High temperature resistant antitack agent and processing method before metal tape annealing

A treatment method and anti-sticking agent technology, which is applied in the field of metal surface spraying treatment, can solve the problems affecting the shape of the plate, and achieve the effect of cost saving and reasonable proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Copper strip: T2, 0.25mm thick; rolling mill process medium: rolling oil; coil weight: 4 tons.

[0033] Experimental method: online spraying on the finishing mill.

[0034] Evaluation symbols: ☆—no bonding, O—slight bonding, ▲—serious bonding

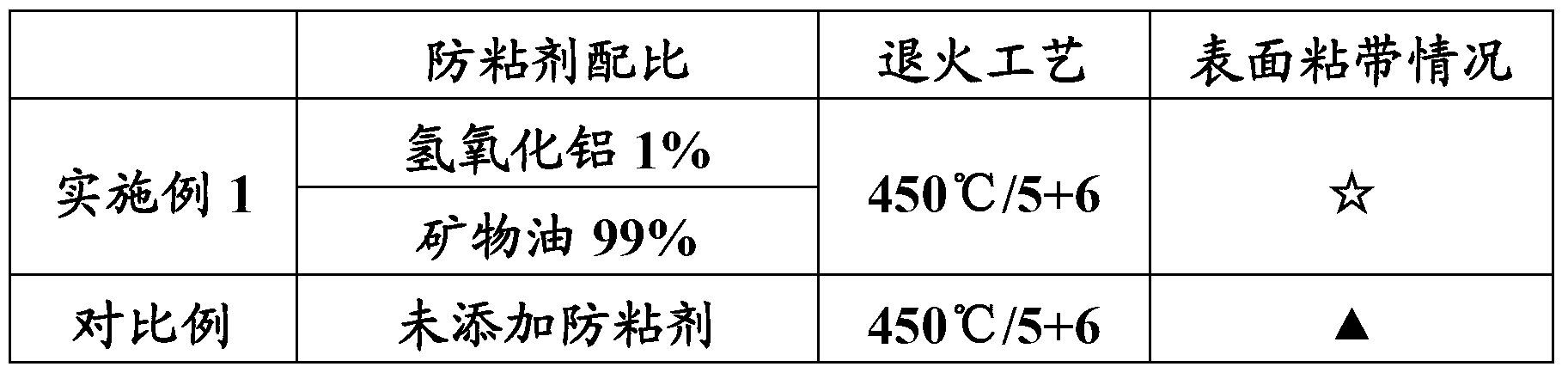

[0035] Table 1

[0036]

[0037] Table 1 shows: adopt the red copper tape annealing antisticking agent of embodiment 1 to thickness be 0.25mm, the red copper tape of mineral oil lubrication is processed, and red copper tape surface has no bonding, and surface quality is good.

[0038] The high-temperature anti-sticking agent formula of red copper strip among the embodiment 1 adopts aluminum hydroxide 1.5% and mineral oil 98.5%, aluminum hydroxide 2% and mineral oil 98%, aluminum hydroxide 2.5% and mineral oil 97.5% or aluminum hydroxide 3% and mineral oil 97%, also can reach the technical effect identical with embodiment 1.

[0039] If the content of aluminum hydroxide exceeds 50% in embodiment 1, viscosity increases, is u...

Embodiment 2

[0041] Copper strip: T2, 0.25mm thick; rolling mill process medium: rolling oil; coil weight: 4 tons.

[0042] Experimental method: online spraying on the finishing mill.

[0043] Evaluation symbols: ☆—no bonding, O—slight bonding, ▲—serious bonding

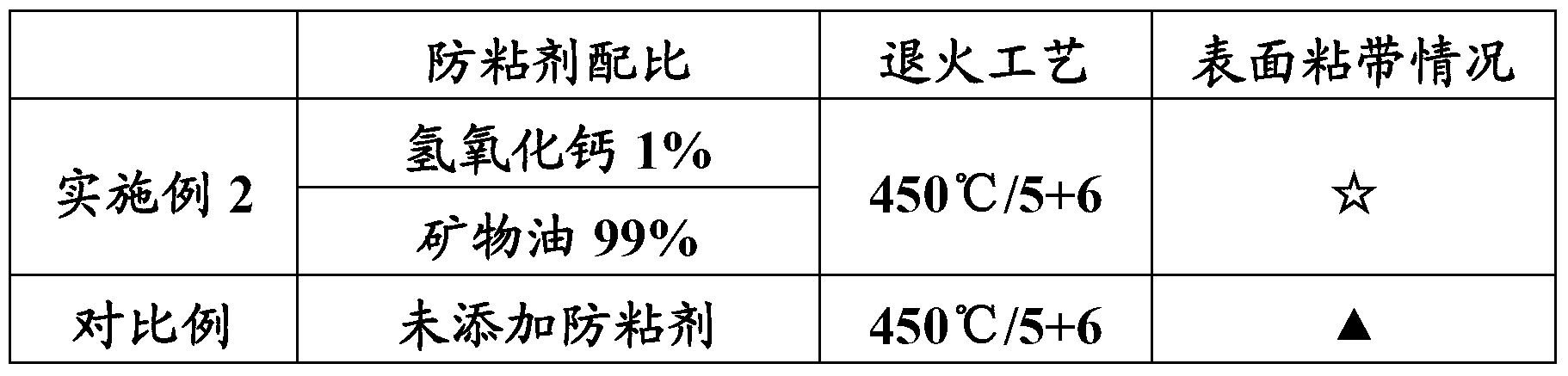

[0044] Table 2

[0045]

[0046] Table 2 shows: adopt the red copper tape annealing antisticking agent of embodiment 1 to process the red copper tape that thickness is 0.25mm, mineral oil lubrication, the red copper tape surface has no bonding, and surface quality is good.

[0047] The high-temperature anti-sticking agent formula of red copper band among the embodiment 2 adopts calcium hydroxide 1.5% and mineral oil 98.5%, calcium hydroxide 2% and mineral oil 98%, calcium hydroxide 2.5% and mineral oil 97.5%, or hydroxide Calcium 3% and mineral oil 97%, also can reach the technical effect identical with embodiment 2.

[0048] If the content of calcium hydroxide exceeds 50% in embodiment 2, the viscosity increase has certai...

Embodiment 3

[0050] Copper alloy strip: T2, 0.25mm thick; rolling mill process medium: rolling oil; coil weight: 4 tons.

[0051] Experimental method: online spraying on the finishing mill.

[0052] Evaluation symbols: ☆-no bonding, O-slight bonding, ▲-severe bonding

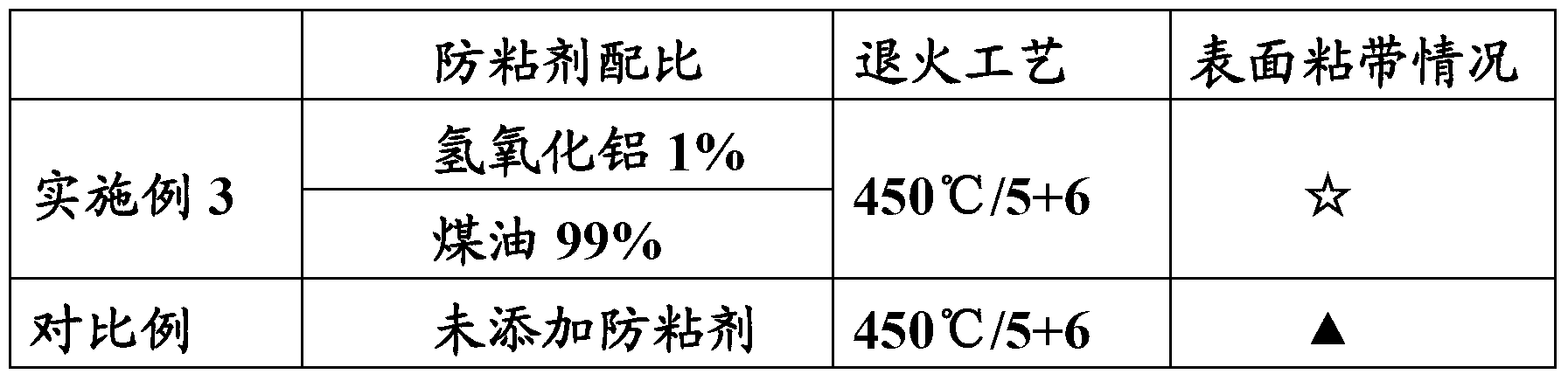

[0053] table 3

[0054]

[0055] Table 3 shows: the copper alloy strip annealing antisticking agent of embodiment 3 is used to process the copper alloy strip with a thickness of 0.25mm and kerosene lubrication, and the copper alloy strip surface has no bonding, and the surface quality is good.

[0056]Copper alloy strip high temperature anti-sticking agent formula adopts aluminum hydroxide 1.5% and mineral oil 98.5% in embodiment 3, aluminum hydroxide 2% and mineral oil 98%, aluminum hydroxide 2.5% and mineral oil 97.5% or aluminum hydroxide 3% and mineral oil 97%, also can reach the technical effect identical with embodiment 3.

[0057] If the content of aluminum hydroxide exceeds 50% in embodiment 3, the viscosity i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com