Method for preparing polyimide fiber

A polyimide fiber and polyimide technology, applied in the field of polyimide fiber preparation, can solve problems such as unfavorable operation and inaccurate temperature control, achieve a high limit oxygen index, overcome inaccurate temperature control, The effect of UV radiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

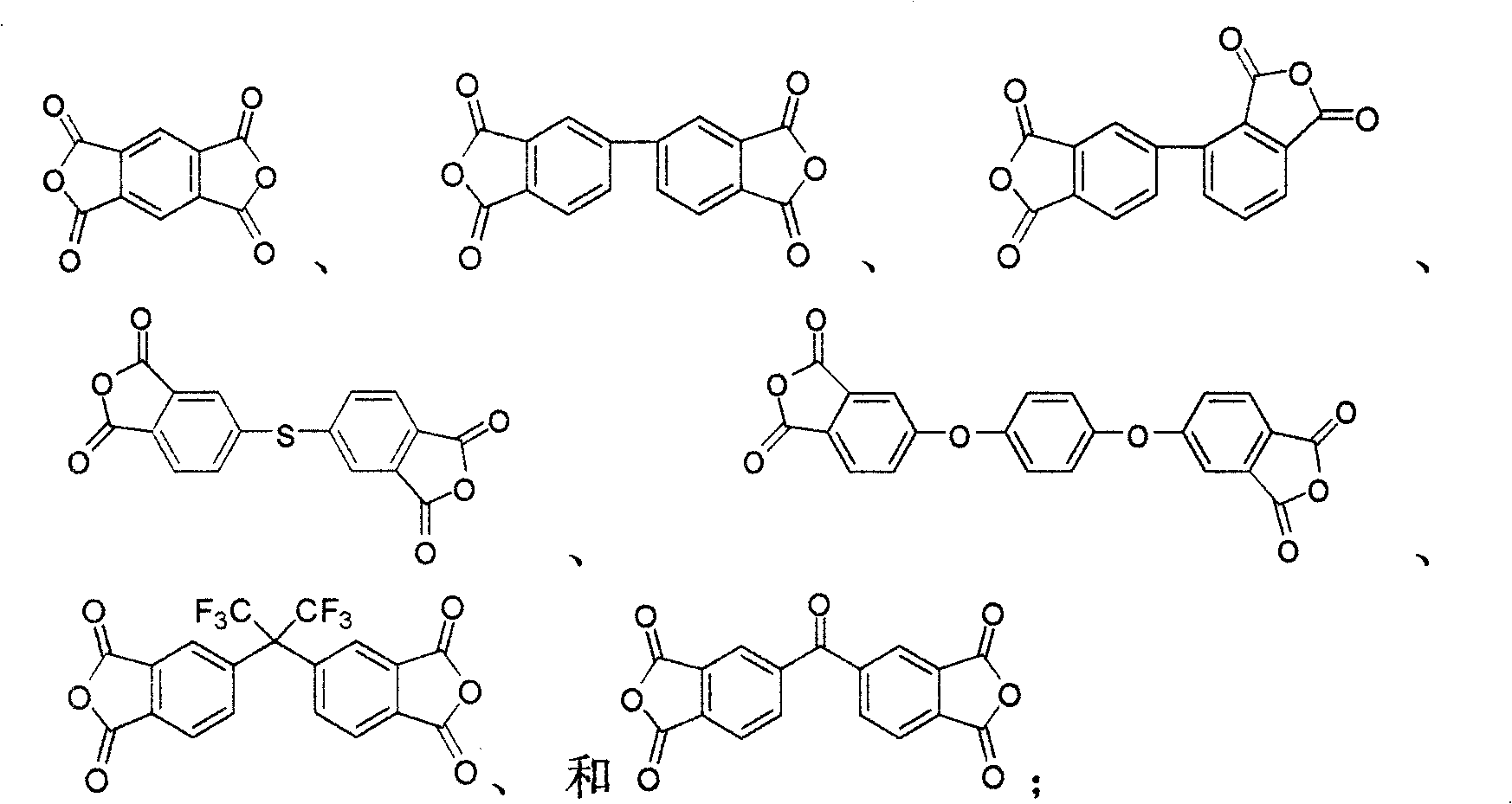

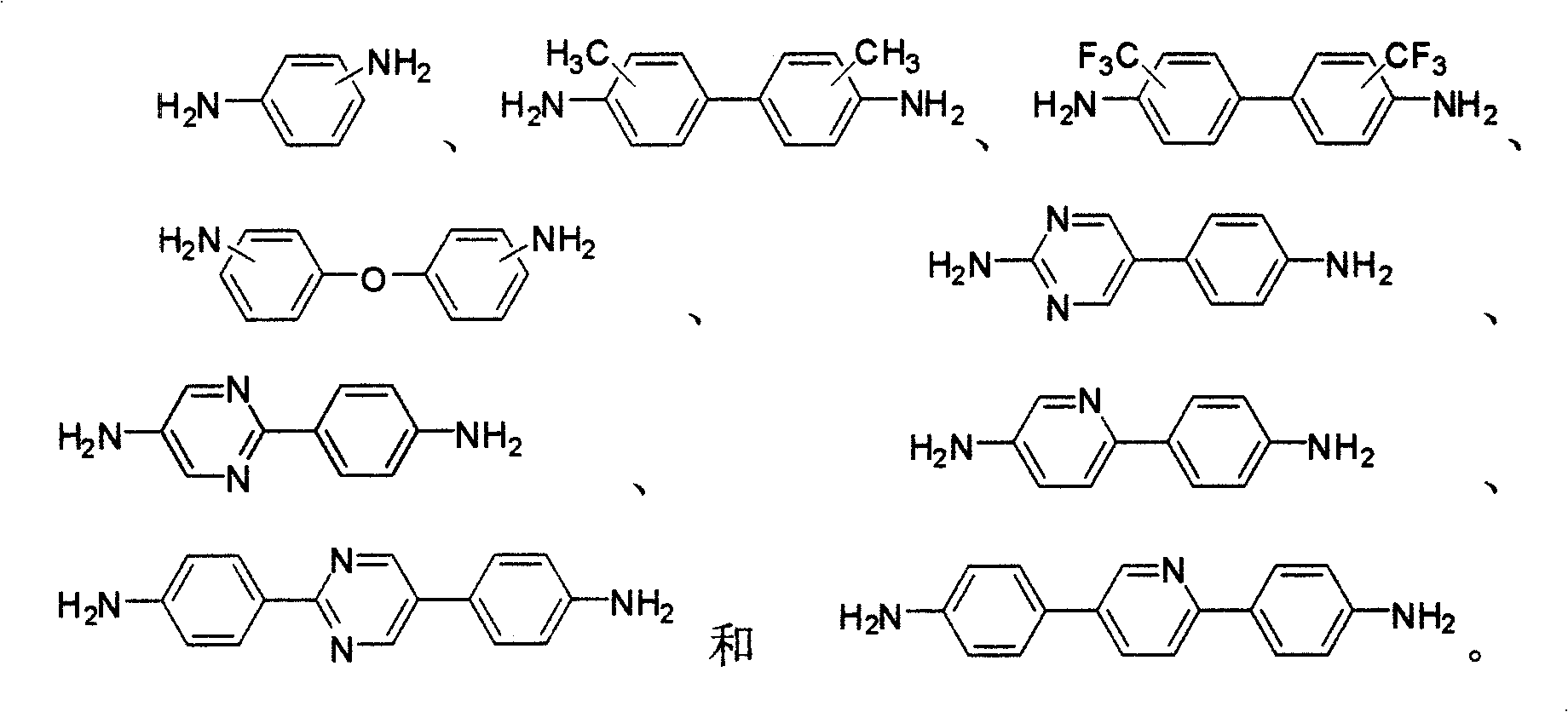

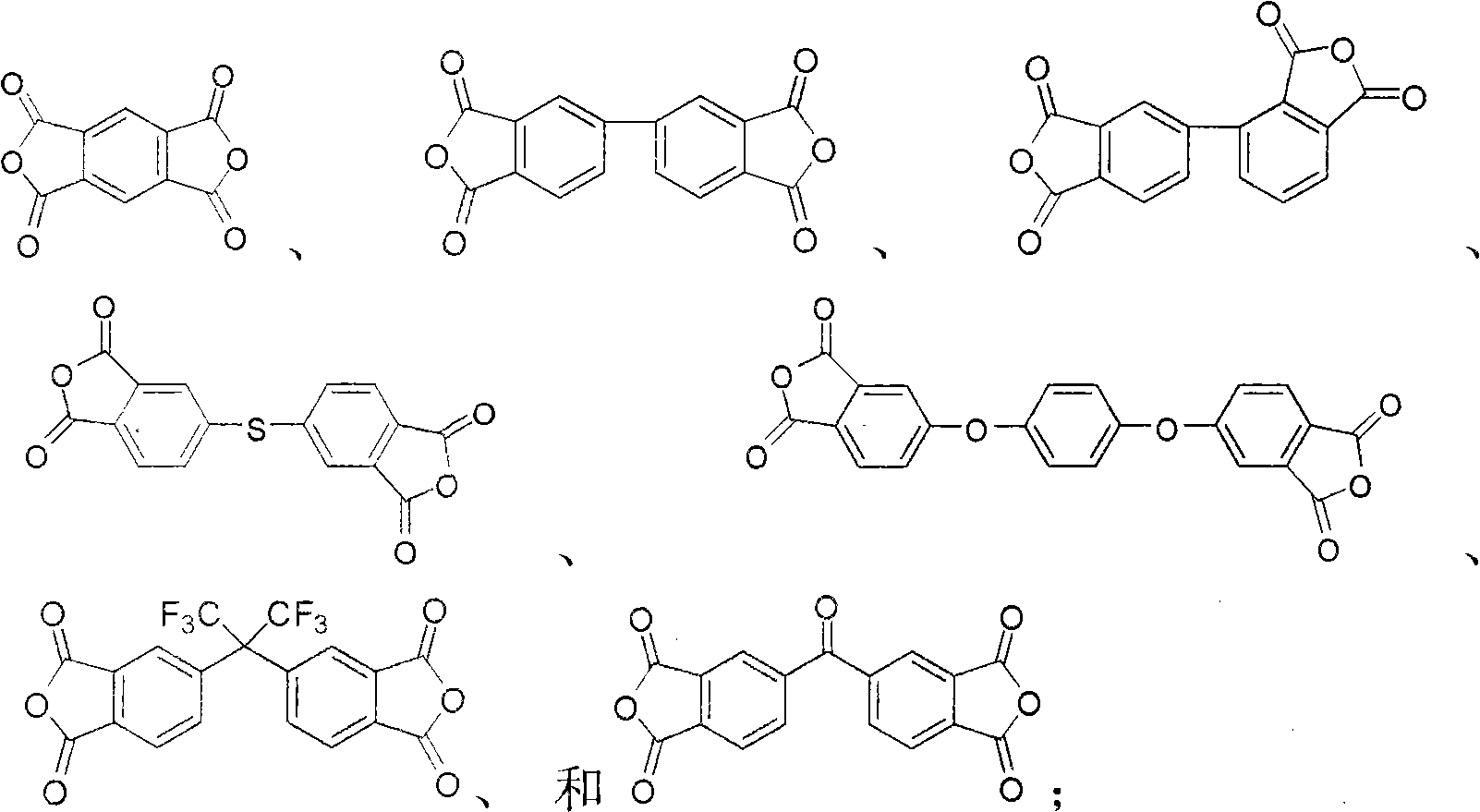

Method used

Image

Examples

Embodiment 1

[0018] Example 1: 35.14 g (0.325mol) p-phenylenediamine and 352.32g (1.100mol) 2,2'-bis(trifluoromethyl)4,4'-biphenylenediamine were dissolved in 4470ml N,N- In the dimethylacetamide, 327.18 g (1.500 mol) pyromellitic dianhydride was added under stirring state, and reacted at room temperature for 10 hours to obtain a pale yellow viscous polyamic acid spinning solution. The solution is directly used as spinning slurry after filtration.

[0019] The above-mentioned polyamic acid slurry is spun and formed by the dry-jet wet spinning method, and the spinning slurry at room temperature is accurately metered by a metering pump, and then extruded from the spinneret and enters the N,N-dimethyl In a coagulation bath of acetamide and water (1:1 volume ratio). The spinneret has 100 holes, the hole diameter is Φ0.08mm, the spray ratio is 3.0 times, the spinneret speed is 60m / min, and the air layer height is 30mm. The nascent polyamic acid fiber is treated in a gradient temperature-raisi...

Embodiment 2

[0020] Example 2: Dissolve 300.36g (1.500mol) of 4,4'-diaminodiphenyl ether in 3707ml of N,N-dimethylformamide, and add 218.12g (1.000mol) of pyromellitic dianhydride under stirring React with 147.11 g (0.500 mol) of 3,4'-biphenyldianhydride at -5°C for 10 hours to obtain a light yellow viscous polyamic acid spinning solution. The solution is directly used as spinning slurry after filtration.

[0021] The above-mentioned polyamic acid slurry is spun and formed by a dry-wet method, and the spinning slurry at room temperature is accurately metered with a metering pump, extruded from the spinneret, and then enters ethanol and water (1:2 volume ratio) through the air layer. ) in the coagulation bath. The spinneret has 150 holes, the hole diameter is Φ0.10mm, the spinning speed is 100m / min, the spray ratio is 7.0 times, and the air layer height is 50mm. The nascent polyamic acid fiber is treated in a gradient temperature-raising heat treatment furnace under a nitrogen atmosphere ...

Embodiment 3

[0022] Example 3: 315.38g (1.575mol) of 3,4'-diaminodiphenyl ether was dissolved in 1264ml of N-methylpyrrolidone, and 218.12g (1.000mol) of pyromellitic dianhydride and 147.11g of pyromellitic dianhydride were added under stirring (0.500mol) 3,4'-biphenyldianhydride, reacted at -10°C for 10 hours to obtain a light yellow viscous polyamic acid spinning solution. The solution is directly used as spinning slurry after filtration.

[0023] The above-mentioned polyamic acid slurry is spun and formed by dry-jet wet spinning method, and the spinning slurry at room temperature is accurately metered by a metering pump, extruded from the spinneret, and then enters N-methylpyrrolidone and ethanol through the air layer. and water (1:1:6 volume ratio) coagulation bath. The spinneret has 30 holes, the hole diameter is Φ0.20mm, the spray ratio is 1 times, the spinneret speed is 30m / min, and the air layer height is 70mm. The nascent polyamic acid fiber is treated in a gradient temperature-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com