Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Dyeing firm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

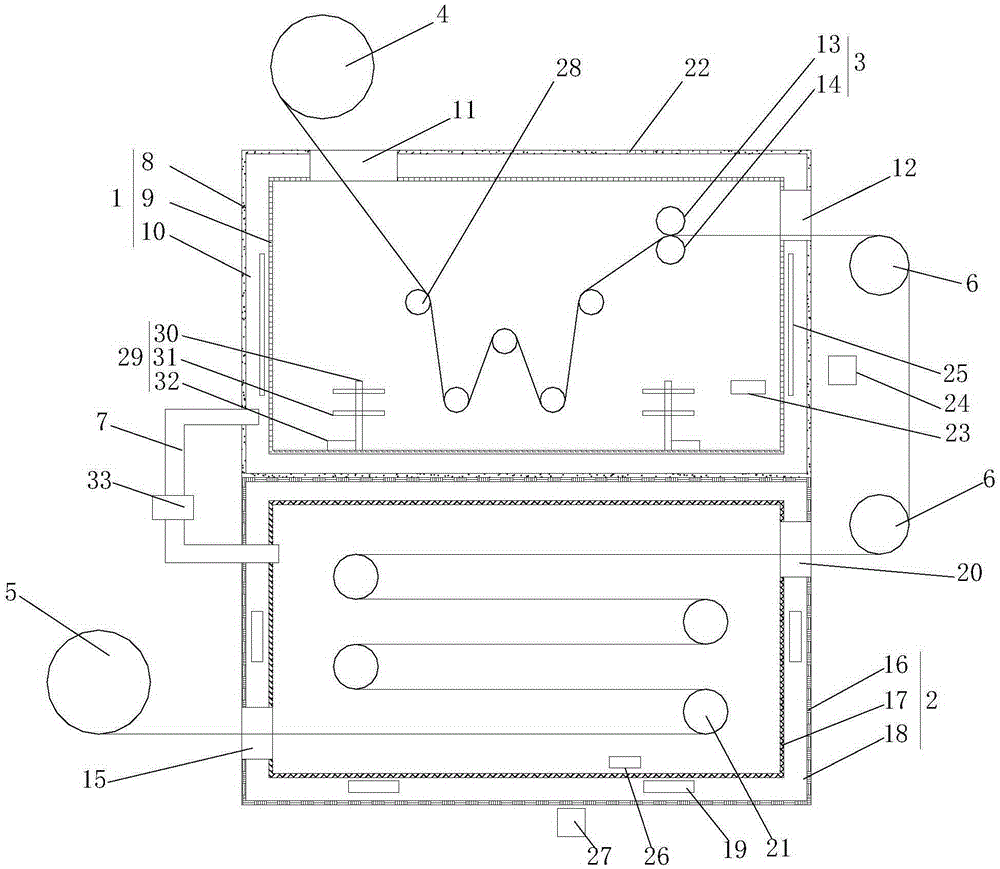

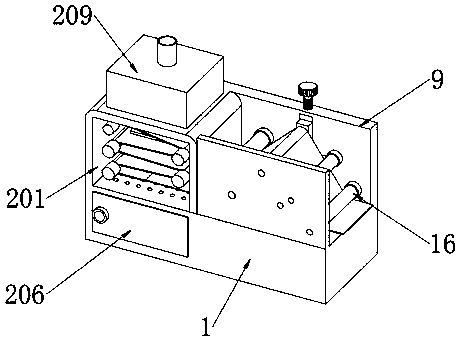

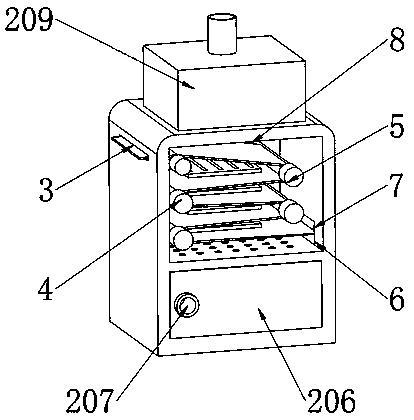

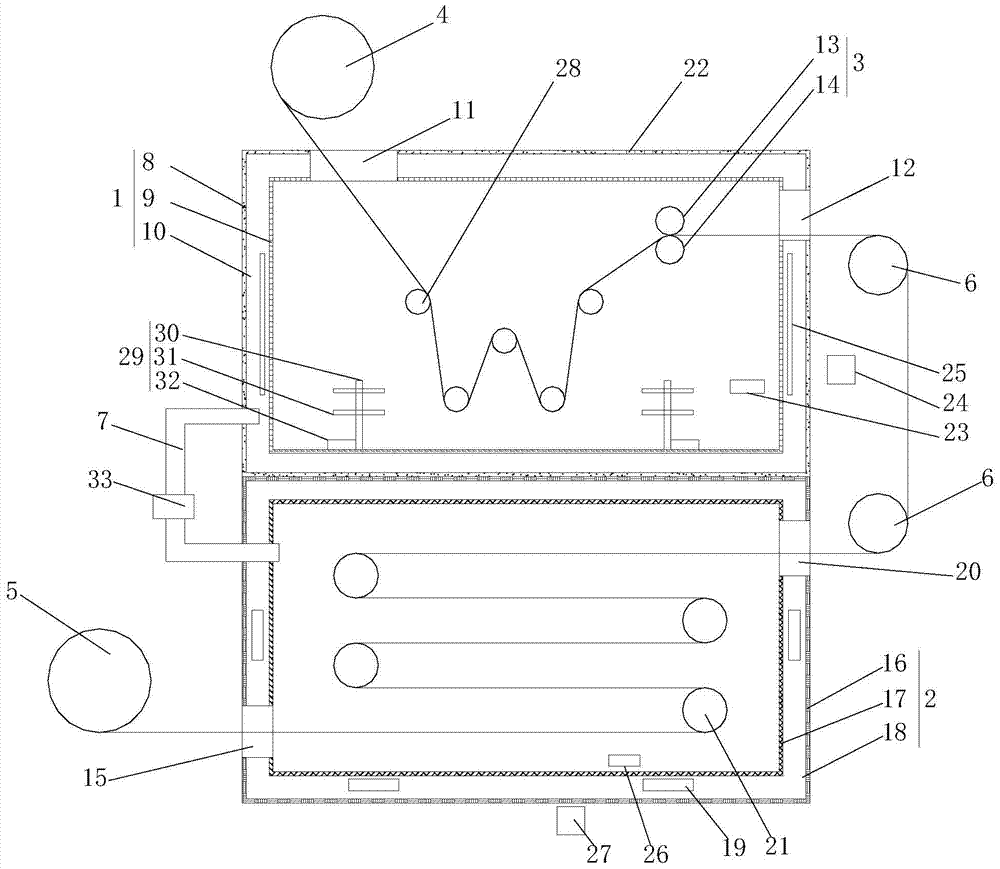

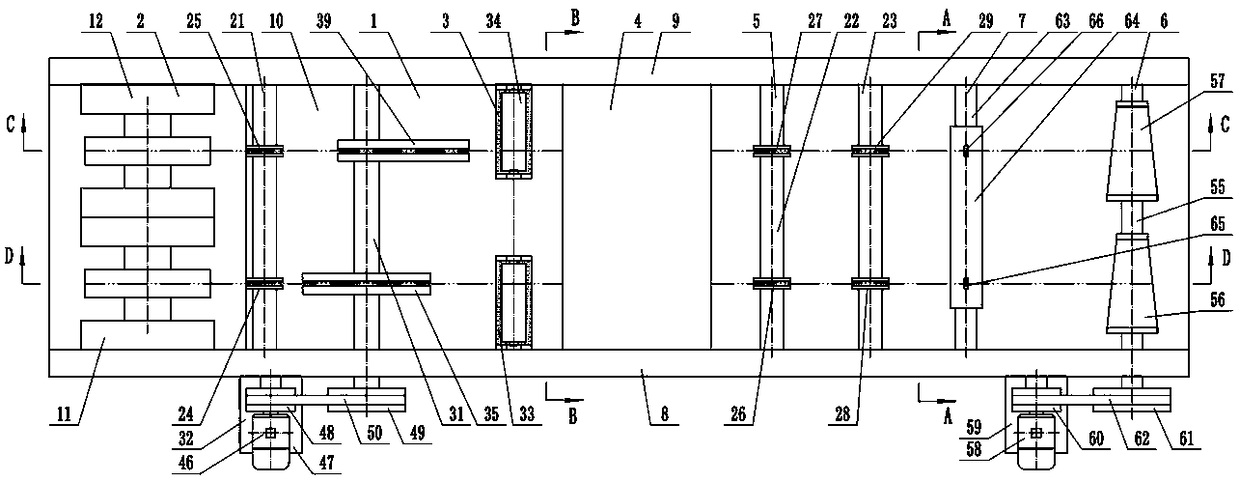

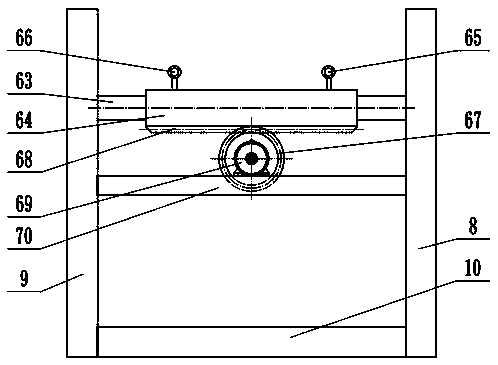

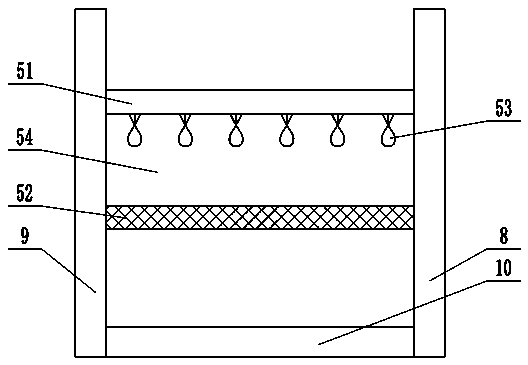

Cloth printing and dyeing device

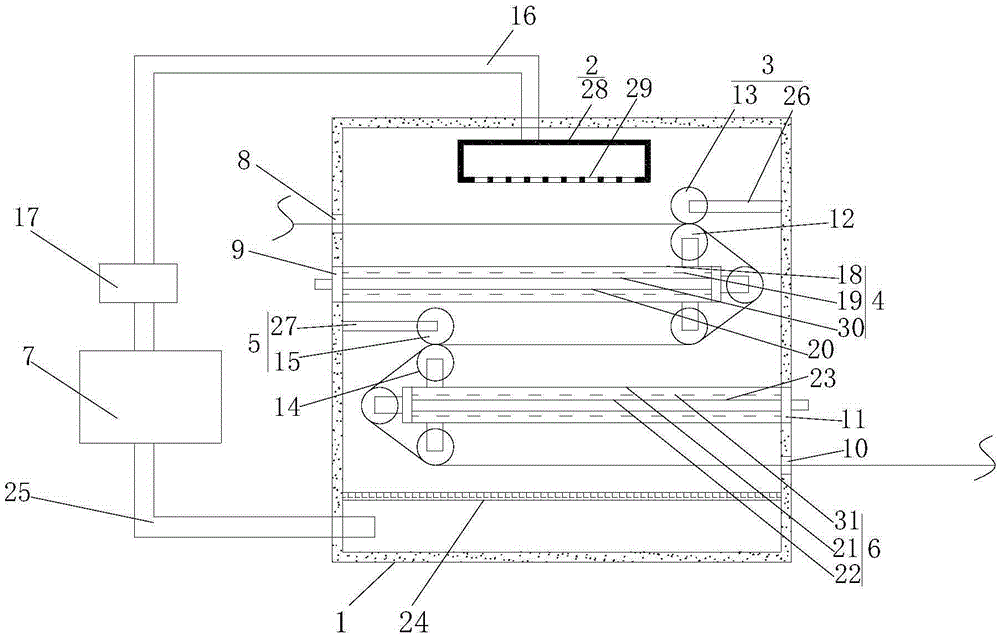

ActiveCN105332189ADry evenlySimple structureLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringMechanical engineering

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

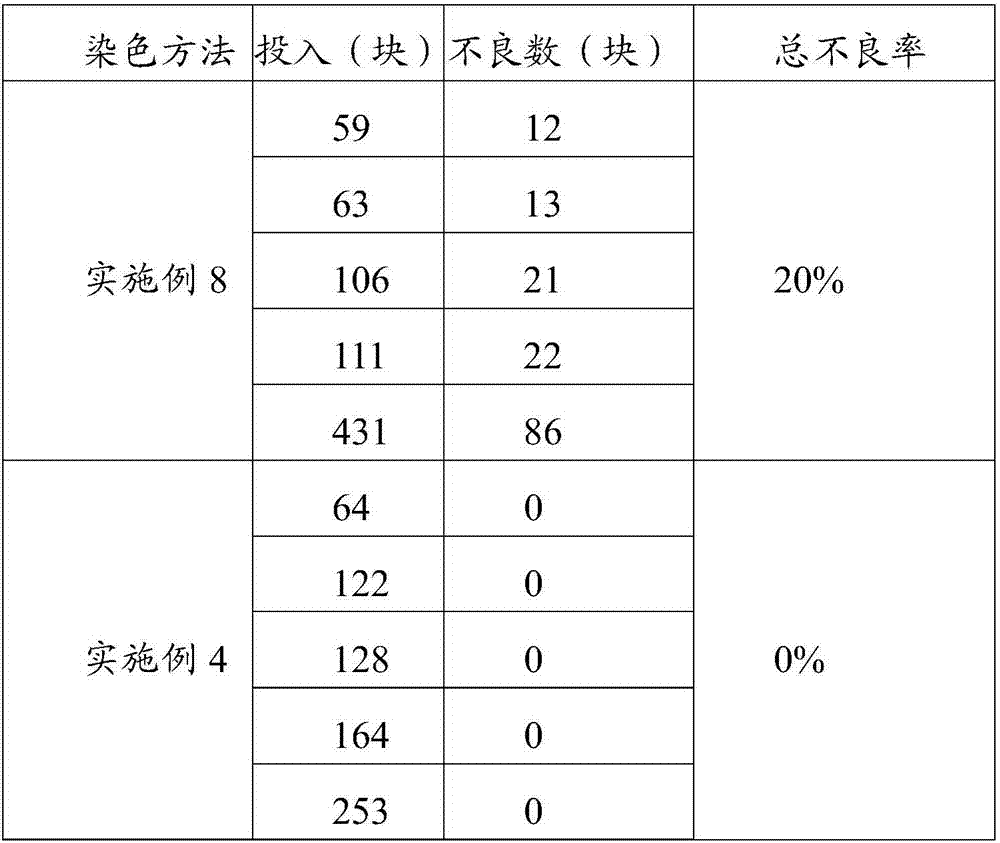

Preparation method of black dyestuff for dyeing aluminum alloy and dyeing method of aluminum alloy

The invention discloses a preparation method of a black dyestuff for dyeing an aluminum alloy and a method for dyeing the aluminum alloy by adopting the black dyestuff. The prepared black dyestuff comprises 1.0g / L to 2.0g / L of a reddish black dyestuff, 1.0g / L to 1.5g / L of a bluish green dyestuff and 0.5g / L to 1.0g / L of a red dyestuff. The inventor accidentally finds out that the black dyestuff, which is formed by mixing the reddish black dyestuff, the bluish green dyestuff and the red dyestuff according to the ratio, regulating the pH (Potential of Hydrogen) value to 5.0 to 5.5, and adding 10g / L to 15g / L of a pH stabilizer, is more suitable for dyeing of the aluminum alloy than a traditional black dyestuff and the aluminum alloy can be easily dyed black. Especially, when the aluminum alloy subjected to anode oxidation is dyed, the mixed black dyestuff can easily dye the aluminum alloy to black with a stable color and coloring durability.

Owner:GUANGDONG EVERWIN PRECISION TECH

Milk protein fiber or its filament or its blended yarn dyeing method and coloured woven fabric producing method

ActiveCN1865574ASolve the problem of not being able to dyeHigh dye utilization rateHeating/cooling textile fabricsWoven fabricsAlcoholPolyvinyl acetate

The invention discloses a manufacturing method of milk protein fiber or filament or blended yarn dyeing and yarn-colored product, which is characterized by the following: changing coiling density of yarn; controlling heating temperature; adopting segmented contraction in the cylinder yarn dyeing course; adding self-producing milk protein fiber dyeing specific adjuvant; utilizing polyacrylonitile or polyvinyl acetate alcohol as carrier realize active dyeing technology of milk protein fiber; solving the difficulties of flower color, weak color and bad fastening degree problem to produce excellent washing shrinkage and stable size yarn-dyed product through weaving, shrinking and softening and final disposal.

Owner:SHANGHAI TIQIAO TEXTILE & YARN DYEING

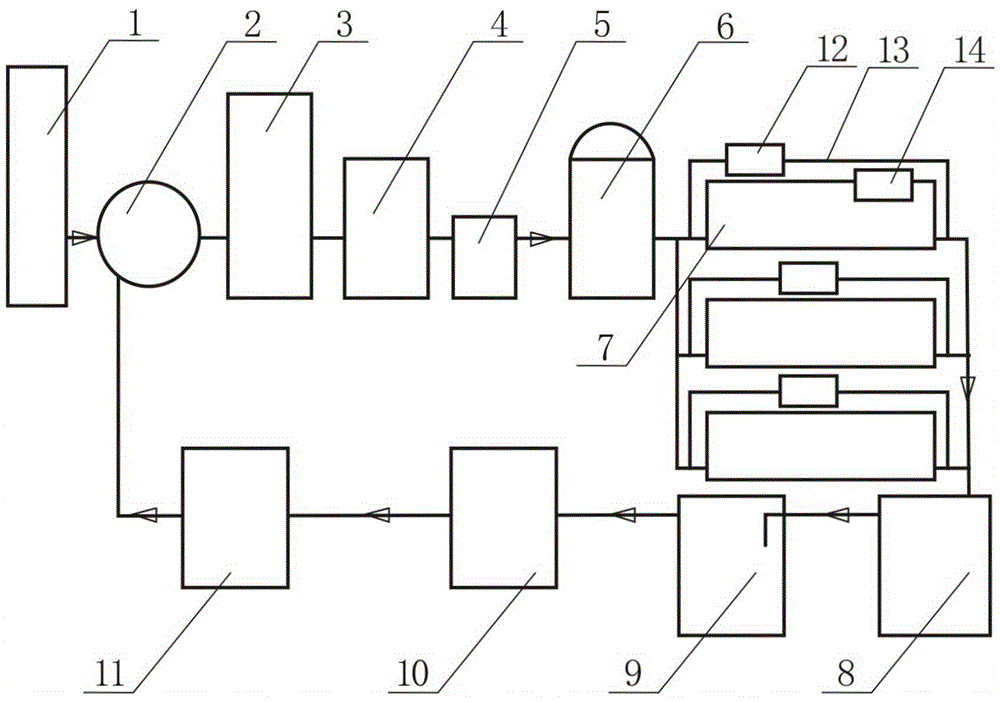

Supercritical CO2 waterless dyeing system and cloth dyeing method thereof

InactiveCN105297320AImprove permeabilityImprove solubilityTextile treatment containersSolvent treatment with solvent recoveryCirculating pumpCotton material

The invention discloses a supercritical CO2 waterless dyeing system and a cloth dyeing method thereof. The method comprises the following steps of A, preparing and storing of CO2; B, cooling; C, pressurizing; D, heating, wherein a heating device is utilized for enabling CO2 to form supercritical fluid, and the supercritical fluid is heated to 120-150 DEG C; E, dyeing, wherein a circulating pump pushes a mixture of the supercritical fluid and dye to circularly flow inside a circulation channel, cloths inside a pressure kettle are dyed, the pressure inside the pressure kettle is 28-30 MPA, the temperature is 120-150 DEG C, the circulation flowing time is 20-40 min, and the circulation flow is not smaller than 10 M<3> per hour; F, pressure relieving, wherein a nanoscale color masterbatch is dissolved through the supercritical CO2 fluid, the cloths are dyed, and dyeing technological conditions such as pressure, temperature and time are optimized at the same time so as to improve the dyeing efficiency and dyeing quality.

Owner:梁鼎天 +1

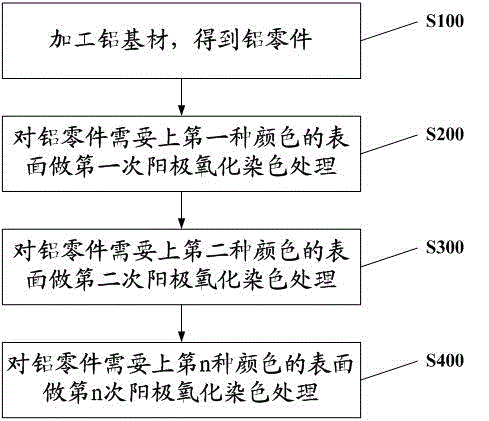

Processing method for aluminum components

ActiveCN102747401AStrong metal textureGuaranteed accuracySurface reaction electrolytic coatingComputer terminalDyeing

The invention discloses a processing method for aluminum components. The processing method is used for exterior processing of an exterior aluminum component of a mobile terminal so as to allow an exterior surface of the aluminum component to have n different colors, i.e., a first color, a second color,..., and an n color, wherein n is a natural number no less than 2. The processing method for aluminum components comprises the following steps: carrying out first exterior processing on the part of an aluminum component to be colored with the first color; carrying out first anodization dyeing treatment on the part of the aluminum component to be colored with the first color; carrying out second exterior processing on the part of the aluminum component to be colored with the second color; and carrying out second anodization dyeing treatment on the part of the aluminum component to be colored with the second color. The processing method for aluminum components provided in the invention has the advantages of simple operation, solid dyeing, a few processing procedures and capacity of realizing indiscriminate application of a plurality of colors on a same aluminum component.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

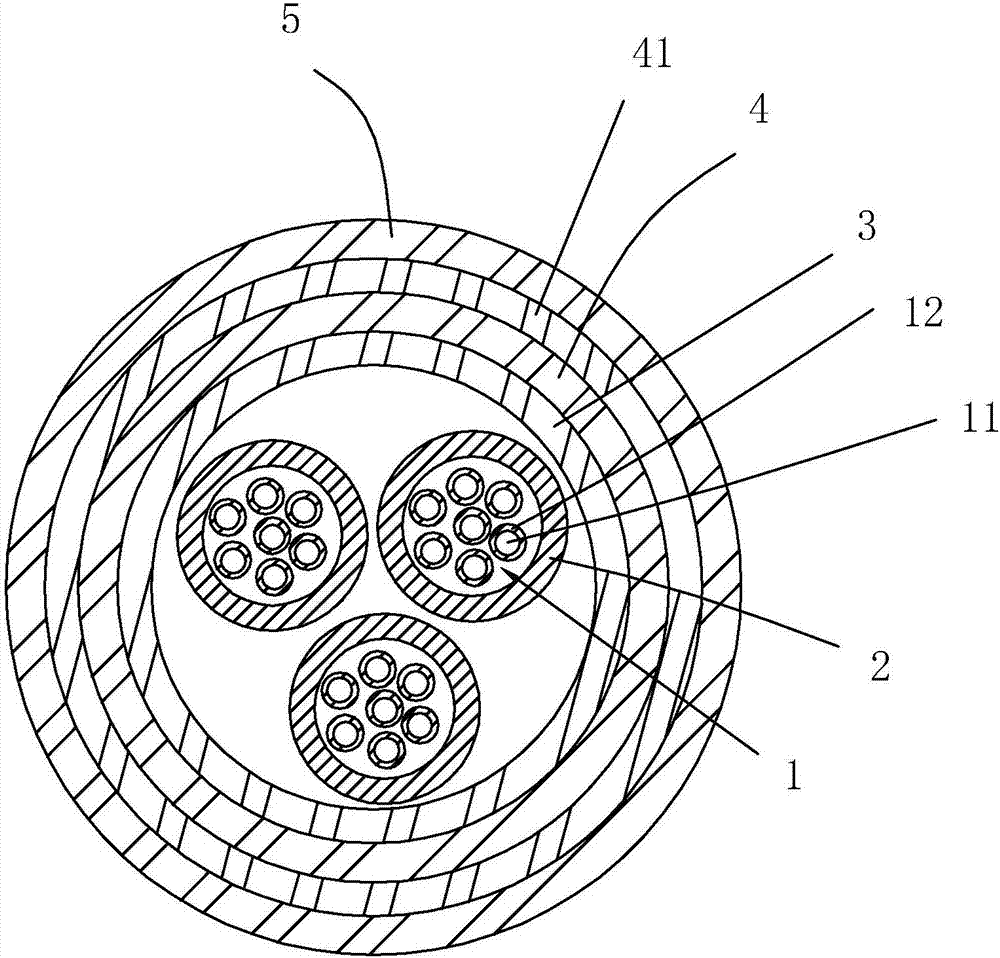

Low-smoke, halogen-free, flame-retarding and fireproof polyolefin insulated cable and preparation method thereof

InactiveCN107383537ADyeing firmImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesFiberPolyolefin

The invention discloses a low-smoke, halogen-free, flame-retarding and fireproof polyolefin insulated cable and a preparation method thereof. According to the key point of the technical scheme, the low-smoke, halogen-free, flame-retarding and fireproof polyolefin insulated cable comprises insulated wire core groups, fireproof layers, an insulating layer, an oxygen separation layer and a protecting jacket layer in sequence from interior to exterior, wherein the fireproof layer is prepared from the following components in parts by weight: 5 to 15 parts of mineral flame retardant, 50 to 70 parts of polyethylene resin and / or polyvinyl chloride resin, 5 to 15 parts of glass fiber, 5 to 15 parts of polysulfonamide fiber, 5 to 10 parts of melamine amide-inorganic montmorillonite, 10 to 35 parts of polyorganosiloxane, 0.5 to 5 parts of solubilizer and 0.5 to 5 parts of microcapsule pigment; the insulating layer is prepared from the following components in parts by weight: 50 to 70 parts of polyethylene resin and / or polyvinyl chloride resin, 5 to 15 parts of Kevlar fiber and 5 to 15 parts of mineral flame-retarding filling. The exteriors of insulated wire cores are cladded with the fireproof layers, the insulating layer, the oxygen separation layer and the protecting jacket layer; the structure with sequential distribution can be used for decelerating the spreading speed of a fire behavior in the condition that the cable is on fire.

Owner:宏胜电线电缆股份有限公司

Method of continuous pigment dyeing for fabric

InactiveCN101509184AWell mixedDyeing firmDrying solid materials with heatTextile treatment machine arrangementsSURFACTANT BLENDPigment

The invention relates to a continuous pigment dyeing method for fabrics, in which the fabrics during travelling are subjected to the steeping of a composite dye solution in a steeping tank that is continuously supplemented with the composite dye solution, and then to the rolling of rollers, and the time the fabrics are subjected to the composite dye solution by the fabrics is 2.5-5 seconds. The composite dye solution comprises the components having the following concentrations: 10g / L-50g / L of a pigment paste, 1g / L-8g / L of a cation modifying agent, 3g / L-5g / L of a surfactant and 5g / L-20g / L of a cation bonding agent. The padding fabrics are continuously subjected to an infrared pre-drying apparatus for drying, a hot-air pre-drying tank for drying and a steam drying cylinder apparatus for drying. The inventive method has superior stability of the dyeing effect and is free from agglomeration.

Owner:常州市东高染整有限公司

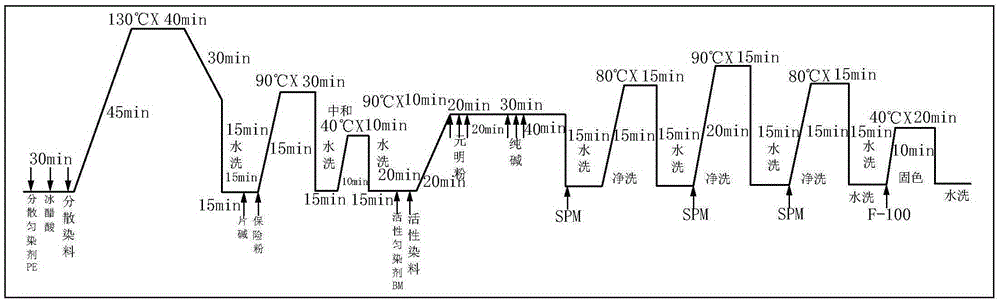

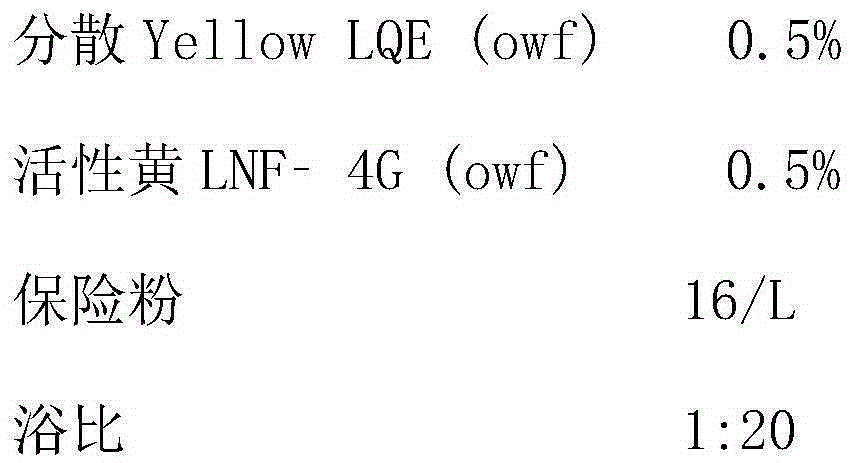

One bath process dyeing process of polyester cotton dispersing dye and reactive dye

ActiveCN105421105AHigh color fastnessDyeing firmDry-cleaning apparatus for textilesDyeing processReactive dyePhotochemistry

The invention discloses a one bath process dyeing process of polyester cotton dispersing dye and reactive dye. The one bath process dyeing process comprises the steps that a dyeing assistant, the dispersing / active dye and anhydrous sodium sulphate are sequentially added to a coagulating bath at the temperature of 40 DEG C to 50 DEG C, and then glacial acetic acid is added till the pH of the system reaches 4-6; the temperature is raised to 120 DEG C to 135 DEG C, the heating rate ranges from 1 DEG C / min to 1.5 DEG C / min, and the temperature is kept for 15 min to 50 min; then the temperature is reduced to 80 DEG C to 90 DEG C, treatment is carried out, and the bath ratio of the coagulating bath is 1:(10-60); the dispersing / active dye is prepared from, by weight, 0.5%-1.5% of dispersing dye and 0.5%-1.5% of reactive dye, the dispersing dye is selected from at least one of dispersing brownish yellow XF2, dispersing ruby XF2 and dispersing dark blue XF2, and the reactive dye is selected from at least one of active black G, active red C-D and active orange C-3R. The one bath process dyeing process has the advantages of being stable in color and firm in color fixation.

Owner:杭州集美印染有限公司

Dyeing method of acrylic fiber fabric

InactiveCN102619112ADyeing firmImprove dye uptakeDry-cleaning apparatus for textilesDyeing processEngineeringProcedure preparation

The invention discloses a dyeing method of an acrylic fiber fabric. The dyeing method is characterized by comprising the dyeing steps of working procedure preparation, dye preparation, temperature rising, initial dyeing, temperature preservation, temperature reduction, washing, finishing, quality testing and packaging. The dyeing method is suitable for industrial production; the dye-uptake of the fabric is increased by changing the dyeing method and simplifying the dyeing steps; and the dyeing method leads the dyeing of the fabric to be stable under the condition that the quality of the fabric is not damaged.

Owner:太仓市隆丝达针织时装有限责任公司

Polyester two-way-stretch fabric dyeing process

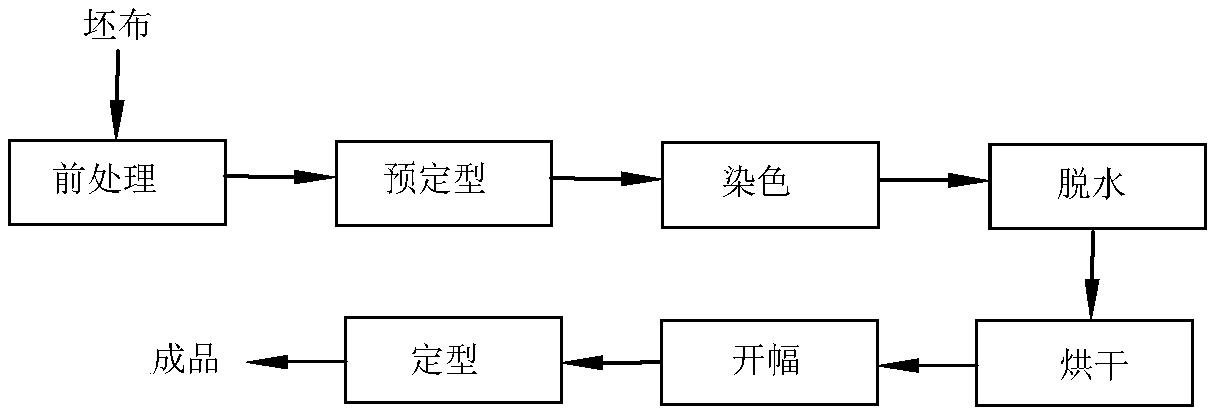

InactiveCN109403010AUniform dyeingDyeing firmDry-cleaning apparatus for textilesDyeing processDisperse dyeSewage

The invention discloses a polyester two-way-stretch fabric dyeing process including the steps of pretreatment, preshaping, dyeing, dehydration, drying, scotching and shaping to obtain a dyed polyestertwo-way-stretch fabric. In the method, under a low bath ratio condition, a dispersed dye is used for dyeing the fabric in two stages in a heat insulation manner, then the temperature is slowly decreased, sewage is discharged and the fabric is cleaned in clear water. The process is used for dyeing the polyester two-way-stretch fabric, is high in dyeing rate and good in color fastness, can reduce folds, shorten operation time and save energy, and can reduce cost.

Owner:SHAOXING COUNTY KWONG FUNG PRINTING & DYEING

Preparation method of reproduced cotton-like polyester fiber capable of being dyed by cationic dye

ActiveCN111088545ASimple processLow costMonocomponent copolyesters artificial filamentPolyesterFiber

The invention relates to the field of polyester synthesis, and discloses a preparation method of a reproduced cotton-like polyester fiber capable of being dyed by cationic dye. The preparation methodcomprises the steps: 1) carrying out an esterification reaction on isophthalic acid sodium pentasulfonate, dimethyl isophthalate-5-sodium benzenesulfonate or a mixture of the isophthalic acid sodium pentasulfonate and the dimethyl isophthalate-5-sodium benzenesulfonate and ethylene glycol, and then adding polyethylene glycol to react, thus acquiring a trimonomer ester; 2) sorting and crushing therecycled polyester; 3) uniformly mixing the recycled polyester with a reaction auxiliary, and then mixing with the trimonomer ester, melting and extruding to prepare a regenerated polyester slice; and4) spinning. According to the method, the recycled polyester does not need to be degraded, the modified trimonomer ester and the reaction auxiliary are ingeniously utilized to directly react with therecycled polyester to prepare the regenerated polyester; the method has the advantages of simple process and low cost; and polyester molecular chains have modified trimonomer ester blocks, so that the fiber has excellent moisture regain and cationic dyeing effect, and achieves the cotton-like effect.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

Polyester-covering cotton knitted fabric dyeing method

InactiveCN105040487ADyeing firmUniform dyeingBleaching apparatusDyeing processSodium carbonatePolyester

The invention discloses a polyester-covering cotton knitted fabric dyeing method. The dyeing method comprises the steps of pretreatment, polyester dyeing, cotton dyeing, soaping, fixation, softening, and dewatering and drying, wherein in the polyester dyeing process, a 1.0 g / L polyester leveling agent, 1.2 g / L acetic acid and 0.6 g / L sodium acetate are used; in the cotton dyeing process, 80 g / L sodium sulfate, 20 g / L sodium carbonate and a 1.0 g / L cotton leveling agent are used. The obtained polyester-covering cotton knitted fabric is firm and uniform in dyeing and good in hand feeling.

Owner:ZHANGJIAGANG CITY HUAYANG KNITTING TEXTILE

Method for manufacturing shell fabric with bananas being used as raw materials

InactiveCN104032450AHigh yieldLess impuritiesFabric breaking/softeningWoven fabricsColor effectEngineering

The invention discloses a method for manufacturing shell fabric with bananas being used as raw materials, and belongs to the technical field of the textile industry. According to the method, stems and leaves of the bananas are used as the raw materials, and the shell fabric is obtained by conducting the steps of blasting, enzymolysis, rinsing, degreasing, rolling extrusion, throwing and the like on the raw materials. According to the method, banana threads made from the stems and the leaves of the bananas are high in yield and low in impurity content, the shell fabric made from the banana threads is soft and not prone to yellow discolouration, and the shell fabric is solid in dyeing and good in coloring effect.

Owner:赖禄波

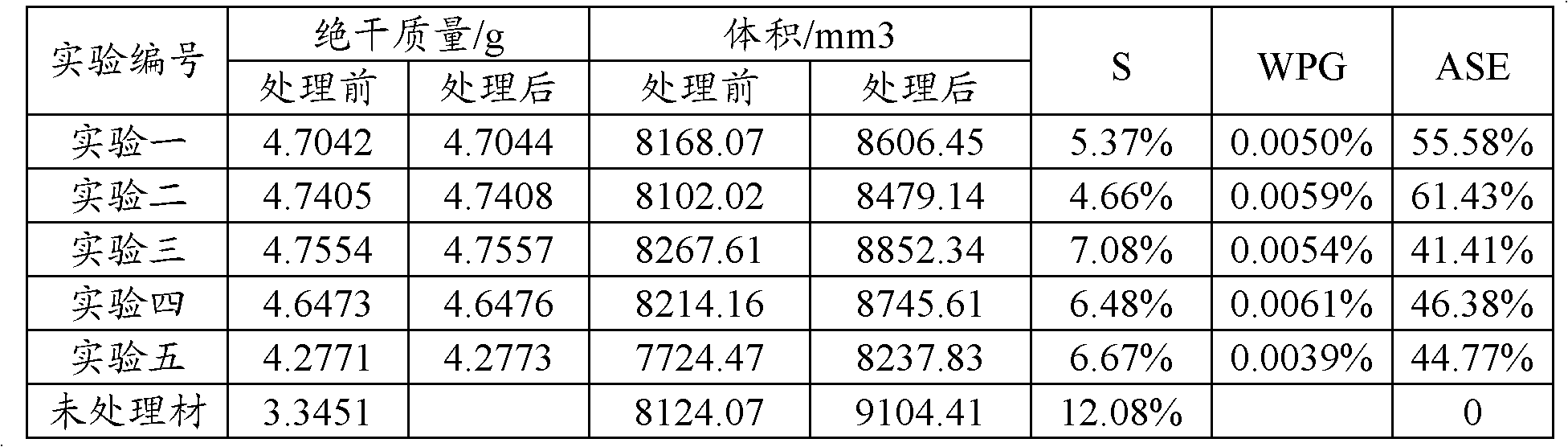

Wood dyeing modifier and preparation method thereof

The invention relates to a modifier for wood dyeing and a preparation method thereof. The modifier comprises the following components in parts by weight: 200 parts of formaldehyde, 50 to 80 parts of phenol, 300 to 370 parts of urea, 50 to 80 parts of melamine, 20 to 30 parts of ammonia water, 1 to 10 parts of basic catalyst, 10 to 30 parts of auxiliary, 50 to 70 parts of extender, and 1 to 5 parts of acid dye, wherein the formaldehyde is an aqueous solution with formaldehyde mass concentration between 35 and 40 percent, and the ammonia water is an aqueous solution with mass concentration between 20 and 30 percent. The wood dyeing modifier can be used for improving the uniform diffusivity and dyeing property of the dye in woods and the light resistance of the dye, and certainly improving the size dimension and hardness of woods.

Owner:成都安居天下实业有限责任公司

High-temperature environmentally-friendly chemical fiber dyeing technology

InactiveCN107164976AGuaranteed functionAvoid damageBiochemical treatment with enzymes/microorganismsDyeing processFiberCellulose

The invention relates to a high-temperature environmentally-friendly chemical dyeing technology. The technology comprises preprocessing, pre-setting, dyeing, water washing, soaping, dye fixation, softening, drying, setting and winding. A stepped heating dyeing method is adopted, and the heating and cooling rates and the dyeing time are strictly controlled, so dyeing of a fiber fabric has high fastness, the dyeing is uniform, and the dyeing has good stability; an anti-dyeing salt S is added in the dyeing process, so the destroy of potential aldehyde groups in cellulose molecules in chemical fiber filaments to a dye is greatly improved, thereby a dyed product has pure color light, the color difference of dyeing is avoided, and the reappearance and the stability of the dyeing are good. Chemical fiber filaments finally produced in the invention have the advantages of uniform dyeing, stability, strong recurrence, elasticity, softness and high dyeing fastness.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

Dye liquor for printing and dyeing of flocked cloth

The invention relates to a dye liquor for printing and dyeing of flocked cloth. The dye liquor is prepared by mixing the following components in parts by weight: 1 to 5 parts of lithospermum / phellodendron dye, 5 to 10 parts of ethanol, 3 to 8 parts of sodium dodecyl sulfonate, 10 to 15 parts of petroleum ether, 3 to 5 parts of antifoaming agent, and 0.5 to 1.5 parts of water. The flocked cloth dyed by the provided dye liquor has a certain medicinal effect, the color fastness is high, and fading is difficult.

Owner:CHANGSHU HONGQIAO PRINTING & DYEING CO LTD

Practical cloth dyeing device

ActiveCN105420963AUniform colorNo impuritiesTextile treatment machine arrangementsTextile treatment by spraying/projectingPulleyComputer engineering

The invention provides a practical cloth dyeing device which comprises a shell, a spraying device, a first press roll device, a first filtering device, a second press roll device, a second filtering device, guide pulleys and a dye storage box. The spraying device, the first press roll device, the first filtering device, the second press roll device and the second filtering device are sequentially arranged from top to bottom; the first filtering device and the second filtering device are both slidably installed in the shell, the end side of the second end of the first filtering device and the bottom of the second end of the first filtering device are both provided with the guide pulleys, and a first lower press roll is arranged over the second end of the first filtering device and matched with a first upper press roll of the first press roll device; the end side of the second end of the second filtering device and the bottom of the second end of the second filtering device are both provided with the guide pulleys, and a second lower press roll is arranged over the second end of the second filtering device and matched with a second upper press roll of the second press roll device. According to the practical cloth dyeing device, the dyeing effect is good, dyeing is uniform and firm, and dye is saved.

Owner:桐乡市织盟知识产权运营有限公司

Dyeing method of flame retardant blended fabric

The invention relates to a dyeing method of a flame retardant blended fabric. The method comprises the following steps: (1) carrying out pretreatment, namely, boiling the flame retardant blended fabric in a pretreatment agent for 30-50 minutes at the temperature of 70-95 DEG C; (2) dyeing in a first bath, namely, transferring the flame retardant blended fabric obtained in the step (1) into a first dye vat; and (3) dyeing in a second bath, namely, transferring the flame retardant blended fabric obtained in the step (2) into a second dye vat. The flame retardant blended fabric comprises the following components in parts by weight: 40-60 parts of meta-position aramid fiber and 40-60 parts of flame retardant viscose fiber. According to the dyeing and finishing method, in the process of dyeing in the first bath, the meta-position aramid fiber is dyed, and in the process of dyeing in the second bath, the flame retardant viscose fiber is dyed, so that different dyeing and finishing processes are carried out on the two fibers with different functions; the dyeing method has the advantages of being uniform in dyeing, stable, washable, good in flame retardant property and the like.

Owner:游晟纺织科技(深圳)有限公司

Shaping device for non-woven fabric dyeing production line and dyeing process of device

ActiveCN110117882AScientific and reasonable structureEasy to useHeating/cooling textile fabricsTextile treatment machine arrangementsProduction lineWater vapor

The invention discloses a shaping device for a non-woven fabric dyeing production line and a dyeing process of the device. The shaping device comprises a base seat, wherein a drying shaping componentis mounted on one side of the base seat. The device has a scientific and reasonable structure, is safe and convenient to use, the drying shaping component is arranged to dry and shape two sides of thenon-woven fabric simultaneously through the action of a plurality of heating plates and grooves, so that the shaping effect is improved; meanwhile gas in a drying chamber flows through the action ofan air inlet pipe, an air outlet filter plate and an air outlet pipe, so that the water vapor generated in the drying process is taken away; observation and supervision of the internal condition of the drying chamber by a user is facilitated through the action of a transparent organic glass plate; the non-woven fabric is staggered distributed along a first roller shaft and a second roller shaft through the action of the first roller shaft and the second roller shaft; and class drying is preformed on the non-woven fabric, and preliminary stretching is preformed on the non-woven fabric at the same time, and thus the surface of the non-woven fabric is smooth, and the surface wrinkles are prevented from affecting the drying effect, so that the drying effect is improved.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

A cloth printing and dyeing device

ActiveCN105332189BRealize the heating effectUniform colorLiquid/gas/vapor removalTextile treatment machine arrangementsEngineeringEnergy conservation

The invention provides a cloth printing and dyeing device. The cloth printing and dyeing device is used for dyeing cloth and comprises a first box, a second box, a cloth rolling roller set, a first cloth roller, a second cloth roller, transitional rollers and a communicating pipe. The first box is arranged above the second box, the body wall of the first box comprises a first outer shell, a first inner shell and a first heating cavity between the first outer shell and the first inner shell, and the cloth rolling roller set is arranged in the first box. The body wall of the second box comprises a second outer shell, a second inner shell and a second heating cavity between the second outer shell and the second inner shell, a plurality of heating pieces are arranged in the second heating cavity, and a plurality of cloth winding rollers are arranged in the second box and used for changing the direction of cloth. The first heating cavity is communicated with the interior of the second box through the communicating pipe. Exhaust holes are formed in the first outer shell and are away from the port, located in the first heating cavity, of the communicating pipe. The cloth printing and dyeing device is simple and practical in structure, uniform in dyeing and firm, and the purpose of saving energy is achieved by recycling heat.

Owner:湖州众创小微创业园企业管理股份有限公司

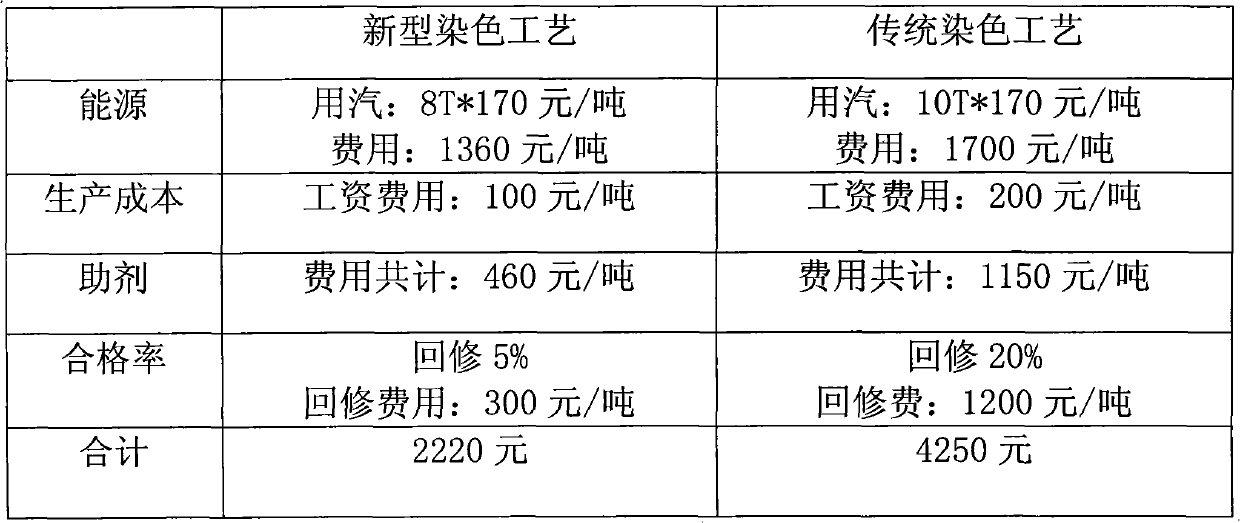

Novel dyeing process for blended knitting yarn

The present invention provides a novel dyeing process for blended knitting yarns, which adopts a novel assistant PS liquid; leaves out formic acid, acetic acid, anhydrous sodium sulphate, a leveling agent, ammonium sulfate, an osmotic agent and a dispersant; simplifies production process; and stabilizes dyeing process. The novel dyeing process has the advantages that only the novel assistant agent PS liquid is used when dyeing by using a wool reactive weak acid dye and a cationic dye; dyeing defects in the process of high count yarn hank dyeing is not easy to generate, which improves the degree of dyeing and saves the dye; the stable dyeing-accelerating property can increase the improvement of color fastness; the dyeing time is shortened, which can save massive energy and increase labor productivity; a softening treatment for dyeing water is not necessary and tap water can be used for dyeing directly, and the water treatment cost is reduced because of no dyeing defects and seasonal aberration; and the assistant agent cost is reduced greatly.

Owner:TIANJIN TEXTILE ENG RES INST

Water-free washing method of pigment dyeing denim fabric

The invention provides an ultraviolet light water-free washing method of a denim fabric made of pigment dyeing yarns. The water-free washing method is characterized by comprising the following process flows of: (1) providing denim clothes made of the pigment dyeing yarns; (2) conducting pretreatment such as washing treatment, softening treatment and modified TiO2 treatment on the denim clothes made of the pigment dyeing yarns; (3) placing special parts or a whole set of the denim clothes to be washed under an ultraviolet lamp for irradiation; and (4) conducting aftertreatment such as washing and drying on the denim clothes after irradiation. Compared with a traditional denim fabric washing method, the water-free washing method has the advantages of short flow, wide color spectrum, firmness in dying, high dye uptaking rate, low cost, less energy consumption and water saving, capability of basically achieving zero emission, and the like. Compared with coating, the water-free washing method has the advantages of good flexibility, excellent air permeability, good weather fastness, resistance to sunlight, resistance to washing, and the like, and effectively solves the problems of pollution, denim shrink after washing, and the like in a washing industry. In addition, the water-free washing method also has the advantages of capabilities of saving water to 100% and regularly washing.

Owner:GUANGDONG JUNAN JEANS RES INST +1

A method for optimizing the color of seawater pearls

Owner:GUANGZHOU QIFU PEARL PROCESSING

Treating agent with characteristic of convenient corn skin dyeing

InactiveCN105171873AThe preparation method is simple and easyEasy to dyeReed/straw treatmentPolyvinyl alcoholPotassium

The present invention relates to a treating agent with a characteristic of convenient corn skin dyeing, wherein the treating agent is prepared from the following raw materials by weight: 2.5 parts of sodium nitrate, 1.6 parts of sodium acetate trihydrate, 0.5 part of potassium chloride, 0.25 part of sodium citrate, 3 parts of sodium carbonate, 6 parts of 5% nitric acid, 30 parts of water, and 1.8 parts of polyvinyl alcohol. According to the present invention, the treating agent preparation method is simple, the treating method after completing the preparation is simple, the treated corn skin is easy to dye, the dyed color is stable, the fading can not be generated, the non-uniform core dyeing can not be generated in a short term, and the corn skin product quality can be improved.

Owner:阜南县永盛工艺品有限公司

Processing method for aluminum components

ActiveCN102747401BStrong metal textureGuaranteed accuracySurface reaction electrolytic coatingDyeingAluminium

The invention discloses a processing method for aluminum components. The processing method is used for exterior processing of an exterior aluminum component of a mobile terminal so as to allow an exterior surface of the aluminum component to have n different colors, i.e., a first color, a second color,..., and an n color, wherein n is a natural number no less than 2. The processing method for aluminum components comprises the following steps: carrying out first exterior processing on the part of an aluminum component to be colored with the first color; carrying out first anodization dyeing treatment on the part of the aluminum component to be colored with the first color; carrying out second exterior processing on the part of the aluminum component to be colored with the second color; and carrying out second anodization dyeing treatment on the part of the aluminum component to be colored with the second color. The processing method for aluminum components provided in the invention has the advantages of simple operation, solid dyeing, a few processing procedures and capacity of realizing indiscriminate application of a plurality of colors on a same aluminum component.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

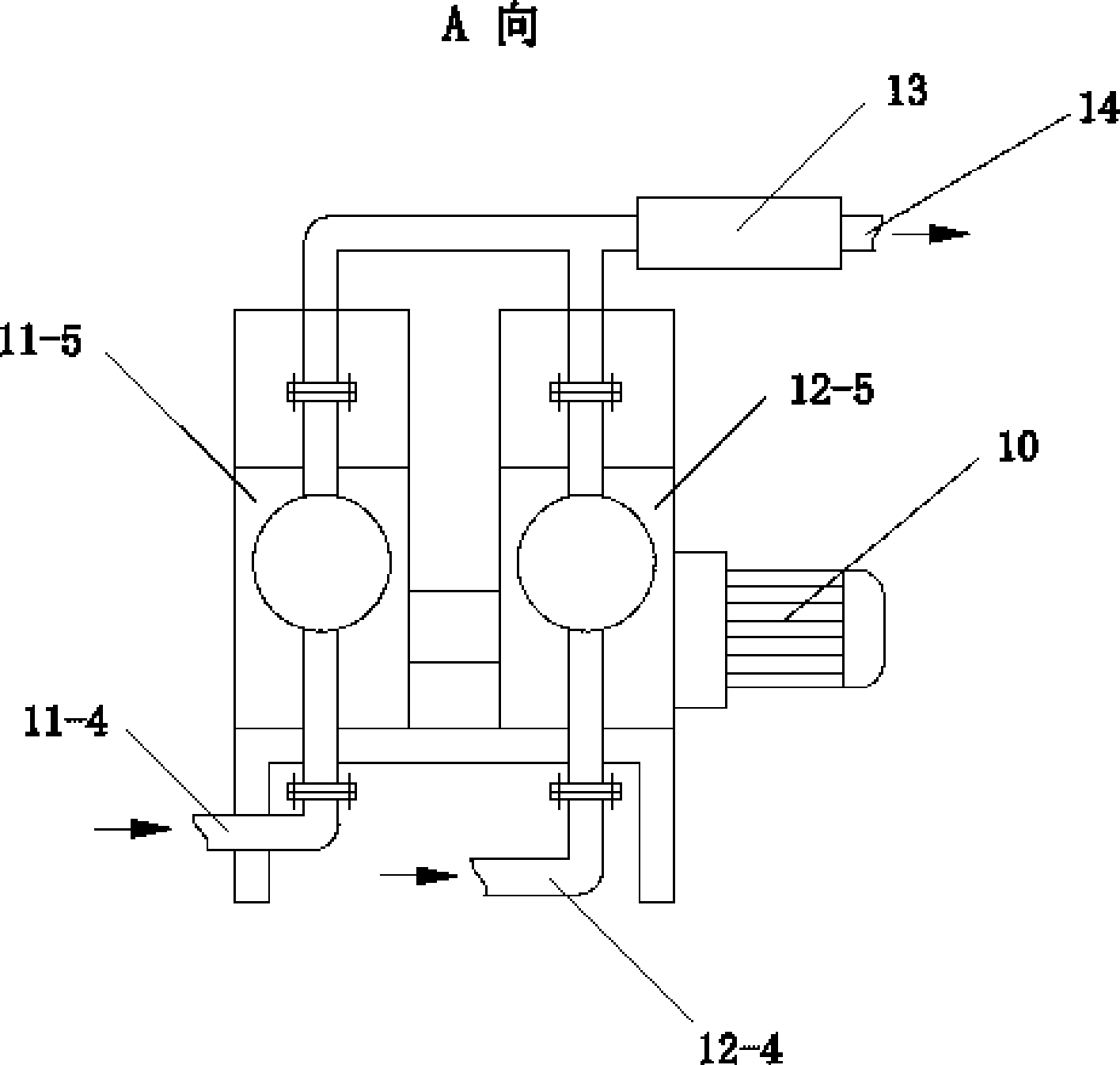

Double-rough-yarn dyeing device

InactiveCN108625074AInterval stainingDyeing firmSucessive textile treatmentsTwo or more solvent application treatmentYarnBobbin

The invention provides a double-rough-yarn dyeing device, and belongs to the technical field of textile equipment. The double-rough-yarn dyeing device comprises a dyeing mechanism and a drying and color fixing mechanism. A first dyeing disc of a first dyeing component of the dyeing mechanism is arranged on a dyeing support roller coaxially. A first dyeing roller is arranged on a first dyeing roller support base rotatably. A second dyeing cam of a second dyeing component is arranged on the dyeing support roller coaxially. A second upper dyeing roller is arranged on a second upper dyeing rollersupport base rotatably. A second lower dyeing roller is arranged on a second lower dyeing roller support base rotatably. A drying and color fixing cavity is formed between an upper drying and color fixing support plate and a lower drying and color fixing support plate of the dyeing and color fixing mechanism. A first bobbin and a second bobbin of a take-up mechanism are mounted on a take-up rollercoaxially. A reciprocation guide slider of a take-up reciprocation guide mechanism is arranged on a reciprocation guide sliding rod in a front-back sliding mode. The double-rough-yarn dyeing device has the advantages that first rough yarns can be dyed with single colors rapidly, second rough yarns can be dyed with spaced double colors rapidly, and the structure is reasonable and compact.

Owner:姚钟钟

Color glass wall brick and production process thereof

InactiveCN107226618AImprove crushing efficiencyEvenly crushedGlass productionPotassium feldsparColor glass

The invention provides a color glass wall brick and a production process thereof, and relates to the technical field of glass production. The color glass wall brick is prepared from the following raw materials in parts by weight: 75 to 85 parts of waste and old glass, 4 to 6 parts of fluorite, 1 to 3 parts of potassium feldspar, 1 to 3 parts of anorthite, 2 to 5 parts of sodium carbonate, 1 to 7 parts of dolomite and 0.2 to 0.4 part of coloring agents. The production process comprises the following steps of (1) raw material weighing; (2) smashing; (3) mixing; (4) smelting; (5) pressing formation; (6) annealing cooling. The color glass wall brick and the production process thereof disclosed by the invention solve the problems that in the production process of the existing color glass wall brick, the utilization rate of waste and old broken glass is very low, and the compressive strength of the prepared color glass wall brick is low.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Hemp and denim active dye and dyeing technology

The invention provides a hemp and denim active dye and a dyeing technology. The dye is prepared from active yellow 3RS, sodium chloride, sodium carbonate, polyvinylamine and a penetrant TR. The dye and the dyeing technology are high in reproducibility, high in stability and high in dry and wet fastness; after being dyed, a fabric has a high fixation rate and is full in chromaticity and bright in color. Multiple practices prove that a yarn sample is finally very close to that supplied by a customer; meanwhile, dyeing is quite stable; the sizing percentage is proper, and the cloth machine efficiency is over 95 percent; a final denim product is extremely close to a sample supplied by the customer in the style, the color and the quality, and the enzyme wash and stone grinding effect of the final denim product is almost the same with that of the sample supplied by the customer.

Owner:浙江丝之美服饰染整有限公司

Dyeing and finishing process of linen type cloth

The invention discloses a dyeing and finishing process of linen type cloth and relates to the technical field of textiles. The dyeing and finishing process comprises steps as follows: alkali-minimization treatment, dyeing, dewatering, after-finishing, detection as well as packing and storage. According to the dyeing and finishing process of the linen type cloth, the alkali-minimization treatment is performed before dyeing of the cloth, so that hand-feeling, softness and elasticity of the cloth are improved, furthermore, contaminants on the surface of the cloth can be eliminated, subsequent dyedyeing is enabled to be more stable and more uniform, and color points and color spots on the surface of the cloth are prevented during dyeing.

Owner:嘉兴市金乐染织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com