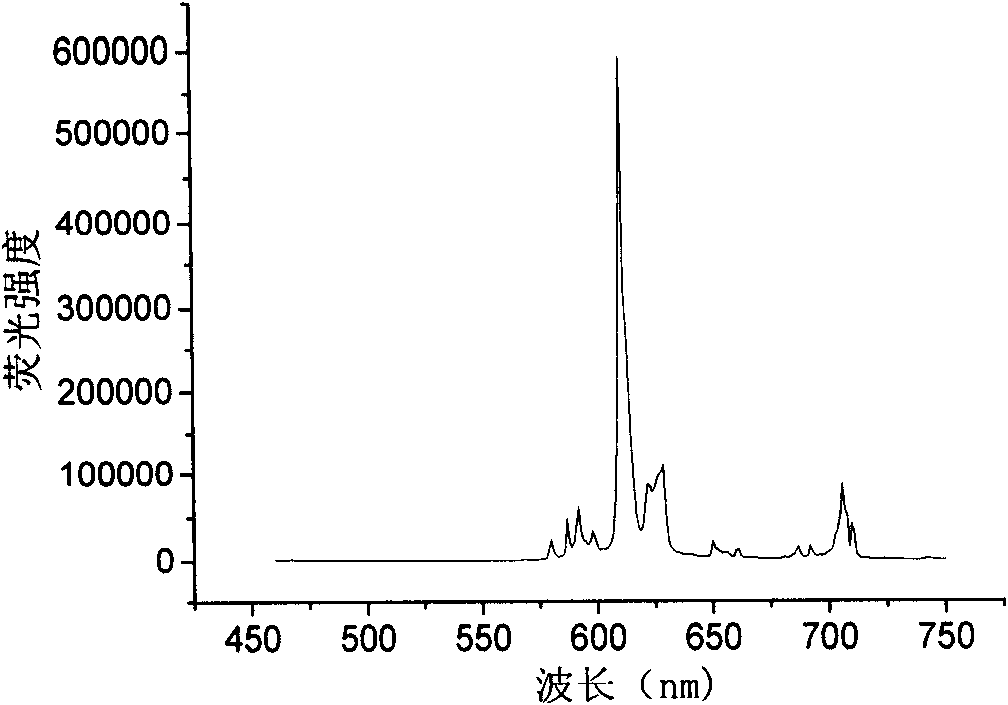

Polyimide nano-fiber and preparation method thereof

InactiveCN101603213AExcellent fluorescence effectImprove heat stabilityFilament/thread formingMonocomponent synthetic polymer artificial filamentDiaminodiphenyl etherFluorescence

The invention relates to a polyimide nano-fiber and a preparation method thereof. The invention adopts the technical scheme that 4,4'-oxydianiline (ODA) and pyromellitic dianhydride (PMDA) are used as polycondensation monomers to synthesize a polyamic acid (PAA) solution; in the reaction process, europium oxide which is processed by a coupling agent and has fluorescent effect is added, and then, the PAA / europium oxide nano-fiber is prepared by using the electrostatic spinning technology, wherein the fiber diameter can be controlled to be between 50 and 200nm; and then, the PAA / europium oxide nano-fiber is put in an oven to be heated gradually for imidization to enable the PPA / europium oxide to carry out polycondensation, thereby generating the polyimide nano-fiber with the fluorescent effect. The application of the polyimide in the high-technology fields, such as anti-falsification certificates, bills, aerospace, microelectronics and the like is extended.

Owner:SUZHOU UNIV

Biaxially oriented polyimide film for flexible printed circuit board base material and preparation method of biaxially oriented polyimide film

ActiveCN102391532AGood chemical propertiesMeet the requirementsCoatingsDiaminodiphenyl etherEngineering

The invention relates to a biaxially oriented polyimide film for flexible printed circuit board base material and a preparation method of the biaxially oriented polyimide film. The method is characterized by mainly comprising the following steps of: (1) polymerizing: preparing a basic solution of polyimide acid according to the following proportions: 1-5% of p-phenylenediamine, 2-8% of biphenyltetracarboxylic dianhydride, 5-10% of diaminodiphenyl ether, 8-15% of pyromellitic dianhydride and 62-84% of dimethylacetylamide; (2) salivating the solution into a film; (3) longitudinally stretching the film according to the stretching ratio of 1:1.02-1.15; (4) transversely stretching the film according to the stretching ratio of 1:1.05-1.2 and carrying out imidization; (5) cutting the edge and rolling up the film; (6) postprocessing the film; and (7) cutting and packaging the film. The special biaxially oriented polyimide film material conforming to the flexible printed circuit board base material can be obtained by using the preparation method provided by the invention.

Owner:朱宏清

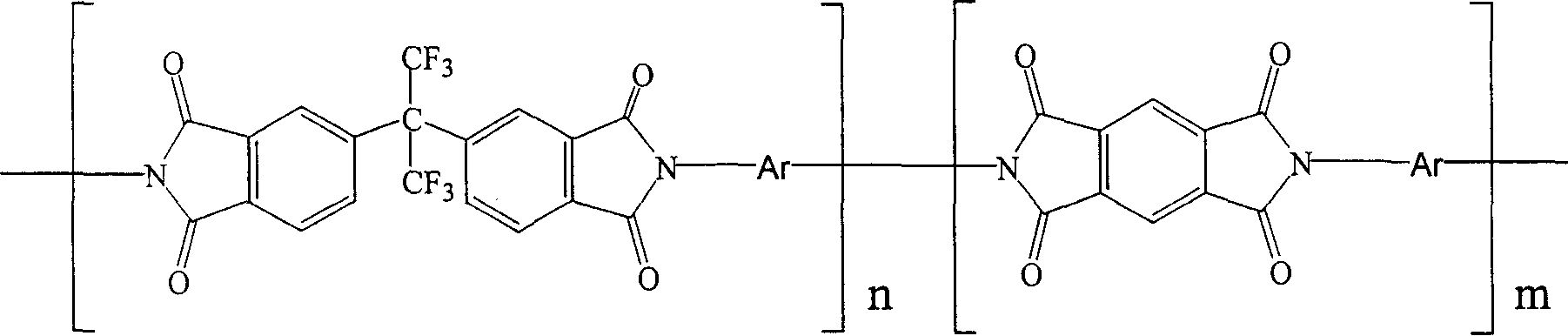

Polyimide polymer, preparation method and application

A polyimide is prepared from 4, 4í»-hexafluoro isopropylene-phthalic anhydride, sym-phenylbutanoic anhydride, and 3,5-diamino-2,4,6-trimethyl phenylsulfonic acid or its salt. A process for using said polymer to prepare gas separating membrane is also disclosed. Said gas separating membrane has high gas permeability and selectivity, and high solubility.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Organic electrode material of organic electrolyte sodium iron battery and preparation method thereof

InactiveCN106328949AHigh voltageLarge capacityCell electrodesNaphthalenetetracarboxylic dianhydrideSodium-ion battery

The invention discloses an organic electrode material, which comprises an estolide part and a diamine part with electrochemical activity, wherein the estolide is one or several of pyromellitic dianhydride, naphthalenetetracarboxylic dianhydride or perylenetetracarboxylic dianhydride; the diamine is one or two of 2,6-diamino-anthraquinone, 1,4-diamino-2,3-dicyano anthraquinone; n(estolide):n(diamine) is 1 to (0.8 to 1.2). The invention also provides a preparation method of the organic electrode material. The invention also discloses a sodium ion battery with the organic electrode material. The organic electrode material provided by the invention has the advantages that the voltage of the material is improved; through increasing the electrochemical activity centers of the material, the volume of the material is increased; in addition, the preparation process of the material is simple; the sodium ion battery with the organic electrode material shows good electrochemical performance.

Owner:HUAZHONG UNIV OF SCI & TECH

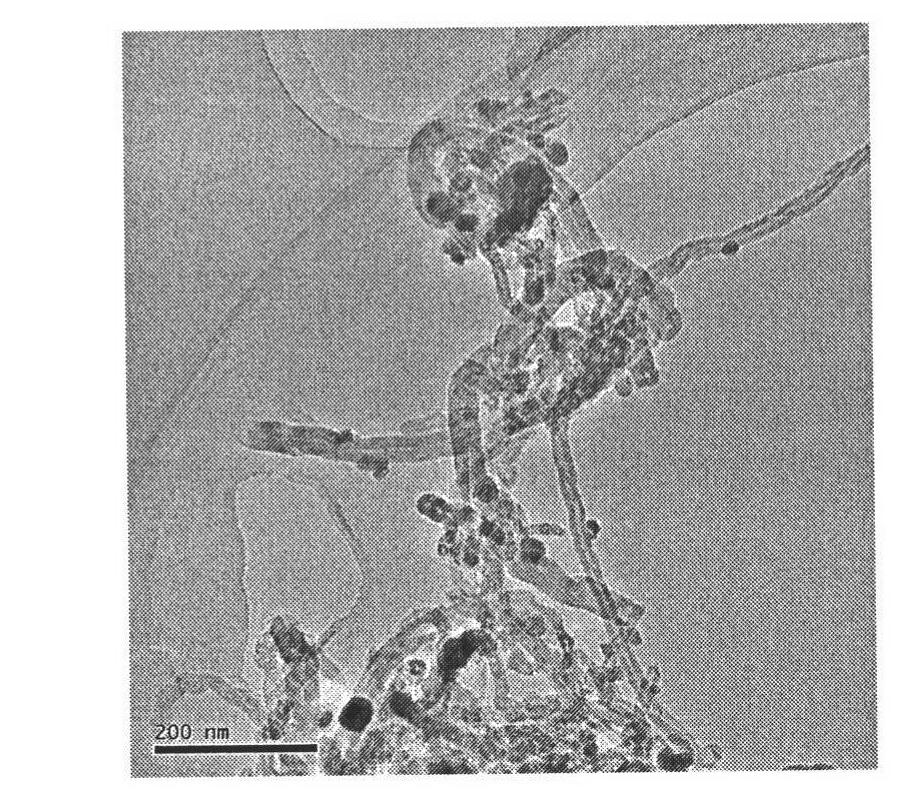

Method for preparing modified carbon nanotube and ferrite and polyimide composite absorbing material

InactiveCN102329425ATo achieve the effect of surface modificationDoes not affect heat resistanceOther chemical processesModified carbonIn situ polymerization

The invention discloses a method for preparing a modified carbon nanotube and ferrite and polyimide composite absorbing material. The method comprises the following steps of: modifying carbon nanotubes by using argon plamas, and preparing the modified carbon nanotubes and ferrite into composite powder by using a chemical coprecipitation method; and preparing the composite powder, 4,4-dioctyldiphenylamine and pyromellitic dianhydride into the modified carbon nanotube / ferrite / polyimide composite absorbing material by using an in situ polymerization method. The method has the advantages that: onthe premise of not influencing good heat resistance of polyimide, the mechanical properties of the composite material are improved, and the light and high-frequency absorbing material is prepared. Bythe method for preparing the modified carbon nanotube and ferrite and polyimide composite absorbing material, the mechanical properties of the composite material are improved, and the prepared composite material with wave-absorbing performance can be widely applied to the field of aerospace.

Owner:TIANJIN UNIV

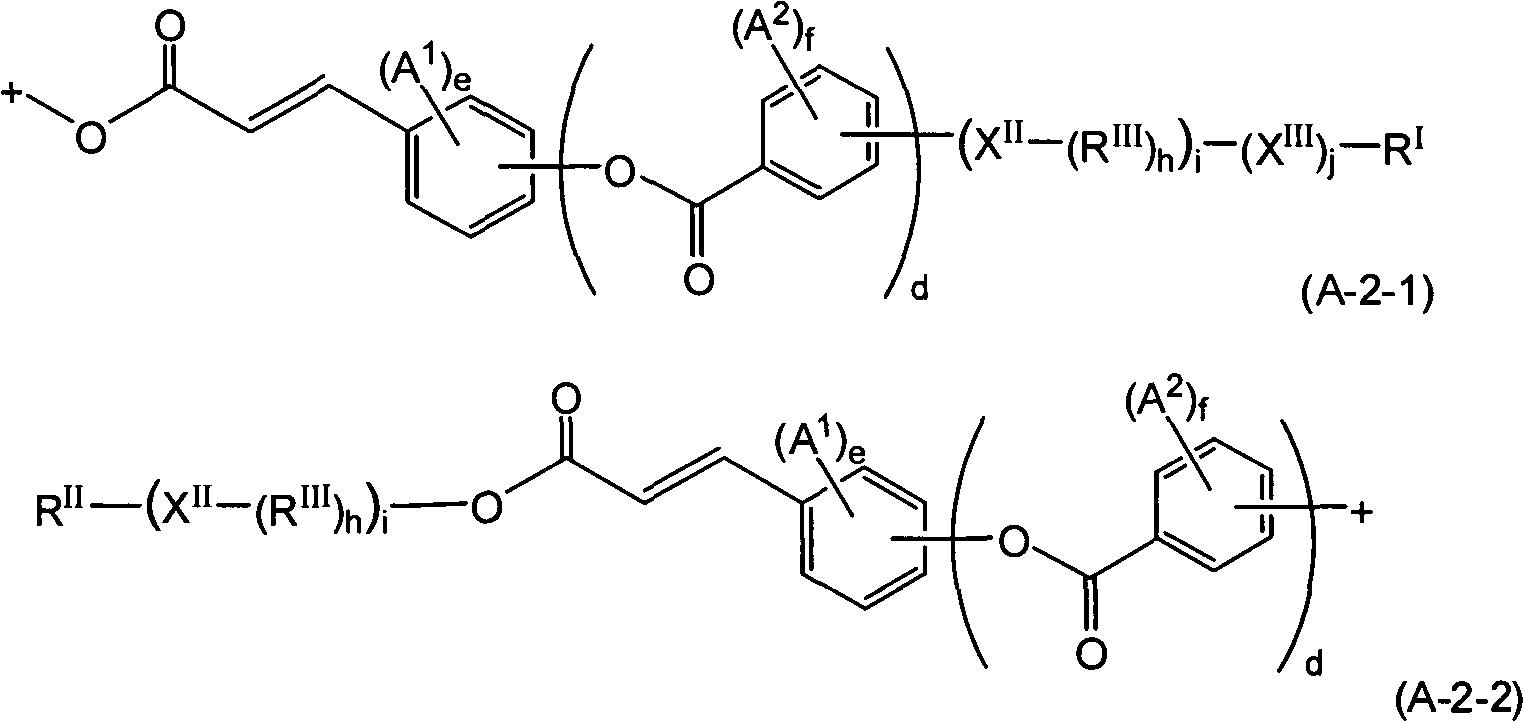

Liquid crystal aligning agent, liquid crystal aligning film and liquid crystal display element

InactiveCN102140352ANo degradation in display performanceGood printabilityLiquid crystal compositionsNon-linear opticsDiaminodiphenyl etherLiquid-crystal display

The invention relates to a liquid crystal aligning agent, a liquid crystal aligning film and a liquid crystal display element. The invention provides a liquid crystal aligning agent which is provided with an excellent pretilt angle property by an optical alignment method, and can form a liquit crystal aligning film which does not result in poor display performance even when drived continuously for a long time. The liquit crystal aligning agent contains: (A) polyamide acid A, which is obtained by allowing tetracarboxylic dianhydride to react with diamines containing a diamine with a photoreactive structure; (B) polyamide acid B, which is obtained by allowing at least one tetracarboxylic dianhydride selected from a group composed of 1, 2, 3, 4-cyclobutane tetracarboxylic dianhydride, pyromellitic dianhydride to react with at least one diamine selected from a group composed of 2, 2'-dimethyl-4, 4'-diaminobiphenyl, p-phenylenediamine, 4, 4'-diaminodiphenylmethane, 4, 4'-diaminodiphenyl ether (with the polyamide acid A excluded).

Owner:JSR CORPORATIOON

Preparation method of graphene/polyimide composite material

InactiveCN105820569AEnhanced interface bindingImprove mechanical propertiesCell component detailsMeth-Diaminodiphenyl ether

The invention discloses a preparation method of a graphene / polyimide composite material, belonging to the technical field of composite materials. The preparation method comprises the following steps: performing ultrasonic dispersion of graphene oxide in a dimethyl sulfoxide solvent to obtain graphene oxide dispersion; crosslinking and coupling the graphene with 2-vinyl-5-aminothiophenol under the effect of a coupling agent vinyldimethoxysilane and a crosslinking agent N,N-methylene bisacrylamide to obtain modified graphene containing mercapto, carbon-carbon double bond and amino cross-linkable groups; condensing 4,4-diaminodiphenyl ether and pyromellitic dianhydride to obtain polyamide acid; and crosslinking the modified graphene containing different cross-linkable groups with polyamide acid to obtain a modified graphene / polyimide composite material. In the invention, the interface bonding between graphene and polyimide matrix is strong, the compatibility with a polymer is good, and the mechanical properties of the material are improved.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

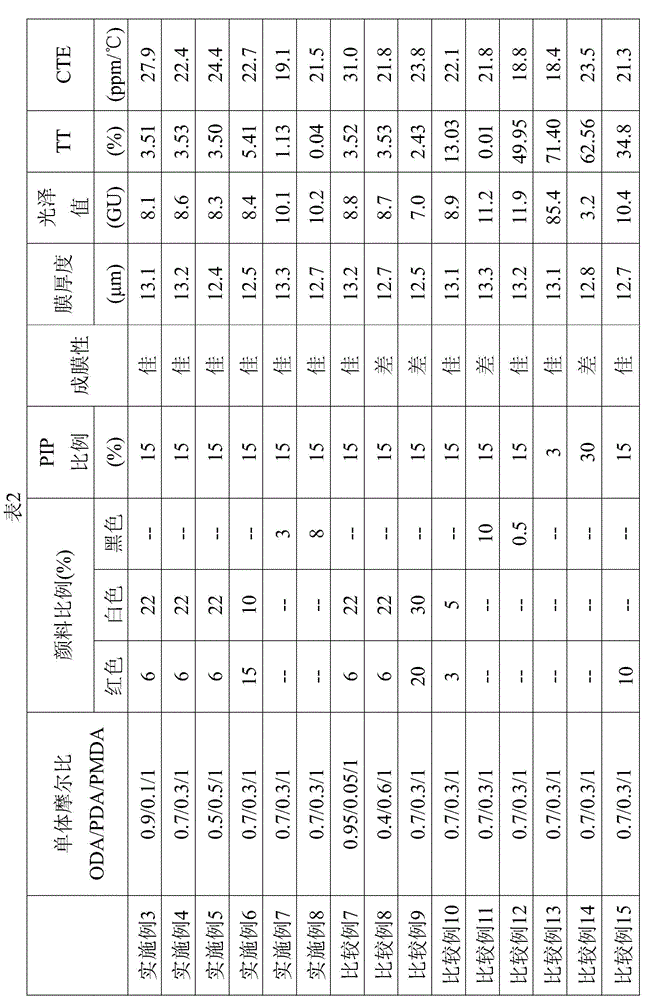

Colored polyimide film

A colored polyimide film includes a polyimide polymer obtained by reacting diamine monomers with dianhydride monomers, wherein the diamine monomers are oxydianiline (ODA) and phenylene diamine (PDA) monomers, and the dianhydride monomers are pyromellitic dianhydride (PMDA); a matting agent comprised of polyimide particles; and one or more color pigment. The polyimide films described herein have low gloss, low transparency, and low coefficient of thermal expansion.

Owner:TAIMIDE TECH

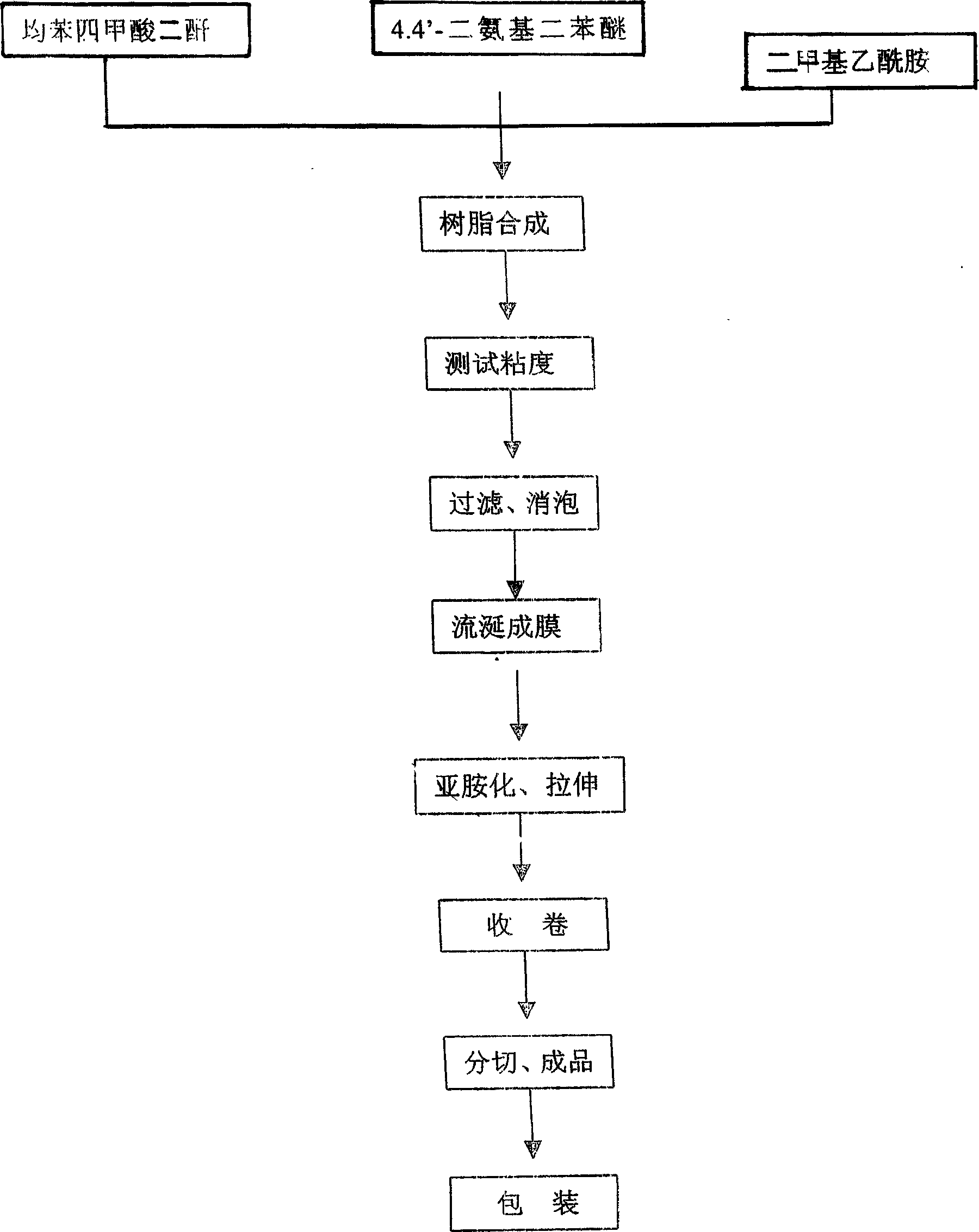

Polyimide film and its producing process

InactiveCN1748985AOrientation crystallization is goodMeet the marketFlat articlesDiaminodiphenyl etherPolymer science

The polyimide film and its production process belong to the field of insulating material producing technology. The production process has pyromellitic dianhydride as main material, and 4, 4-diaminodiphenyl ether and dimethylacetamide as supplementary material, and includes the main steps of: resin synthesis, viscosity measurement, filter, debubbling, casting to form film, winding and cutting. The present invention features the polyimide film with thickness of 0.25-0.35 mm and width of 1250-1500 m, the reaction of pyromellitic dianhydride and 4, 4-diaminodiphenyl ether in dimethylacetamide and the optimized technological process to make the product meet the requirement of producing flexible printed circuit board and other information industry production.

Owner:JIANGSU YABAO INSULATION MATERIAL

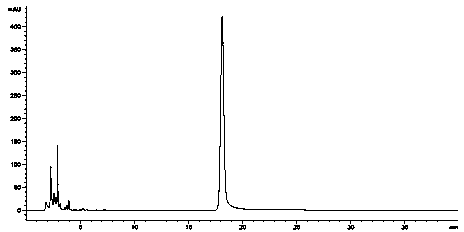

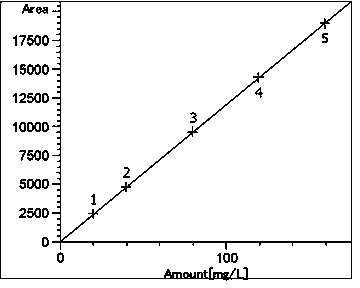

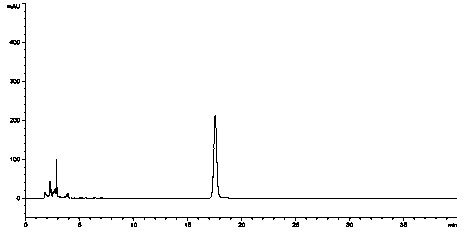

High performance liquid chromatographic analysis method for pyromellitic dianhydride

InactiveCN103969392ASimple processing capacitySimple analysis procedureComponent separationSimple sampleQuality control

The invention discloses a high performance liquid chromatographic analysis method for pyromellitic dianhydride. The method comprises the following steps: (1) adopting chromatographic conditions, (2) preparing a mobile phase, (3) preparing a PMDA standard solution, (4) building a standard curve, (5) preparing a PMDA sample solution, and (6) carrying out quantitative analysis by using an external standard percentage method. The invention provides the method for quantitatively analyzing pyromellitic dianhydride, which fills the technological gaps of corresponding fields. The method has the advantages of simple sample treatment and analytical procedure process, good peak shape, high analysis result accuracy, good reproducibility and the like and has an important practical significance in the fields of quality analysis and quality control of PMDA.

Owner:常熟联邦化工股份有限公司

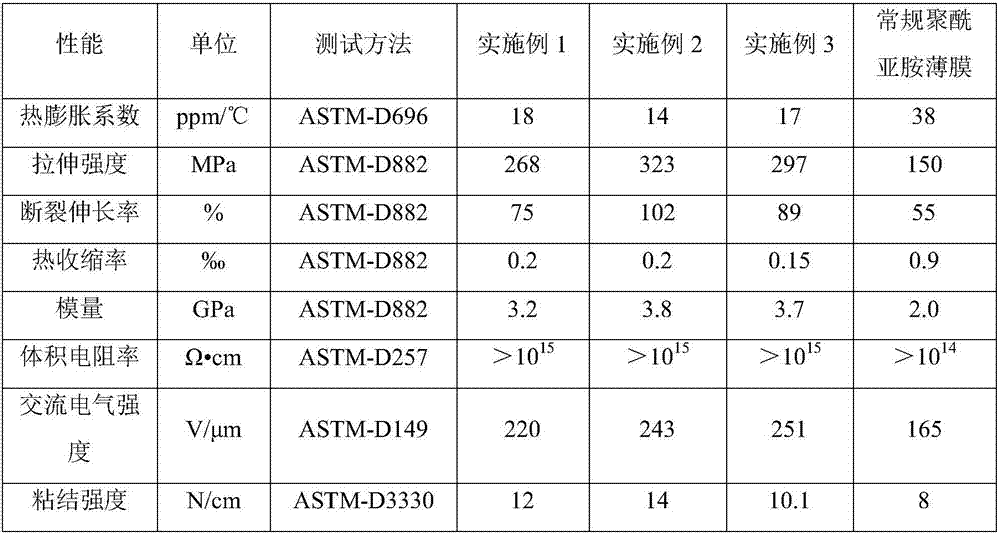

Stable dimension type polyimide film and preparation method thereof

The invention discloses a dimension stable polyimide film, which contains the following components: component A: copolymer of biphenyl tetracarboxylic acid dianhydride, pyromellitic dianhydride and p-phenylenediamine in dimethyl acetamide solvent; component B: copolymer of pyromellitic dianhydride and p-phenylenediamine in dimethyl acetamide solvent; copolymer of pyromellitic dianhydride and p-phenylenediamine, 4, 4'-diaminodiphenyl ether in dimethyl acetamide solvent; wherein, the weight percent of the component A is 20 to 50 percent; the weight percent of the component B is 5 to 20 percent; the weight percent of the component C is 30 to 60 percent; the invention also discloses a preparation method of the dimension stable polyimide film. The dimension stable polyimide film of the invention has high tensile elastic modulus, low thermal expansion coefficient, low shrinkage rate and good dimensional stability, and is mainly used as a substrate of flexible circuit FPC and achieves high performance of FPC.

Owner:无锡高拓新材料股份有限公司

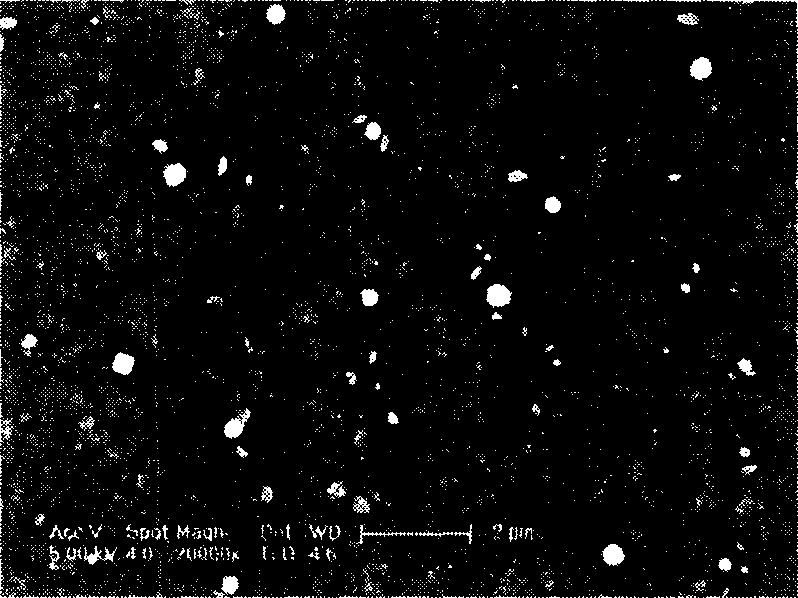

Method for improving dispersion of nano silica granules in polyimide resin

The invention relates to a method for improving the dispersity of nanometer silicon dioxide particles in polyimide resin. The method comprises the following steps: firstly, the nanometer silicon dioxide particles are dried for 3 to 5 hours at a temperature between 75 and 85 DEG C; secondly, atmospheric-pressure plasma treatment parameters are adjusted to ensure the distance between a nozzle and a matrix loaded with nanometer silicon dioxide is 2 to 3 mm, and the time for treating the nanometer silicon dioxide is 20 to 40 seconds; thirdly, the treated nanometer silicon dioxide particles are mixed with dimethyl acetamide solvent, and then pyromellitic dianhydride and 4, 4'-diaminodiphenyl ether are added in, well stirred and mixed; and fourthly, a nanometer composite material with the high dispersity of the nanometer silicon dioxide particles in the polyimide resin is obtained through thermal cyclization. The method is friendly to environment and effective to treat the nanometer silicon dioxide particles.

Owner:DONGHUA UNIV

Low density polylactic acid polymeric foam and articles made thereof

This invention presents a process whereby thermoplastic polylactic acid polymers foams having the desirable properties for manufacture of thermoformed articles may be made. It has been found that introduction of a dual functional reactive agent into the melt will improve the relevant properties of the melt and thus, the resultant foam. An example of such an agent is pyromellitic di-anhydride, but it is envisioned that a wide number of dual functional reactive agents can be utilized. It has been found that such dual functional reactive agents do not shift crystalline melt point of the material by any appreciable amount. It has been found that, by carefully controlling such a reaction, melt strength can be increased sufficiently to produce stable foam at temperatures above the melt point of the polymer, to permit the production of foamed polylactic acid polymer and product formed therefrom on conventional process equipment.

Owner:AJOVER

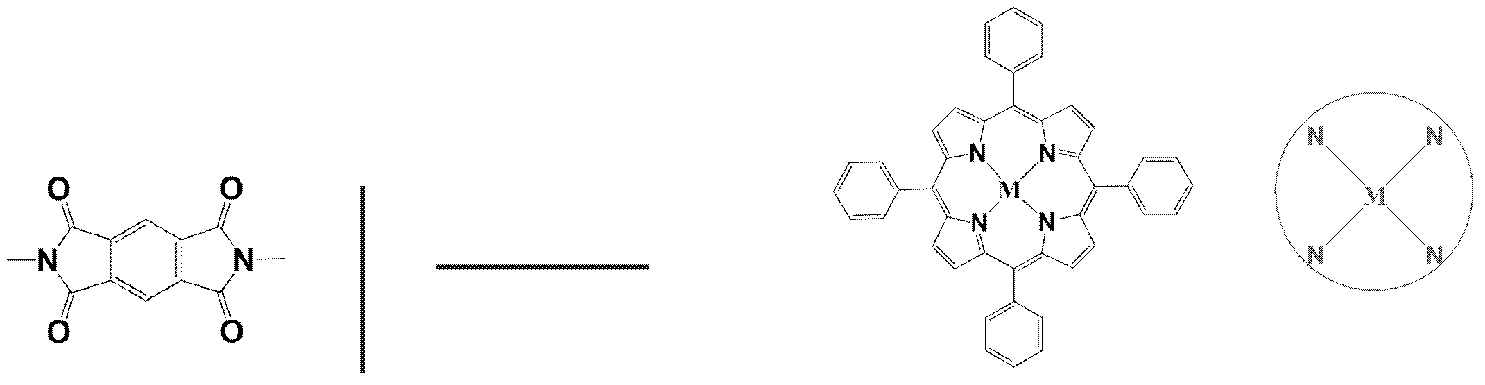

Metal-porphyrin polymer catalyst and preparation and application thereof

ActiveCN102658202AEasy to makeImprove stabilityPreparation by oxidation reactionsOrganic compound preparationFiltrationPorphyrin

The invention relates to a metal-porphyrin polymer material and preparation and the application thereof. 4-amino-phenyl-porphyrin and pyromellitic dianhydride react under the 60-DEG C room temperature with N-methyl-pyrrolidone as a solvent and pyridine and acetic oxide as catalysts under protection condition of nitrogen, the obtained solution is poured into a carbinol solution, separated solid is porphyrin polymer, suction filtration is conducted, carbinol and water are respectively used for washing the solid till the filtering liquid is colorless, drying is conducted, and metal ions Ru3+, Pd2+, Fe2+, Mn2+, Cu2+, Co2+, Ni2+ or Zn2+ and the porphyrin polymer are solved in the N-methyl pyrrolidone, react under 60-DEG C temperature and are poured into carbinol solvent to separate out the metal-porphyrin polymer material. The catalyst is mild in reaction condition, free of pollution, high in selection of being used in thioether and arene conversion rate and sulfoxide and simple in post-processing and can be recycled by simple filtering.

Owner:PETROCHINA CO LTD

Preparation method of high performance and low thermal expansion coefficient polyimide film

InactiveCN107286653AImprove thermal stabilitySmall coefficient of thermal expansionDiaminodiphenyl etherIn situ polymerization

The invention discloses a preparation method of a high performance and low thermal expansion coefficient polyimide film. The preparation method comprises: 1) adding nanometer SiO2 and a silane coupling agent into a dimethylacetamide solvent, and carrying out ultrasound mixing-uniform dispersing to obtain a solution A; 2) adding biphenyl tetracarboxylic diandhydride and 4,4'-diaminodiphenyl ether to the solution A, and carrying out an in situ polymerization reaction to obtain a polyamic acid solution B; 3) adding pyromellitic dianhydride and p-phenylenediamine to the solution A, and carrying out an in situ polymerization reaction to obtain a polyamic acid solution C; 4) carrying out high speed stirring on the polyamic acid solution B and the polyamic acid solution C to achieve a uniform mixing state so as to obtain a polyamic acid solution D; and 5) casting the polyamic acid solution D onto a supporting body, drying to obtain a polyamic acid gel film, and carrying out imidization treatment to obtain the high performance and low thermal expansion coefficient polyimide film. The high performance and low thermal expansion coefficient polyimide film prepared through the method of the present invention has advantages of high mechanical property, high electrical property and low thermal expansion coefficient, wherein the thermal expansion coefficient can achieve 14-18 ppm / DEG C.

Owner:ANHUI GUOFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com