A preparation method of a sol-gel catalyst for deep removal of a small amount of hydrogen in industrial CO gas

A technology of sol-gel and catalyst is applied in the field of preparation of sol-gel catalyst to achieve the effects of superior catalytic performance, solving purification problems and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

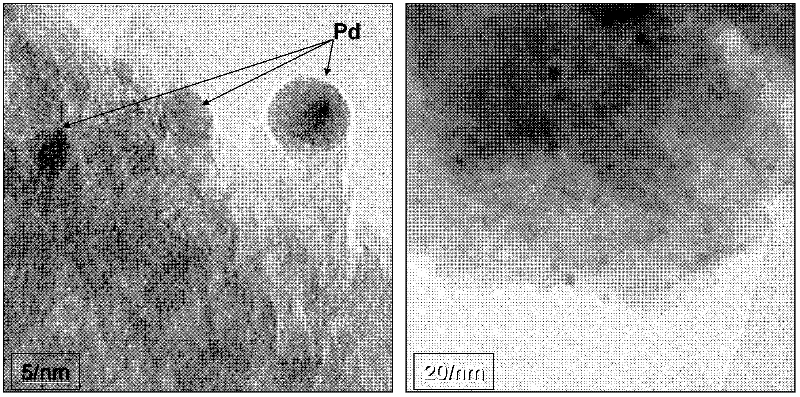

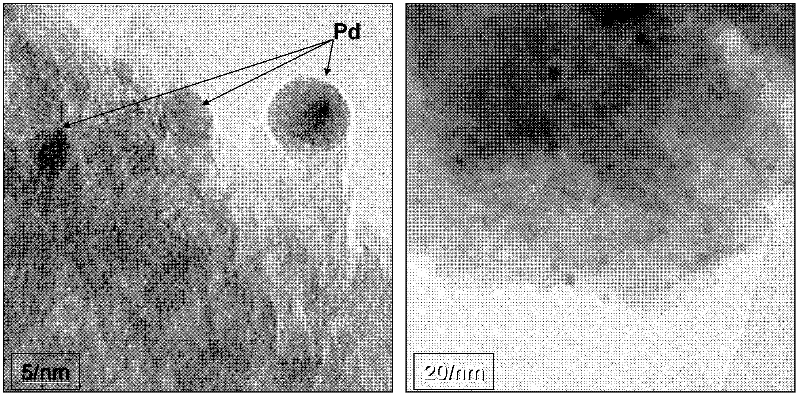

Image

Examples

example 1

[0022] Weigh 44.8 g of aluminum isopropoxide and grind it into powder with a mortar, put it into a pre-washed and dried beaker, add about 800 g of deionized water, put it in a heat-collecting water bath, and hydrolyze it at 80 °C for 3 h, and the hydrolysis is complete After evaporating the water to dryness, add 55.2 ml of dilute nitric acid (1 mol / L), stir evenly, add about 750 g of deionized water, and seal and age the solution at 80 ℃ for 18 h to obtain a clear sol solution. Dissolve 0.078 g of palladium chloride in 8 ml of dilute hydrochloric acid (1 mol / L) to prepare a chloropalladium acid solution. The chloropalladium acid solution was dropped into the sol, stirred evenly for 1 h, and evaporated at 90 °C for 8 h to get the catalyst precursor. The precursor was put into an oven for two stages of drying at 80 °C and 120 °C, then placed in a muffle furnace for 5 h at 350 °C and cooled to room temperature to obtain the desired dehydrogenation catalyst. Take 10 ml of catalys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com