Double-effect isolation liquid for oil-based mud cementing, and preparation method thereof

A technology of oil-based mud and spacer fluid, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of oil-based mud demulsification, etc., to promote penetration, enhance solubility and permeability, and good isolation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

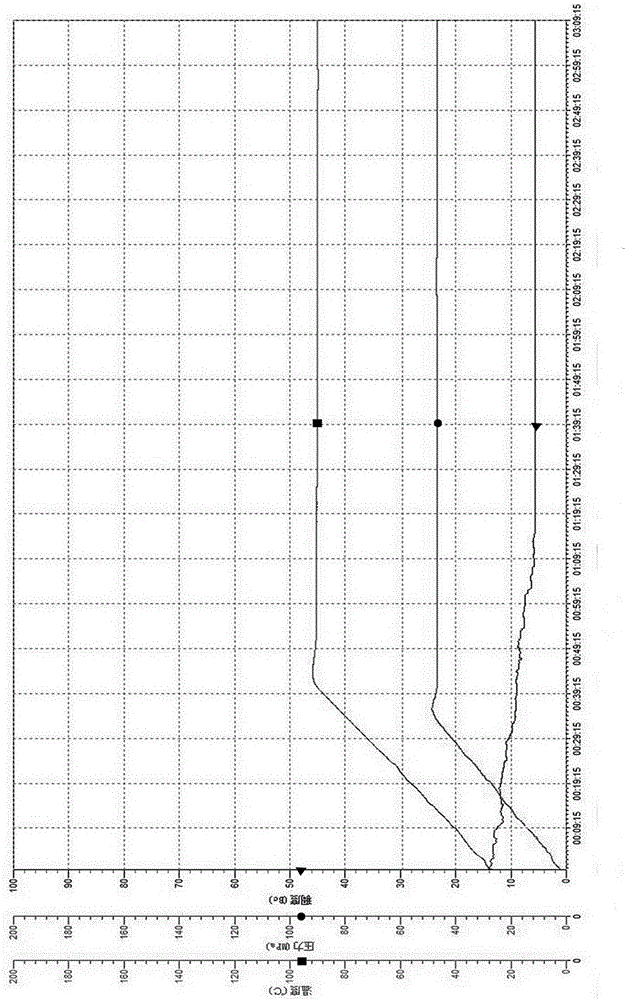

Image

Examples

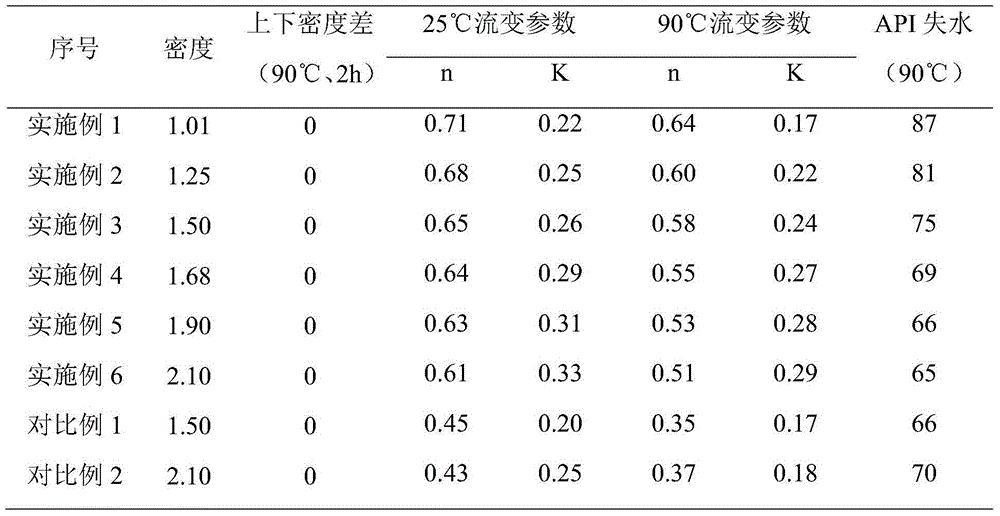

Embodiment 1

[0024] [Example 1] A double-effect spacer fluid for oil-based mud cementing provided by the present invention, with a density of 1.01g / cm 3 , it contains the following raw materials in parts by weight, 95 parts of clear water, 10 parts of flushing agent, 10 parts of filler, 1 part of retarder, 0.1 part of defoamer, and 1 part of release agent. The flushing agent is a phospholipid composite surfactant; the filler is an ultrafine particle material; the retarder is an AMPS polymer retarder; the defoamer is a polyether defoamer; the release agent is a polyethylene Organic polymer release agent.

[0025] A double-effect spacer fluid for oil-based mud cementing. Its preparation method is: add 1 part of spacer to 95 parts of clear water, stir well at low speed, then slowly add 10 parts of filler and 1 part of retarder After stirring evenly, add 10 parts of flushing agent and keep rotating at low speed. After the liquid is evenly distributed, finally add 0.1 part of defoamer, and kee...

Embodiment 2

[0026] [Example 2] A double-effect spacer fluid for oil-based mud cementing provided by the present invention, with a density of 1.25g / cm 3 , it contains the following raw materials in parts by weight, 100 parts of clear water, 12 parts of flushing agent, 12 parts of filler, 2 parts of retarder, 0.2 part of defoamer, 1.5 parts of release agent, and 38 parts of weighting agent. The flushing agent is a phospholipid composite surfactant; the filler is an ultrafine particle material; the retarder is an AMPS polymer retarder; the defoamer is a polyether defoamer; the release agent is a polyethylene The organic polymer release agent, the weighting agent is barite.

[0027] A double-effect spacer fluid for oil-based mud cementing. Its preparation method is: add 1.5 parts of spacer to 100 parts of clear water, stir well at low speed, then slowly add 12 parts of filler and 2 parts of retarder After the base liquid configuration is completed, add 38 parts of weighting agent, stir evenl...

Embodiment 3

[0028] [Example 3] A double-effect spacer fluid for oil-based mud cementing provided by the present invention, with a density of 1.50g / cm 3 , it contains the following raw materials in parts by weight, 100 parts of clear water, 12 parts of flushing agent, 10 parts of filler, 2 parts of retarder, 0.15 part of defoamer, 1.5 parts of release agent, and 85 parts of weighting agent. The flushing agent is a phospholipid composite surfactant; the filler is an ultrafine particle material; the retarder is an AMPS polymer retarder; the defoamer is a polyether defoamer; the release agent is a polyethylene Organic polymer release agent; weighting agent is iron ore powder.

[0029] A double-effect spacer fluid for oil-based mud cementing. Its preparation method is: add 1.5 parts of spacer to 100 parts of clear water, stir well at low speed, then slowly add 10 parts of filler, 2 parts of retarder After the base liquid is prepared, add 85 parts of weighting agent. After stirring evenly, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com