Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

551 results about "Dimethyl acetamide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

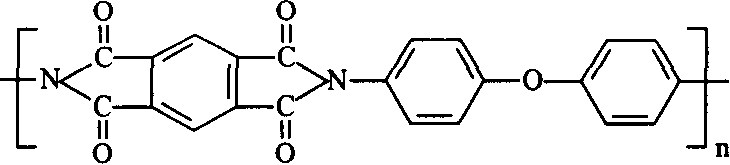

Polyimide film with high visible light permeability and preparation thereof

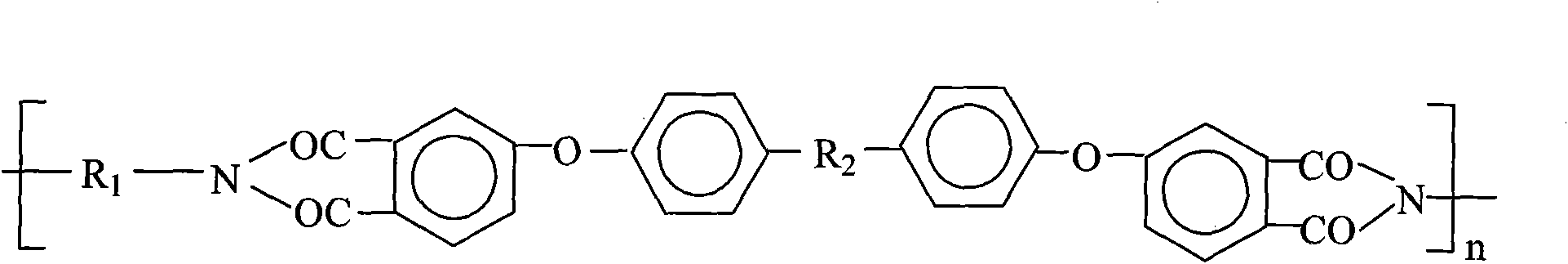

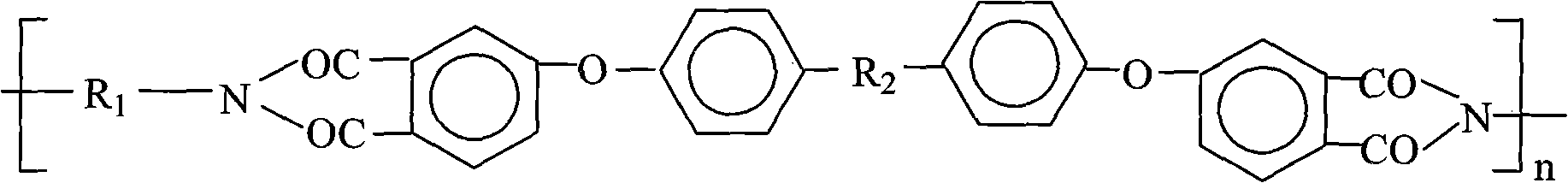

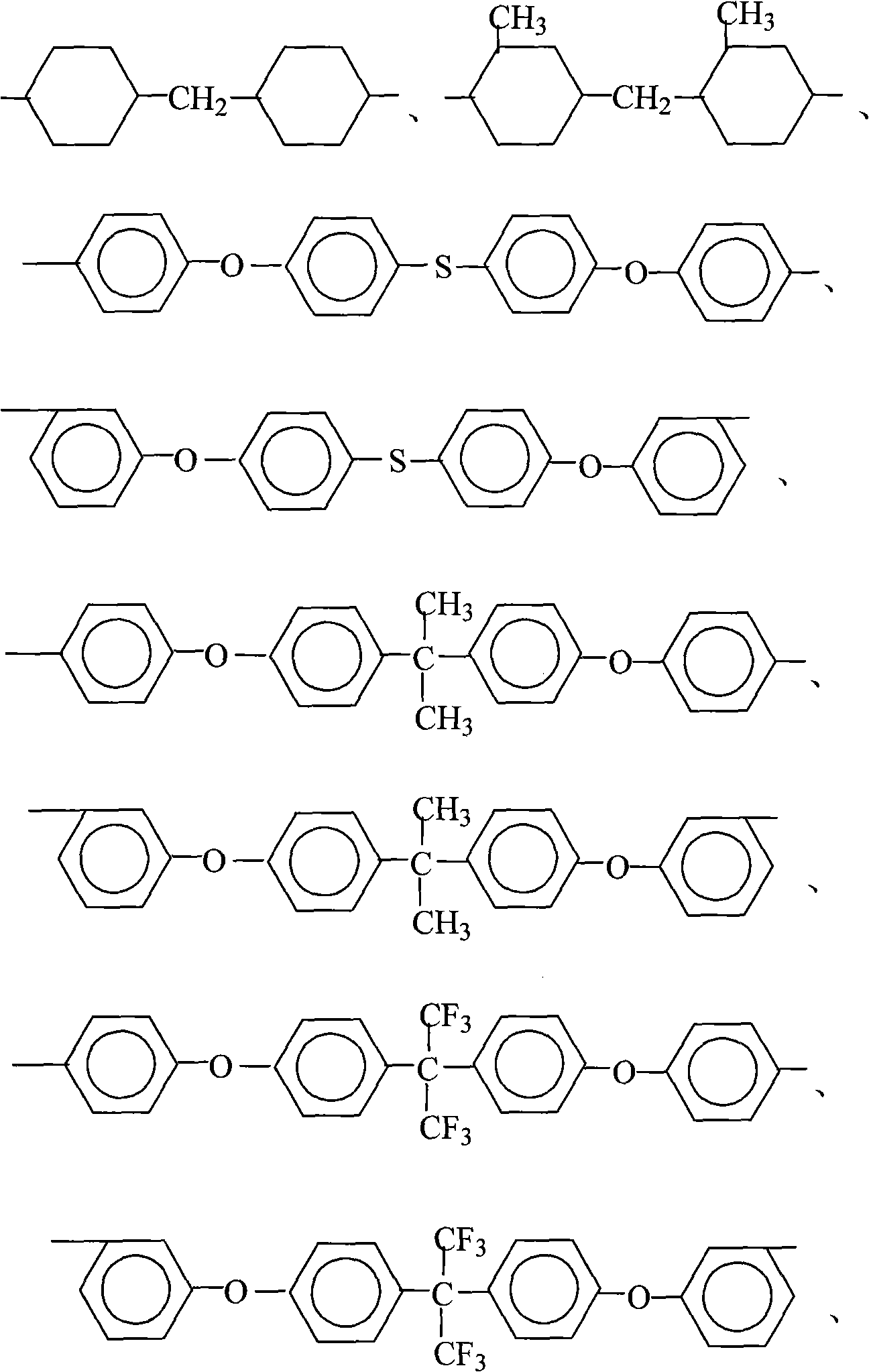

The invention related to a polyimide film with high visible light permeability, molecular structure formula of which is: (shown in figure). Preparation comprises steps of: dissolving primary diamine in a strongly polarnon-proton solvent, cooling the same by cold water to 5 DEG. C to 10 DEG. C, adding aromatic dianhydride, mixing, reacting 4h to 10h at 5 DEG. C to 10 DEG. C, acquiring homogeneous, transparent, sticky polyamic acid resin solution; wherein mol number of aromatic dianhydride is equal to that of primary diamine; adjusting viscosity of polyamic acid resin solution by N,N-dimethyl acetamide, forming film in a casting machine, heating to raise temperature, processing dehydration heat imidization, cooling, deciduating to acquire homogeneous and transparent polyimide thin film. The preparation method has mild reaction condition, sample to operate, low in cost and environmental friendly; mechanical property and thermal stability of the polyimide thin film are excellent with high visible light permeability reaching 94% and film thickness 50 micrometers.

Owner:DONGHUA UNIV +1

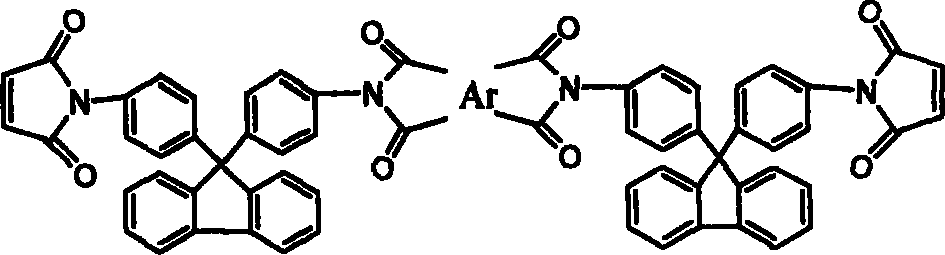

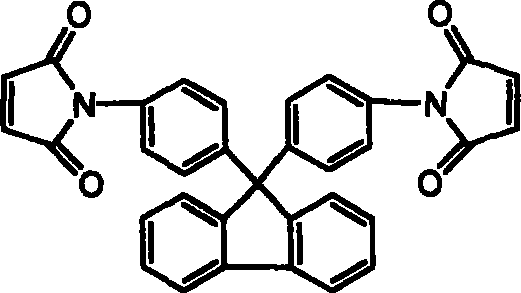

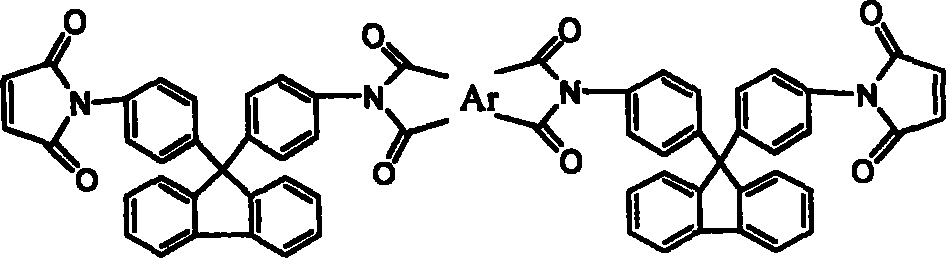

Chain-prolonged type fluorenyl bimaleimide and its preparation method

The invention discloses a making method of new chain-extending typed fluorenyl dimaleimide, which comprises the following steps: dissolving 9, 9-di(4-amino phenyl) fluorene into N, N-dimethyl acetamide; stirring; dripping maleic anhydride of N, N-dimethyl acetamide with the same molar weight to react for 2h; adding dianhydride directly with the same molar weight; stirring 3h; adding the compound of acetic anhydride and potassium acetate; stirring under indoor temperature to react for 4h; sedimenting in the water; obtaining the product with receiving rate over 95%.

Owner:FUDAN UNIV

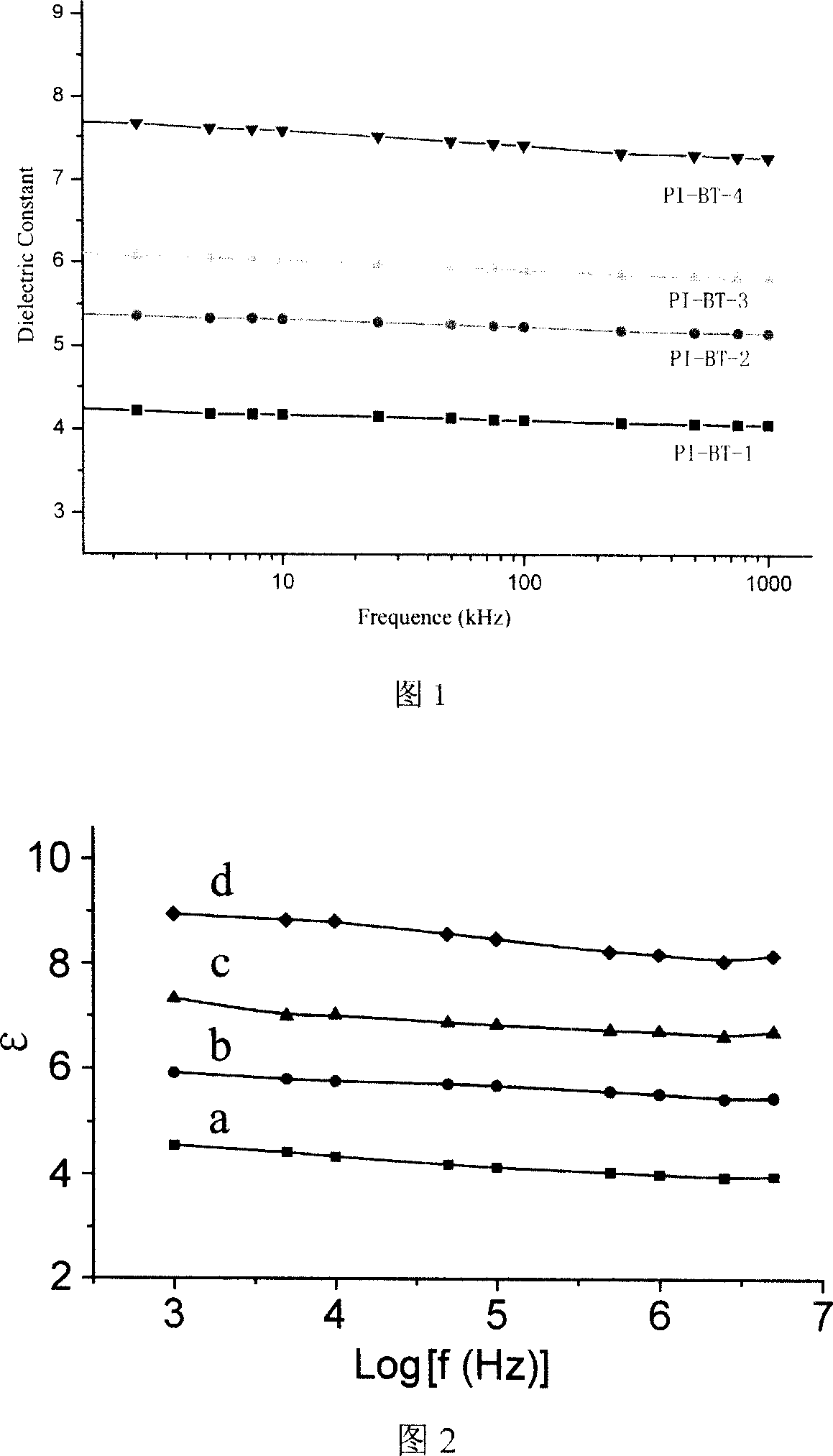

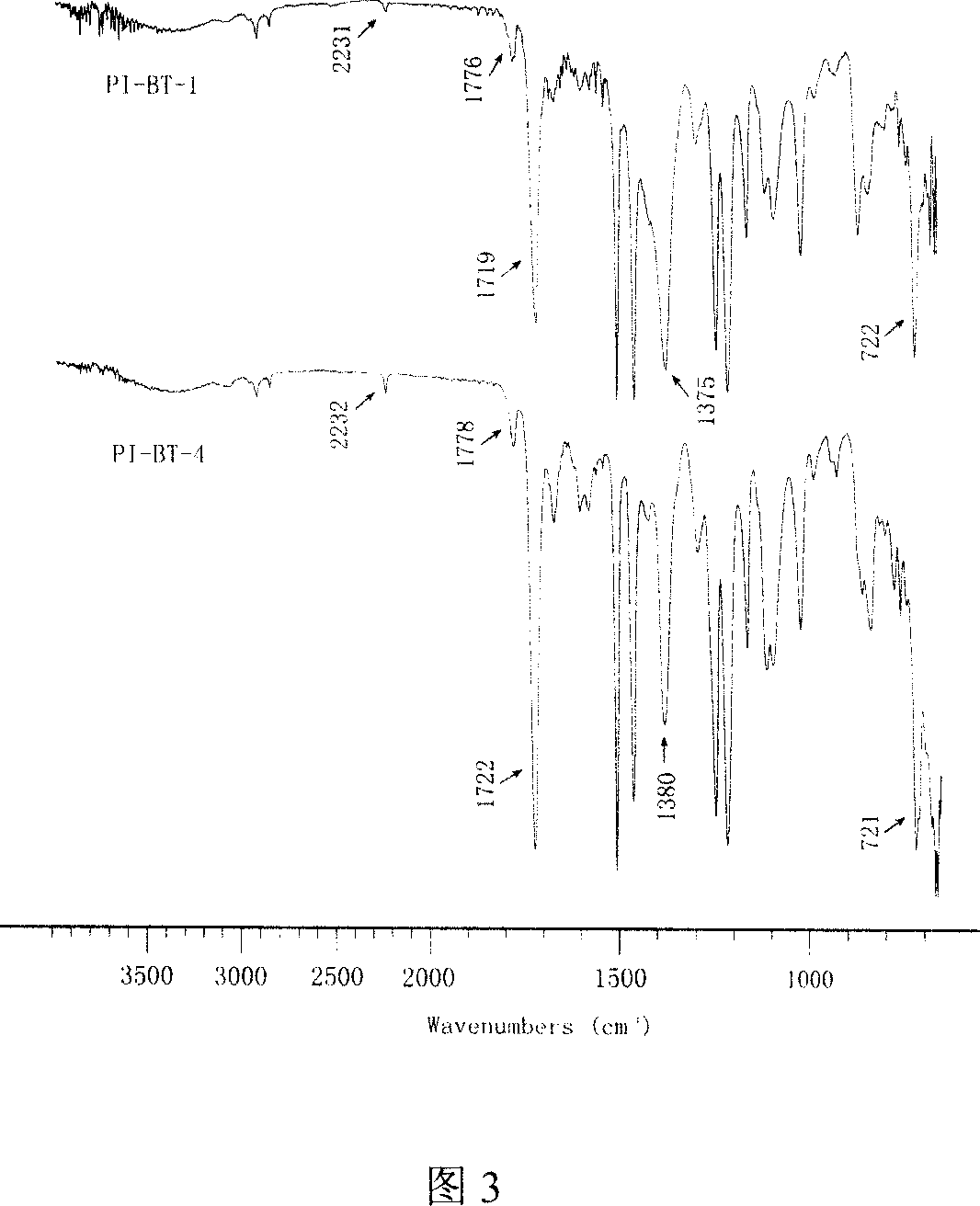

Process for synthesizing composite film of polyacylimide/nano barium phthalate with high deelectric constant

The process of synthesizing composite polyimide / nanometer barium titanate film with high dielectric constant includes the following steps: adding maleic anhydride and diamine in the same molar amount into N-methyl-2-pyrrolidone or N, N-dimethyl acetamide as solvent to compound solution with solid content of 10-20 %, adding nanometer modifying barium titanate particle in the amount less than 40 % of the composite film weight into the solution and ultrasonically dispersing, stirring continuously at room temperature for 18-24 hr to obtain polyamic acid, pouring the polyamic acid on glass plate mold, and vacuum heating to eliminate solvent and iminate to obtain the composite polyimide / nanometer barium titanate film. Thus prepared film has excellent heat stability, high oxidative degradation resistance, high dielectric constant and low dielectric loss, and may be used for wound film capacitor, printed circuit board, semiconductor device, etc.

Owner:SOUTHEAST UNIV

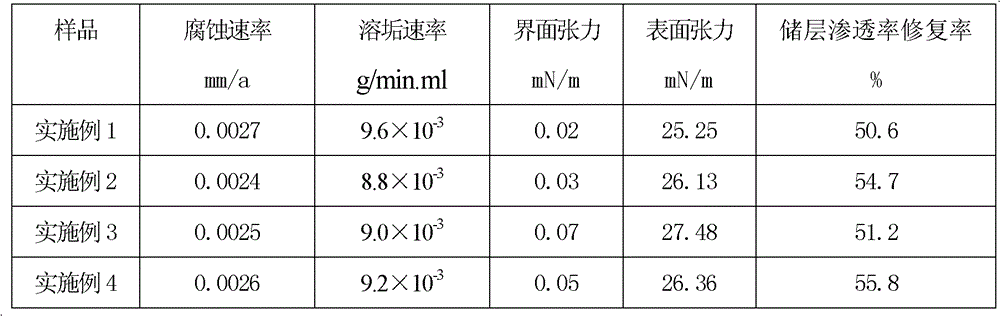

Blocking remover of gas well shaft

The invention relates to a blocking remover of a gas well shaft. The blocking remover comprises, by weight, 5-25% of an alcohol ether compound, 0.5-10% of a dispersant, 1-10% of a cleaning agent, and 0.5-5% of chelating agent, with the balance being a nitrogen-containing polar solvent, wherein the nitrogen-containing polar solvent is one selected from N,N dimethyl formamide, N,N dimethyl acetamide, and N-methyl pyrrolidone, the alcohol ether compound is one selected from glycol-ether, glycol-propyl ether, glycol-butyl ether, and diglycol-ether, the disperant whose micelle particle size is from 20nm to 100nm is a middle-phase microemulsion-type dispersant mixed by kerosene, water, a surfactant and a cosurfactant, the cleaning agent is one selected from allene diamine, acetonitrile and pentylamine, and the chelating agent is one selected from sodium citrate and EDTA. The blocking remover has the advantages that corrosivity is weak, that the speed of dissolving blockage is fast, that the product performance is stable in high temperatures, and that the blocking remover can reduce damages caused by water locking and fouling in areas close to gas wells, and can recover the permeability of storing layers.

Owner:PETROCHINA CO LTD

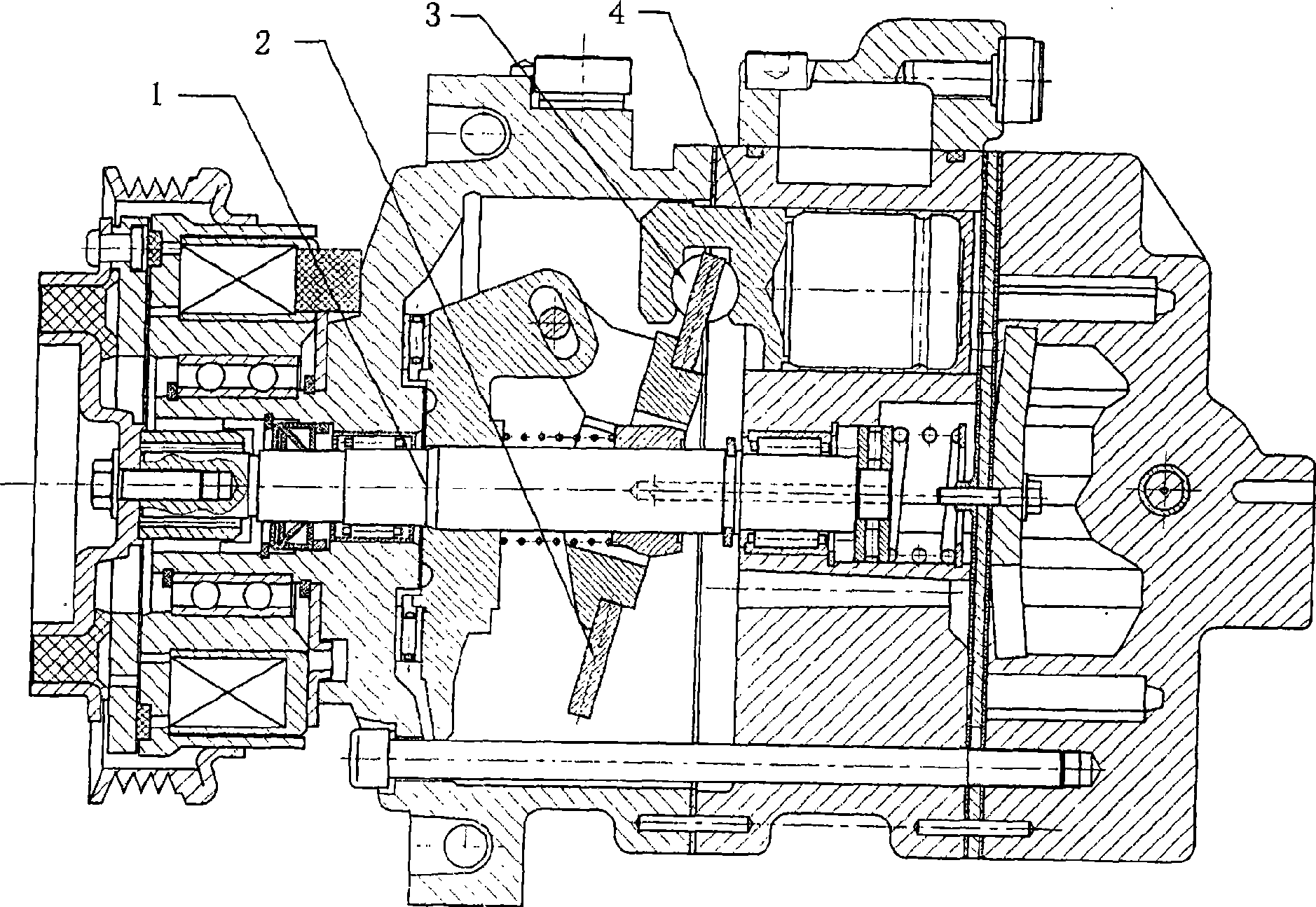

Self-lubricating wear-resistant coating swash plate and technique for producing the same

ActiveCN101503995AMeet the development requirements of lead-freeSimple production processLiquid surface applicatorsPositive displacement pump componentsWear resistantMolecular materials

The invention relates to a self-lubricating wear-resistant coating swash plate, which consists of a metallic matrix and a self-lubricating wear-resistant coating, wherein annular planes on two sides of the metallic matrix are coated with the self-lubricating wear-resistant coating, and the components of the self-lubricating wear-resistant coating comprise a main material of high molecular materials, fluoroplastics, solid lubricants and inorganic matters. A process for producing the self-lubricating wear-resistant coating swash plate comprises that: the self-lubricating wear-resistant coating is coated on the swash plate after being prepared into a liquid coating, and a method for preparing the liquid coating comprises the steps of using a solvent of N-methyl pyrrolidone or dimethyl acetamide to dissolve the main material of the high molecular materials first, and then adding the fluoroplastics, the solid lubricants and the inorganic matters into the mixture to perform sufficient stirring and dispersion so as to prepare the liquid coating with certain solid content. The swash plate has the advantages of good self-lubricating and wear-resistant performance, simple production process and low production cost, and does not contain metallic lead which is harmful to human bodies and the environment.

Owner:ZHEJIANG CHANGSHENG SLIDING BEARINGS

Cellulose acetate/nano titanium dioxide mixed media hollow fiber positive osmotic membrane

The invention discloses a cellulose acetate / nano titanium dioxide mixed media hollow fiber positive osmotic membrane. 0.05-4.0% (w / w) of nano titanium dioxide and 0.01-1.0% (w / w) of oxidized graphene are added into a solution composed of N-methyl-pyrrolidone or dimethylacetamide or dimethylformamide and 1,4-dioxane, 3.0-21.0% (w / w) of additives is added, uniform stirring is carried out for 5-60min, then 15.0-40.0% (w / w) of cellulose acetate is added, full stirring is carried out at a temperature of 20-70 DEG C, the mixture is allowed to stand, and a hollow fiber positive osmotic membrane is obtained through spinning. The osmotic membrane employs 1M of NaCl as a drive liquid and deionized water as a raw material liquid, the water flux is 16.5L / m2h, the reverse salt flux is less than 3.5g / m2h, and the contact angle is 60.2 degrees in test time of 1h.

Owner:UNIV OF JINAN

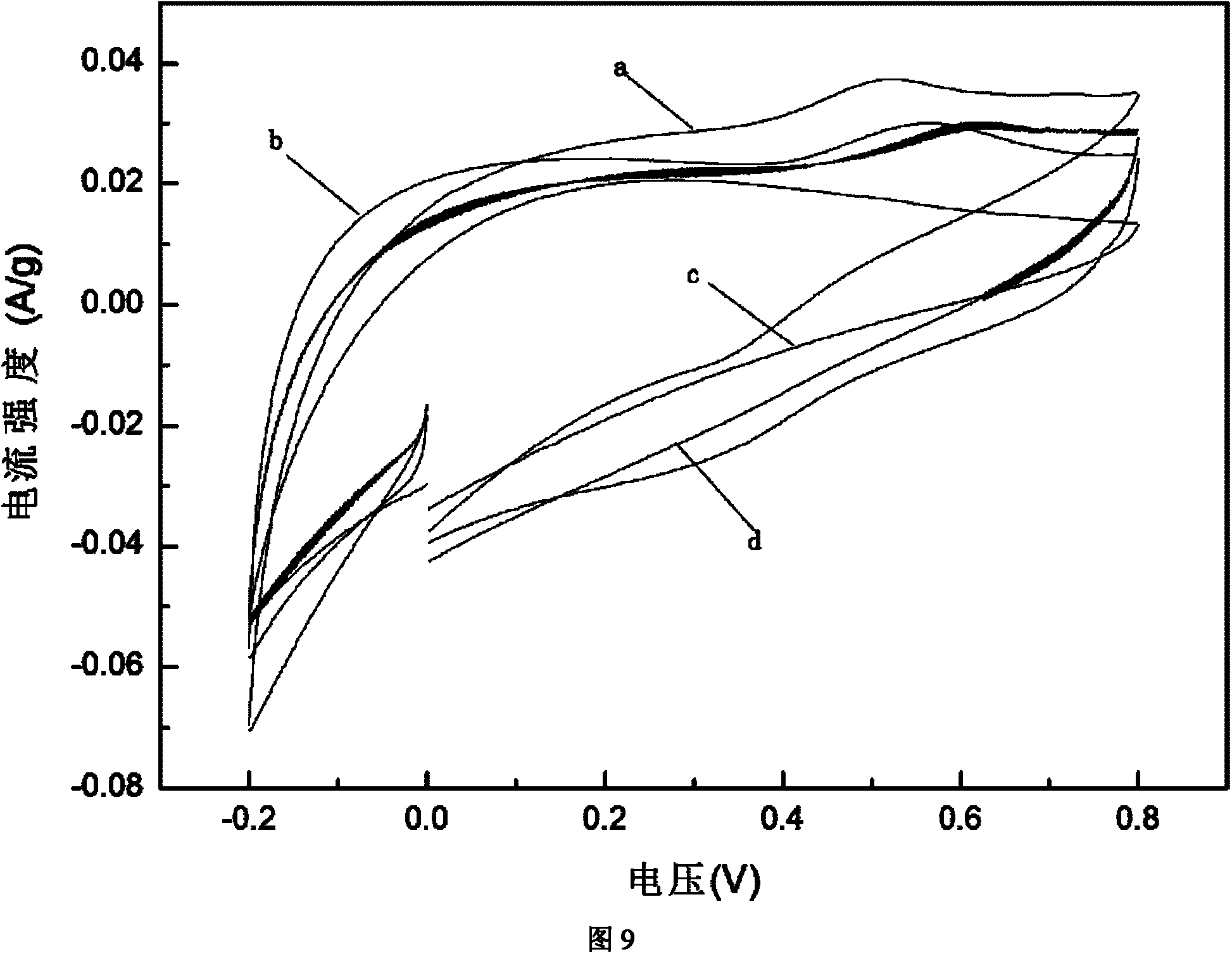

Method for preparing carbide film by carbonizing graphene reinforced polyimide resin

ActiveCN102560453AIncrease internal stressReduce brittlenessSolid/suspension decomposition chemical coatingCapacitancePolymer science

The invention discloses a method for preparing a carbide film by carbonizing graphene reinforced polyimide resin, and relates to a method for preparing a carbide film. The method solves the technical problems of high carbonizing temperature, high energy consumption, long carbonizing period and low carbonizing rate and low strength of the carbide film in the conventional method for preparing the carbide film. The method comprises the following steps of: 1, adding 4,4'-diamino diphenyl ether (ODA) and 3,3',4,4'-benzophenonetetracarboxylic dianhydride (BTDA) into N,N-dimethyl acetamide (DMAC), and performing mechanical stirring to obtain a polyamide acid (PAA) solution; 2, adding graphene into the PAA solution, and performing in-situ polymerization reaction to obtain a solution A; 3, spreading the solution A on a clean glass plate, heating to the temperature of 60 DEG C and preserving the heat for 2 hours, heating to the temperature of 100 DEG C and preserving the heat for 1 hour, heating to the temperature of 200 DEG C and preserving the heat for 1 hour, heating to the temperature of 300 DEG C and preserving the heat for 1 hour, and thus obtaining a composite film; and 4, carbonizing, naturally cooling to room temperature, and thus obtaining the carbide film. The carbide film has excellent mechanical properties; and because the adding proportion of the graphene is increased, the mechanical properties of the carbide film are improved, the specific capacitance of the graphene is also improved, and the carbide film is suitable to be used as an electrode material.

Organic-inorganic ultrafiltration composite membrane and preparation method thereof

InactiveCN103480281AImprove mechanical propertiesImprove pollutionSemi-permeable membranesSilanesUltrafiltration

The invention relates to an organic-inorganic ultrafiltration composite membrane and a preparation method thereof. The organic-inorganic ultrafiltration composite membrane comprises the following components in parts by weight: 15-20 parts of polymer resin, silane functionalized graphene oxides, 75-90 parts of N-N dimethyl acetamide and 1-3 parts of polyvinyl pyrrolidone, wherein the silane functionalized graphene oxides account for 0.02%-2.0% of the polymer resin. According to the invention, a membrane preparation process is simple and easy to realize; the silane functionalized graphene oxides are well dispersed to polymeric matrix through ultrasonic and mechanical stirring; the silane functionalized graphene oxides can be well dispersed in the polymeric matrix due to superhigh combination property, superhigh specific surface and more surface long polymer chains between the silane functionalized graphene oxides and the polymeric matrix; in addition, abundant oxygen-containing functional groups positioned on the surfaces of the silane functionalized graphene oxides can well enhance the hydrophilicity of the ultrafiltration composite membrane so as to synergically improve the mechanical property and pollution resistant property of the ultrafiltration composite membrane.

Owner:TIANJIN POLYTECHNIC UNIV

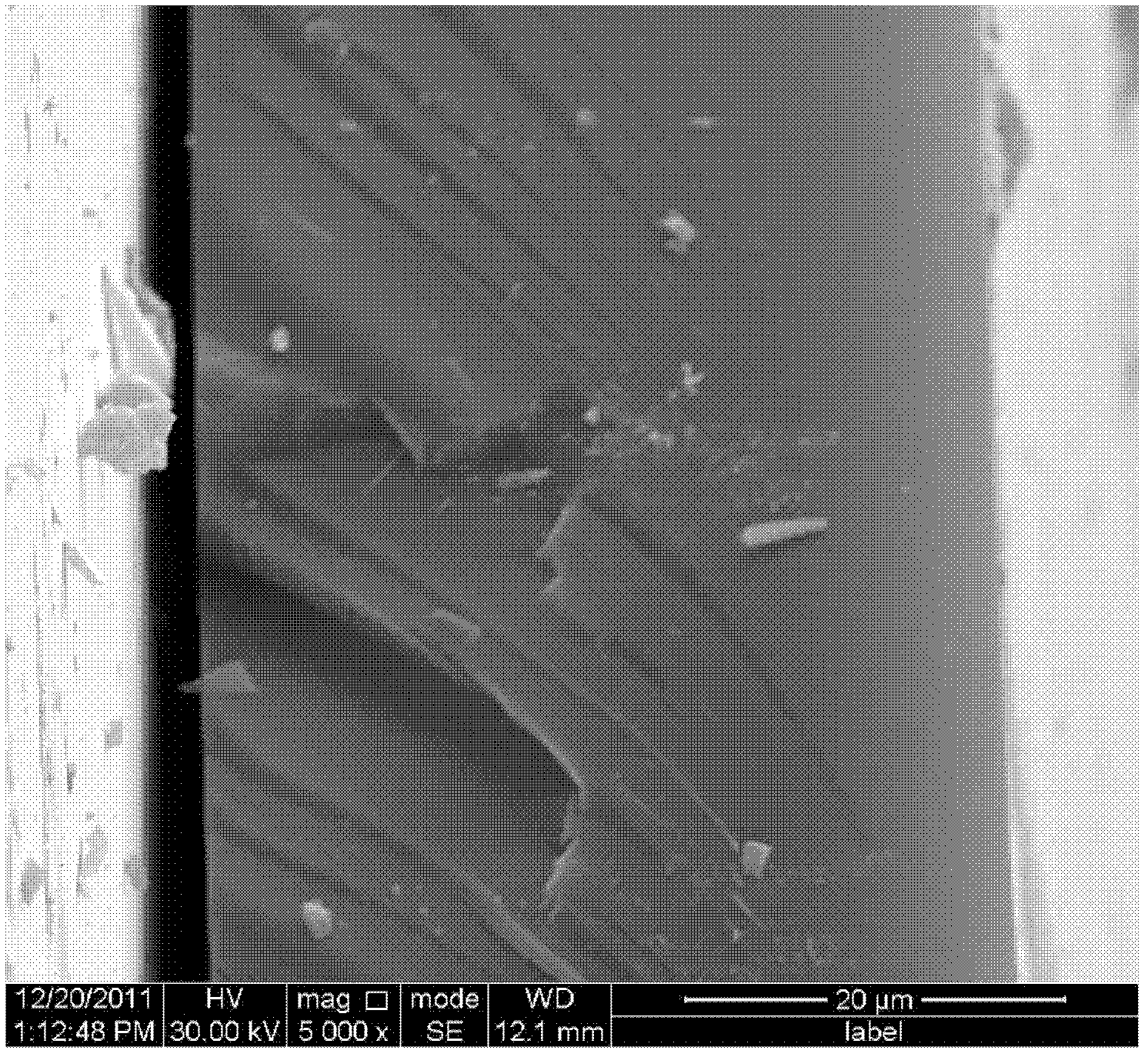

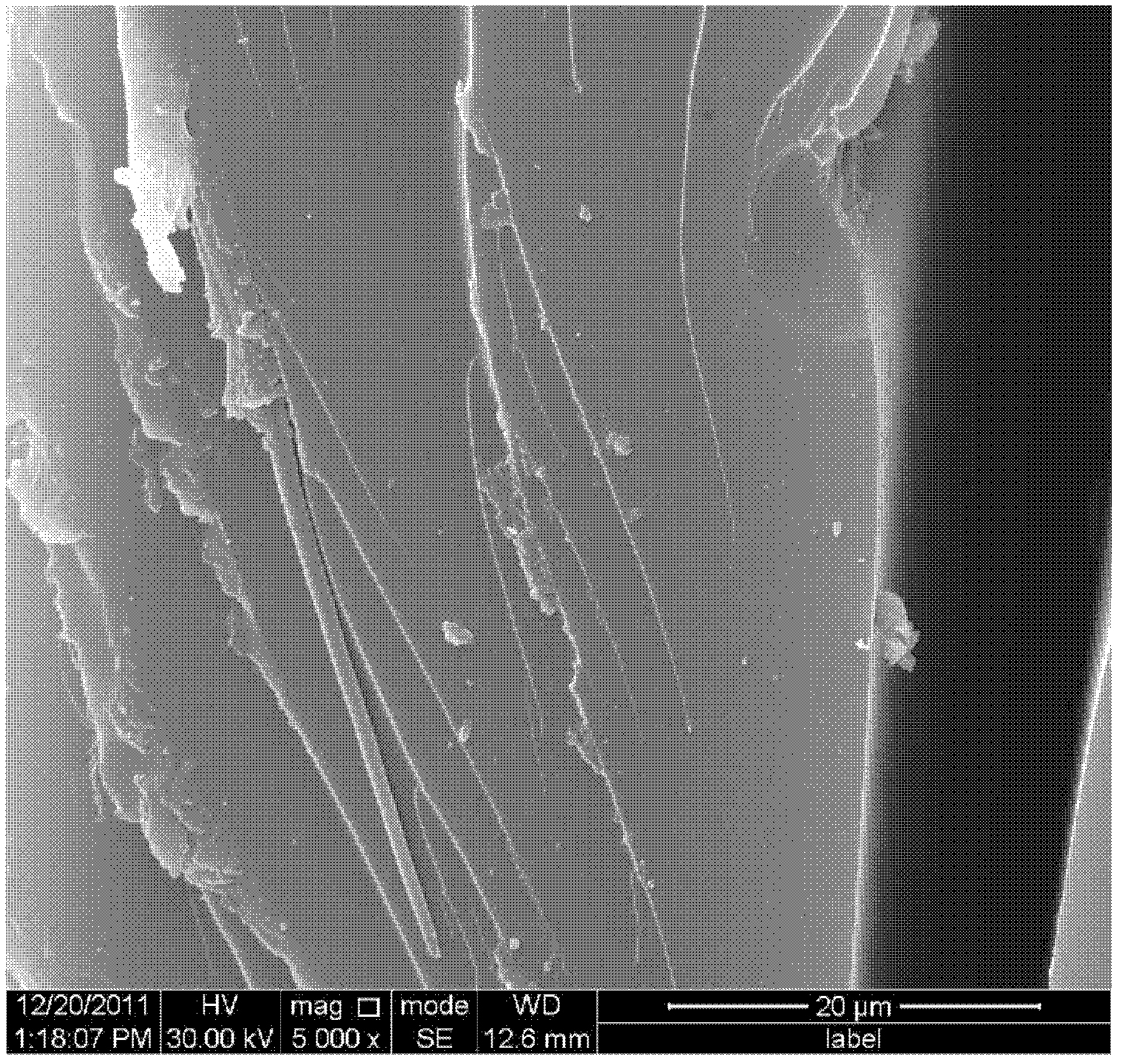

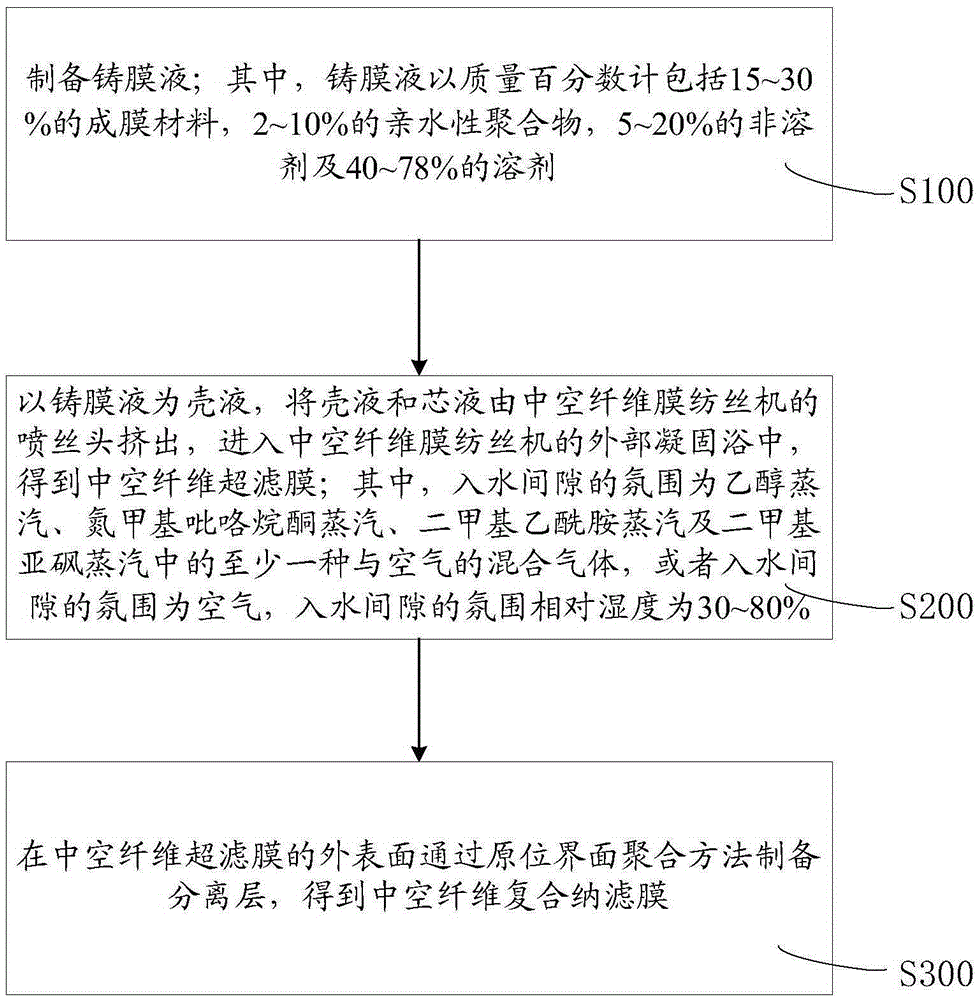

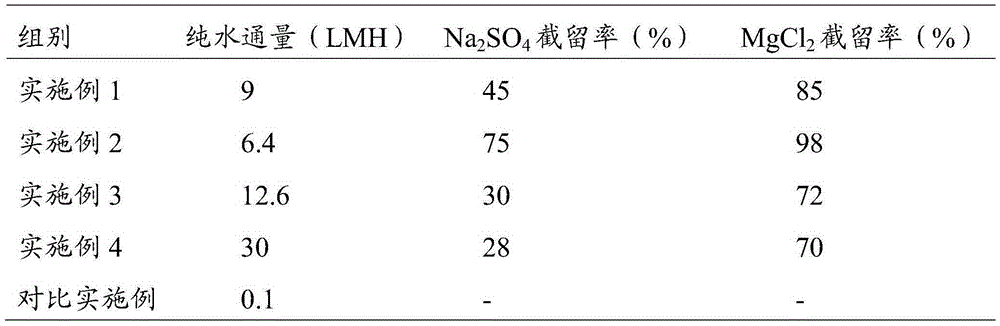

Hollow fiber composite nanofiltration membrane and preparation method thereof

The invention relates to a preparation method for a hollow fiber composite nanofiltration membrane. The preparation method comprises the following steps: with membrane casting liquid as shell liquid, extruding the shell liquid and core liquid into an external coagulation bath from a spinning nozzle so as to obtain a hollow fiber ultrafiltration membrane, wherein the membrane casting liquid comprises, by mass, 15 to 30% of a membrane forming material, 2 to 10% of a hydrophilic polymer, 5 to 20% of a poor solvent and 40 to 78% of a solvent, a water entry gap of the spinning nozzle is 5 to 30 cm, the atmosphere of the water entry gap is air or mixed gas of air and at least one selected from the group consisting of ethanol steam, nitrogen methyl pyrrolidone steam, dimethyl acetamide steam and dimethyl sulfoxide steam, and the relative humidity of the atmosphere of the water entry gap is 30 to 80%; and preparing a separating layer on the external surface of the hollow fiber ultrafiltration membrane by using an interfacial polymerization method so as to obtain the hollow fiber composite nanofiltration membrane. The prepared hollow fiber composite nanofiltration membrane has good mechanical strength, shows good permeability at low driving pressure and is small in driving pressure and high in separation efficiency. The invention also provides the hollow fiber composite nanofiltration membrane.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

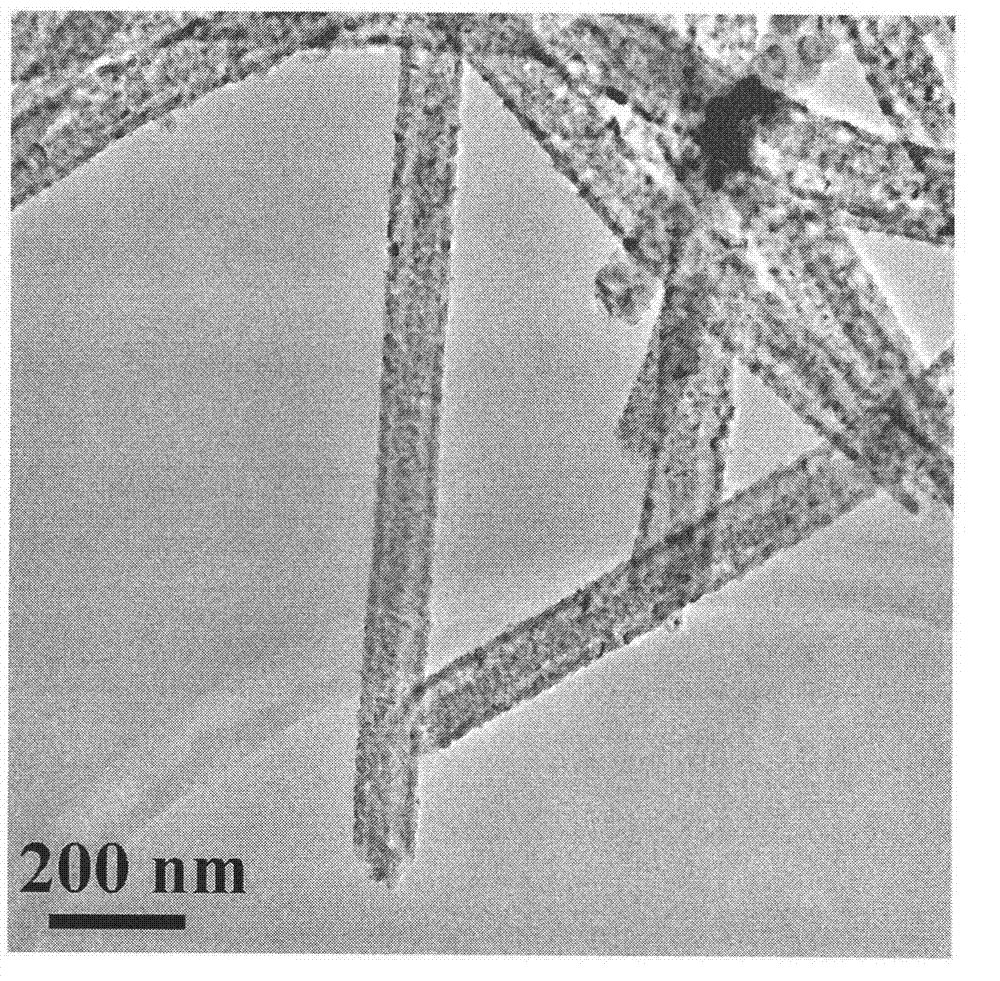

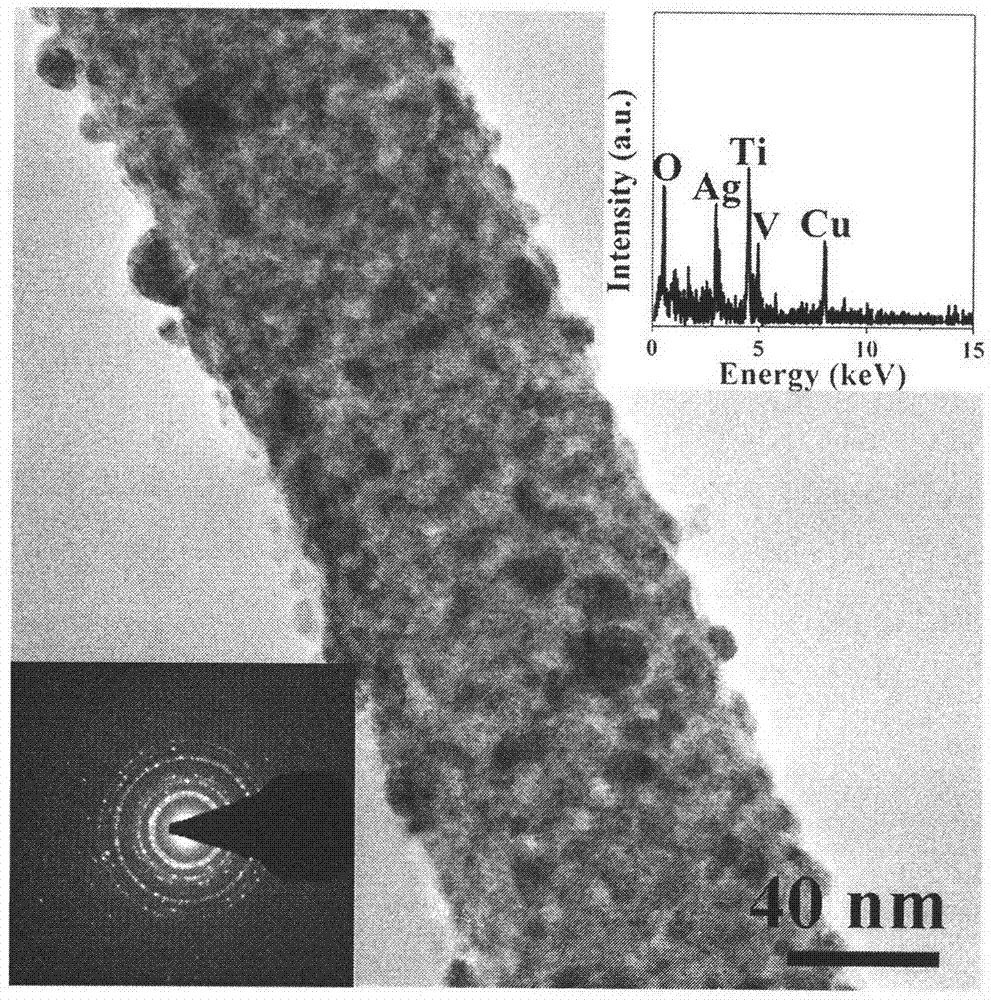

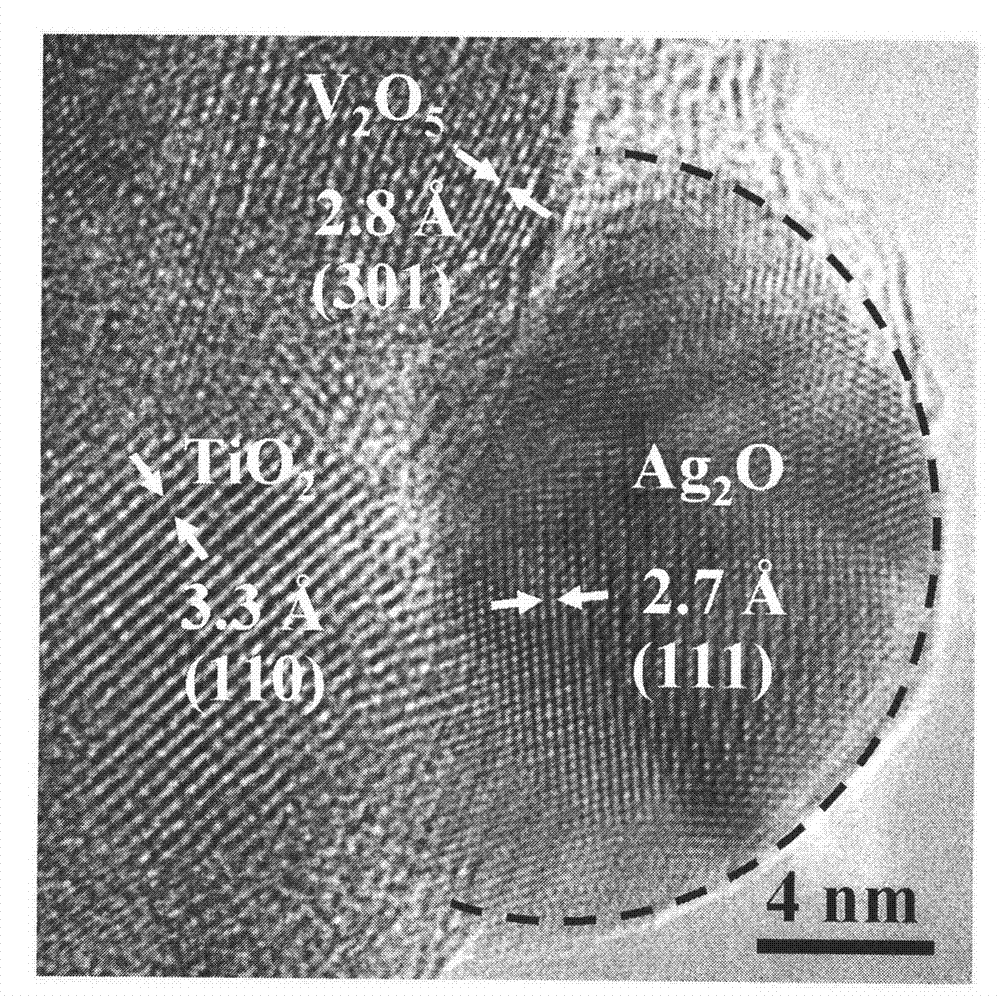

Sunlight responding nano hetero-structure photocatalyst and preparation method thereof

InactiveCN103706362ASolving the problem of difficult near-infrared photoresponseEfficient separationMetal/metal-oxides/metal-hydroxide catalystsFiberSolar photocatalysis

The invention provides a sunlight full-spectrum responding Ag2O / TiO2 / V2O5 nano hetero-structure photocatalyst and a preparation method thereof. The preparation method is characterized by comprising the following steps: mixing tetrabutyl titanate, polyvinylpyrrolidone, absolute ethanol, dimethyl acetamide and glacial acetic acid so as to obtain a solution A, mixing vanadium(IV) oxide acetylacetonate, polyvinylpyrrolidone and dimethyl acetamide so as to obtain a solution B, mixing the solution A and the solution B so as to obtain a polyvinylpyrrolidone / titanate / vanadium(IV) oxide acetylacetonate mixed solution, spinning the mixed solution by an electro-spinning method so as to obtain TiO2 / V2O5 nano fibers, then soaking AgNO3 and the TiO2 / V2O5 nano fibers in deionized water, injecting a NaOH solution into the deionized water, and drying so as to obtain the Ag2O / TiO2 / V2O5 nano hetero-structure photocatalyst. The Ag2O / TiO2 / V2O5 nano hetero-structure photocatalyst can well absorb lights in the ultraviolet zone, visible zone, and near infrared zone; at the same time, energy bands of the Ag2O, TiO2, and V2O5 are reasonably matched, thus the photo-produced electronic cavities can be effectively separated, so the Ag2O / TiO2 / V2O5 nano hetero-structure photocatalyst has a very high sunlight catalytic activity.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Post-treatment new process for aramid fibre III raw tow

InactiveCN1473969AGuaranteed uniformityImprove yieldArtificial filament heat treatmentMonocomponent polyamides artificial filamentNitrogen gasSolvent

The aramid III fiber as a new kind of high-strength material has wide application. Aramid III liquid is prepared with the materials including p-phenlenediamine, terephthalyl chloride and 5(6)-amino-2-(3-aminophenyl) benzimidazole and through low temperature copolymerization in dimethyl acetamide solvent; and is produced into aramid III fiber through serial spinning steps. The present invention provides the post-treatment technological process to raise the strength of aramid III fiber from 1.5 GPa to 4.5 GPa. The post-treatment process includes the treatment in the apparatus comprising tensioner, oiling machine, heating furnace and winding machine with the tension controlled in 0.2-1.0 CN / tex, temperature inside the nitrogen protected furnace 320-500 deg.c, and heating time 0.5-5 min. The raw tow is heated under motion inside the furnace homogeneously.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

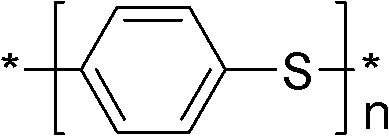

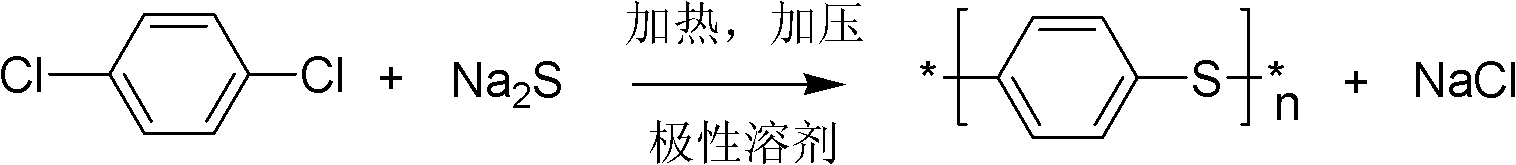

Method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin

ActiveCN103073720AThe average molecular weight is largeMolecular distribution index is smallMonocomponent synthetic polymer artificial filamentFiberPolymer science

The invention discloses a method for synthesizing low-color high-purity fiber-grade polyphenylene sulfide resin. According to the invention, sodium sulfide and p-dichlorobenzene are adopted as raw materials; N-methyl pyrrolidone, N,N-dimethyl acetamide, and the like are adopted as solvents; under the existence of a basic salt, through a four-step method comprising pre-polymerization, polymerization, chain extension and end-capping, the high-purity low-color fiber-grade polyphenylene sulfide resin is synthesized. By adjusting process parameters, polyphenylene sulfide average molecular weight and distribution index can be effectively controlled. Also, purification process can be simplified, and metal ion embedding can be reduced. Resin slice color is reduced, resin processing stability is improved, and resin performance is improved.

Owner:CHINA PETROLEUM & CHEM CORP

Fire-resistant high-resiliency spandex fabric and method for making same

InactiveCN101113534AIncrease elasticityHigh temperature high elasticityMonocomponent polyurethanes artificial filamentFilament/thread formingYarnPolymer science

The invention discloses a urethane elastic fiber with high temperature resistance and high elasticity and a preparation method thereof, the materials of the urethane elastic fiber comprise: polyether diols, diisocyanate, butanol, amine admixture, anti-oxidant, reelability agent, ultraviolet absorber, yellowing resistant agent and dimethyl acetamide; the preparation method of the urethane elastic fiber is that: a prepolymer is obtained through prepolymerization reation, and macromolecule polymer is also obtained through continuous chain extension reactions, then spinning solution is formed by adding different auxiliary agents; finally winding and dry spinning through round spinning channel are performed to obtain a high temperature high elastic urethane fiber spinning can which has the advantages of high temperature resistance, high elasticity, excellent reelability, outstanding yarn evenness, etc, and the preparation method can realize the continuous process of chain extension reactions and addition of auxiliary agents with continuous and stable production process and high product evenness and can completely meet the requirements of all kinds of novel fabrics and high grade fabrics.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

Polyimide containing benzimidazole unit and preparation method thereof

The invention relates to polyimide containing a benzimidazole unit and a preparation method thereof. The polyimide has the following structural formula. The preparation method comprises the following steps of: firstly, performing the reaction on 2,6-disubstituted aniline and aldehyde under the acidic condition to generate a diamine compound 3,3',5,5'-tetra-substituted aromatic diamine; and then, after mixing the synthesized aromatic diamine and a heterocyclic diamine monomer 6-aminophenyl-2-aminobenzimidazole according to a certain ratio, performing the reaction on the mixture and a dianhydride monomer in an organic solvent to obtain the polyimide. The polyimide provided by the invention has excellent solubility property, can be dissolved in conventional solvents such as NMP (N-methyl-2-pyrrolidone) and DMAc (dimethyl acetamide), has excellent heat resistance and mechanical property and has excellent thermal properties of glass-transition temperature of over 410 DEG C, decomposition temperature of over 500 DEG C and the like.

Owner:DONGHUA UNIV

Preparation for continuous fibre reinforced poly(phthalazinone ehter sulfone ketone) composite materials

The invention belongs to the advanced compound materials science domain. Publicized a kind of continual textile fiber enhancement to gather the fragrant ether sulphone alkone (PPESK, when its S / K=0 was PPEK; When S / K=1 is the PPES advanced compound material preparation) its characteristic is gathers the fragrant ether sulphone alkone (PPES) to dissolve in N, the N- dimethyl acetamide (DMAc) either the N- methyl pyrrolidone (NMP) or in the chloroform or their component solvent, compounds 20%-40% (quality content) the PPESK solution, separately soaks the continual glass fiber, the carbon fiber, the fragrant black silk ribbon textile fiber, the system results in the preliminary dip material piece. Twines the preliminary dip thin slice after the textile fiber or pulls crowds takes shape the craft system type, carries on the thermo-compression to take shape, its main craft parameter as follows: Cold-press: 25~35MPa / 2~10min+ preheating: 380deg.C / 40~90min+ thermo-compression: 20~40MPa / 380deg.C / 40~90min+ cooling: 100deg.C / natural cooling + drawing of patterns. The invention effect and the profit are causes the continual textile fiber high performance thermosplastic tree fatty group compound material solution preliminary dip to take shape the craft to become possibly, has the practical value regarding the impetus advanced compound material development and the development in the astronautics aviation domain application.

Owner:DALIAN UNIV OF TECH

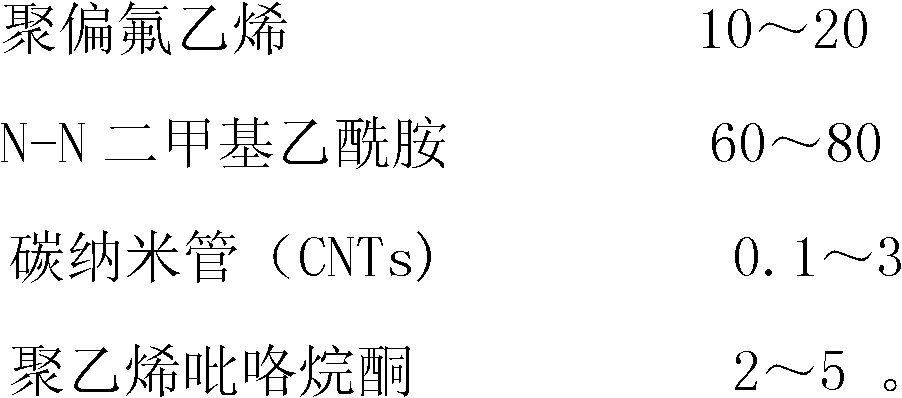

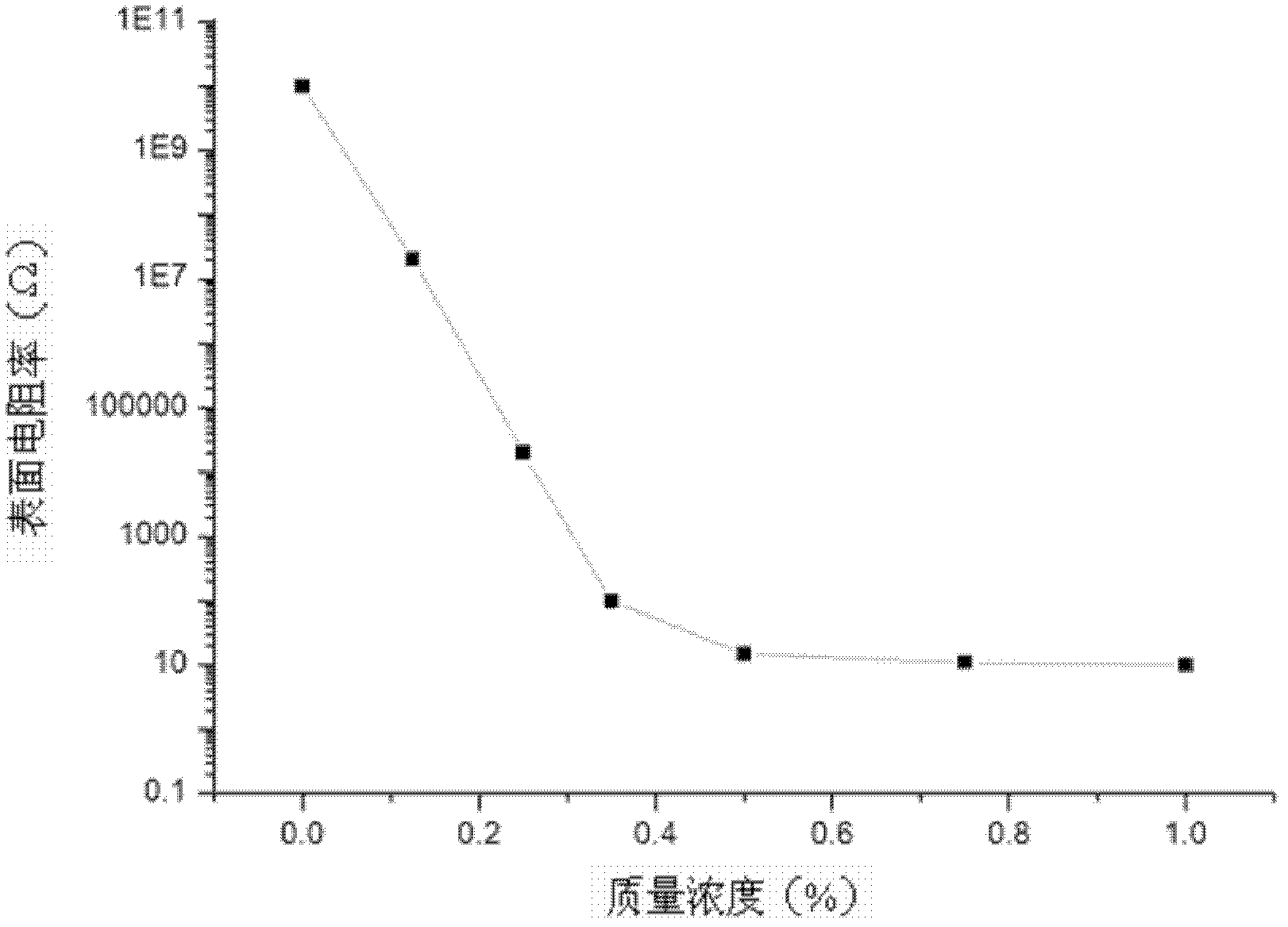

Polyvinylidene fluoride-carbon nano tube composite separation film and preparation method thereof

InactiveCN102614784AImprove hydrophilicityImprove anti-pollution performanceSemi-permeable membranesComposite filmCarbon nanotube

The invention discloses a polyvinylidene fluoride-carbon nano tube composite separation film and a preparation method thereof. The separation film consists of the following components in part by weight: 10 to 20 parts of polyvinylidene fluoride, 60 to 80 parts of N-N dimethyl acetamide, 0.1 to 3 parts of carbon nano tube and 2 to 5 parts of polyvinyl pyrrolidone. The method for preparing the polyvinylidene fluoride-carbon nano tube composite separation film comprises the following steps of: uniformly dispersing carbon nano tubes in the polyvinylidene fluoride by an ultrasonic and mechanical stirring method, and finally preparing a carbon nano tube-doped polyvinylidene fluoride composite film by a wet-phase inversion method. Due to the carbon nano tubes, the surface energy of the polyvinylidene fluoride can be well improved, the hydrophilicity of the film is improved, and the pollution resistance of the film is improved, so that pure water flux of the film is greatly improved; and moreover, the original excellent properties of the polyvinylidene fluoride are not influenced by the carbon nano tubes, the spatial association of the film is improved, the strength of the film is improved, and the service life of the film is prolonged. The preparation method is simple in process and convenient to operate.

Owner:TIANJIN POLYTECHNIC UNIV

Lithium sulfur battery

ActiveCN104143614ASufficient conductivityThe charge and discharge reaction is smoothMaterial nanotechnologyLi-accumulatorsLithium chlorideLithium bromide

The invention belongs to the technical field of lithium sulfur batteries, and concretely relates to a lithium sulfur battery new system. The new system comprises an electrolyte and a diaphragm matched with the electrolyte. The electrolyte is a lithium salt solution with the concentration of 0.1-3mol / L, and a lithium salt solute in the lithium salt solution is one or a mixture comprising two or more of lithium fluoride, lithium chloride, lithium bromide or lithium iodide; a solvent is one of or a mixture comprising two or more of N,N-dimethyl formamide, N,N-dimethyl acetamide, dimethyl sulfoxide, tetramethyl sulfone, tetrahydrofuran, N-methyl-2-pyrrolidone and acetonitrile; and the diaphragm is a micro-porous membrane with the aperture of 0.5-10nm or a dense membrane containing anions. The micro-porous diaphragm subjected to surface modification and hot pressing can be fully infiltrated in the micro-molecular lithium salt electrolyte and has an appropriate dimension to make electrolyte ions freely go through in order to inhibit or prevent the migration of polysulfide. The lithium salt has a low price, so the battery has the cost advantage.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method of surface self-assembly of graphene/polyimide transparent electric conduction film

ActiveCN102592749AImprove incompatibilitySimple processConductive layers on insulating-supportsCable/conductor manufactureOmegaUltrasonic dispersion

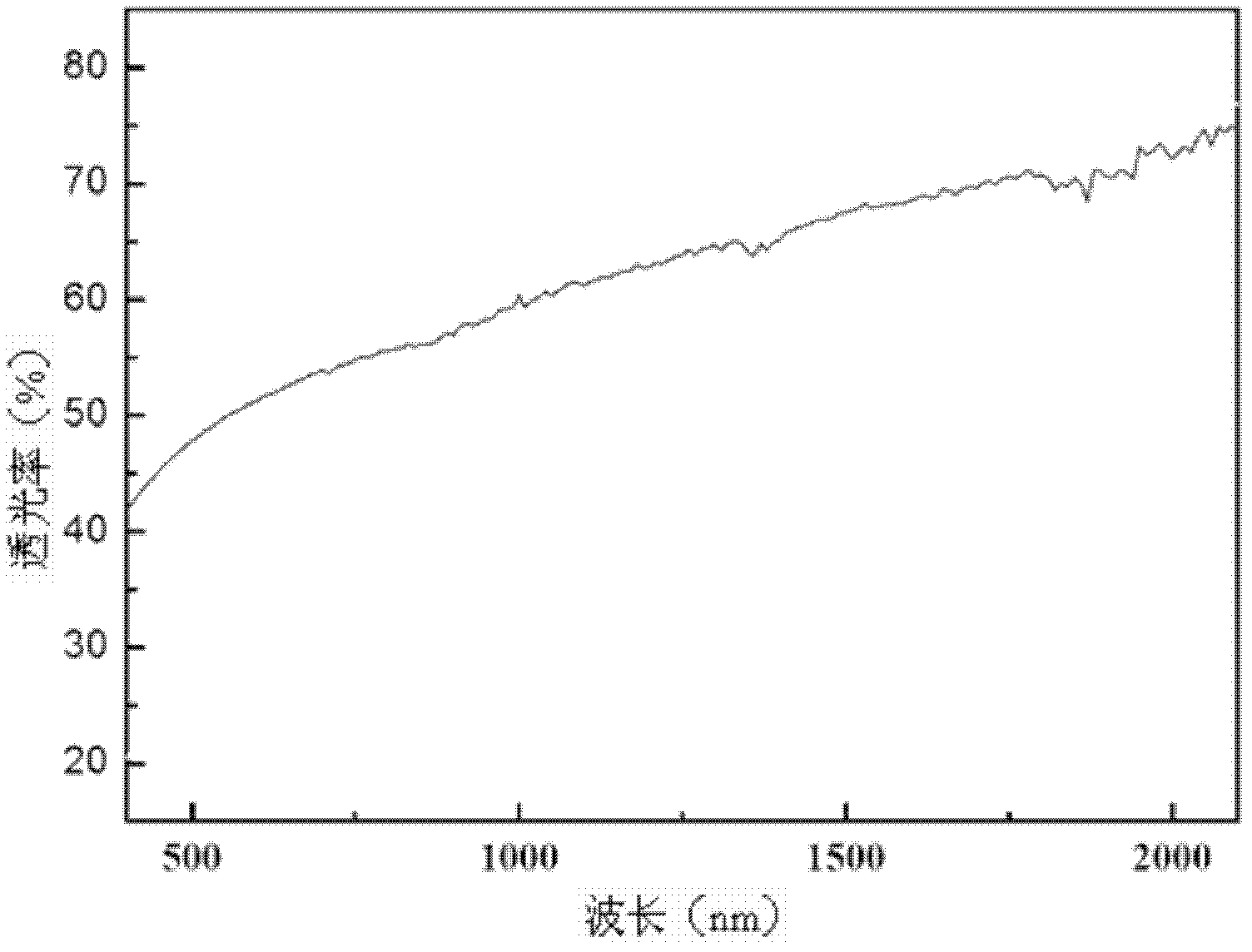

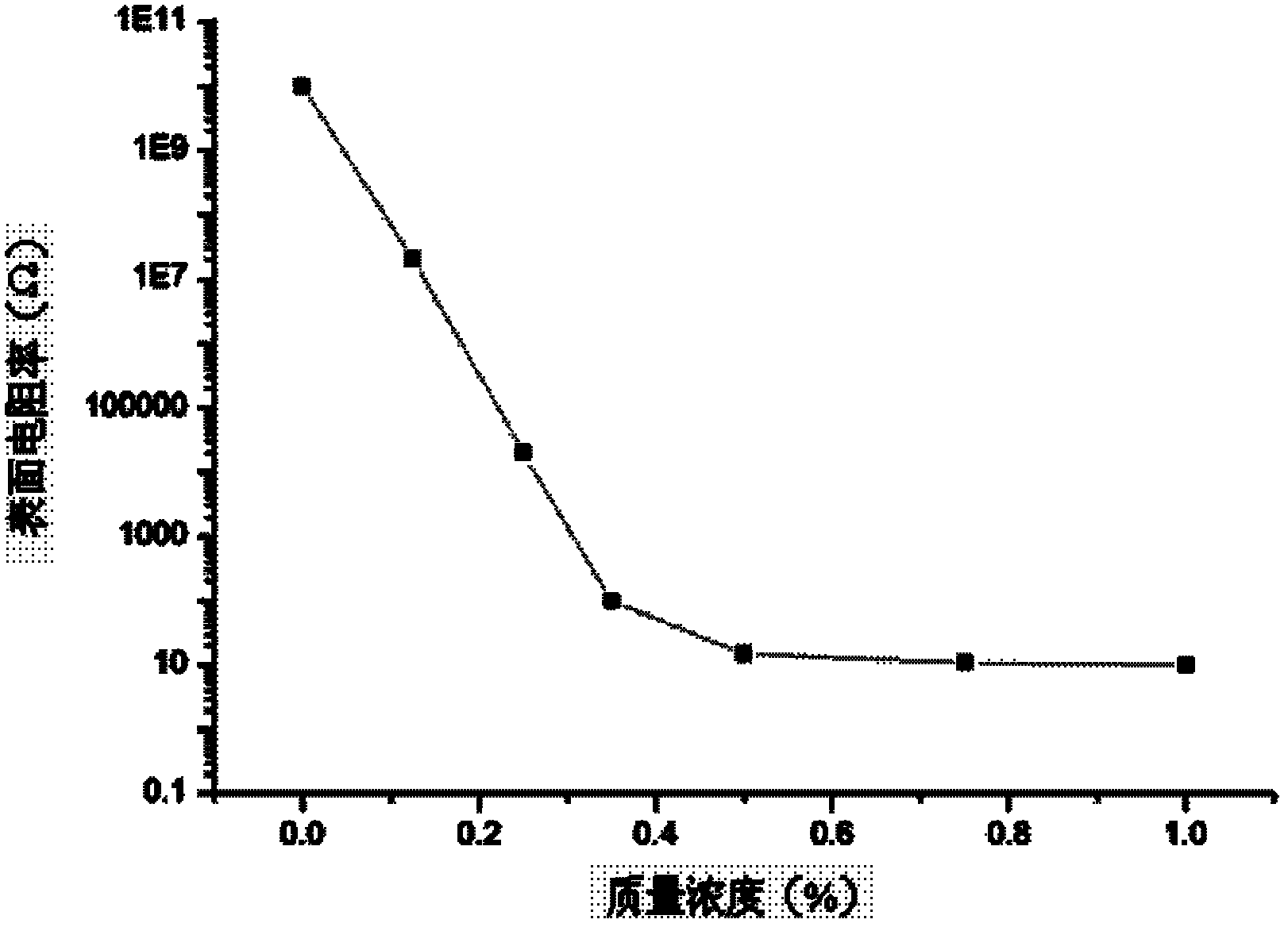

The invention relates to a method of surface self-assembly of graphene / polyimide transparent electric conduction film, and relates to a preparation method of the graphene / polyimide transparent electric conduction film. The invention aims to solve the technical problems that the adhesive force of a flexible substrate and a settled layer in the existing flexible electric conduction film is weak, and an inorganic electric conduction layer and an organic base are incompatible. The method comprises the following steps: firstly, placing graphite oxide respectively in N,N-dimethyl acetamide or N-methyl pyrrolidone, carrying out ultrasonic dispersion, adding a reducing agent, and carrying out reduction reaction, thereby obtaining a graphene organic solution system; secondly, adding a dianhydride monomer and a diamine monomer in N, N-dimethyl acetamide, and stirring in an inert atmosphere, thereby obtaining a PAA (poly acrylic acid) solution; and thirdly, mixing and stirring the graphene organic solution system and the PAA solution, then coating on a clean and dry glass plate, volatilizing the solvent and curing. The surface resistance of the graphene / polyimide transparent electric conduction film prepared by the method provided by the invention is 10-20 omega, and the graphene / polyimide transparent electric conduction film has favorable light transmissivity at the visible light wave band and the near-infrared wave band.

Owner:HARBIN INST OF TECH

Polyimide fiber and its preparing method

InactiveCN1821457AOptimize synthesis conditionsGood mechanical propertiesMonocomponent synthetic polymer artificial filamentDiphenyl etherFiber

The present invention discloses a kind of polyimide fiber and its preparation process. The preparation process includes the following steps: 1. reacting 4, 4í»-diamino diphenyl ether and pyromellitic dianhydride in the weight ratio of 1 to 1.02 with N, N-dimethyl acetylamide solution of 15-20 % concentration at 0-5 deg.c to obtain polyamic acid solution; 2. wet spinning the polyamic acid solution and imidation reaction of the polyamic acid fiber to obtain polyimide fiber through dewatering and cyclization; and 3. mixing the polyimide fiber with acetic anhydride and triethylamide, flushing with acetone, soaking and drying to obtain the polyimide fiber. The present invention has positive effects of optimized synthesis condition of spinning solution, prolonged solidification period of initially formed fiber in the solidification bath, and fiber with ideal mechanical performance.

Owner:DONGHUA UNIV

Method for preparing 5-hydroxymethylfurfural with fructose

InactiveCN102153527AHigh yieldMild reaction conditionsOrganic chemistryChemical recyclingLithium chlorideHeteropoly acid

The invention discloses a method for preparing 5-hydroxymethylfurfural with fructose. The method includes the following steps: taking N, N-dimethyl acetamide as solvent, lithium chloride as additive, fructose as a reaction material, and heteropoly acid loaded by titanium dioxide as a catalyst, reacting at the temperature of 80-150DEG C to generate 5-hydroxymethylfurfural. The method has the characteristics of few by-products, high yield, environment-friendly property, moderate reaction conditions, small corrosion to equipment, recyclability of catalyst, and the like, and has industrial prospect.

Owner:海宁市袁花镇工业投资有限公司

Method for preparing organic and inorganic nanometer assorted fibre

InactiveCN101338459AEven mixing effectUniform dispersionOther chemical processesPharmaceutical delivery mechanismFiberWater baths

The invention relates to a preparation method of an organic / inorganic nano-assorted fiber. The preparation method comprises the procedures that (1) inorganic substance suspends in dimethyl acetamide or formic acid spinning solvent in the water bath with the temperature of 20 to 60 DEG C; macromoleclar polymer is added and stirred at the rotating speed of 200 to 450rpm and swells for 24 hours in the water bath with the temperature 20 to 60 DEG C; and the macromoleclar polymer is cooled to room temperature to acquire dope with even dispersion: and (2) the dope is poured into a liquid reservoir; a bullet-shaped syringe needle is adopted as a capillary for spraying a streamlet; after HYEF spinning, the dope is dried under vacuum and normal temperature; and optional post-treatment is carried out, the functional composite nano fiber is made. The preparation method is simple with mild preparation condition and simplifies compound process. The composite nano fiber has high superficial area and is widely dispersed, so the composite nano fiber is applicable for preparing a drug delivery system, anti-bacterial textile, material separation, the water pollution treatment of metal ions and organic compound, etc.

Owner:DONGHUA UNIV

Formulation comprising a gemcitabine-prodrug

This invention relates to pharmaceutical formulations of gemcitabine-[phenyl-benzoxy-L-alaninyl)]-phosphate, a monophosphate derivative of the well-known oncology drug gemcitabine. In particular, the invention relates to formulations which comprise a polar aprotic solvent, preferably dimethyl acetamide (DMA). Formulations comprising these solvent provide therapeutically effective treatments of gemcitabine-[phenyl-benzoxy-L-alaninyl)]-phosphate. The invention also relates to methods of using said formulations and kits comprising said formulations.

Owner:NUCANA PLC

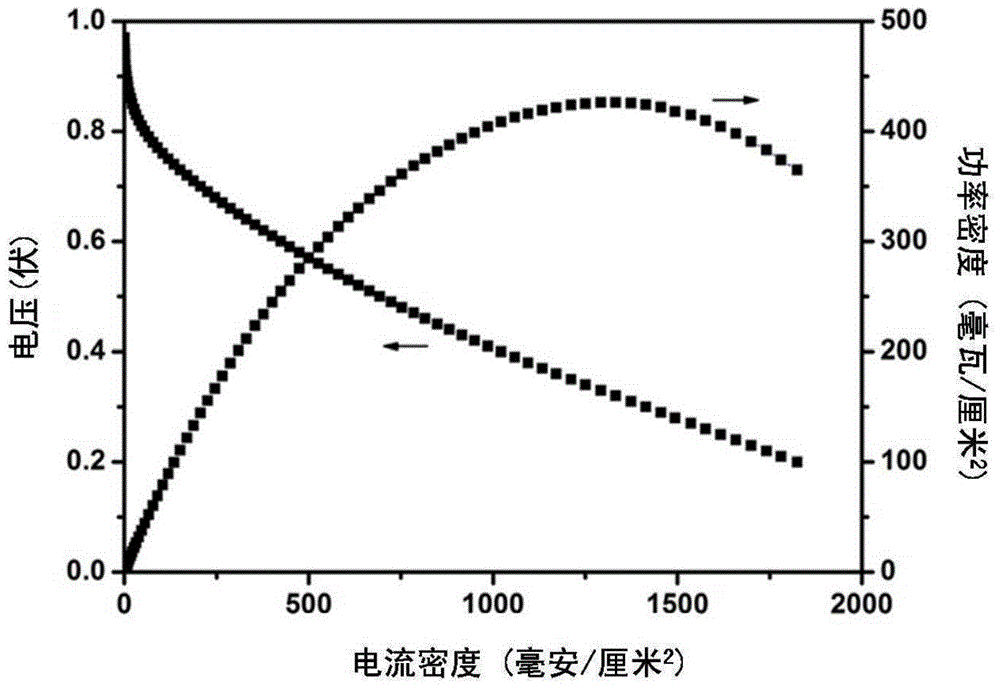

Organic-inorganic composite proton exchange membrane for proton exchange membrane fuel cell and preparation method thereof

ActiveCN104659395AImprove developmentMeet the needs of different application fieldsFinal product manufactureSolid electrolyte fuel cellsSide chainHeteropoly acid

The invention discloses an organic-inorganic composite proton exchange membrane for a proton exchange membrane fuel cell and a preparation method thereof. The proton exchange membrane comprises a functional polymer (such as polyvinylpyrrolidone) of which the side chain contains N-heterocycle, heteropoly acid and skeleton polymers (such as polyvinylidene fluoride, polyethersulfone, polysulfone and polyethylene sulfone). The preparation method comprises adding the functional polymer, the skeleton polymers and the heteropoly acid into an organic solvent (such as N, N-dimethyl formamide, N, N-dimethyl acetamide and N-methyl-2-pyrrolidone), heating the mixture with stirring until complete dissolution so that a transparent and uniform proton exchange membrane solution is obtained, and carrying out solution casting or curtain coating to obtain the organic-inorganic composite proton exchange membrane. The organic-inorganic composite proton exchange membrane is uniform, transparent and compact, has excellent chemical stability, heat stability, mechanical properties and proton conductivity, and does not lost a proton conductor easily. The preparation method utilizes easily available and cheap raw materials, has simple processes, is suitable for large-scale production and can be widely used in fuel cells, flow cells, plumbic acid cells and a water-electrolyser.

Owner:北京海得利兹新技术有限公司

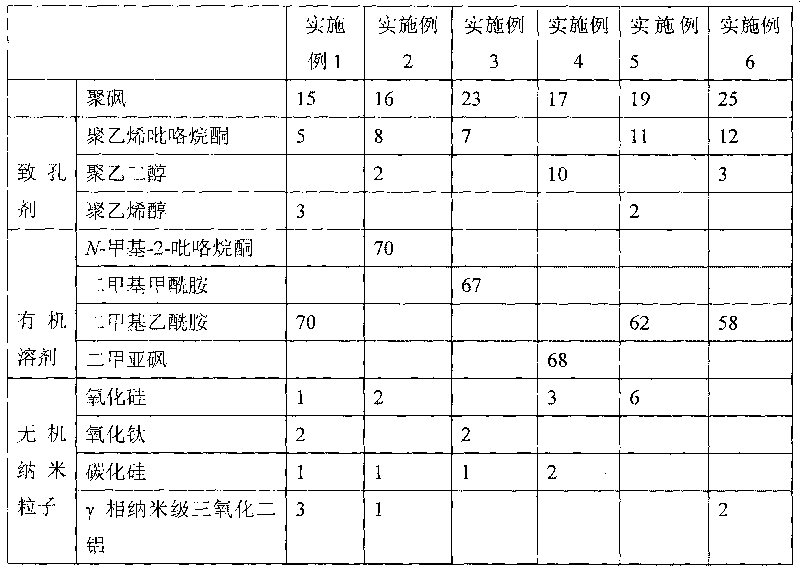

Blending modified hollow polysulfone fiber film, preparation method and application thereof

InactiveCN101711954AImprove featuresGood biocompatibilitySemi-permeable membranesSuction devicesFiberPolyethylene glycol

The invention relates to a blending modified hollow polysulfone fiber film which comprises the following components in percentage by weight: 3-40 percent of polysulfone, 0.5-20 percent of porogen, 50-90 percent of organic solvent and 0.5-20 percent of inorganic nano particles, wherein the inorganic nano particles are one or the mixture of more than two of silicon oxide nano particles, titanium oxide nano particles, silicon carbide nano particles and gamma-phase aluminium oxide nano particles; the viscosity-average molecular weight of the polysulfone is 40,000-200,000; the organic solvent is one of N-methyl-2-pyrrolidone, dimethyl acetamide or dimethyl sulfoxide; and the porogen is one or a mixture of any two of polyvinylpyrrolidone, polyethylene glycol and polyvinyl alcohol. The invention improves the surface property, the hydrophilic property and the mechanical strength of the film through modifying the hollow polysulfone fiber film, has simple film preparation process, and can realize industrial mass production.

Owner:江苏朗生生命科技有限公司

Production of black polyamide thin film

Production of black polyimide thin film is carried out by high-speed agitating while crushing for carbon black methyl acetamino solution 10-20 wt% with poly(diphenyl ether) tetramethyl-imide precursor solution at 2800-6000 / min below 20-50 degree to obtain black slurry with granular diameter <5mum, reacting of aromatic dianhydride and aromatic diamino in dimethyl acetamide solution at 20-45 degree for 3-4.5 hrs to obtain polyamide acid solution, high-speed agitating for black slurry for 1-2 hrs, adding into polyamide acid solution with viscosity 10-25 mins, agitating at 150 / min for 2-3 hrs to obtain black solution with viscosity 10-25 mins, doctor blade casting or latex dipping and filming. The thickness is 25-125mum, the extensibility is 18-20%, tensile strength is 140-160 MPa, and dielectric strength is 20-30 MV / m.

Owner:SHANGHAI PLASTICS RES INST CO LTD

Method for winding cardo-containing polyaryletherketone or polyarylethersuifone resin matrix composite

The invention discloses a method for winding a cardo-containing polyaryletherketone or polyarylethersuifone resin matrix composite, which comprises the following steps that: N-methylpyrrolidone, chloroform, N,N-dimethyl acetamide, morpholine or methylene dichloride and other solvents are used to prepare a PEK-E or PES-C resin solution at a certain concentration; continuous fibers are impregnated with gum and the solvent is removed to prepare a prepreg; during winding, the prepreg is first pre-heated to a certain temperature before reaching a mandrel, and then wound on the surface of the mandrel in a longitudinal direction, circumferential direction or alternately in the two directions under the action of a certain tensile force; and at the same time, the prepreg is further heated to promote the rise matrix to be fused quickly to adhere winding layers and finally consolidates and cools to form a compact winding structure. The method of the invention can manufacture high-performance thermoplastic composite winding members which are light in weight, high in strength and high temperature-resistance, and can meet the needs of petrochemical, sports, building and aerospace fields and other fields.

Owner:SHENYANG INST OF AERONAUTICAL ENG +1

Lithium ion sieve membrane and preparation method thereof

InactiveCN102211012AImprove permeabilityEasy to makeOther chemical processesAlkali metal oxides/hydroxidesPhysical chemistryAcid washing

The invention discloses a lithium ion sieve membrane and a preparation method thereof. The preparation method of the lithium ion sieve membrane is characterized by comprising the following steps of: dissolving polyvinylidene fluoride in N,N-dimethyl acetamide to prepare membrane casting liquid, and then adding lithium manganese oxide precursors; after mixing, heating and agitating; fully dispersing the lithium manganese oxide in the membrane casting liquid through ultrasound, standing, curing, fully defoaming, scraping a clean glass plate into a membrane, and immersing the membrane in a coagulation bath for coagulating; and finally acid-washing the made membrane, and extracting lithium ions in the precursors to obtain the lithium ion sieve membrane. The invention has the advantages of simple preparation process and convenience for use and has good application prospects in seawater lithium extraction.

Owner:OCEAN UNIV OF CHINA

Prepn of polyimide film for copper to be clad on

The preparation process of polyimide film includes mixing diamine, maleic anhydride and dimethyl acetamide in certain molar ratio to form resin, dip coating or flow casting resin at 50-250 deg.c to form polyamide film, high temperature ring closing imidizing and cross-linking at 300-450 deg.c to form polyimide film for copper to be clad on. The polyimide film has heat stability of size, tin ironing resistance and flexibility except excellent characteristic of common polyimide film. It has double-bond component, such as maleic anhydride or maleimide, added for modification to reach the size stability.

Owner:SHANGHAI JINSHAN QIANFENG INSULATING MATERIAL

Method for preparing low-temperature finalizing polyurethane elastic fiber

ActiveCN102899740AReduce energy consumptionGood shaping effectMonocomponent synthetic polymer artificial filamentPolyesterPolymer science

The invention relates to a method for preparing a low-temperature finalizing polyurethane elastic fiber, comprising the steps of carrying out condensation polymerization on polyether diol PTMG, polyester diol PE, diphenylmethane diisocyanate MDI and tetramethyl benzene dimethyl diisocyanate m-TMXDI to obtain a carbamic acid ester prepolymer, fully dissolving the prepolymer by taking DMAC (Dimethyl Acetamide) or DMF (Dimethyl Formamide) as the solvent, carrying out chain extension and chain termination on the prepolymer by using a chain extender and a chain terminator to obtain polyurethane urea solution, and finally adding various functional auxiliaries in the polyurethane urea solution and preparing to obtain the polyurethane elastic fiber with low-temperature finalizing performance via a dry spinning system.

Owner:ZHEJIANG HUAFENG SPANDEX

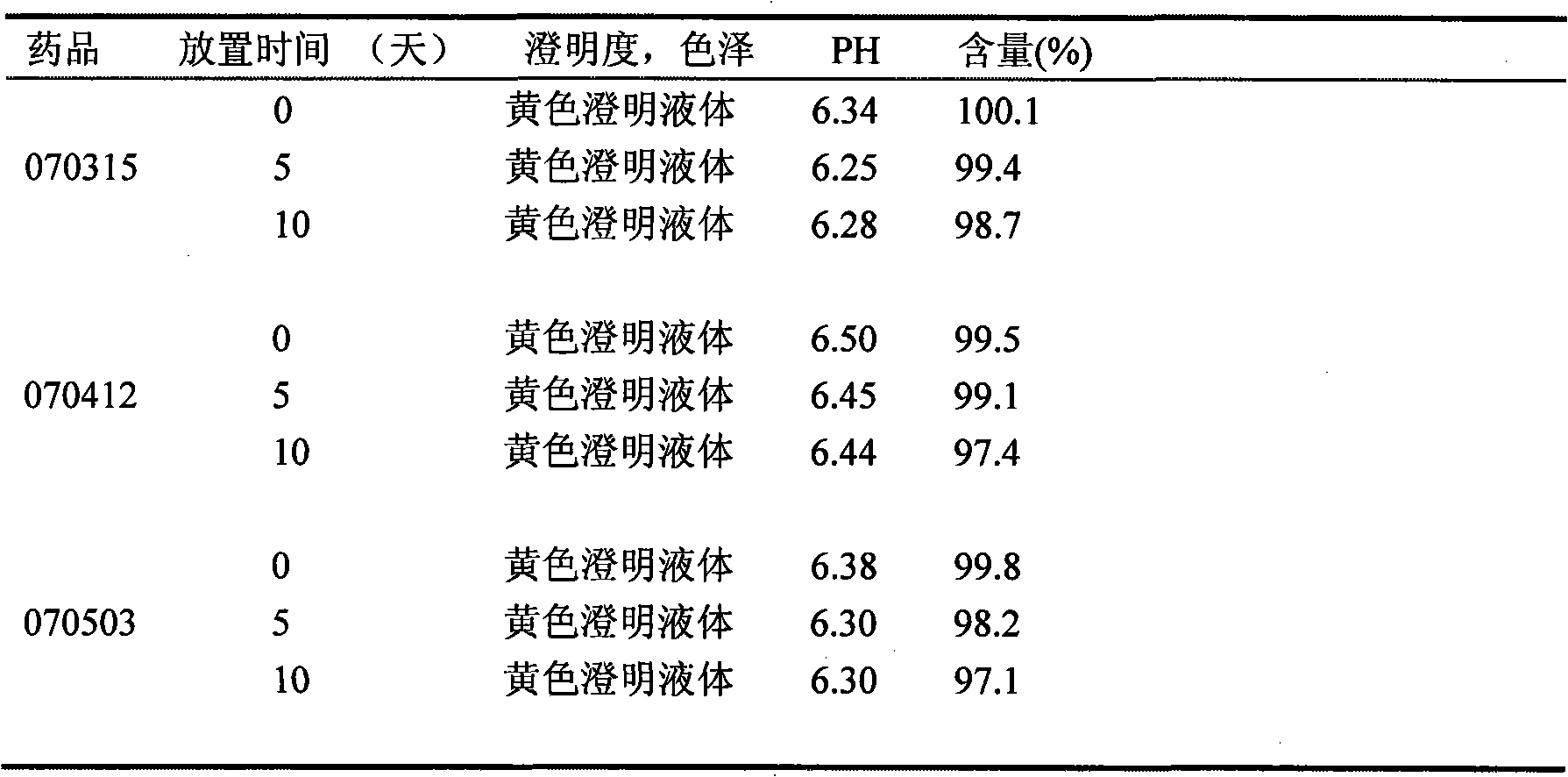

Composition of doxycycline hydrochloride injection for animals and preparation technique thereof

InactiveCN101301268AImprove solubilityIncrease pHTetracycline active ingredientsPharmaceutical delivery mechanismSolubilityIrritation

The invention discloses a composition of animal doxycycline hydrochloride injection and a process for making the same, belonging to the animal medicine technical field. The injection consists of principal medicine, solvent, a doxycycline hydrochloride complexing agent and antioxidant, wherein metal ion (Mg<2+>) of higher content is used as the doxycycline hydrochloride complexing agent so as to remarkably increase the solubility and the pH value of the doxycycline hydrochloride and to reinforce the stability of the injection at the same time; above all, the toxicity and the tissue irritation of medicine are reduced after complexation. Dissolvant mixed by 2-pyrrolidone and propylene glycol or dimethyl acetamide is used as solvent so as to increase the stability of the injection; therefore, the injection can not be separated out and frozen under a low-temperature (4 DEG C) condition; moreover, concentrated hydrochloric acid and ethanolamine are used as pH regulator. The invention develops the high-content doxycycline hydrochloride injection for veterinary clinic, and the injection has advanced process, convenient use and remarkable curative effect.

Owner:CHENGDU QIANKUN VETERINARY PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com