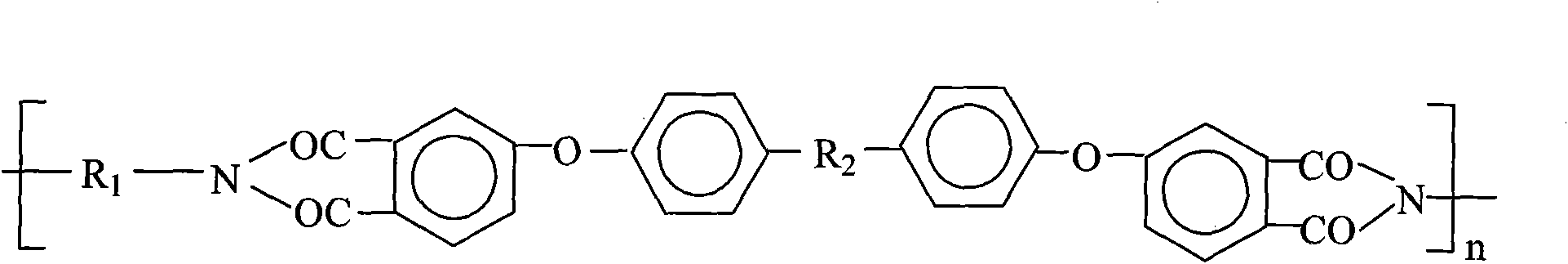

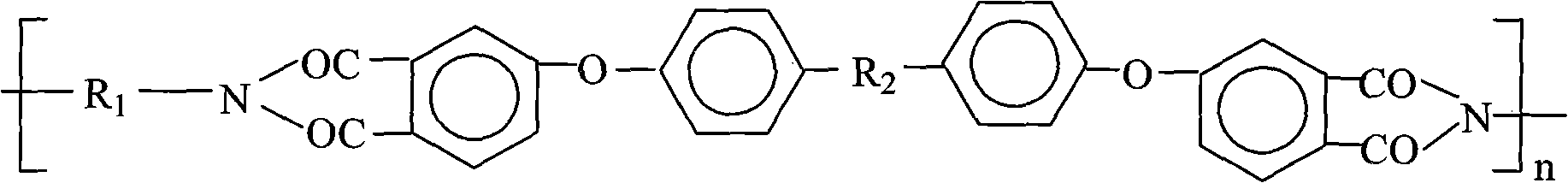

Polyimide film with high visible light permeability and preparation thereof

A technology of polyimide film and visible light, which is applied in the field of high visible light transmittance polyimide film and its preparation, can solve the problem that it is difficult to prepare high molecular weight polyimide resin, and there are no published documents or patents Reporting, film product comprehensive performance decline and other issues, to achieve excellent dimensional stability, low cost, and fewer types of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

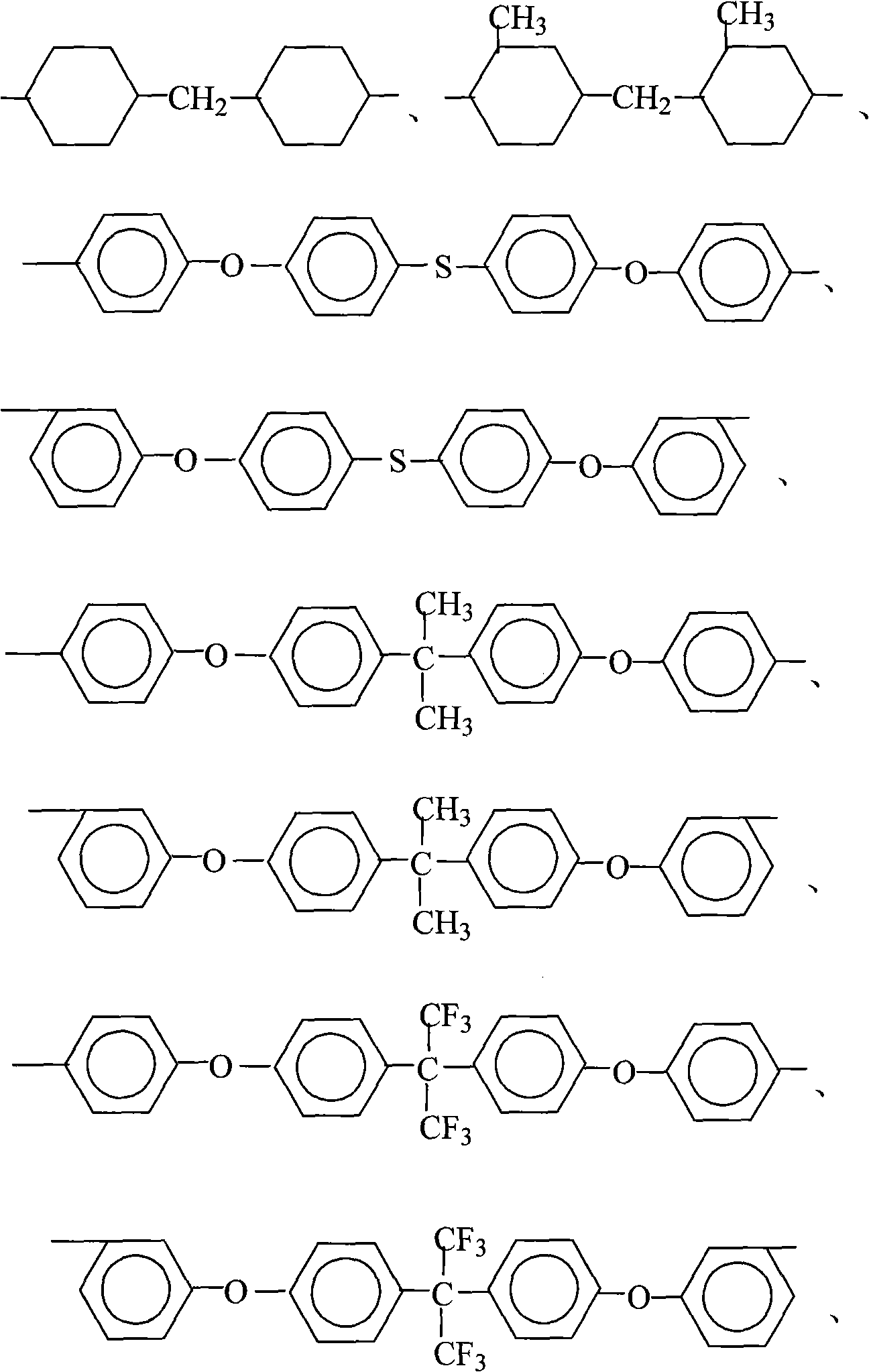

[0056] 23.8 g (0.1 mole) of 3,3'-dimethyl-4,4'-diaminodicyclohexylmethane, 40.0 g (0.1 mole) of 4,4'-bis(4-aminophenoxy) di Phenylsulfide and 900 ml of N, N-dimethylacetamide were put into the reaction kettle, stirred, and after they were completely dissolved, cooled to 5°C-10°C in an ice-water bath, and 104.1 grams (0.2 moles) of 2,2-bis [4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride, stirred in the temperature range of 5°C-10°C, after completely dissolving, keep the reaction for 4 hours to obtain homogeneous transparent viscous Polyamic acid solution.

[0057] Use N,N-dimethylacetamide solvent to adjust the viscosity of the polyamic acid solution so that it is between 80 seconds and 120 seconds (No. 4 viscosity cup), form a film in a casting machine, and heat up to remove Remove the organic solvent (recycle and reuse) and carry out dehydration heat imidization reaction, cooling, and stripping to obtain a tough and transparent polyimide film (thickness: 50 microns). Th...

Embodiment 2

[0061] 65.4 grams (0.1 mol) of 2,2-bis[4-(2-trifluoromethyl-4-aminophenoxy)phenyl]hexafluoropropane, 200 milliliters of N,N-dimethylformamide and 400 milliliters of N,N-dimethylacetamide was put into the reaction kettle, stirred, and after it was completely dissolved, cooled to 5°C-10°C in an ice-water bath, and 52.0 grams (0.1 moles) of 2,2-bis[4-( 3,4-Dicarboxyphenoxy)phenyl]propane dianhydride, stirred within the temperature range of 5°C-10°C, after completely dissolving, keep the reaction for 10 hours to obtain a homogeneous transparent viscous polyamic acid solution .

[0062] Use N,N-dimethylacetamide solvent to adjust the viscosity of the polyamic acid solution so that it is between 80 seconds and 120 seconds (No. 4 viscosity cup), form a film in a casting machine, and heat up to remove Remove the organic solvent (recycle and reuse) and carry out dehydration heat imidization reaction, cooling, and stripping to obtain a tough and transparent polyimide film (thickness: 5...

Embodiment 3

[0066] 54.7 grams (0.1 moles) of 2,2-bis[4-(2-trifluoromethyl-4-aminophenoxy)phenyl]propane, 51.8 grams (0.1 moles) of 2,2-bis[4 -(4-Aminophenoxy)phenyl]hexafluoropropane and 950 ml of N-methyl-2-pyrrolidone solvent were put into the reaction kettle, stirred and dissolved completely, cooled to 5°C-10°C in an ice-water bath, and added 104.1 grams (0.2 moles) of 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane dianhydride, stirred in the temperature range of 5°C-10°C, after completely dissolving, maintain After reacting for 8 hours, a homogeneous transparent viscous polyamic acid solution was obtained.

[0067] Use N-methyl-2-pyrrolidone solvent to adjust the viscosity of the polyamic acid solution so that it is between 80 seconds and 120 seconds (No. 4 viscosity cup), form a film in a casting machine, and heat up to remove Organic solvent (recycling) and thermal imidization reaction for dehydration, cooling, and film removal to obtain a tough and transparent polyimide film (film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com