Preparation method of fabric with flame-retardant and hydrophobic functions

A fabric and water-repellent technology, applied in the direction of flame-retardant fibers, animal fibers, textiles and papermaking, etc., can solve the problems of unsatisfactory results and less research, achieve good flame-retardant and hydrophobic functions, low reaction temperature, and benefit the environment The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

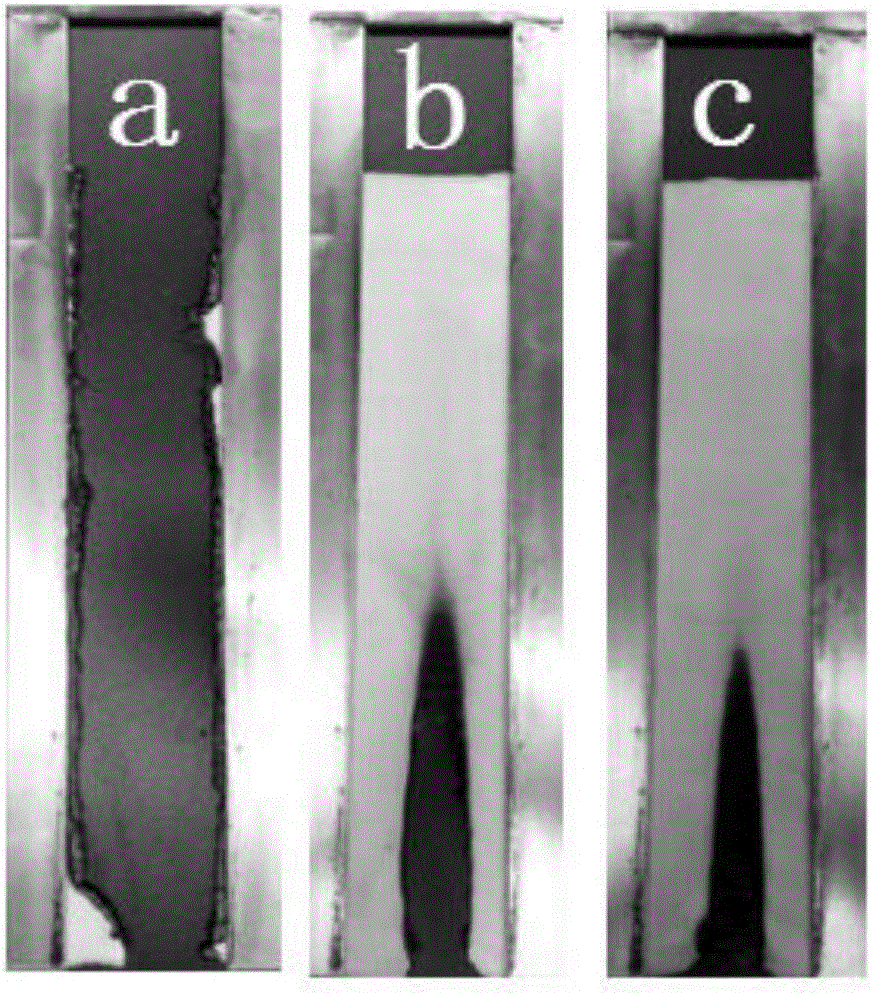

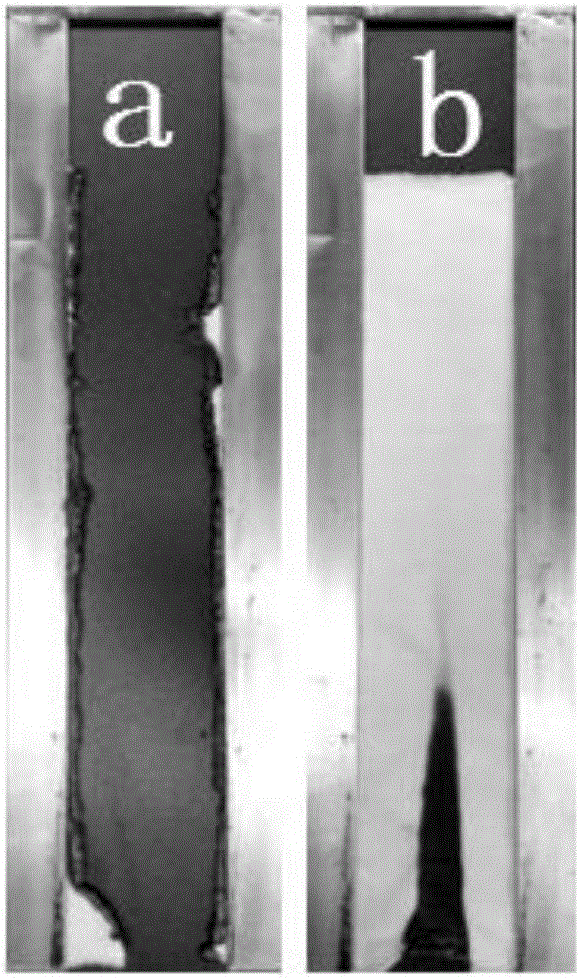

Embodiment 1

[0048]Dissolve 6g of BTCA and 4g of sodium hypophosphite monohydrate in 90g of distilled water, then immerse the woolen fabric in the aqueous solution for 30 minutes, adopt the double-dip and double-rolling method, the excess rate is 80%, and then bake at 80°C for 5-10 minutes to obtain Pre-treat woolen fabrics.

[0049] Mix 1.5g of methyltrimethoxysilane, 0.36g of hexadecyltrimethylammonium chloride, 0.54g of Tween 60 and 100mL of water, and shear at high speed for 10-15min to obtain a solution after shearing. Dissolve 8 g of hexamethylenediamine tetramethylene phosphate in the sheared solution, adjust the pH to 2 with ammonia water, then transfer it to a three-necked flask, and stir and react in a magnetic stirrer at 30°C for 4 hours to obtain doped flame-retardant agent sol system. Then slowly add 2g of tetraethyl orthosilicate to the above-mentioned sol system doped with flame retardant, continue to react at 30°C for 2h, finally slowly add 1g of hexadecyltrimethoxysilane,...

Embodiment 2

[0055] Dissolve 6g of BTCA and 4g of sodium hypophosphite monohydrate in 90g of distilled water, then immerse the woolen fabric in the aqueous solution for 30 minutes, adopt the double-dip and double-rolling method, the excess rate is 80%, and then bake at 80°C for 5-10 minutes to obtain Pre-treat woolen fabrics.

[0056] Mix 2g of methyltrimethoxysilane, 0.36g of cetyltrimethylammonium chloride, 0.54g of Tween 60 and 100mL of water, and shear at high speed for 10-15min to obtain a solution after shearing. Dissolve 10 g of hexamethylenediamine tetramethylene phosphate in the sheared solution, adjust the pH to 2 with ammonia water, then transfer it to a three-necked flask, and stir and react in a magnetic stirrer at 30°C for 4 hours to obtain doped flame-retardant agent sol system. Then slowly add 2g tetraethyl orthosilicate dropwise to the above sol system doped with flame retardant, continue to react at 30°C for 2h, finally slowly add 1g of hexadecyltrimethoxysilane dropwise...

Embodiment 3

[0060] Dissolve 5 g of citric acid, 4 g of tartaric acid, and 4 g of sodium hypophosphite monohydrate in 87 g of distilled water, then soak the woolen fabric in the aqueous solution for 30 minutes, adopt two dipping and two rolling methods, and the excess rate is 80%, and then bake at 80 ° C for 5 -10min, to obtain the pretreated woolen fabric.

[0061] Mix 2g of methyltrimethoxysilane, 0.36g of cetyltrimethylammonium chloride, 0.54g of Tween 60 and 100mL of water, and shear at high speed for 10-15min to obtain a solution after shearing. Dissolve 10 g of hexamethylenediamine tetramethylene phosphate in the sheared solution, adjust the pH to 2 with ammonia water, then transfer it to a three-necked flask, and stir and react in a magnetic stirrer at 30°C for 4 hours to obtain doped flame-retardant agent sol system. Then slowly add 2g tetraethyl orthosilicate dropwise to the above sol system doped with flame retardant, continue to react at 30°C for 2h, finally slowly add 1g of he...

PUM

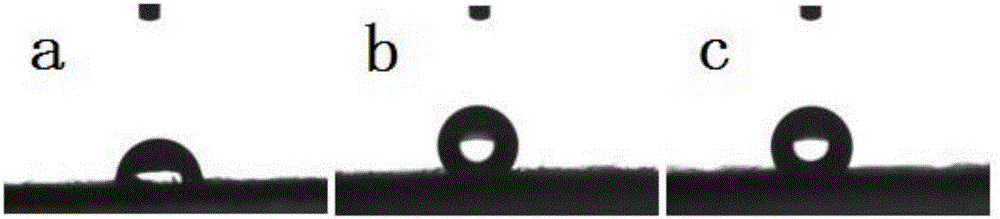

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com