Halogen-free flame-retardant antistatic TPU (thermoplastic polyurethane) material and preparation method thereof

A flame retardant antistatic and antistatic agent technology, which is applied in the field of halogen-free flame retardant and antistatic materials and polyurethane materials, can solve the problems affecting the life safety of the parties involved, a large amount of toxic and harmful gases, and low char formation rate, etc., so as to facilitate industrial production , excellent mechanical properties, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

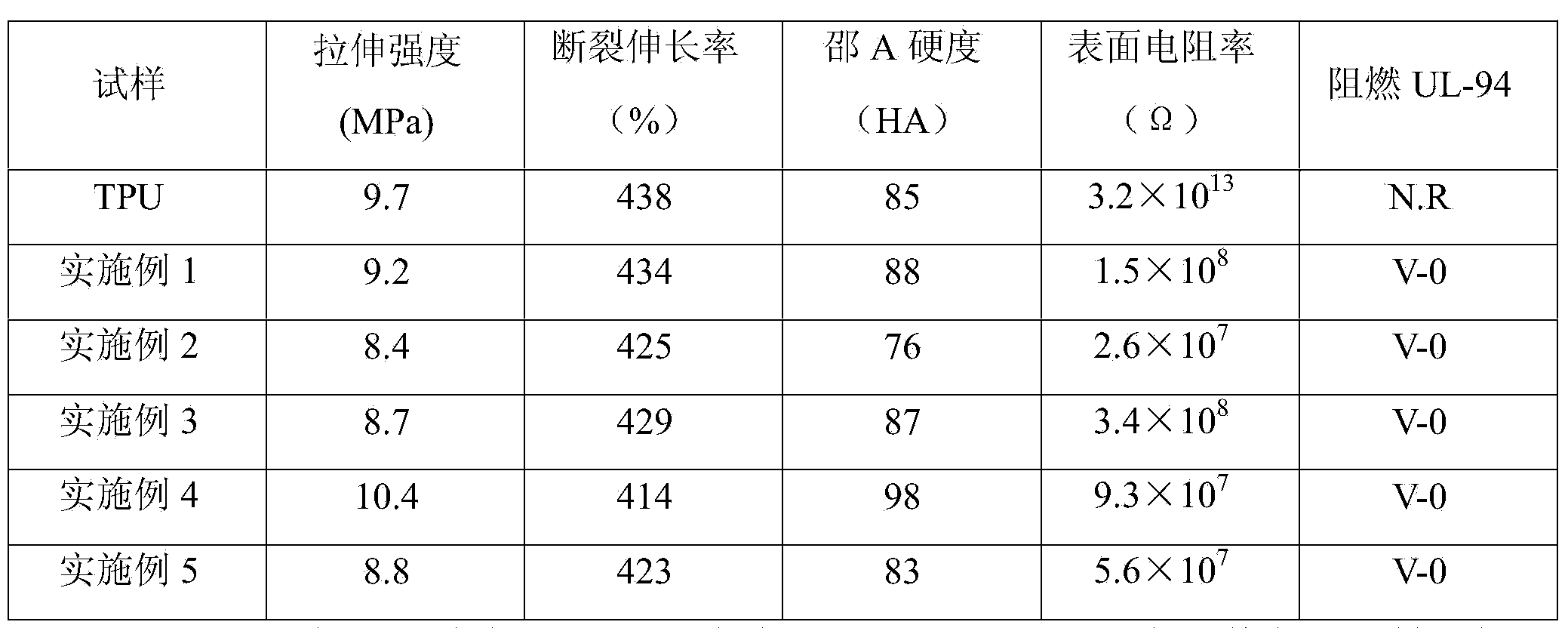

Examples

Embodiment 1

[0034] The method for preparing a halogen-free flame-retardant antistatic TPU material in this embodiment includes:

[0035] 1), material selection: in this embodiment, the selected raw materials are 85 parts of TPU (Shore A hardness is 85HA), 12 parts of flame retardant (magnesium diisobutylphosphinate), 2 parts of antistatic agent, and 0.2 parts of antioxidant part, 0.8 part of lubricant;

[0036] 2), mixing: mix the raw materials selected in step 1) in a high-speed mixer for 3 minutes;

[0037] 3) Pelletizing: put the raw materials mixed in step 2) into a twin-screw extruder, melt and knead, and extrude to granulate.

[0038] In the method for preparing halogen-free flame-retardant and antistatic TPU materials in this example, step 3) during granulation, the conveying section is 150°C, the melting section is 160°C, the mixing section is 170°C, the exhaust section is 180°C, and the homogenization section is 170°C. The screw speed is 350r / min.

[0039] In this example, the...

Embodiment 2

[0043] The method for preparing a halogen-free flame-retardant antistatic TPU material in this embodiment includes:

[0044] 1), material selection: in this embodiment, the selected raw materials are 64.7 parts of TPU (Shore A hardness is 70HA), 30 parts of flame retardant (calcium methyl ethyl phosphinate), 5 parts of antistatic agent, and 0.1 parts of antioxidant part, 0.2 part of lubricant;

[0045] 2), mixing: mix the raw materials selected in step 1) in a high-speed mixer for 4 minutes;

[0046] 3) Pelletizing: put the raw materials mixed in step 2) into a twin-screw extruder, melt and knead, and extrude to granulate.

[0047] In the method for preparing halogen-free flame-retardant and antistatic TPU materials in this example, step 3) during granulation, the conveying section is 160°C, the melting section is 170°C, the mixing section is 180°C, the exhaust section is 180°C, and the homogenization section is 180°C. The screw speed is 400r / min.

[0048] In this example, ...

Embodiment 3

[0052] The method for preparing a halogen-free flame-retardant antistatic TPU material in this embodiment includes:

[0053]1), material selection: in the present embodiment, the selected raw material is 79.5 parts of TPU (TPU with Shore A hardness of 80HA accounts for 50%, and TPU with Shore A hardness of 90HA accounts for 29.5%), flame retardant (lanthanum hypophosphite) 18 parts, 1 part of antistatic agent, 0.2 part of antioxidant, 0.3 part of lubricant;

[0054] 2), mixing: mix the raw materials selected in step 1) in a high-speed mixer for 5 minutes;

[0055] 3) Pelletizing: put the raw materials mixed in step 2) into a twin-screw extruder, melt and knead, and extrude to granulate.

[0056] In the method for preparing halogen-free flame-retardant and antistatic TPU materials in this example, step 3) during granulation, the conveying section is 150°C, the melting section is 180°C, the mixing section is 190°C, the exhaust section is 200°C, and the homogenization section is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com