Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Bonding problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing magnetizable ceramic

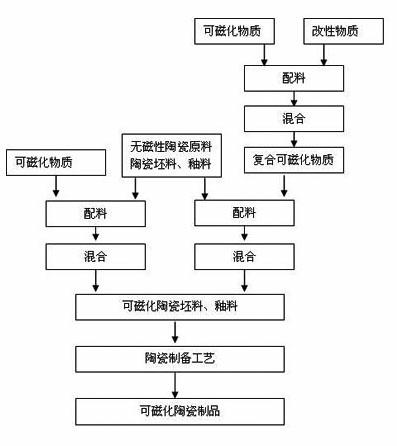

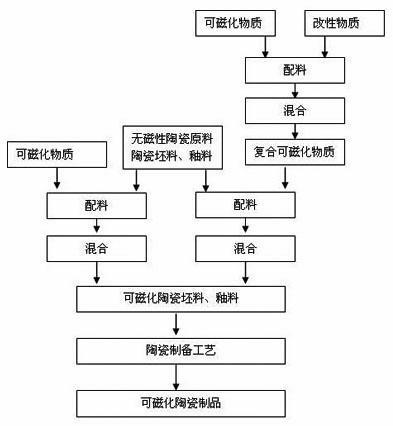

The invention discloses a method for preparing magnetizable ceramic. The method is characterized in that: a magnetizable substance is added into nonmagnetic ceramic powder, and a magnetizable ceramic product is prepared by adopting a ceramic preparation process; and the ceramic preparation process comprises proportioning, blending, shaping and sintering. The magnetizable substance is directly added into the ceramic raw materials, and the magnetizable substance is sintered in a ceramic body by a ceramic high-temperature sintering process at the same time of keeping the original magnetizable property, so that the bonding problem of the magnetizable substance and the ceramic product is solved, the process is simple, the preparation is convenient, and the method has good popularization value.

Owner:FOSHAN CERAMIC R & D CENT SHANGHAI INST OF CERAMICS CHINESE ACAD OF SCI

Method for making fluxed iron ore powder composite pellet

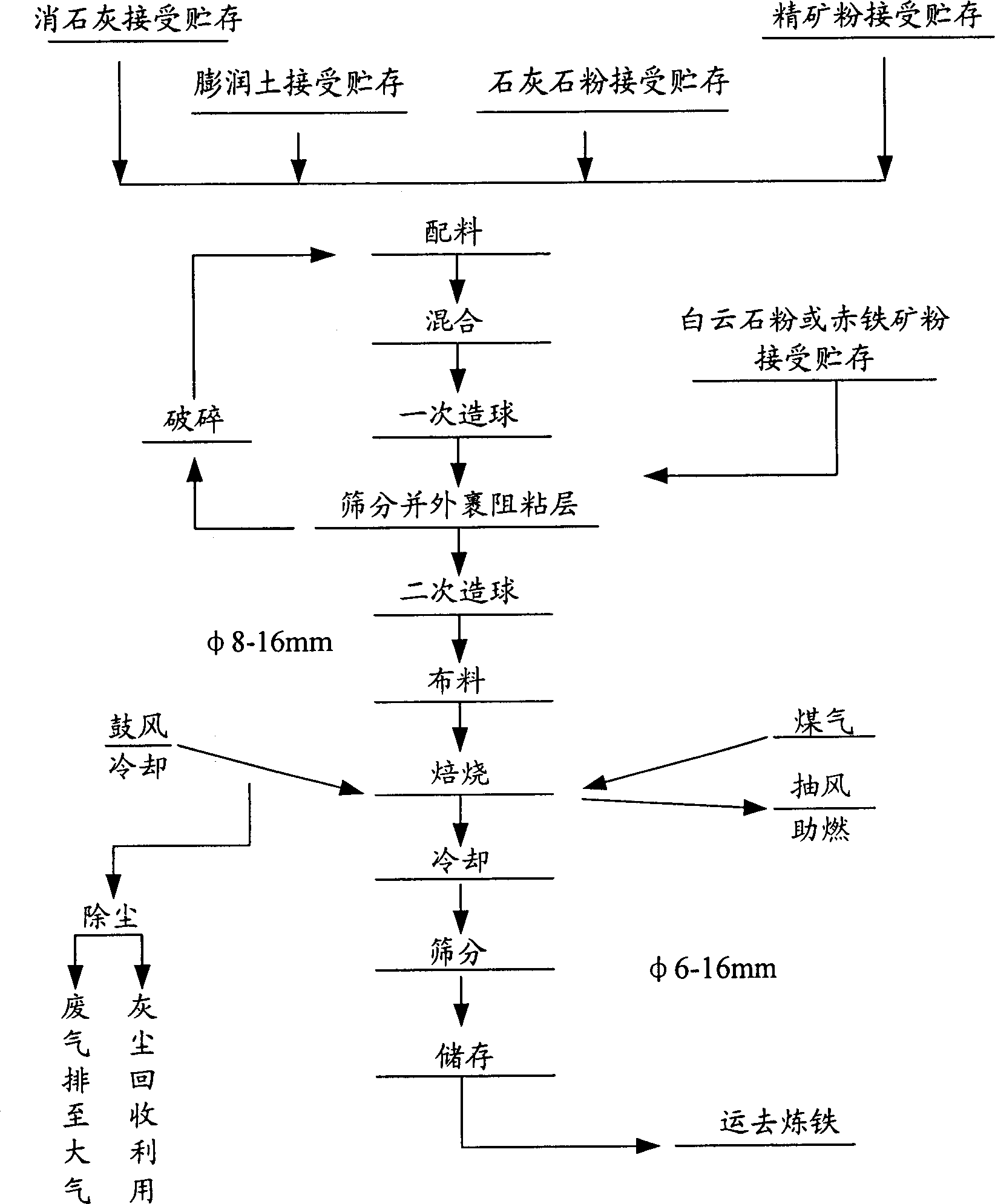

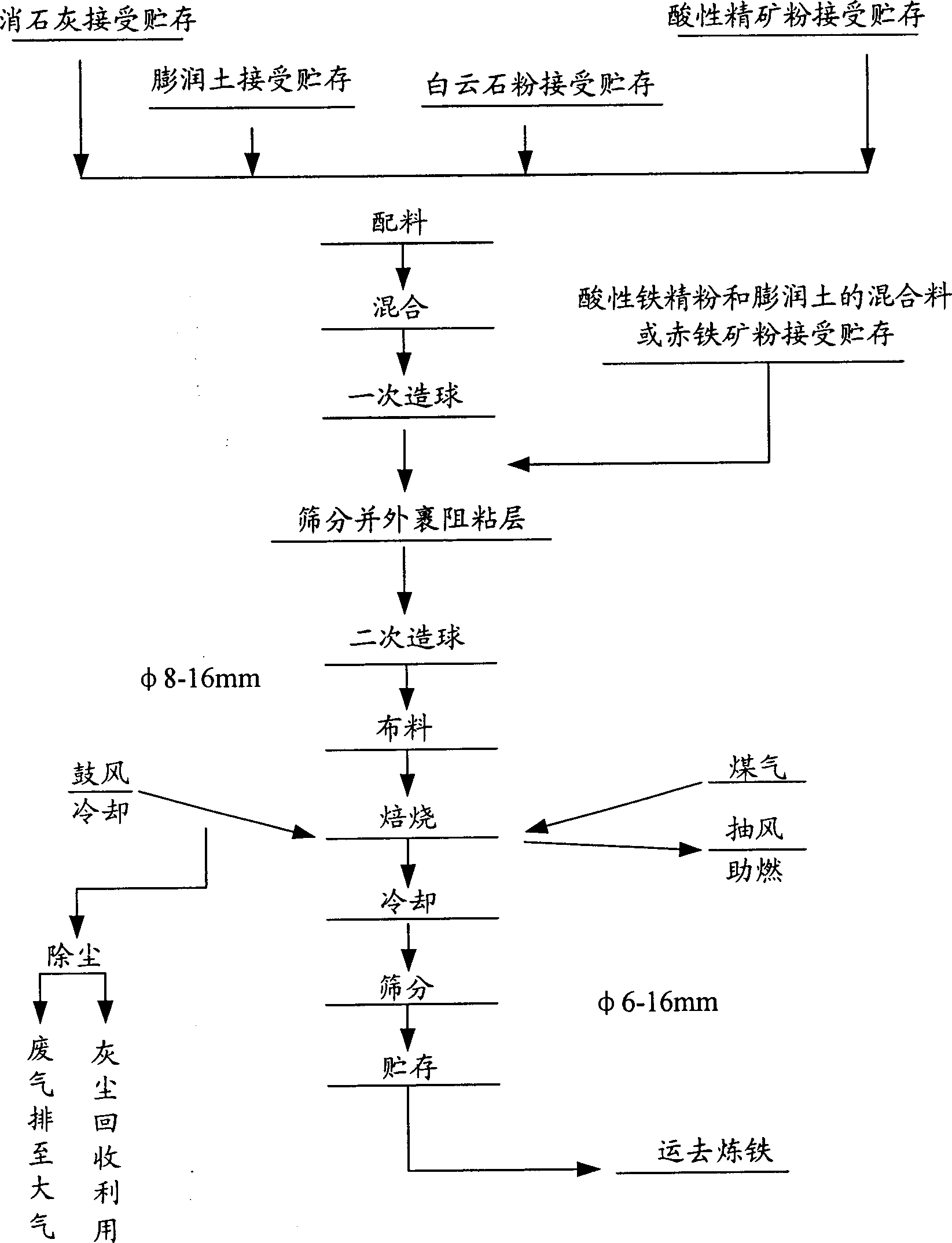

The preparation method for a solvent-type iron ore composite aggregate comprises: ensuring the proper CaO and 2-4% MgO with weight o.5-2.0 in the first process; then coming the secondary time, wrapping one block layer evenly of CaCo3 powder, dolomite powder, hematite dried powder or acidic iron concentrate ore; then, baking as the acidic aggregate baking temperature and means to ensure the ore not bond. This invention overcomes bonding problem with low cost and little pollution, and improves blast furnace yield even meets the pH balance or desulfurization request.

Owner:许贵宾

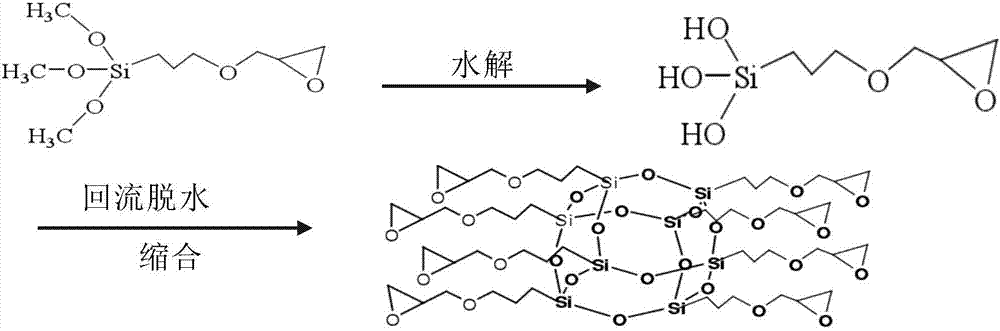

Silanization treatment method before coating of steel piece

InactiveCN102094194AAccelerated corrosionImprove anti-aging propertiesMetallic material coating processesEpoxyPretreatment method

The invention relates to a silanization treatment method before coating of a steel piece, in particular to a pretreatment method which is cheap, simple in operation, environmentally-friendly and pollution-free and effectively improves the bonding strength of the steel piece and a subsequent organic coating. The method solves the bonding problem of the steel piece and the coating in the prior art. The method comprises the following steps of: performing pretreatment such as surface grinding, polishing, degreasing and the like on the steel piece; and then performing silanization treatment on the degreased workpiece, wherein a silane film obtained on the surface of the workpiece has functional group components such as epoxy group, amino group and the like matched with the coating. By the method, chemical bonding of the subsequent coating and the steel piece is realized by silanization treatment, the bonding force of the coating is improved, no slag is produced in the treatment process, treatment time is short, and the method is simple and convenient to control; and the treatment step is few, surface conditioning and passivation processes can be saved, and bath solution is long in service life and simple in maintenance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

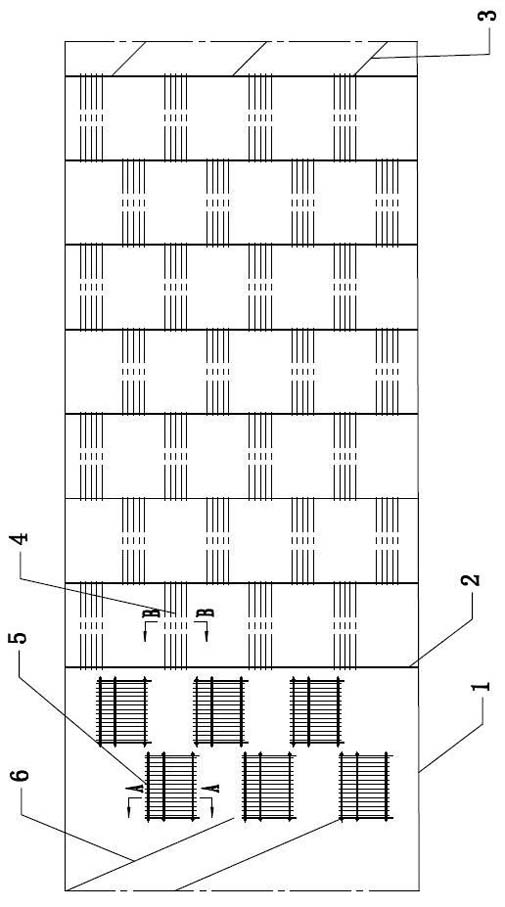

Composite type pavement structure and pavement method thereof

ActiveCN101597878AImprove fatigue resistanceIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelRoad engineering

The invention discloses a composite type pavement structure and a pavement method, and relates to a road engineering structure and a construction method thereof. In the invention, the thermal expansion coefficient, the cement concrete and the fiber-reinforced composite material substrate which performance is near to the steel plate are adopted to reinforce for the bottom surface of the asphalt layer; thus improving the performance of anti-fatigue and anti-reflecting crack of the asphalt surface course, effectively preventing the lower bearing layer from being eroded due to infiltration of the rain water from the asphalt surface course, avoiding bonding problem between the asphalt surface course and the cement concrete or the steel plate, increasing stiffness of the steel bridge surface, and particularly reinforcing the steel bridge surface the steel plate of which has insufficient thickness, so as to reduce the thickness of the asphalt surface course, avoid the damages, such as cracking and falling of the asphalt pavement layer caused by the insufficient thickness of the steel bridge surface and the like.

Owner:广州大象超薄路面技术开发有限公司

Fluorine-containing nanoparticles with high dispersibility and bonding property and superamphiphobic surface

The invention discloses fluorine-containing nanoparticles with high dispersibility and bonding property and a superamphiphobic surface prepared from the nanoparticles. The fluorine-containing nanoparticles with high dispersibility and bonding property are prepared by the steps of grafting a fluorine-containing polymer with an upper terminal group to be a compound D on the surfaces of the nanoparticles, and reacting an epoxy resin polymer with a terminal group to be a compound A with the fluorine-containing polymer through a heat-breaking Diels-Alder reaction. The superamphiphobic surface disclosed by the invention is prepared by the steps of dispersing the fluorine-containing nanoparticles with high dispersibility and bonding property in a low-boiling-point fluorine-free solvent, uniformly mixing with an epoxy resin curing agent, carrying out spray coating on the surface of a substrate material, and carrying out vacuum drying. According to the fluorine-containing nanoparticles disclosed by the invention, the epoxy resin polymer with high dispersibility is introduced, as the epoxy functional group contained in the dispersing polymer can take place a curing reaction with the epoxy group by using the epoxy resin curing agent in the solvent to fix the fluorine-containing nanoparticles on the surfaces of most substrates, the bonding problem of the fluorine-containing nanoparticles on the substrate surface is solved.

Owner:中科瑞丽分离科技无锡有限公司

Oxygen supply sizing agent groove system and ceramic surface exposure 3D continuous printing method

ActiveCN105034138AUniform air pressureAvoid bondingAdditive manufacturing apparatusCeramic shaping apparatusBonding problemsSizing

The invention discloses an oxygen supply sizing agent groove system and a ceramic surface exposure 3D continuous printing method. The oxygen supply sizing agent groove system comprises an oxygen supply device, a base plate, a connecting pipe, an air-permeable thin film and a sizing agent groove which is of a cylindrical structure; an annular protrusion is horizontally arranged on the inner wall of the sizing agent groove, the upper surface of an annular groove is covered with the air-permeable thin film, the annular groove is formed in the lower surface of the annular protrusion, the base plate is fixed to the bottom of the sizing agent groove, an annular seal structure is defined by the annular groove and the base plate, and a seal chamber is defined by the base plate, the annular protrusion and the air-permeable thin film; multiple through holes are evenly formed in the side wall of the annular protrusion, the annular seal structure is communicated with the seal chamber through the through holes, one end of the connecting pipe is connected with the oxygen supply device, and the other end of the connecting pipe passes through the wall surface of the sizing agent groove and the side face of the annular groove and is inserted into the annual seal structure. By means of the oxygen supply sizing agent groove system, the bonding problem of ceramic biscuits and base plates can be effectively solved, and thereby the continuous ceramic printing is achieved.

Owner:陕西科陶增材智造科技有限公司

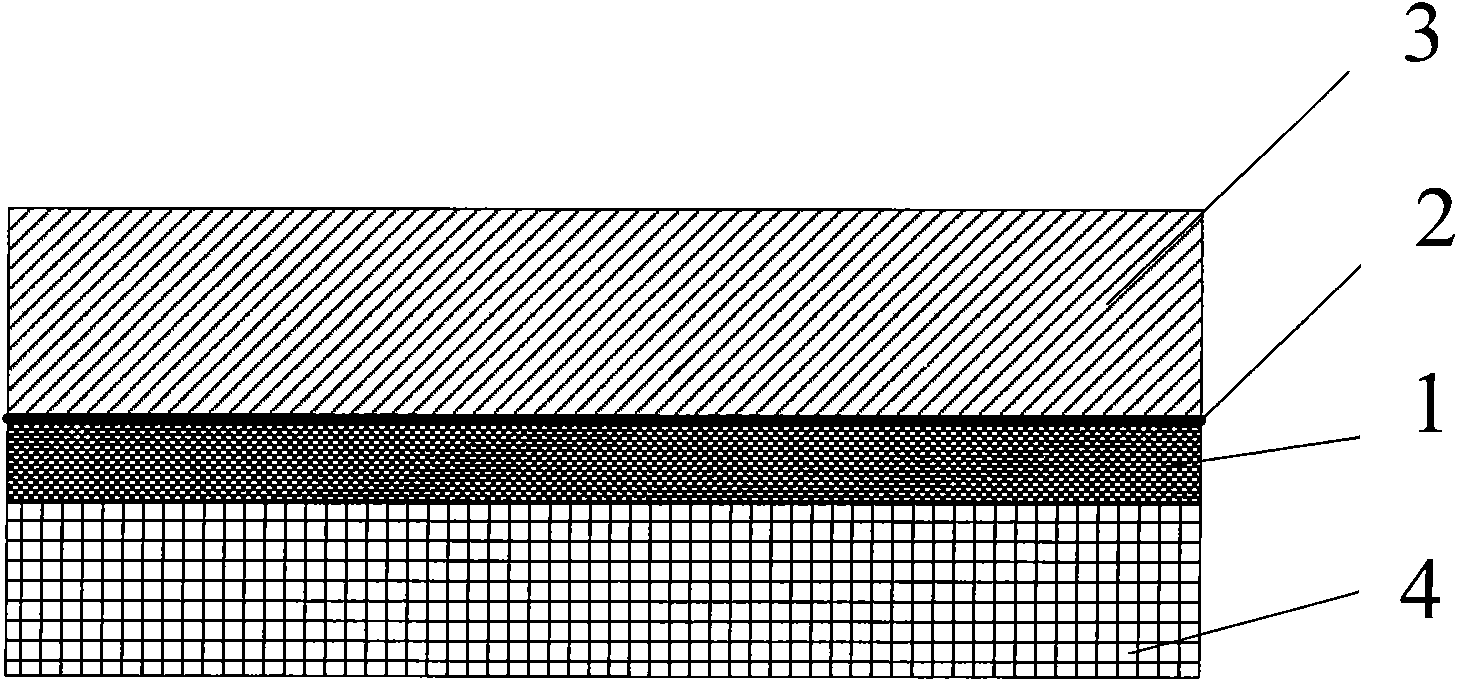

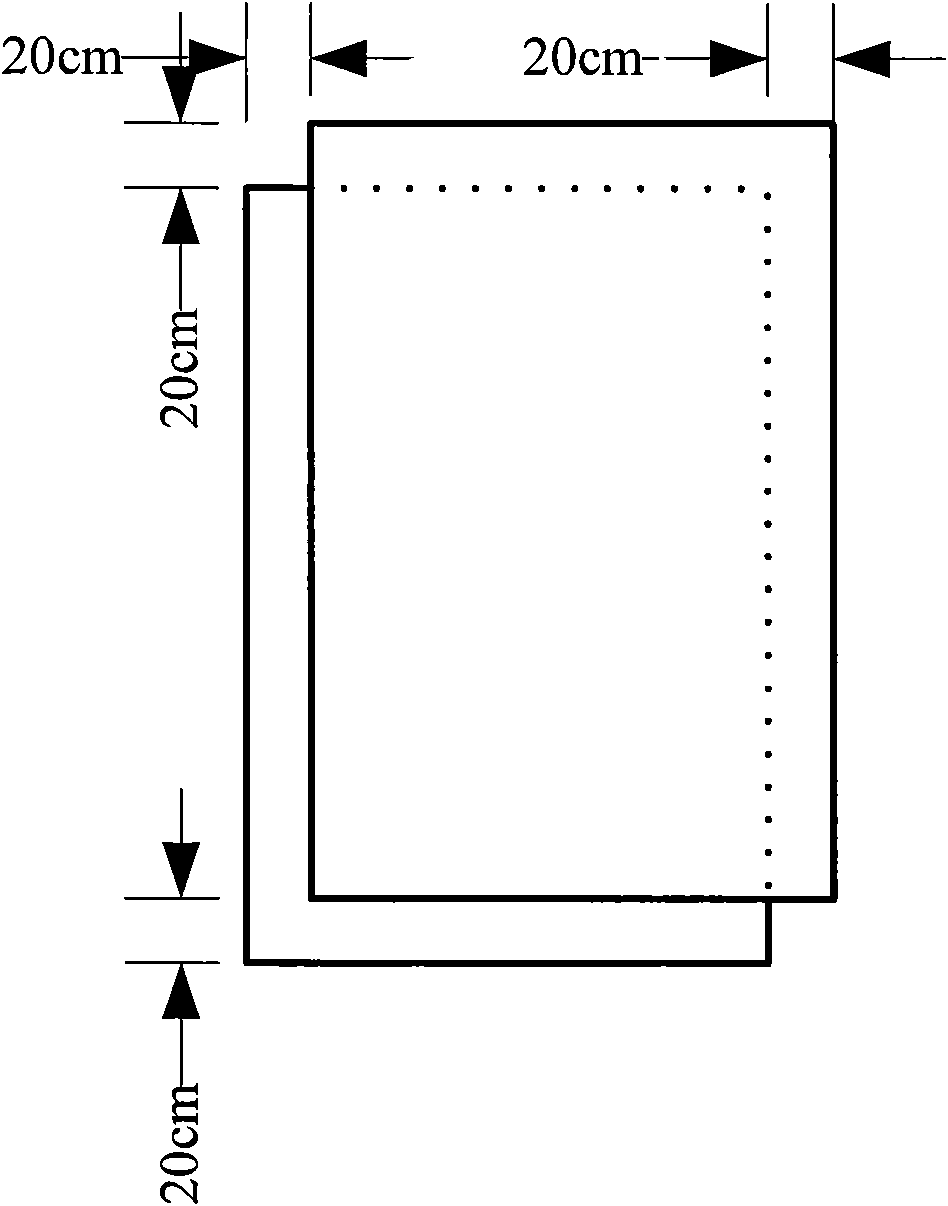

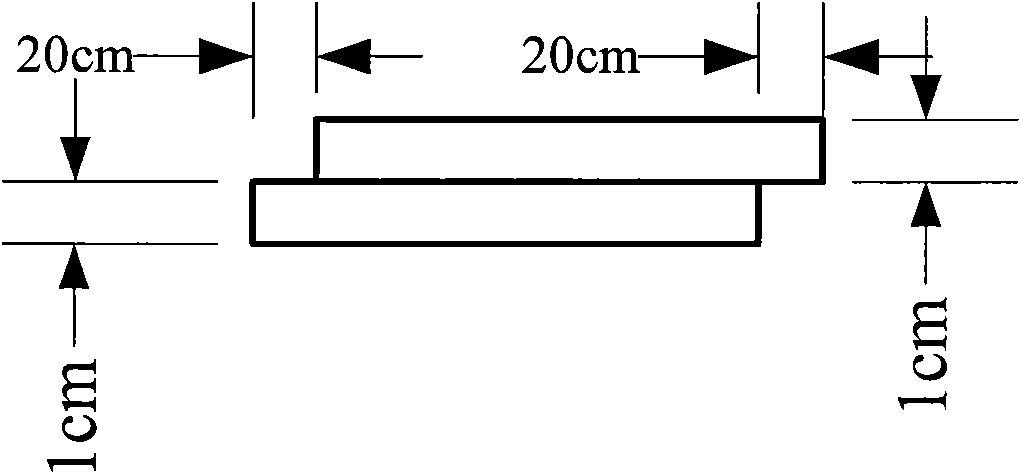

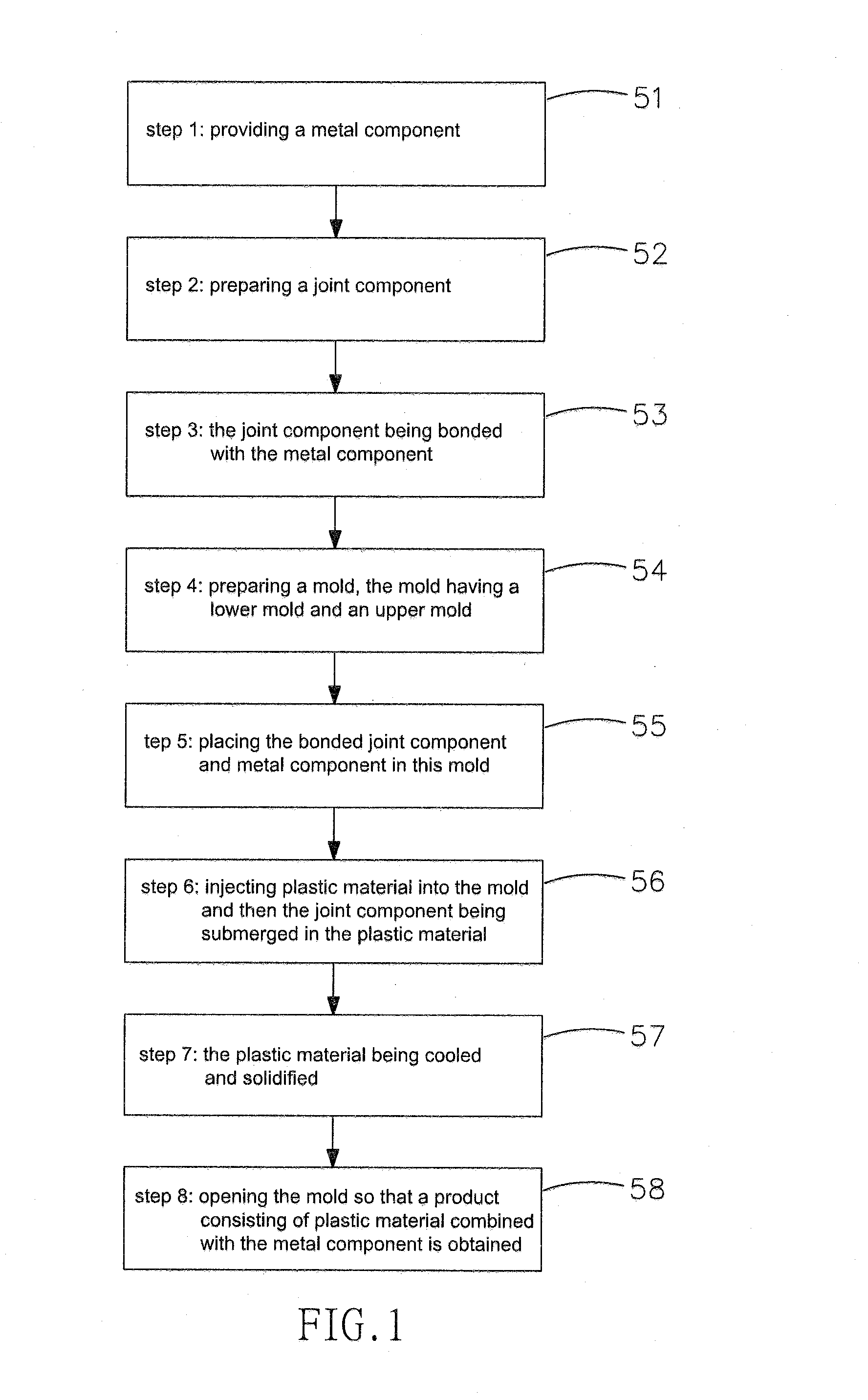

Method of selective plastic insert molding on metal component

InactiveUS20100215938A1Shorten production timeLow costSlide fastenersLayered productsJoint componentManufacturing technology

This invention discloses a method of selective plastic insert molding on metal component and its product. A metal joint component is bonded with a metal component. After which, the joint component is submerged in plastic so that the molded plastic can be secured on the metal component firmly. Hence, a desired plastic structure can be formed on the metal component. This invention can shorten the manufacturing process and reduce the cost. In addition, it solves the traditional bonding problem between the plastic and the metal component as well as the problem concerning processing time and high cost.

Owner:TAIWAN GREEN POINT ENTERPRISE

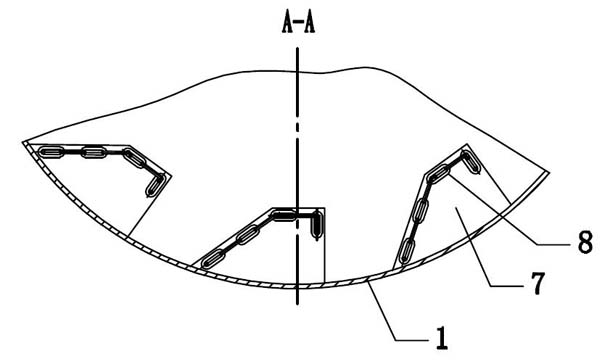

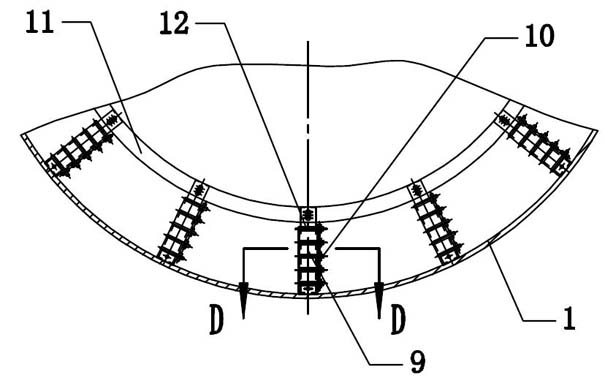

Method for bonding carbon fiber/phenolic-nitrile rubber materials

ActiveCN104861884AComplete structureMeet the design requirementsAdhesive processes with surface pretreatmentAdhesive processes with adhesive heatingStructural reliabilityFiber

The invention discloses a method for bonding carbon fiber / phenolic-nitrile rubber materials, and belongs to the field of the manufacturing of a solid rocket engine insulator, and aims at solving the bonding problems of an engine housing, a first EPDM insulation material, a carbon fiber / phenolic-nitrile rubber materials and a second EPDM insulation material and improving the structural reliability. The method mainly comprises the steps of preparation, coating, prefabrication, cleaning, glue coating, setting, thermal pre-pressing, flaw detection, curing and the like. The structural integrity of the engine housing, a first EPDM insulation material, the carbon fiber / phenolic-nitrile rubber materials and the second EPDM insulation material are ensured by using a secondary bonding method, a secondary curing mode, a prefabrication forming method, a stepped temperature rising / dropping mode and other methods; the method has no de-bonding, air-entraining air hole and other quality problems, completely can meet the design requirements, and ensures the safety and reliability of a system.

Owner:HUBEI SANJIANG AEROSPACE JIANGHE CHEM TECH +1

Preparation method and application of epoxy-based POSS (polyhedral oligomeric silsesquioxane)/ammonium polyphosphate composite flame retardant

InactiveCN107190515ASolve binding problemsImprove bonding fastnessHeat resistant fibresLiquid repellent fibresEpoxySilsesquioxane

Owner:SHANGHAI UNIV OF ENG SCI

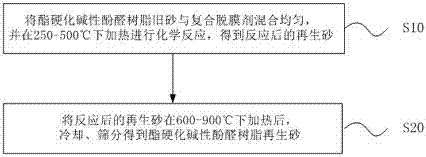

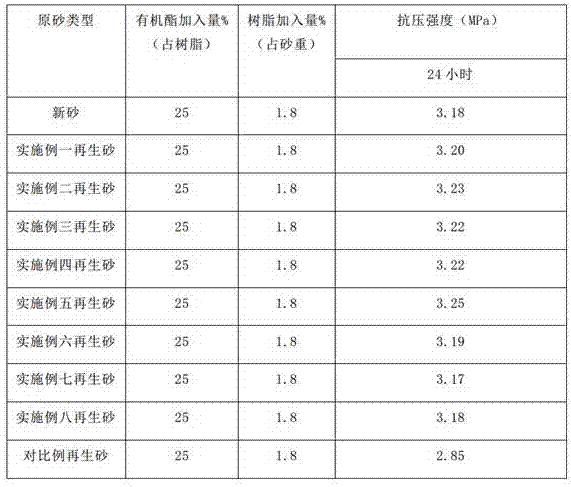

Reclaiming method for ester-hardened alkaline phenolic resin used sand

ActiveCN107321912AGuaranteed performanceImprove performanceMould handling/dressing devicesOrganic acidInorganic salts

The invention provides a reclaiming method for ester-hardened alkaline phenolic resin used sand. The reclaiming method for the ester-hardened alkaline phenolic resin used sand comprises the steps that the ester-hardened alkaline phenolic resin used sand and a compound film-releasing agent are evenly mixed, and then conduct chemical reaction after being heated at 250-500 DEG C, wherein the compound film-releasing agent comprises inorganic acid, organic acid, inorganic salt and water; and reclaimed sand after reaction is heated at 600-900 DEG C and then subjected to cooling and screening, and ester-hardened alkaline phenolic resin reclaimed sand is obtained. According to the reclaiming method for the ester-hardened alkaline phenolic resin used sand, resin films alkaline oxide adhering to the surface of the ester-hardened alkaline phenolic resin used sand can be removed, a sand grain bonding problem and a potassium and sodium remaining problem are avoided, and it is ensured that the obtained ester-hardened alkaline phenolic resin reclaimed sand has the excellent performance which is the same as or similar to the excellent performance of new sand.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

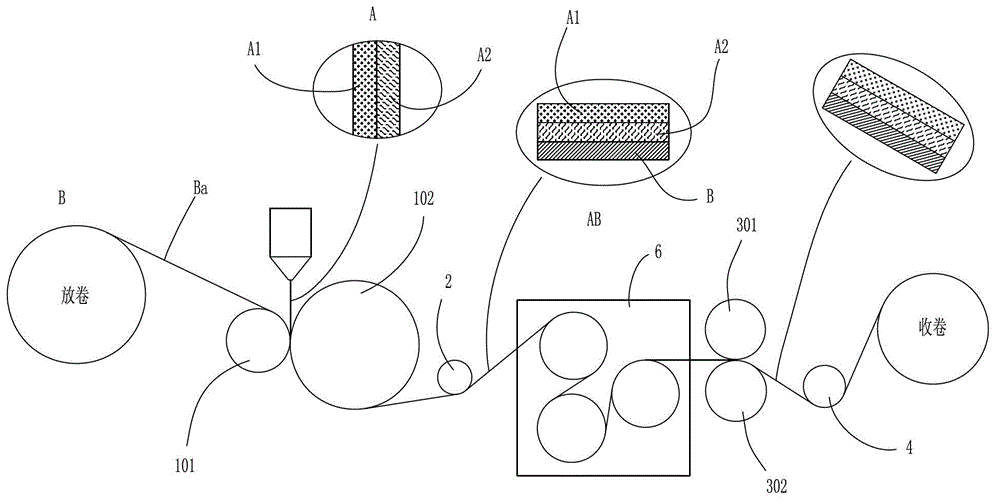

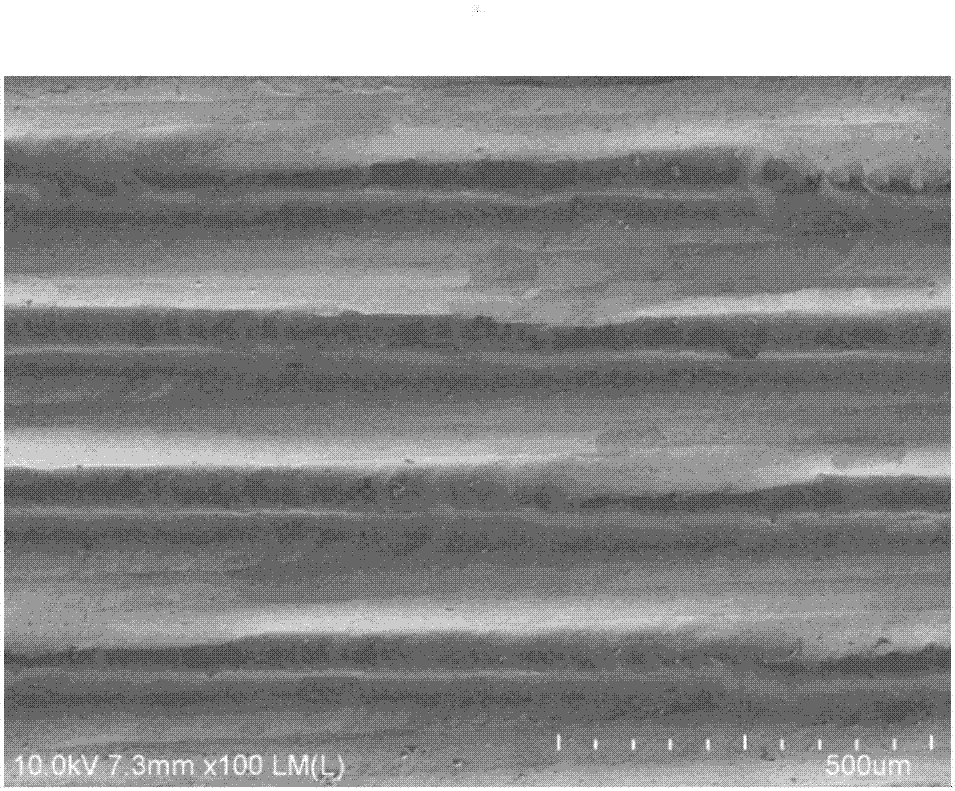

High sealing flexible composite film material for cold punching molding and its manufacturing method

InactiveCN103587165AHigh peel strength between layersImprove interlayer adhesionLamination ancillary operationsLaminationComposite filmPunching

The invention provides a high sealing flexible composite film material for cold punching molding. The composite film material comprises: a thermoplastic resin film inner layer, an aluminum foil metal core layer, and a heat resistant film outer layer. Specifically, the aluminum foil metal core layer is positioned between the thermoplastic resin film inner layer and the heat resistant film outer layer. The thermoplastic resin film inner layer is a multi-layer coextrusion layer containing at least two resin layers. The multi-layer coextrusion layer at least includes a surface heat seal layer and an inner composite layer, and the inner composite layer contacts the aluminum foil metal core layer. The surface heat seal layer contains a non-migrating inorganic additive with lubrication. The upper and lower surfaces of the aluminum foil metal core layer both undergo surface pretreatment. By adding the non-migrating inorganic additive with lubrication to the surface heat seal layer, the bonding problem caused by clinging of a composite material surface and a die can be prevented, and at the same time, air can permeate into the space between the composite material and the die along the gaps between tiny protuberances, so that the whole composite material is easy to undergo cold punching molding and die release. The invention also provides a preparation method of the flexible composite film material.

Owner:FSPG HI TECH

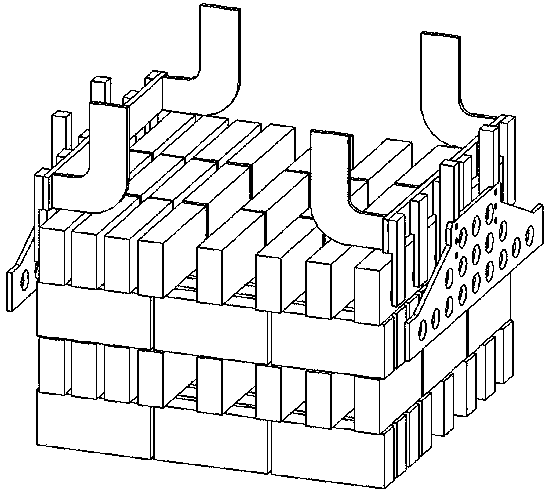

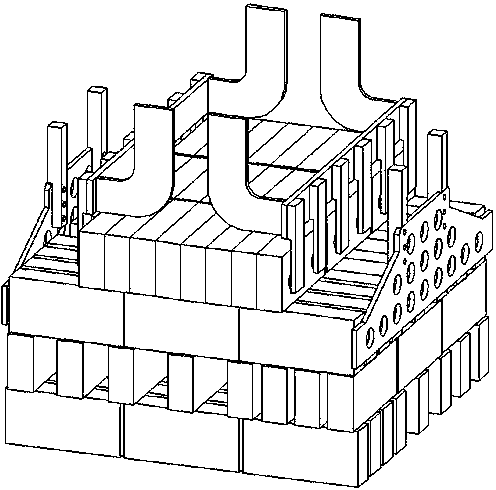

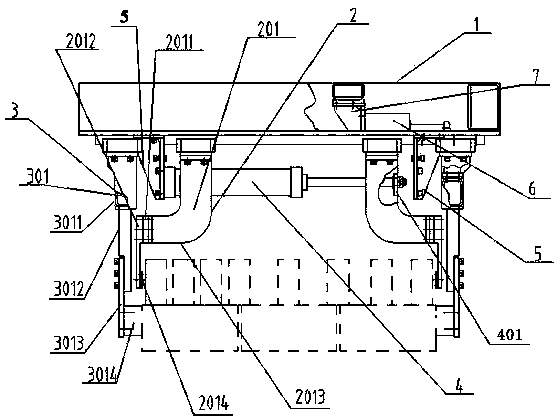

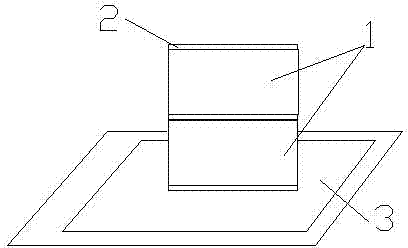

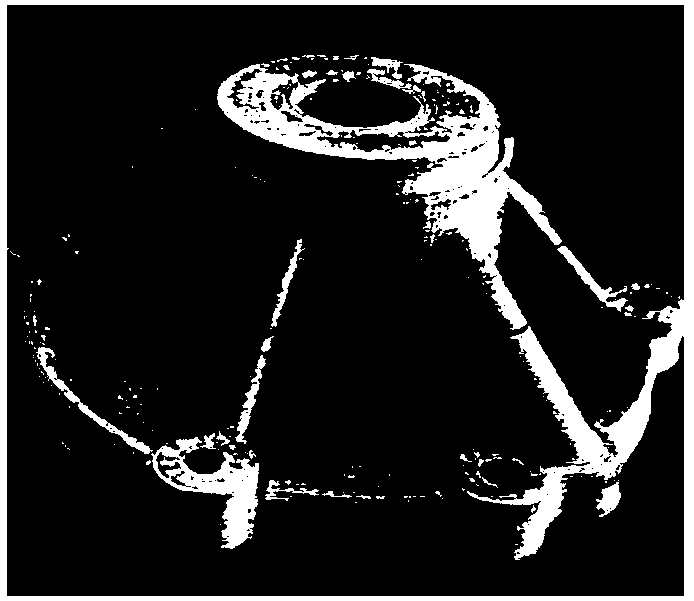

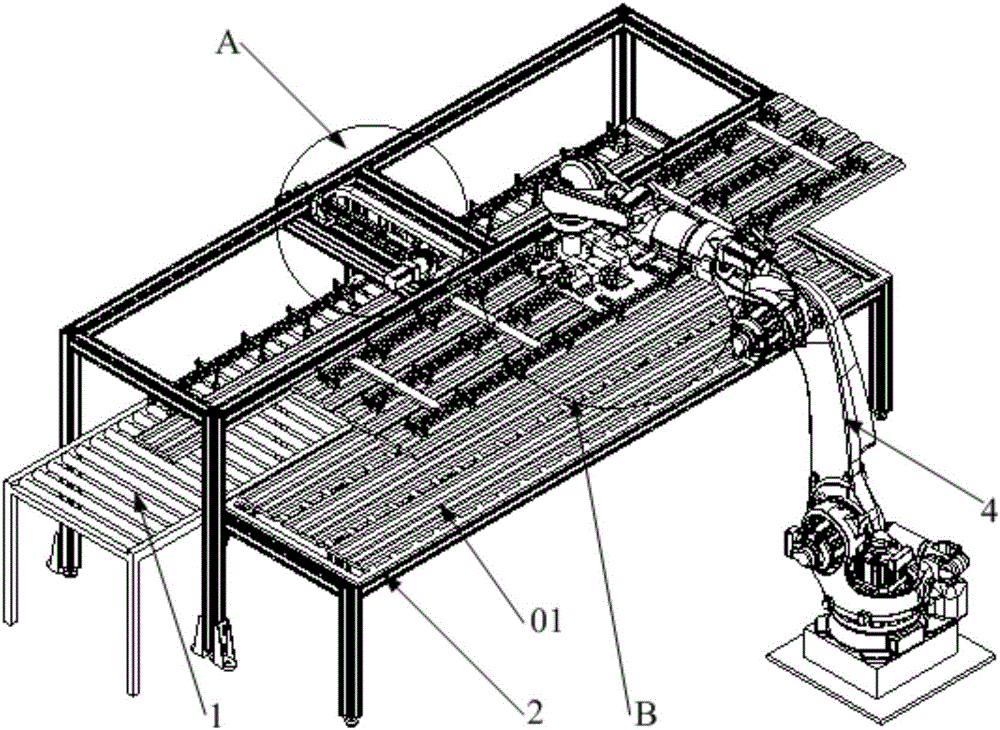

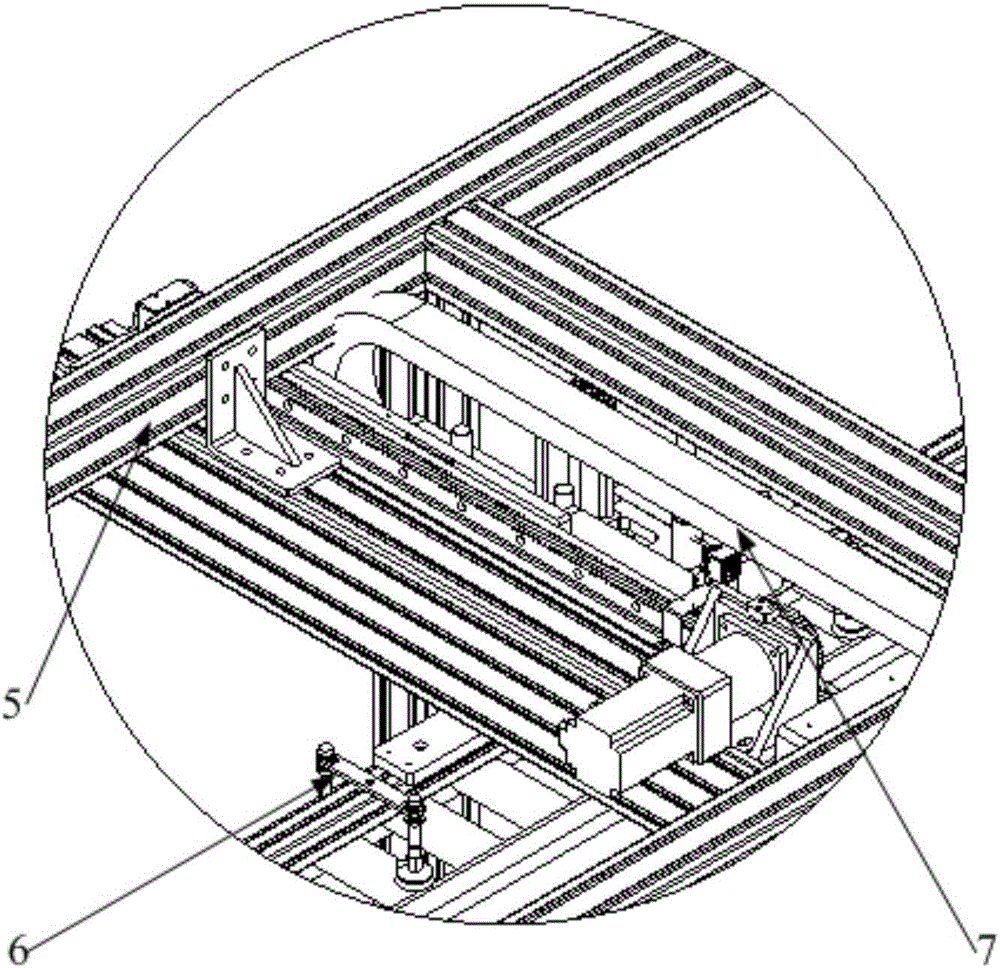

Sintered brick layered composite brick unloading method and device thereof

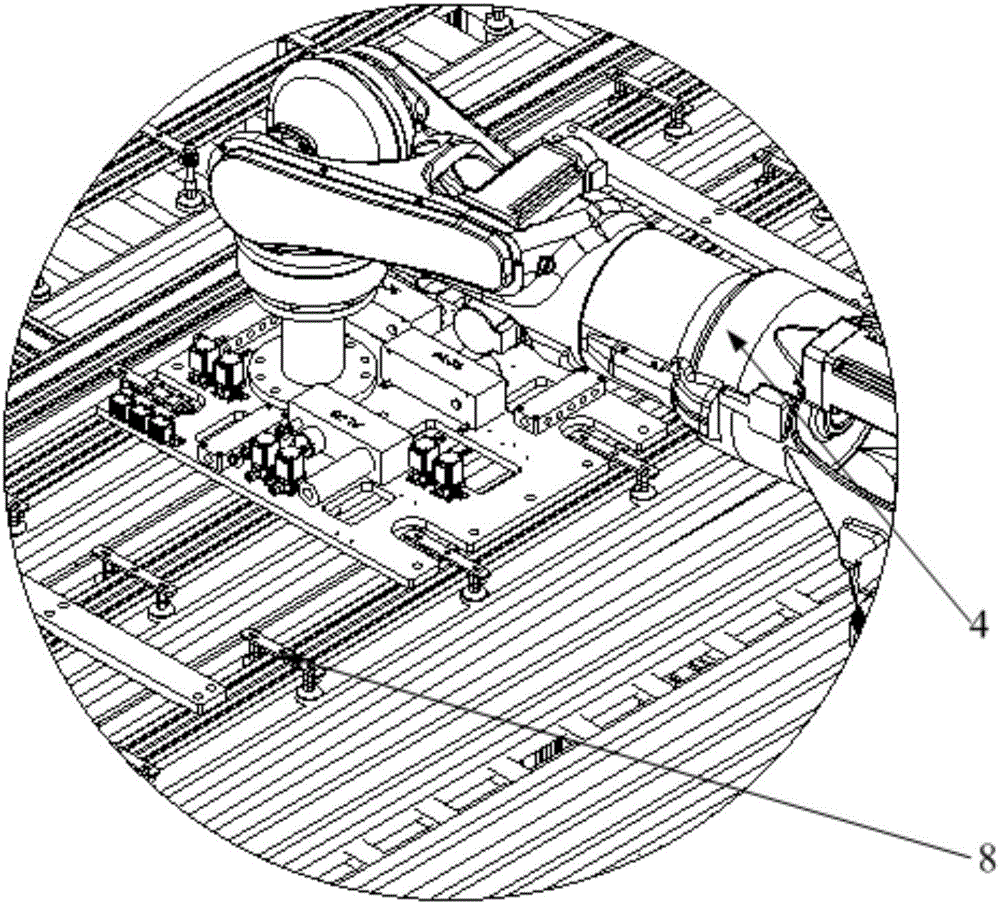

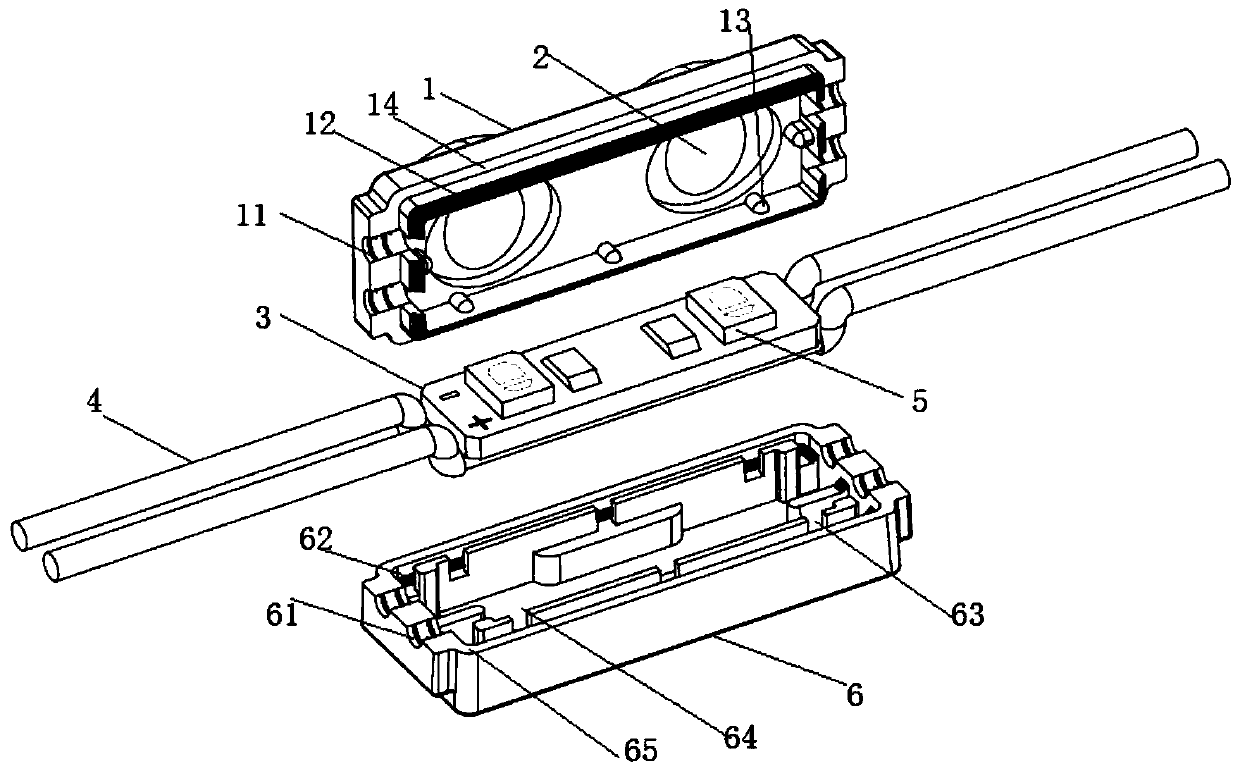

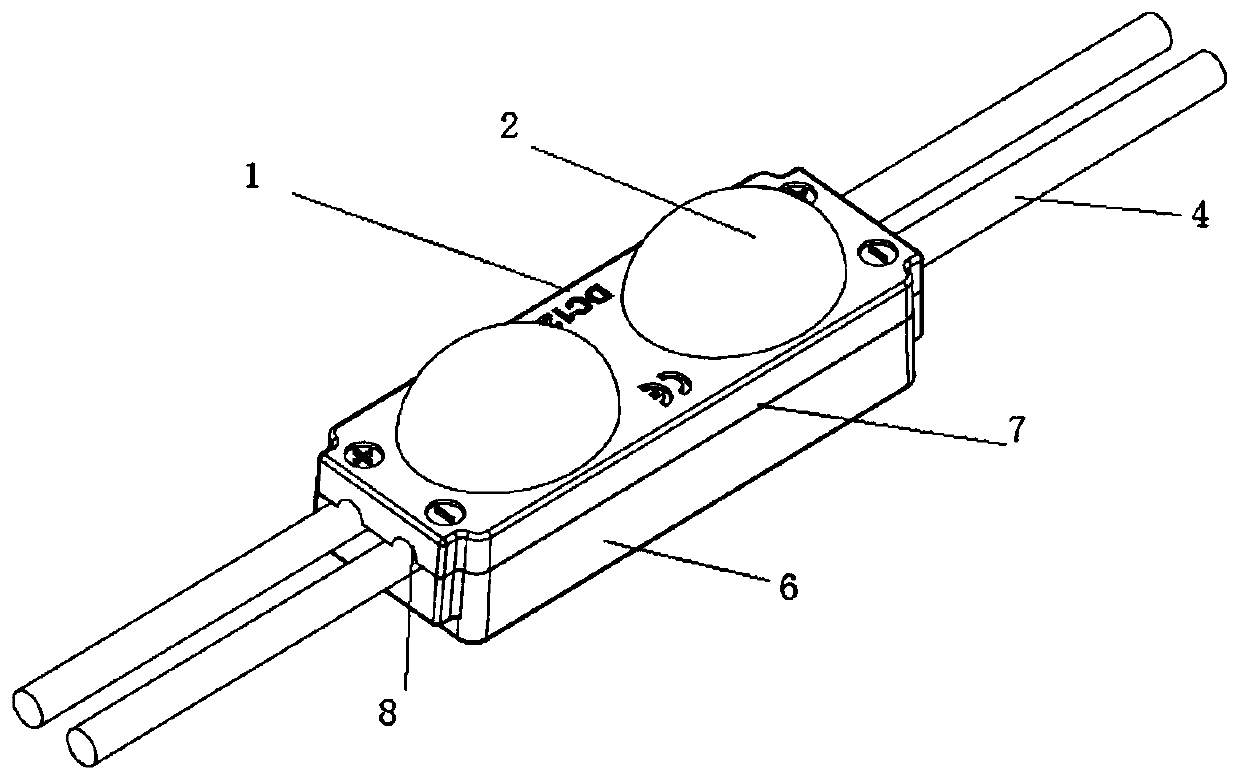

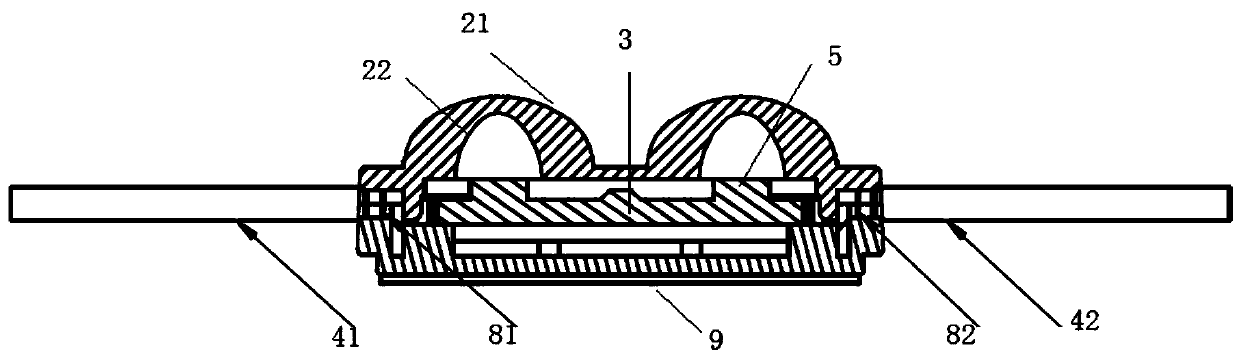

ActiveCN103434851ASolve sticking problemsReduce labor intensityStacking articlesDe-stacking articlesBrickEngineering

Provided are a sintered brick layered composite brick unloading method and a device thereof. The device comprises a hanging frame, an upper clamping hand and a lower clamping hand, wherein the upper clamping hand and the lower clamping hand are arranged on the hanging frame through a linear moving pair, the lower clamping hand is arranged on the outer side of the upper clamping hand, the upper clamping hand and the lower clamping hand are respectively provided with a set of driving mechanism, and the driving mechanisms drive the upper clamping hand and the lower clamping hand to be unfolded and folded. The lower clamping hand comprises two sets of lower clamping arm components, each lower clamping arm component comprises a lower clamping arm, a lower clamping sheet and a guide rod which is connected with the lower clamping arm and the lower clamping sheet, each lower clamping arm and each guide rod or each guide rod and each lower clamping sheet can move freely in an up-down relative mode, and the lower edge of each lower clamping sheet is lower than the lower edge of the upper clamping hand. According to the sintered brick layered composite brick unloading method and the device thereof, a layered composite is adopted, after seam closing is conducted on bricks, the bricks are clamped and stacked, the labor of manual seam closing is replaced, moreover, when the upper clamping hand clamps the bricks on the upper layer, the lower clamping hand can fix the bricks on the adjacent lower layer, the bricks on the upper layer are prevented from being driven to move or rise, the bonding problem of adjacent layers of bricks is solved, mechanical brick loading is achieved, the production efficiency is greatly improved, and the labor intensity of workers is lowered.

Owner:LUOYANG ZHONGYE HEAVY IND GRP CO LTD

Joint coating method for oil gas pipeline after repairing the corrosion detection

ActiveCN1952463AImprove insulation performanceImprove the sealing effect of reinforced insulationBituminous material adhesivesCorrosion preventionBonding problemsPetroleum

The invention relates to a joint patch method after corrosion bug reinforced of oil pipe, characterized in that reinforced material is winded on the polished steel tube to the joint position, middle glue is pasted and winding patch material is used. Said middle glue comprises 10 size petroleum asphalt and copolymer of vinyl and vinyl acetate, whose weight ratio is 1 to 1-1.3; petroleum resin is 3-10% of the sum of petroleum asphalt and the copolymer of vinyl and vinyl acetate; glass flake is 20-25% of the sum of petroleum asphalt and the copolymer of vinyl and vinyl acetate. The benefit is that insulation performance is improved under the moisture circumstance after oil pipe is strengthened; the quality problem of joint face in anti-corrosion layer, reinforced material, and repairing and strengthening material is solved; the bonding problem between joint material and tube is solved. It improves reinforced insulation sealing performance and prolongs the service life of bug pipe after repairing under the moisture section with more serious corrosion.

Owner:PETROCHINA CO LTD

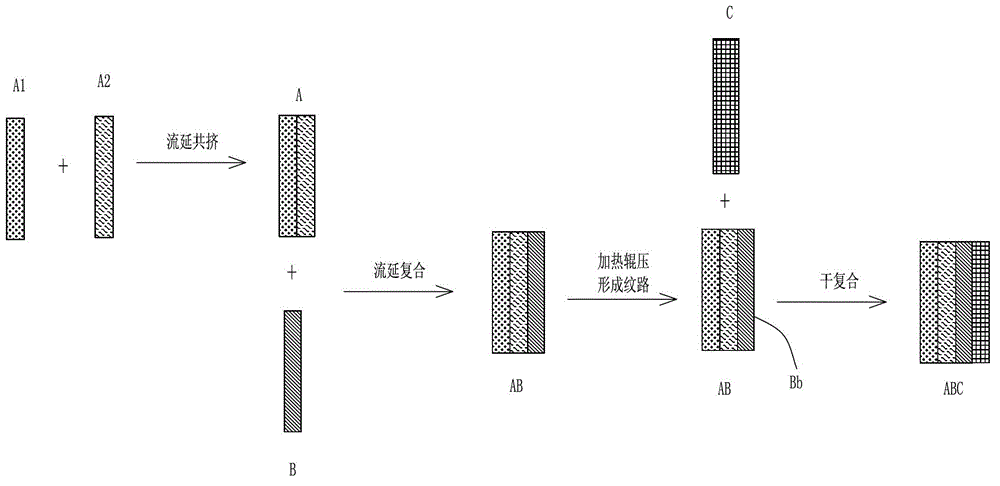

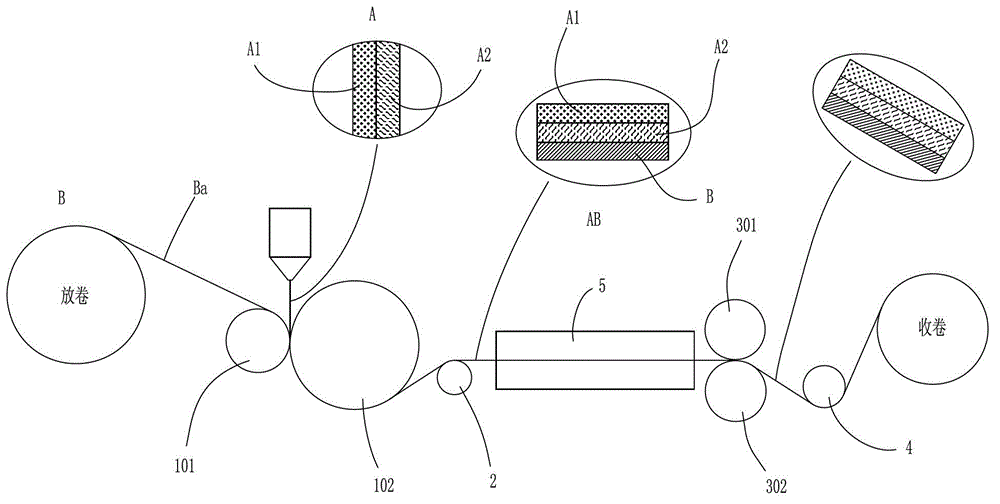

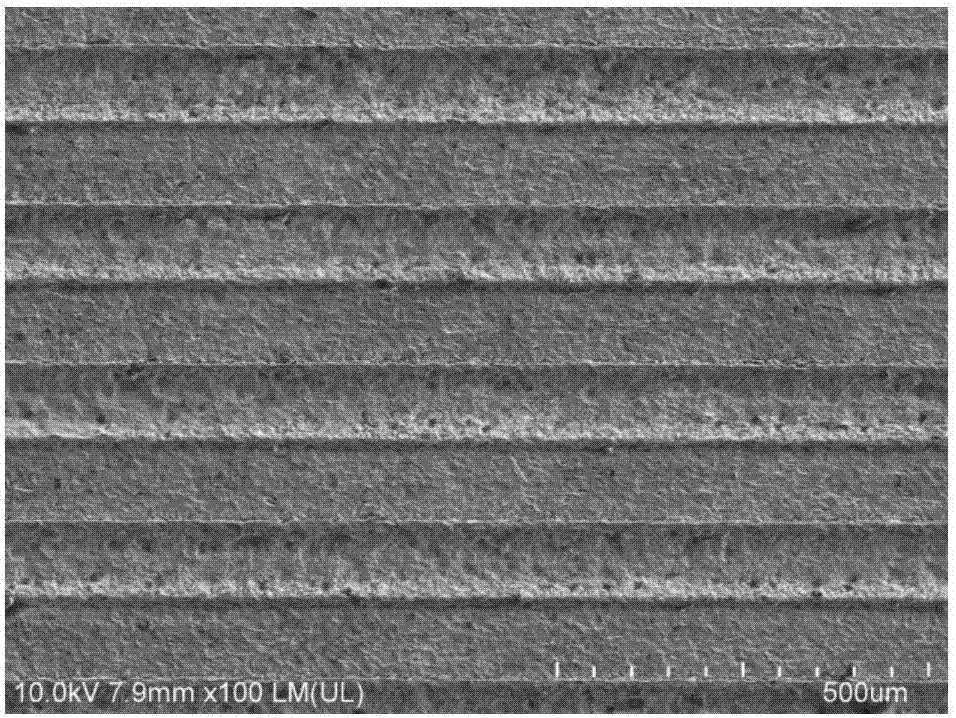

Easy-cold-punch-molding soft packaging composite material, and preparation method and molding method thereof

ActiveCN103331957AAvoid "sticking" problemsThe surface coefficient of friction value is reducedMetal layered productsAluminum foilBonding problems

The invention provides an easy-cold-punch-molding soft packaging composite material. The composite material comprises a thermoplastic resin film layer, an aluminum foil metal core layer, and a heatproof or printing film layer; the aluminum foil metal core layer is positioned between the thermoplastic resin film layer and the heatproof or printing film layer; the thermoplastic resin film layer comprises a surface heat-sealing layer and a hot melt adhesive resin layer compounded with the aluminum foil metal core layer; and the surface of the heat-sealing layer has fine slight convex-concave lines formed through heating roll molding in the compounding process, and the convex-concave depth of the fine slight convex-concave lines is 0.5-25mum. By utilizing the fine convex-concave characteristics of the fine slight convex-concave lines, a bonding problem formed by the clinging of the surface of the composite material and a die can be avoided during stamping, and air can be residual in a slit between the die and the convex-concave lines on the surface of the composite material during the stamping, so the surface friction coefficient value of the composite material is greatly reduced, and it is in favor of demolding the composite material in the cold punch molding process. The invention also provides a preparation method of the composite material, and a molding method when used.

Owner:FSPG HI TECH

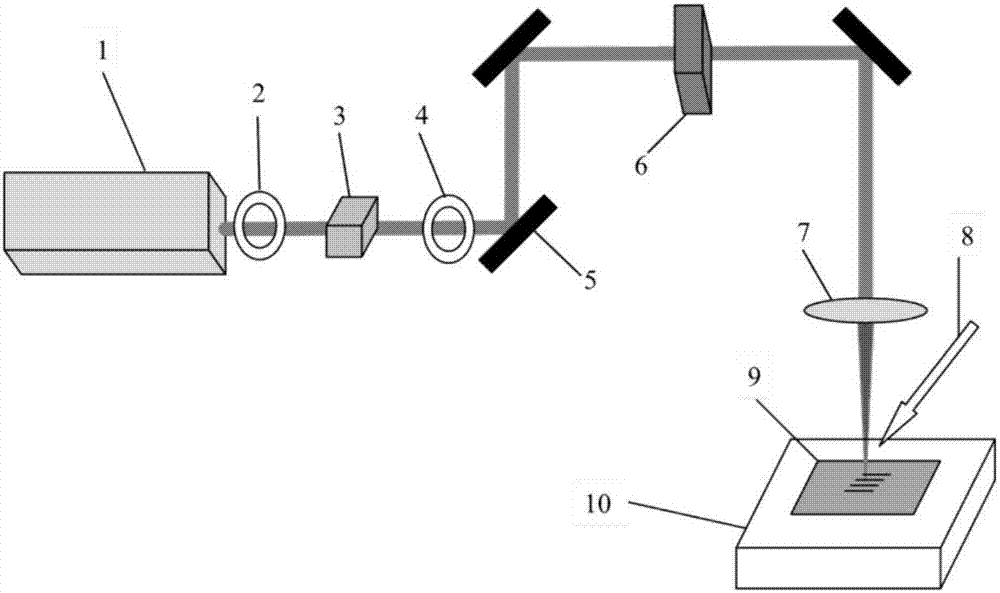

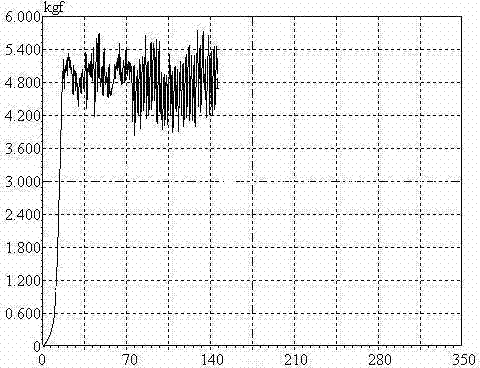

Electrotome surface laser grooving and polishing integral machining method

ActiveCN107363486AImprove processing speedImprove machining accuracySurgical instruments for heatingLaser beam welding apparatusLaser scanningPicosecond

The invention discloses an electrotome surface laser grooving and polishing integral machining method. The method comprises the following steps: (1) a metal high-frequency electrotome sample is ultrasonically cleaned by alcohol, and is dried; (2) a picosecond fiber laser with a pulse width of 600 ps is used for setting a laser scanning area of 4 mm*15 mm to machine a microgroove in the surface of the electrotome; (3) the machined electrotome is ultrasonically cleaned; (4) a nanosecond pulse laser with a pulse width of 220 ns is used for setting a laser scanning area of 6 mm*20 mm to polish the microgroove area on the surface of the electrotome; and (5) the machined electrotome is ultrasonically cleaned. The method can improve the electrotome bonding problem in operations, and polishes the surface to facilitate relief of the corrosion failure of the electrotome and prolonging of the service life of the electrotome. The method uses the advantages of a laser micromachining technology for efficiently and precisely prepare a microstructure on the surface of the electrotome by using a laser direct writing system; and the machining area and the machining range can be adjusted according to actual demands.

Owner:BEIHANG UNIV

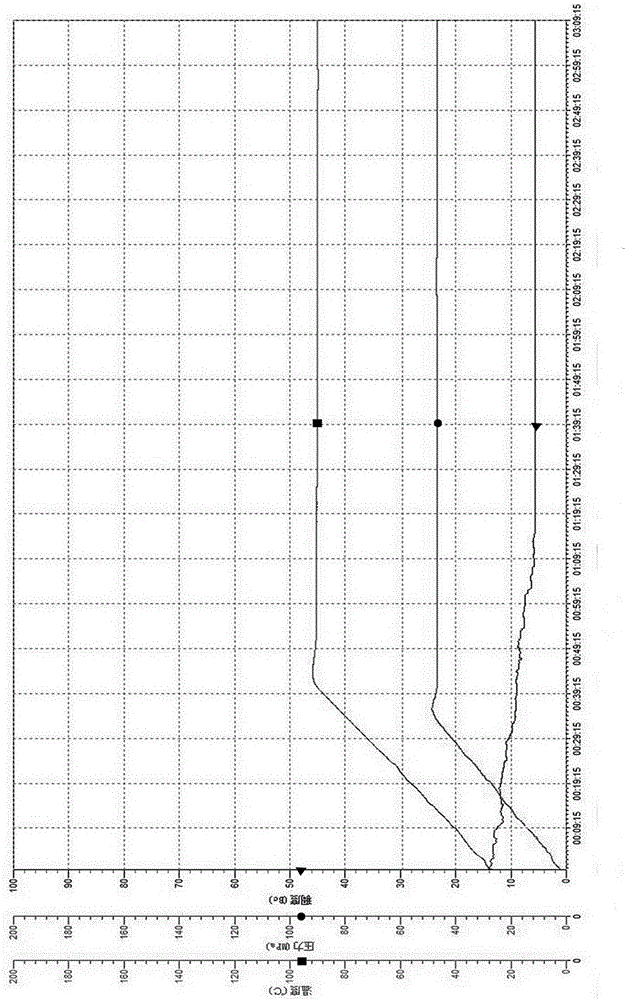

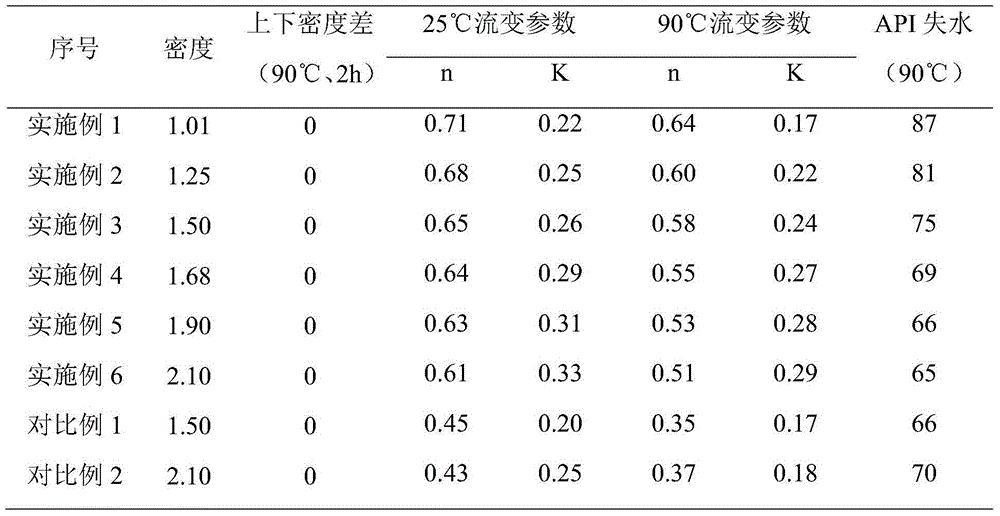

Double-effect isolation liquid for oil-based mud cementing, and preparation method thereof

The present invention discloses a double-effect isolation liquid for oil-based mud cementing, and a preparation method thereof, wherein the raw materials comprise, by weight, 100 parts of clear water, 10-20 parts of a rinsing agent, 10-15 parts of a filler, 1-5 parts of a retarding agent, 0.1-0.2 part of an antifoaming agent, 0-260 parts of a weighting agent, and 1-2 parts of an isolation agent. The preparation method comprises: adding 1-2 parts of an isolation agent to 100 parts of clear water, completely and uniformly stirring at a low speed, slowly adding 15-20 parts of a filler and 1-5 parts of a retarding agent, adding a weighting agent according to a density requirement after the base liquid preparation is completed, uniformly stirring, adding 10-15 parts of a rinsing agent, maintaining low speed rotation, adding 0.1-0.2 part of an antifoaming agent after the liquid distribution is uniform, and continuously stirring for 1-2 h while maintaining the rotation speed. According to the present invention, with the double-effect isolation liquid for oil-based mud cementing, the lipophilic interface is converted into the hydrophilic interface, such that the pollution of the oil-based on the conventional cement slurry system is reduced, the bonding problem of the two interfaces is solved, the high quality cementing and the sealing fixing of the annulus interface are achieved, and the stability of the mud is ensured.

Owner:成都欧美克石油科技股份有限公司

Method for preventing directly reduced metallic pellets from bonding

Belonging to the technical field of metallurgy, the invention relates to a method for preventing directly reduced metallic pellets from bonding. The method comprises the steps of: (1) mixing anthracite carbon powder, lime powder, clay and bentonite uniformly so as to prepare peritoneal powder; (2) making a material to be reduced into mineral powder pellets; (3) placing the peritoneal powder into the pelletizing disc of a pelletizer, then putting the mineral powder pellets to be reduced on the peritoneal powder in the pelletizing disc, and initiating the pelletizer so as to prepare composite pellets; (4) subjecting the composite pellets and a pulverized coal reducing agent to a reduction reaction at a temperature of 1180-1220DEG C for 3-4h, thus obtaining metallic iron pellets. The method of the invention solves the bonding problem of directly reduced metallic pellets, and is especially suitable for producing high density metallic pellets, and also especially suitable for production of metallic pellets with high grade iron ore powder.

Owner:辽宁博联特冶金科技有限公司

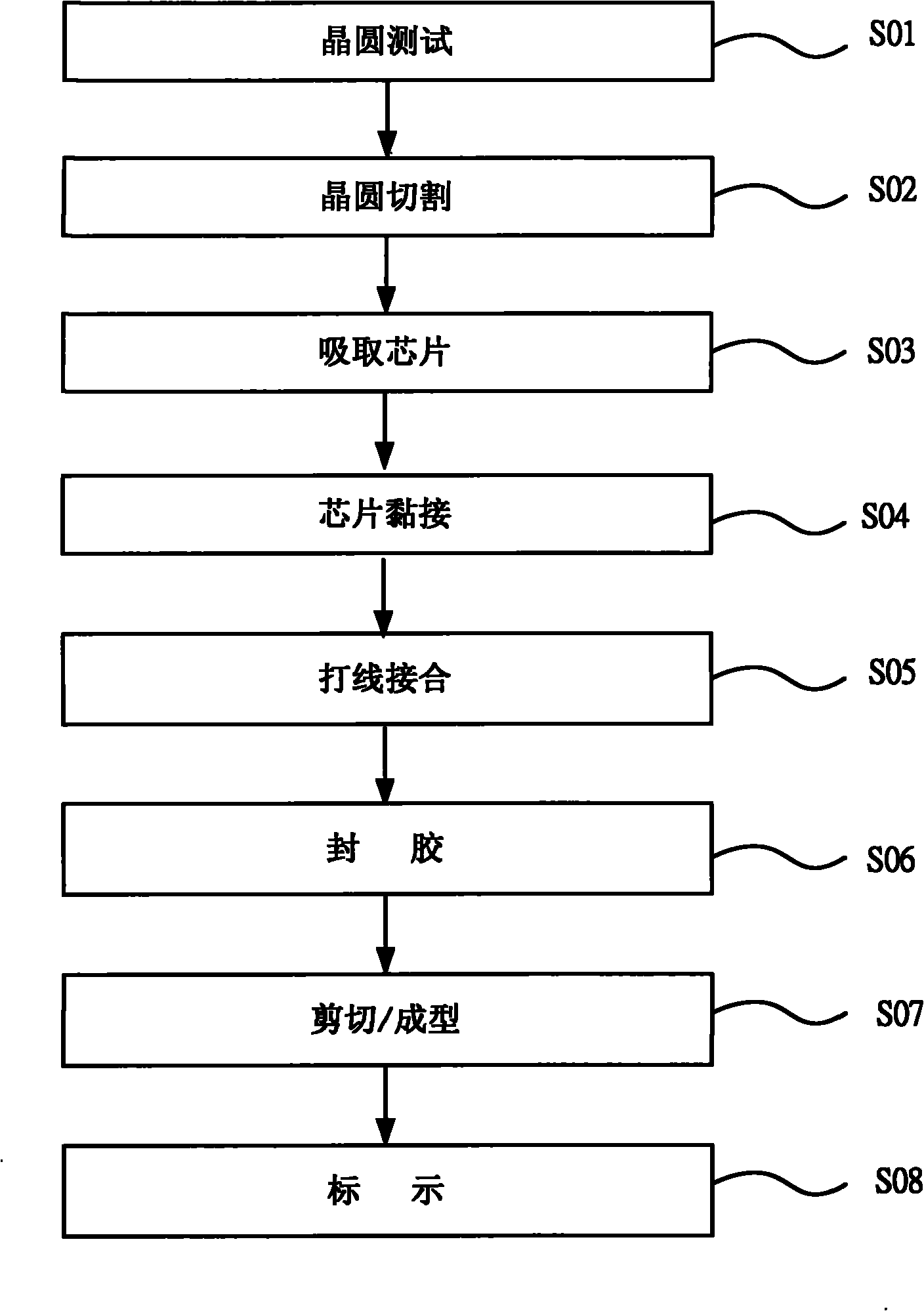

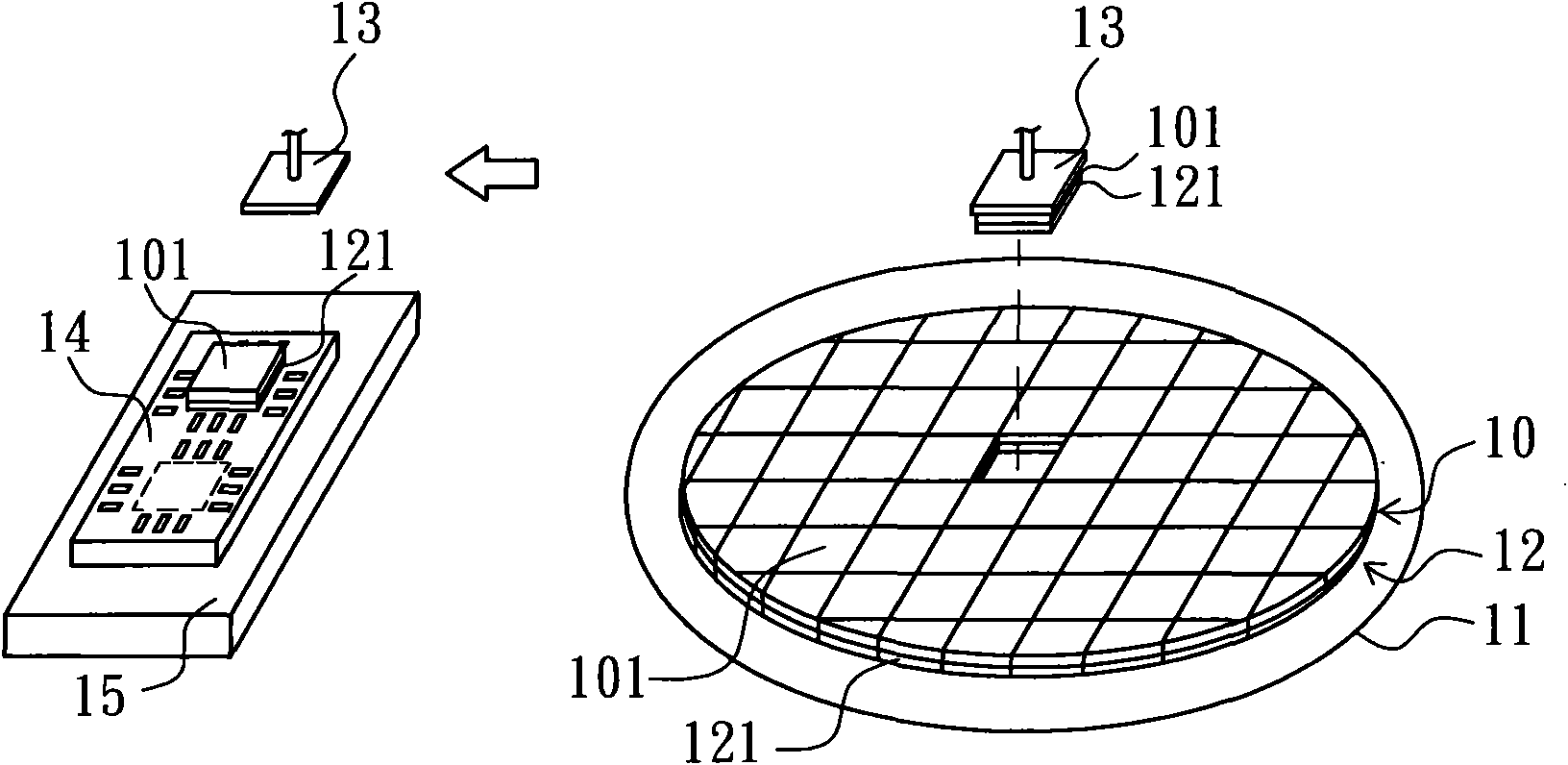

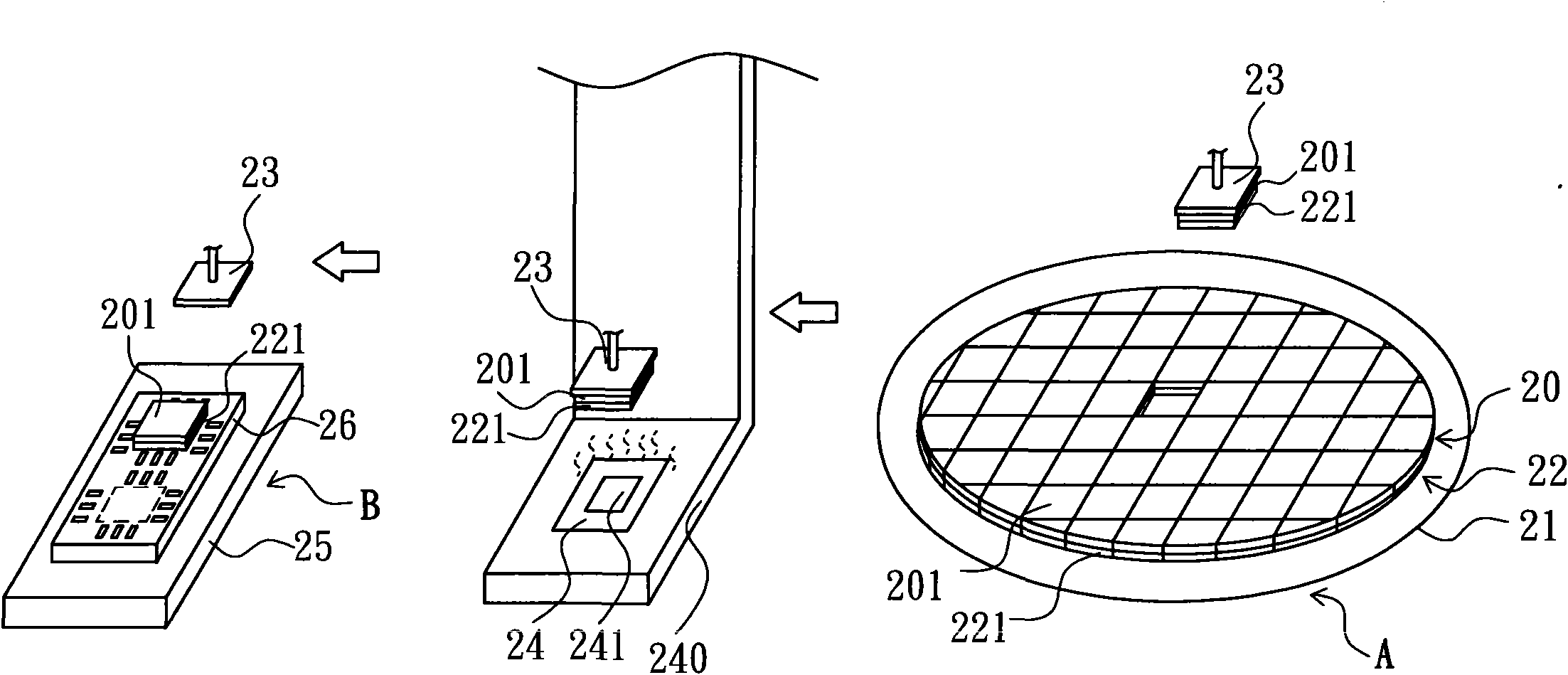

Device and method for heating adhesive film used for bonding chips

InactiveCN102054657AImprove bonding efficiencyShorten the time required for heating and softeningSemiconductor/solid-state device manufacturingProduction lineSemiconductor chip

The invention discloses a device and a method for heating an adhesive film used for bonding chips. The adhesive film used for bonding semiconductor chips sucked by a chip picking and placing head on the moving path of the chip picking and placing head is subjected to non-contact heating in a fixed point mode or a synchronous moving mode through a non-contact heating unit, so that the time required for heating and softening the adhesive film and the time required for bonding the chips can be shortened, the efficiency for bonding the chips are improved and the yield of an encapsulated product within unit time is increased; the adhesive film can be prevented from being heated and softened prematurely, so that the adhesive film is prevented from sticking an adhesive film used for bonding wafers or sticking adjacent chips and adhesive films at the sucking positions of the chips unexpectedly; therefore, unexpected bonding problems are effectively solved and the reliability of production line operation is improved.

Owner:ASE ASSEMBLY & TEST SHANGHAI

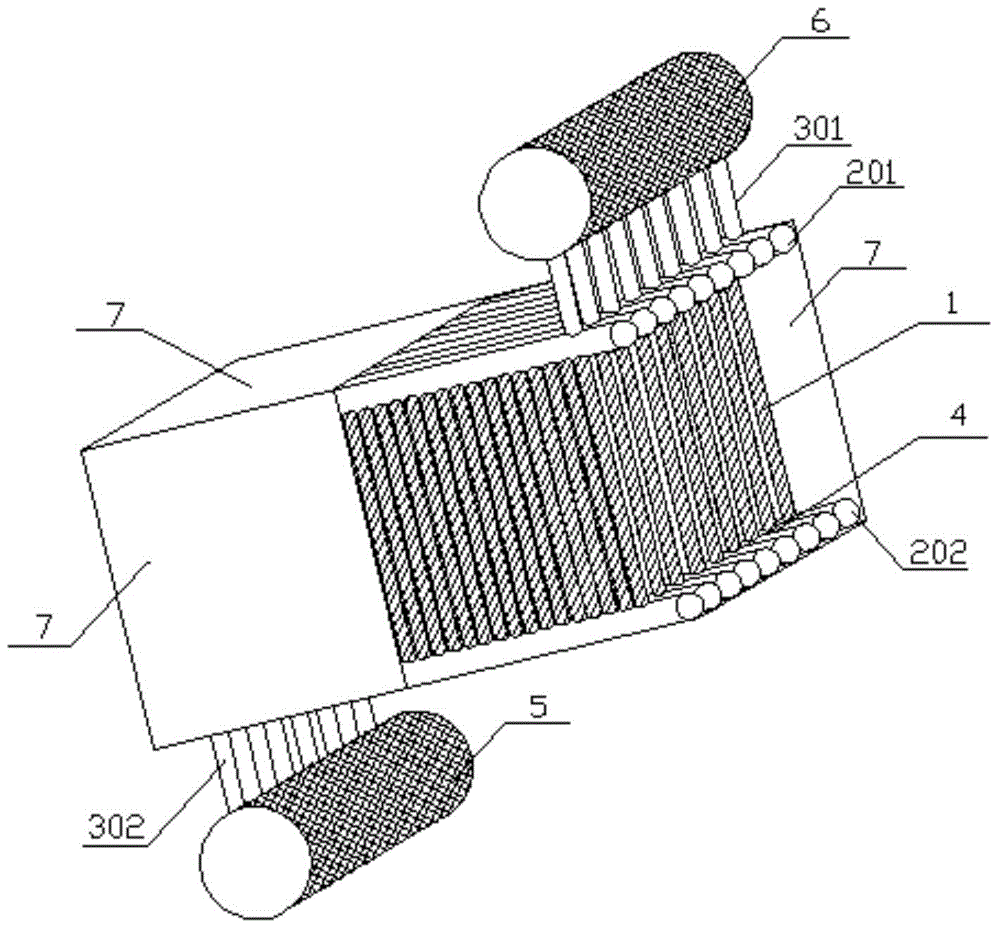

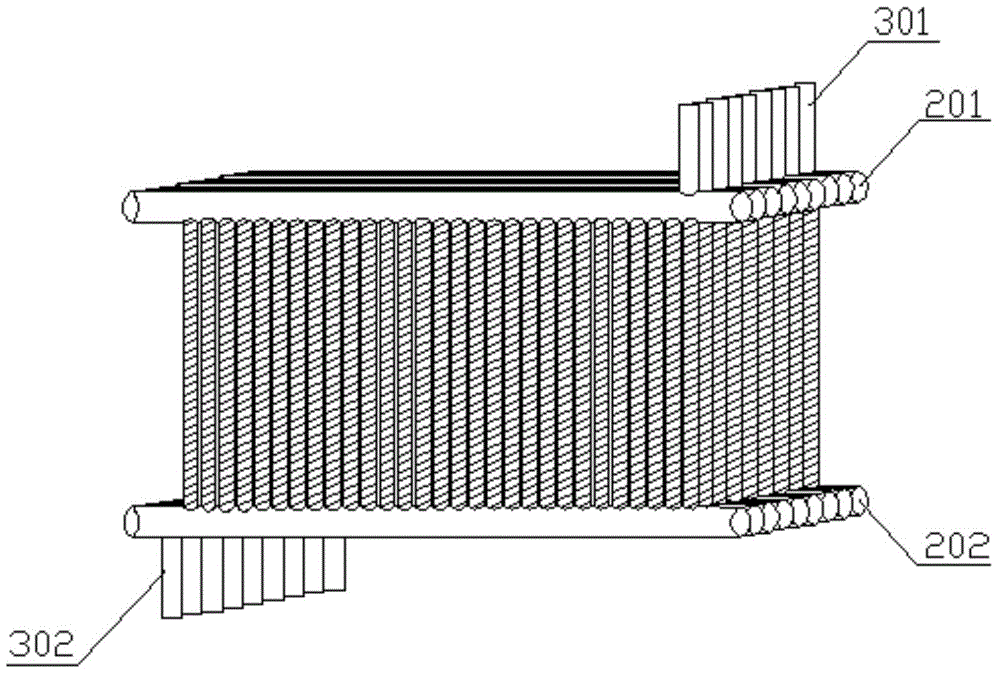

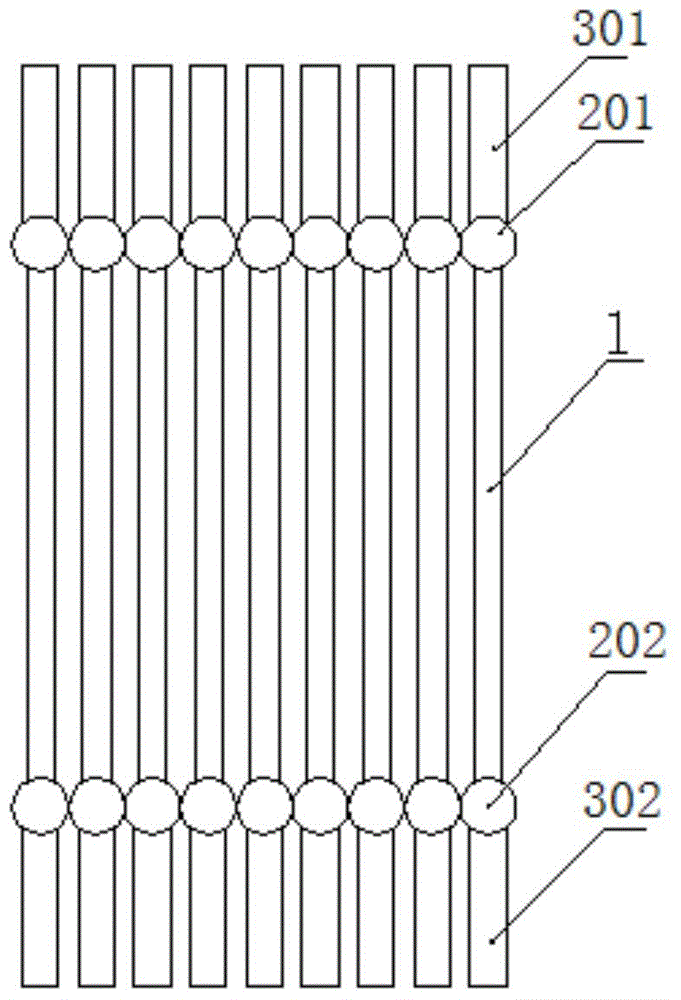

Raw gas waste heat recycling and exchanging unit of anti-bonding gravity-flowing coke oven

ActiveCN104677143AAvoid stickingAvoid cokingStationary tubular conduit assembliesCoatingsTarGravity flow

The invention discloses a raw gas waste heat recycling and exchanging unit of an anti-bonding gravity-flowing coke oven, and belongs to the technical field of recycling raw gas waste heat produced in the coking process. A heat exchange unit body comprises a plurality of single-row components, the plurality of the single-row components are arranged in same spaces and fixed together to form a cuboid structural heat exchange unit body, the single-row components are formed by welding heat exchange vertical pipes, heat exchange transverse pipes and heat exchange working medium conveying pipes in a permutation and combination way. Non-viscous coatings are coated on the surfaces of the single-row components, and the heat exchange unit body is inclined upwards along a horizontal plane. According to the arrangement, the tar bonding problem, which is produced in the process of recycling the raw gas waste heat, is solved; and meanwhile, recycled tar is reused, and resources are saved. According to the raw gas waste heat recycling and exchanging unit of the anti-bonding gravity-flowing coke oven, after heat is exchanged, the discharge temperature of the raw gas is reduced below 250 DEG C, the heat exchange effect of the raw gas is greatly improved, effective sensible heat in the raw gas is completely recycled, heat waste is prevented, and requirements on energy conservation and emission reduction are met.

Owner:MAANSHAN TIANZHOU ENERGY SAVING ENG TECH

Heat vulcanization bonding technology for fluorine rubber and silica gel

InactiveCN102786701AReduce manufacturing costLow costAdhesivesRubber layered productsCalcium silicateMethacrylate

The invention belongs to the technical field of rubber manufacture, and relates to a heat vulcanization bonding technology for fluorine rubber and silica gel with low cost and excellent performance, the technology enabling ordinary fluorine rubber and silica gel to bond vulcanizedly. The heat vulcanization bonding technology for the fluorine rubber and the silica gel rolls bonding compositions to thin sheets, puts the bonding compositions between the inner layer fluorine rubber and the silica gel to form a semi-finished product having a structure of the inner layer fluorine rubber, the bonding compositions and the silica gel, and then heats and vulcanizes to fixedly bond the inner layer fluorine rubber and the silica gel. The inner layer fluorine rubber is mixed from the following components in part by weight: 100 parts of fluorine rubber, 8 to 10 parts of active magnesium oxide, 5 to 6 parts of calcium hydrate, 0.5 to 1 part of magnesium methacrylate, 8 to 10 parts of carbon black, 5 to 6 parts of calcium silicate, 1.2 to 1.5 parts of bisphenol AF, 2 to 3 parts of a cross-linking agent and 2 to 2.5 parts of a vulcanizing agent. The bonding compositions is mixed from the inner layer fluorine rubber, the silica gel and a fluorine coupling agent F-1 in a weight ratio of 3.8-4.2 : 4.6-5.5 : 1. The technology employs an intermediate transition layer to solve the bonding problem of the fluorine rubber and the silica gel.

Owner:NINGBO FENGMAO FAR EAST RUBBER

Method for producing high permeability mangan zinc ferrite

A method for producing high permeability mangan zinc ferrite particularly relates to a method for improving electromagnetic performance and mechanical strength of products by using slaked magnetic powder for replacing the original alumina powder or zirconium oxide powder in a superposition sintering production process of high permeability mangan zinc (Mn-Zn) ferrite products. The method for producing high permeability mangan zinc ferrite includes the following steps: (1) leading high permeability Mn-Zn ferrite grain powder materials and deduster return fine powder during spray granulation production to be conducted with first flashback in a kiln with flashback temperature above 1300 DEG C, and obtaining slaked Mn-Zn ferrite magnetic powder, and (2) scattering the slaked Mn-Zn ferrite magnetic powder among blank products evenly. The slaked Mn-Zn ferrite magnetic powder and the blank products belong to the same species of materials and do not react with each other, and therefore the bonding problem is solved and products with high performance are obtained.

Owner:JIANGSUSR MAGNETIC MATERIAL & DEVICE ENG TECH RES

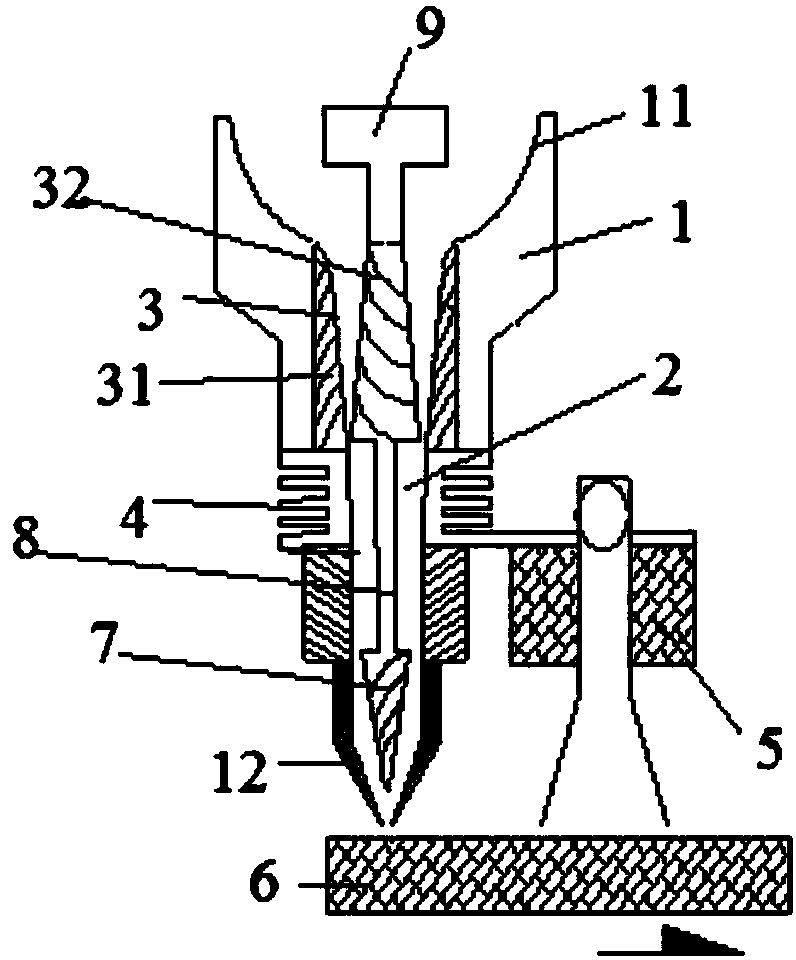

3D printer head and 3D printer

PendingCN108356269ASimple pretreatment processAvoid crackingAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringBonding problems

The invention provides a 3D printer head and a 3D printer. The 3D printer head comprises a printer head main body and a machine frame, wherein the printer head main body comprises a feeding end and adischarging end; a feeding cavity is formed between the feeding end and the discharging end, and two end parts of the feeding cavity are correspondingly in communication with the feeding end and the discharging end; a rotating shaft is arranged in the feeding cavity, the machine frame is connected with the top of the rotating shaft through a connecting block, and a material extruding mechanism isconnected with the bottom of the rotating shaft; a heating and melting mechanism is annularly arranged on the outer wall of the feeding cavity, a crushing mechanism is arranged on the inner wall of the printer head body, and the heating and melting mechanism is connected with the bottom of the crushing mechanism; and a pre-heating mechanism is arranged on the side portion of the discharging end, and the pre-heating mechanism is connected with the bottom of the heating and melting mechanism. The 3D printer is not limited to a feeding form, the bonding problem among printing layers are effectively improved, and bad bonding phenomena such as cracking, faults, warping and the like among the printing layers are solved.

Owner:KUNSHAN KADAM NEW MATERIAL TECH CO LTD

Regenerative drying barrel

InactiveCN102061657AImprove acceleration performanceSolve sticking problemsRoads maintainenceEngineeringChain type

The invention relates to a regenerative drying barrel, comprising a barrel body provided with a feed port and a discharge port; the inner wall of the barrel body is provided with a current guide plate, an annular chain device, a chain type material raising device and a scraper blade in sequence from the feed port to the discharge port. The regenerative drying barrel is provided with the annular chain device and the chain type material raising device; when in use, the chains of the annular chain device and the chain type material raising device shake freely along with the rotation of the barrel body; and the shaking of the chain effectively avoids the bonding problem of asphalt milling material. Moreover, by using the chain type material raising device, the material lifting ability is alsoimproved, and a good material curtain is formed in the barrel body so that the material is completely contacted with the thermal air current, thereby improving the drying efficiency, decreasing the equipment energy consumption, and meeting the requirement of energy saving emission reduction.

Owner:WUXI HUAZHONG TECH

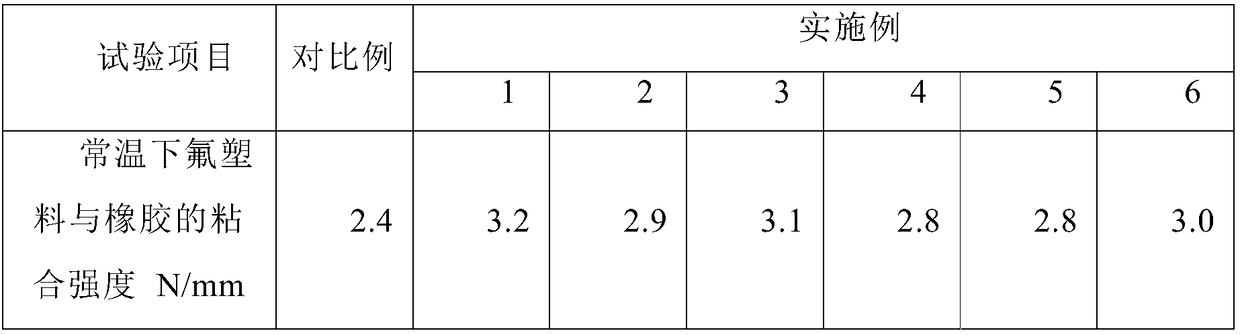

Fluoroplastic-rubber bonding method

ActiveCN108117845AEvenly dispersedHigh bonding strengthAdhesive processes with surface pretreatmentVulcanizationSolvent

The invention relates to a fluoroplastic-rubber bonding method. The method comprises the following steps: (1) preparing a treatment liquid from a catalyst, a treatment agent and a solvent; (2) puttingsurface cleaned fluoroplastic into the treatment liquid, carrying out treatment at 70-140 DEG C for 1-30 minutes, taking out, cleaning, and airing; and (3) compounding the treated fluoroplastic withrubber, so as to realize bonding in a vulcanization process of the rubber. Compared with the prior art, the bonding method has the advantages that the bonding problem between the fluoroplastic and therubber is solved, the method is simple and wide in applicability, the performance of the rubber is not influenced, and meanwhile, the bonding effect between the fluoroplastic and the rubber is good,and the bonding strength is high.

Owner:EAST CHINA UNIV OF SCI & TECH

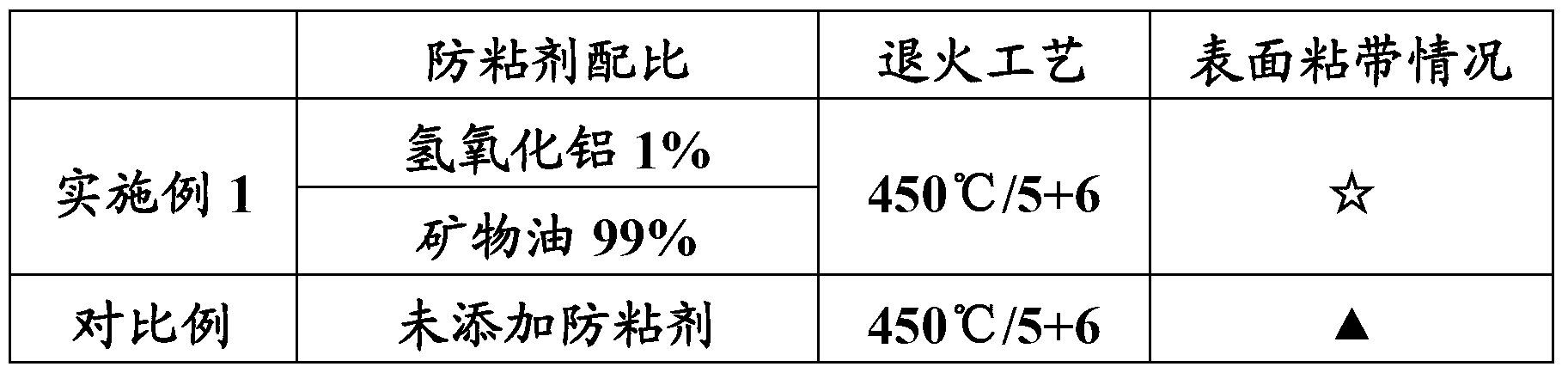

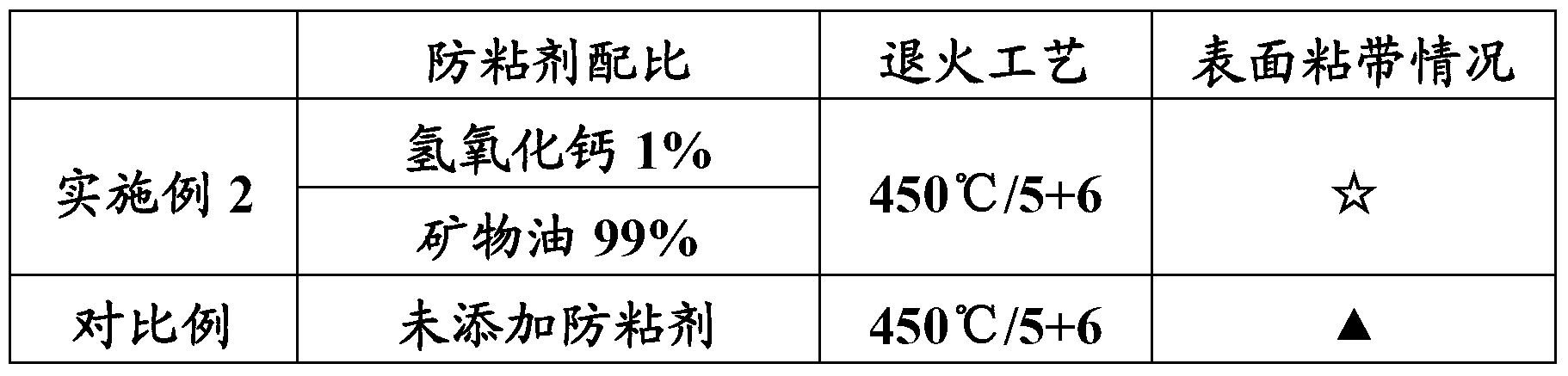

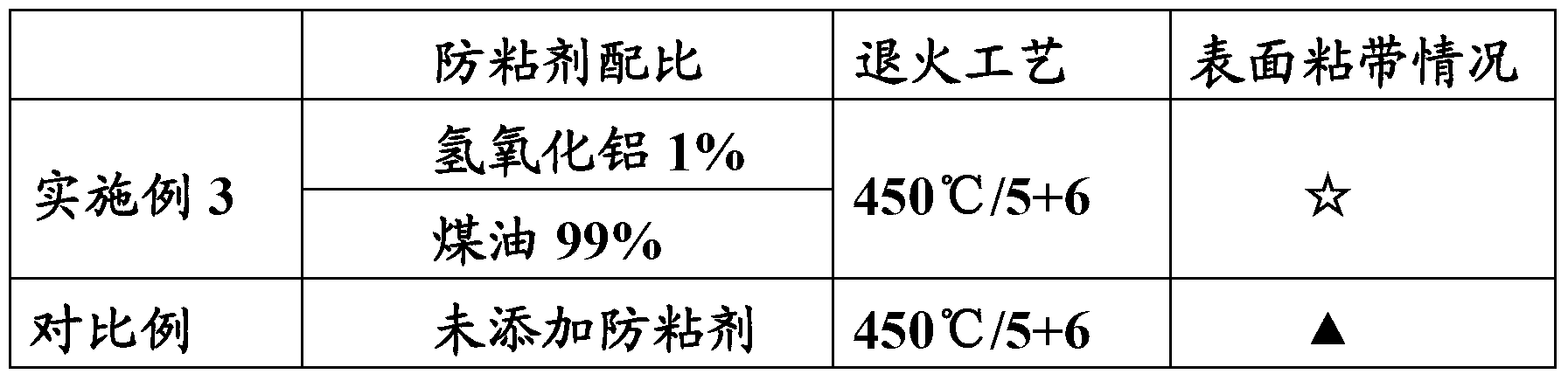

High temperature resistant antitack agent and processing method before metal tape annealing

InactiveCN103320588AReasonable ratioSolve the problem of annealing stickingZinc hydroxideAluminium hydroxide

The invention discloses a high temperature resistant antitack agent and a processing method before metal tape annealing. The high temperature resistant antitack agent is prepared by uniformly mixing the following components: by weight, 1-50% of a substance A and 50-99% of a substance B, wherein the substance A is at least one substance selected from the group consisting of aluminium hydroxide, alumina, calcium hydrate, calcium carbonate, calcium oxide, magnesium hydroxide, copper oxide, zinc hydroxide and zinc oxide; and the substance B is mineral oil or kerosene. The invention also discloses a processing method before annealing of a metal tape by the use of the above high temperature resistant antitack agent, comprising the following steps: uncoiling the metal tape and rolling, spraying the high temperature resistant antitack agent on the surface of a copper belt, crimping and annealing. The copper belt annealing antitack agent provided by the invention has an advantage of reasonable ratio, and can be used to solve the annealing bonding problem of a copper belt bell-type furnace. By the utilization of the copper belt annealing antitack agent provided by the invention, production processes are reduced.

Owner:苏州白云信息科技有限公司

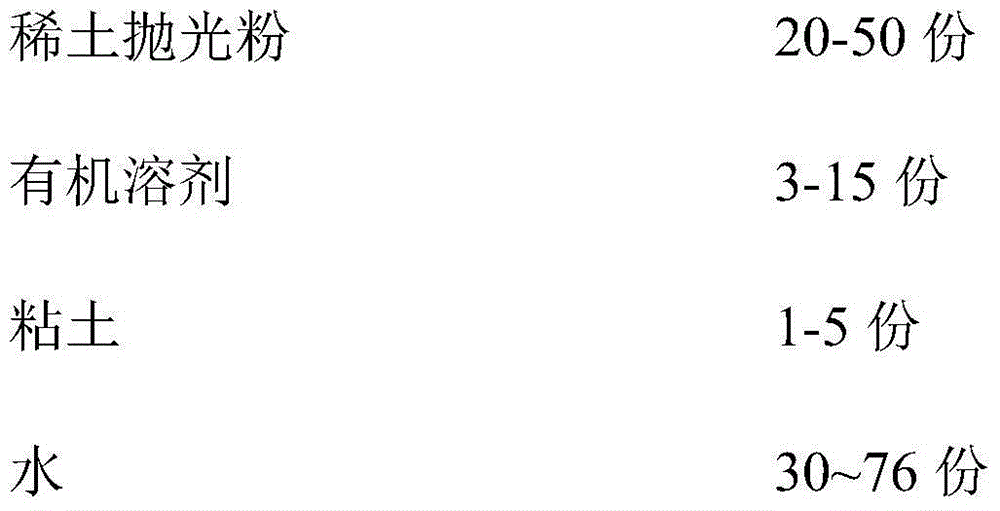

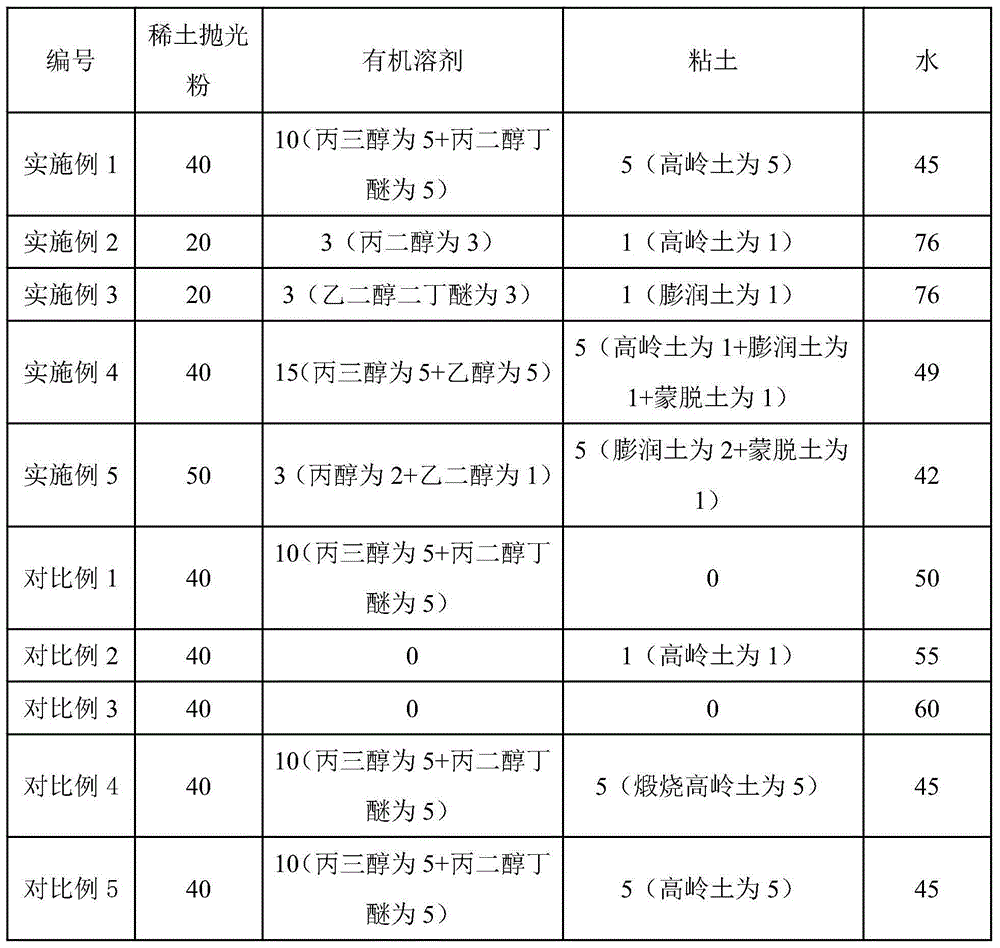

Rare earth polishing liquid and preparation method thereof

ActiveCN104479555AEasy to prepareSolve the ease of cleaningPolishing compositions with abrasivesOrganic solventRare earth

The invention provides a rare earth polishing liquid and a preparation method thereof; the rare earth polishing liquid comprises the following components in parts by weight: 20-50 parts of a rare earth polishing powder, 3-15 parts of an organic solvent, 1-5 parts of clay, and 30-76 parts of water. The rare earth polishing liquid solves the problem of suspension dispersion of a polishing powder in water, overcomes the bonding problem of the polishing liquid in preparation and storage processes and good cleaning problem of the polishing liquid in a use process at present, and has the characteristics of good suspension dispersibility, fast polishing speed, high polishing precision, excellent cleaning performance of polished products and the like. The rare earth polishing liquid is suitable for surface polishing processing of integrated circuits, flat panel display, optical glass and other electronic information industry precision devices, and meets polishing yield rate requirements of increasingly-strict business on polishing materials in accuracy, polishing corrosion amount, easy cleaning and the like.

Owner:NUOXUAN CHEM TECH SHANGHAI

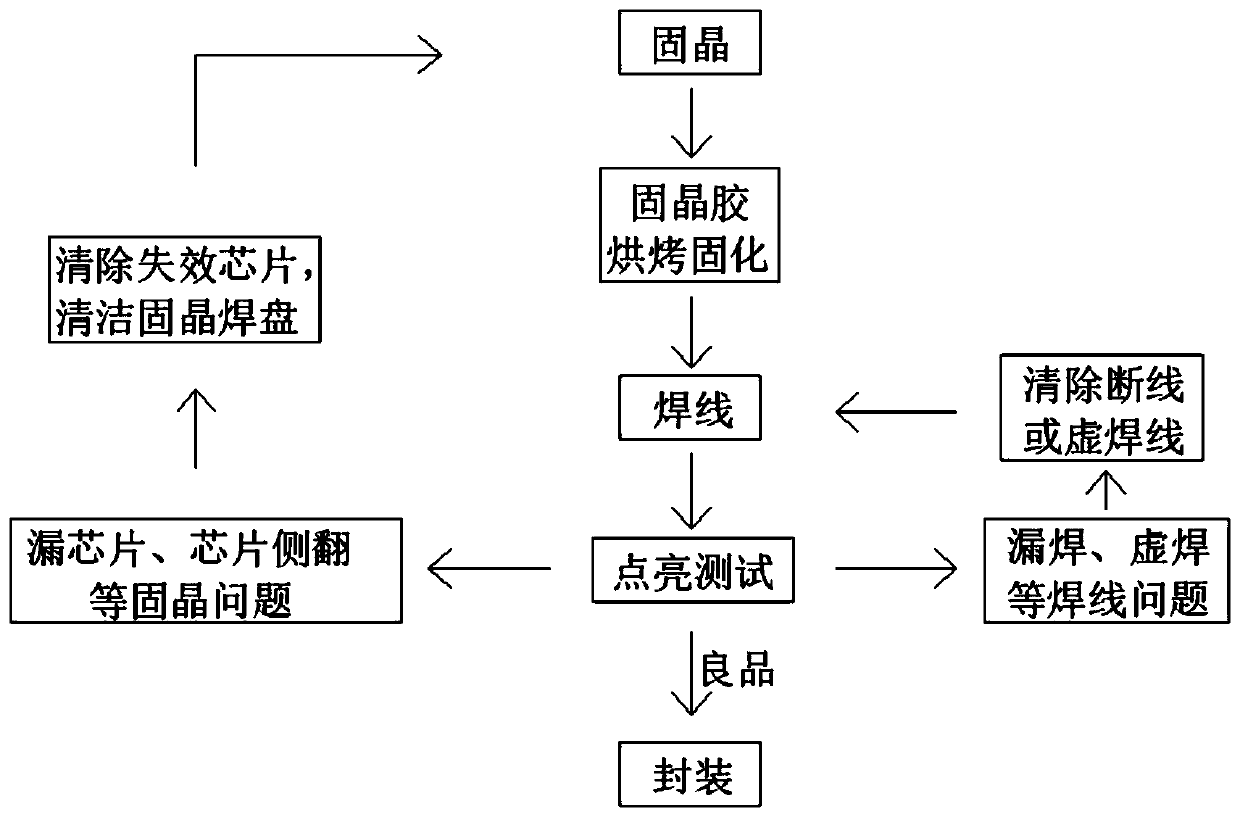

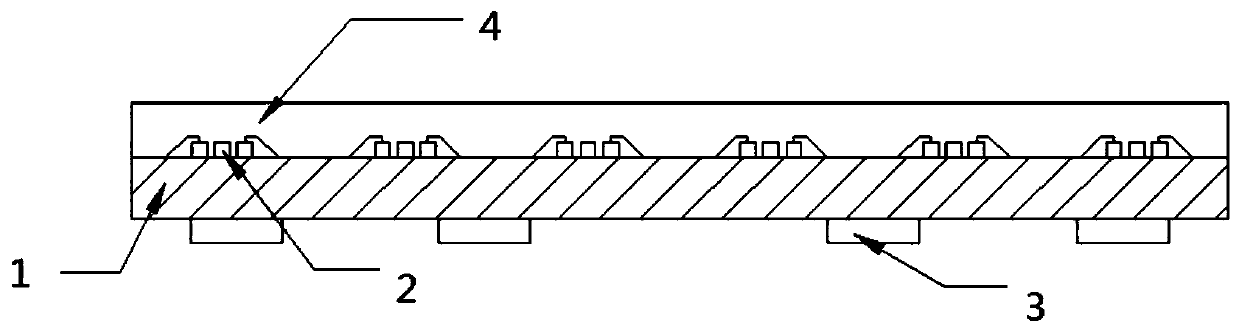

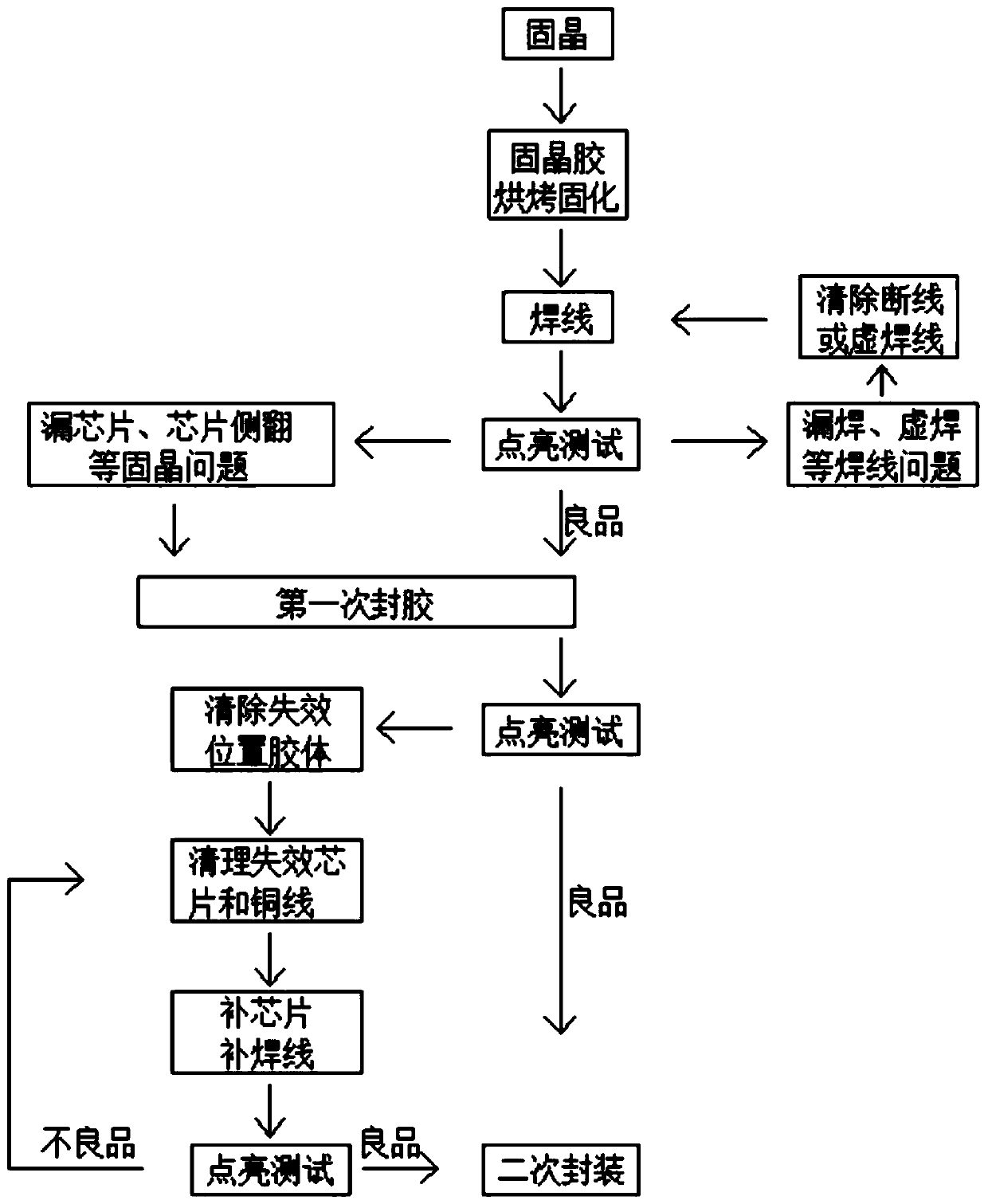

COB display screen packaging method based on copper wire bonding

The invention provides a COB display screen packaging method based on copper wire bonding. The COB display screen packaging method comprises the following steps of S1, carrying out die bonding; S2, baking and curing the die bonding glue; S3, welding copper wires, and forming a COB display module based on copper wire bonding; S4, carrying out a lightening test, if the product is a good product or adie bonding problem exists, carrying out the next step, if a wire bonding problem exists, removing damaged wires or pseudo soldering wires, and returning to the step S3 again; S5, carrying out packaging for the first time, adopting discrete glue for packaging, and manufacturing an inner protective colloid on each pixel point, wherein the inner protective colloids are not connected with one another and n a discrete state; S6, removing the inner protective colloid at a failure position; S7, cleaning the failed chip and the copper wires; S8, repairing the chip, baking and curing the die bondingglue, and repairing and welding the copper wires; and S9, carrying out the lightening test, if the product is a defective product, returning to the step S7, and if the product is a good product, carrying out secondary packaging. The beneficial effects are that the copper wire welding technology is applied to production of the COB display screen, and the cost is reduced.

Owner:深圳市科米三悠科技有限公司

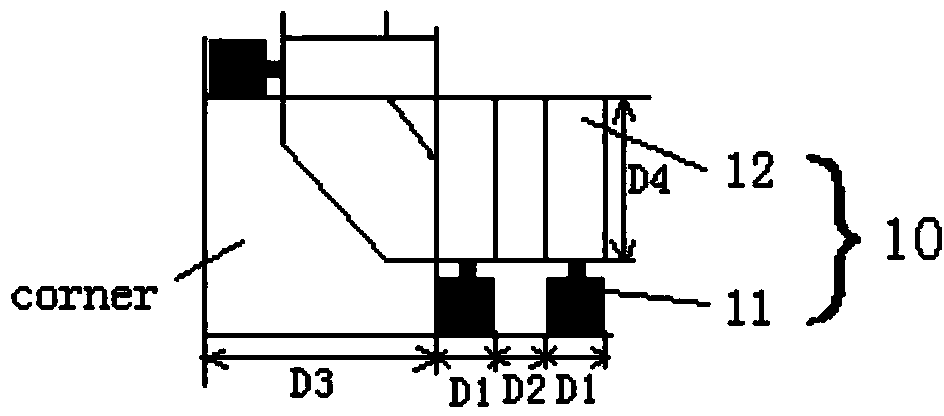

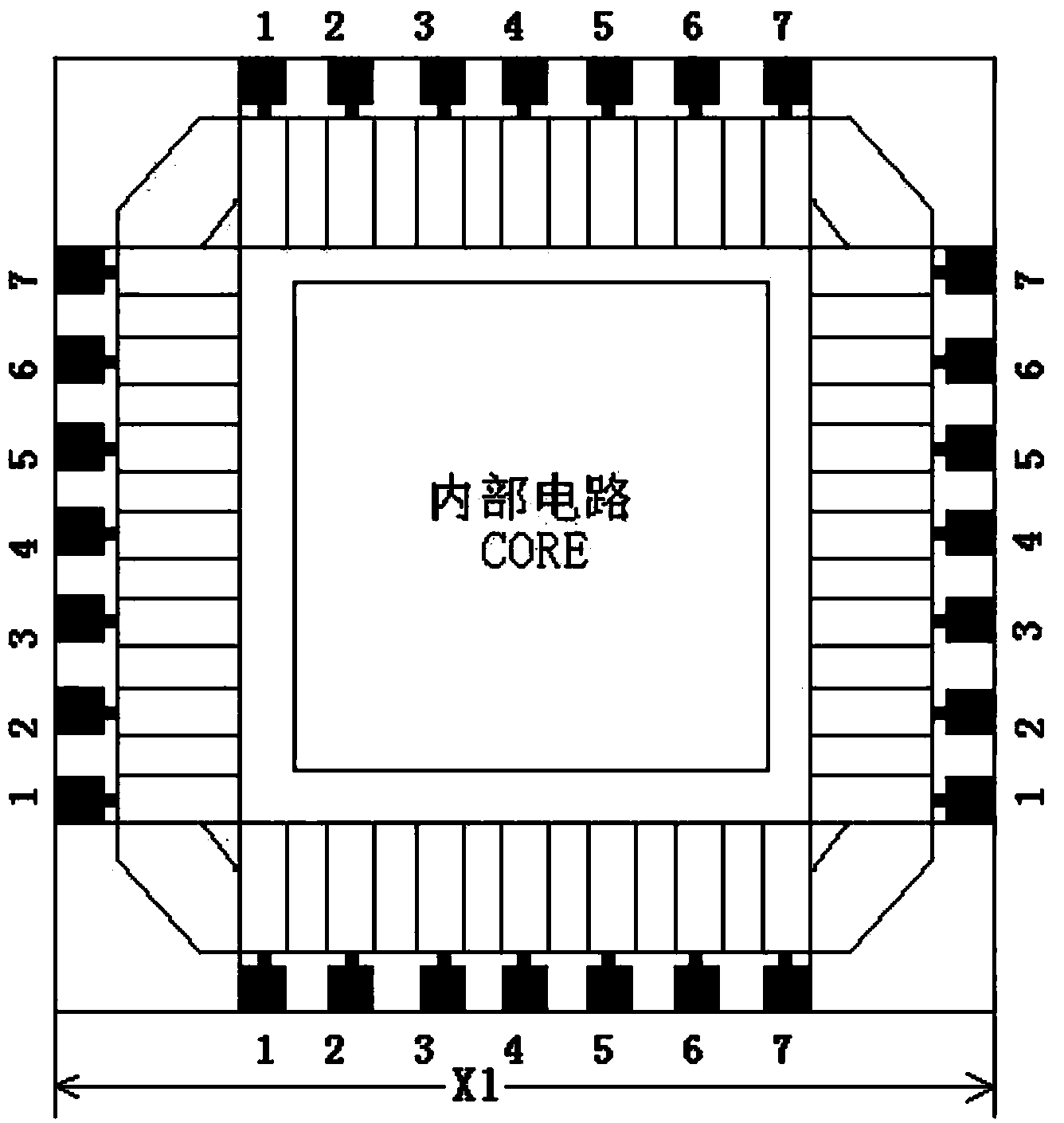

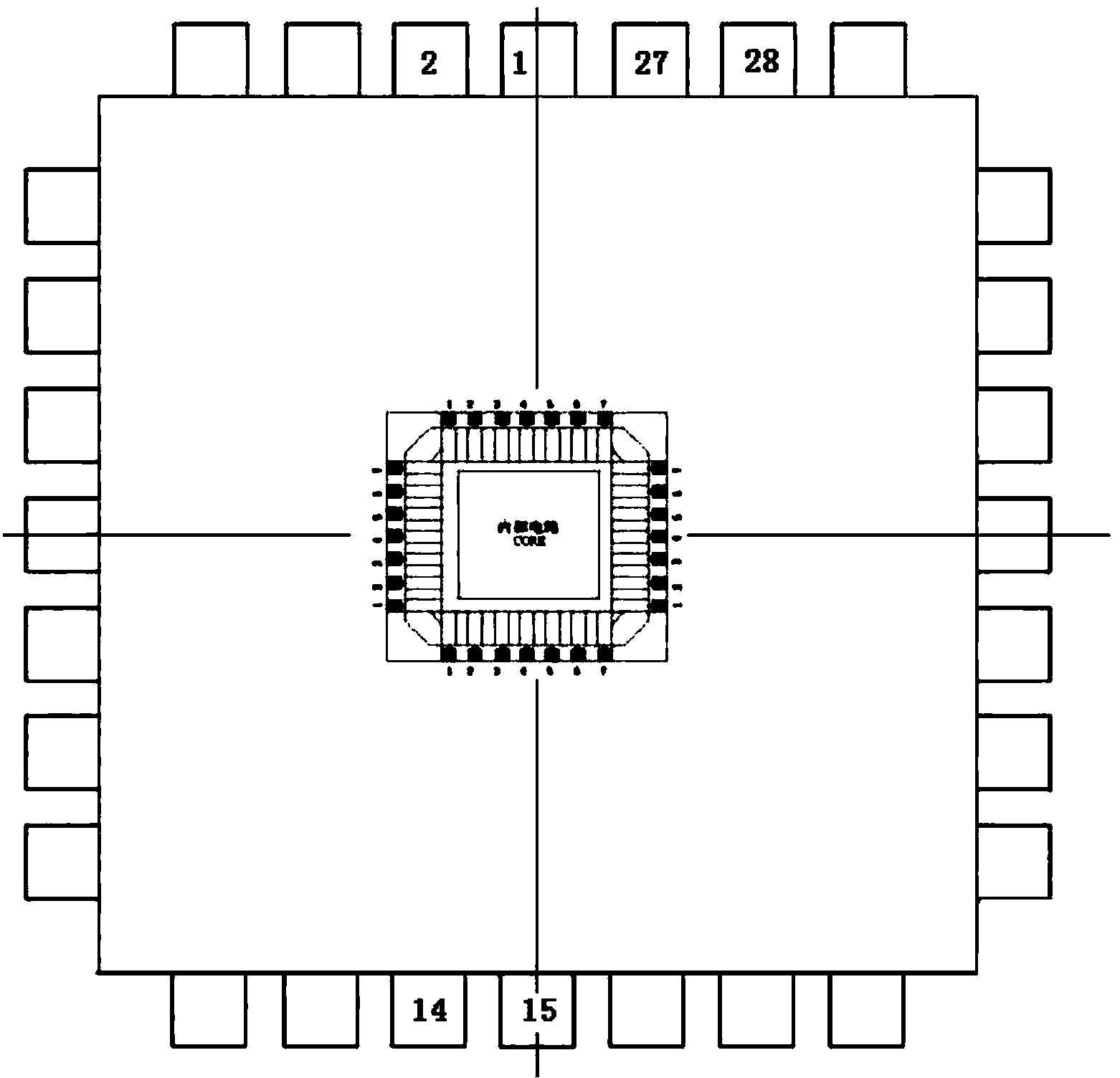

Chip bonding pad layout design method suitable for multiple different encapsulation requirements

ActiveCN103903996AMeet the requirements of adapting to different packagesLow costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringBonding problems

The invention discloses a chip bonding pad layout design method suitable for multiple different encapsulation requirements. According to the total number of bonding pads, the number of the bonding pads at each side of a chip and the dimensions of the chip in the length direction and in the width direction are determined; a basic encapsulation type is determined; the number and the positions of the bonding pads at each side of the chip are adjusted; another encapsulation type is selected, and a bonding figure is designed; optimizing methods of bonding the different bonding pads that the bonding pads with the bonding problem or different encapsulation types are replaced by moving the bonding pad positions with the bonding problem and increasing the number of the bonding pads are adopted, so that the bonding pads can meet the requirements of the different encapsulation types; the final bonding figure is designed. By means of the optimized layout of the chip bonding pads designed by the adoption of the design method, the phenomenon that the different encapsulating can not be conducted to the same chip unless the layout design is changed is solved, the requirement that the same chip can be suitable for different encapsulating is met, flexibility of chip encapsulating and chip applying is achieved, and cost is reduced.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Tire tread carrying auxiliary equipment

ActiveCN106115254ARealize automatic transferAvoid Pendulum Sticking ProblemsConveyorsConveyor partsEngineeringBonding problems

The invention provides tire tread carrying auxiliary equipment. The tire tread carrying auxiliary equipment comprises a louvered vehicle for placing treads, a driving device for shifting out the treads output by a tread production line and arranged at an output end of the tread production line, and an automatic carrying device for carrying the treads on the driving device onto the louvered vehicle and provided with a tread gripper in the length directions of the treads. The tire tread carrying auxiliary equipment firstly uses the driving device for shifting out the treads output by the tread production line, and uses the tread gripper of the automatic carrying device for carrying the treads on the driving device onto the louvered vehicle to realize automatic carrying of the treads, so that the labor intensity of workers is reduced, and the labor cost is reduced; and meanwhile, the treads are carried and placed through the tread gripper, so that the tread placing and bonding problems caused in manual carrying and placing processes are prevented, and the tread production quality is improved.

Owner:MESNAC

Super-strength waterproof LED light-emitting module and processing method

PendingCN110440155ASolve the tightness problemImprove waterproof levelGas-tight/water-tight arrangementsSemiconductor devices for light sourcesInterference fitBonding problems

The invention provides a super-strength waterproof LED light-emitting module and a processing method, and belongs to the field of lamp processing. The super-strength waterproof LED light-emitting module comprises a shell and a light source module arranged in the shell; the light source module comprises a PCB and a lamp bead arranged on the PCB; the LED light-emitting module further comprises a wire connected with the PCB; wire leading-out passages which are in interference fit with the wire are arranged in the two ends of the shell respectively; threads are arranged on the matching surfaces ofthe wire leading-out passages and the wire; and the wire sheath and the threads of the wire leading-out passages are welded. The light-emitting module has the beneficial effects that the bonding problem of the wire outer sheath wire and the outer shell structural member is effectively improved, and the waterproof grade is effectively increased.

Owner:SHENZHEN LINGBENYANG TECHNICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com