Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

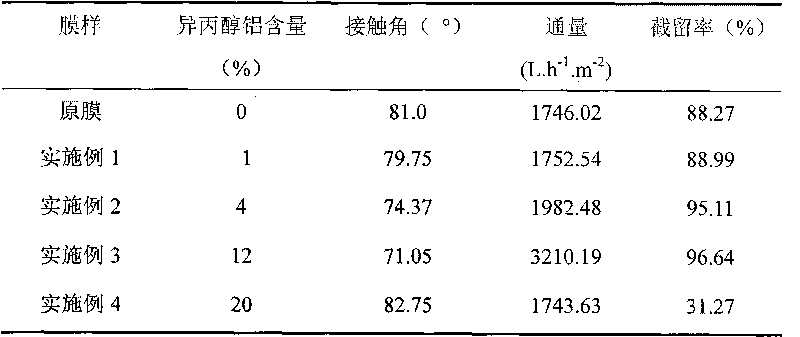

557 results about "Aluminium isopropoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium isopropoxide is the chemical compound usually described with the formula Al(O-i-Pr)₃, where i-Pr is the isopropyl group (–CH(CH₃)₂). This colourless solid is a useful reagent in organic synthesis. The structure of this compound is complex, possibly time-dependent, and may depend on solvent.

Method for preparing integral macroporous alumina

InactiveCN101200297AEasy to operateEasy to manufactureCatalyst carriersOther chemical processesPseudoboehmiteEmulsion

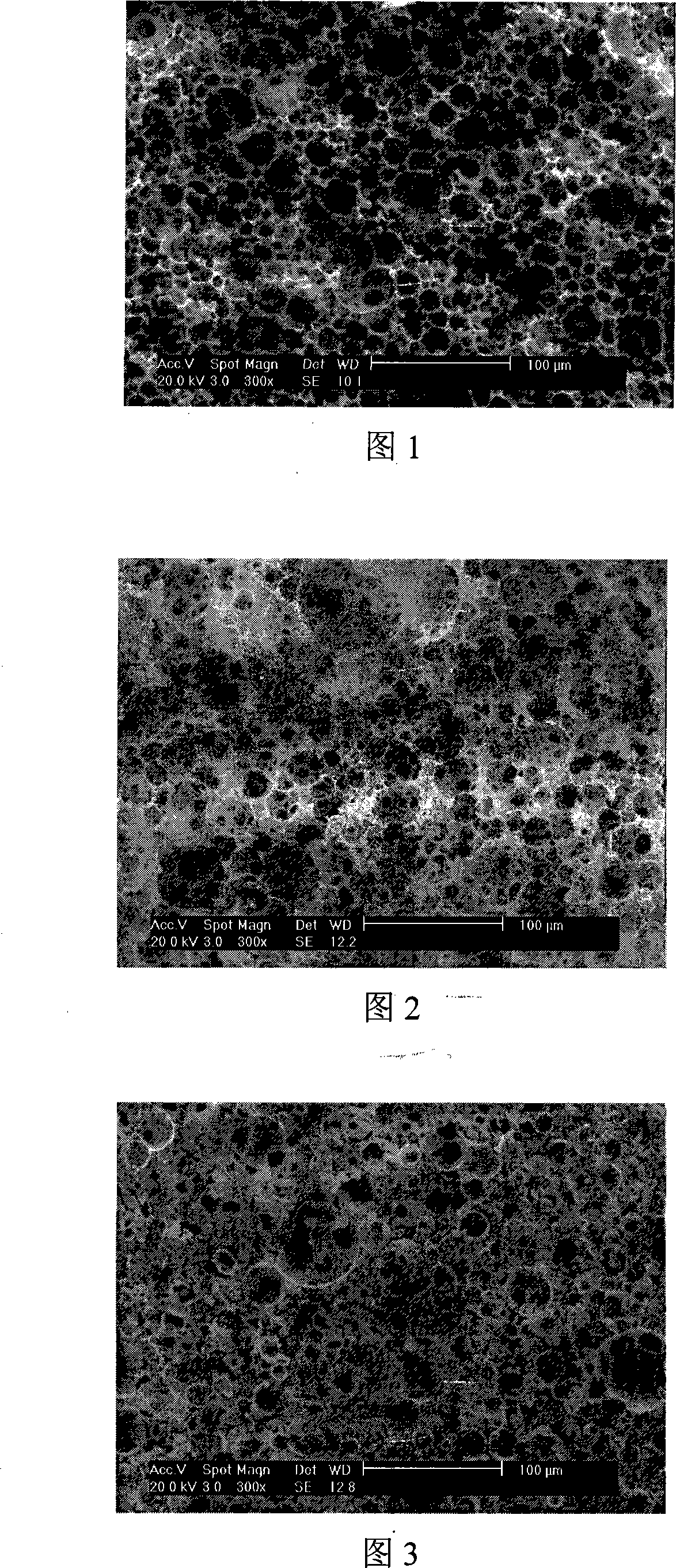

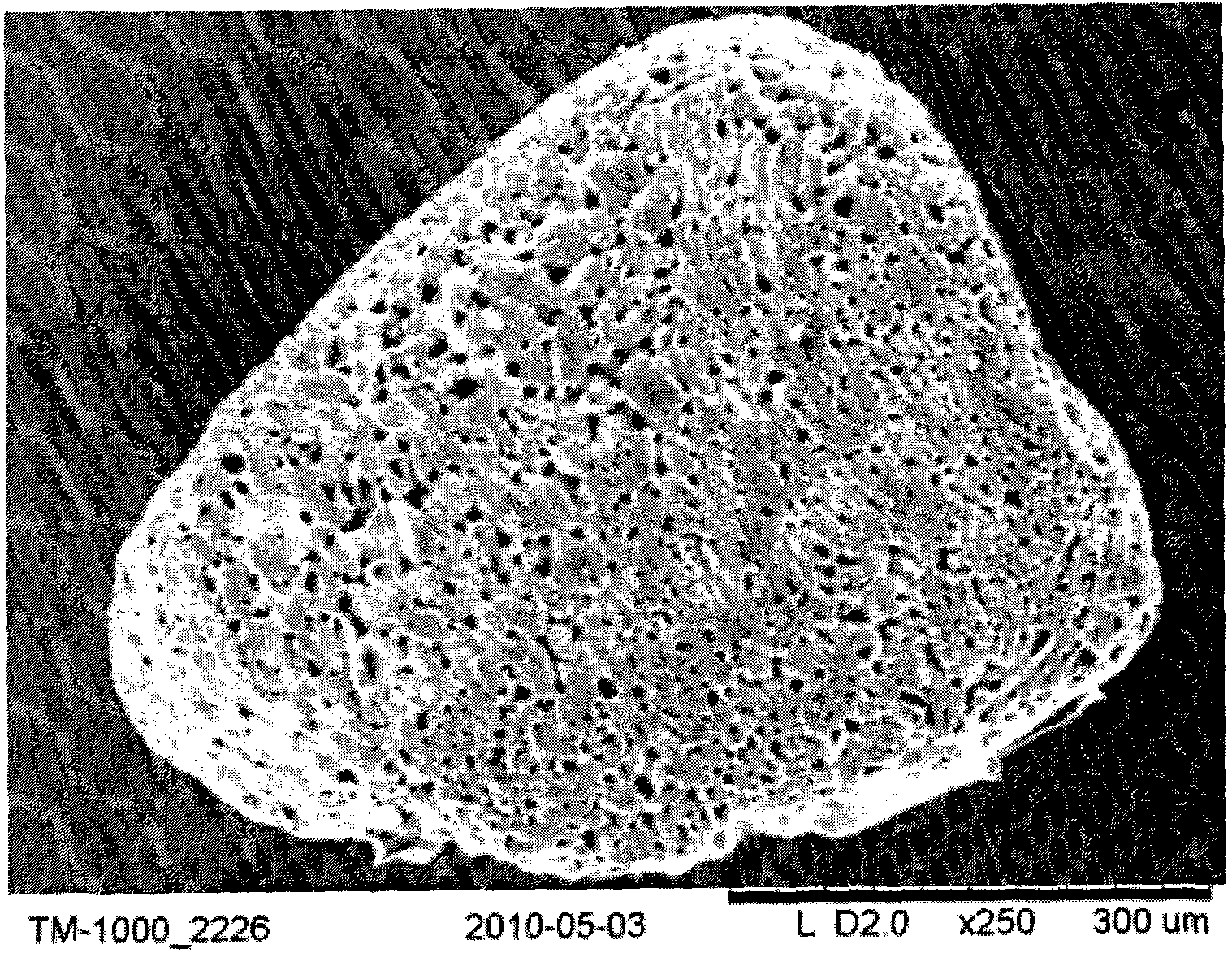

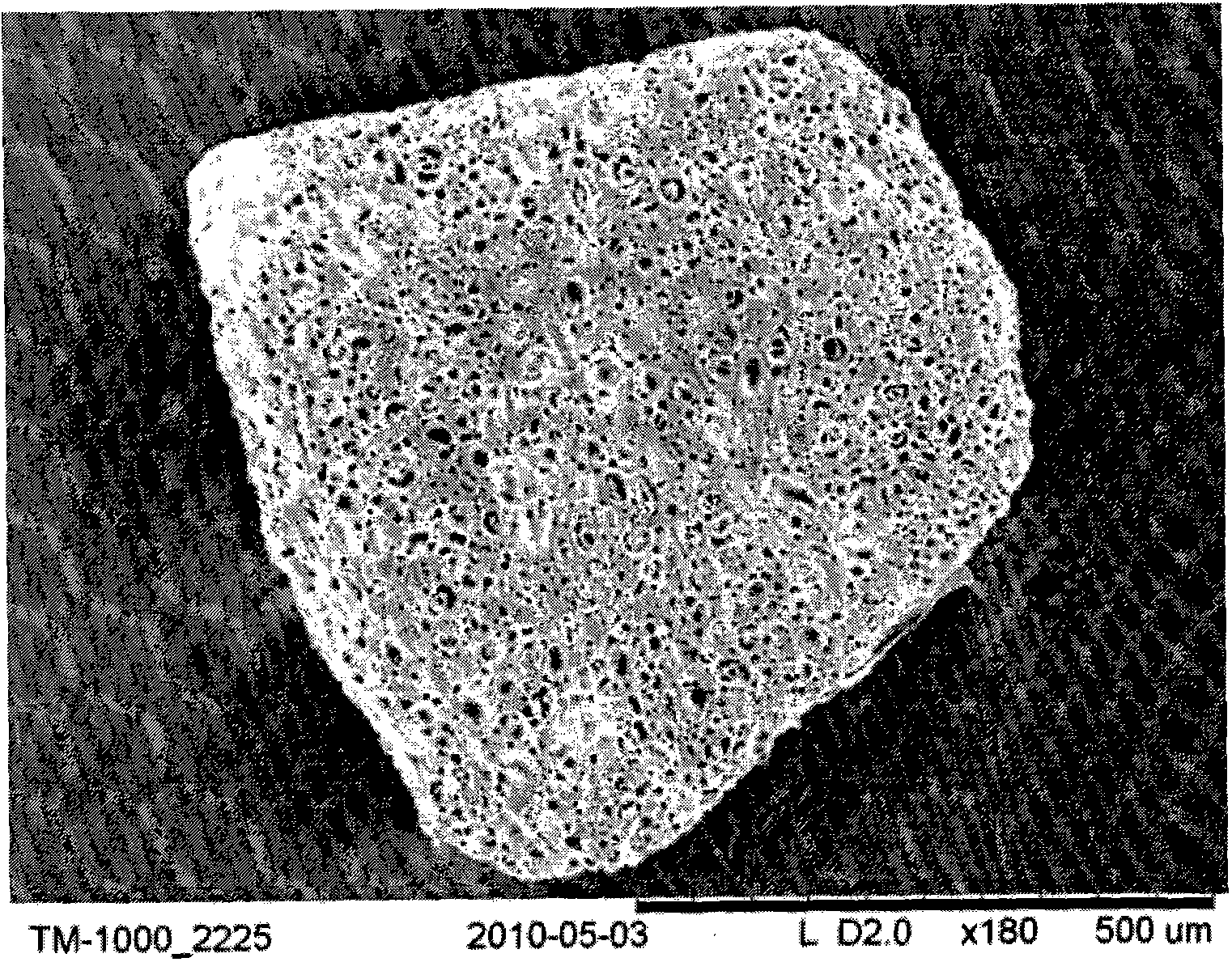

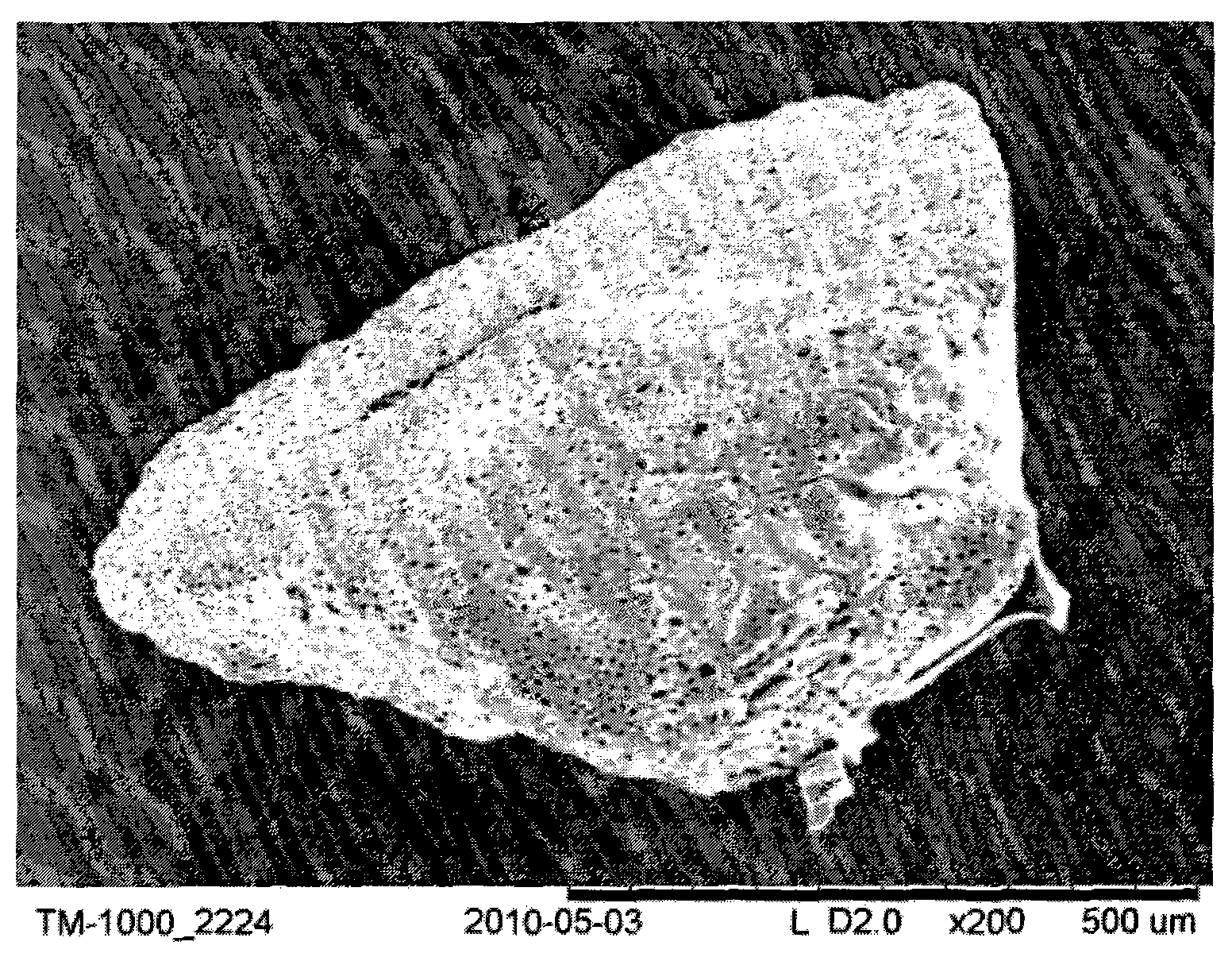

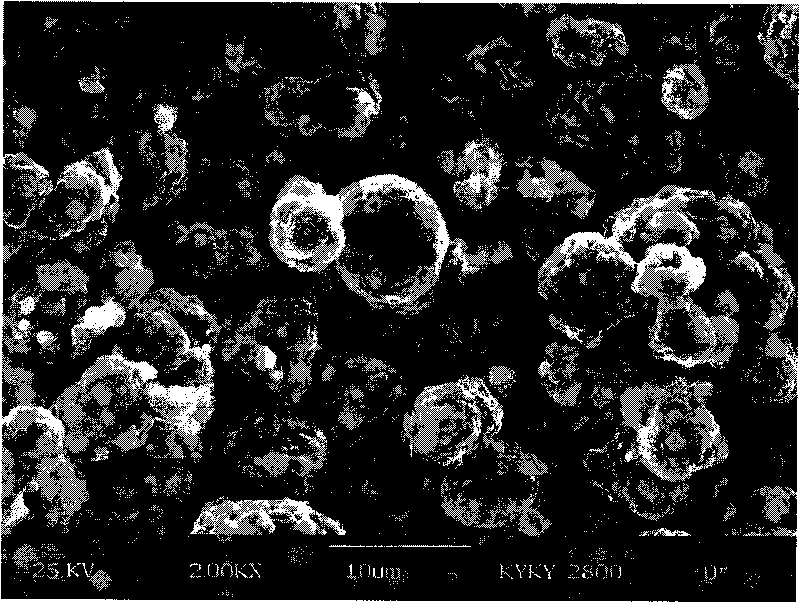

The invention discloses a preparation method of integrated large-hole alumina, belonging to a preparation technique of integrated multi-hole inorganic oxide. The method comprises the following process: reverse concentrated emulsion method is adopted to prepare integrated large-hole organic template taking cinnamene and divinylbenzene as monomer; aluminum isopropoxide or pseudoboehmite is primarily used for preparing Al2O3 hydrosol; the Al2O3 hydrosol is filled into the integrated large-hole organic template; the filled integrated organic / inorganic composites are dried and then are roasted to remove the template, so as to obtain the integrated large-hole alumina. The invention has the advantages of simple and feasible preparation process, moreover the prepared integrated large-hole alumina has micrometer grade communicated large-hole channels (1-50um). The invention is applicable for catalyst carrier, absorption materials and separation materials.

Owner:TIANJIN UNIV

Aluminium nitride ceramics material and preparation method thereof

ActiveCN101386539ADoes not significantly affect colloidal propertiesGood dispersion propertiesAluminium acetylacetonateNano al2o3

The invention discloses an aluminium nitride ceramic material and a preparation method thereof. The method is to add nano-alumina to raw materials in the prior preparation method for preparation according to the prior preparation process. In-situ growing nano-alumina can be obtained directly through adding the nano-alumina, or indirectly through adding organic aluminum, such as aluminium secondary butylate, aluminium isopropoxide or aluminium acetylacetonate, and by means of low-temperature decomposition of the organic alumina. The method can be applied to dry pressing and tape casting shaping, can obtain slurry with good dispersing characteristic and even mixing of the aluminium nitride and the nano-alumina by the ceramic preparation process, such as normal pressure, hot pressed sintering or the like, and is favorable for the improvement of sintering activity of materials, the reduction of sintering temperature, the improvement of luster uniformity, planeness and roughness for a ceramic substrate, and the reduction of production cost. The aluminium nitride ceramic material and the preparation method thereof can be widely applied to the field of aluminium nitride ceramic production.

Owner:无锡海古德新技术有限公司

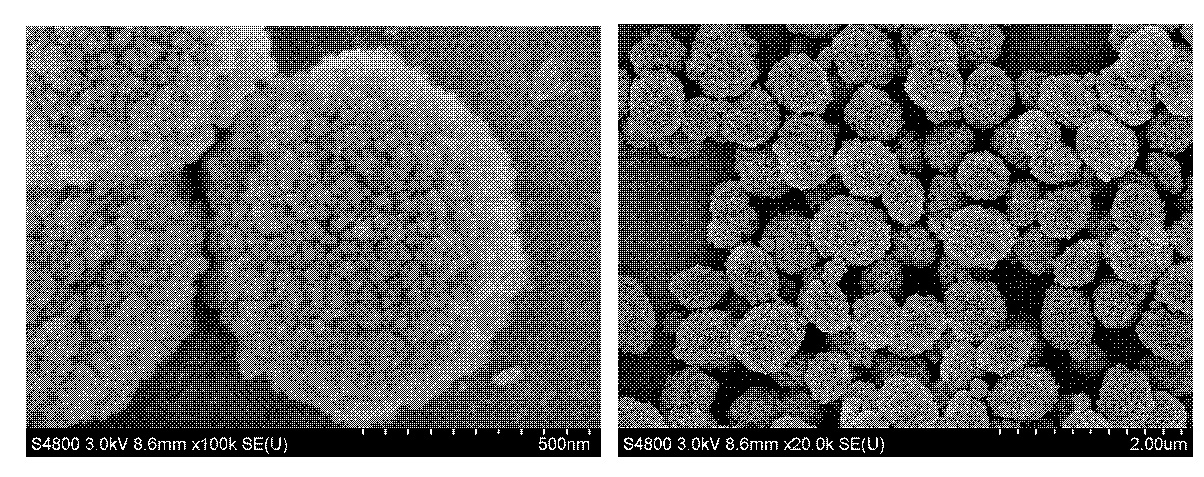

Alumina membrane coated activated carbon and preparation method thereof

InactiveCN101890333APore structure properties are not affectedHigh mechanical strengthCatalyst carriersOther chemical processesActivated carbonAluminium isopropoxide

The invention provides alumina membrane coated activated carbon and a preparation method thereof. The alumina membrane with the thickness of between 10 and 50nm is coated on the surface of the activated carbon. The preparation method comprises the following steps of: 1) hydrolyzing aluminum isopropoxide, adding nitric acid, refluxing at the temperature of between 90 and 100 DEG C, and preserving temperature to obtain an alumina sol; 2) soaking the activated carbon in the alumina sol for dipping, mixing, drying, heating the mixture to 400 DEG C in a velocity of 40 DEG C / h for calcining, and cooling the mixture to normal temperature in the velocity of 40 DEG C / h. The preparation method has simple process, and the prepared alumina membrane coated activated carbon has the advantages of not influencing the property of the porous structure of the activated carbon and greatly improving the mechanical strength of the activated carbon.

Owner:ZHEJIANG UNIV

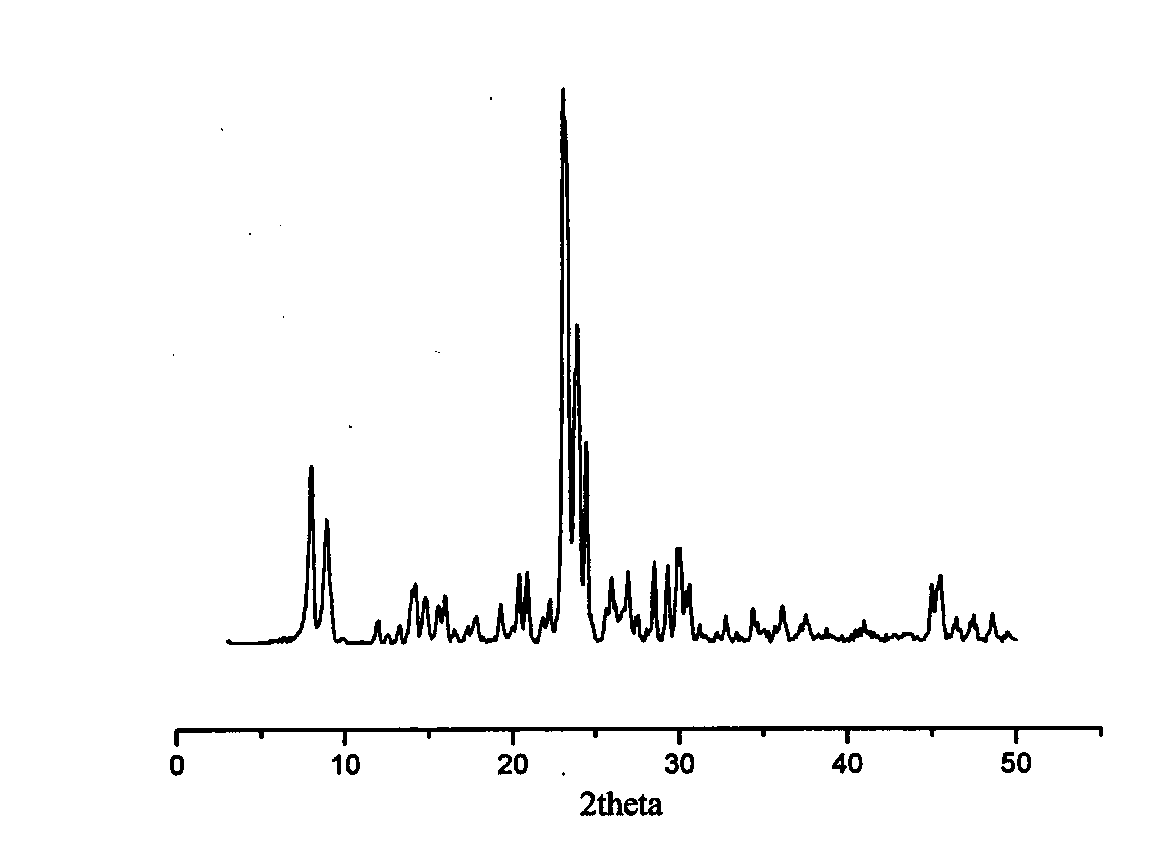

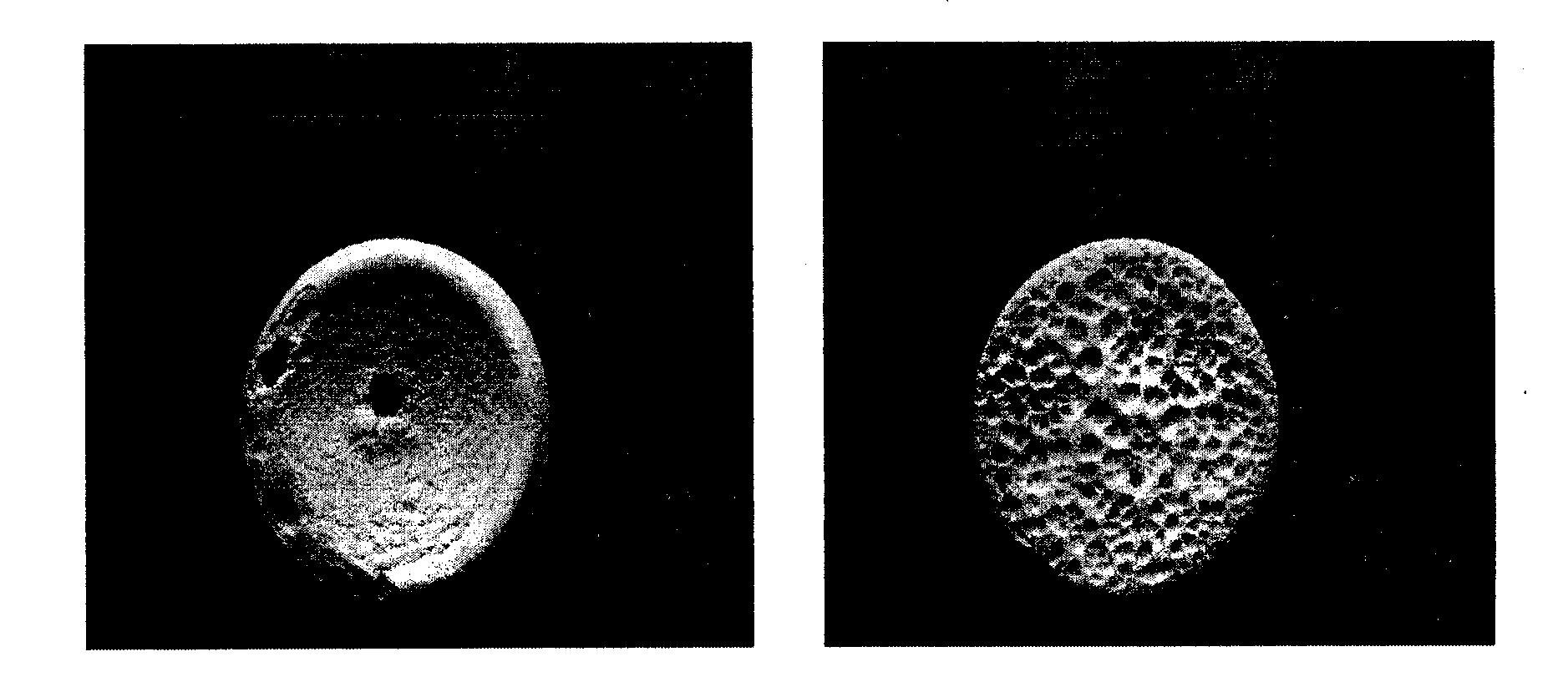

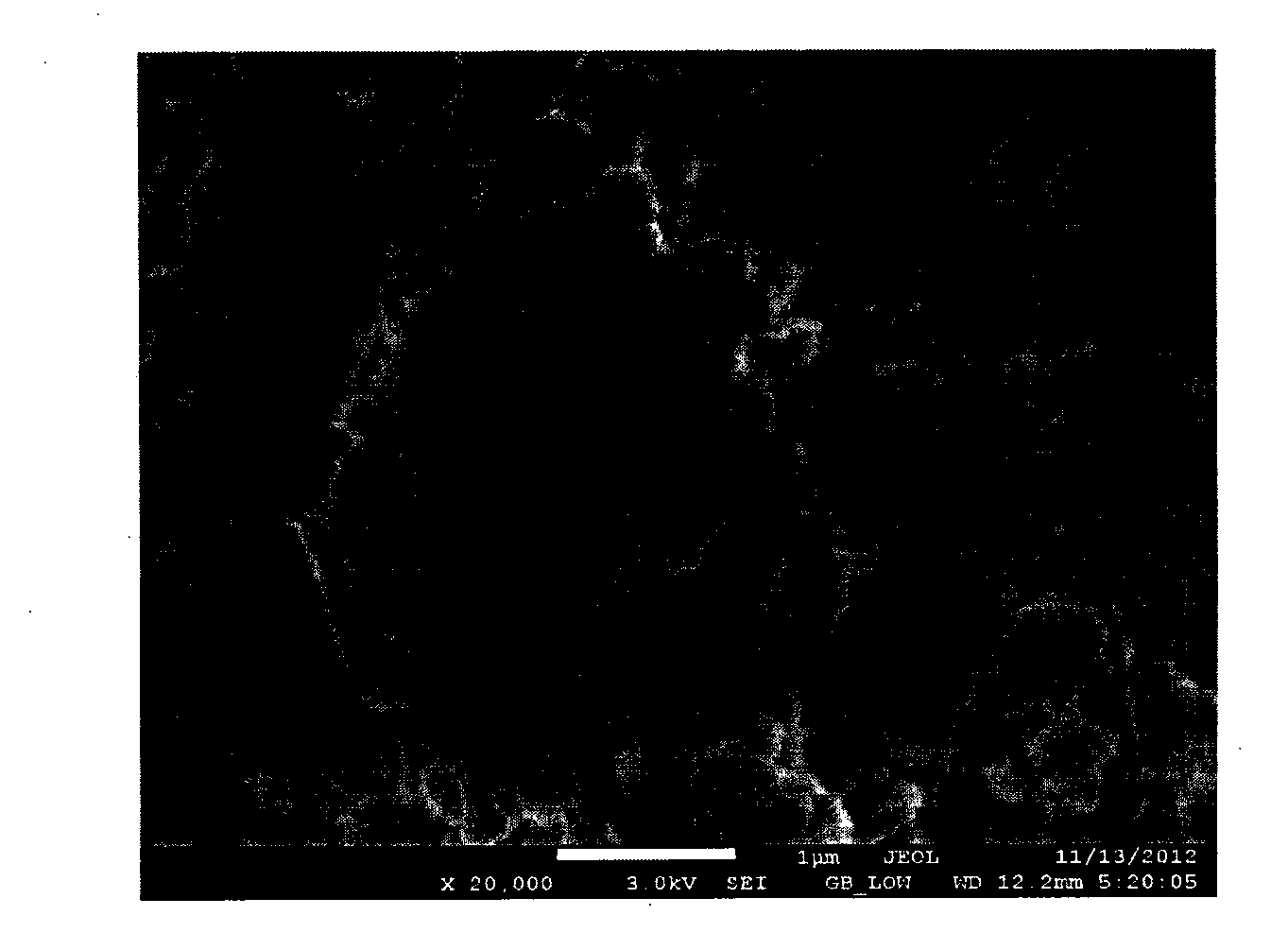

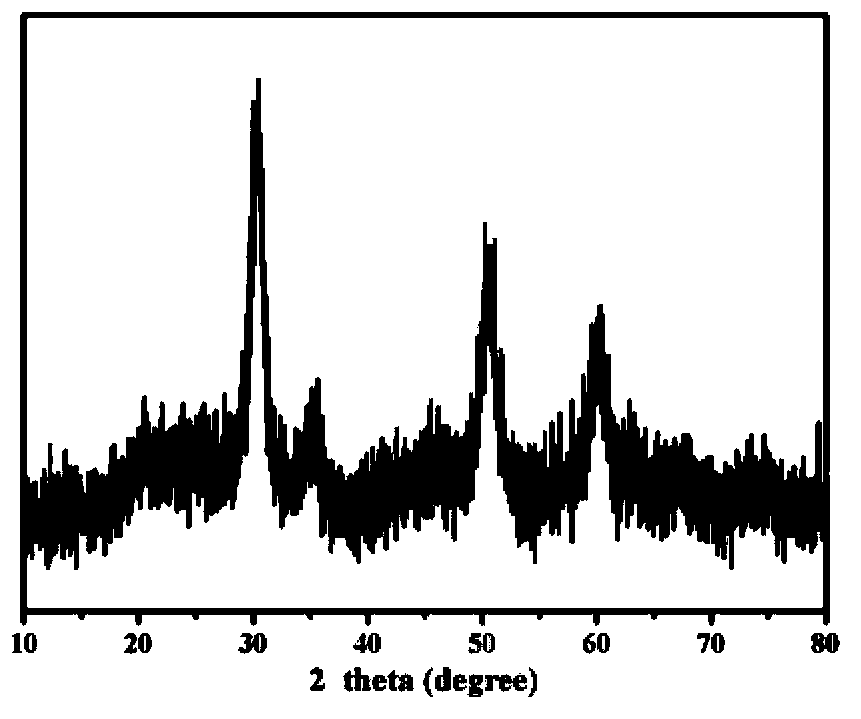

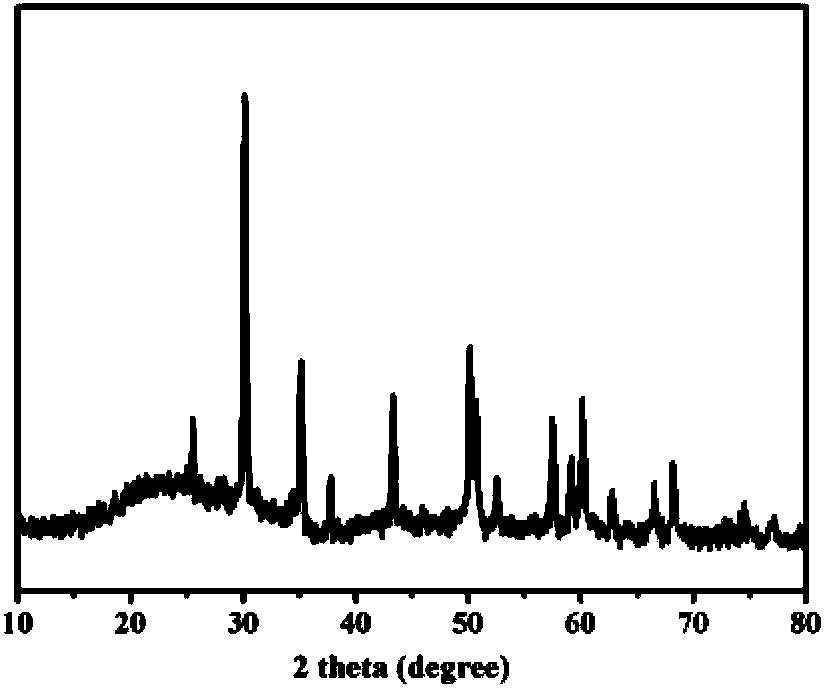

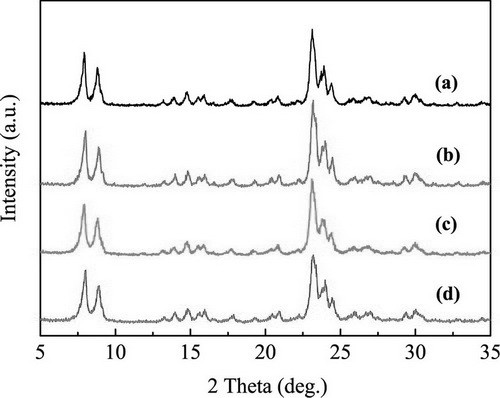

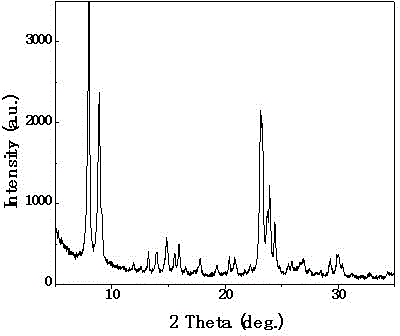

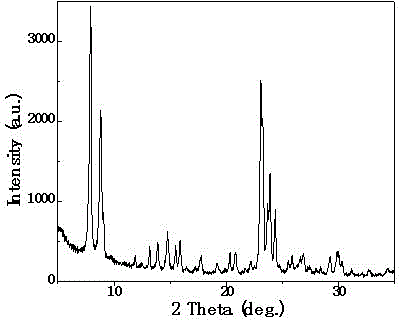

Hierarchical pore ZSM-5 molecular sieve and synthetic method thereof

InactiveCN103288100AHigh crystallinityHigh yieldPentasil aluminosilicate zeolitePotassium hydroxideSurface-active agents

The invention discloses a hierarchical pore ZSM-5 molecular sieve and a synthetic method thereof. The hierarchical pore ZSM-5 molecular sieve is formed by the accumulation of crystalline grains with order nano-layered structures and is integrally structured. The synthetic method comprises the following steps of: with quaternary ammonium salt as a structure-directing agent (SDA), tetraethoxysilane (TEOS) as a silicon source, aluminium isopropoxide (AIP) as an aluminum source, and potassium hydroxide (KOH) as an alkali source, adding a cationic surface active agent (CSF) to prepare a synthetic liquid with the molar ratio of (20-100) SiO2: (1-3) Al2O3: (10-30) SDA: (10-50) KOH: (1,000-3,000) H2O: (1-10) CSF; adding 10 to 20% of Silicalite-1 molecular sieve seed crystal gel; performing hydrothermal crystallization according to the conventional method; processing a product by washing, drying and roasting to obtain the ZSM-5 molecular sieve. The molecular sieve is an agglomeration which is formed by the self-assembly under mutual effect of CSF, seed crystal gel and an inorganic species and is of a lamella and hierarchical zeolite structure; the molecular sieve is relatively high in specific surface area, relatively short in a diffusion path and relatively high in stability. The preparation method also has the advantages of high degree of crystallinity, high yield and simple operation steps, and is easy to separate.

Owner:NINGXIA UNIVERSITY

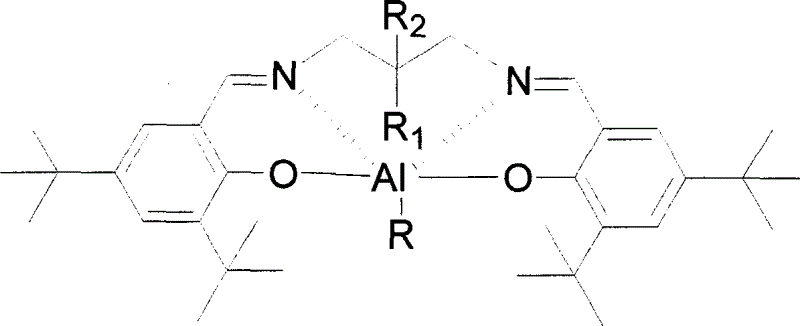

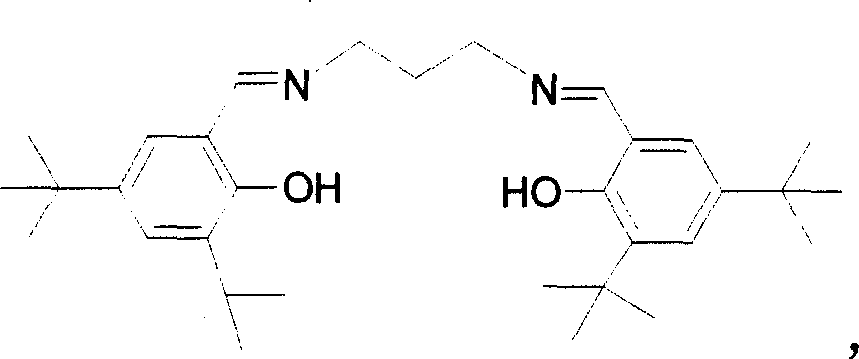

Catalyst for ring-opening polymerization of cyclic ester and preparation method thereof

The invention relates to a category of cyclic ester open loop polymerization catalyst and method for preparation, it also relates to the process for polymerizing racemic lactide by using these catalysts, wherein the catalysts are the product of the reaction between Schiff's base and aluminium triethide or aluminium isopropoxide, they exhibit stereoselectivity to the polymerization of racemic lactide, thus crystallinity polylactic acid can be obtained through polymerizing racemic lactide.

Owner:长春宸泰科技有限公司

Filter plate of porous ceramic covered by Nano ceramic membrane filter, and fabricating method

InactiveCN101092307AAvoid easy cloggingExtended service lifeCeramicwareCzochralski methodNanoceramic

This invention discloses a porous ceramic filtration plate coated with nanoscale ceramic filtration film for liquid-solid separation. The nanoscale ceramic filtration film is prepared by: hydrolyzing aluminum isopropoxide, preparing a sol with HNO3, refluxing, aging to form aluminum sol, adding Al2O3 nanopowder, mixing, dispersing to form uniform nanoscale film gel, uniformly coating onto the surface of a substrate by Czochralski method, drying and sintering. The obtained porous ceramic filtration plate can effectively block the majority of fine particles in ore slurry, and has such advantages as no blockage, long service life and wide applications.

Owner:江苏省陶瓷研究所有限公司

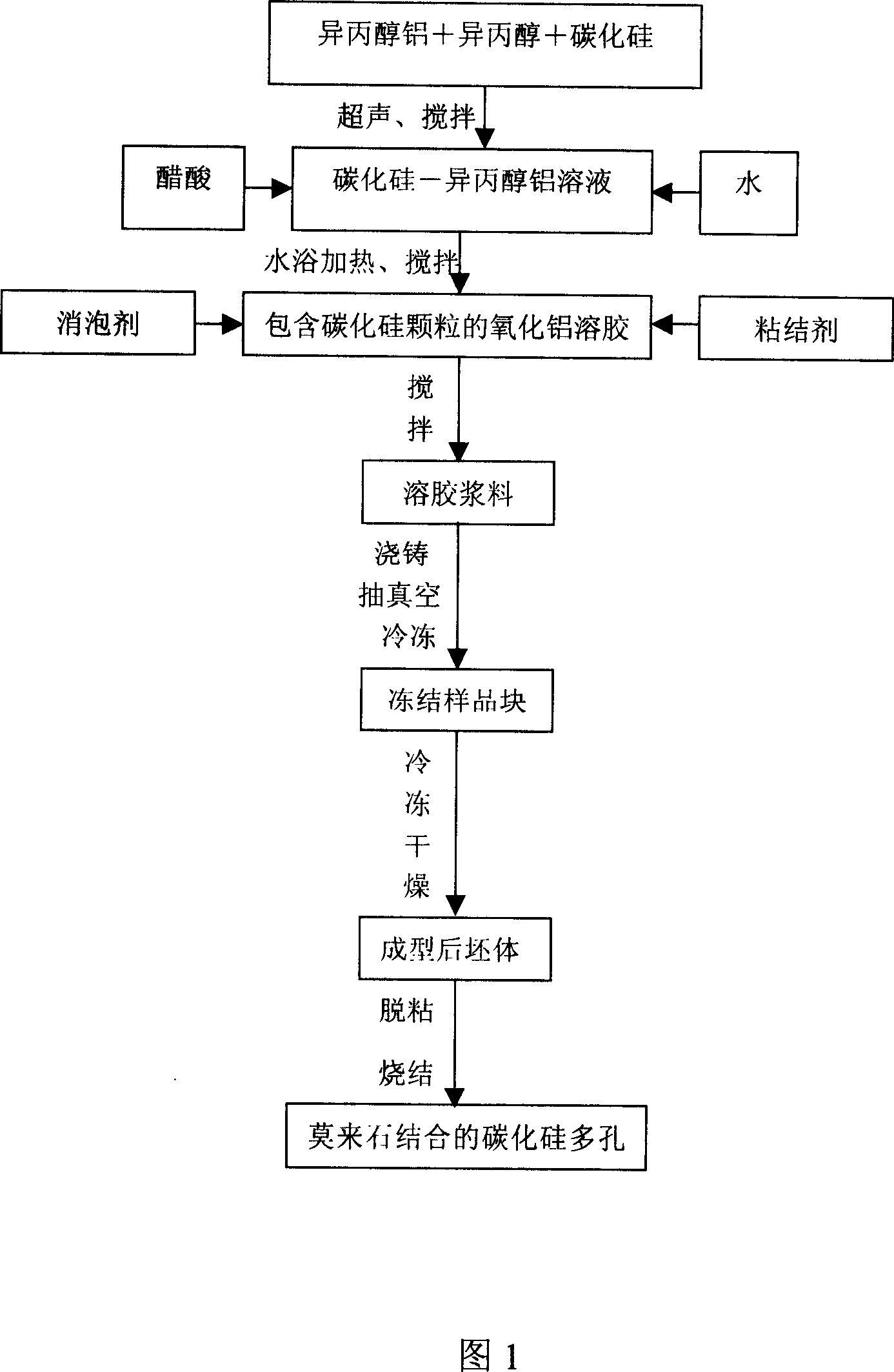

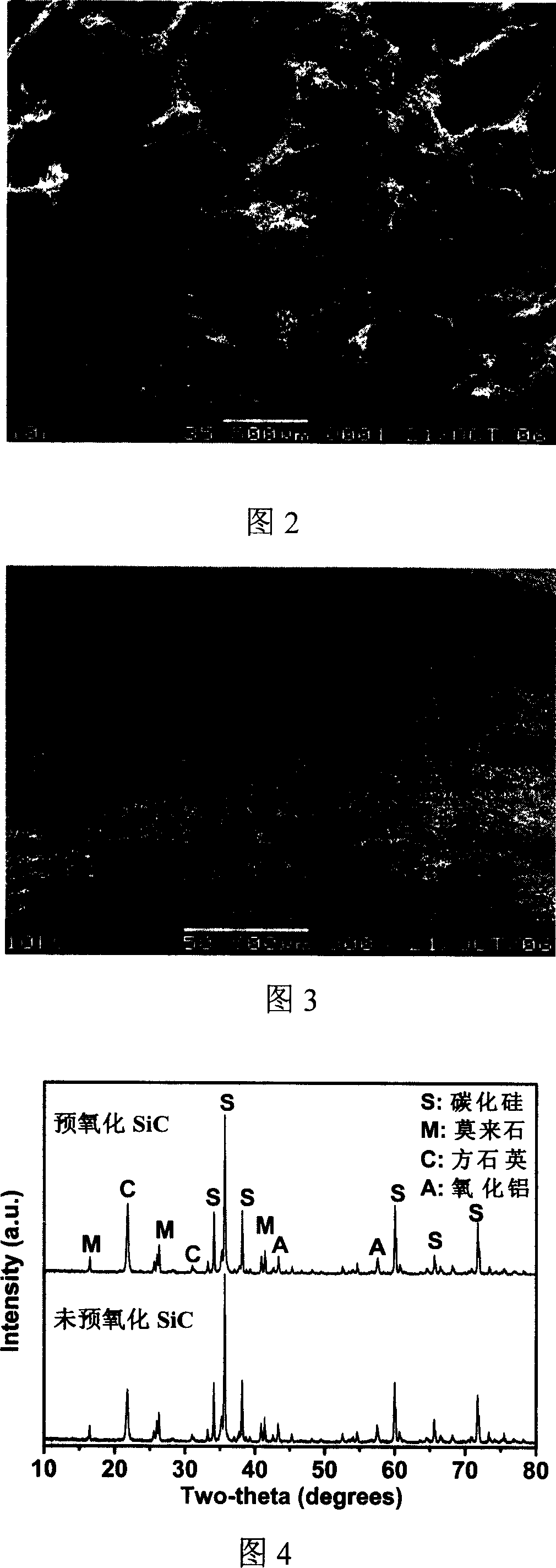

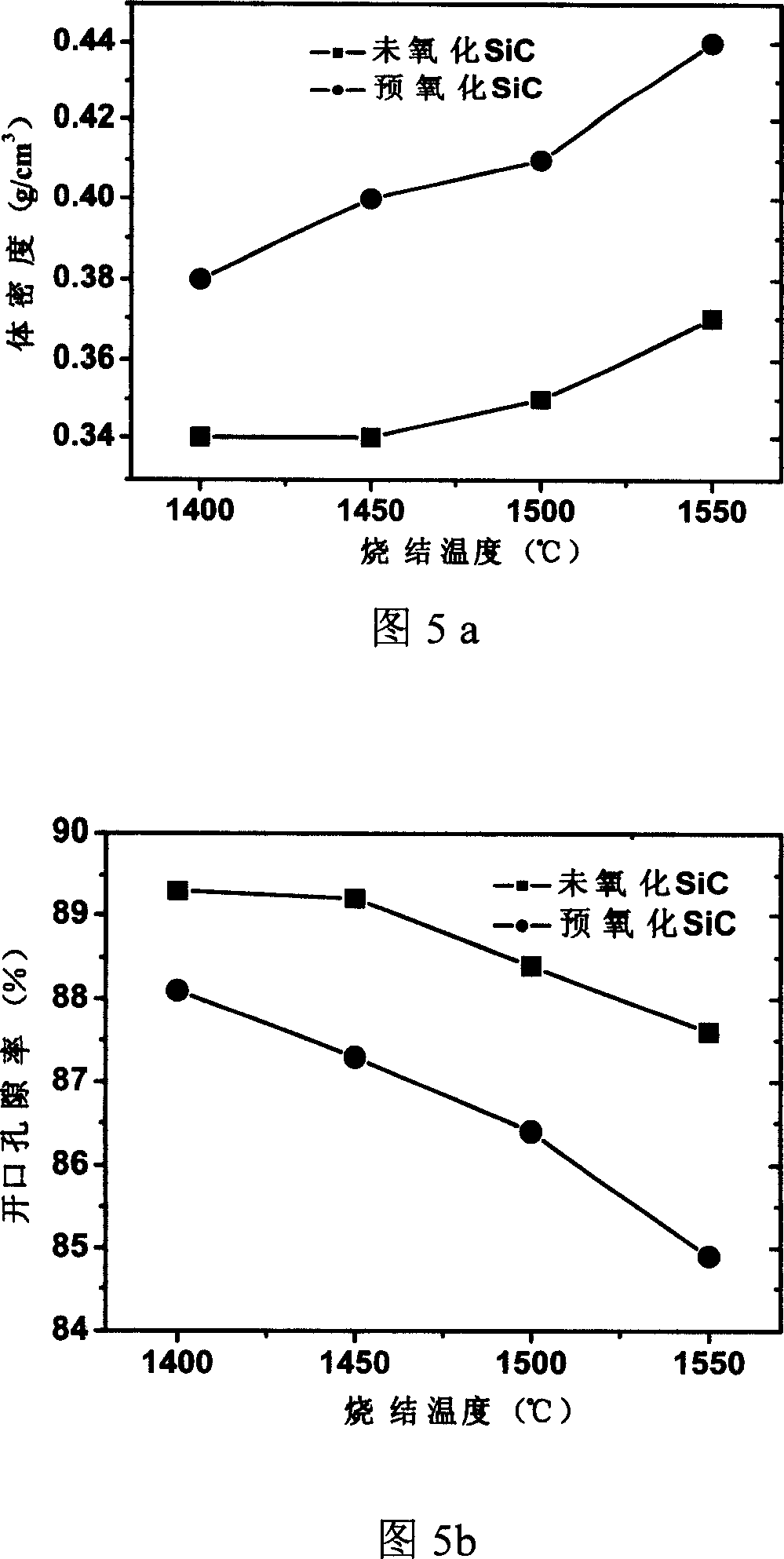

Method for preparing silicon carbide porous ceramic using gelatin wrapping-freeze drying process

The invention discloses a preparing method of carborundum porous ceramic through gel parcel-freezing drying technique, which comprises the following steps: preparing alumina sol; using alumina sol to parcel the carborundum particle; controlling the solid sol content; freezing sol slurry; drying; moulding; sintering; possessing oriental and mutual connecting pore with hole opening rate at 40-90% and aperture at 1-500 um; connecting carborundum through mullite; dispersing aluminium isopropoxide and carborundum particle in the isopropanol; hydrolyzing aluminium isopropoxide to form alumina sol slurry; adding adhesive and defoamer; casting; moulding; removing air to form vacuum; freezing to dry; forming porous blank; detackifying; sintering in the air; oxidizing carborundum particle surface into silica and alumina to obtain mullite; combining carborundum particle to obtain the porous carborundum ceramics.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

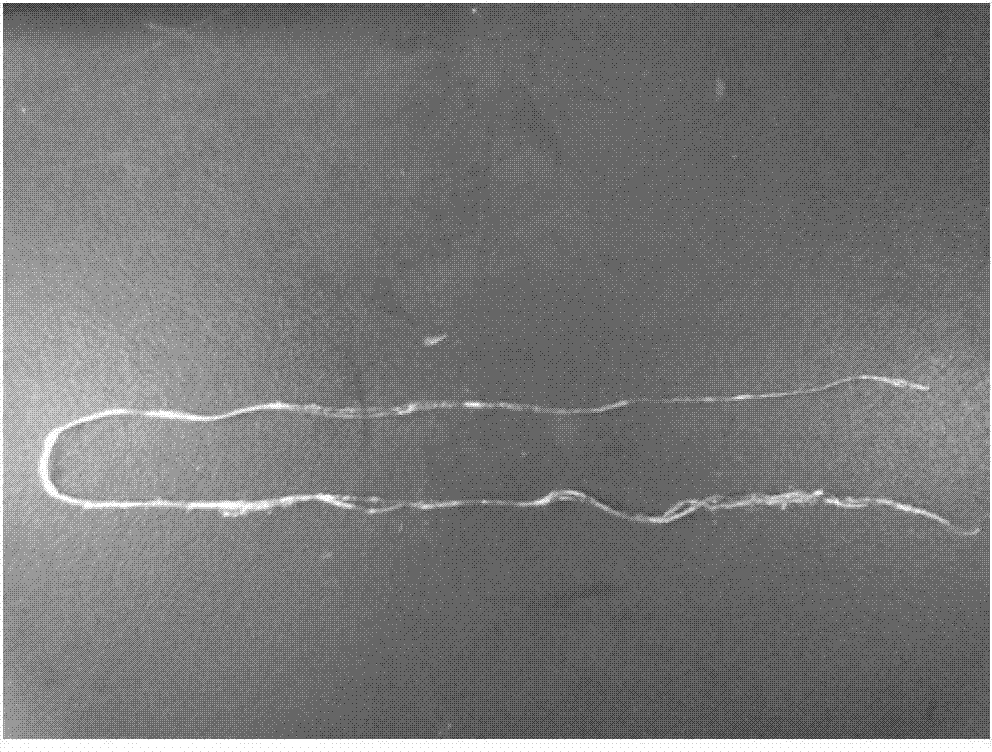

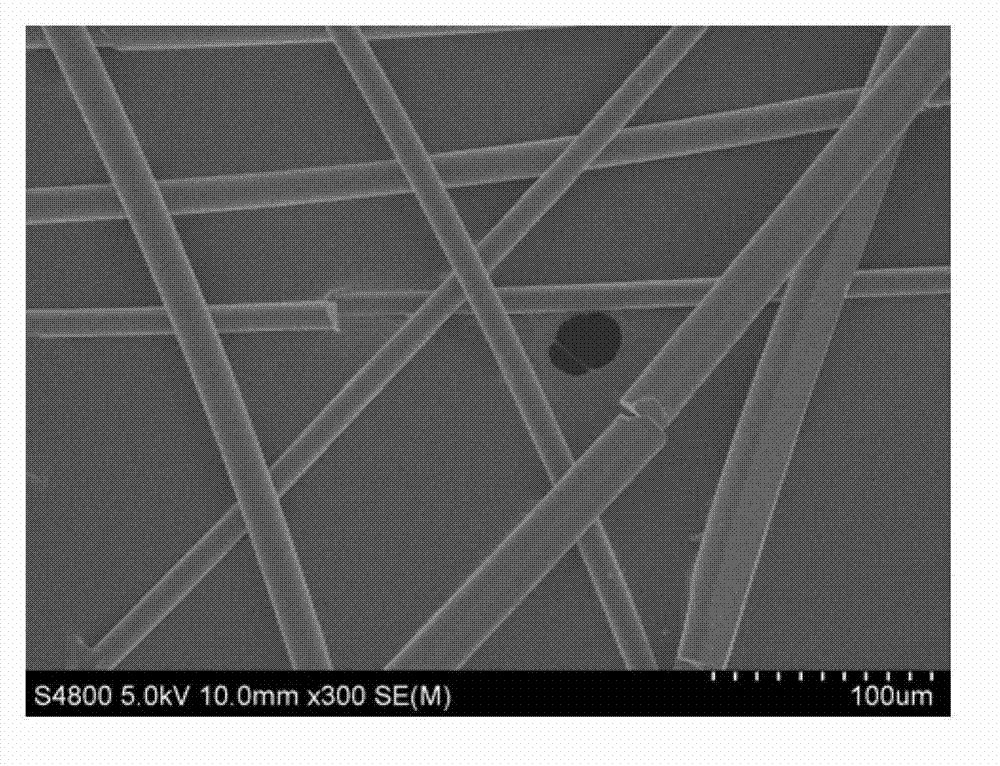

Preparation method for alumina-zirconia ceramic fiber

The invention relates to a preparation method for alumina-zirconia ceramic fiber. The method comprises the following steps: utilizing aluminium isopropoxide, formic acid, zirconium acetate and / or additive to prepare spinnable colloidal sol precursor, adopting a centrifugal fiber forming technology to prepare gel fibre, and then calcining to obtain the alumina-zirconia ceramic fiber with the diameter of 1 to 8 micrometers. The colloidal sol prepared by the invention is stable in framework, cheap in used raw materials, mild in fiber forming condition and simple in preparation process. The calcined ceramic fiber is good in flexibility and low in heat conductivity coefficient, and can be used for high temperature thermal insulation material.

Owner:SHANDONG UNIV

Multistage pore structure nano molecular sieve catalyst and preparation method thereof

InactiveCN102000601AThe synthesis steps are simpleLarge specific surface areaMolecular sieve catalystsHydrocarbonsMolecular sievePtru catalyst

The invention discloses a multistage pore structure nano molecular sieve catalyst, belonging to the field of materials and catalysts. A preparation method of the catalyst comprises the following steps of: mixing tetraethoxysilane, aluminum isopropoxide and an organic template agent to obtain a molecular sieve original solution; directly adding organosilane into the molecular sieve original solution, and grafting organosilane to a ZSM-5 molecular sieve under condensation and flux conditions; and roasting to remove the organosilane and the organic template agent. The multistage pore structure nano molecular sieve catalyst with micropores and mesopores can be obtained by using the method, contains nano particles with proper nano particle size, has high stability and is applied to macromolecule reactions.

Owner:SHANGHAI NORMAL UNIVERSITY

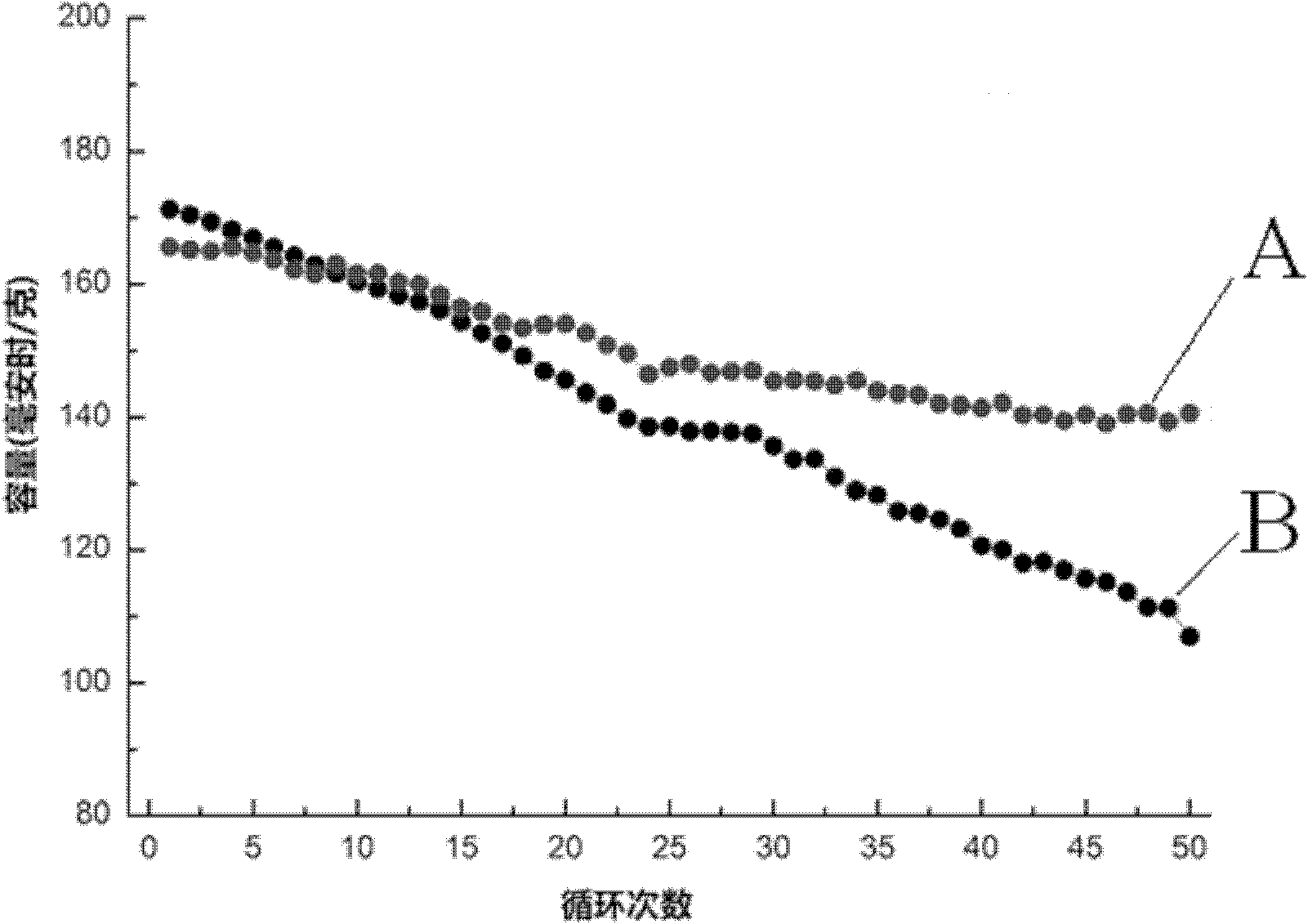

Preparation method of wet-processed aluminium-coated lithium ion battery cathode material

ActiveCN102306751AEvenly dispersedCoating process conditions are easy to controlCell electrodesPower batteryManganese

The invention relates to a preparation method of wet-processed aluminium-coated lithium ion battery cathode material. The method comprises the following steps: preparing a precursor and preparing size with a certain solid content; dropwise adding an isopropanol solution in which aluminium isopropoxide is dissolved in advance into the precursor size at a certain speed, wherein the dropwise adding speed, the temperature and the stirring speed are controlled appropriately; after the dropwise add of the isopropanol solution ends, aging for a certain time, filtering, washing and drying to obtain a aluminium-coated Ni-Co-Mn precursor; and evenly mixing the aluminium-coated precursor with lithium salt, carrying out a high-temperature treatment for a certain time, cooling and smashing to obtain the wet-processed aluminium-isopropoxide-coated lithium ion battery cathode material. The wet-processed aluminium-isopropoxide-coated lithium ion battery cathode material provided by the invention has better high-temperature safety performance and cycle characteristic, and can be used for power batteries.

Owner:山东天骄新能源有限公司

A preparation method of a sol-gel catalyst for deep removal of a small amount of hydrogen in industrial CO gas

ActiveCN102284286ASimple catalytic performanceImprove catalytic performanceCarbon monoxideMetal/metal-oxides/metal-hydroxide catalystsIndustrial gasPtru catalyst

The invention discloses a preparation method of a sol-gel catalyst for deeply removing a little H2 in industrial CO synthetic gas through selective oxidation reaction, and a related process. The method comprises the following steps of: dissolving palladium chloride serving as a palladium source in hydrochloric acid solution with certain concentration, and adding aluminum isopropoxide, water and nitric acid in a certain ratio to form sol at a certain temperature; and gelatinizing the sol at a certain temperature to form gel, and drying and roasting at a certain temperature to obtain the required catalyst. The catalyst prepared by the method has the advantages that: active ingredients are uniformly distributed, the using amount of noble metal palladium salt is reduced, reaction conditions are mild, the phenomena of violent heat release and temperature runaway are avoided, the catalyst has superior performance, the H2 in the industrial CO synthetic gas can be removed to be less than 100ppm, and the requirement on the purity of the CO gas in a carbonyl synthesis process can be effectively met.

Owner:贵州鑫醇科技发展有限公司

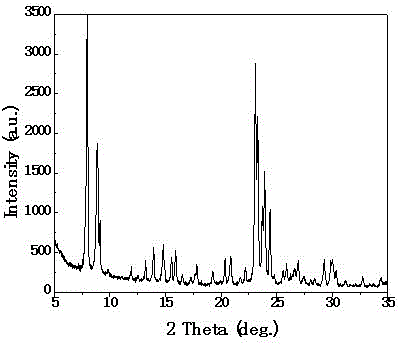

Quick synthesis method for nano-scale ZSM-5 molecular sieve

ActiveCN102874843ASynthesis fastAvoid growing upMaterial nanotechnologyPentasil aluminosilicate zeoliteMolecular sieveSynthesis methods

The invention discloses a quick synthesis method for a nano-scale ZSM-5 molecular sieve. The method includes process steps: (1), uniformly mixing aluminum isopropoxide, tetraethoxysilane, tetrapropylammonium hydroxide with water, stirring for ageing, drying aged sol-gel into dry gel, and grinding the dry gel into powdered dry gel powder to obtain dry gel seed crystal; (2), mixing water, silicon source and aluminum source into mixed solution, uniformly stirring, adding the mixed solution into the dry gel crystal seed, and uniformly stirring; (3), placing the mixed solution added with the dry gel crystal seed into a reaction kettle for static crystallization to obtain a crystallized product; and (4), taking out the crystallized product for washing, drying and roasting to obtain the nano-scale ZSM-5 molecular sieve. The dry gel serving as the crystal seed is added into ZSM-5 mixture, to induce quick formation of molecular sieve crystal during crystallization to realize quick synthesis of the ZSM-5 molecular sieve. The quick synthesis method for the nano-scale ZSM-5 molecular sieve has the advantage of simplicity, time saving, easiness to get raw materials, low cost, low pollution and high product crystallinity.

Owner:KAILUAN ENERGY CHEM

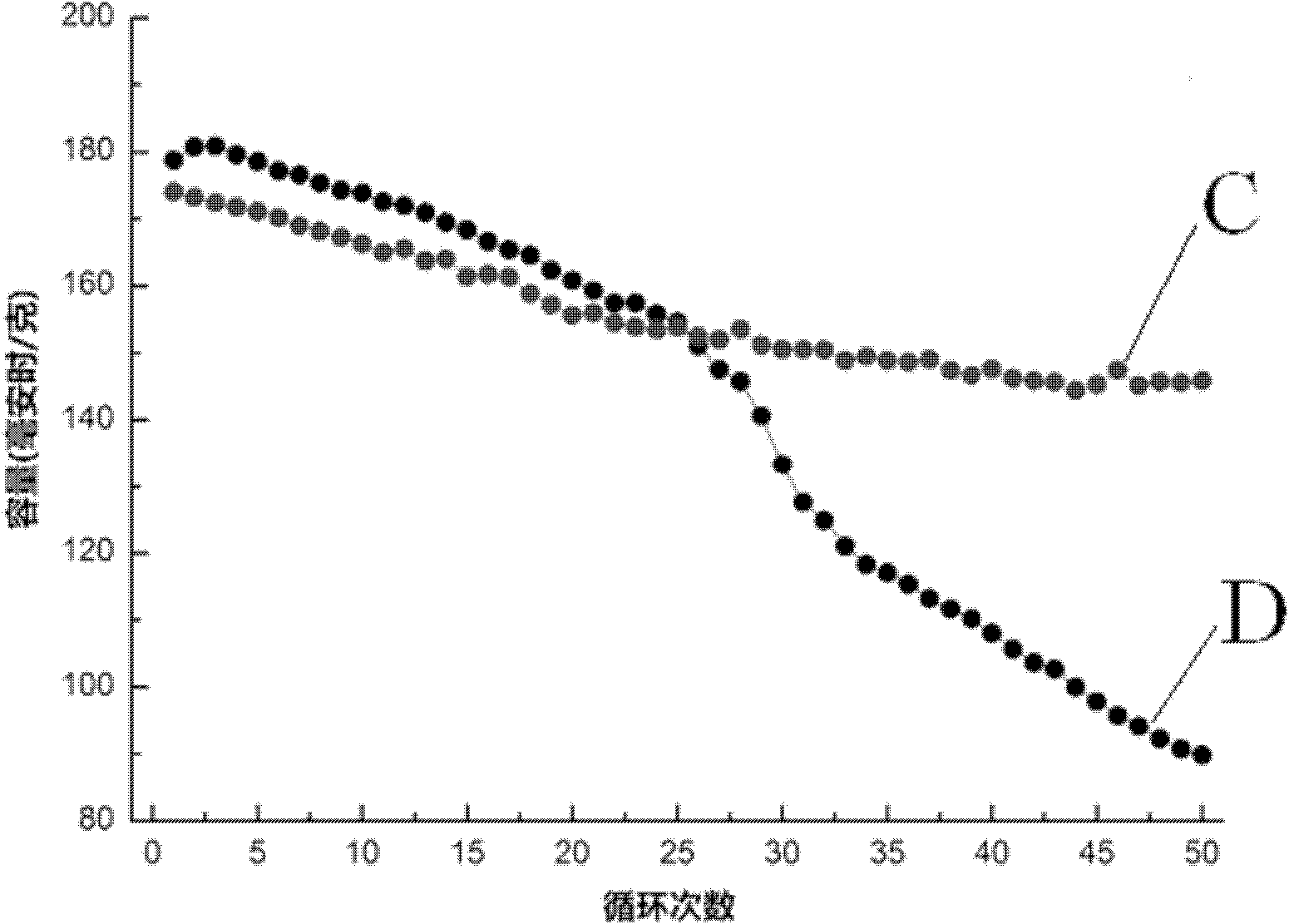

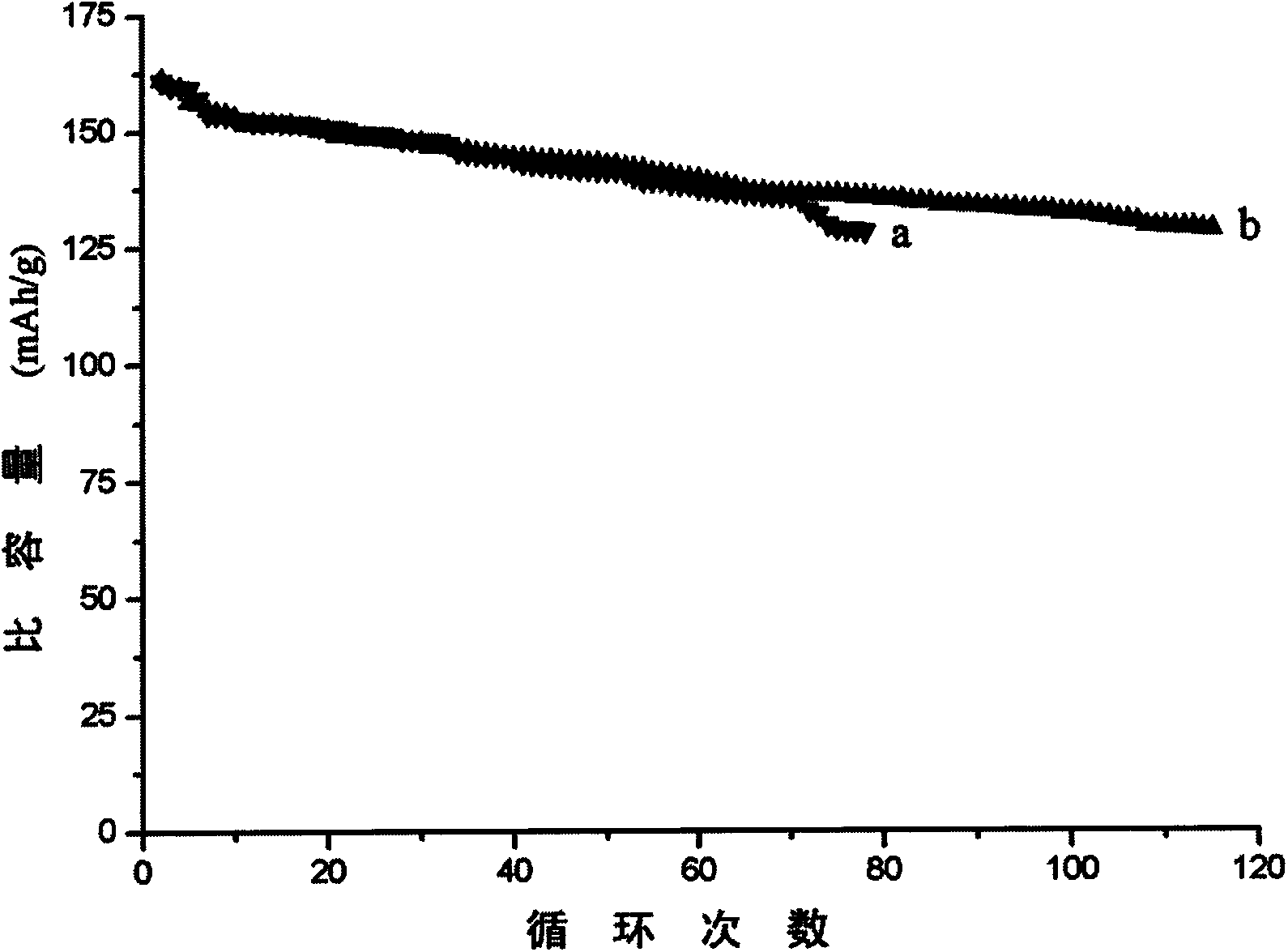

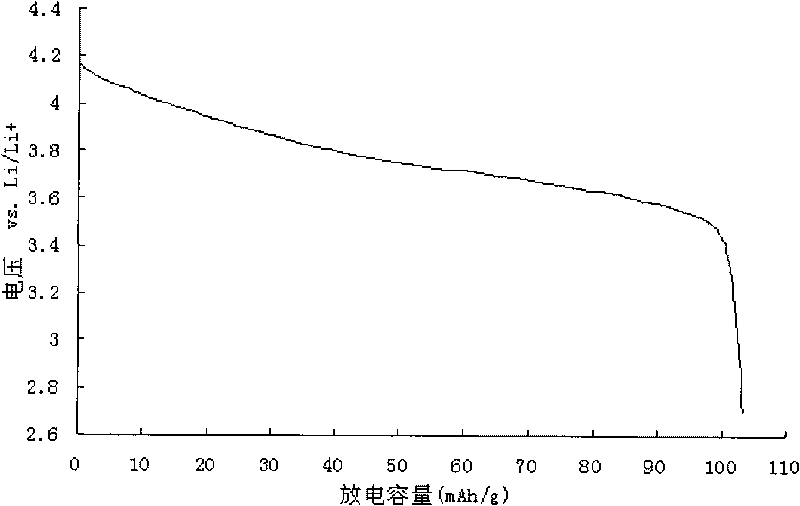

Preparation method of alumina coated Li(NixCoyMn1-x-y)O2 lithium ion battery anode material

The invention discloses a preparation method of an alumina coated Li(NixCoyMn1-x-y)O2 lithium ion battery anode material, belonging to the field of application of the lithium ion battery anode material. The preparation method is characterized by comprising the following steps: introducing aluminum isopropoxide during synthesis of Li(NixCoyMn1-x-y)O2 precursor through a hydroxyl coprecipitation method to prepare aluminum hydroxide modified coated Li(NixCoyMn1-x-y)O2 precursor; doping lithium and performing high-temperature calcining to prepare alumina modified coated Li(NixCoyMn1-x-y)O2. According to the preparation method, the problem of oxidation occurring in washing and drying of the synthesis process of the Li(NixCoyMn1-x-y)O2 precursor through the hydroxyl coprecipitation method is solved; the alumina modified coated Li(NixCoyMn1-x-y)O2 obtained by using the method shows superior stability and high-temperature cyclicity.

Owner:QINGDAO GUOXUAN BATTERY CO LTD

Abrasion-resistant paint and preparation method thereof

InactiveCN104231831AImprove the lubrication effectImprove wear resistanceEpoxy resin coatingsCarbon monofluoridePolymer science

The invention discloses abrasion-resistant paint and a preparation method thereof. The paint comprises a first component and a second component, wherein the first component is double-component composition formed by mixing of a component A and a component B in a ratio of 1:1, the component A in the first component comprises components as follows: E-20 epoxy resin, silicon carbide micro powder, carbon monofluoride and a coupling agent; the component B in the first component comprises components as follows: methyl methacrylate, butyl acrylate, aluminum isopropoxide, triethoxy vinyl silane and 20-25 parts of a solvent; the second component comprises components as follows: a curing agent, an antifoaming agent, a leveling agent and a solvent. The components A and B in the first component are prepared separately and then mixed, and finally, the first and second components are cured to obtain the abrasion-resistant paint.

Owner:JIANGSU MARINE VICTORY COATING

Preparation method of ultrahigh-purity and superfine aluminium oxide powder

The invention relates to a preparation method of ultrahigh-purity and superfine alumina powder. The preparation method comprises the following process steps of: (1) injecting a high-purity aluminium sheet, isopropanol and a catalyst into a synthetic reaction tower to generate gaseous aluminium isopropoxide; cooling gaseous aluminium isopropoxide into liquid aluminium isopropoxide by virtue of a condenser; (2) injecting liquid aluminium isopropoxide into a reduced pressure distillation purification tank for evaporating to form steam, injecting the steam to a material receiving tank to become liquid ultrahigh-purity aluminium isopropoxide; (3) adding ultrahigh-purity aluminium isopropoxide into a vacuum stirring and drying machine, injecting high-purity water, and carrying out hydrolysis reaction under the circulating water cooling condition, so as to obtain ultrahigh-purity aluminium hydroxide and isopropanol aqueous solution; and drying in a vacuum stirring and drying machine; and (4) placing ultrahigh-purity aluminium hydroxide powder into a corundum crucible, and calcining in an electrically pushed slab kiln until the aluminium hydroxide powder is changed into alpha-Al2O3 powder, thus preparation is completed.

Owner:DALIAN HILAND PHOTOELECTRIC MATERIAL

Lithium ion battery anode material and manufacturing method thereof

InactiveCN101728529AImprove structural stabilityImprove thermal stabilityCell electrodesLithiumEmulsion

The invention provides a lithium ion battery anode material Li1+x[Ni(1 / 3-y)Co(1 / 3-y)Mn(1 / 3-y)M3y]1-xO2-zFz-Al(OH)3 (wherein M can be Mg, Al, Cr, Fe or Ti; x is not less than 0 and not more than 0.15; and z is not less than 0 and not more than 0.1) and a manufacturing method thereof. The method comprises the following steps of: doping a metal element M in LiCo1 / 3Ni1 / 3Mn1 / 3O2 by adopting a codeposition method to form a precursor; then calcining the precursor and a lithium salt doped with LiF at the temperature of 950-1000 DEG C to from an intermediate; next, preparing an Al(OH)3 emulsion from aluminium isopropoxide, isopropanol and distilled water; and finally adding the intermediate into the emulsion, stirring for 4-6 hours at the temperature of 45-55 DEG C, filtering and drying to form the anode material of the invention.

Owner:深圳市天骄科技开发有限公司

Preparation method of aluminum oxide ceramic continuous fiber

The invention relates to a preparation method of aluminum oxide ceramic continuous fiber, which comprises the following steps of: preparing a sol spinnable precursor by use of inorganic aluminum salt, aluminum powder, aluminum isopropoxide, nitric acid and crystal grain inhibitor; spinning gel fiber by a dry spinning technology; and performing drying and high-temperature calcination to obtain the aluminum oxide ceramic continuous fiber with diameter of 10-60 microns. According to the invention, the prepared sol system is particularly stable, the cost of the raw materials is low, and the preparation process is simple; and the filament can be obtained without adding auxiliaries such as macromolecules and the like. The filamentation environment is mild in the dry spinning. The calcined ceramic continuous fiber has flexibility and can be used as reinforcement in a composite material to improve strength and heat resistance of the material.

Owner:SHANDONG UNIV

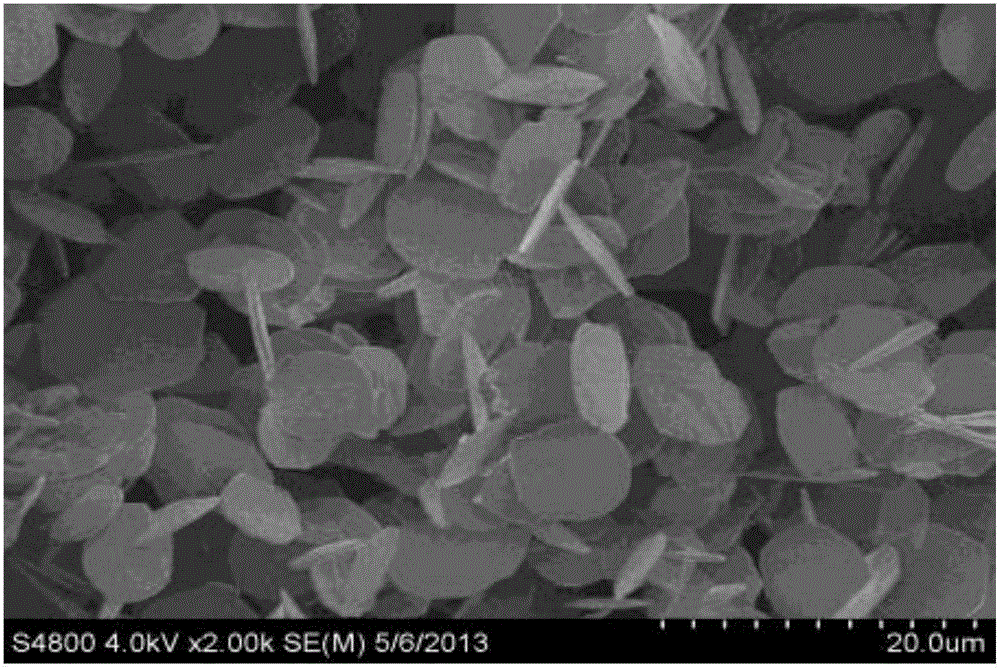

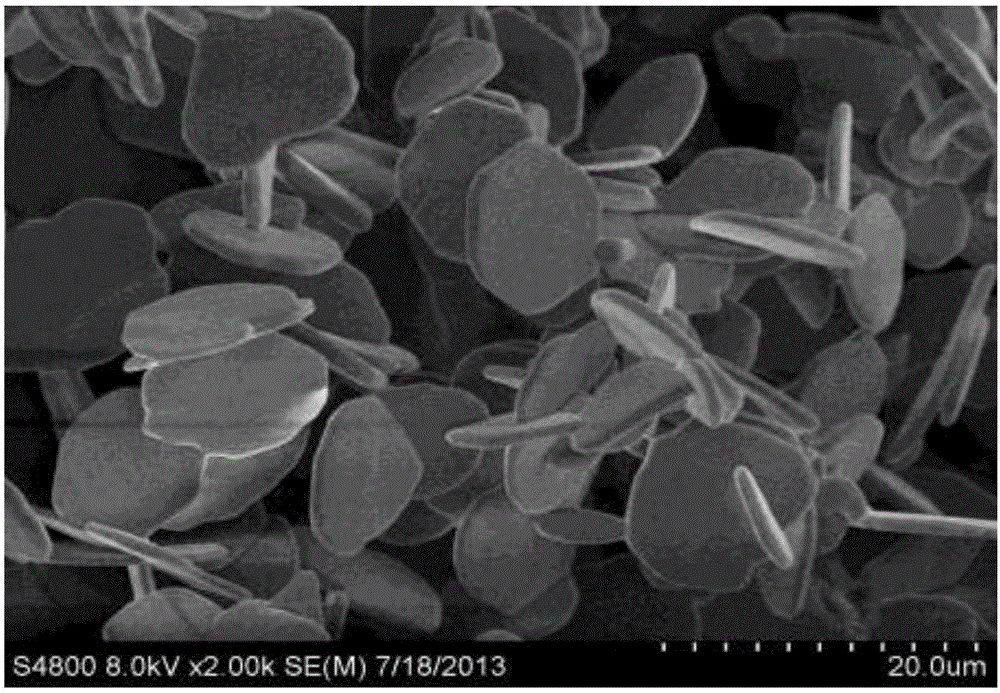

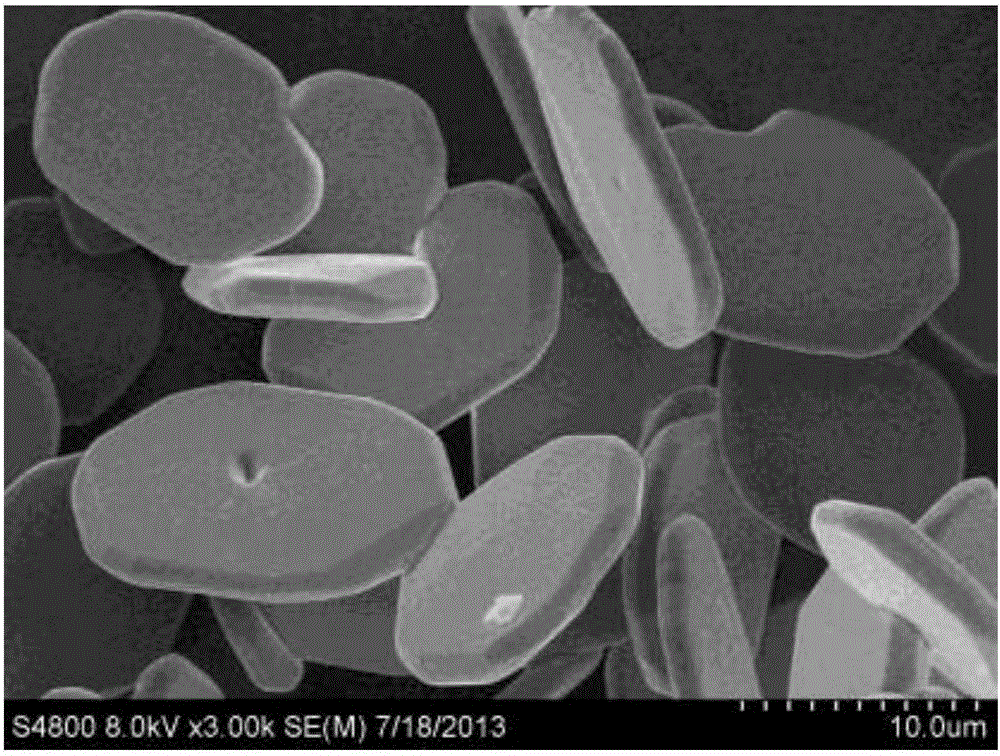

Preparation method for high-purity flaky alumina

ActiveCN105347377AHigh purityImprove doping uniformityAluminium hydroxide preparationAluminium oxides/hydroxidesAluminium isopropoxideAmmonium bifluoride

The invention discloses a preparation method for high-purity flaky alumina, belonging to the technical field of preparation of special powder. The preparation method comprises the following steps: with high-purity aluminum isopropoxide with a purity of 99.999%, pure water and isopropanol as main raw materials and ammonium bifluoride or ammonium fluoride as a crystal morphology controlling agent, dissolving the high-purity aluminum isopropoxide in isopropanol to prepare a solution A; preparing a solution B from pure water, isopropanol and ammonium bifluoride; then gradually adding the solution A into the solution B drop by drop at a certain addition speed; carrying out a reaction under the conditions of heating and stirring so as to produce hydrated alumina; and then successively carrying out filtering, drying and roasting so as to obtain the high-purity flaky alumina. The high-purity flaky alumina prepared by using the method has crystal grain thickness of no more than 1.0 [mu]m, a radial size of 5 to 20 [mu]m, a smooth surface, a flaky shape, no agglomeration and crystal twinning, and good dispersibility, and can be used in fields like cosmetics, pearlescent pigment, high-grade coatings and fine ceramics.

Owner:SHENGNUO OPTOELECTRONICS TECH QH CO LTD

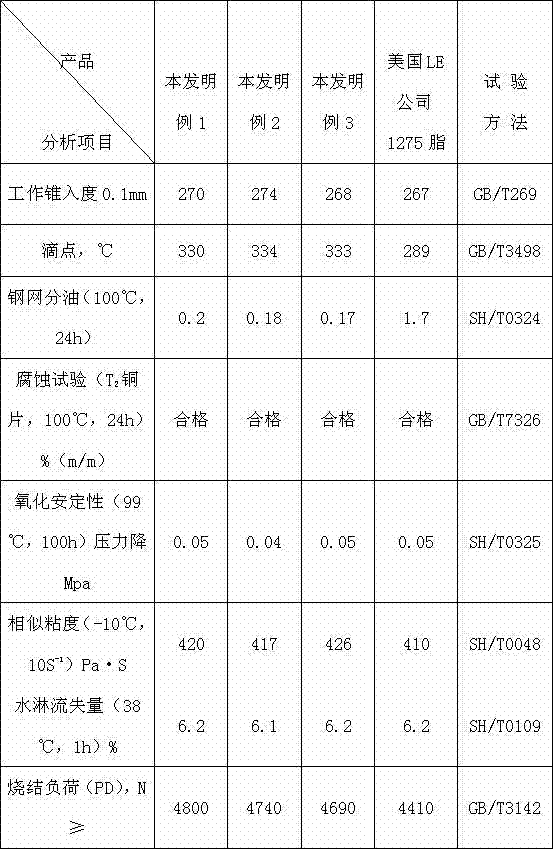

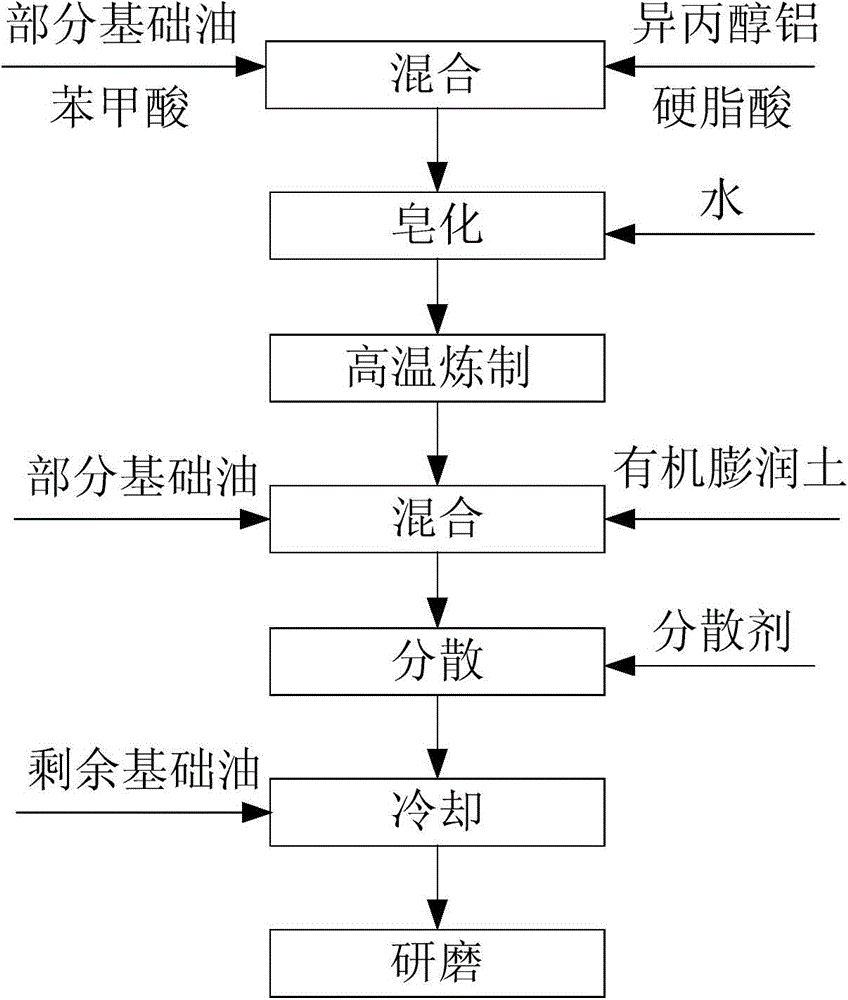

1206 lubricating grease

InactiveCN103897781AEnhanced pumpabilityGood reversibilityLubricant compositionBenzoic acidPhosphoric acid

The invention relates to a 1206 lubricating grease, comprising the following components by weight percent: 2-4% of aluminum isopropoxide, 4-6% of aminated bentonite, 3-5% of stearic acid, 1-3% of benzoic acid, 37-41% of viscous oil in refined naphthenic base, 29-43% of viscous oil in refined paraffin base, 1-3% of zinc dialkyl dithiophosphate, 1.6-2.9% of triazole fatty acid ammonium salt, 0.1-0.5% of a triazole derivative, 0.8-1.8% of tricresyl phosphate, 1.2-5% of polyisobutene and 0.7-1% of ethyl carbamate. Compared with the prior art, the 1206 lubricating grease is high in dropping point, large in sintering load data and relatively good in compression and wear resistance, and the more outstanding feature is as follows: the steel mesh is excellent in oil dividing, the embodiment 3 is 1 / 10 of the 1275 grease of LE company of America, and the embodiment 1 is not greater than 1 / 8; obviously, the pollution in the operation is smaller, the resource can be saved more, and the operation period of the equipment can be prolonged.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

Compound aluminum-base lubricating grease composition and preparation method

InactiveCN103980991ASolve the problem of large oil separation at high temperatureImprove high temperature performanceLubricant compositionBenzoic acidSodium Bentonite

Owner:SUZHOU HUIFENG LUBRICANT

Method for preparing polyvinylidene fluoride/aluminum oxide hybridization film

ActiveCN101698141AImprove hydrophilicityHigh strengthSemi-permeable membranesHYDROSOLAluminium isopropoxide

The invention discloses a method for preparing polyvinylidene fluoride / aluminum oxide hybridization film, comprising taking polyvinylidene fluoride to be dissolved into solvent; after fully dissolving the polyvinylidene fluoride, adding aluminium isopropoxide and coupling agent into the solution in a stirring state; adding water for hydrolyzation, adding acid for catalysis, and then adding pore-forming agent; stirring for at least 20h to obtain even casting film liquid, and standing still at the room temperature; scraping the casting film liquid into a panel film at the room temperature, placing the panel film in the air, soaking in coagulating bath, and forming a hyperfiltration film; and soaking the hyperfiltration film in the water, and taking out to be dried. The method uses strong chelating ligand and high activity aggregation group to respectively carry out chemical modification on PVDF organic macromolecule and Al2O3 inorganic precursor, so that the hybridization film prepared by a sol-gel method maintains the excellent chemical stability and mechanical performance of a PVD film; furthermore, the hydrophilicity and the film contamination resistance of the hybridization film are added, so that the separation property and the stability of the film can be remarkably improved.

Owner:SOUTH CHINA UNIV OF TECH +2

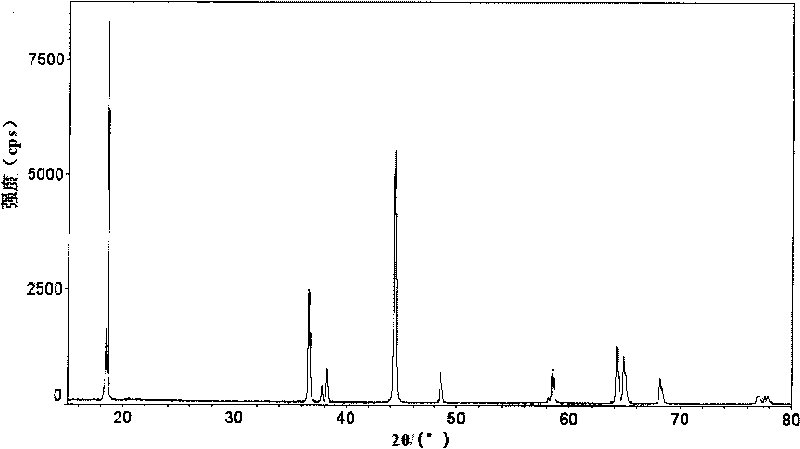

Preparation method of LiAlO2-coated lithium manganese oxide spinel cathode material

InactiveCN102903904AIncrease capacityImprove cycle performanceCell electrodesMixed materialsAluminium isopropoxide

The invention relates to a preparation method of a LiAlO2-coated lithium manganese oxide spinel cathode material. The preparation method comprises the steps of: (a) blending electrolytic manganese dioxide, lithium carbonate and chromium oxide at a molar ratio of Li to Mn of 0.51, and a molar ratio of Cr to Mn of 0.026, crushing and mixing; (b) sintering the material mixture in an air sintering furnace, grinding, sieving, and mixing for the second time; (c) placing the mixed material in the air sintering furnace, and keeping temperature for 10 to 20 hours; (d) blending the product sintered for the second time with lithium fluoride, crushing, and mixing; (e) placing the mixture obtained in the step (d) in the air sintering furnace to obtain LiMn1.95Cr0.05O3.95F0.05; and (f) preparing a 0.2mol / L mixed solution containing lithium hydroxide monohydrate and aluminium isopropoxide, and coating to obtain the final product, namely LiAlO2-coated LiMn1.95Cr0.05O3.95F0.05. The capacity and the cycle performance of the cathode material can be improved effectively by modifying the lithium manganese oxide spinel cathode material by coating.

Owner:JIANGSU KING LITHIUM CELL

Porous composite micro balls for cosmetics and preparation method for porous composite micro balls

InactiveCN102659973AGood parenthoodImprove wettabilityCosmetic preparationsMake-upWater basedFiltration

The invention discloses porous composite micro balls for cosmetics and a preparation method for the porous composite micro balls. According to the method, the porous micro balls are modified by a chemical method, and the porous micro balls have high amphipathicity and can be applied to water-based and oily cosmetic systems well, and the application range of the porous micro balls in the field of the cosmetics is widened. The method comprises the following steps of: adding the prepared porous polymer micro balls, deionized water and ethanol in a mass ratio into a reactor, and dissolving ester compounds or a metal saline solution in the ethanol, dripping into the reactor, stirring for 2 to 8 hours for centrifugal separation, washing, performing suction filtration at room temperature, and performing vacuum drying to obtain the porous composite micro balls, wherein the ester compounds are tetraethoxysilane or butyl titanate; and the metal saline solution is zinc nitrate, zinc acetate, aluminum nitrate, aluminum isopropoxide, aluminum ethylate or aluminum sec-butoxide. Porous structures of the prepared composite micro balls are in an empty cage shape, and the porous structures can be regulated and controlled by changing the process, so that the requirements of different release effects of the cosmetics are met.

Owner:SOUTH CHINA UNIV OF TECH

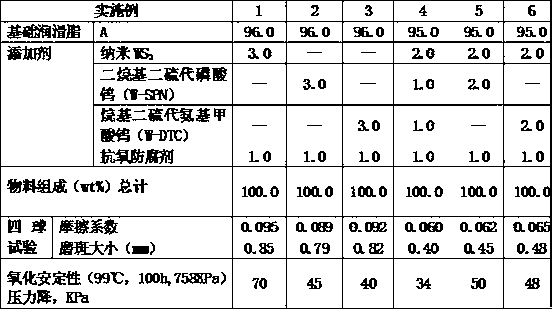

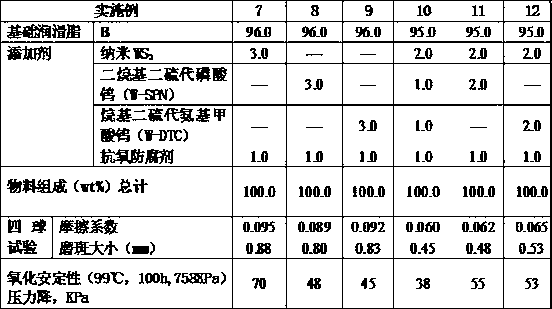

Complex aluminum-based grease composition and preparation method thereof

The invention relates to a complex aluminum-based grease composition, in particular relates to a high-temperature grease composition of a tungsten-containing compound and a preparation method thereof. The complex aluminum-based grease composition comprises a base grease composition consisting of the following components in percentage by weight: 80-95% of base oil and 5-20% of composite aluminum-based thickening agent; based on the total weight of the base grease composition, the complex aluminum-based grease composition further comprises the following components in percentage by weight: 0.1-5% of nanometer tungsten disulfide (WS2), 0.1-5% of oil-soluble organic tungsten compound, and 0.5-2% of anti-oxygen preservative. The composite aluminum soap thickening agent is generated through reaction among aromatic acid, fatty acid and aluminum isopropoxide tripolymer. According to the invention, since the nanometer WS2 and the oil-soluble organic tungsten are added to the complex aluminum-based grease, excellent extreme-pressure anti-wear property is achieved,and high-temperature load-carrying property and anti-oxidation property of the grease can be improved.

Owner:SHENZHEN EUBO NEW MATERIAL TECH

Wear-resistant SCR (Selective Catalytic Reduction) denitration catalyst and preparation method thereof

ActiveCN103240078AImprove compactnessHigh hardnessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsWear resistantAmmonium metatungstate

The invention discloses a wear-resistant SCR (Selective Catalytic Reduction) denitration catalyst and a preparation method thereof. The wear-resistant SCR denitration catalyst comprises the following main components in parts by weight: 80-90 parts of titanium dioxide, 0.5-3 parts of vanadium pentoxide, 3-7 parts of tungsten trioxide, 1-5 parts of aluminum oxide and 3-8 parts of silicon dioxide. The preparation method comprises the following steps of: (1) adding aluminum isopropoxide into a nitric acid solution to prepare hydrated alumina sol; (2) uniformly and dryly mixing the titanium dioxide powder, ammonium metavanadate powder and ammonium metatungstate powder, then adding the hydrated alumina sol, deionized water and oxalic acid, and mixing and stirring the mixture; (3) adding silica sol into the material obtained in the step (2); (4) uniformly mixing the material obtained in the step (3), and then, adding a structure promoter; and (5) extruding the material obtained in the step (4), and drying and roasting the carrier blank. The wear resistant property of the wear-resistant SCR denitration catalyst disclosed by the invention is improved by 20-40%, and the service life of the catalyst is prolonged.

Owner:CHONGQING YUANDA CATALYST MFG

Method for preparing high-purity pseudo-boehmite

ActiveCN104192880ALow toxicityImprove responseAluminium oxides/hydroxidesHydrolysateSubstance amount

The invention belongs to the technical field of inorganic materials and relates to a method for preparing high-purity pseudo-boehmite. The method for preparing the high-purity pseudo-boehmite comprises the following steps: under the condition of stirring, adding hydrolysate containing a pore-forming agent into an aluminium isopropoxide-isopropanol solution according to a given ratio, and carrying out hydrolysis reaction at the temperature of 60-80 DEG C for 2-8 hours, wherein the hydrolysate containing the pore-forming agent is prepared from deionized water and isopropanol in a mass ratio of 1:(0.5-3) and in ratio by amount of substance of (2-20):1; drying hydrolysis products at the temperature of 60-260 DEG C, so that the high-purity pseudo-boehmite is obtained. The method for preparing the high-purity pseudo-boehmite has the advantages that no waste is discharged in the whole preparation process, and an environment-friendly technology is realized; and meanwhile, a reaction flow is simple, and control is easy.

Owner:DALIAN UNIV OF TECH

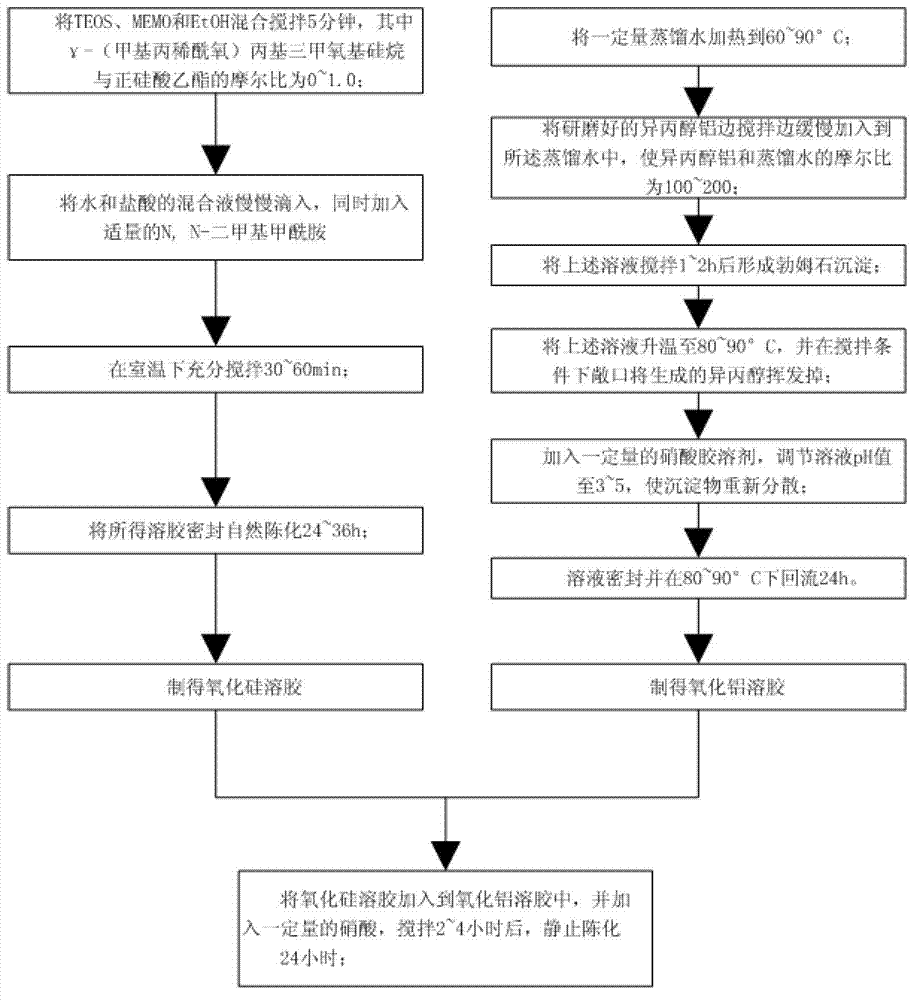

Composite sol and method for preparing material for anti-radiation space suit by use of same

InactiveCN102964993AGuaranteed stabilityGuaranteed compactnessFibre treatmentCoatingsN dimethylformamideSilicon oxide

The invention relates to composite sol and a method for preparing a material for an anti-radiation space suit by use of the same. The silicon oxide-aluminum oxide composite sol comprises silicon oxide sol and aluminum oxide sol; the silicon oxide sol comprises tetraethoxysilane, gamma-(methacryloxy)propyltrimethoxylsilane, absolute ethyl alcohol, hydrochloric acid and N,N-dimethylformamide; and the aluminum oxide sol comprises aluminum isopropoxide, distilled water and nitric acid. Meanwhile, the invention also relates to a material for a space suit prepared by use of the silicon oxide-aluminum oxide composite sol and a preparation method. Through the composite sol provided by the invention, a space composite structure is formed between silicon oxide and aluminum oxide to guarantee the stability, density and flexibility of a membrane layer; after irradiation in a space radiation environment, the generation of cracks and micropores is avoided on the surface of the aluminum oxide-silicon oxide composite membrane; and the material for an anti-radiation space suit can bear long-time radiation in the space radiation environment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Desulphurization and denitration catalyst and preparation method thereof

InactiveCN101518736AWide variety of sourcesEasy accessDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsParaffin waxCopper nitrate

The invention discloses a desulphurization and denitration catalyst. The catalyst comprises the following components by mass percentage: 4 to 18 percent of CuO, 80 to 95 percent of gamma-Al2O3, and 1 to 2 percent of promoter. A method for preparing the catalyst comprises the following steps: (1) adding aluminum isopropoxide into distilled water, stirring the mixture, adding a nitric acid solution into the mixture dropwise, and carrying out the evaporation in the air to obtain a boehmite sol; (2) adding the promoter into a copper nitrate solution, then adding the mixture into the boehmite sol, then adding the nitric acid solution dropwise, stirring the mixed solution for ageing, and aggregating the mixed solution into a semi-gel; and (3) adding the semi-gel dropwise into a gel pool containing ammonia water and liquid paraffin through a dropper, and obtaining the catalyst after ageing, drying and baking. The prepared catalyst can be used for synchronous desulphurization and denitration, and can be regenerated and used cyclically with low raw material cost. As the byproducts can be reutilized, the catalyst brings about no secondary pollution.

Owner:HUAZHONG UNIV OF SCI & TECH

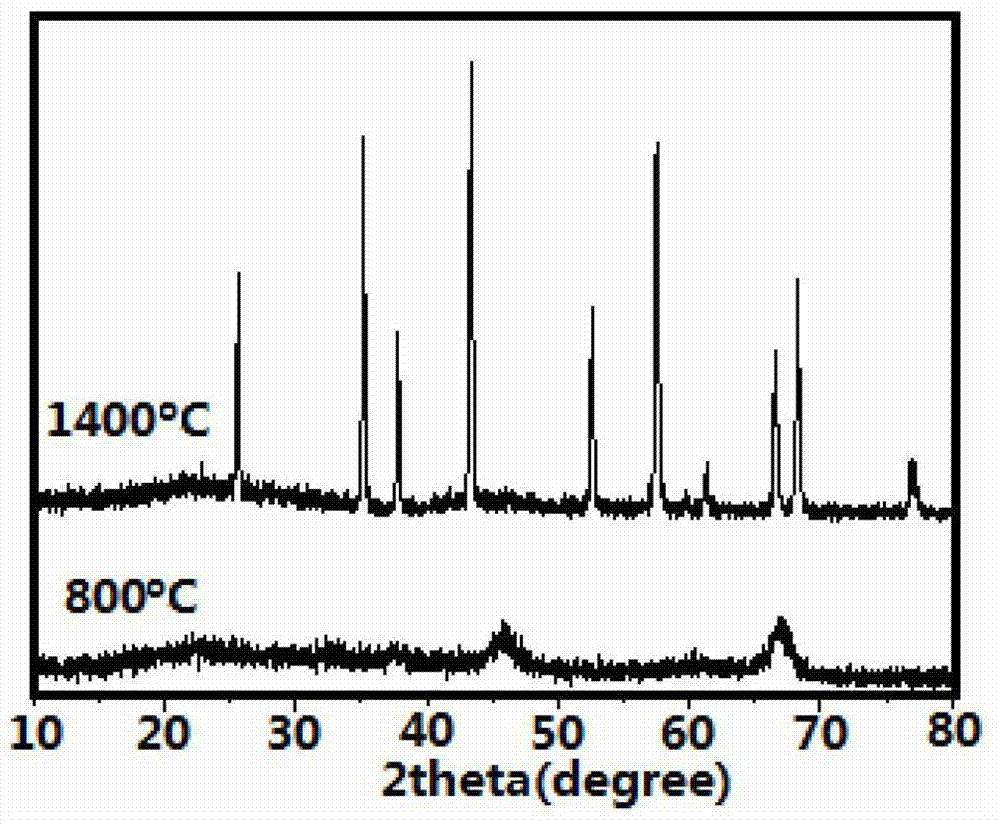

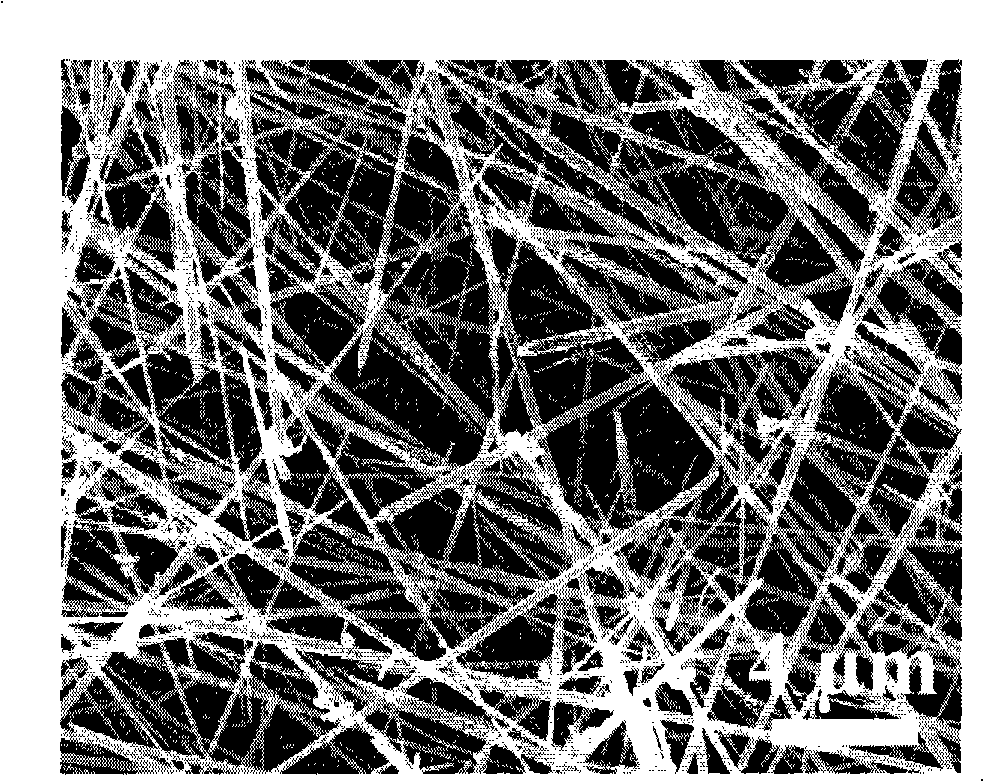

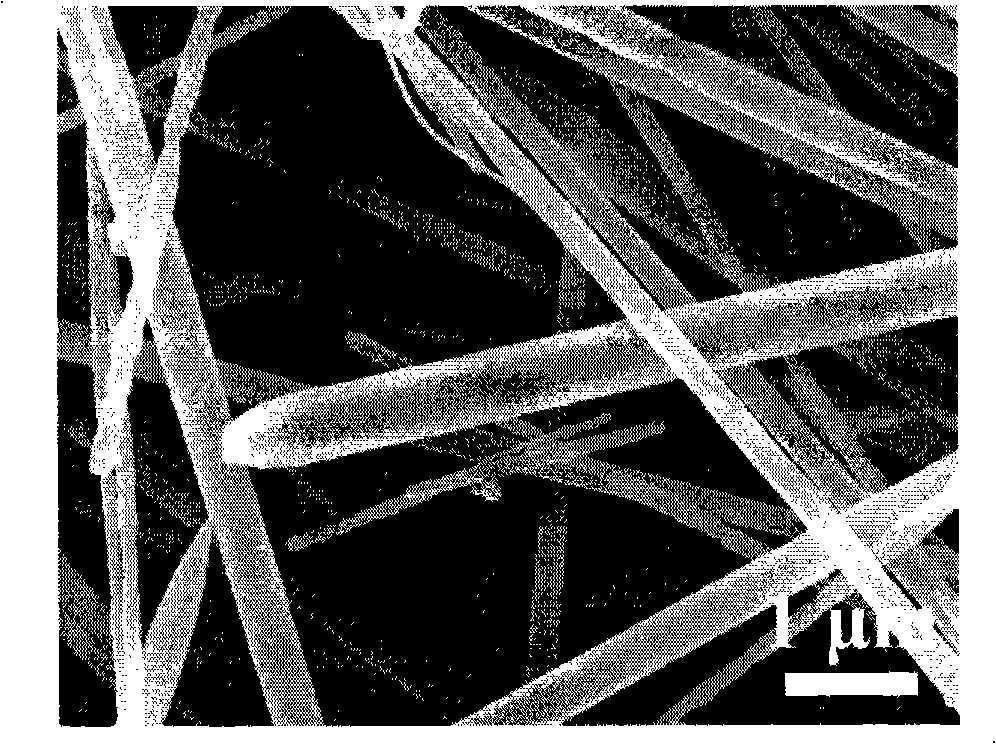

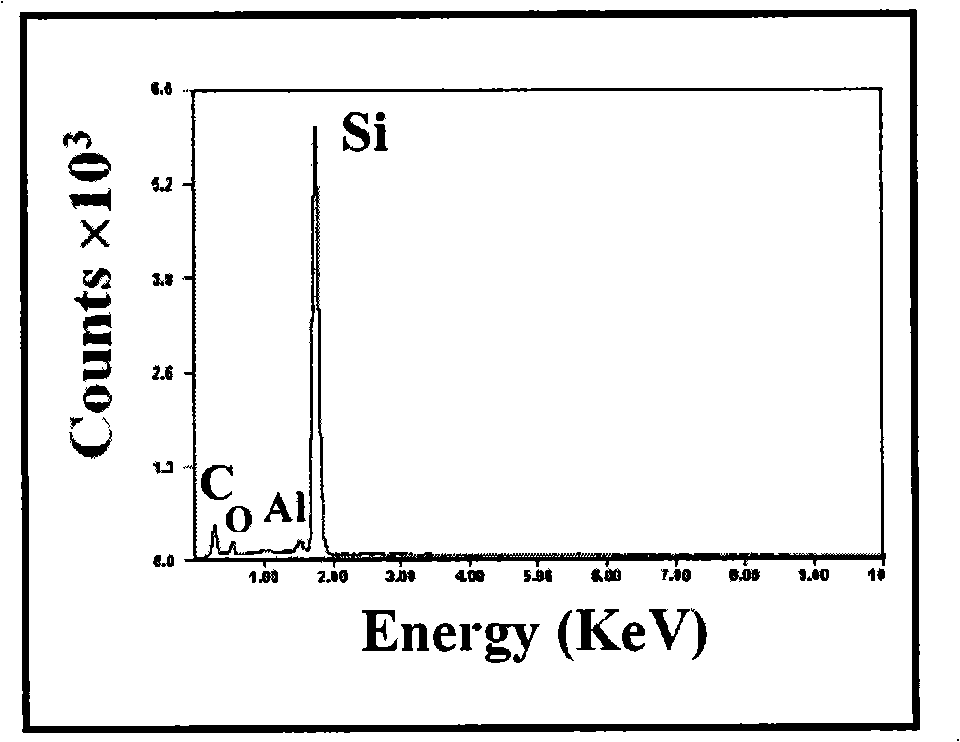

Controllable doping of SiC single crystal low-dimensional nano material

InactiveCN101311378AAchieving controllable dopingSimple processPolycrystalline material growthSingle crystal growth detailsCross-linkNano-device

The invention relates to a new method for realizing the controllable doping of SiC single crystal low dimensional nano material by co-pyrolyzing organic precursors, which comprises the following concrete steps: (1) ball milling and well mixing two organic precursors PSZ and aluminum isopropoxide according to different proportions; (2) after mixing, cross-linking and solidifying the precursors to obtain amorphous solid; (3) putting the amorphous solid into a nylon resin ball milling tank and introducing a catalyst, and carrying out ball milling in a ball mill; (4) high temperature pyrolyzing the milled mixture. The method can realize the controlling and designing of the doping level of SiC single crystal low dimensional nano material on molecular level, therefore, the control of properties such as photoelectricity, and the like, of the SiC single crystal low dimensional nano material is realized and certain foundation for developing nano devices thereof is laid.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Preparation method of quaternary xerogel

The invention relates to a preparation method of SiO2-TiO2-Al2O3-ZrO2 quaternary xerogel, which adopts tetraethoxysilane, zirconium Oxychloride, aluminium iso-propoxide, Tetrabutyl orthotita, ammonia water and ethanol as main raw materials; during the preparation process of the SiO2 xerogel, the compositions of Al2O3, TiO2 and ZrO2 are firstly simultaneously introduced by adopting the sol-gel method, and the net skeleton strength of the gel is improved by adjusting the proportion of different raw materials and controlling the formation condition of the gel. The formation of the gel is characterized in that: aluminium iso-propoxide and zirconium Oxychloride hydrolysate and the tetraethoxysilane and tetrabutyl orthotita hydrolysate are respectively prepared by a two-step method according to the properties of the raw materials, and the gel is prepared under a given condition after mixing the aluminium iso-propoxide and zirconium Oxychloride hydrolysate and the tetraethoxysilane and tetrabutyl orthotita hydrolysate. The SiO2-TiO2-Al2O3-ZrO2 quaternary xerogel can be prepared under the condition of the atmospheric pressure of 50 DEG C through the aging, dipping and washing and hydrophobic modification treatment. The quaternary xerogel can be used for the heat preservation and the heat insulation. The analysis of the instruments approves that: the porosity of the prepared xerogel can reach 90 percent, the specific surface area is 190 to 210m2 / g, and the wetting angle of the water is more than 130 degrees in the air.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com