Cloth printing and dyeing device

A technology for fabrics and fabrics, applied in the field of fabric printing and dyeing devices, can solve problems such as unevenness and inability to recover heat, and achieve the effects of even dyeing, saving dye liquor and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

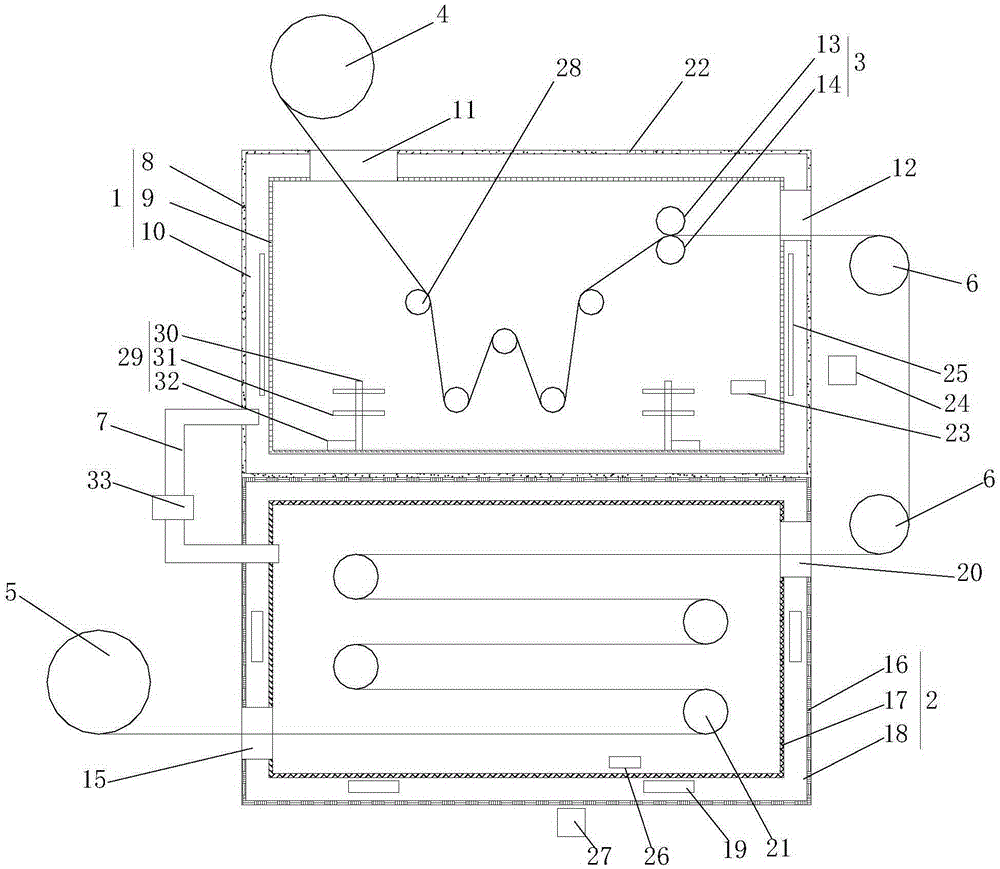

[0025] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a cloth printing and dyeing device proposed by the present invention.

[0026] refer to figure 1 , a cloth printing and dyeing device proposed by the present invention is used for dyeing cloth, comprising a first box 1, a second box 2, a cloth rolling roller group 3, a first cloth rolling roller 4, and a second cloth rolling roller 5 , transition roller 6 and connecting pipe 7, the first casing 1 is a dyeing casing, and the second casing 2 is a drying casing;

[0027] The first box body 1 is arranged above the second box body 2, and the body wall of the first box body 1 includes a first outer shell 8, a first inner shell 9, and a first outer shell 8 and a first inner shell 9 between the first outer shell 8 and the first inner shell 9. Heating cavity 10, the top wall of the first box body 1 is provided with a first cloth inlet 11, and its side wall is provided with a first cloth outlet 12, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com