Prepn process of polyimide fiber

A technology of polyimide fiber and polyamic acid, which is applied in the direction of wet spinning, can solve the problems of low fiber strength, low production efficiency, and no practical value, and achieve the effect of good chemical corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

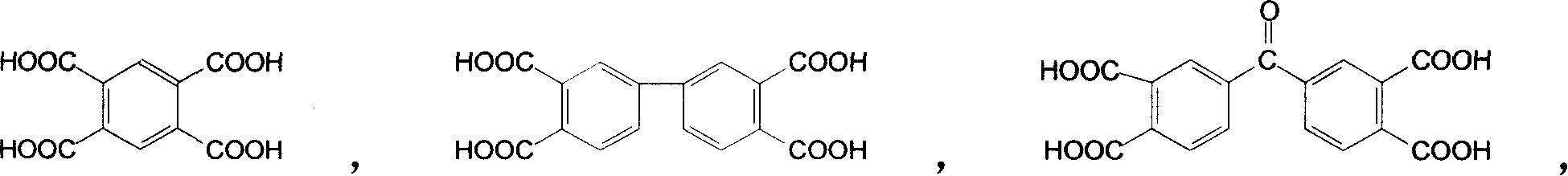

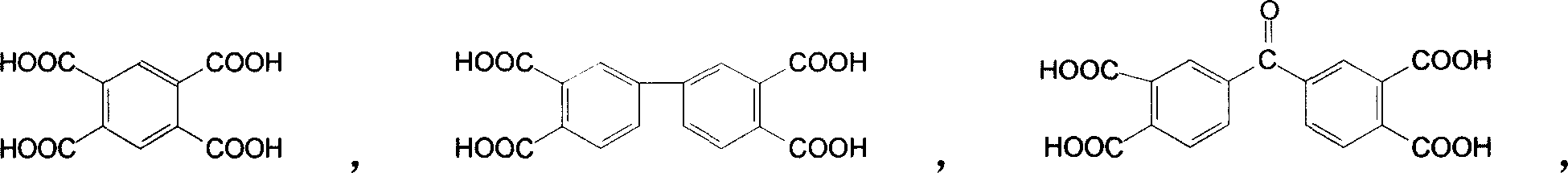

Method used

Image

Examples

Embodiment 1

[0018] Add 200g of 4,4'-diamine diphenyl ether into 2000ml of dimethylacetamide and stir until completely dissolved. Afterwards, 222 g of pyromellitic dianhydride was added to the solution in batches, and stirred at room temperature for 8 hours to obtain a light yellow viscous polyamic acid spinning solution.

[0019] After defoaming the polyamic acid spinning solution prepared above, dry spinning is carried out on a dry spinning machine. The length of the tunnel is 10 meters, and the temperature of the upper section of the tunnel is 170°C, the middle section is 200°C, and the lower section is 220°C, and then winding and forming A polyamic acid fiber is obtained. The polyamic acid fiber is made of polyimide fiber by thermal imidization, and the two-stage treatment temperature is 270°C and 370°C respectively; stretching 5 times at 430°C, the high-performance polyimide fiber can be obtained.

Embodiment 2

[0021] Add 108g of phenylenediamine into 1000ml of dimethylformamide and stir until completely dissolved. Afterwards, 344 g of dimethylmethylene diphenylamine was added to the solution in batches, and stirred at room temperature for 10 hours to obtain a pale yellow viscous polyamic acid spinning solution.

[0022] After defoaming the polyamic acid spinning solution prepared above, dry spinning is carried out on a dry spinning machine. The length of the tunnel is 12 meters. The temperature of the upper section of the tunnel is 150 ° C, the middle section is 200 ° C, and the lower section is 210 ° C. After that, it is wound into shape A polyamic acid fiber is obtained. The polyamic acid fiber is made of polyimide fiber by thermal imidization, the two-stage treatment temperature is 185°C and 330°C respectively; stretching 3 times at 350°C, the high-performance polyimide fiber can be obtained.

Embodiment 3

[0024] Stir 246g of 4,3'-diaminodiphenylene in a mixed solvent of 2000ml dimethylformamide and dimethylacetamide (1:1) until completely dissolved. Afterwards, 302 g of biphenyl dianhydride was added to the solution in batches, and stirred at room temperature for 6 hours to obtain a light yellow viscous polyamic acid spinning solution.

[0025] After defoaming the polyamic acid spinning solution prepared above, carry out dry spinning on a dry spinning machine. The length of the tunnel is 10 meters. The temperature of the upper section of the tunnel is 170°C, the middle section is 210°C, and the lower section is 230°C, and then it is wound into shape A polyamic acid fiber is obtained. Polyamic acid fibers are chemically imidized in a mixture of acetic anhydride / pyridine to obtain polyimide fibers; the fibers are stretched 6 times at 430°C to obtain high-performance polyimide fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com