Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Good dyeing stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

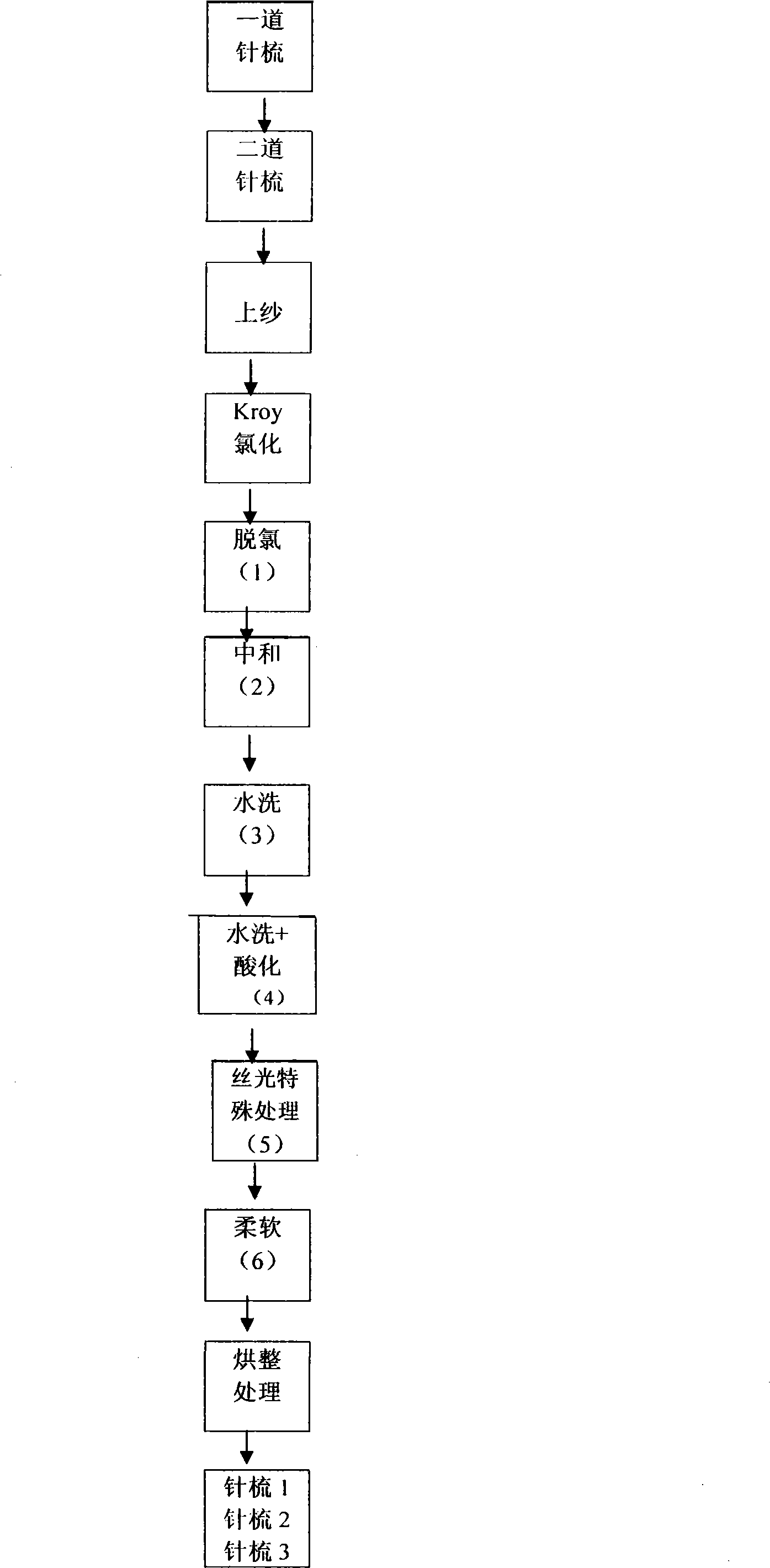

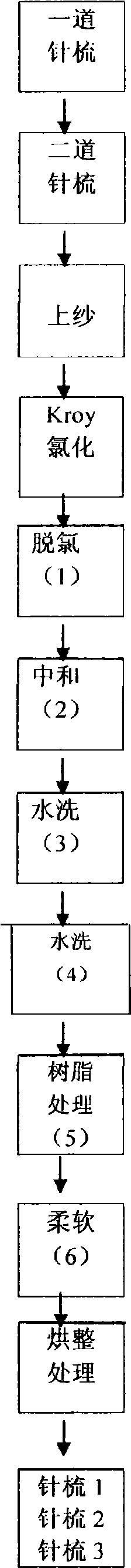

Wool shrinkproof mercerization method

ActiveCN101519838AGorgeous ingredientsRaw materials are simpleMercerising of sliversBiochemical fibre treatmentChlorinated solutionsEngineering

The invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloriThe invention provides a wool shrinkproof mercerization method which comprises the following steps: wools are combed by a needle, combed and opened again through secondary needle combing before chloridization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thedization, and wetting agent is added during the needle combing for the chemical preliminary treatment; the secondary needle combing further ensures the opening and the fully and evenly wetting of thewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequewools; chlorination scale stripping of chlorination solution is performed for the wools after the spraying of the wetting agent and the combing opening are performed, and the wools uniformly and sequentially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared wntially pass through a chlorination solution spraying device under the conditions of no tension and no twist number of each wool and are sprayed twice by adopting the chlorination solution. Compared with the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advith the technical level held by China, international fellow traders and international wool office at present, the product of the wools obtained by the wool shrinkproof mercerization method has the advantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool prodantages of shrinkproof size stability, soft hand feeling, attractive cloth cover, stable coloring and other excellent properties, improves the coloring stability, expands the function of the wool product and prolongs the service life of the wool product for wearing.uct and prolongs the service life of the wool product for wearing.

Owner:浙江新中和羊毛有限公司

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

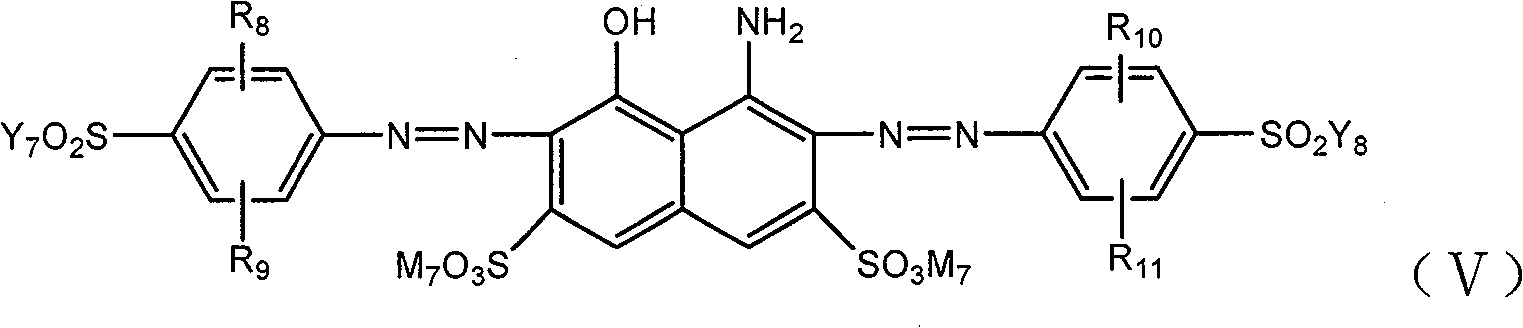

Active black dye

The invention relates to active black dye which essentially comprises fuchsine component A, orange yellow component B and navy component C, and is based on the component A, the component B and the component C; the weight percentage of the component A is 1 to 25 percent, the weight percentage of the component B is 1 to 25 percent, and the weight percentage of the component C is 50 to 95 percent; and the component A comprises at least a dye shown as formula (I) and a dye shown as formula (II), the component B comprises at least a dye shown as formula (III) and a dye shown as formula (IV), and the component C comprises at least a dye shown as formula (V). The active black dye has the advantages of high product solubility, strong salt and alkali resistance, high uptake date and color fixing rate, excellent dyeing fastness and environmental protection.

Owner:ZHEJIANG LONGSHENG GROUP +1

Natural dyestuff dyeing and finishing process of polyester fabric

The invention discloses a natural dyestuff dyeing and finishing process of polyester fabric. The natural dyestuff dyeing and finishing process of the polyester fabric comprises pretreatment, preshaping, modification treatment, dyeing, mordant removing, soaping, fixation, finishing, drying, shaping, calendering and winding. According to the natural dyestuff dyeing and finishing process of the polyester fabric, helicase and alhpa-amylase are adopted to conduct pretreatment, modification treatment is radically conducted on the performance of the polyester fabric through a acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane, and the dyeing rate of the fabric is increased; in the dyeing process, a large amount of alkaline matter and inorganic salt are not used, a levelling agent and diffusant are added, the level-dyeing property is improved, natural dyestuff is used, therefore, environmental pollution is avoided, and requirements of green environmental protection are met; modification treatment and fire-retardant treatment are conducted on the fabric through montmorillonite, and the fire resistance of the fabric is high; anti-yellowing reagents are used in the preshaping and the shaping, and the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Dyeing and finishing process for linen and cotton blended fiber fabric

InactiveCN105063998AProcess temperature changeLow processing temperaturePhysical treatmentBiochemical fibre treatmentInorganic saltsManufacturing engineering

The invention discloses a dyeing and finishing process for linen and cotton blended fiber fabric. The dyeing and finishing process comprises preprocessing, pre-sizing, modified processing, dyeing, mordant removing, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Helicase, scouring enzyme and alpha-amylase are used for pretreatment, modification treatment is adopted before dyeing, the performance of linen and cotton blended fabric is modified fundamentally, and the dye-uptake rate is increased; the dyeing procedure does not require a large quantity of alkaline substances and inorganic salt, a leveling agent, substitutive alkali, a migration inhibitor and a dispersing agent are added, the dye uniformity is improved, environment pollution is avoided due to use of natural dye, and requirements for environmental protection are met; self-cleaning processing is added in the after finishing procedure, and the self-cleaning capacity, the crease-resistant performance, the washing resistance and the color fastness of the fabric are improved; crease-resistance finishing is added, and the crease-resistant performance of the fabric is improved; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Chinlon dyeing process adopting natural dye

InactiveCN104695241AReduce pollutionAvoid damageFibre typesHeating/cooling textile fabricsColour fastnessFiber

The invention provides a chinlon dyeing process adopting natural dye. The method comprises the steps of pretreatment, presetting, dyeing, soaping, fixation, softening treatment, drying, setting and rolling. The natural dye, alizarin, is adopted, rare earth chloride is adopted as dye mordant, the dyeing effect is better, the washability is greatly enhanced, and meanwhile dyed chinlon fibers have the good antibacterial property. The washing and fixation process is added, the dyeing firmness is good, environment-friendly formaldehyde-free TCD-R is adopted in the fixation process, chinlon is dried step by step after fixation, and the firmness of the chinlon is greatly improved. The softening treatment process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and elastic.

Owner:TAICANG TIANLONG CHEM FIBER

Environment-friendly dyeing and finishing technology of cotton cellulose fabric

InactiveCN105002720AHigh whitenessAvoid damagePhysical treatmentBiochemical fibre treatmentEpoxyCellulose

The invention discloses an environment-friendly dyeing and finishing technology of a cotton cellulose fabric. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and acetic acid aqueous solution of chitosan, hydrogen peroxide and epoxy chloropropane is adopted, so that the property of the cotton cellulose fabric is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent and a dispersing agent are added, so that the dye uniformity is improved; natural dye is used, so that environmental pollution is avoided, and the demand of environmental protection is met; modification treatment and fire retardant treatment are carried out on the fabric through the adoption of montmorillonite, so that the fire resistance of the fabric is high; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG CHENGLE CHEM FIBER

Flax fabric dyeing and finishing process

InactiveCN104988768AReduce pollutionAvoid damageUltrasonic/sonic fibre treatmentDyeing processInorganic saltsMontmorillonite

The invention discloses a flax fabric dyeing and finishing process including pretreatment, pre-sizing, modification treatment, dyeing, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. Ultrasonic waves are used for pretreatment, and at the same time, the modification treatment step is added; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; montmorillonite is used for modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high; and an anti-yellowing reagent is used in the processes of pre-sizing, sizing and post-finishing, so that a final fabric does not easily turn yellow.

Owner:太仓市宝明化纤有限公司

Dyeing process of polyester cotton fiber fabric

ActiveCN103993487AAvoid wrinklesAvoid severe shrinkageHeating/cooling textile fabricsDyeing processDisperse dyePolymer science

The invention provides a dyeing process of a polyester cotton fiber fabric. The dyeing process comprises the following steps of preforming, pretreatment, drying, dyeing, washing, soaping, color fixing, drying, forming and winding. According to the dyeing process, a high-temperature leveling agent is added during dyeing, so that the problem that level dyeing effect and penetration dyeing effect are affected and even generate color dots and color patches occur caused by gathering of dyes because the heat stability resistance of fuel is reduced due to temperature increase is avoided, and the dyeing effect is good; the temperature is increased in a stepped progressive mode in the dyeing procedure, and the temperature increase and decrease velocity and the dyeing time are strictly controlled, so that high dyeing fastness, dyeing uniformity and good dyeing stability of the polyester cotton fiber fabric are achieved; the dyes with single property are not used and dispersed dyes and neutral dyes are compounded in the dyeing procedure, and the dispersed dyes and the neutral dyes supplement each other, so that good dyeing fastness is achieved; the traditional two-bath two-step method dyeing is abandoned, and the one-bath one-step method dyeing is adopted, so that the energy is saved, and the emission amount is reduced.

Owner:广东欣薇尔服装有限公司

Aramid fabric high-efficiency dyeing and finishing process

InactiveCN104988711AImprove hydrophilicityImprove dye uptakePhysical treatmentFibre typesInorganic saltsProcess engineering

The invention discloses an aramid fabric high-efficiency dyeing and finishing process including modification treatment, scouring and dyeing in one bath, soaping, color fixation, post-finishing, drying, sizing, calendering, and coiling. According to the dyeing and finishing process, before the dyeing process, a fabric is subjected to low temperature plasma treatment, then the fiber fabric is subjected to modification treatment with 2,3-epoxypropyltrimethylammonium chloride and chitosan, and thus the fabric dyeing degree is increased, and the difficulty of the subsequent dyeing steps is reduced; at the same time, ultrasonic treatment is adopted during modification treatment, so that the time is saved and the treatment efficiency is improved; with adopting of scouring and dyeing in one bath, the efficiency is increased, and the cost is reduced; in the dyeing process, a large amount of alkaline substances and inorganic salts are not used, natural dyes are used, and at the same time, a colophony powder is added as a color fixing agent, so that the color fixing effect is enhanced, besides, the environmental pollution is avoided, and the requirements of environmental protection are met; and with increase of anti-yellowing finishing, a final fabric does not easily turn yellow.

Owner:TAICANG SHUANGYU CHEM FIBER CO LTD

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Dyeing and finishing process of polyester and cotton blended fiber fabric

InactiveCN105063997AHigh whitenessAvoid damageSucessive textile treatmentsBiochemical fibre treatmentPolyesterFiber

The invention discloses a dyeing and finishing process of polyester and cotton blended fiber fabric. The process comprises pretreatment, presetting, modification treatment, dyeing, mordant removal, soaping, color fixing, after finishing, drying, sizing, calendaring and rolling. Snailase and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the polyester and cotton blended fabric is modified fundamentally, and the dye-uptake of the fabric is increased; in the dyeing procedure, fewer alkaline substances and inorganic salt are used, a dye leveler, substitution alkali, a migration inhibitor and a diffusant are added, the dye leveling performance is improved, natural dye is used, environmental pollution is avoided, and the environment-friendly requirement is met; self-cleaning treatment is added during aftertreatment, and the self-cleaning capacity, the crease-resistant performance, the wash durability and color fastness are improved; silk fibroin and sericin are adopted for afterfinish, and the anti-pilling performance and the antistatic performance of the fabric are provided; the whole process is environment-friendly and pollution-free.

Owner:TAICANG TIANLONG CHEM FIBER

Low-temperature dyeing and finishing technology for bamboo fiber fabric

InactiveCN105019250AAvoid damageLower processing temperaturePhysical treatmentBiochemical fibre treatmentAmylaseFiber

The invention discloses a low-temperature dyeing and finishing technology for bamboo fiber fabric. The low-temperature dyeing and finishing technology includes the steps of pretreatment, preshaping, modification treatment, dyeing, mordant removal, soaping, color fixation, after finishing, drying, shaping, calendering and rolling. Helicase, scouring enzyme and alpha-amylase are adopted for pretreatment, modification treatment is adopted before dyeing, the performance of the bamboo fiber fabric is modified fundamentally, and the dye-uptake rate of the fabric is increased; as in the dyeing working procedure, alkaline substance and inorganic salts are not used in quantity, and a levelling agent is added, the dyeing levelness is improved; environment pollution is avoided by using natural dyestuff, which meets the requirement for environmental protection; as self-cleaning treatment is added in after treatment, the self-cleaning capacity, crease-resistant performance and wash-resisting firmness of the fabric are improved; crease-resistant finishing is added, and therefore the crease-resistant performance of the fabric is improved; the whole technology is environmentally friendly and free from pollution.

Owner:TAICANG TIANLONG CHEM FIBER

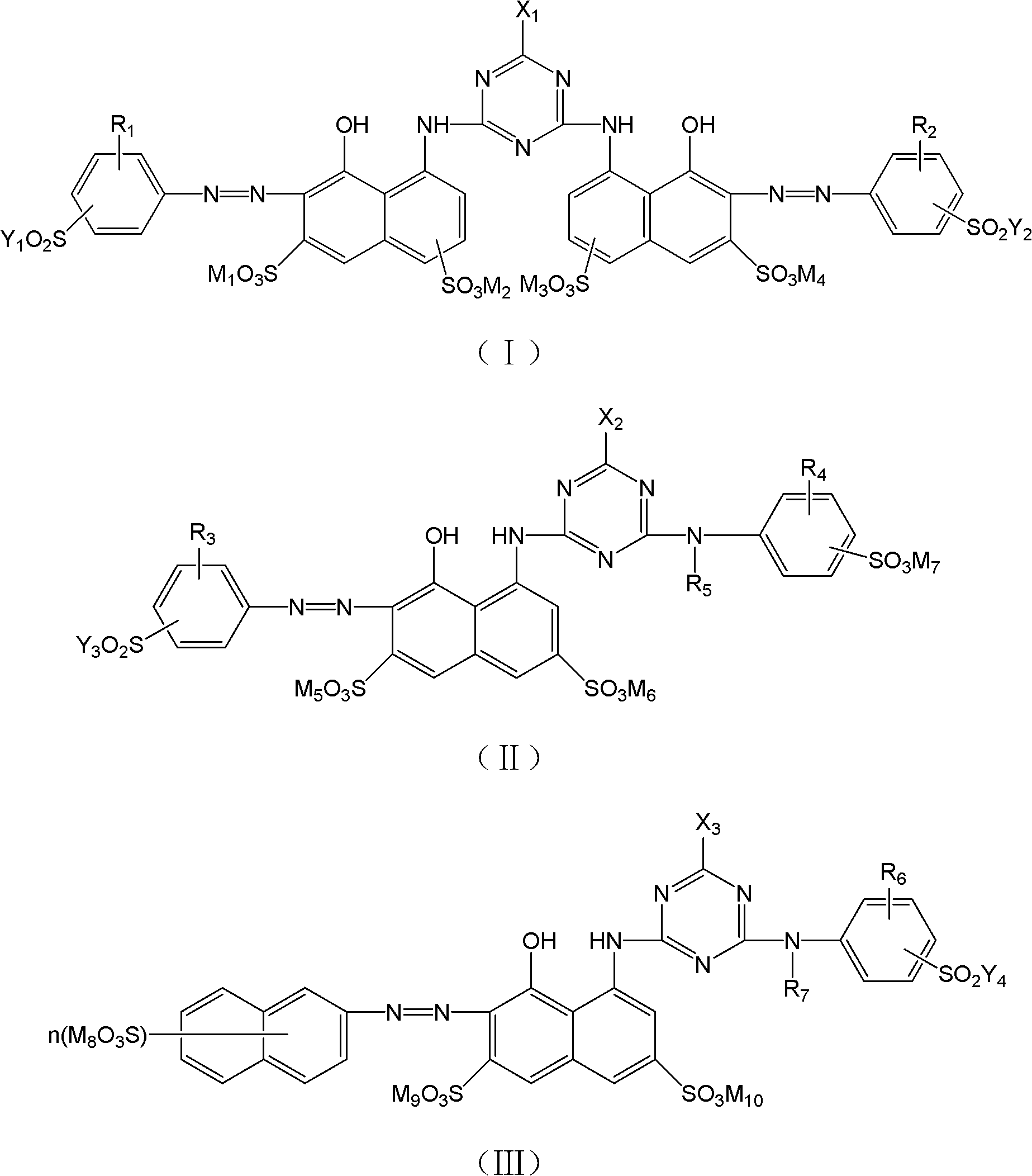

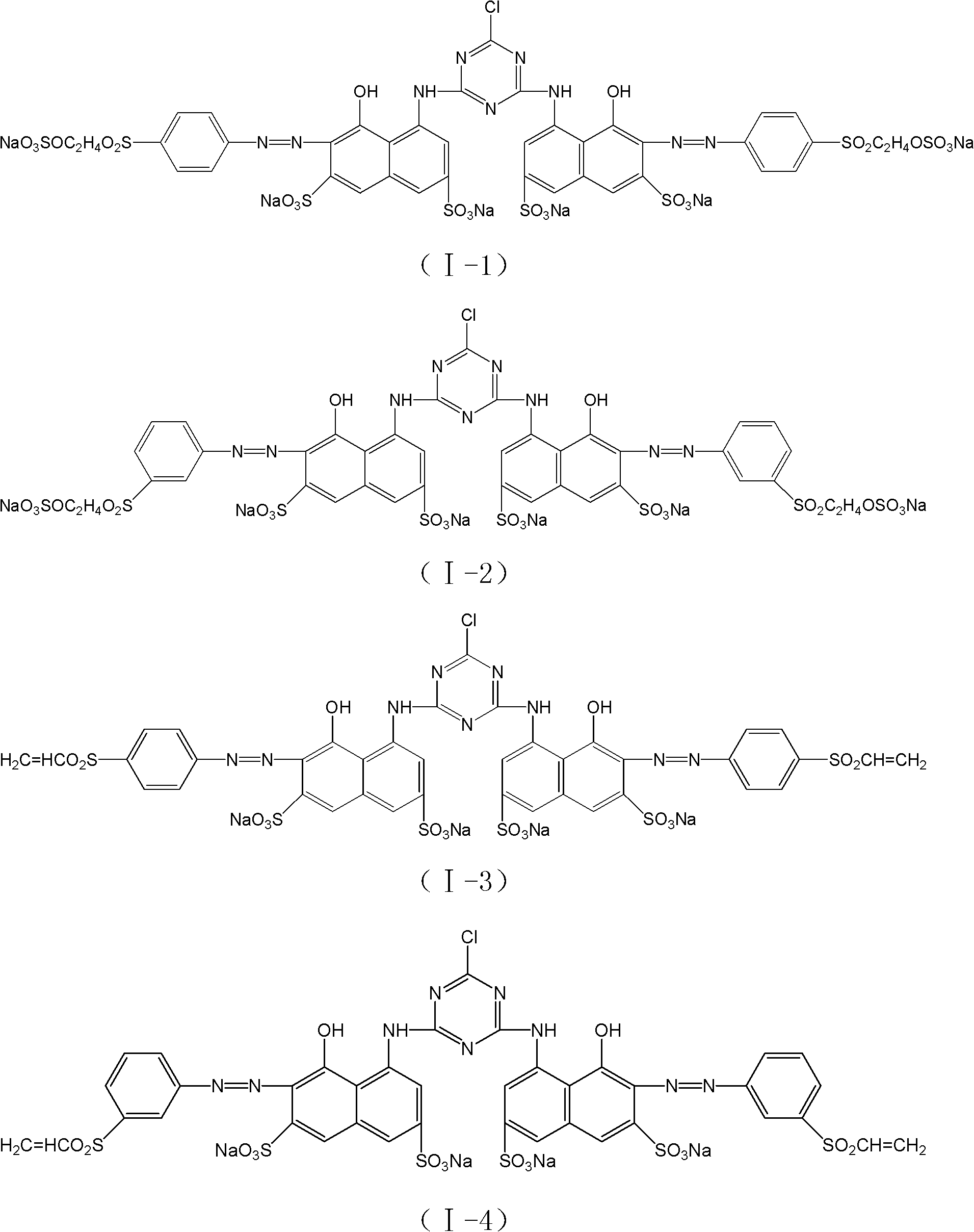

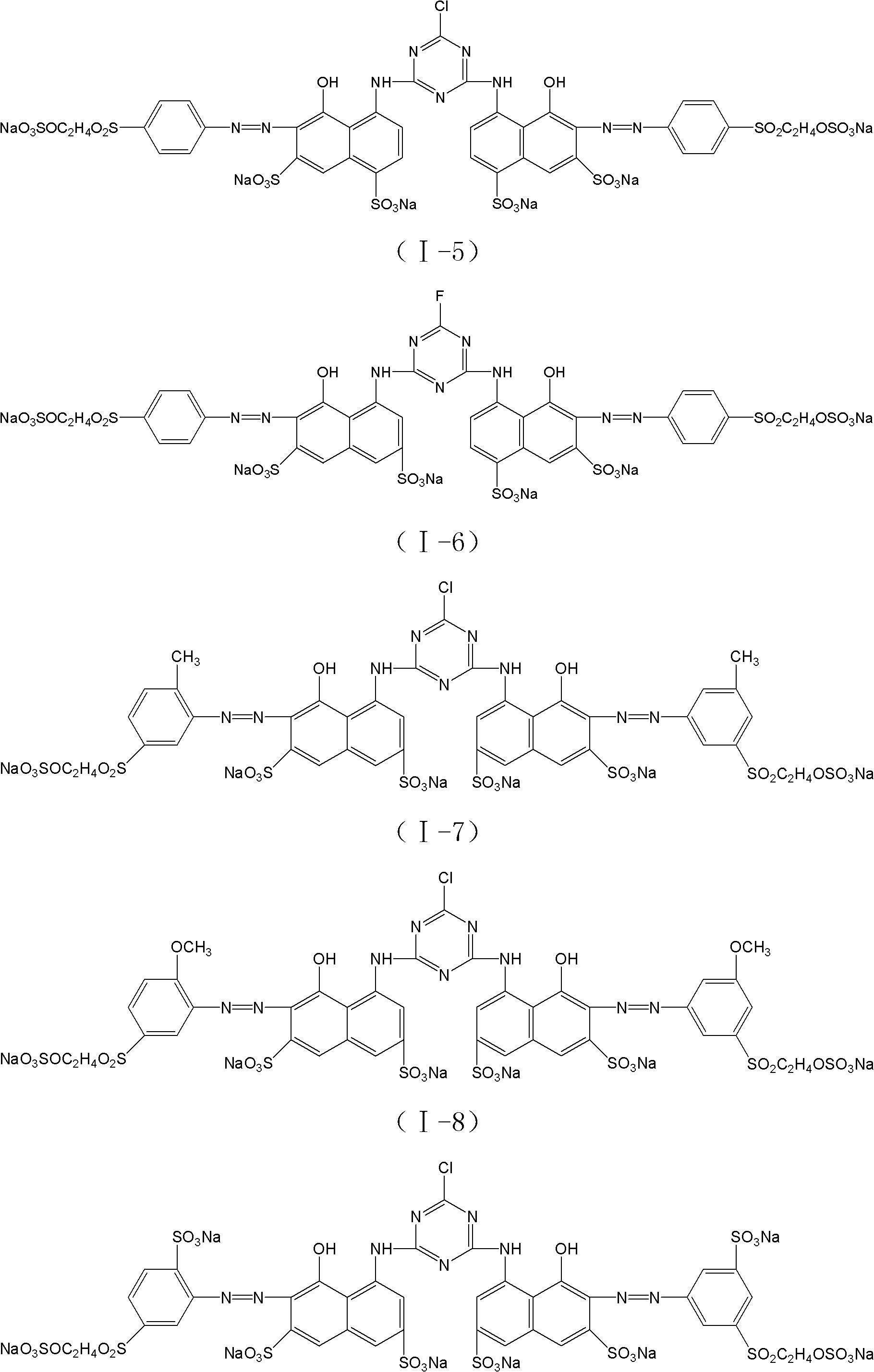

Active red dye composition

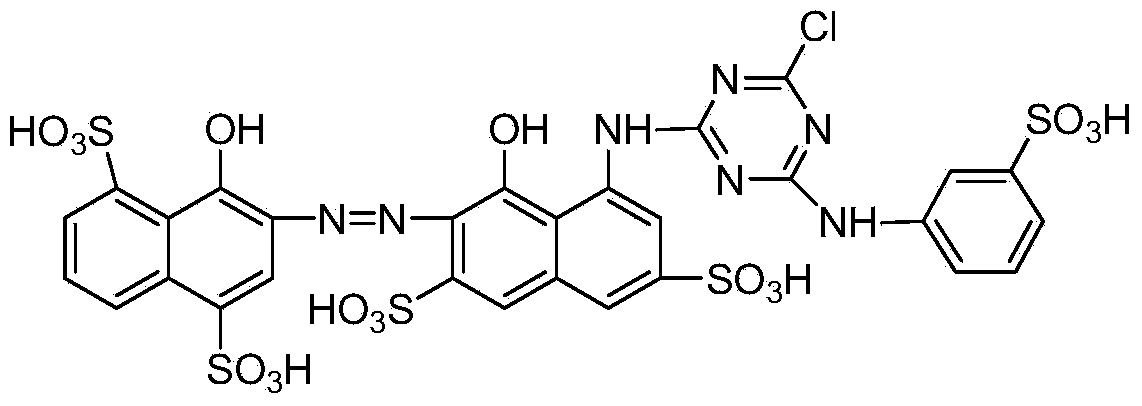

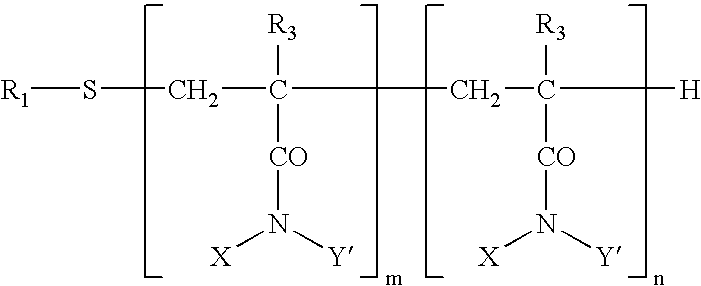

InactiveCN101935466AImprove dye uptake and color fixationGood dyeing stabilityOrganic dyesDyeing processPhotochemistryDye uptake

The invention provides an active red dye composition which mainly comprises 0.1-99% of by weight of one or more than one component A represented by the structural formula (I), 0.1-99% of one or more than one component B represented by the structural formula (II) and 0.1-99% of one or more than one component C represented by the structural formula (III) by mass. When being used for dyeing cellulose fiber, polyarmide fiber and fabrics thereof, the active red dye composition has the advantages of high dye uptake rate and color fixation rate and good lifting property, leveling property and dyeingstability, and various dyeing properties are excellent.

Owner:ZHEJIANG KEYONG CHEM CO LTD +2

Salt-free dyeing process for natural silk fabric

InactiveCN104746365AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsFiberInorganic salts

The invention provides a salt-free dyeing process for natural silk fabric. The salt-free dyeing process comprises the following steps: pre-treatment, pre-setting, modified treatment, dyeing, soaping, fixation, after-treatment, drying, setting, calendaring and rolling. The fabric is subjected to modified treatment with a cationic modifying agent, so that the dyeing rate of the fabric is increased; and the difficulty in the subsequent dyeing step is reduced. In the dyeing procedure, inorganic salts such as anhydrous sodium sulphate or table salt are not used, so that the pollution is reduced. Due to the addition of the soaping and fixation processes, the dyeing fastness is good. Green environment-friendly aldehyde-free TCD-R is adopted in the fixation process; and the fiber is gradually dried after fixation, so that the fastness of the fiber is greatly improved. Due to the addition of the after-treatment process, the color fastness and the softness of the fabric are improved; the roughness sense of the fabric is relieved; and the fabric is fluffy and elastic.

Owner:太仓市宝明化纤有限公司

Dyeing and finishing process for modal fabric

InactiveCN104975499AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsProcess engineering

The invention discloses a dyeing and finishing process for modal fabric. The process comprises the procedures of pretreatment, pre-setting, modification treatment, dyeing, soaping, fixation, after-finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave, and a step of modification treatment is added; in the dyeing procedure, a base substituent SA is used, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out modification treatment and flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedures of pre-setting, sizing and after-finishing, so that the final fabric cannot become yellow easily.

Owner:TAICANG CHENGLE CHEM FIBER

High-fixation high-flame retardation polyester fabric dyeing and finishing technology

InactiveCN105113286AProcess temperature changeLow processing temperatureFibre typesUltrasonic/sonic fibre treatmentPolyesterFlame resistance

The invention discloses a high-fixation high-flame retardation polyester fabric dyeing and finishing technology. The technology comprises pre-treatment, pre-setting, modification treatment, dyeing, soaping, dye fixation, after finishing, drying, setting, calendering and rolling. Supersonic wave is used for pre-treatment and a modification treatment process is used. In dyeing, a lot of alkaline substances and inorganic salts are avoided, natural dye is adopted and colophony powder is used as a dye-fixing agent so that dye fixation effects are improved, environmental pollution is avoided and environmental protection requirements are satisfied. Through modification and flame retardation treatment on the fabric by montmorillonite, fabric fire resistance is high. Through the dyeing and finishing technology, the high-fixation high-flame retardation polyester fabric is obtained.

Owner:太仓市宝明化纤有限公司

Polyamide fabric modifying, dyeing and finishing process

InactiveCN105019266AProcess temperature changeLow processing temperatureBiochemical fibre treatmentFibre typesPolyamideDyeing

The invention discloses a polyamide fabric modifying, dyeing and finishing process. The process comprises the steps of pretreatment, pre-setting, modification treatment, dyeing, soaping, color fixing, after treatment, drying, setting, calendering and rolling. Helicase and alpha-amylase are adopted for carrying out pretreatment, mixed liquor of nanometer titanium dioxide, gamma-(2, 3-epoxypropoxy) trimethoxypropylsilane and caprolactam is adopted for modifying performance of polyamide fabric fundamentally, and the dye-uptake rate of the fabric is increased; in the dyeing working procedure, a large number of alkaline substances and inorganic salts are not used, a leveling agent and a dispersing agent are added, and dyeing levelness is improved; meanwhile, as rosin powder is added to serve as a color fixing agent, the color fixing effect is enhanced, environmental pollution is avoided, and the requirement for environmental protection is met; moreover, montmorillonite is adopted for carrying out modifying and flame retarding on the fabric, and therefore the fire retarding property of the fabric is high; anti-yellowing reagents are used in the presetting and setting steps, and therefore the final fabric is not prone to yellowing.

Owner:TAICANG CHENGLE CHEM FIBER

Grey dyeing production method for removing chemical pulp and oligomers

ActiveCN104213441AEasily biodegradableLong-term storage stabilitySucessive textile treatmentsBiochemical fibre treatmentOligomerDesizing

The invention relates to a printing and dyeing method, and especially relates to a grey dyeing production method for removing chemical pulp and oligomers. The method comprises the following steps: selecting a sample cloth, carrying out pretreatment desizing, pre-setting a grey, singeing the grey, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, carrying out alkali amount reduction in a sample jar, designing a dyeing formula, carrying out jar dyeing on the sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The grey dyeing production method for removing chemical pulp and oligomers has the advantages of dyeing stability increase, effective increase of the one-time success rate, reduction of the dyeing repairing rate, and obvious energy saving and emission reduction effects, produced fabrics have good handle resilience, drapability and flexibility, and various quality indexes of the fabrics can meet requirements of clients.

Owner:ZHEJIANG HANGMIN STOCK

Efficient dyeing and finishing process for chemical fiber fabric

InactiveCN104975498AImprove hydrophilicityImprove dye uptakeHeating/cooling textile fabricsDry-cleaning apparatus for textilesInorganic saltsFiber

The invention discloses an efficient dyeing and finishing process for a chemical fiber fabric, which comprises the procedures of modification treatment, one-bath scouring dyeing, soaping, fixation, after finishing, drying, sizing, calendering and rolling. According to the invention, pretreatment is carried out by adopting ultrasonic wave; before the procedure of dyeing, the fabric is subjected to low-temperature plasma treatment, and then 2, 3-glycidyl trimethyl ammonium chloride is adopted for carrying out modification treatment on the fiber fabric, so that the degree of dyeing of the fabric is increased, and the difficulty of subsequent dyeing step is lowered; since one-bath scouring dyeing is adopted, the efficiency is increased, and the cost is lowered; in the dyeing procedure, use of a large quantity of alkaline substances and inorganic salt is avoided, nature dye is adopted, and colophony powder is added as a fixing agent, so that the color fixing effect is enhanced, environmental pollution is avoided, and the requirement of green environmental protection is met; furthermore, montmorillonoid is adopted to carry out flame retardant treatment on the fabric, so that the flame retardancy of the fabric is high. According to the invention, a yellowing-resisting reagent is used in the procedure of sizing, so that the final fabric cannot become yellow easily.

Owner:TAICANG TIANLONG CHEM FIBER

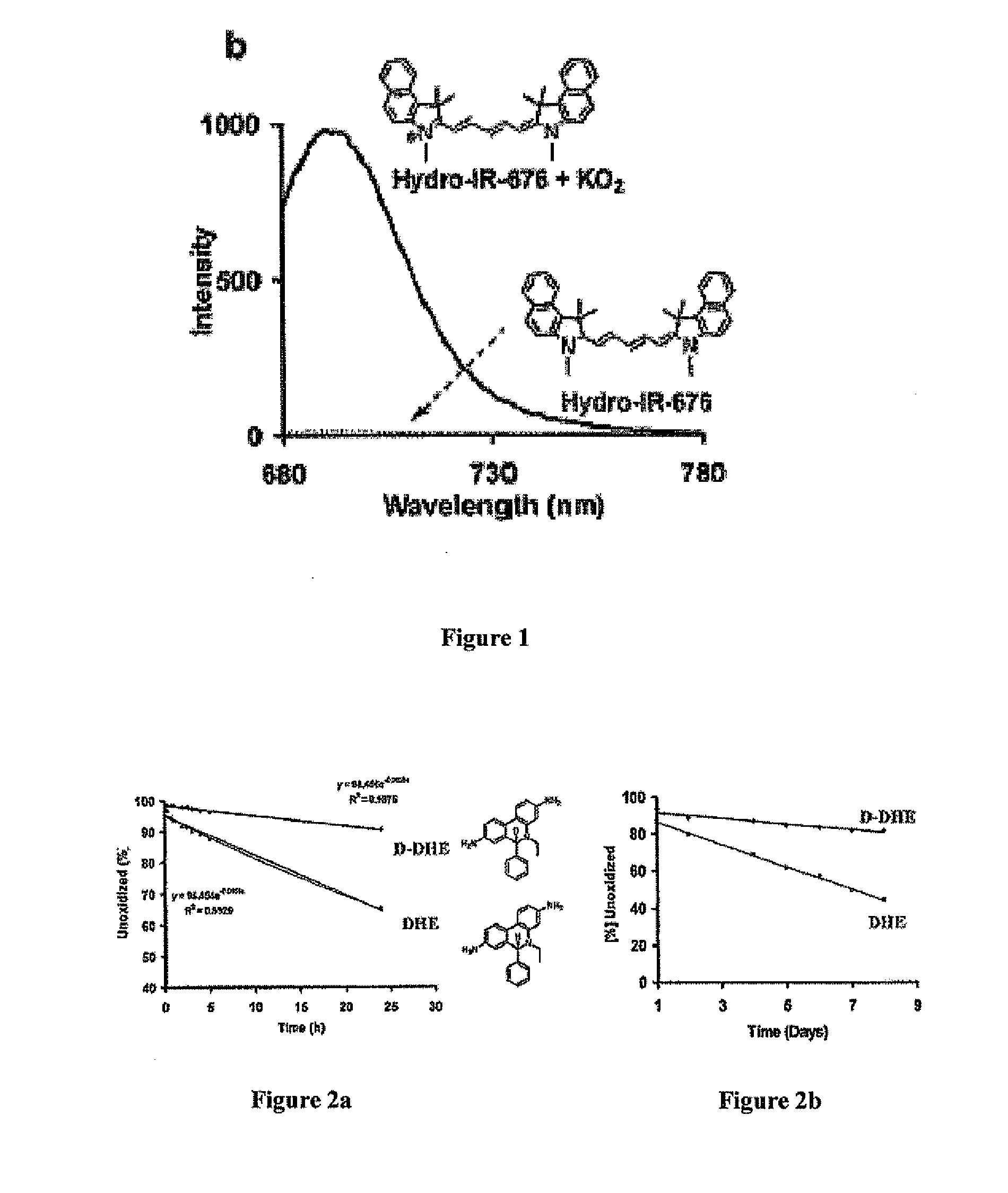

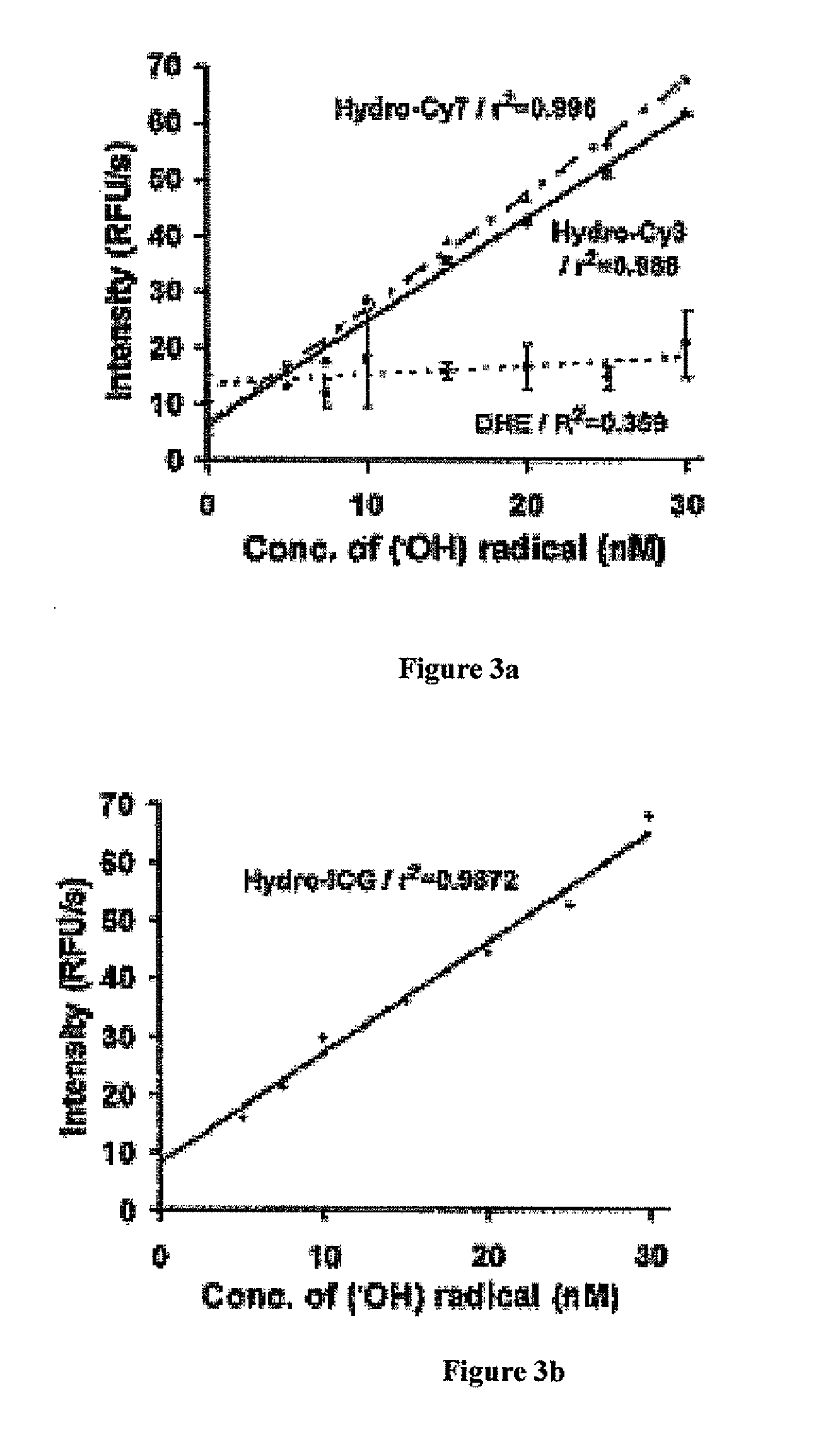

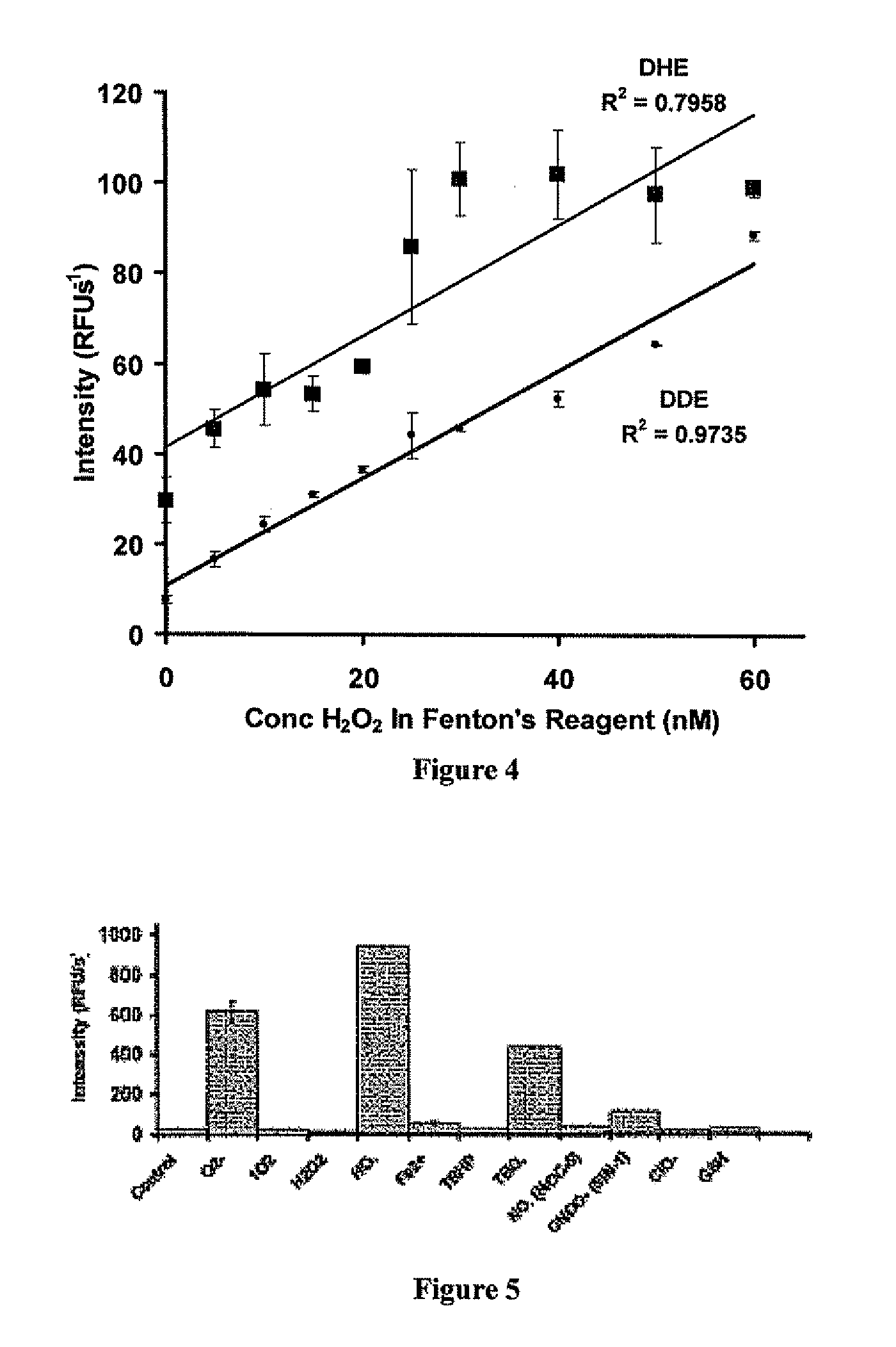

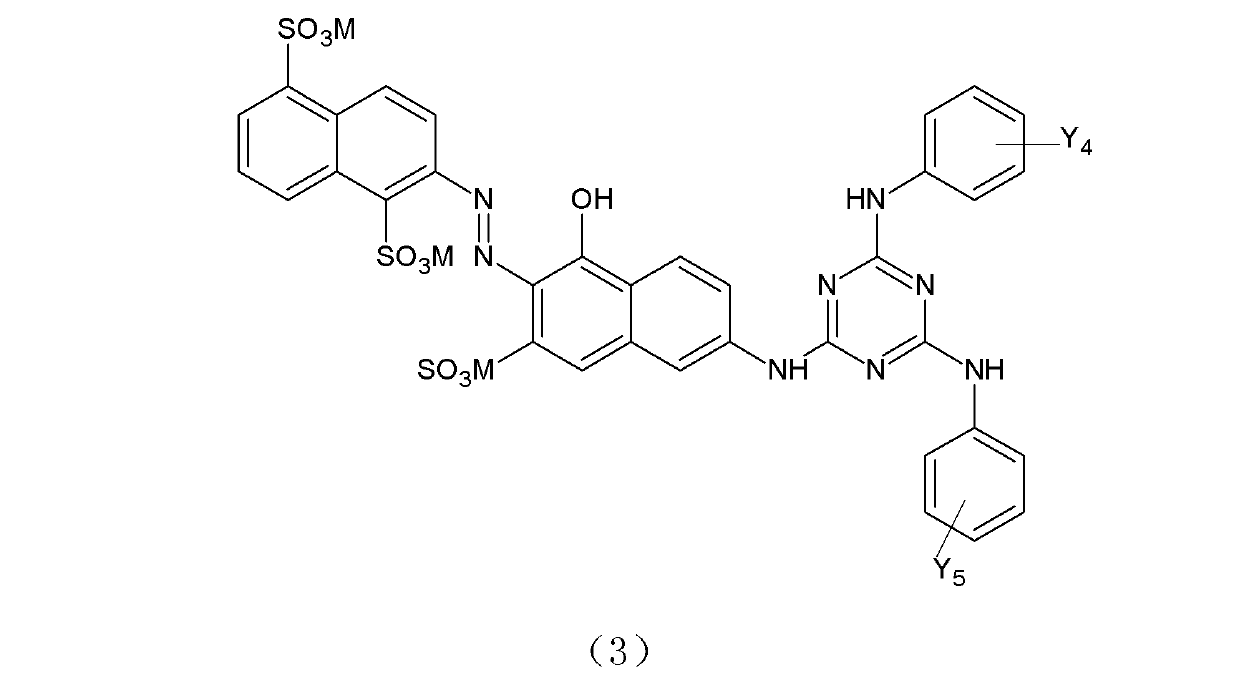

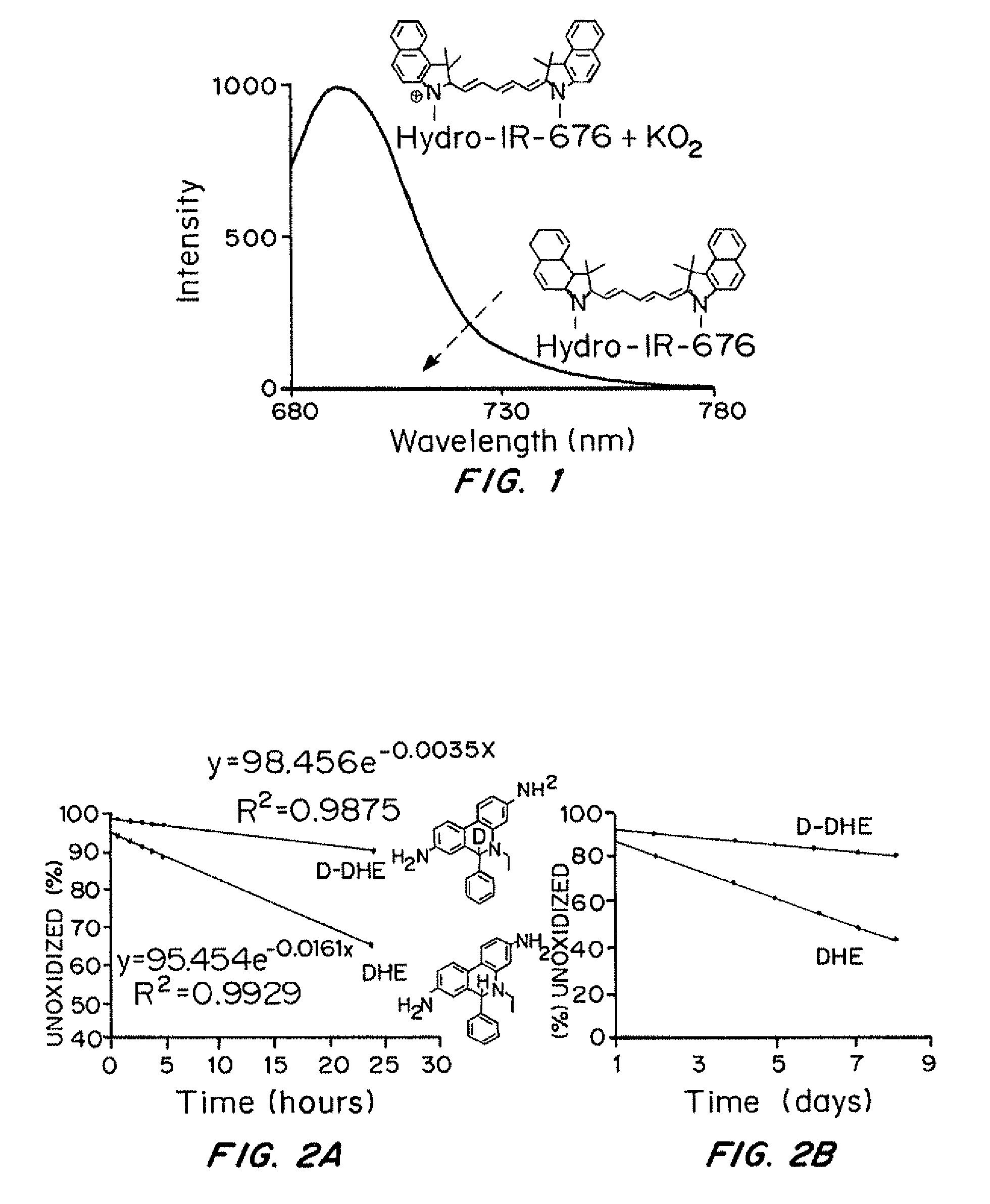

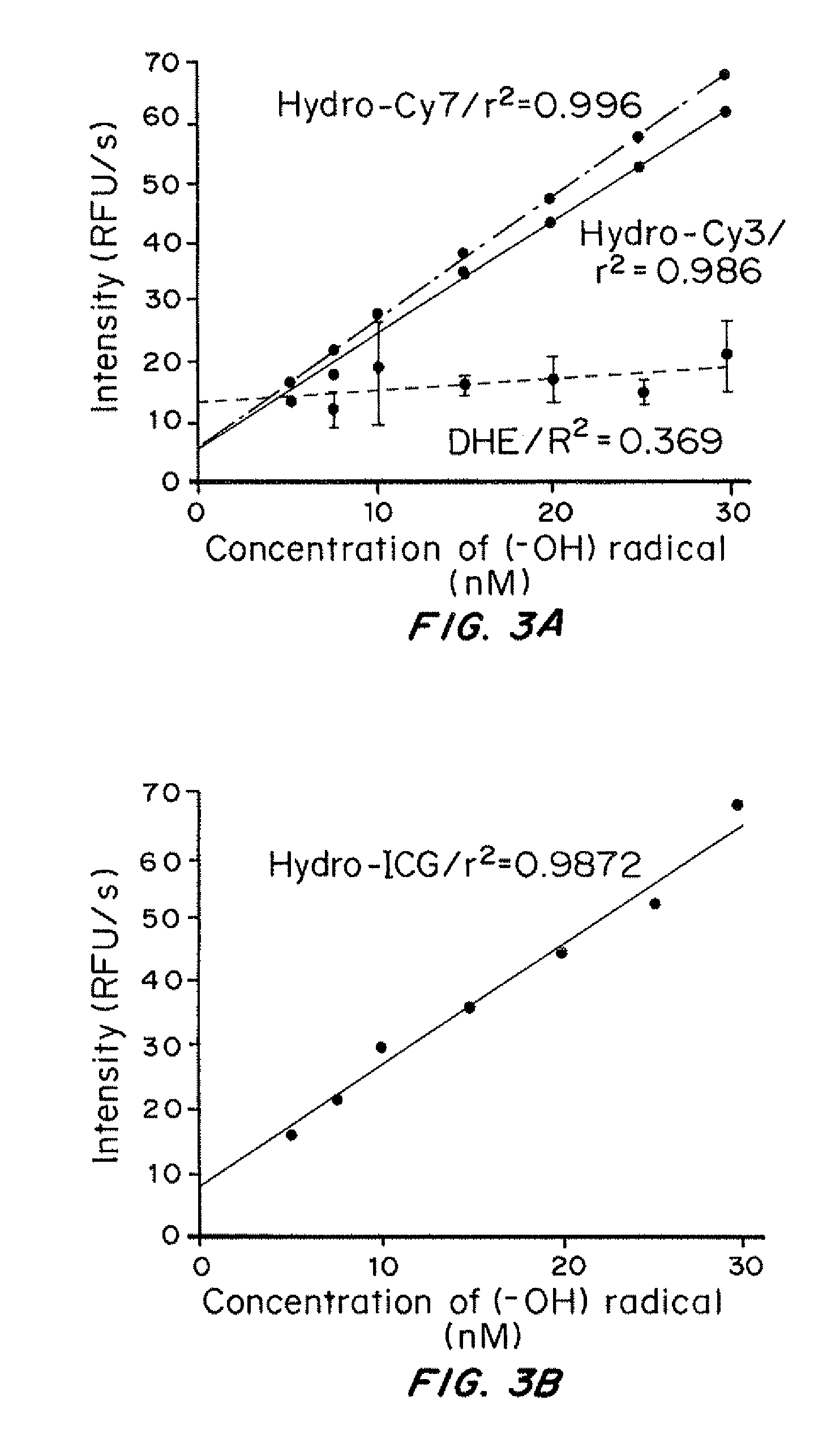

Reduced dye probes for the detection of radical oxygen species

ActiveUS20110070166A1Weak fluorescenceHigh fluorescence quantum yieldUltrasonic/sonic/infrasonic diagnosticsOrganic chemistrySuperoxideOxygen

Reduced dyes, such as hydrocyanines, deuterocyanines, and / or other deuterated dyes capable of detecting one or more reactive oxygen species are described herein. The reduced dyes exhibit little or no fluorescence due to the disrupted π conjugation. However, upon reaction with ROS, the reduced dyes are oxidized, regenerating the extended π conjugation and causing a substantial increase in fluorescence intensity. In many case, the oxidized dye is generally membrane impermeable. However, upon reduction, many of the reduced dyes are membrane permeable. Thus, reduced dyes can accumulate in cells and / or tissue to amplify the signal. Once inside the cell or tissue, the reduced dye is reoxidized upon reaction with ROS, and the oxidized dye again becomes membrane impermeable, trapping the dye within the cell. The reduced dyes can be used to image ROS, such as hydroxide radical and superoxide, in serum, cell cultures, tissue explants, and in vivo.

Owner:EMORY UNIVERSITY +1

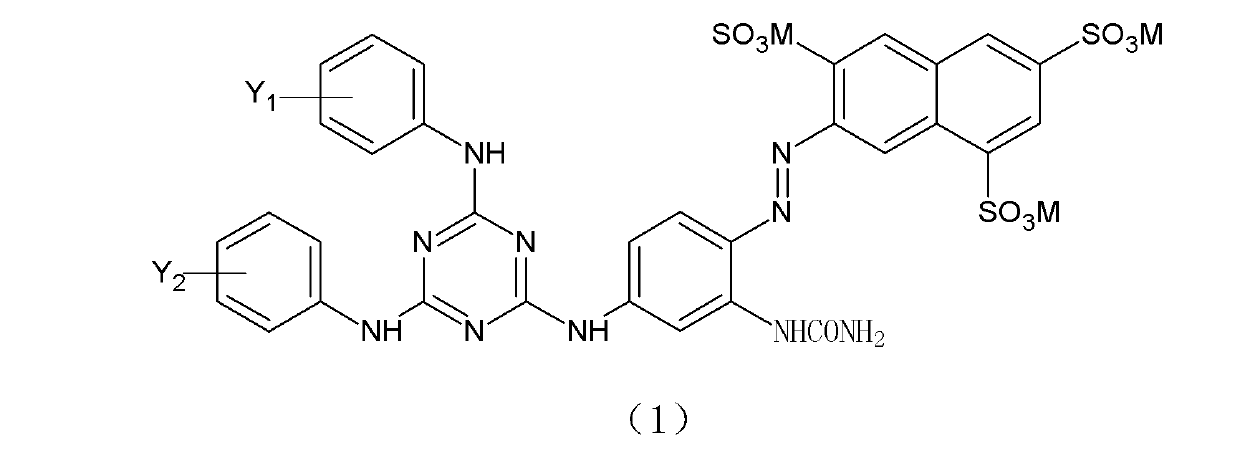

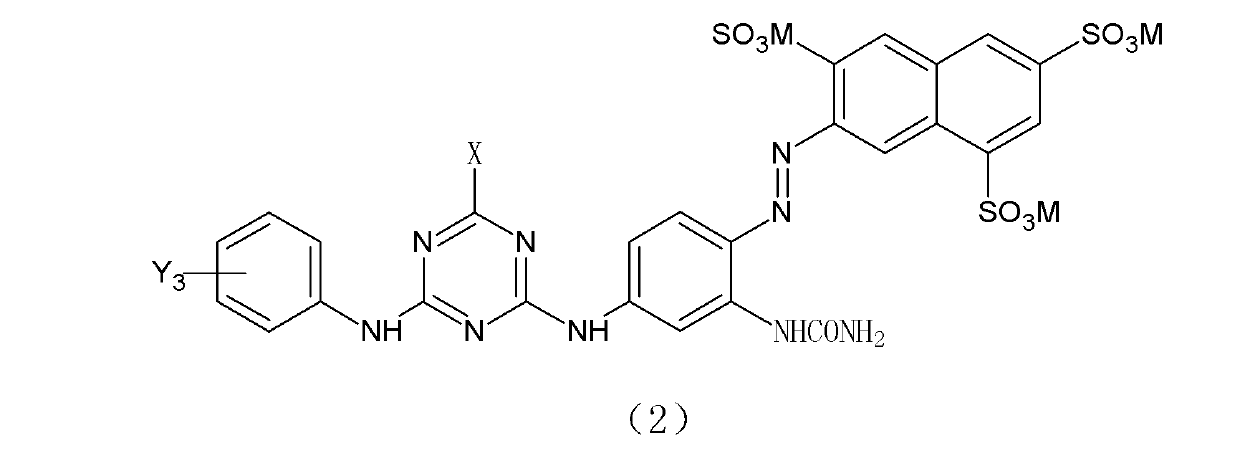

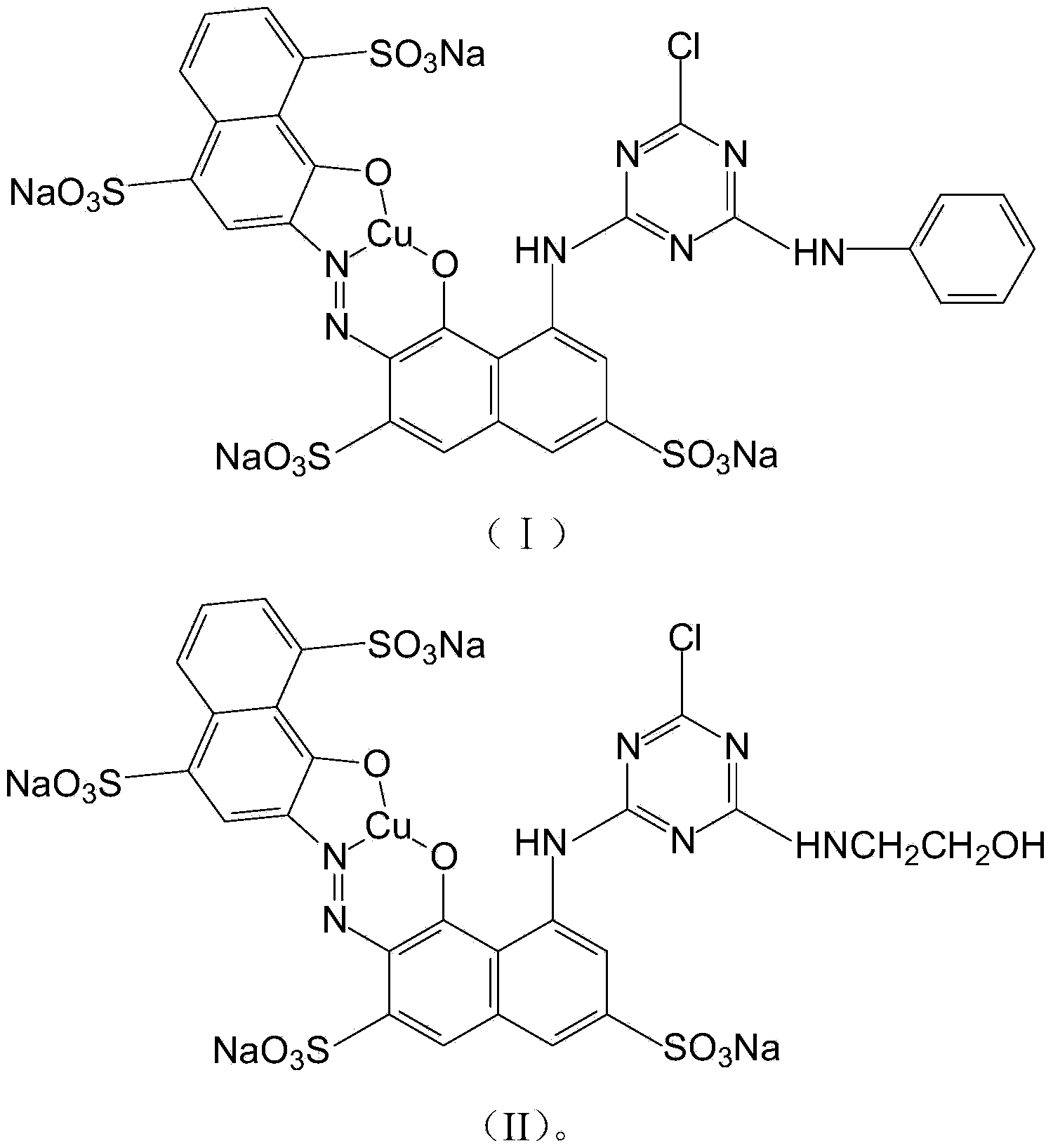

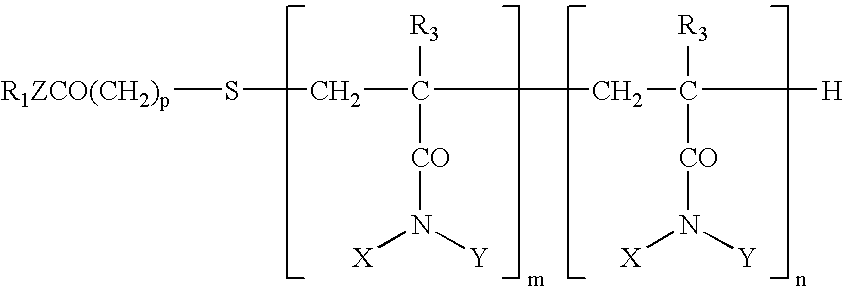

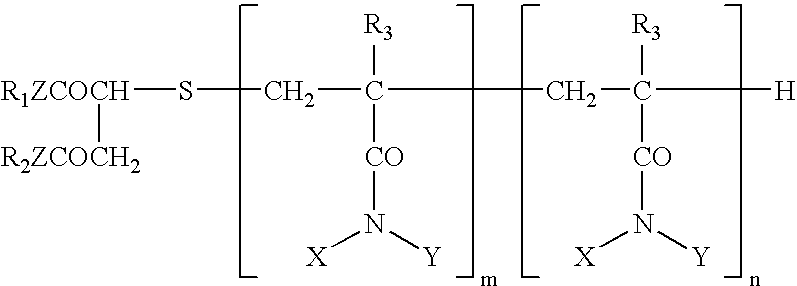

Composite type reactive dye composition and dyeing method by using composition

ActiveCN102850822AGood reproducibilitySame concentrationOrganic dyesDyeing processPhotochemistryReactive dye

The invention relates to a composite type reactive dye composition, which is characterized in that the composition is formed by mixing four kinds of reactive dyes A, B, C and D in percentage by mass: 50 to 100 percent of dye A, 0 to 50 percent of dye B, 0 to 50 percent of dye C, 0 to 50 percent of dye D, and the balance is auxiliaries, and the structure general formulas of the four kinds of reactive dyes A, B, C and D are respectively (1), (2), (3) and (4) shown as the accompanying drawing. The composite type reactive dye composition has better compatibility, the dyeing process is easy to control, and good dyeing stability is realized.

Owner:ZHEJIANG YIDE CHEM

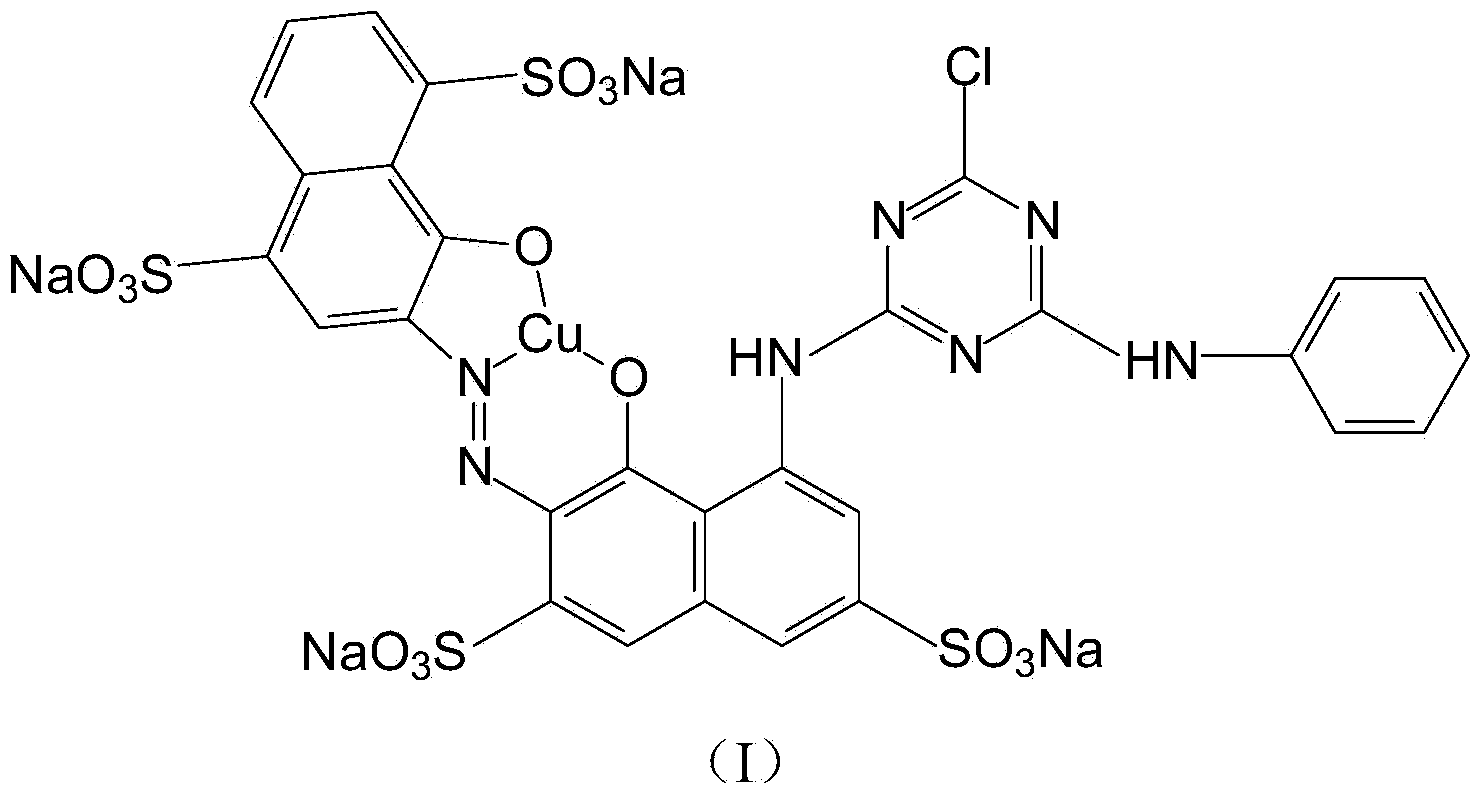

Active deep blue dye composition and high-solubility active deep blue dye, and preparation method and applications of high-solubility active deep blue dye

ActiveCN104164097AImprove light fastnessIncrease lifting powerOrganic dyesDyeing processSolubilityHigh color

The invention discloses an active deep blue dye composition and a high-solubility active deep blue dye, and a preparation method and applications of the high-solubility active deep blue dye. The high-solubility active deep blue dye comprises 10-90 parts by weight of a component A represented by a formula (I), 10-90 parts by weight of a component B represented by a formula (II) and 0-50 parts by weight of an auxiliary agent. The composition as the active deep blue dye has the following advantages of high solarization fastness, high elevating power, high color fixation rate, high solubility, good level-dyeing property and good dyeing stability.

Owner:ZHEJIANG RUIHUA CHEM

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

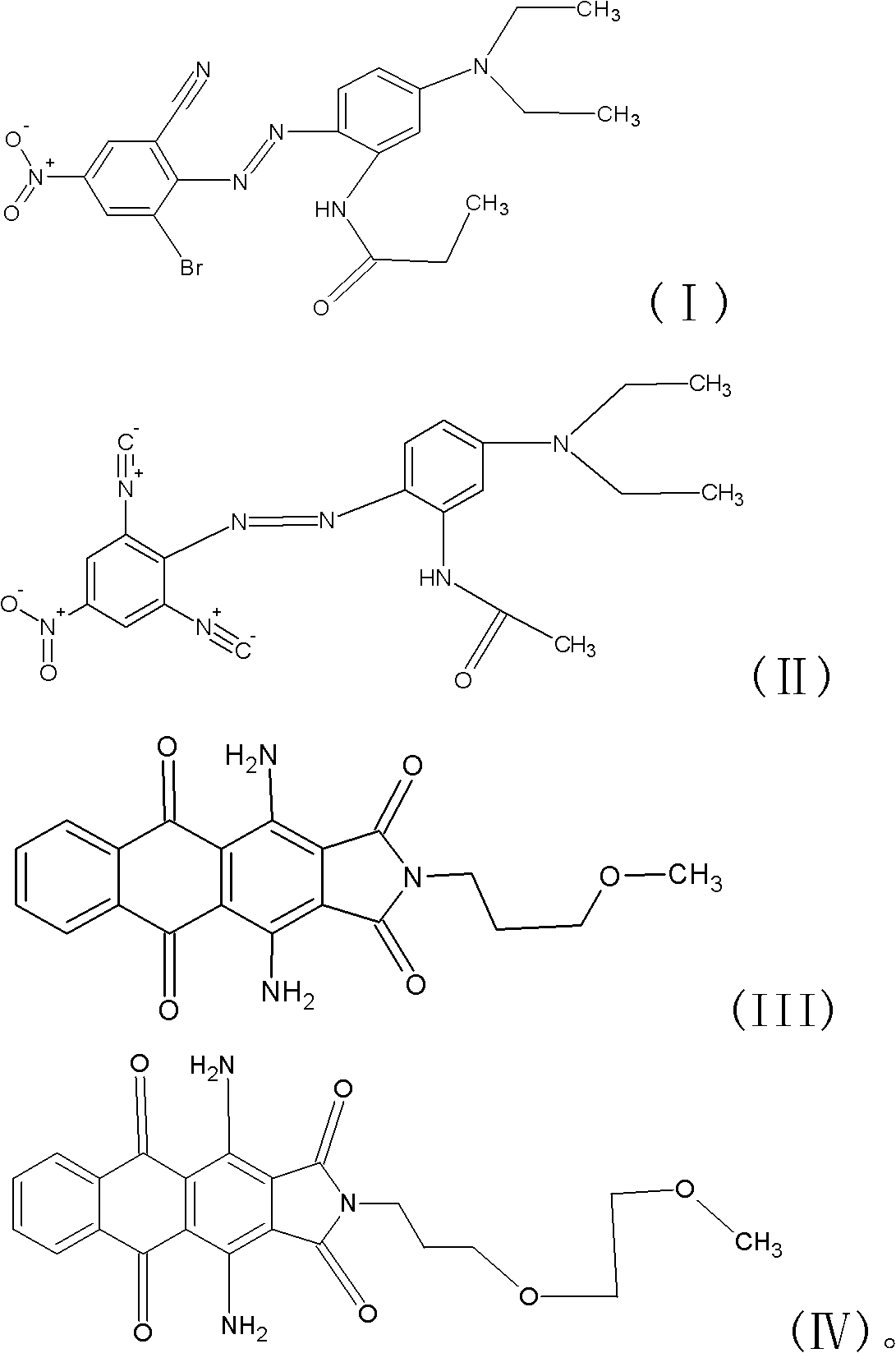

Blue disperse dye

The invention discloses a blue disperse dye. The blue disperse dye mainly comprises the following components: 5-25 parts by weight of dye monomers A as shown in formula (I), 1-5 parts by weight of dye monomers B as shown in formula (II), 1-5 parts by weight of dye monomers C as shown in formula (III), 0.5-5 parts by weight of dye monomers D as shown in formula (IV), and auxiliaries can also be added in the blue disperse dye. The blue disperse dye disclosed by the invention is suitable for dyeing polyester materials, dyeing yarn and printing, and has the advantages of excellent high-temperature pad-dry-cure dyeing performance and excellent fastness performances, such as fastness to sunlight, fastness to sublimation and fastness to washing, and the certain performances are better than those of a commercially available finished product dye C. I. disperse blue 56.

Owner:ZHEJIANG BOAO DYESTUFF IND

Ink recording element containing stabilized polymeric particles

InactiveUS6866902B2Quality improvementImprove image qualityDecorative surface effectsElectrography/magnetographyRecord elementPolymer chemistry

An ink recording element is described comprising a support having thereon at least one image-receiving layer comprising polymeric particles in a polymeric binder, wherein the polymeric particle is stabilized by a hydrophobically-capped oligomeric acrylamide dispersant.

Owner:EASTMAN KODAK CO

Chemical fiber dyeing technology with ultraviolet protection function

InactiveCN104695240AReduce pollutionAvoid damageFibre treatmentHeating/cooling textile fabricsFiberAnti bacteria

The invention provides a chemical fiber dyeing technology with the ultraviolet protection function. The chemical fiber dyeing technology comprises pretreatment, pre-shaping, dyeing, washing, soaping, color fixing, softening treatment, drying, shaping and rolling. The natural dyestuff of sophora flower bud is adopted, aluminum potassium sulfate dodecahydrate is used as a mordant, the dyeing effect is better, and the washability is greatly enhanced; meanwhile, due to the performance of the sophora flower bud, dyed chemical fiber has the good ultraviolet protection performance and the antibacterial and oxidation resistance; the washing technology and the color fixing technology are added, the dyeing firmness is good, green and environment-friendly and aldehyde-free TCD-R is adopted in the color fixing technology, and the chemical fiber obtained after color fixing is dried step by step, so that the firmness of the chemical fiber is greatly improved; the softening treatment technology is added, the fabric color firmness and flexibility are improved, the fabric roughness is lightened, and the fabric is fluffy and full of elasticity.

Owner:TAICANG TIANLONG CHEM FIBER

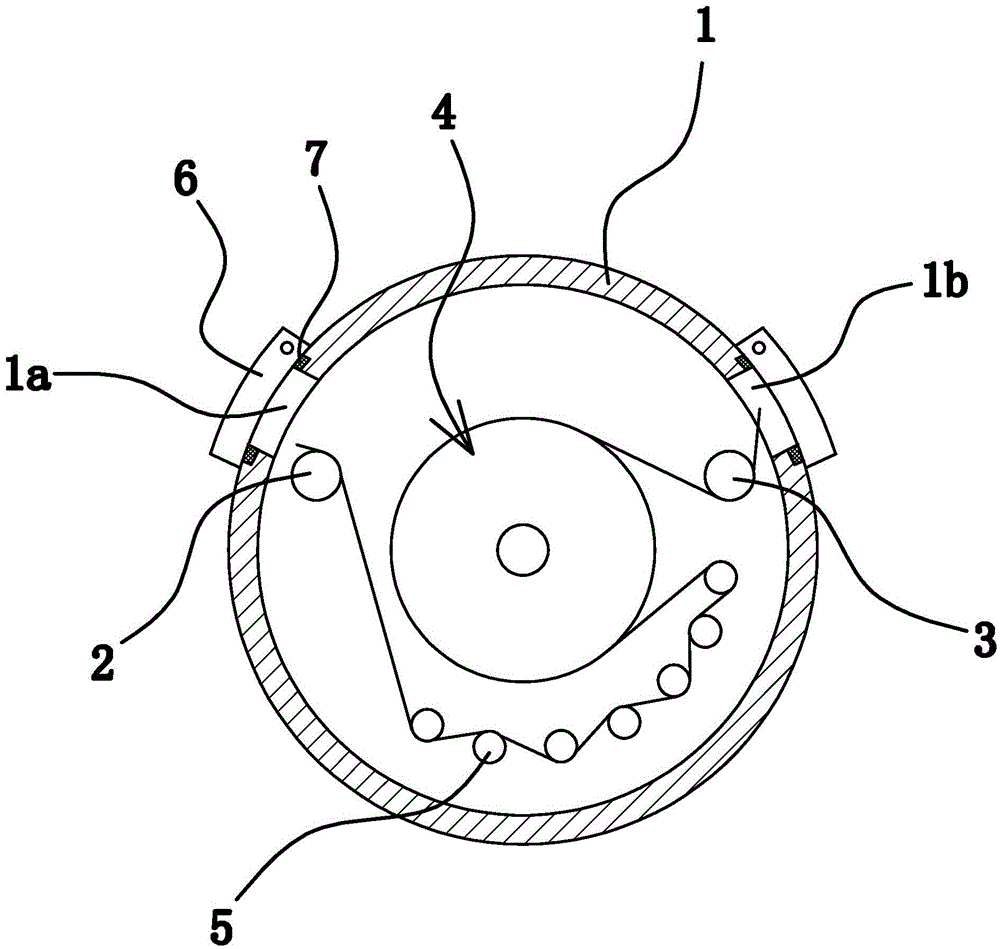

Fabric dyeing process and dye jar for same

InactiveCN104928904AStable washingImprove cleanlinessSucessive textile treatmentsTextile treatment containersBiochemical engineeringHeat setting

The invention provides a fabric dyeing process and a dye jar for the same, and belongs to the technical field of printing and dyeing. The problem of low quality of conventional printing and dyeing is solved. The fabric dyeing process comprises the following steps of A, preparation of washing liquor; B, cloth washing; C, dyeing; D, dehydration and heat setting. The dye jar comprises a jar body with an internal cavity, and is characterized by further comprising a feeding roller, a discharging roller, a cloth roller and a plurality of cloth guide rollers, which are axially and fixedly connected in the jar body, wherein the jar body is cylindrical, and the axis of the jar body is parallel to the ground; an inlet and an outlet are formed in the two sides of the upper part of the jar body respectively, and are communicated with the internal cavity; cover plates capable of exposing and sealing the inlet and the outlet are arranged at the inlet and the outlet; the feeding roller is close to the inlet; the discharging roller is close to the outlet; the cloth roller is positioned between the feeding roller and the discharging roller. The process is convenient and high in dyeing quality.

Owner:浙江佳力织染制衣有限公司

Reduced dye probes for the detection of radical oxygen species

ActiveUS8628753B2Weak fluorescenceHigh fluorescence quantum yieldUltrasonic/sonic/infrasonic diagnosticsMethine/polymethine dyesSuperoxideOxygen

Reduced dyes, such as hydrocyanines, deuterocyanines, and / or other deuterated dyes capable of detecting one or more reactive oxygen species are described herein. The reduced dyes exhibit little or no fluorescence due to the disrupted π conjugation. However, upon reaction with ROS, the reduced dyes are oxidized, regenerating the extended π conjugation and causing a substantial increase in fluorescence intensity. In many case, the oxidized dye is generally membrane impermeable. However, upon reduction, many of the reduced dyes are membrane permeable. Thus, reduced dyes can accumulate in cells and / or tissue to amplify the signal. Once inside the cell or tissue, the reduced dye is reoxidized upon reaction with ROS, and the oxidized dye again becomes membrane impermeable, trapping the dye within the cell. The reduced dyes can be used to image ROS, such as hydroxide radical and superoxide, in serum, cell cultures, tissue explants, and in vivo.

Owner:EMORY UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com