New type copolymerization type polyester in use for halogen free flame retardant

A production process and copolymerization technology, which is applied in the manufacture of fire-retardant and flame-retardant filaments, single-component polyester rayon, etc. , low cost, bright color effect

Inactive Publication Date: 2007-12-26

郭明海

View PDF0 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After finishing flame retardants, the flame retardant effect is often reduced or disappeared after several times of washing; the blending type and copolymerization type are currently mainly used in the market as phosphinic acid or phosphinate flame retardants. The flame-retardant finished products produced are easy to melt and drip when they encounter combustion or high temperature, causing burns or triggering new ignition points, and the cost is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 2

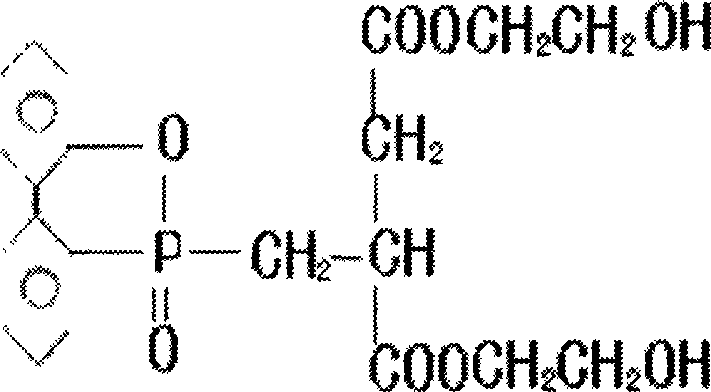

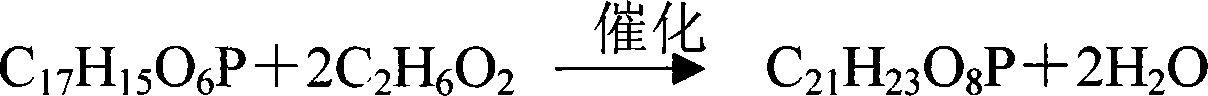

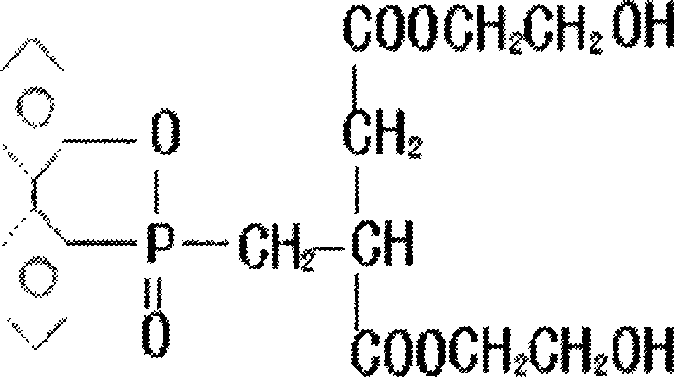

[0011] In the reactor, add ethylene glycol (C 2 h 6 o 2 ) and 9,10-dihydro-9-oxa-10-phosphophenanthrene (C 17 h 15 o 6 P), then add the catalyst, stir, heat up to 240°C, and vacuumize (negative pressure-0.08Mpa) at the same time, the reaction ends after about 2 hours, and then cool down to 30°C to obtain a droplet-resistant flame retardant liquid. This product is light yellow viscous liquid.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

This invention discloses a process for producing a novel halogen-free flame retardant for terylene. The flame retardant is produced by: mixing 9,10-dihydro-10 [2,3-di(hydroxycarbonyl)propyl]-10-phosphaphenanthrene-9-oxide and ethylene glycol, adding catalyst, stirring, heating, reducing pressure, and cooling. The flame retardant is yellowish liquid, and can be added into polycondensation reaction of p-terephthalic acid and ethylene glycol without any pretreatment. The flame retardant can effectively retard droplets during combustion.

Description

Technical field: [0001] The invention relates to a phosphate chemical additive suitable for flame retardant and droplet resistance of polyester polyester and its production process, which has the characteristics of environmental protection, permanent flame retardancy and delaying the droplet of polyester chips when burning or high temperature. Background technique: [0002] Currently commonly used polyester flame retardants include finishing, blending and copolymerization. After finishing flame retardants, the flame retardant effect is often reduced or disappeared after several times of washing; the blending type and copolymerization type are currently mainly used in the market as phosphinic acid or phosphinate flame retardants. The flame-retardant finished products produced are easy to melt and drip when they encounter combustion or high temperature, causing burns or triggering new ignition points, and the cost is relatively high. Invention content: [0003] In order to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L67/00C08K5/5357D01F6/62D01F1/07

Inventor 郭明海

Owner 郭明海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com