Polyimide thin film for preparing artificial graphite film and preparation method of polyimide thin film

A technology of polyimide film and artificial graphite, which is applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of low flexibility, graphite film tensile strength, poor mechanical properties of elongation at break, etc. , to achieve the effects of good flexibility, excellent isotropy, and good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

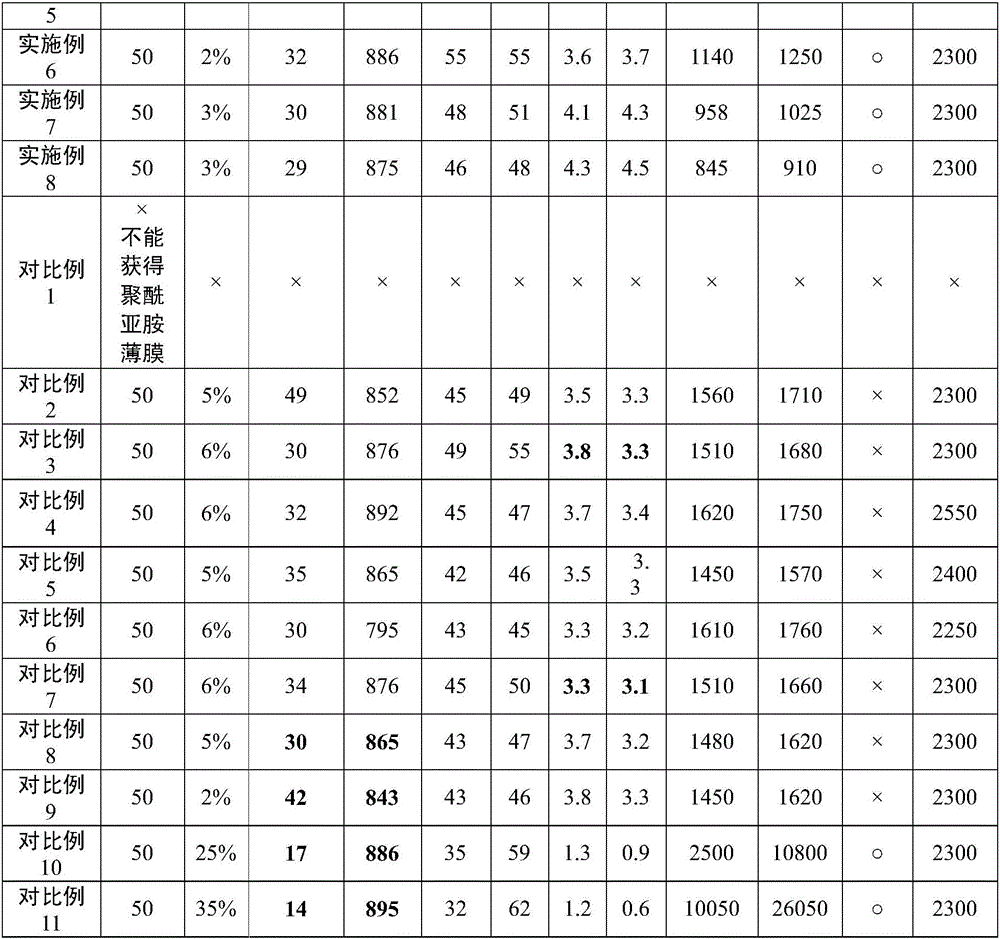

Examples

preparation example Construction

[0040] One, the preparation method of polyimide film

[0041] 1.1 Preparation of polyamic acid resin

[0042] The polyimide film that can prepare the artificial graphite film of excellent mechanical property described in the present invention, the preparation of its polyamic acid resin adopts the preparation method of known polyamic acid resin: the described diamine raw material and dianhydride The polyamic acid resin solution is obtained by carrying out polycondensation reaction in dimethylacetamide equivalent to 3 to 6 times the total weight of the diamine and dianhydride raw materials according to the molar ratio of the polyamic acid raw materials.

[0043] 1.2 Preparation of slurry containing inorganic fillers

[0044] Using dimethylacetamide as a solvent, adding a calcium-containing compound inorganic filler and making the inorganic filler uniformly dispersed in the solvent to prepare a slurry A containing 5-30% (by weight) of a calcium-containing compound;

[0045] Usi...

Embodiment 1

[0050] React pyromellitic dianhydride, 4,4'-diaminodiphenyl ether, and p-phenylenediamine in dimethylacetamide at a molar ratio of 100:50:50 to obtain a viscosity of 100,000 centipoise. A polyamic acid resin solution with a solid content of 20%.

[0051] Slurry A: Calcium hydrogen phosphate filler, with an average particle size of 3 μm, was added to dimethylacetamide and dispersed by high-speed stirring to prepare a slurry with a solid content of 10%.

[0052] Slurry B: filler ferric oxide, with an average particle size of 3 μm, was added to dimethylacetamide, and dispersed by high-speed stirring to prepare a slurry with a solid content of 10%.

[0053] Add slurry A and slurry B to the prepared polyamic acid resin solution respectively, wherein the filler content in slurry A is controlled to be 0.5% by solid weight of the polyamideimide film material. The filler content in the slurry B is 0.06% by solid weight of the polyamideimide film material.

[0054] Then the resin is e...

Embodiment 2

[0056] Pyromellitic dianhydride, 3,3',4,4'-biphenyltetracarboxylic dianhydride, 4,4'-diaminodiphenyl ether, p-phenylenediamine in the ratio of 80:20:50:50 The molar ratio is reacted in dimethylacetamide to obtain a polyamic acid resin solution with a viscosity of 100,000 centipoise and a solid content of 20%.

[0057] Slurry A: Calcium hydrogen phosphate filler, with an average particle size of 2 μm, was added to dimethylacetamide and dispersed by high-speed stirring to prepare a slurry with a solid content of 10%.

[0058] Slurry B: filler ferric oxide, with an average particle size of 4 μm, was added to dimethylacetamide, and dispersed by high-speed stirring to prepare a slurry with a solid content of 10%.

[0059] Add slurry A and slurry B to the prepared polyamic acid resin solution respectively, wherein the filler content in slurry A is controlled to be 1.0% by solid weight of the polyamideimide film material. The filler content in the slurry B is 0.05% by solid weight o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com