Ink scraping structure of oil printing equipment

A kind of equipment and ink technology, applied in the field of printing industry, can solve the problems of easy accumulation and dripping, affecting the integrity of the roller and ink, and more ink, etc., to achieve the effect of complete inking, clear text or pattern, and stable ink level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

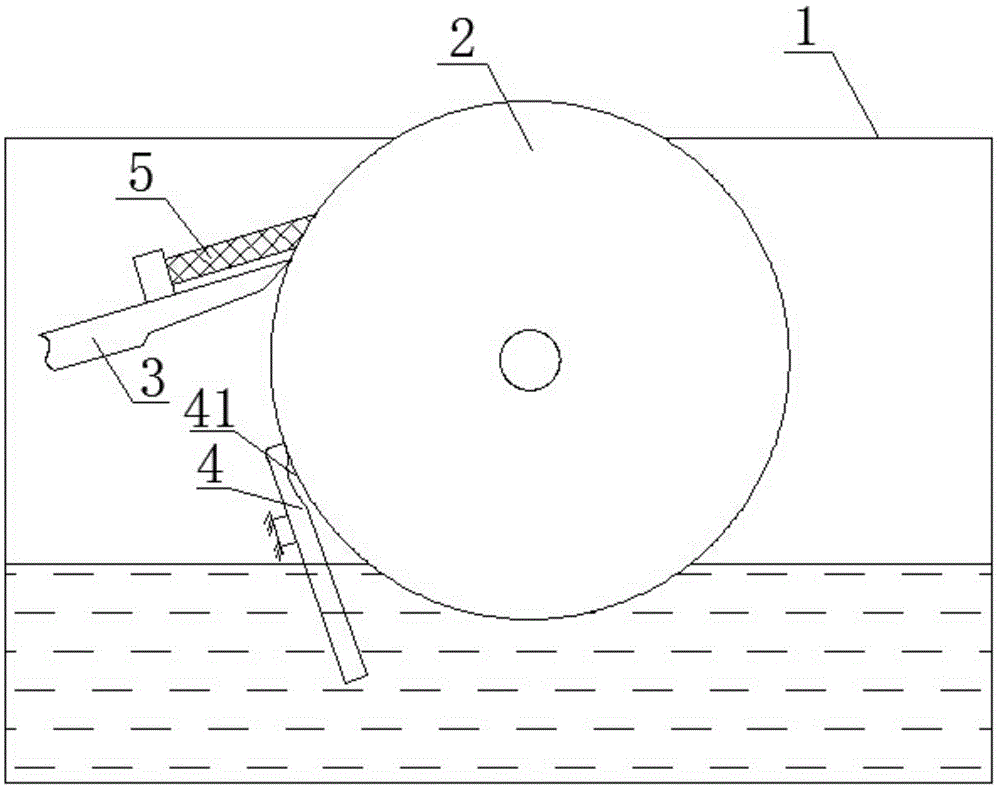

[0013] Such as figure 1 As shown, a scraping structure of mimeograph equipment includes an ink tray 1 containing ink, a roller 2 partially submerged in the ink tray 1, and a main scraper 3 cooperating with the roller 2. The main scraper 3 is installed on the Near the upper end of 2, there is also a lower scraper 4. The middle position of the lower scraper 4 is fixedly connected to the inner wall of the ink tray. The lower scraper 4 is set near the top of the ink liquid surface. Immersed in the ink in the ink tray 1; the scraping angle of the lower scraper 4 is 0° to 10°; the upper end of the lower scraper 4 is attached to the roller 2 and has an arc-shaped groove 41 that deviates from the roller 2; the main scraper 3 ends Head is connected with auxiliary scraper 5, and the material of auxiliary scraper 5 is rubber, and auxiliary scraper 5 head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com