Environment-friendly anti-flaming fabric compound for motor vehicle interior and preparation method thereof

A technology for flame-retardant fabrics and motor vehicles, which is applied in the field of flame-retardant materials, can solve the problems such as the difficult limit oxygen index of polyurethane soft foam sponges, and achieve the effect of wide application and improvement of flame-retardant performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

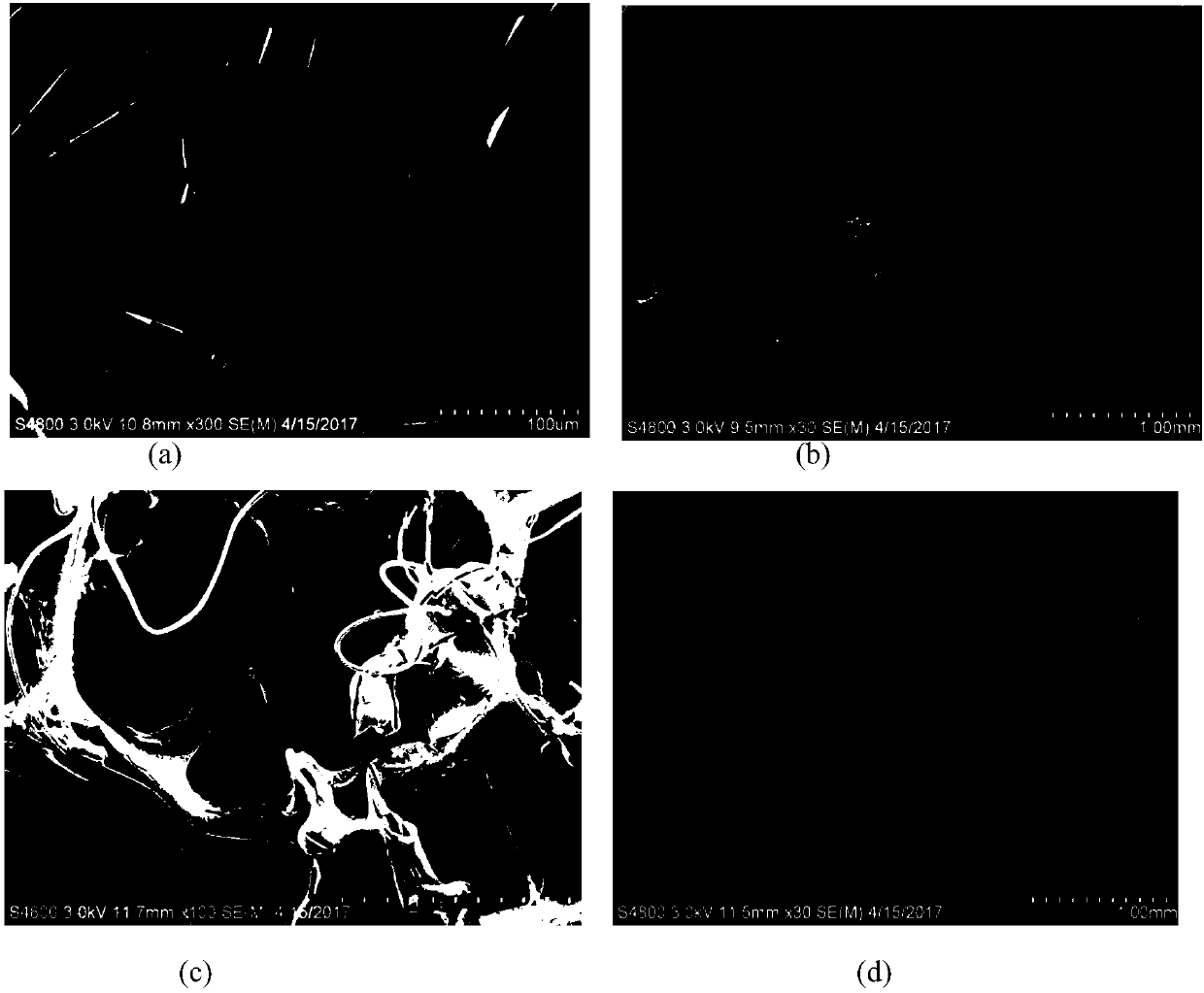

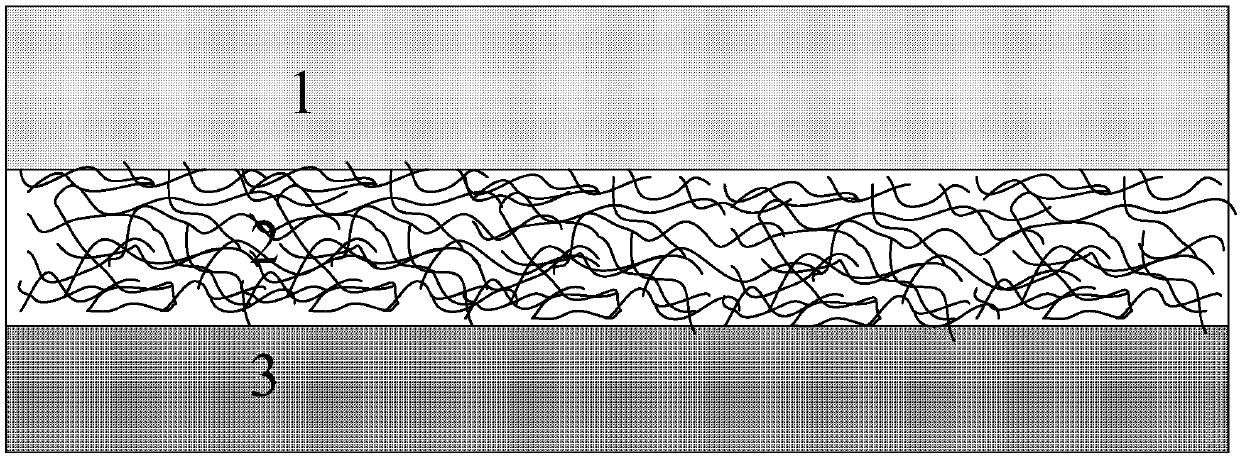

Embodiment 1

[0052] With 50 kilograms of fineness at 3 denier macromolecule main chain phosphorus-containing essential flame-retardant polyester copolyester staple fiber (permanent flame-retardant staple fiber product of Hangzhou Xiangjun Flame Retardant Technology Co., Ltd., phosphorus content is 0.65wt% , the limiting oxygen index is 31.9%) and 50 kg of PET staple fibers with a fineness of 3 deniers (the conventional polyester staple fiber products of Yizheng Chemical Fiber) are opened, carded, and laid into a fiber web, and then the fiber web is reinforced by a needle. Cloth, manufactured by needle-punching process, and pressed to produce a flame-retardant non-woven fabric with a thickness of 4.0 mm, an area density of 230 g / m2, and a bulk density of 57.5 kg / m3. The lining is The phosphorus content of the flame-retardant non-woven fabric is 0.325wt%, and the limiting oxygen index of the flame-retardant non-woven fabric, that is, the flame-retardant lining 2, is 26.7%;

[0053] 50 kg of ...

Embodiment 2

[0057] With 70 kilograms of fineness at 2 denier macromolecule backbone phosphorus-containing essential flame-retardant polyester copolyester staple fiber (permanent flame-retardant staple fiber product of Hangzhou Xiangjun Flame Retardant Technology Co., Ltd., phosphorus content is 0.70wt% , the limiting oxygen index is 32.9%) and 30 kg of PET fiber staple fibers with a fineness of 4 deniers (Yizheng Chemical Fiber’s conventional polyester staple fiber products) are opened, carded, and laid into a fiber web, and then the fiber web is reinforced by a needle Finished cloth, manufactured by needle-punching process, and pressed to produce a flame-retardant non-woven fabric with a thickness of 3.3 mm, an area density of 250 g / m2, and a bulk density of 72.0 kg / m3. The phosphorus content of the cloth is 0.49wt%, and the limiting oxygen index of the flame-retardant non-woven fabric, that is, the flame-retardant lining 2, is 29.1%;

[0058] 50 kg of flame-retardant lining 2 is placed ...

Embodiment 3

[0062]With 70 kilograms of fineness at 5 denier macromolecule main chain phosphorus-containing essential flame-retardant polyester copolyester staple fiber (permanent flame-retardant staple fiber product of Hangzhou Xiangjun Flame Retardant Technology Co., Ltd., phosphorus content is 0.68wt% , the limiting oxygen index is 32.5%) and 30 kg of PET fiber staple fibers with a fineness of 4 deniers (Yizheng Chemical Fiber’s conventional polyester staple fiber products) are opened, carded, laid into a fiber web, and then the fiber web is reinforced by a needle Finished cloth, manufactured by needle-punching process, and pressed to produce a flame-retardant non-woven fabric with a thickness of 3.3 mm, an area density of 250 g / m2, and a bulk density of 72.0 kg / m3. The phosphorus content of the cloth is 0.476wt%, and the limiting oxygen index of the flame-retardant non-woven fabric, that is, the flame-retardant lining 2, is 29.2%;

[0063] 50 kg of flame-retardant lining 2 is placed on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com