Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

An anti-graffiti and coating technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of water resistance, acid and alkali resistance, poor solvent resistance, anti-graffiti, poor sticking resistance, poor weather resistance, etc., to achieve durability Good scrubbing performance, tough paint film, good self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Component A is: 30 parts of hydroxyl acrylic resin, 30 parts of fluorocarbon resin, 14 parts of modified polydimethylsiloxane resin, 5 parts of polyacrylate modified silicone resin, smooth flow agent 1 0.25 parts of leveling agent, 0.25 parts of defoamer, 0.2 parts of drier, 0.05 parts of dibutyltin dilaurate, 5 parts of butyl acetate, 13 parts of xylene; component B is: hexamethyl diisocyanate 70 parts of urea, 15 parts of butyl acetate, 15 parts of ethylene glycol ethyl ether acetate; the proportion of component A and component B is: 3 parts of component A and 1 part of component B.

[0015] The method for preparing the oily anti-graffiti and anti-stick coating of the present invention is component A: add hydroxyacrylic resin and fluorocarbon resin into the stirring tank, stir with the agitator at a speed of 800 rpm, and then add modified polydimethylsilane The mixture of oxane resin, polyacrylate modified silicone resin and smooth flow agent, after stirrin...

Embodiment 2

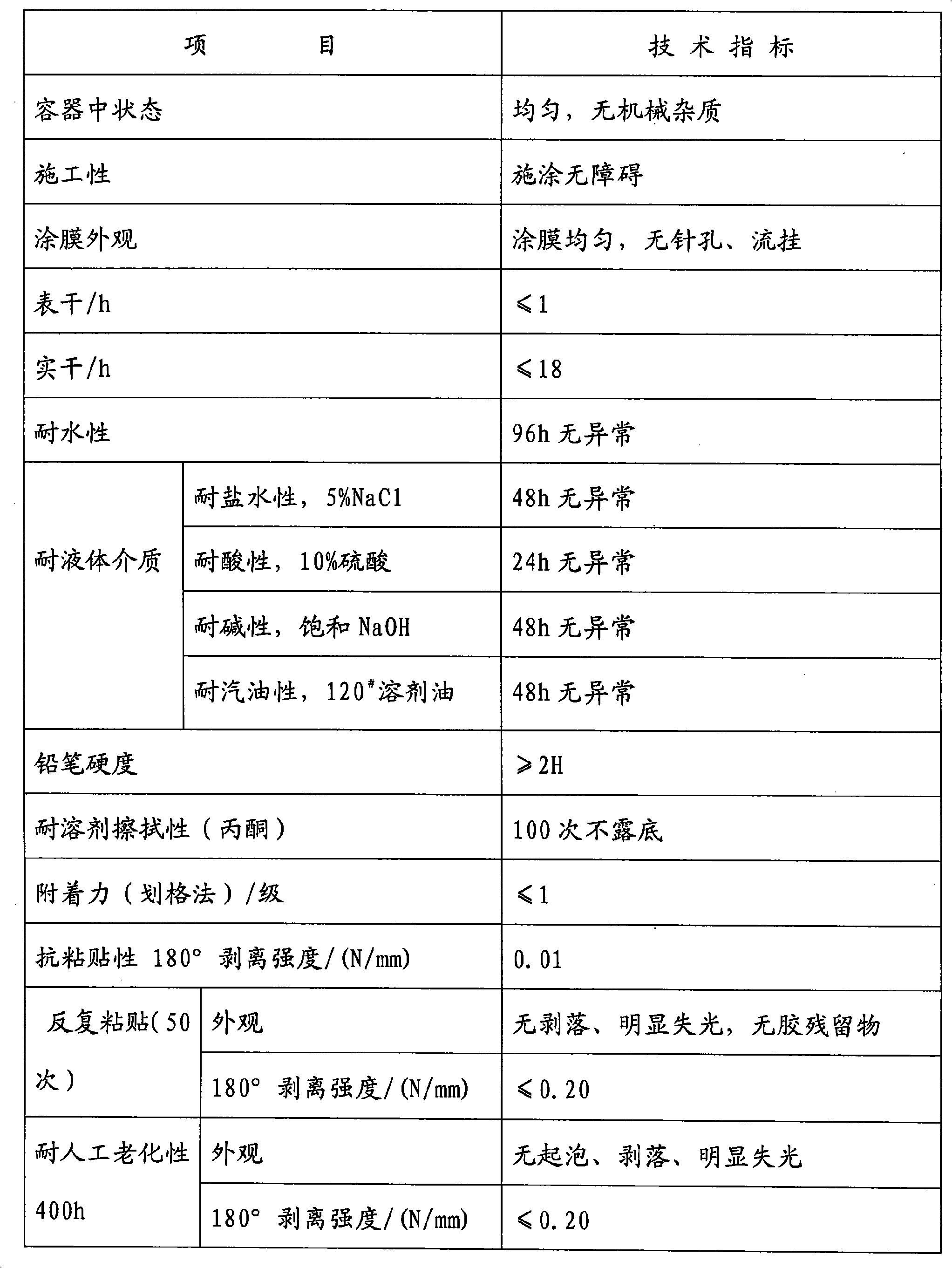

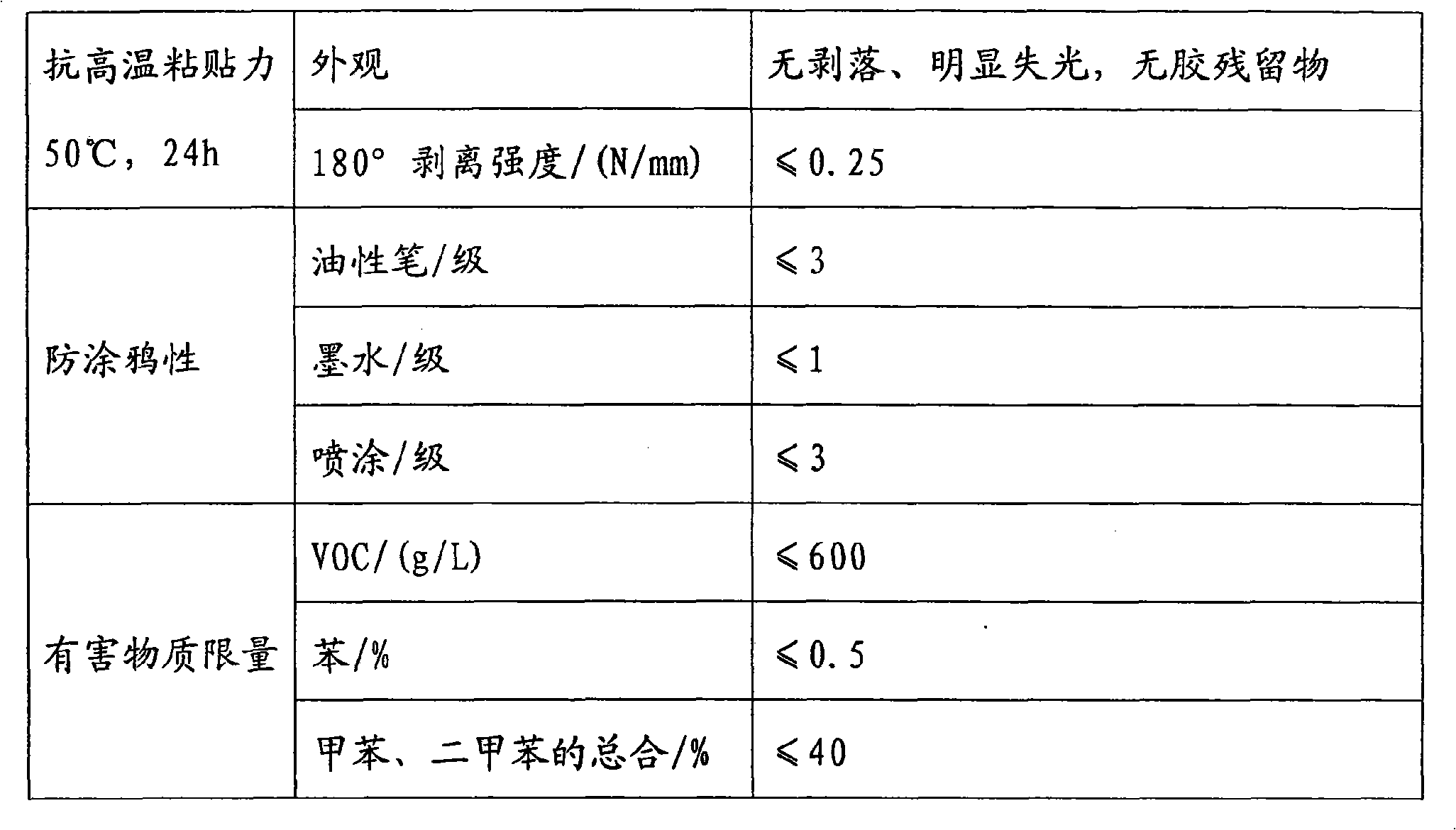

[0020] Embodiment 2: press the specified component of embodiment 2 listed in table 2, repeat the preparation method of embodiment 1A component (but the stirrer rotating speed is 850 rev / min); repeat the preparation method of embodiment 1B component ( But the stirrer rotating speed is 600 rev / min), obtain coating, according to the proportioning and method of A component and B component described in Example 1, and test as described in Example 1 as described in Example 1 Technical performance and technical performance indicators are shown in Table 1. The test results are good and meet the technical performance indicators.

Embodiment 3

[0021] Embodiment 3: by the specified component of the embodiment 3 listed in table 2, repeat the preparation method of the embodiment 1A component (but the stirrer rotating speed is 830 rpm); repeat the preparation method of the embodiment 1B component ( But the stirrer rotating speed is 550 rev / min), obtain coating, according to the proportioning and method of A component and B component described in Example 1, and test as described in Example 1 as described in Example 1 Technical performance and technical performance indicators are shown in Table 1. The test results are good and meet the technical performance indicators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com