Shaping device for non-woven fabric dyeing production line and dyeing process of device

A sizing device and non-woven fabric technology, applied in the processing of textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve the problems of uneven heating of non-woven fabrics, affecting the quality of finished products, and poor drying effect. Achieve the effect of improving the effect of smoothing and setting, improving the setting effect and improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

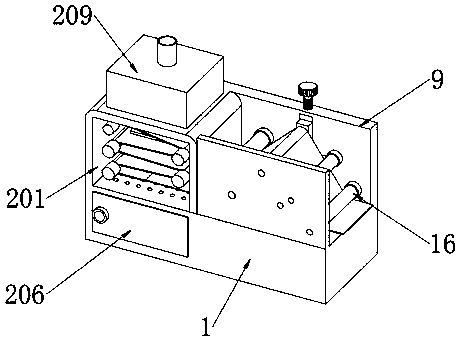

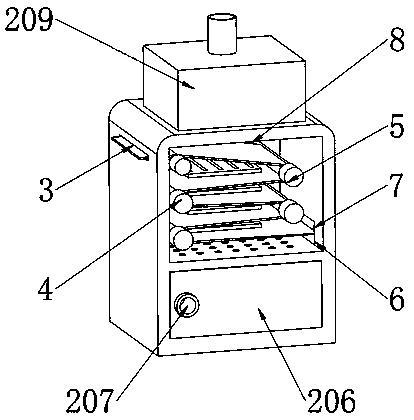

[0046] Embodiment 1: as Figure 1-6 As shown, the present invention provides a technical solution, a sizing device for a non-woven fabric dyeing production line, including a base 1, and a drying and sizing component 2 is installed on one side of the base 1;

[0047] The drying and setting assembly 2 comprises a drying chamber 201, a heating plate 202, a groove 203, a transparent plexiglass plate 204, an air inlet filter plate 205, an air inlet storage chamber 206, an air inlet pipe 207, an air outlet filter plate 208, a collection box 209 and Outlet pipe 210;

[0048]A drying chamber 201 is installed on the top side of the base 1, and a heating plate 202 is evenly installed inside the drying chamber 201. The input end of the heating plate 202 is connected to the output end of the mains by electric wires, and grooves are uniformly opened on one side of the heating plate 202 203, a transparent plexiglass plate 204 is embedded and installed on one side of the drying chamber 201,...

Embodiment 2

[0054] Embodiment 2: as Figure 7 Shown, a kind of dyeing process of non-woven fabric dyeing production line, comprises the steps:

[0055] S1, pretreatment: separate and spray water on the cloth to be dyed;

[0056] S2, dyeing: immerse the treated cloth to be dyed in the dyeing vat for dyeing;

[0057] S3, cleaning: cleaning the dyed non-woven fabric;

[0058] S4, dewatering: dewatering the cleaned non-woven fabric;

[0059] S5, shaping: the non-woven fabric after the water is shaped through the shaping device;

[0060] S6. Rolling: Rolling and storing the shaped non-woven fabric.

[0061] According to the above technical scheme, in step S1, the cloth to be dyed is separated and sprayed with water. Separation refers to the separation and transmission of multi-layered cloth to be dyed by multiple rollers, and water spray refers to the separation of the separated multi-layered cloth to be dyed. Spray water to soften, and take out the burrs on the surface of the multi-layer...

Embodiment 3

[0064] Embodiment 3: as Figure 7 Shown, a kind of dyeing process of non-woven fabric dyeing production line, comprises the steps:

[0065] S1, pretreatment: separate and spray water on the cloth to be dyed;

[0066] S2, dyeing: immerse the treated cloth to be dyed in the dyeing vat for dyeing;

[0067] S3, cleaning: cleaning the dyed non-woven fabric;

[0068] S4, dewatering: dewatering the cleaned non-woven fabric;

[0069] S5, shaping: the non-woven fabric after the water is shaped through the shaping device;

[0070] S6. Rolling: Rolling and storing the shaped non-woven fabric.

[0071] According to the above technical scheme, in step S1, the cloth to be dyed is separated and sprayed with water. Separation refers to the separation and transmission of multi-layered cloth to be dyed by multiple rollers, and water spray refers to the separation of the separated multi-layered cloth to be dyed. Spray water to soften, and take out the burrs on the surface of the multi-layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com