Light guiding body structure and manufacturing method thereof

A production method and technology for light guides, applied in the directions of light guides, optics, optical components, etc., can solve the problems affecting the appearance of products, softening and deformation of light guides, dead lights, etc., to achieve good light output, quality assurance, and improved aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

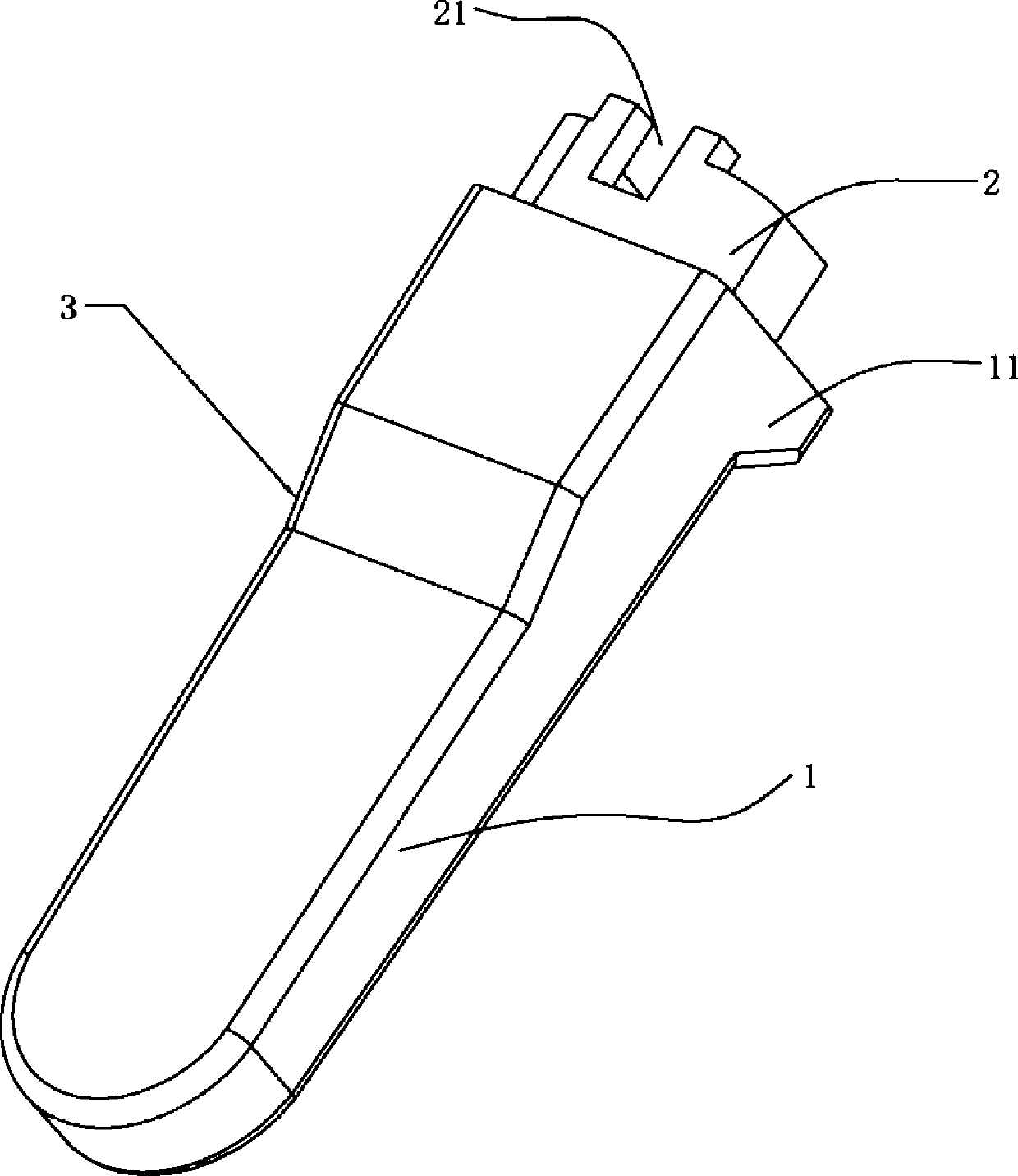

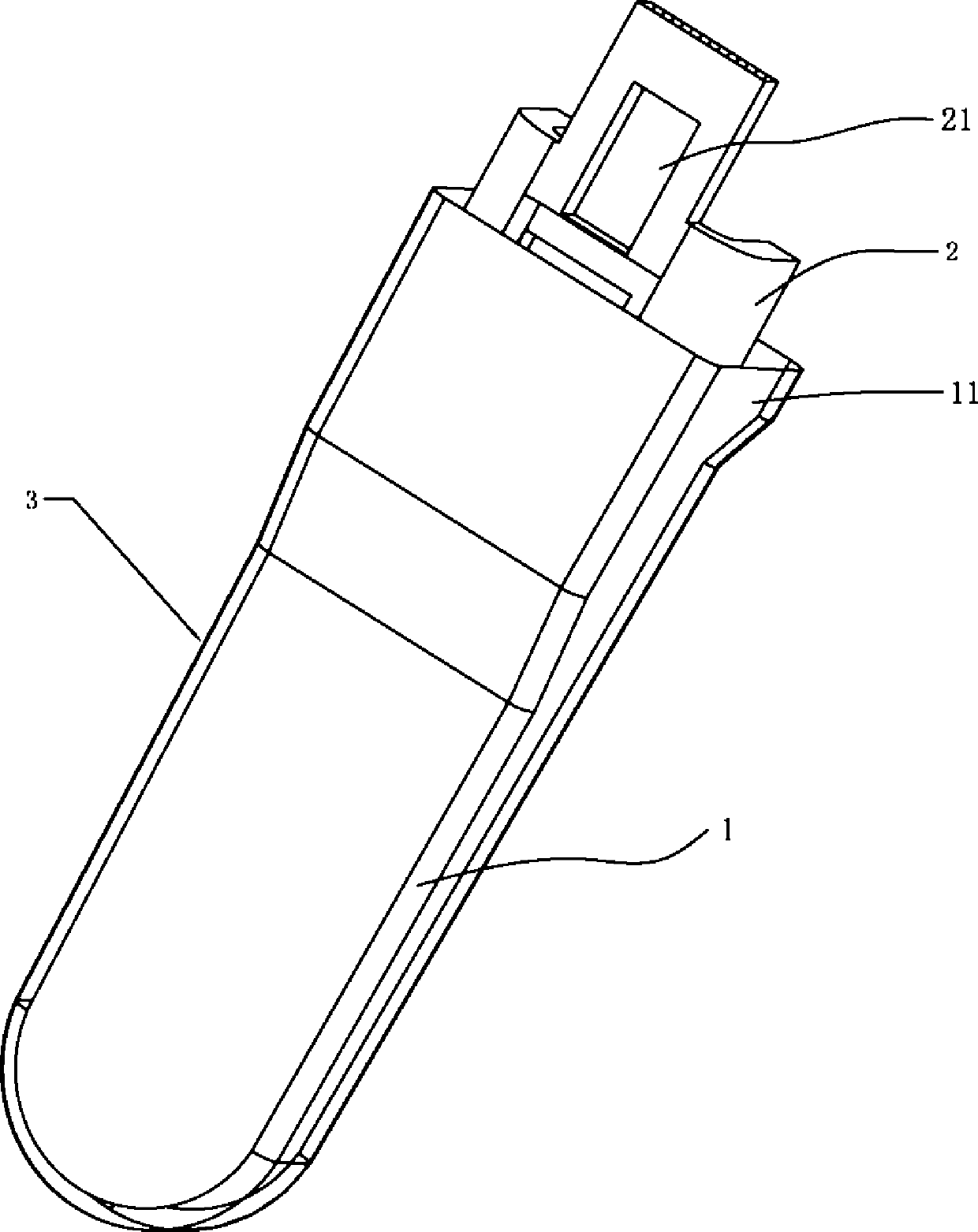

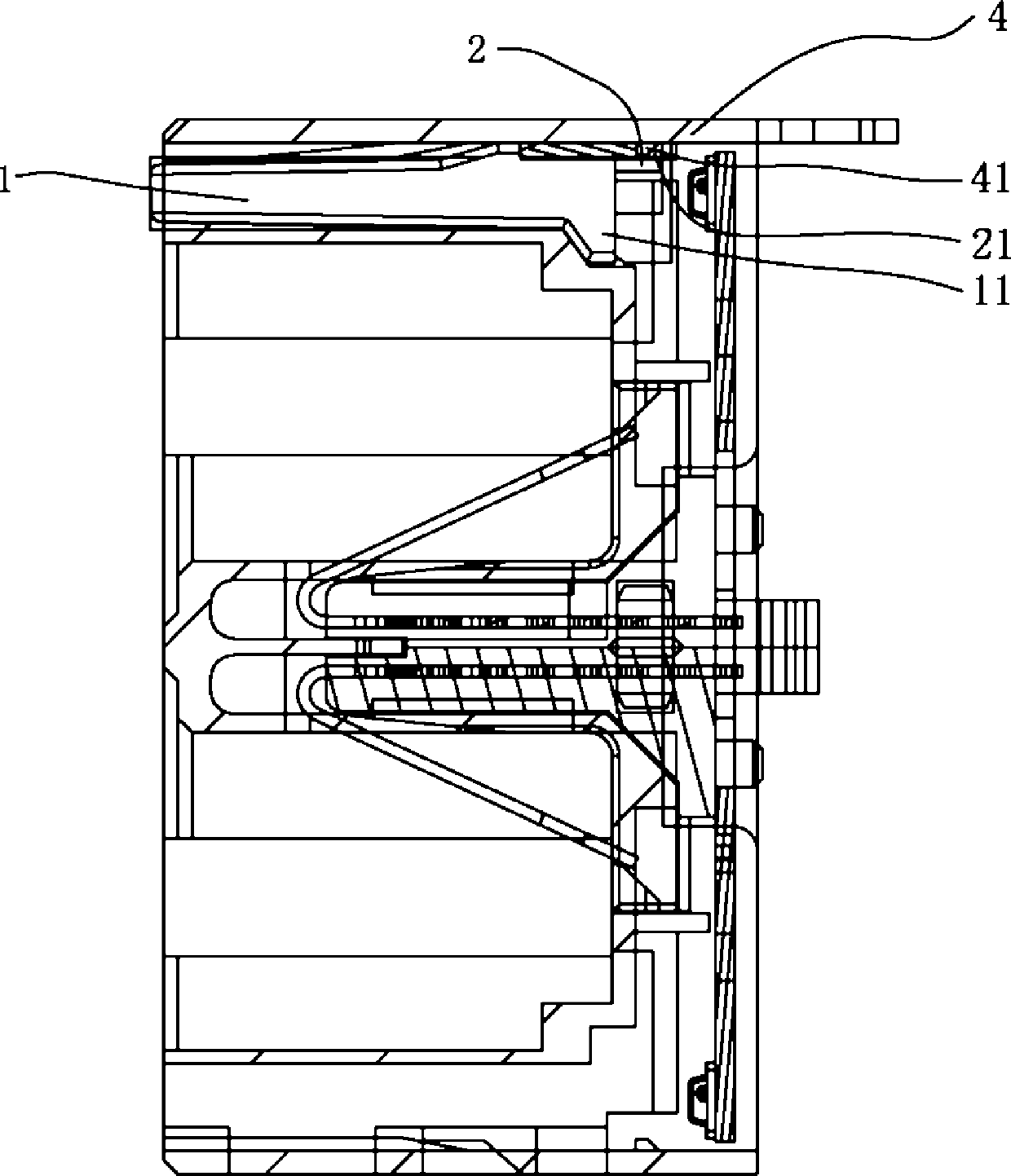

[0039] see Figure 1 to Figure 8 , the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] A light guide structure according to the present invention includes a bracket, and also includes a light guide body 1, the bracket is a metal bracket 2, and the light guide body 1 is a light guide body 1 made of a high temperature resistant material , the metal bracket 2 is inserted into the colloid forming the light guide body 1 to form a light guide body structure 3 in which the light guide body 1 and the metal bracket 2 are integrated; wherein, the metal bracket 2 is provided at the connection with the connector housing 4 There is a coupling end 21 . In this invention, the inventor changed the PC plastic commonly used in the current light guide body 1 through innovative thinking, and used high temperature resistant materials for the light guide body 1, thereby replacing the PC used in the current light guide body 1. It is made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com