1206 lubricating grease

A technology of lubricating grease and stearic acid, which is applied in the field of 1206 lubricating grease, can solve the problems of high equipment maintenance cost, frequent shutdown, oiling, and affecting normal production, etc., to reduce production safety risks, good pumping performance, and save maintenance the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

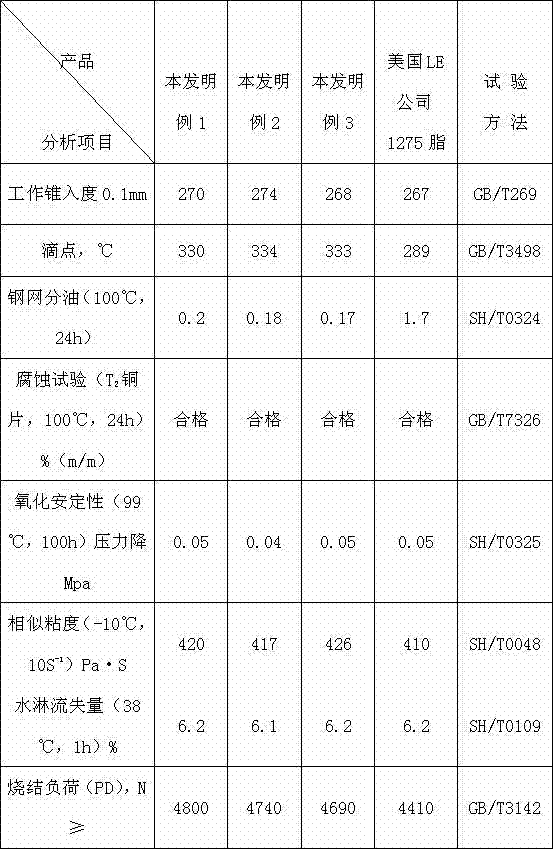

Examples

Embodiment 1

[0028] Example 1 : 1206 grease, by weight percentage, its components are as follows: 3% aluminum isopropoxide, 4% aminated bentonite, 3% stearic acid, 2% benzoic acid, 40% refined naphthenic medium viscous oil, refined paraffin Base medium viscous oil 40%, zinc dialkyldithiophosphate 2.3%, benzotriazole fatty acid ammonium salt 1.6%, benzotriazole derivatives 0.3%, tricresyl phosphate 1.6%, polyisobutylene 1.2%, urethane Esters 1.0%.

[0029] Example 1 : 1206 grease, by weight percentage, its components are as follows: 2% aluminum isopropoxide, 5% aminated bentonite, 4% stearic acid, 1% benzoic acid, 37% refined naphthenic medium viscous oil, refined paraffin Base medium viscous oil 43%, dialkyl zinc dithiophosphate 1%, benzotriazole fatty acid ammonium salt 2.9%, benzotriazole derivatives 0.1%, tricresyl phosphate 1.8%, polyisobutylene 1.5%, urethane Esters 0.7%.

[0030] Example 1 : 1206 grease, by weight percentage, its components are as follows: 4% aluminum isopropoxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com