Colored polyimide film

A color polyimide film and polyimide technology, applied in the field of color polyimide film, can solve the problem that the polyimide film and the printed circuit board cannot be well matched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

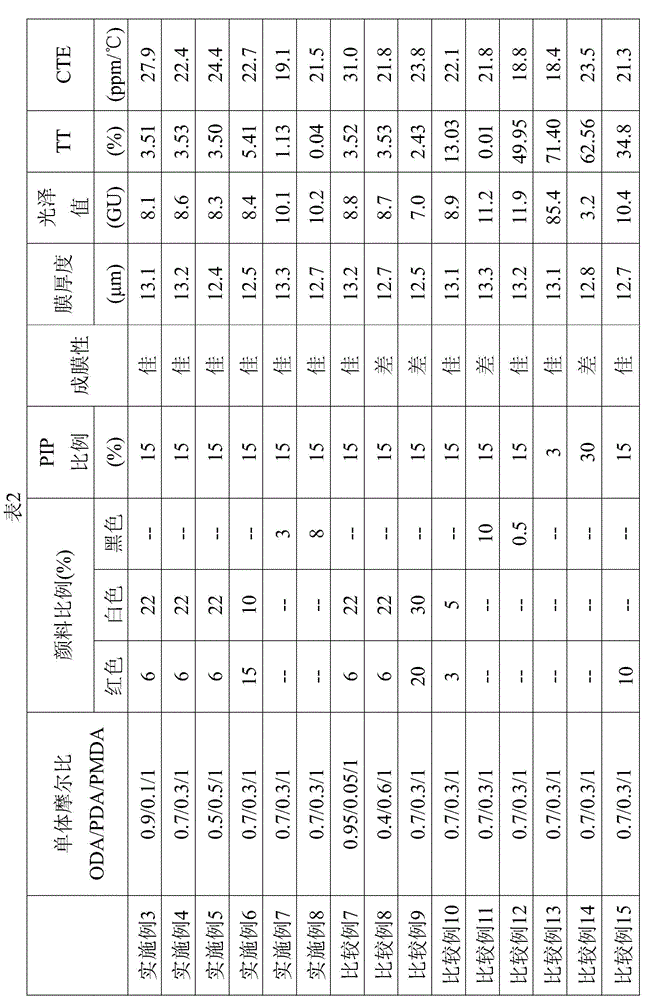

Examples

Embodiment 2

[0043] Repeat the steps of Example 1, but the weight of each component is changed to about 38g of the PAA solution of Example 1, about 26.47g of DMAc, about 2.71g of carbon black slurry, and about 3.33g of PIP slurry.

[0044]

[0045] Put about 400g of DMAc into the reaction flask, add about 47.85g (0.2393mole) of 4,4'-ODA and stir until completely dissolved, then add about 51.11g (0.2344mole) of PMDA, and continue stirring for about 4 hours to carry out the reaction , forming a polyamic acid solution with a viscosity of about 200,000 cps.

[0046] The obtained polyamic acid solution of about 30g, the DMAc of about 26.47g, the red slurry of about 7.95g, the white slurry of about 2.38g are mixed with the PIP slurry of about 3.33g, then with the same step as Example 1 A polyimide film was prepared.

[0047]

[0048] Repeat the steps of Comparative Example 1, but the weight of each component is changed to about 38g of the polyamic acid solution of Comparative Example 1, abo...

Embodiment 3

[0070] Put about 400g of DMAc into the reaction flask, add about 44.03g (0.2202mole) of 4,4'-ODA and about 2.64g (0.0244mole) of p-PDA, stir until completely dissolved, then add about 52.26g ( 0.2397mole) of PMDA, continued stirring for about 4 hours to react, forming a polyamic acid (PAA) solution with a viscosity of about 200,000cps.

[0071] The obtained polyamic acid solution of about 25g, the DMAc of about 22.62g, the red slurry of about 4.8g, the white slurry of about 3.52g are mixed with the PIP slurry of about 8.39g, then with the same step as Example 1 A polyimide film was prepared.

Embodiment 4

[0073] Repeat the steps of Example 1, but each component weight is changed to the PAA solution of Example 1 of about 25g, the DMAc of about 28.55g, the red slurry of about 4.77g, the white slurry of about 3.5g, and the PIP slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com