Method for producing high permeability mangan zinc ferrite

A technology of manganese zinc ferrite and high magnetic permeability, which is applied in the field of high magnetic permeability manganese zinc ferrite, can solve the problems of inseparability, composition change, and inability to obtain high magnetic permeability, etc., and achieve the goal of improving mechanical strength and cost saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. It should be understood that the preferred embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0018] A production method of high magnetic permeability manganese-zinc ferrite, comprising the following steps:

[0019] 1) The high magnetic permeability Mn-Zn ferrite particles are returned to the fine powder by the dust collector in the spray granulation production process for a back-burning through the kiln. Mn-Zn ferrite magnetic powder; the cooked magnetic powder does not react with the product blank, so there is no bonding phenomenon. If it is not cooked, it will still produce bonding with the blank product;

[0020] 2) The expected effect can be obtained by evenly scattering the cooked magnetic powder between the blank products;

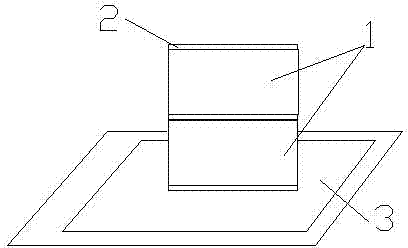

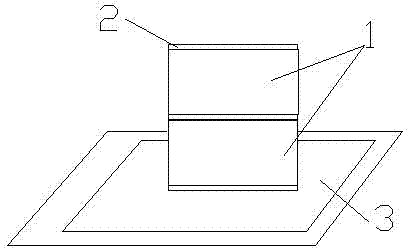

[0021] 3), if figure 1 Shown: The hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com