Method for preparing magnetizable ceramic

A technology for the preparation of ceramics and ceramic products, applied in the field of preparation of magnetizable ceramics, can solve the problems of low yield, limited use, and lack of firm connection, and achieves the effect of solving the combination problem and achieving remarkable innovation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

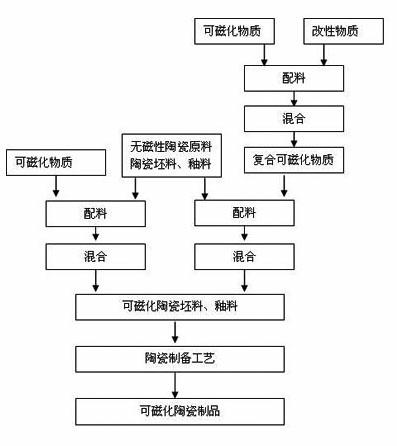

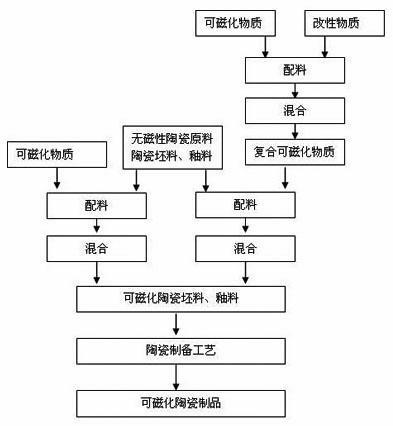

[0026] like figure 1Shown, the present invention is a kind of preparation method of magnetizable ceramics, it is to mix magnetizable substance in non-magnetic ceramic powder, adopt ceramic preparation process, prepare magnetizable ceramic products. Non-magnetic ceramic powder is selected from one or more of various ceramic raw materials, ceramic blanks, and ceramic glazes; ceramic raw materials include: natural minerals, processed minerals, and chemical products; ceramic blanks include: ceramic wall and floor tile blanks, sanitary ceramic blanks , Daily-use ceramic blanks, industrial ceramic blanks; magnetizable substances are selected from substances that can obtain magnetic characteristics under the action of an external magnetic field, including metal oxides, metals, alloys, minerals, and various forms of substances composed of them; metal oxides Substances, metals, alloys, minerals each alone or a mixture of more than one and other substances; metal oxides include soft fer...

Embodiment 1

[0030] Weigh 14 kg of granulated blanks of ceramic polished tiles, 6 kg of nickel-zinc ferrite granulated powders, dry-stir and mix them into a mixture, press the mixture into 400×400×8mm bricks, after drying, Fired at 1200°C for 30 minutes, the resulting ceramic tiles have a magnetizable function.

Embodiment 2

[0032] Weigh 12 kg of ceramic glazed tile blanks, 8 kg of soft magnetic ferrite powder, mix them into a mixed slurry by wet method, dry and granulate the mixed slurry, press it into a brick adobe of 200×300×6mm, and dry it , fired at 1150°C for 30 minutes to obtain a biscuit body, glazed on the biscuit body, and then fired at 1120°C, the obtained ceramic glazed tile has a magnetizable function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com