Liquid level-pressure coordinated control method used for gas-liquid separator

A technology of gas-liquid separator and gas-phase pressure, applied in non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve the adverse effects of electric submersible pumps, cannot provide stable pressure, and unfavorable liquid level stability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

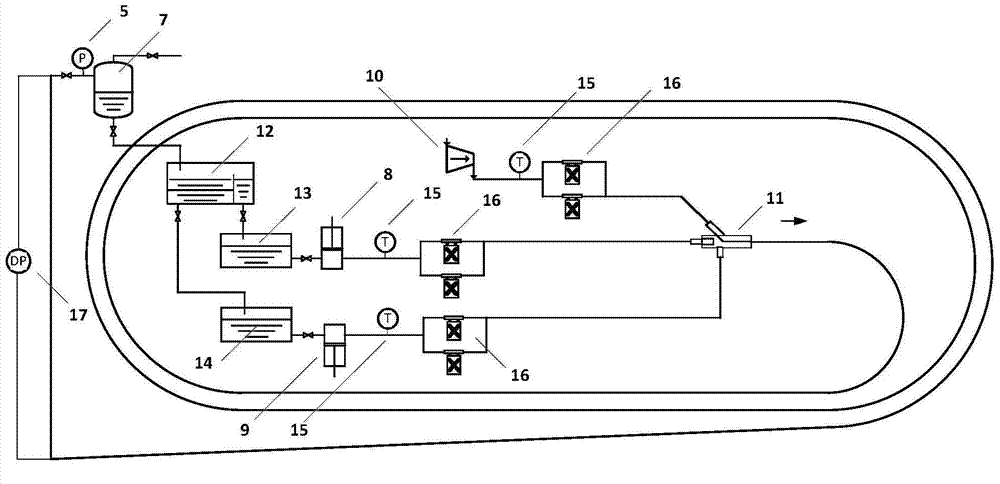

[0077] Example: such as image 3 As shown, a gathering and transportation-riser oil-gas-water multiphase flow experimental system including a gas-liquid separator 7 and a liquid level-pressure linkage control device is set up. The system also includes a plunger oil pump 8, a plunger water pump 9, an air compressor 10. Gas-liquid mixer 11, oil-water separator 12, oil tank 13 and water tank 14. The plunger oil pump 8, the plunger water pump 9, and the air compressor 10 are respectively connected to the inlet of the gas-liquid mixer 11 through the gathering pipeline, and the outlet of the gas-liquid mixer 11 is connected to the gas-liquid inlet port of the gas-liquid separator 7 through a standpipe. connection, the liquid phase outlet of the gas-liquid separator 7 is connected to the inlet of the oil-water separator 12 through the gathering pipeline, the oil outlet of the oil-water separator 12 is connected to the inlet of the oil tank 13, the outlet of the oil tank 13 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com