Preparation method of aluminum oxide ceramic continuous fiber

A technology of alumina ceramics and continuous fibers, applied in the direction of artificial filaments made of inorganic materials, can solve the problems of no longer dense fibers, voids in fibers, and reduced strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

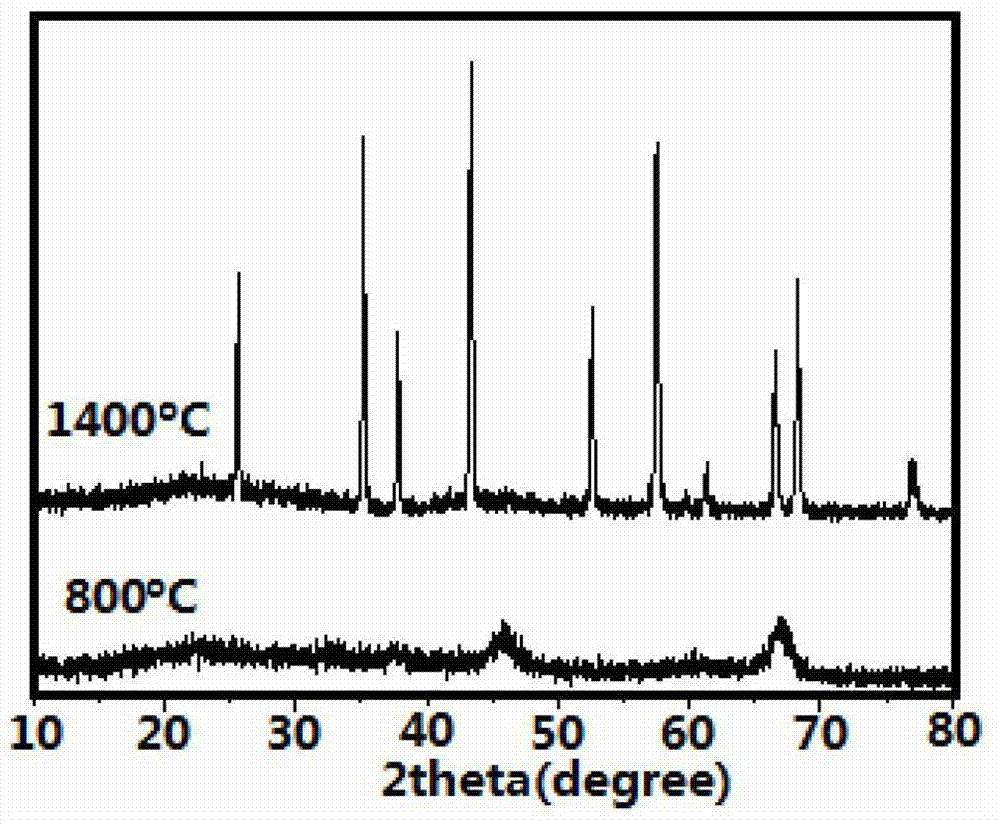

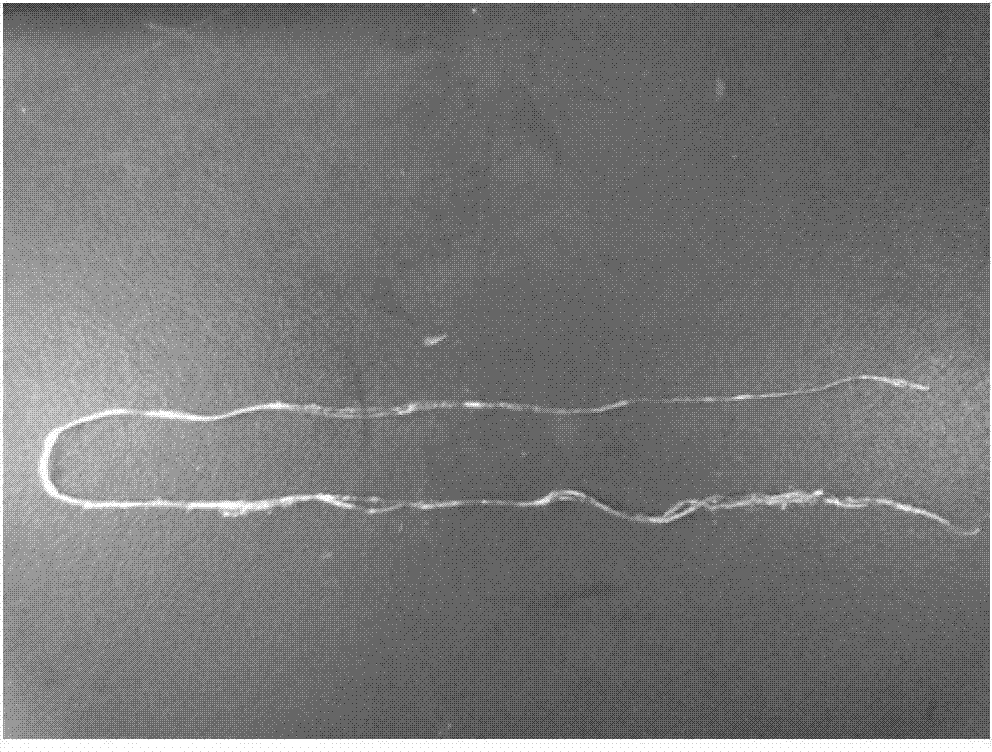

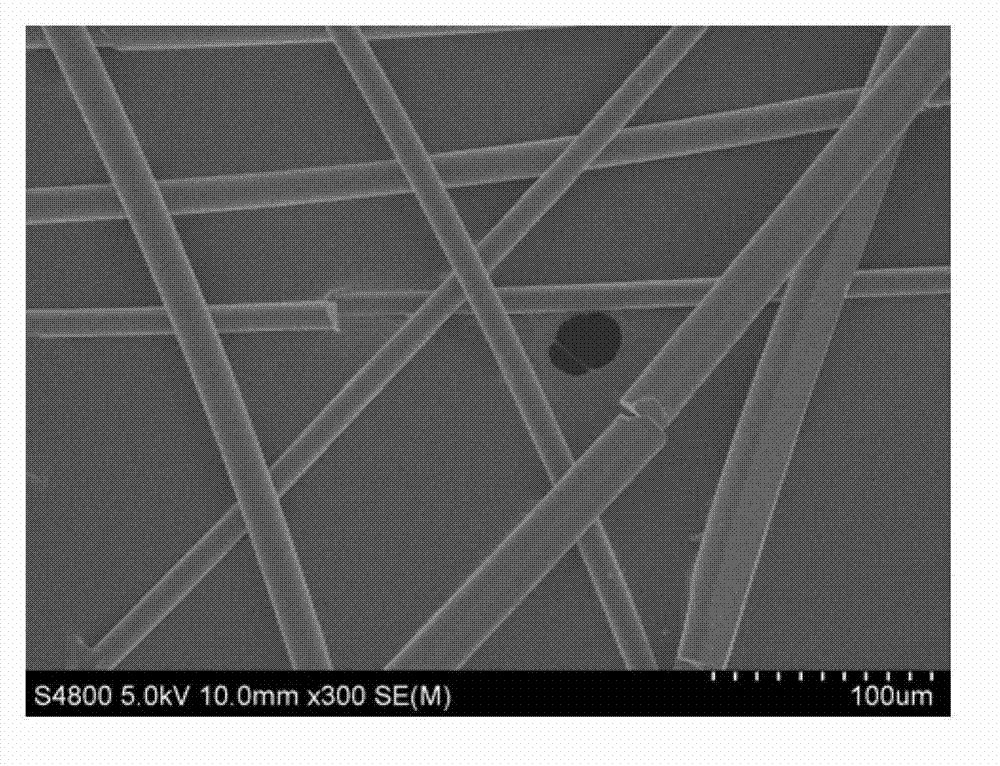

[0009] A method for preparing alumina ceramic continuous fibers, comprising the following steps:

[0010] ⑴ aluminum salt (AlCl 3 ·6H 2 O and Al(NO 3 ) 3 9H 2 (2) and aluminum isopropoxide are added to the dilute nitric acid solution, and grain inhibitors are optionally added, refluxed and stirred until the solution is transparent, then heated at 75 to 90°C, and aluminum powder is added, reacted until the aluminum powder is completely dissolved, The transparent solution is aged in a water bath at 60°C until the viscosity is 50-900Pa·s to obtain a sol; wherein,

[0011] Aluminum salt (AlCl 3 ·6H 2 O and Al(NO 3 ) 3 9H 2 The mass ratio of the total amount of O) to aluminum isopropoxide is (1.4~3.1):1, wherein AlCl in the aluminum salt 3 ·6H 2 O and Al(NO 3 ) 3 9H 2 The mass ratio of O is (1.3~1):(1~3); the mass ratio of aluminum salt to aluminum powder is (1.5~6):1, and the amount of grain inhibitor added accounts for 0~4% of the total weight of raw materials.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com