Quick synthesis method for nano-scale ZSM-5 molecular sieve

A technology of ZSM-5 and synthesis method, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of unfavorable industrial production, expensive raw materials, and long time consumption, and achieve low cost and raw materials. Easy to get, prevent further growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

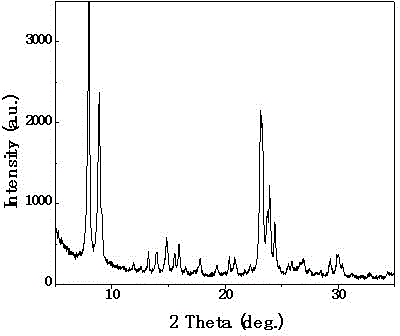

Embodiment 1

[0024] Embodiment 1: The rapid synthesis method of this nano-scale ZSM-5 molecular sieve adopts the following process steps.

[0025] (1) Preparation of dry gel seed crystals: first mix 0.4085g of aluminum isopropoxide, 7.0180g of water and 14.6426g of tetrapropylammonium hydroxide (25%wt) to make solution A, then mix 12.4998g of orthosilicate Ethyl ester was added dropwise into solution A under vigorous stirring to obtain solution B, wherein the molar ratio of aluminum source, silicon source, tetrapropylammonium hydroxide and water was Al 2 o 3 :SiO2 2 :TPAOH:H 2 O=1:60:18:1000; continue to stir solution B until it is uniformly mixed and adjust the pH value to 12.5, then stir and age for 6 hours; then dry the aged sol-gel at 80°C to dry gel, Grinding the dry glue into powdery dry glue powder to obtain dry glue seeds;

[0026] (2) First mix 1.506g of aluminum nitrate (nine water) and 23.4g of water to make solution I, and then mix 53.263g of water glass (SiO 2 Content 27....

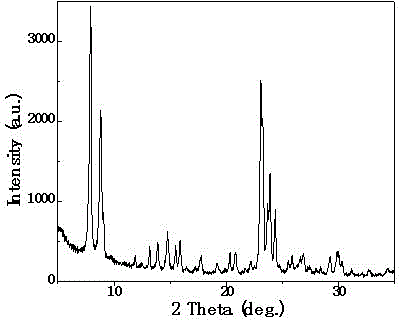

Embodiment 2

[0030] Embodiment 2: The rapid synthesis method of this nano-scale ZSM-5 molecular sieve adopts the following process steps.

[0031](1) The preparation method of dry rubber seed crystals is the same as in Example 1 except for the following differences: Stir solution B until it is uniformly mixed and adjust the pH value to 12; stir and age for 4 hours; the aged sol-gel is at 70 ℃ drying into dry glue;

[0032] (2) First mix 1.137g of aluminum chloride (hexahydrate) and 46.8g of water to make solution I, then mix 26.031g of water glass (SiO 2 Content 27.5wt%) was slowly added to solution I under vigorous stirring to obtain solution II, wherein the molar ratio of aluminum source, silicon source and water was Al 2 o 3 :SiO2 2 :H 2 O=1:30:1300; continue to stir solution II until uniformly mixed and adjust the pH value to 12, stirring for 1h;

[0033] (3) Add dry rubber seeds with a final ZSM-5 molecular sieve yield of 5% to the mixed solution, and stir for 1 hour to make it e...

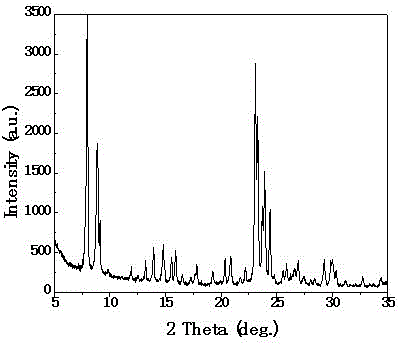

Embodiment 3

[0036] Embodiment 3: The rapid synthesis method of this nano-scale ZSM-5 molecular sieve adopts the following process steps.

[0037] (1) The preparation method of dry rubber seed crystals is the same as in Example 1 except for the following differences: Stir solution B until it is uniformly mixed and adjust the pH value to 13; stir and age for 2 hours; the aged sol-gel is at 60 ℃ drying into dry glue;

[0038] (2) First mix 1.666g of aluminum sulfate (octadecane water) and 38.25g of water to form solution I, then mix 44.386g of water glass (SiO 2 Content 27.5wt%) was slowly added to solution I under vigorous stirring to obtain solution II, wherein the molar ratio of aluminum source, silicon source and water was Al 2 o 3 : 40 SiO 2 : 850H 2 O: Continue to stir solution II until it is evenly mixed and adjust the pH value to 12.5, stirring for 1 hour;

[0039] (3) Add dry rubber seeds with a final ZSM-5 molecular sieve yield of 3% to the mixed solution, and stir for 2 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com