Vanadium-contained semimetallic brake block

A technology of semi-metal brake pads, applied in the field of brake pads, can solve the problems that restrict the application of semi-metal brake pads, brake disc damage, hub corrosion, etc., achieve unique chemical stability, improve wear resistance, increase friction Observe the effect of the coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

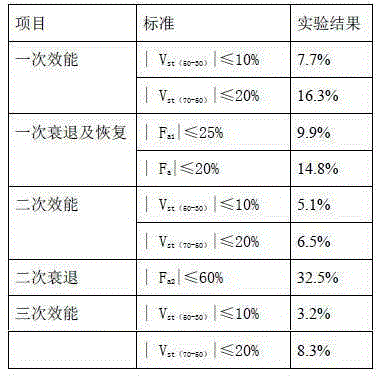

Examples

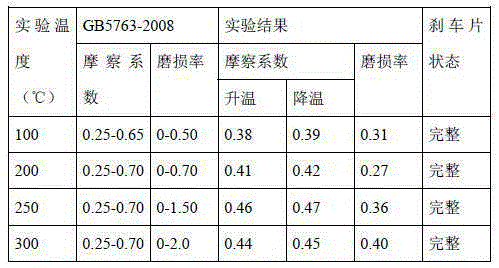

Embodiment 1

[0030]A vanadium-containing semi-metal brake pad, the components of which are calculated by weight: 7 parts of copper fiber, 3 parts of potassium hexatitanate whisker, 5 parts of barium sulfate, 23 parts of vanadium iron powder, 4 parts of friction powder, 15 parts of short stainless steel fiber, 6 parts of graphite, 4 parts of cellulose fiber, 9 parts of coke powder, 1 part of modified resin nitrile fiber, 3 parts of chromite powder, 5 parts of nitrile rubber, 5 parts of ceramic binder, spray Colloidal aluminum silicate fiber 10 parts. The friction powder is cashew nut shell oil friction powder, the ceramic binder is vulcanized titanium and silicate, the grade of vanadium iron powder is FeV40, and the particle size grade is 3.

[0031] The above vanadium-containing semi-metallic brake pads are prepared through the following steps:

[0032] Step 1. Mixing: Put the weighed materials into a high-speed mixer and stir, first mix the modified resin nitrile fiber, nitrile rubber, g...

Embodiment 2

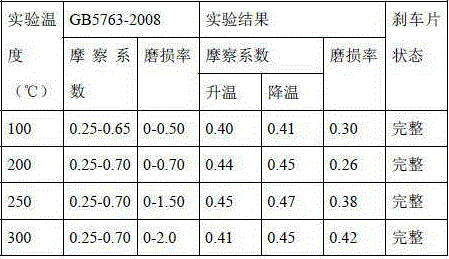

[0044] A vanadium-containing semi-metal brake pad, the components of which are calculated by weight: 6.5 parts of copper fiber, 6 parts of potassium hexatitanate whisker, 4 parts of barium sulfate, 15 parts of vanadium iron powder, 5 parts of friction powder, 14.5 parts of short stainless steel fiber, 10 parts of graphite, 2 parts of cellulose fiber, 7 parts of coke powder, 5 parts of modified resin nitrile fiber, 7 parts of chromite powder, 1 part of nitrile rubber, 9 parts of ceramic binder, spray Colloidal aluminum silicate fiber 8 parts. The friction powder is cashew nut shell oil friction powder, the ceramic binder is vulcanized titanium and silicate, the grade of vanadium iron powder is FeV40, and the particle size grade is 3.

[0045] The above vanadium-containing semi-metallic brake pads are prepared through the following steps:

[0046] Step 1. Mixing: Put the weighed materials into a high-speed mixer and stir, first mix the modified resin nitrile fiber, nitrile rubb...

Embodiment 3

[0058] A vanadium-containing semi-metal brake pad, the components of which are calculated by weight: 5 parts of copper fiber, 3.5 parts of potassium hexatitanate whisker, 4.3 parts of barium sulfate, 25 parts of vanadium iron powder, 6 parts of friction powder, 13 parts of short stainless steel fiber, 6.3 parts of graphite, 3.1 parts of cellulose fiber, 8 parts of coke powder, 2.7 parts of modified resin nitrile fiber, 4.5 parts of chromite powder, 3.2 parts of nitrile rubber, 6.2 parts of ceramic binder, spray Colloidal aluminum silicate fiber 9.2 parts. The friction powder is cashew nut shell oil friction powder, the ceramic binder is vulcanized titanium and silicate, the grade of vanadium iron powder is FeV40, and the particle size grade is 3.

[0059] The above vanadium-containing semi-metallic brake pads are prepared through the following steps:

[0060] Step 1. Mixing: Put the weighed materials into a high-speed mixer and stir, first mix the modified resin nitrile fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com