Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108results about How to "Has a thickening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing inorganic hydrous salt phase transition energy-storing material

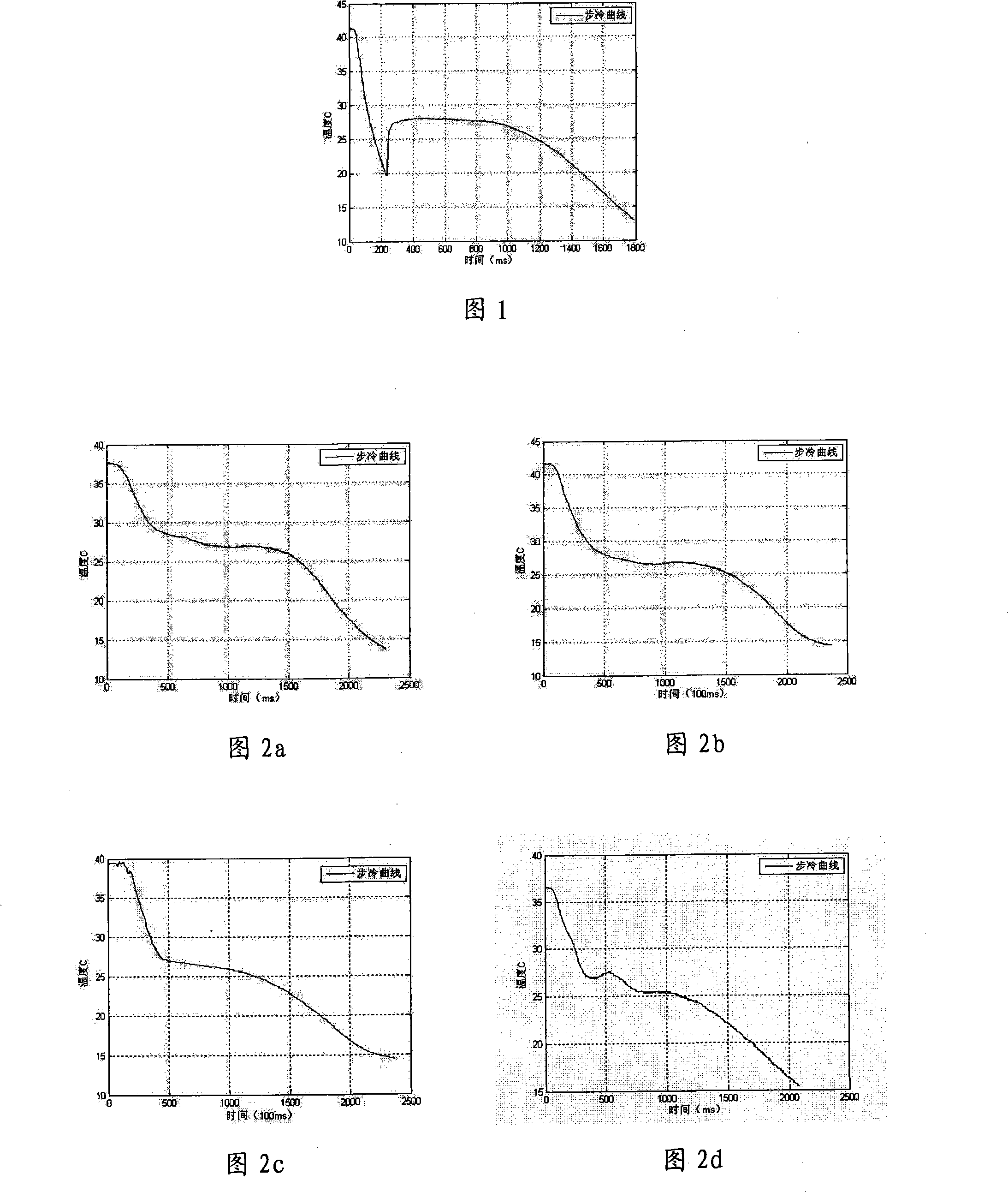

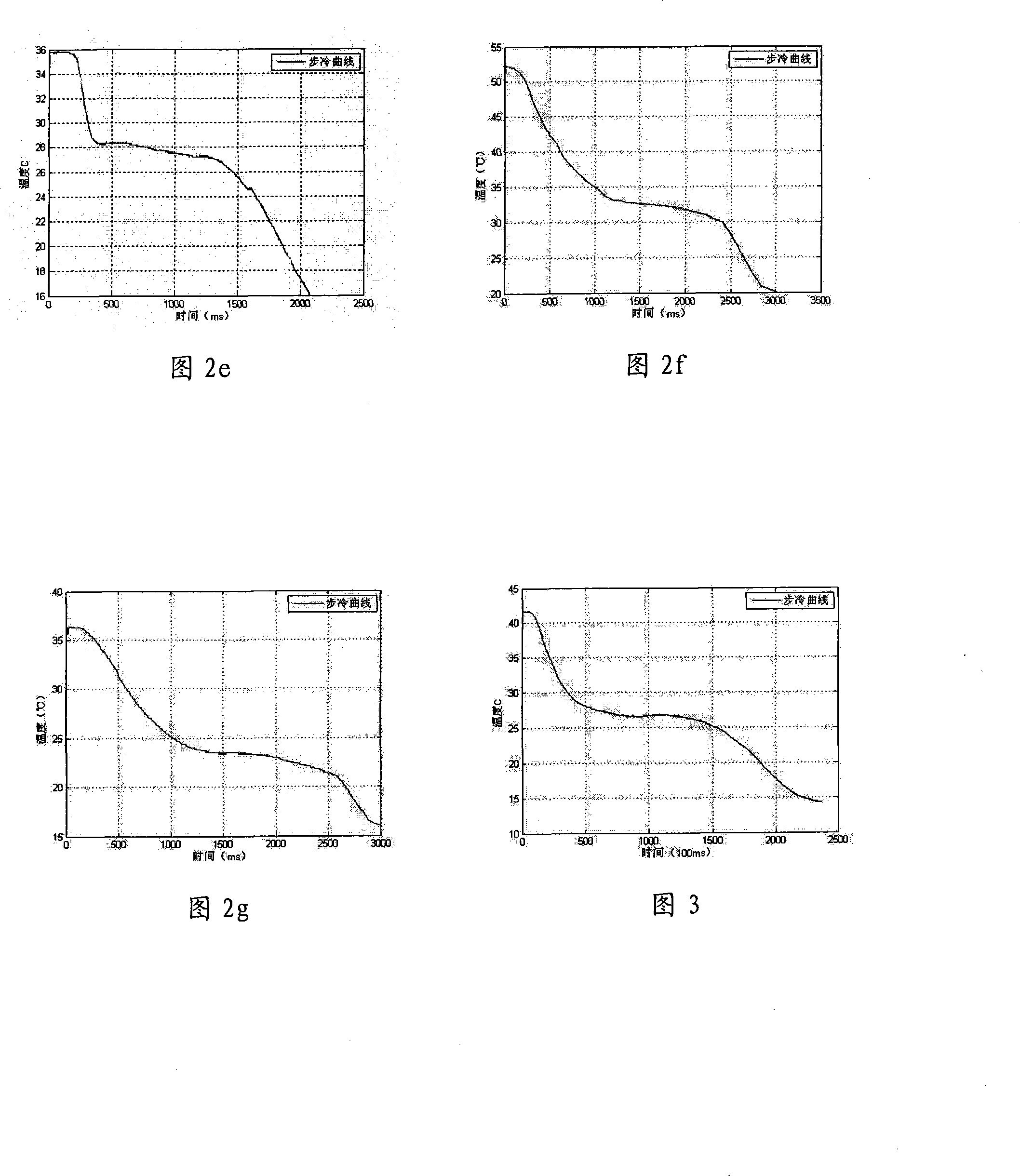

ActiveCN101235272APrevent overcoolingAvoid separabilityHeat-exchange elementsInorganic saltsPhase change

The invention discloses a preparation process of inorganic salt hydrate phase-change energy-storage material, comprises the following steps that adding 40-60g inorganic salt particles and 3-5g overcooling- resistance agent in 100g water, stirring and mixing to prepare hydrating inorganic salt solution, adding 5-10g poly-sodium acrylate in the hydrating inorganic salt solution, and stirring and mixing to prepare viscous hydrating inorganic salt mixed solution. The preparation process of hydrating inorganic salt phase-change material which is provided by the invention is added with overcooling- resistance agent and poly-sodium acrylate in the preparation process, which can effectively avoid the hydrating inorganic salt phase-change material from generating the phenomenon of over-cooling and phase separation in the phase change process, and ensures hydrating inorganic salt phase-change material to keep uniformity after repeated circulating.

Owner:SHENZHEN INST OF ADVANCED TECH

Multifunctional photocatalytic reaction device

InactiveCN102151534ASolve the separation problemWith inert gas protection functionEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionUltraviolet lights

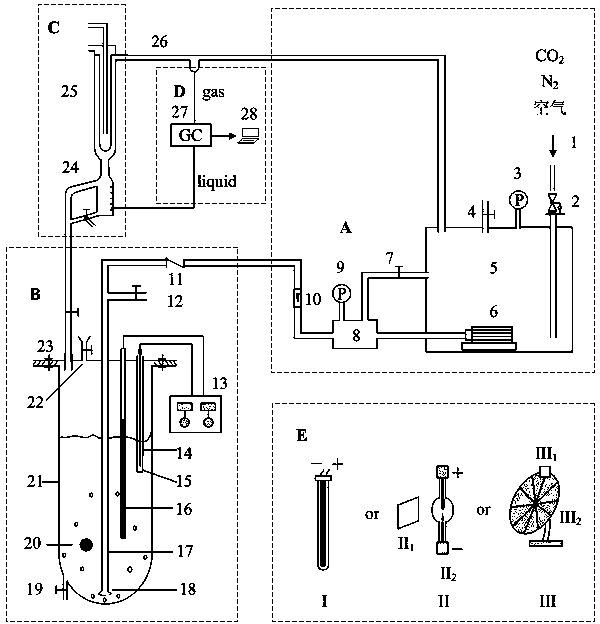

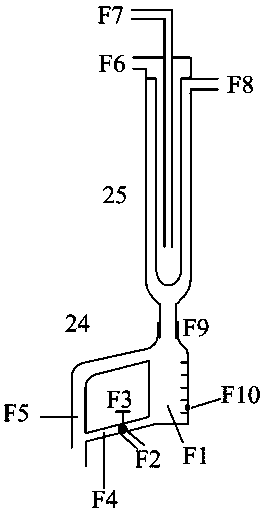

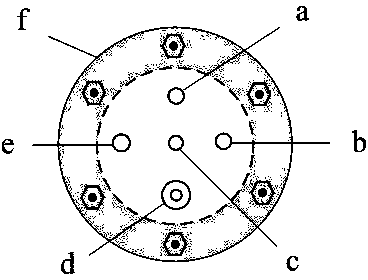

The invention discloses a multifunctional photocatalytic reaction device, which consists of a gas circulation system, a photoreaction system, a separation system, a detection system and a light source system. The light source can be ultraviolet light, visible light and sunlight and is arranged outside a quartz reactor, light penetrates through the quartz reactor to excite a photocatalyst in order to initiate photocatalytic reaction, the photocatalyst can be a thin film which is immobilized, together with a carrier, inside the reactor, or be particles suspended in reaction liquid. The reactor is suitable for liquid-solid, gas-solid and gas-liquid-solid phase photocatalytic reaction, favoring the research on photocatalytic reaction dynamics. The multifunctional photocatalytic reaction device of the invention is suitable not only for photocatalytic reduction CO2 reaction, but also for the fields such as photocatalytic degradation of organic pollutants, hydrogen production by water photolysis, photochemical synthesis and the like, besides, both intermittent operation and continuous operation can be implemented, and inert gas protection can be performed in the reaction process.

Owner:NORTHWEST UNIV(CN)

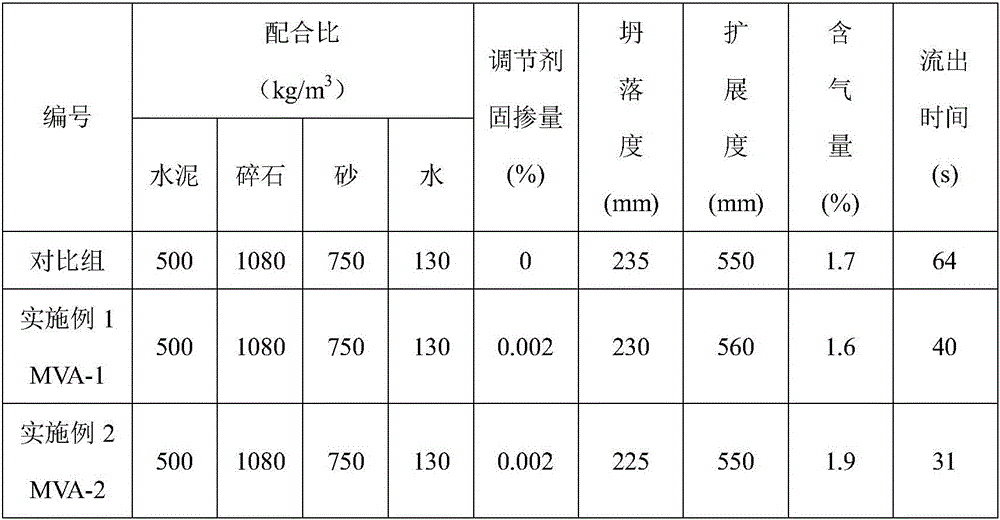

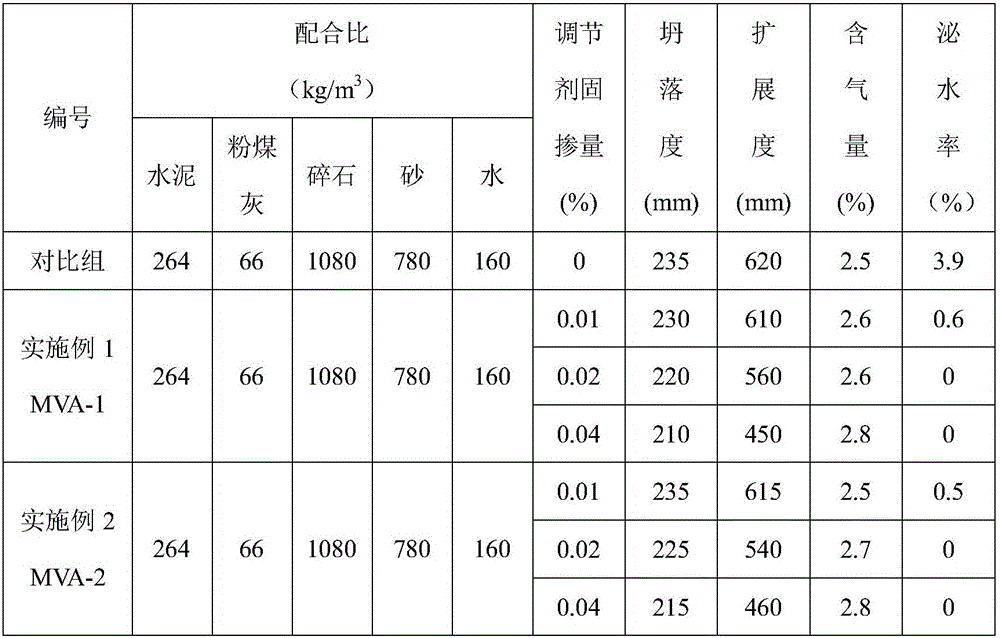

Preparation method for concrete viscosity regulator

The invention discloses a preparation method for a concrete viscosity regulator. The preparation method comprises the following steps: subjecting acrylamide and acrylic acid to copolymerization in an oxidation-reduction system under the condition of 30 DEG C to 35 DEG C, and adding a crosslinking agent polyethylene glycol bisitaconate under the condition of 60 DEG C to 65 DEG C. According to the invention, an acrylamide-acrylic acid copolymer with a high molecular weight is obtained through prepolymerization at a low temperature; the molecular weight of the copolymer is further improved through a reaction by adding the crosslinking agent polyethylene glycol bisitaconate at a high temperature; and the introduction of carboxyl, amide and ester into the molecular structure of the copolymer can guarantee that the copolymer has good hydrophilicity and water-reducing and slump-retaining effects. The concrete viscosity regulator provided by the invention can regulate the workability of a concrete mixture, has viscosity reducing effect at a low mixing amount, has viscosity increasing effect at a high mixing amount, inhibits segregation and bleeding, and has the advantages of good water solubility, convenience in usage, good compatibility with polycarboxylic acid water-reducing agents, etc.

Owner:安徽瑞和新材料有限公司

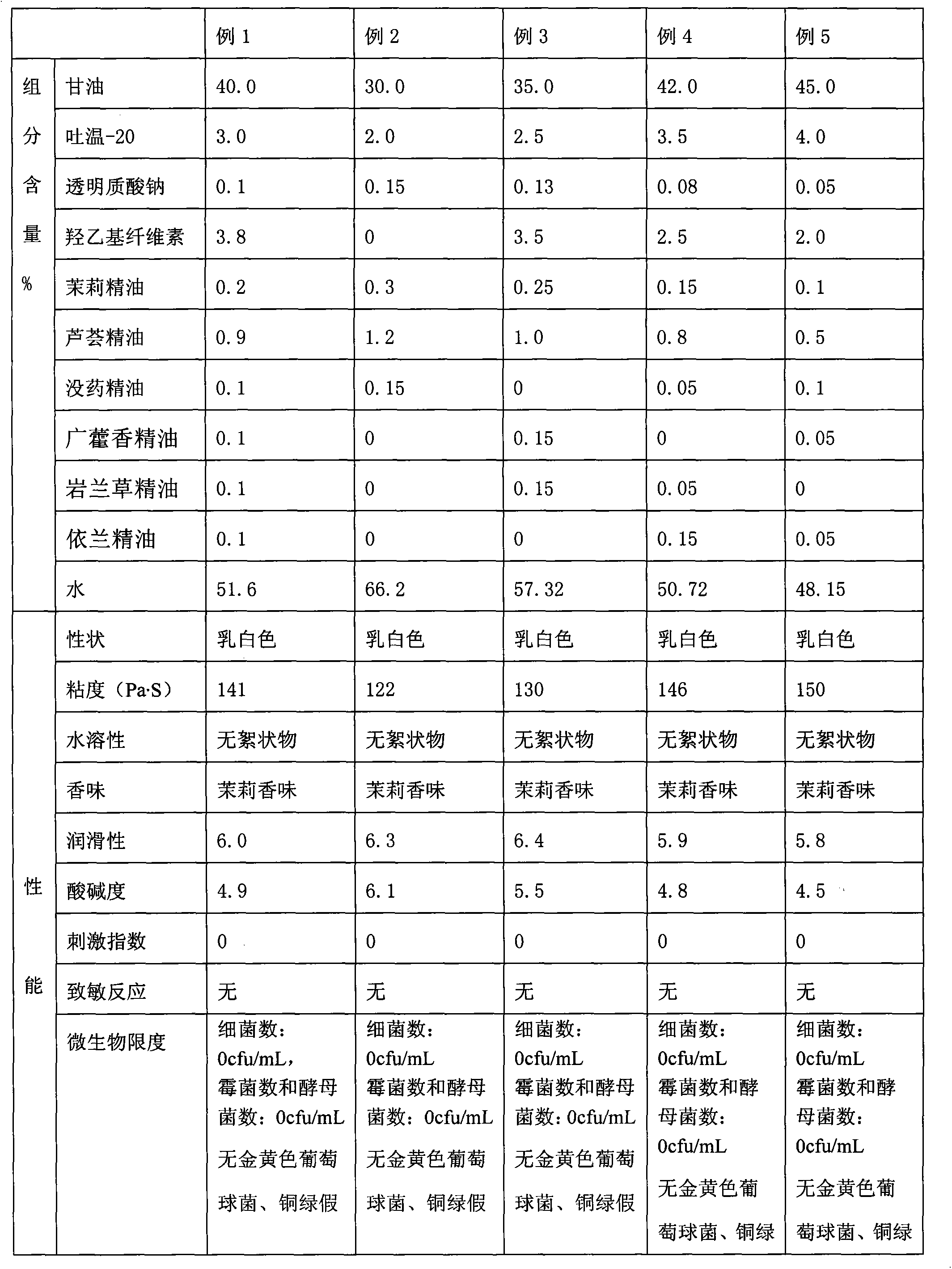

Compact-type water-soluble human lubricant, preparation method of lubricant and condom

InactiveCN103405610ANo greasy feelingEasy to cleanOrganic active ingredientsSurgeryGlycerolVaginal tissue

The invention discloses a compact-type water-soluble human lubricant, a preparation method of the lubricant, and a condom using the lubricant. The compact-type water-soluble human lubricant comprises the following components in percentage by weight: 30-47% of glycerol, 2-4% of tween-20, 0.05-0.15% of sodium hyaluronate, 0.1-0.3% of jasminum essential oil, 0.5-1.2% of aloe essential oil, and 48-66% of water. The compact-type water-soluble human lubricant has good compatibility with the naturally-selected body fluid of human body, is not greasy, has a pH value as same as the pH value of the normal physiological environment of female vagina, and has the effects of nourishing vaginal tissues, promoting cell growth, increasing muscle elasticity, and improving vaginal relaxation.

Owner:明业有限公司

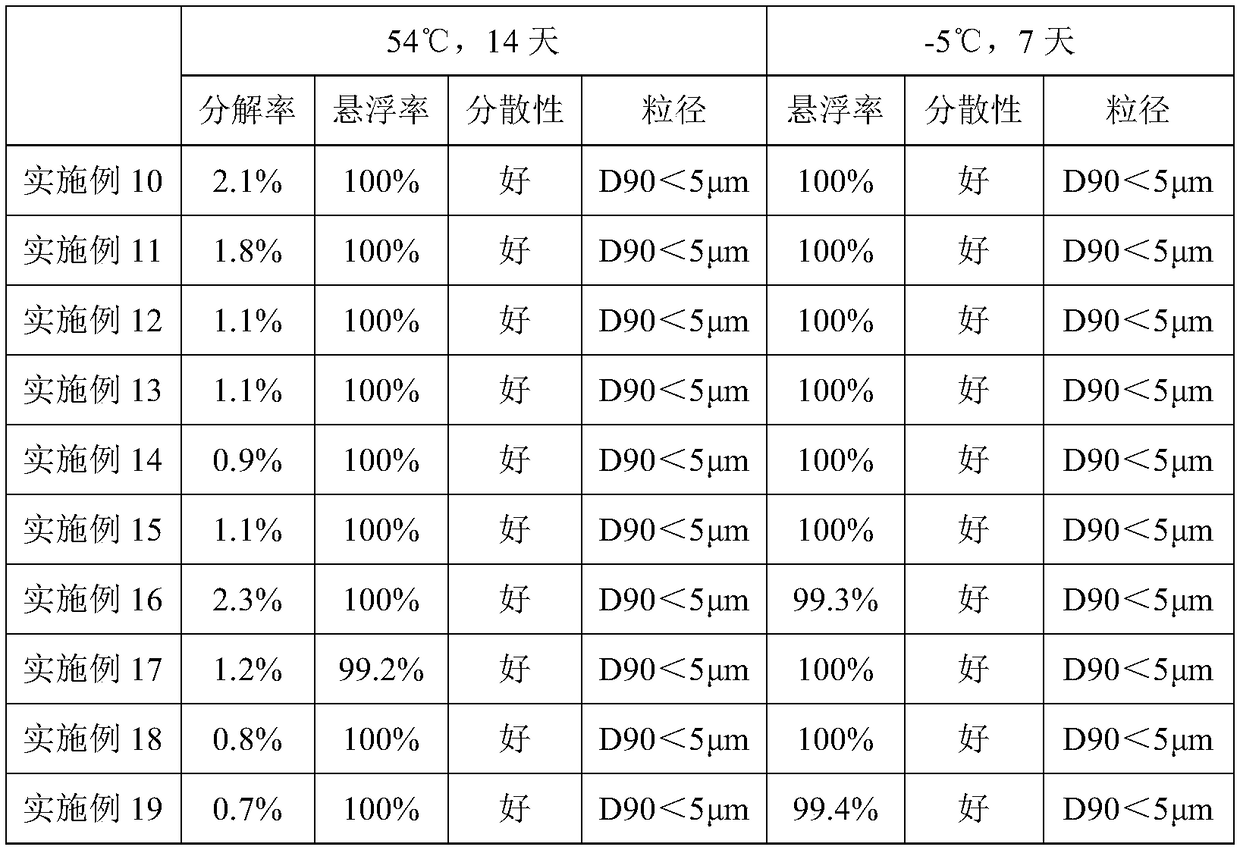

Preparation method of water-containing pesticide preparation and water-containing pesticide preparation

InactiveCN109452267ANarrow particle size distributionUniform particle size distributionBiocideAnimal repellantsDefoaming AgentsChemistry

The invention relates to the technical field of pesticide preparation processing, in particular to a preparation method of a water-containing pesticide preparation. The preparation method at least comprises the following steps an active component is mixed with a wetting agent, a dispersing agent, a defoaming agent and water, the mixture is sanded and filtered, and water concentrated suspension isobtained; an emulgator, a thickener and oil base are mixed to obtain a mixture; and the water concentrated suspension and the mixture are mixed, and the water-containing pesticide preparation is obtained. The water-containing pesticide preparation with the active component grain size being distributed narrowly and uniformly, the median diameter being small and the storage stability being good canbe obtained through the preparation method.

Owner:SHENZHEN NOPOSION AGROCHEM

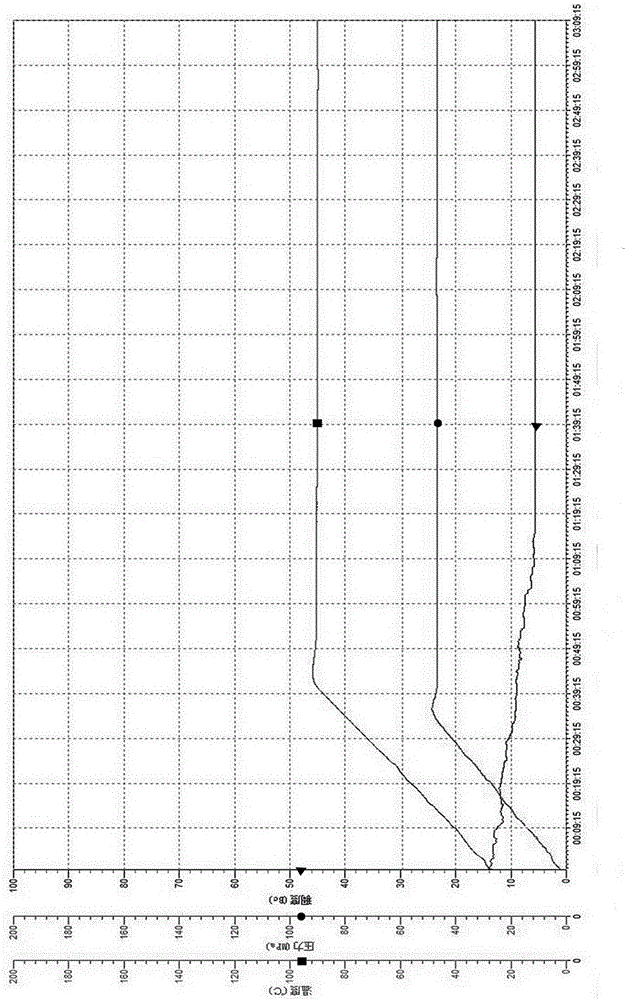

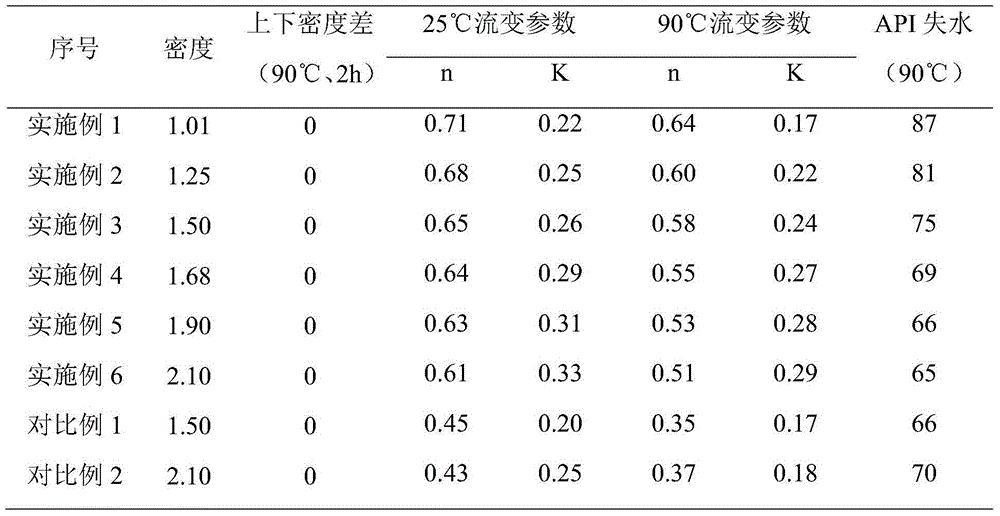

Double-effect isolation liquid for oil-based mud cementing, and preparation method thereof

The present invention discloses a double-effect isolation liquid for oil-based mud cementing, and a preparation method thereof, wherein the raw materials comprise, by weight, 100 parts of clear water, 10-20 parts of a rinsing agent, 10-15 parts of a filler, 1-5 parts of a retarding agent, 0.1-0.2 part of an antifoaming agent, 0-260 parts of a weighting agent, and 1-2 parts of an isolation agent. The preparation method comprises: adding 1-2 parts of an isolation agent to 100 parts of clear water, completely and uniformly stirring at a low speed, slowly adding 15-20 parts of a filler and 1-5 parts of a retarding agent, adding a weighting agent according to a density requirement after the base liquid preparation is completed, uniformly stirring, adding 10-15 parts of a rinsing agent, maintaining low speed rotation, adding 0.1-0.2 part of an antifoaming agent after the liquid distribution is uniform, and continuously stirring for 1-2 h while maintaining the rotation speed. According to the present invention, with the double-effect isolation liquid for oil-based mud cementing, the lipophilic interface is converted into the hydrophilic interface, such that the pollution of the oil-based on the conventional cement slurry system is reduced, the bonding problem of the two interfaces is solved, the high quality cementing and the sealing fixing of the annulus interface are achieved, and the stability of the mud is ensured.

Owner:成都欧美克石油科技股份有限公司

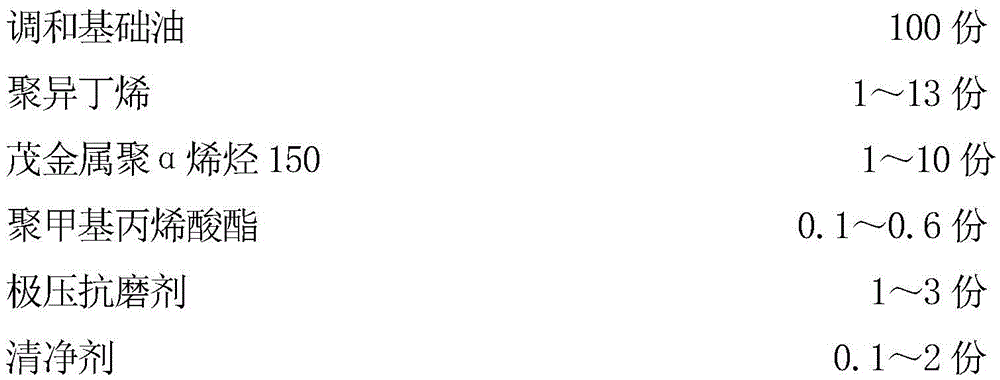

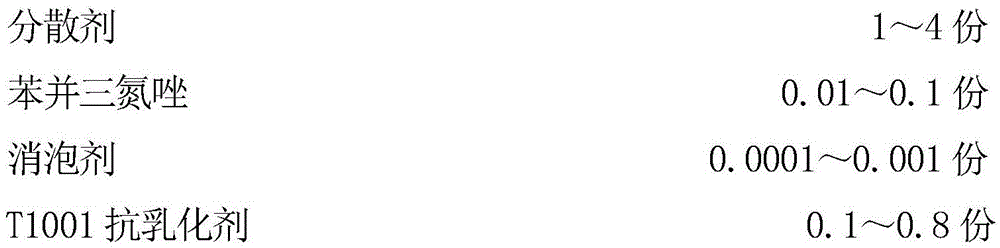

Gear oil special for reduction gearbox of pumping unit

The invention discloses gear oil special for a reduction gearbox of a pumping unit. The gear oil is prepared from, by mass, blend base oil, metallocene polyisobutene, metallocene polymerized alpha olefin 150, polymethacrylate, an extreme pressure anti-wear agent, a cleaning gent, a dispersing agent, benzotriazole, a defoaming agent and a demulsifying agent T1001, wherein the blend base oil is prepared from paraffin-base base oil 600 SN, residual oil 150 BS and hydrofined oil 250 N, and a mixture of thiophosphoric acid amine salt, bisoctyl dithiophosphate zinc and / or oil-soluble molybdenum is adopted as the extreme pressure anti-wear agent. The gear oil for the reduction gearbox is better in physical and chemical index and using performance than industrial closed gear oil, has the good extreme pressure anti-wear performance, thermal oxidation stability, corrosion resistance and anti-emulsification performance and meets the using requirements of oil pumping unit oil of an oil field.

Owner:郑生宏

Popping bead, meat product containing popping bead and preparation method thereof

ActiveCN109793170AHigh viscosityImprove toughnessClimate change adaptationFood shapingAntioxidantCorrosion

The invention discloses a popping bead, a meat product containing the popping bead and a preparation method thereof. The popping bead comprises a shell and a content, and the shell is made from water,sodium alga acid, hydrophobic modified chitosan, Arabic gum and crosslinked starch. The meat product containing the popping bead is made from raw meat, water, the popping bead, table salt, white granulated sugar, a water retention agent, a thickening agent, a preservative, a color retention agent, a colorant, an antioxidant, flavoring agent, starch and soy isolate protein. The invention further discloses the preparation method of the popping bead and the meat product. The shell of the popping bead is high in toughness, compressive resistance and corrosion resistance, small in popping bead diameter and high in shearing resistance; the popping bead has good tightness and can ensure the stable quality of the meat product during the shelf life; the popping bead bursts quickly during chewing to allow the content to flow out, and flavor features of the meat product and fun to eat are improved.

Owner:临沂金锣文瑞食品有限公司

Preparation method of silicon dioxide for transparent tooth cleaning toothpaste

ActiveCN105776230AHigh transparencyHas a thickening effectCosmetic preparationsSilicaToothpasteSulfuric acid

The invention belongs to the technical field of silicon dioxide for toothpaste, and relates to a preparation method of silicon dioxide for transparent tooth cleaning toothpaste.The preparation method comprises the steps that 1, a sodium carbonate solution is prepared and added into a sodium silicate solution to obtain a mixed solution; 2, a sodium sulfate solution is added into a reaction kettle, the sodium silicate solution and a sulfuric acid solution are simultaneously and dropwise added while stirring under heating is performed, the process pH is kept to be 7.5-9.5, the end point pH is controlled to be 6.0-7.0, and stirring is performed; 3, water is added, the mixed solution and the sulfuric acid solution are simultaneously and dropwise added while stirring under heating is performed, the process pH is kept to be 5.5-7.5, the reaction end point pH is controlled to be 6.0-7.0, and stirring, filter pressing, washing, drying and crushing are performed to obtain the silicon dioxide.According to silicon dioxide, the copper loss value is 12-15 mg, the light transmittance reaches up to 98%, the oil absorption value is 130-160 ml / 100 g, the water absorption capacity is 26-32 ml / 20 g, and silicon dioxide is suitable for the transparent tooth cleaning toothpaste.

Owner:GUANGZHOU FEIXUE MATERIAL TECH

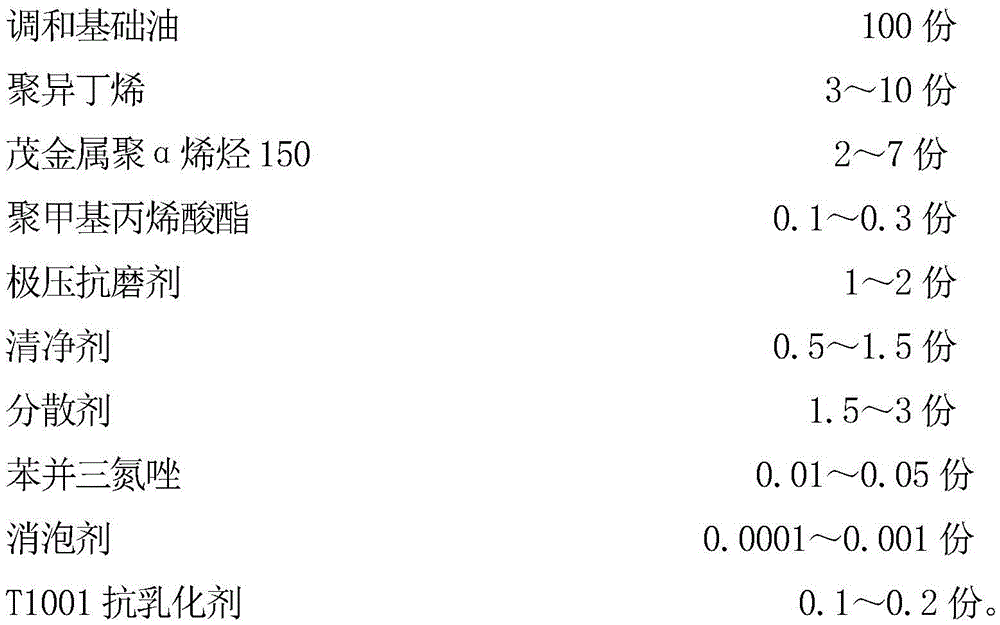

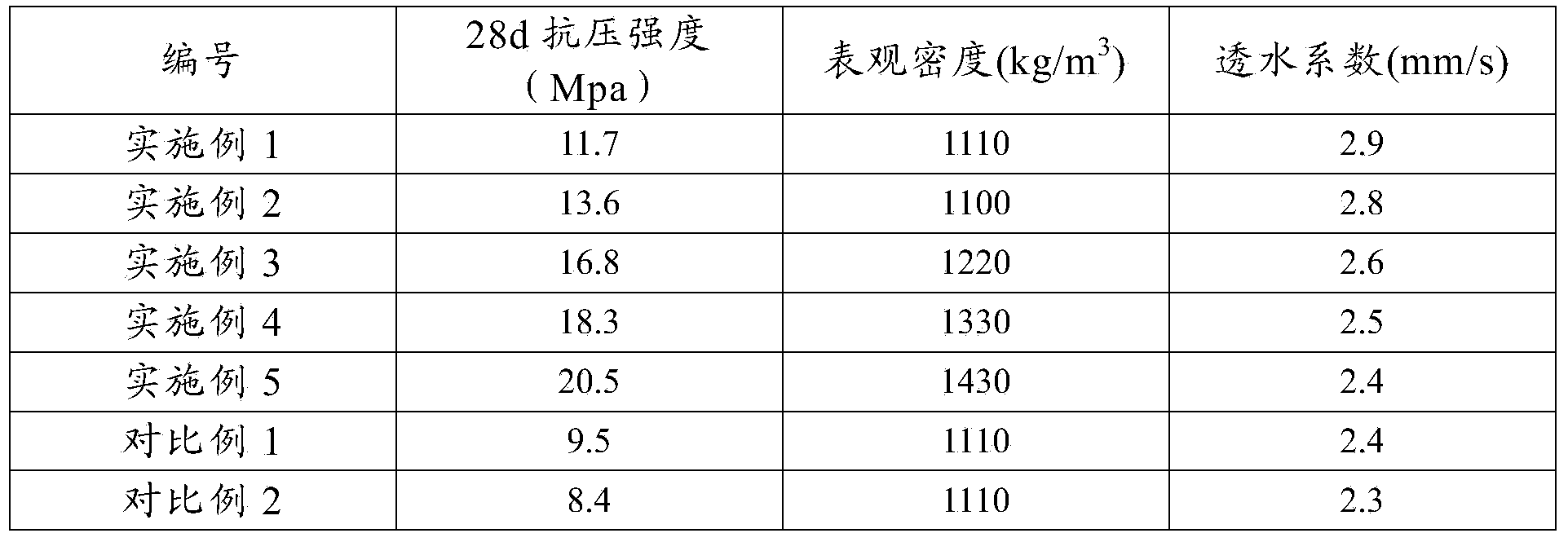

Macroporous concrete containing low grade recycled aggregates and preparation method of concrete

ActiveCN104072061AStrong retardationLower pHSolid waste managementCeramicwareLow gradedConstruction aggregate

The invention discloses macroporous concrete containing low grade recycled aggregates. The macroporous concrete containing low grade recycled aggregates is prepared from the following raw materials: cement, water, low grade recycled aggregates, modified starch and a sugar retarder, wherein the grain size of the low grade recycled aggregates is 5-16mm, and the bulk density is 700-900kg / m<3>. The macroporous concrete containing low grade recycled aggregates is further prepared from additional water, the use level of which is calculated according to the follow formula: delta W=mgr*wgr, wherein delta W is the use level of the additional water of the macroporous concrete containing low grade recycled aggregates; mgr is the use level of the low grade recycled aggregates and wgr is 1h water absorption of the low grade recycled aggregates. According to the invention, the grade recycled aggregates are applied to preparation of the macroporous concrete, so that the mixture state satisfies the using demand under the condition that an additive in an extra amount is not added by virtue of adjusting the raw materials and matching with the sugar retarder and modified starch.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Canned chicken lunch meat

InactiveCN106360398ADoes not affect the tasteIncrease contentFood ingredient as mouthfeel improving agentBiotechnologyDietary fiber

The invention provides canned chicken lunch meat, which includes, by weight, 45-60 parts of chicken meat, 5-8 parts of lentinula edodes, 5-8 parts of bamboo sprouts, 0.5-1.5 parts of red date and wolfberry powder, 3-5 parts of lotus roots, 3-5 parts of corn starch, 1-1.5 parts of salt, 0.5-1.5 parts of white granular sugar, 0.04-0.08 parts of I+G, 0.005-0.02 parts of sodium tripolyphosphate, 0.005-0.02 parts of sodium pyrophosphate, 0.1-0.3 parts of xanthan gum, 0.1-0.4 parts of dry chili powder or fresh red chili, 0.04-0.06 parts of sodium D-isoascorbate and 0.03-0.06 parts of a spice. Special dietary fiber components are added to the canned chicken lunch meat, so that usage of an additive having a thickening function on the food is reduced and the taste of the lunch meat is not influenced. The lunch meat is rich in dietary fibers and has beautiful color.

Owner:遂宁市三丰食品有限公司

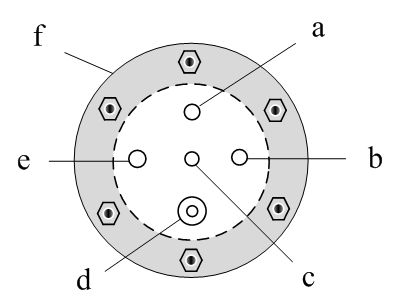

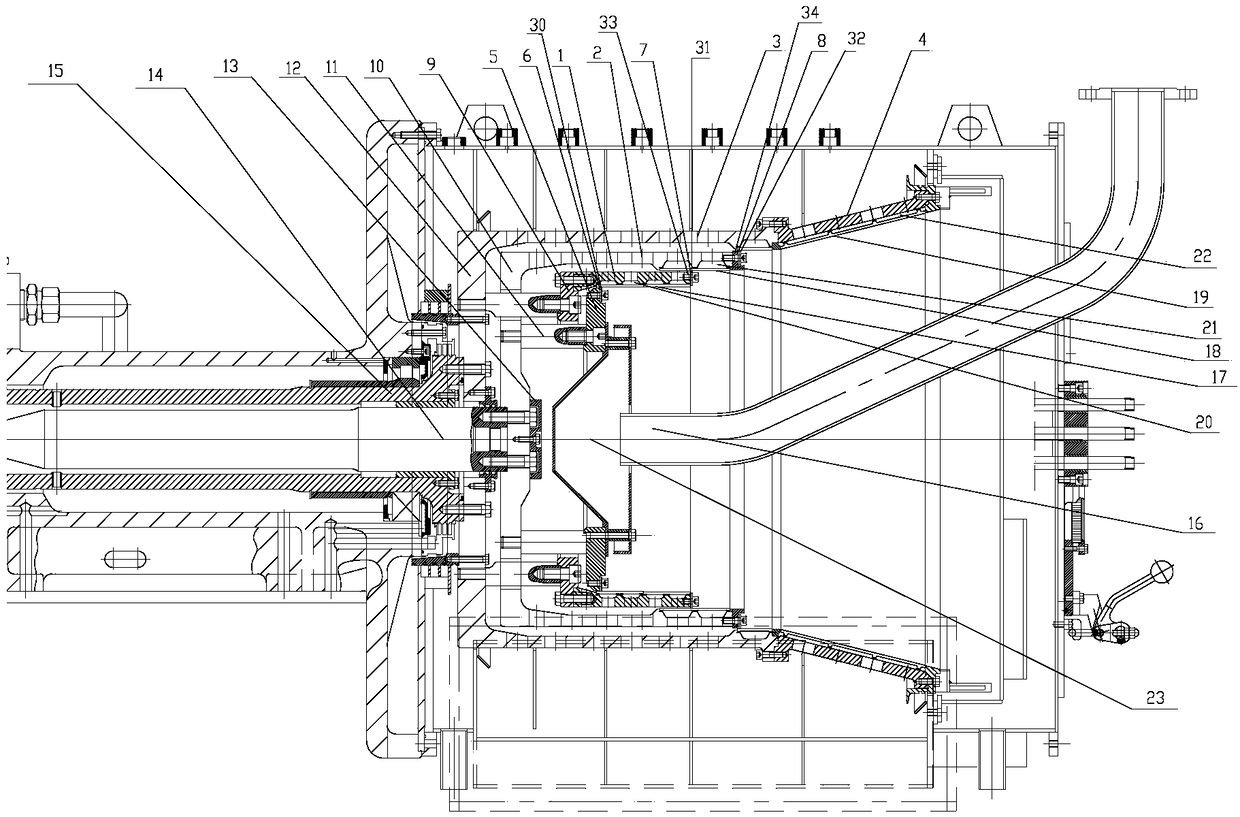

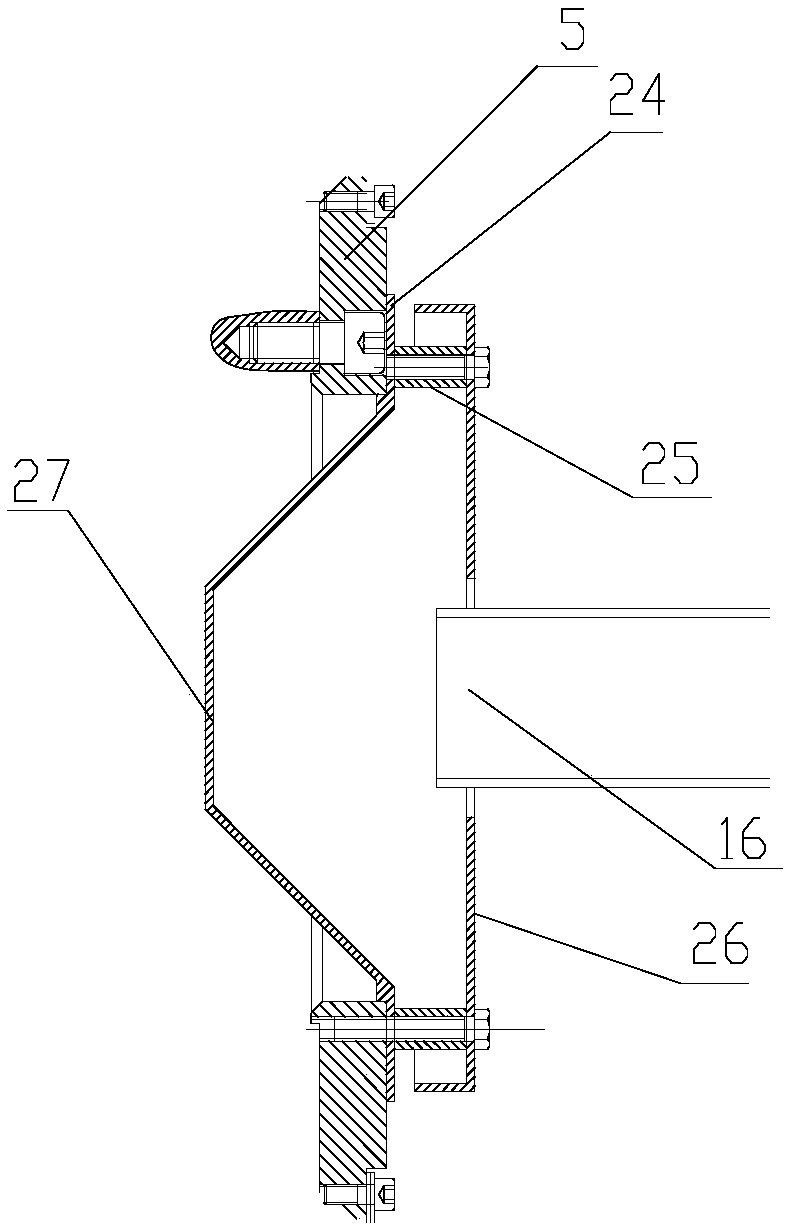

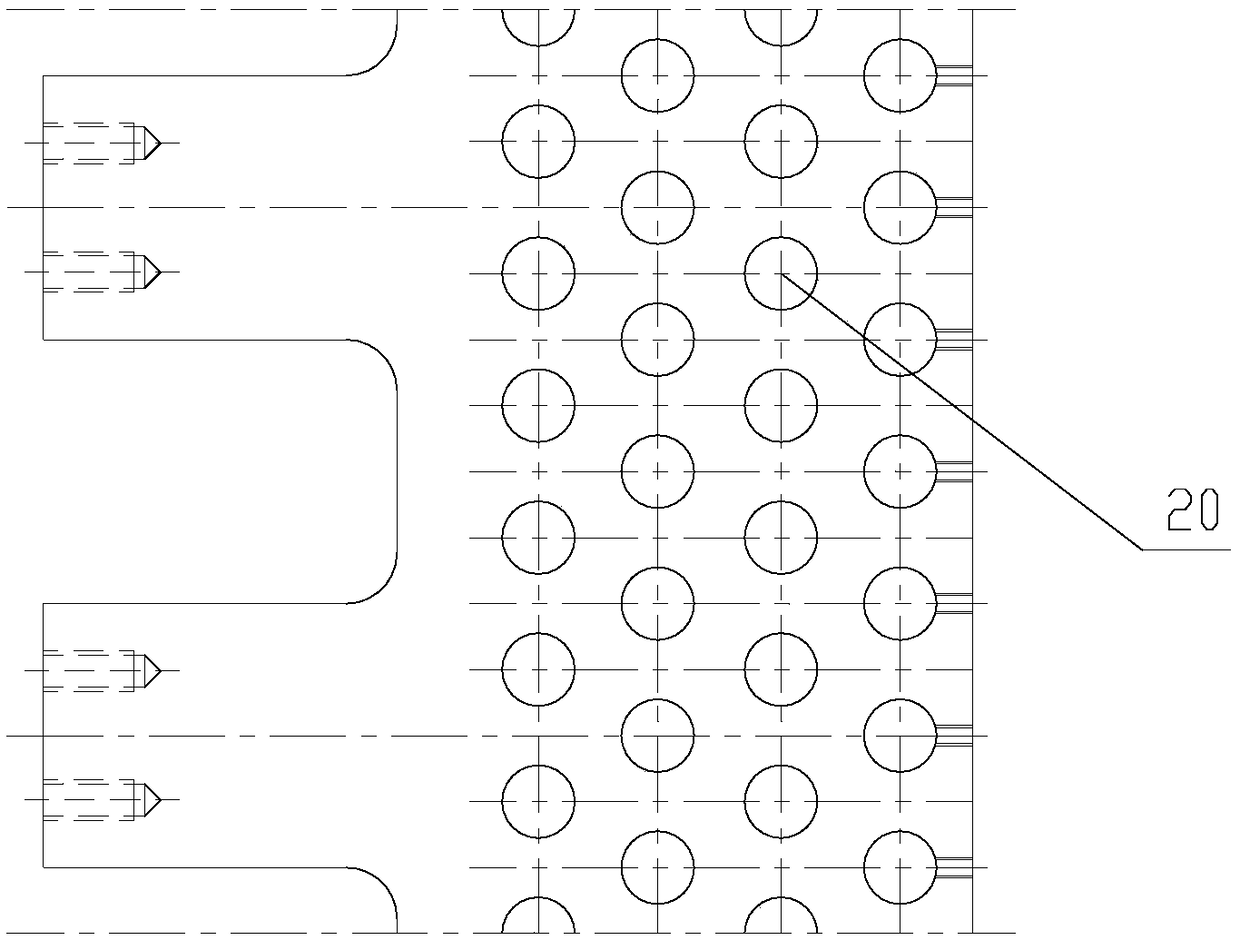

Three-stage piston pushing centrifuge drum device

InactiveCN109499782APlay a buffer roleReduce the amount of running materialRotary centrifugesIsosceles trapezoidThree stage

The invention discloses a three-stage piston pushing centrifuge drum device, and relates to the technical field of mechanical pushing centrifuges. The three-stage piston pushing centrifuge drum devicecomprises a first-stage drum, a second-stage drum and a third-stage drum; the third-stage drum is of a column taper structure, screen cloths in the three-stage piston pushing centrifuge drum device are all made of full-ceramic abrasion-resisting screen cloths; the effective filtering length of the first-stage screen cloth is 300-360 mm, the effective filtering length of the second-stage screen cloth is 360-420 mm, and the effective filtering length of the third-stage screen cloth is 300-360 mm; and a material distributing part in the three-stage piston pushing centrifuge drum device is of a truncated-cone-type structure, and the cross section of a material distributing hopper is in a isosceles trapezoid shape. The three-stage piston pushing centrifuge drum device is simple in structure, capable of conducting equipment maintaining conveniently and lowering the cost, large in drum centrifugal force, good in material dehydration water, large in screen cloth filtering area, capable of prolonging the service life of the screen cloths, and applicable to separation of fine powder materials and low-concentration suspension materials.

Owner:XIANGTAN HUIBO CENTRIFUGE

Method for preparing high-toughness microcrystalline glass

The invention discloses a method for preparing high-toughness microcrystalline glass and belongs to the technical field of preparation of architectural ceramics. According to the method, sludge pyrolyzed powder and fly ash are mixed to obtain a basic glass powder material, sodium oxide, potassium oxide and the like, which are rich in the basic glass powder material, have a thickening effect on molten glass, a titanium dioxide coating on the surface of basic glass is a surface active substance, the surface tension can be lowered to generate thinner bubble walls, and thus, the porosity of the microcrystalline glass is lowered. According to the method, a sintering temperature of coated glass during sintering is above a melting temperature of the basic glass, generated liquid of the basic glass is sintered, and thus, a glass phase has an obvious network structure during liquid-phase sintering; and the glass phase accounts for a relatively high proportion in the microcrystalline glass and is continuously dispersed in the microcrystalline glass, the microcrystalline glass cracks in case of an impact load, the network structure of the glass phase will fork cracks, the crack scattering stress is increased, and the development of the cracks is inhibited, so that the toughness and processability of the microcrystalline glass are improved, and the application prospect is broad.

Owner:常州万博金属构件厂

Soapberry complete natural plant facial lotion

InactiveCN101411682AHas nutritional conditioning effectHas a thickening effectCosmetic preparationsToilet preparationsSide effectLotion

The invention belongs to the technical field of cosmetics, and discloses a full natural plant face cream containing soapberry, which is characterized that the face cream is prepared from the following substances in percentage concentration by weight: 30 to 55 percent of extract of soapberry pulp, 20 to 30 percent of extract of seaweed, 1 to 10 percent of extract of rhubarb, 1 to 10 percent of extract of soybean, 1 to 10 percent of extract of aloe, and deionized water added to 100 percent. The face cream has the advantages that the face cream is prepared from full natural plant raw materials, has no pollution in production, wide sources of the raw materials of the product, low cost, no toxic and side effects on human body, has the efficacies of whitening and moisturizing and the functions of nutrition and conditioning, and can delay ageing of skin; and the skin after being cleaned by the face cream has natural luster, and is smooth and delicate.

Owner:天台县满园春农林开发有限公司

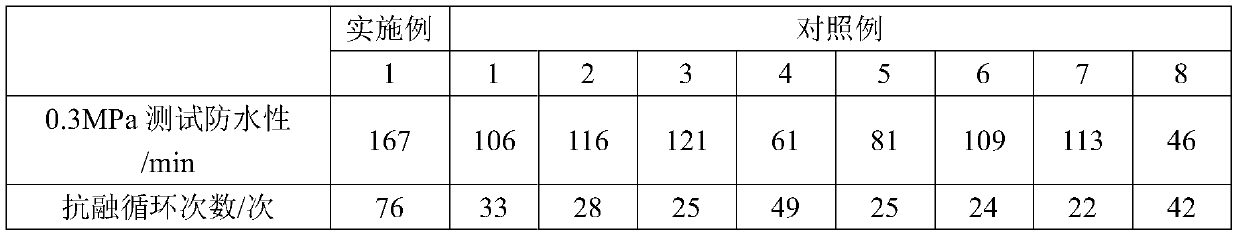

Green waterproof concrete and preparation method thereof

The invention relates to green waterproof concrete and a preparation method thereof. The green waterproof concrete comprises cement, sand, water, an aqueous emulsion, an aqueous epoxy resin emulsion and modified iron cement, wherein the aqueous emulsion is prepared from acrylic acid, acrylamide, iso-octyl acrylate, methyl methacrylate, water, 2-acrylamide-2 methyl propanesulfonic acid, an SE-10 emulsifier, methylene bisacrylamide, ammonium persulfate and hydroxyl terminated polyether-containing modified polysiloxane through reactions; the aqueous epoxy resin emulsion is prepared from an NPED-20 aqueous epoxy resin, NX-8101 aqueous phenolic amine, water and an aqueous elastomer through reactions; the aqueous elastomer is prepared from iso-octyl acrylate, butyl acrylate, acrylic acid, low-viscosity aliphatic series epoxy acrylate, a 819 photoinitiator, polyethylene glycol (200) dimethacrylate and the SE-10 emulsifier through reactions; the iron cement is prepared from iron mud, a waste polyacrylamide flocculant, a waste polymeric aluminum flocculant and carboxymethylcellulose through reactions. The green waterproof concrete provided by the invention has excellent waterproof and anti-freezing properties.

Owner:普宁市吉润混凝土有限公司

Method for preparing modified special wax for rheological additive of solvent-based coating

A method for preparing modified special wax for a rheological additive of a solvent-based coating belongs to the technical field of coating additives, and is characterized by comprising the following steps: adding 10-40 parts of polyethylene wax with the viscosity-average molecular weight of 1,000-1,500 and 10-40 parts of polyethylene wax with the viscosity-average molecular weight of 700-900, obtained through pyrolysis of high density polyethylene, into a compounding kettle, raising the temperature to 130-180 DEG C, performing uniform stirring, adding 5-30 parts of paraffin, and performing uniform stirring; after raising the temperature of a reaction kettle to 120-160 DEG C, and transferring the mixed liquid into the reaction kettle; and putting an oxidizing agent into the mixed liquid, keeping the temperature in the reaction kettle at 120-160 DEG C, and performing continual stirring till the acid value is 10-30 to obtain modified special oxidized polyethylene wax. The physical and chemical properties of the oxidized polyethylene wax are within the index range, and as the rheological additive of the coating, the prepared modified special wax has excellent rheological properties and good matting property and storage stability, causes no influence on the color and the clarity of the coating, and has strong scratch resistance.

Owner:淄博市临淄齐泉工贸有限公司

Silicon-carbon negative electrode slurry and preparation method and application thereof

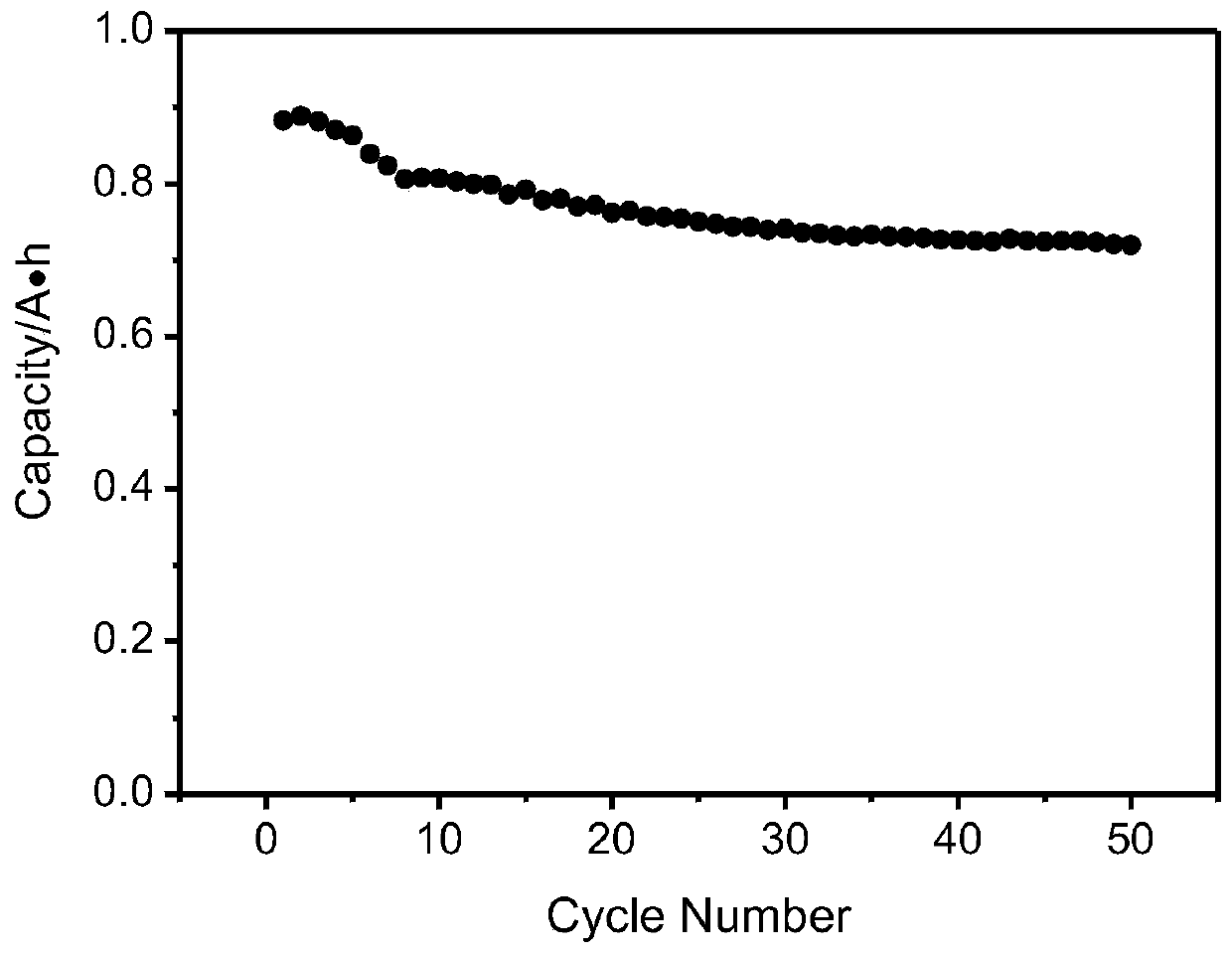

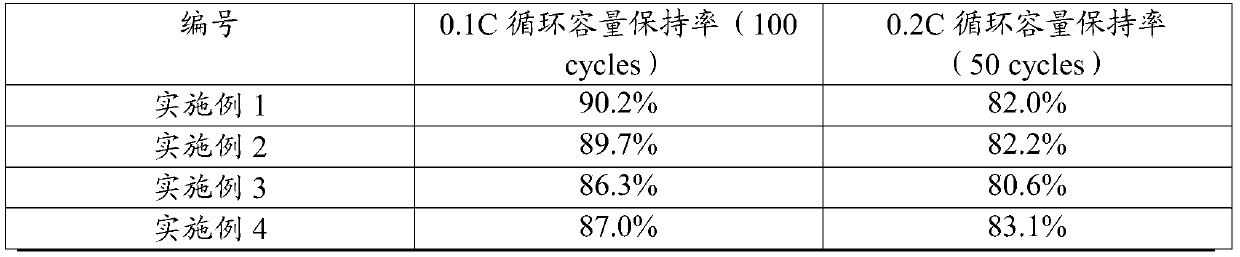

InactiveCN109950540AEasy to prepareImprove cycle performanceElectrode manufacturing processesSecondary cellsMass ratioSlurry

The invention provides silicon-carbon negative electrode slurry and a preparation method and application thereof. The slurry contains silicon carbon, a conductive agent, konjac gum and a binder, wherein the mass ratio of the silicon carbon to the conductive agent to the konjac gum to the binder is (91-96.5): (0.3-4.2): (1-3.8): (1.5-3). The konjac gum is adopted as a binder in a negative electrodeslurry system, has the thickening effect, and is low in cost. Moreover, an electrode piece prepared from the negative electrode slurry has good cycle performances. The binder is environment-friendlyand pollution-free. The preparation method of the silicon-carbon negative electrode slurry is simple, the konjac gum is easy to disperse and dissolve in water, and the time of the homogenizing procedure can be shortened. The capacity retention rate of a high-specific-energy soft-packaged battery cell prepared from the negative electrode plate containing the negative electrode slurry in 100 cyclesat 0.1C is higher than 85%, and the capacity retention rate of a high-specific-energy soft-packaged battery cell prepared from the negative electrode plate containing the negative electrode slurry in50 cycles at 0.2 C is higher than 80%.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High-calcium cartilage fish plate and production method thereof

InactiveCN109007643AEvenly distributed flavorGreat tasteFood freezingMeat/fish preservation by freezing/coolingFlavorFood additive

The invention discloses a high-calcium cartilage fish plate and a production method thereof. The high-calcium cartilage fish plate is prepared from fish and pork cartilage as main raw materials whichare supplemented with a certain amount of soy protein, edible salt, white granulated sugar, konjac flour, food additives, flavoring agents, a compound emulsifier and water, and is prepared by the following steps in turn: fish slicing, first fish rolling, second fish rolling, cartilage fish plate forming, vacuum freezing, demoulding, packaging, boxing and warehousing. The cartilage fish plate is suitable for hot pot and barbecue, and has the advantages of delicate taste and chewiness, unique flavor and rich nutrients.

Owner:雅安利涵商贸有限公司

Preparation method of modified hydroxyethyl cellulose cation slow-cracking asphalt emulsifier

The invention discloses a preparation method of a modified hydroxyethyl cellulose cation slow-cracking asphalt emulsifier. The method comprises the following steps: adding hydroxyethyl celluloses intoisopropanol for dispersion, adding a NaOH solution, then swelling for 12-16 h at normal temperature, heating to the temperature of 40-50 DEG C, adding a long-chain quaternary ammonium salt intermediate, reacting for 4-6 h at the temperature of 40-50 DEG C, cooling to the room temperature, centrifuging and washing; and drying at the temperature of 80 DEG C to obtain the modified hydroxyethyl cellulose cation slow-cracking asphalt emulsifier. The raw materials of the emulsifier prepared by the invention are environmentally friendly, the price is low, a preparation process is simple, the production cost is low, and the emulsification performance is high.

Owner:HEBEI UNIV OF TECH

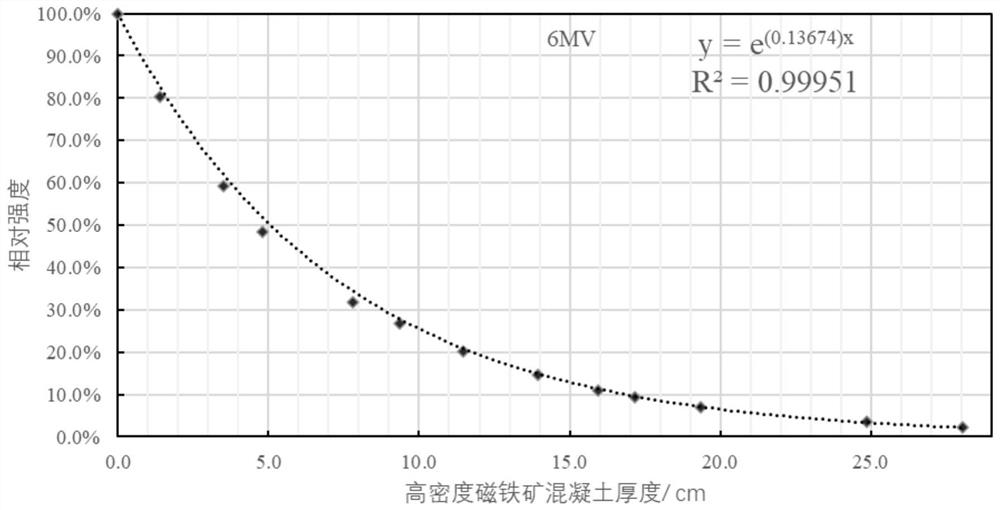

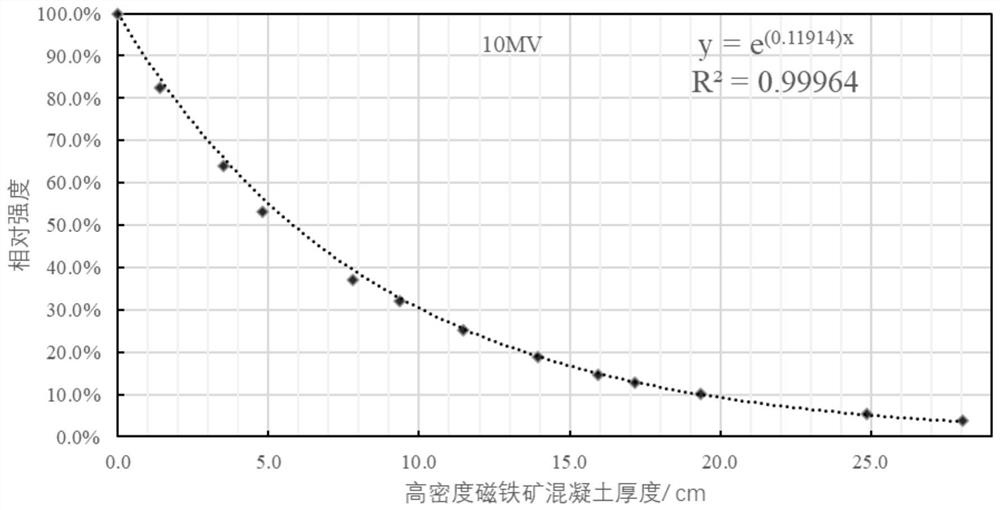

Radiation-proof concrete and production process thereof

The invention provides radiation-proof concrete, and relates to the technical field of concrete. The radiation-proof concrete production technology comprises the following steps of mixed mineral aggregate preparation and finished product preparation, the technological process is simple, cost saving is facilitated, and the prepared concrete is good in radiation-proof performance and high in strength performance. In addition, the invention also provides radiation-proof concrete which comprises the following raw materials in parts by weight: 200-400 parts of cement, 50-180 parts of mineral admixture, 1400-1500 parts of magnetite sand ore, 1800-2000 parts of magnetite ore, 25-45 parts of anti-cracking agent, 6-12 parts of water reducing agent and 150-200 parts of water. The radiation-proof concrete can effectively shield rays, has good radiation-proof effect and high strength performance, is easy to construct, and is economical and environment-friendly.

Owner:山东阳华建筑安装工程有限公司

Method for preparing foamed magnesium alloy through secondary foaming

InactiveCN106367627AHas a thickening effectImprove flame retardant performanceRoom temperatureWater cooling

The invention provides a method for preparing a foamed magnesium alloy through secondary foaming. The method includes the following steps that firstly, magnesium is heated till being molten, the temperature is regulated to 700 DEG C to 750 DEG C, a tackifier accounting for, by mass, 0.5%-3.0% of the molten magnesium is added, and stirring is conducted for 5 min to 15 min at the rotating speed ranging from 600 rpm to 800 rpm, wherein the tackifier is composed of 40 wt%-60 wt% of calcium oxide and 30 wt%-55 wt% of magnesium carbonate; secondly, the melt obtained in the first step is cooled to 580 DEG C to 620 DEG C, calcium carbonate powder accounting for, by mass, 2%-10% of the molten magnesium is added, stirring is stopped after being conducted for 3 min to 7 min at the rotating speed ranging from 800 rpm to 1500 rpm, the temperature is lowered to 300 DEG C to 500 DEG C, and heat preservation is conducted for 20 min to 30 min; and thirdly, the temperature then rises to 800 DEG C to 900 DEG C so that the calcium carbonate in a blank can be subjected to secondary thermal decomposition and secondary foaming, after the mixture is stirred to be uniform, water cooling is conducted till the room temperature is achieved, and the foamed magnesium alloy is obtained. The foamed magnesium alloy prepared through the method can be used for preparing special-shaped pieces complex in appearance, and is uniform in pore size distribution and good in flame retardant property.

Owner:郑州峰泰纳米材料有限公司

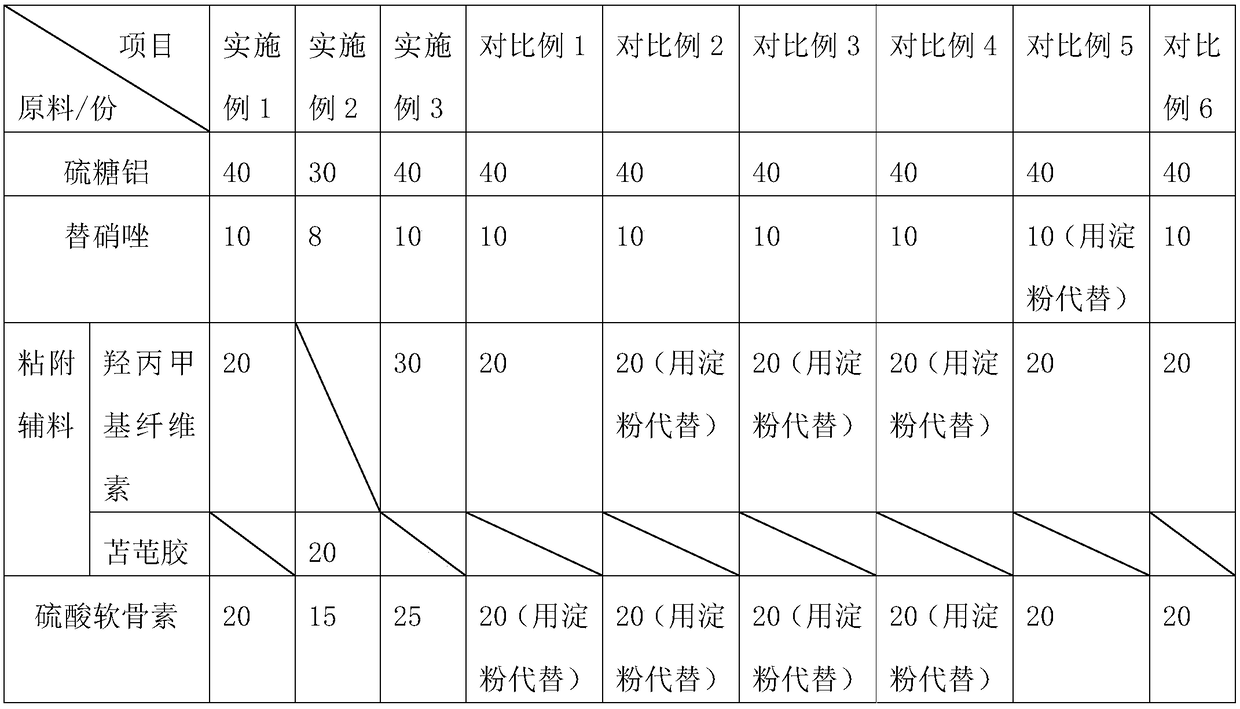

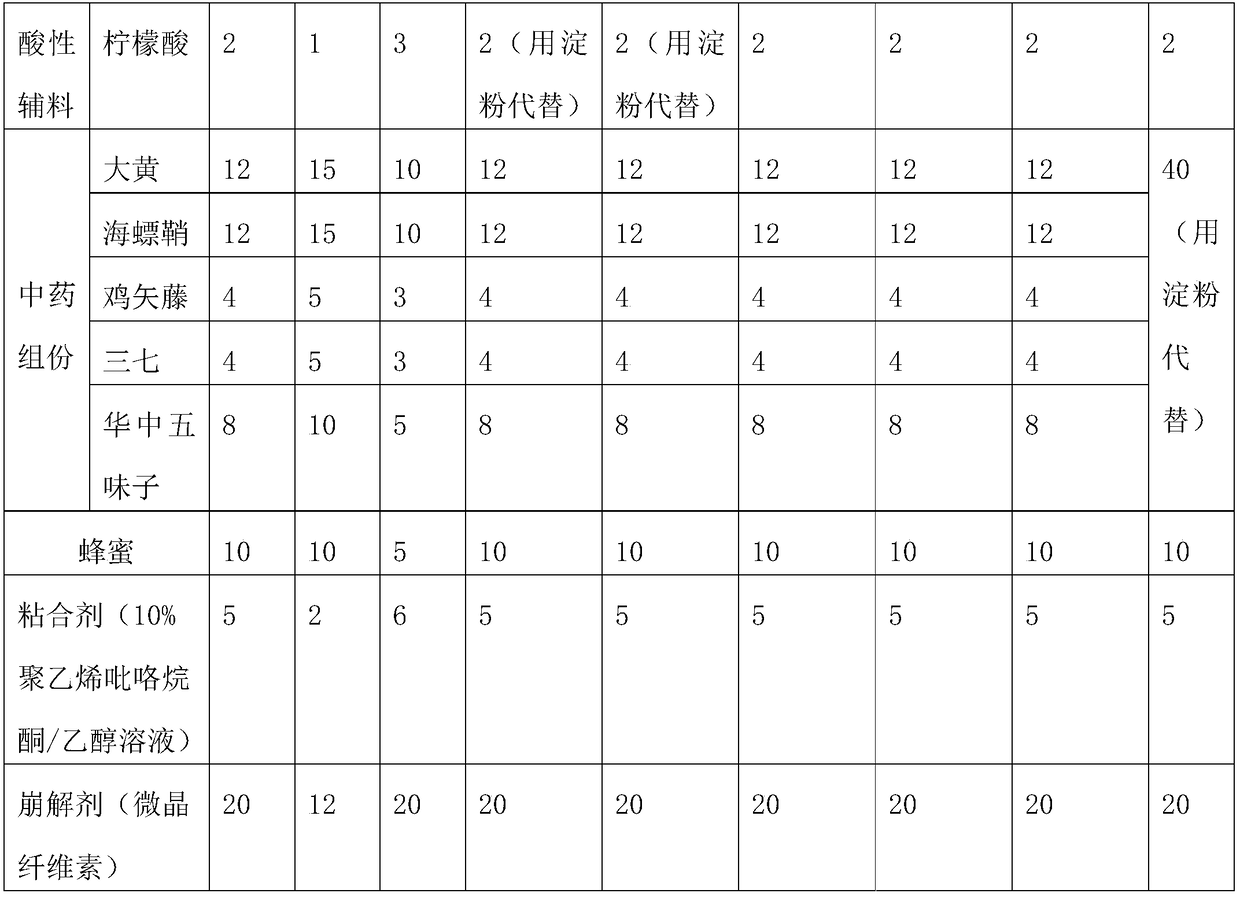

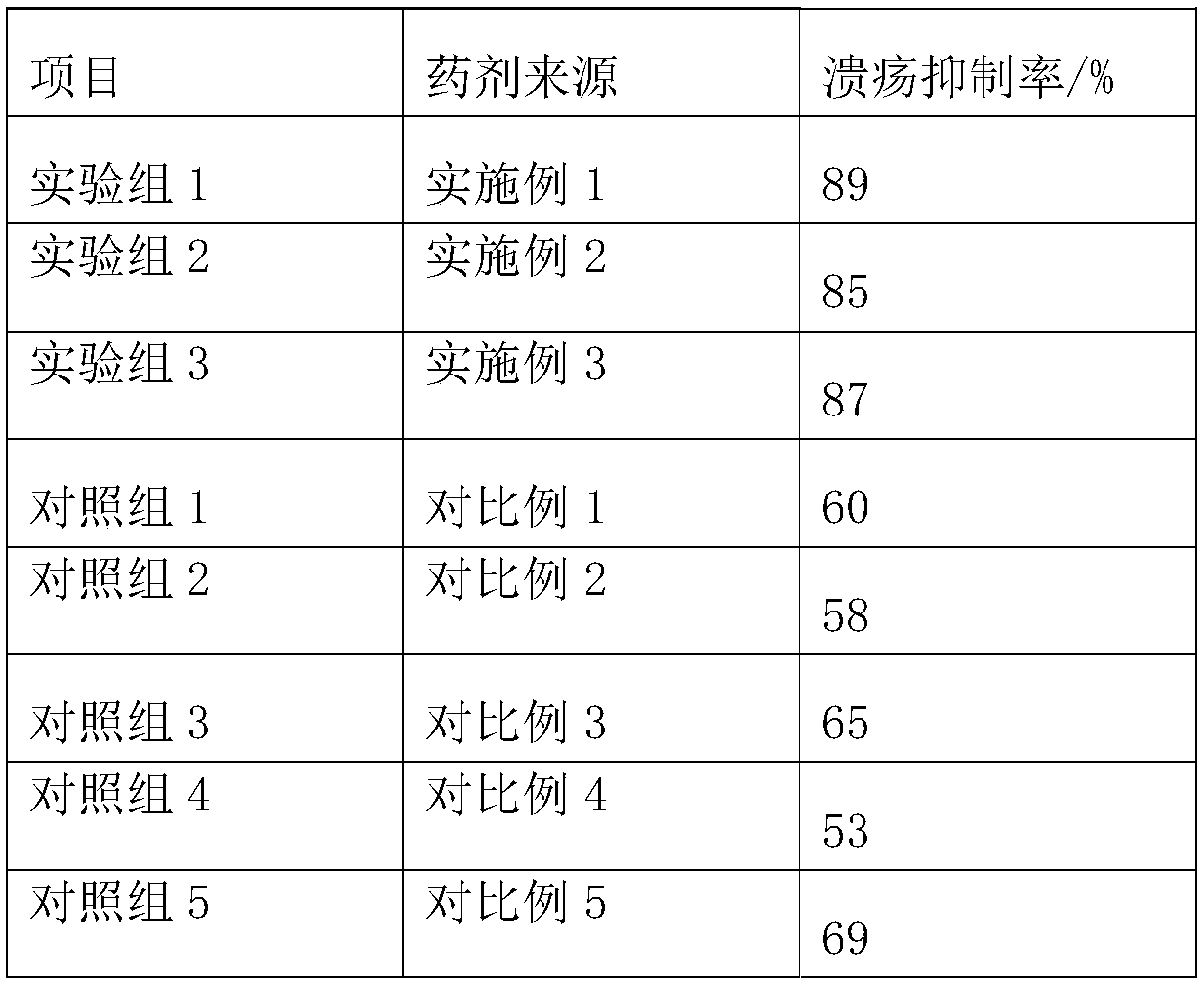

Sucralfate preparation

InactiveCN109432219ATo achieve the purpose of targeted drug deliveryGood treatmentOrganic active ingredientsDigestive systemSucrose sulfateSide effect

The invention belongs to the technical field of pharmaceutic preparations, and particularly discloses a sucralfate preparation, which is prepared from the following materials in parts by weight: 30 to40 parts of sucralfate, 8 to 10 parts of tinidazole, 20 to 30 parts of an adhesive excipient, 15 to 25 parts of chondroitin sulfate, 1 to 3 parts of an acidic excipient, 30 to 40 parts of traditionalChinese medicine component, 5 to 8 parts of honey, 10 to 15 parts of a binder and 2 to 6 parts of a disintegrating agent. The sucralfate preparation is a tablet with the sucralfate, the tinidazole, the traditional Chinese medicine component, the adhesive excipient, the chondroitin sulfate, the acidic excipient and the like as main ingredients, wherein the sucralfate and the tinidazole are main drugs, which have a selective adhesive effect on gastric ulcers and enable the drug to target gastric ulcer sites; the adhesive excipient, the chondroitin sulfate and the acidic excipient can increase the viscosity of the drug, prolonging the retention time of the drug in the stomach; and the traditional Chinese medicine can relieve the side effect of the sucralfate and enhance the immunity of the body. The invention can reduce the frequency and dosage of administration, increase the therapeutic effect and reduce the toxic and side effects of the drug.

Owner:CHONGQING MEDICAL & PHARMA COLLEGE

Nutrient for promoting animal growth and its preparing process

InactiveCN1593511AReduce the cost of farmingInertMetabolism disorderUnknown materialsSodium bicarbonateGrowth promotion

The invention discloses a animal growth promotion nourishing agent which comprises animal blood 25-30kg, bran flour 16-20kg, calcium oxide powder 0.1-0.5kg, yeasts 0.005-0.01kg, ferrous sulfate 0.015-0.03kg, copper sulphate 0.005-0.01kg, zinc sulphate 0.005-0.015kg, manganese dioxide or manganese sulphate 0.015-0.025kg, cobalt chloride 0.0012-0.005kg, potassium iodide 0.003-0.005kg, sodium hydrogen carbonate 0.25-1.5kg, sodium sorbate or potassium sorbate 0.05-0.075kg. The invention also discloses the method for producing the nourishing agent.

Owner:王贵荣

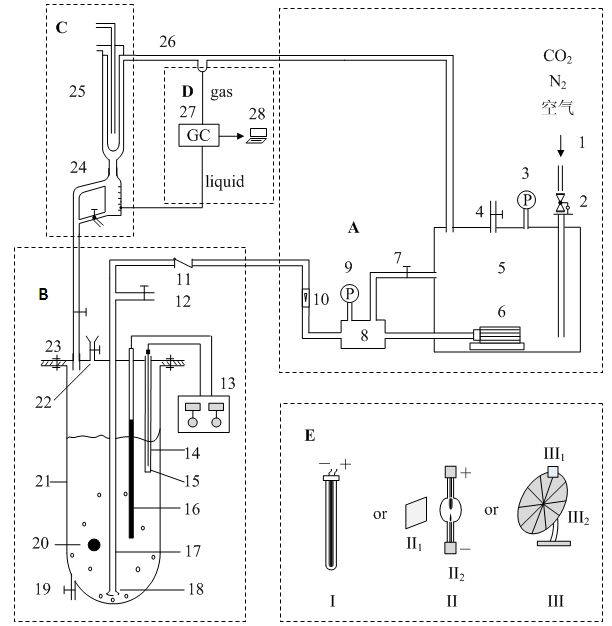

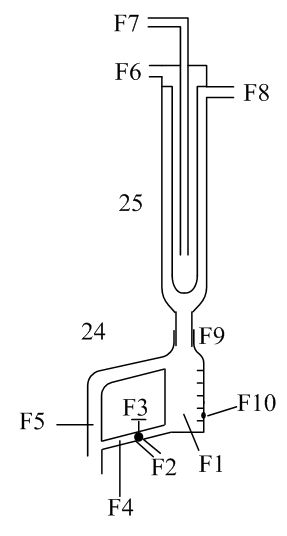

Multifunctional photocatalytic reaction device

InactiveCN102151534BSolve the separation problemWith inert gas protection functionEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionUltraviolet lights

The invention discloses a multifunctional photocatalytic reaction device, which consists of a gas circulation system, a photoreaction system, a separation system, a detection system and a light source system. The light source can be ultraviolet light, visible light and sunlight and is arranged outside a quartz reactor, light penetrates through the quartz reactor to excite a photocatalyst in order to initiate photocatalytic reaction, the photocatalyst can be a thin film which is immobilized, together with a carrier, inside the reactor, or be particles suspended in reaction liquid. The reactor is suitable for liquid-solid, gas-solid and gas-liquid-solid phase photocatalytic reaction, favoring the research on photocatalytic reaction dynamics. The multifunctional photocatalytic reaction device of the invention is suitable not only for photocatalytic reduction CO2 reaction, but also for the fields such as photocatalytic degradation of organic pollutants, hydrogen production by water photolysis, photochemical synthesis and the like, besides, both intermittent operation and continuous operation can be implemented, and inert gas protection can be performed in the reaction process.

Owner:NORTHWEST UNIV

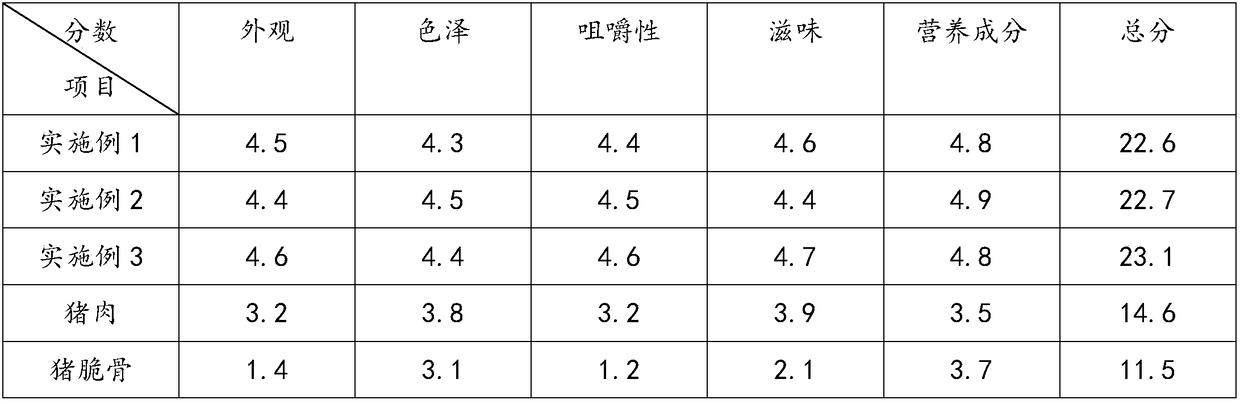

High-calcium gristle beef board and preparation process thereof

The invention discloses a high-calcium gristle beef board and a preparation process thereof. The high-calcium gristle beef board takes beef and pork gristle as main raw materials; a certain amount ofsoybean protein, edible salt, white granulated sugar, konjaku flour, a food additive, edible spice, a compound emulsifier and water are used as auxiliary materials; the beef board is obtained throughthe steps of beef slicing, beef acid discharging, injection material water making, injection, primary rolling of beef, secondary rolling of beef, ultrasonic treatment, gristle beef board forming, vacuum quick freezing, demolding, packaging, boxing and warehousing in sequence, is suitable for hotpots, barbecues and the like, has the advantages of being rich in nutrition and calcium, and enriches the types of traditional beef products.

Owner:雅安利涵商贸有限公司

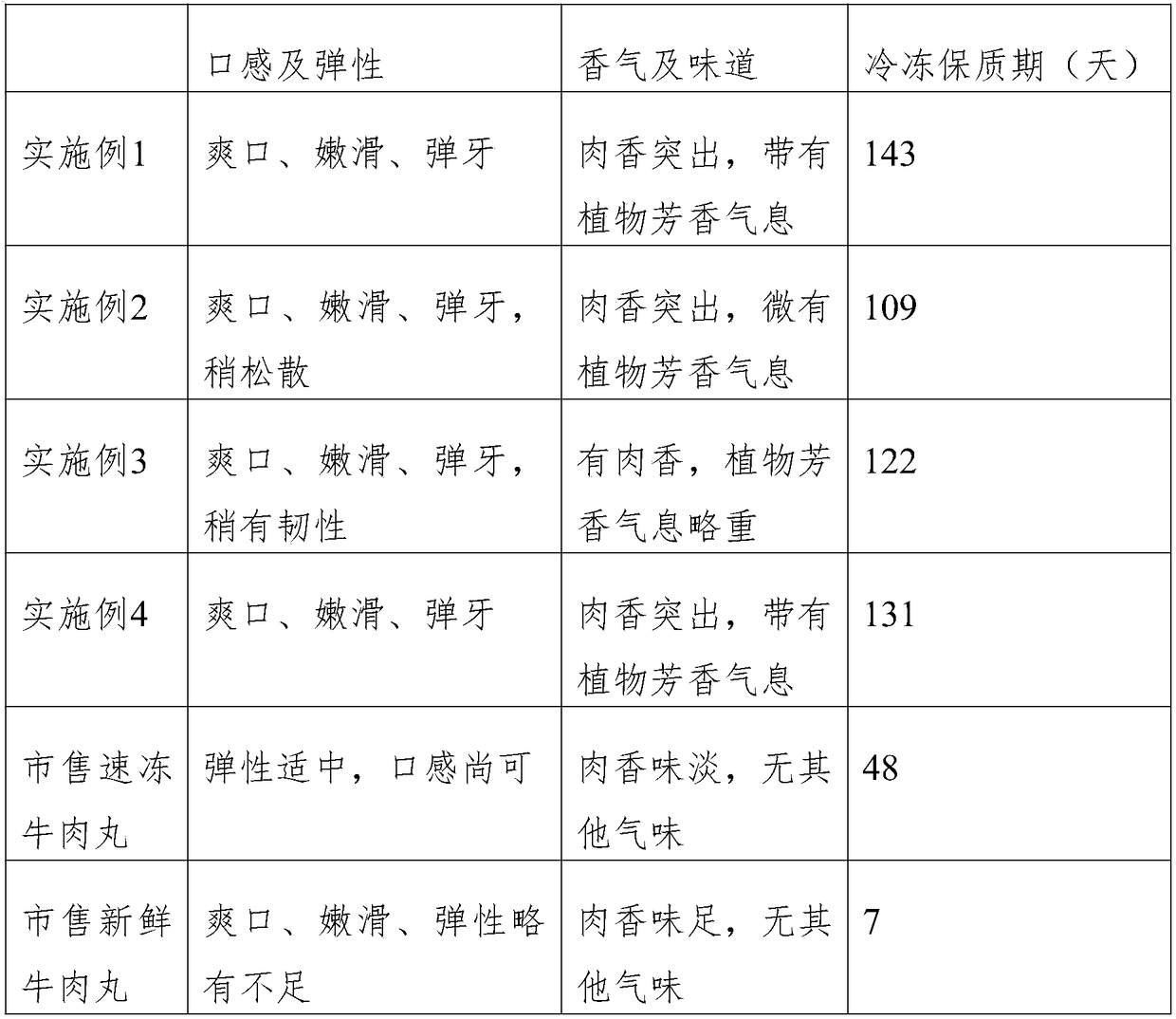

Beef balls and preparation method thereof

PendingCN108576651AHas a thickening effectMoisturizingFood ingredient as antioxidantNatural extract food ingredientsEugenolProduct processing

The invention relates to the field of meat product processing, in particular to beef balls and a preparation method thereof. The method adds bromelain to treat beef in the preparation process, and thebromelain hydrolyzes macromolecular protein of meat protein into small molecular amino acids and proteins which are easy to absorb. Moreover, the method adds a cactus extract liquid, eugenol, pepper,grape seed extract, tea extract, aloe leaf flesh, cinnamon oil, peach gum and sodium alginate into the beef so as to fully play the beneficial effects of the beef, so that the beef balls which are free from chemical additive and starch are finally obtained. The beef balls are better in taste and flavor, and have long shelf life and no harm to human body.

Owner:广西山水牛畜牧业有限责任公司

High-calcium gristle pork plate and manufacture method thereof

InactiveCN109007629AUniform hair colorUnique tasteFood freezingMeat/fish preservation by freezing/coolingFood additiveFlavor

The present invention discloses a high-calcium gristle pork plate and a manufacture method thereof. The high-calcium gristle pork plate is prepared from pork and pork gristle as main raw materials andprepared by combining a certain amount of soybean proteins, edible salt, white granulated sugar, konjac flour, a food additive, edible spices, a compounding emulsifier and water; The high-calcium gristle pork plate is obtained by steps of pork slicing, pork primary rolling, pork secondary rolling, gristle pork plate forming, vacuum freezing, de-molding, packaging, boxing and storing. The high-calcium gristle pork plate is suitable for hot pot, barbecue, etc., has advantages of being delicate and chewy in mouthfeel, unique in flavor and rich in nutrients, and enriches types of traditional porkproducts.

Owner:雅安利涵商贸有限公司

High-adhesion sealant and preparation method thereof

InactiveCN108410395AImprove adhesionLow priceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPotassium feldsparDefoaming Agents

The invention discloses a high-adhesion sealant and a preparation method thereof. The high-adhesion sealant is made from, by weight, 100-200 parts of polyacrylate emulsion, 20-50 parts of potassium feldspar, 10-30 parts of oversaturated urea solution, 5-8 parts of a flexibilizer, 1-5 parts of a defoaming agent, 2-10 parts of a thickener, and 100-200 parts of water. The preparation method includes:mixing the polyacrylate emulsion, potassium feldspar and oversaturated urea solution with water, and allowing standing for 30-60 min; heating to 80-95 DEG C, and stirring at a constant temperature for 15-30 min; cooling to 40-50 DEG C, adding the flexibilizer, defoaming agent and the thickener, and stirring at a constant temperature for 15-30 min. By adding feldspar and limiting its particle grading in conjunction with intercalation of the oversaturated urea solution, the sodium feldspar and polyacrylate emulsion are brought to full contact reaction, so that adhesion of the sealant is improved.

Owner:申轲

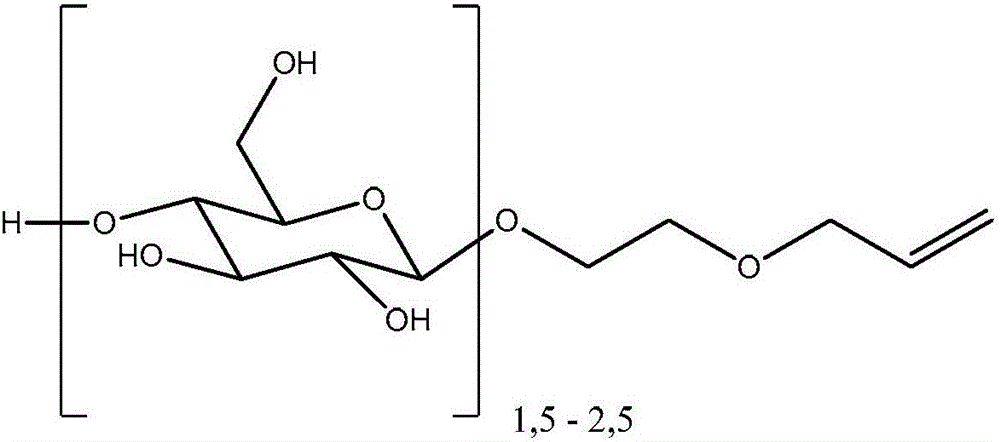

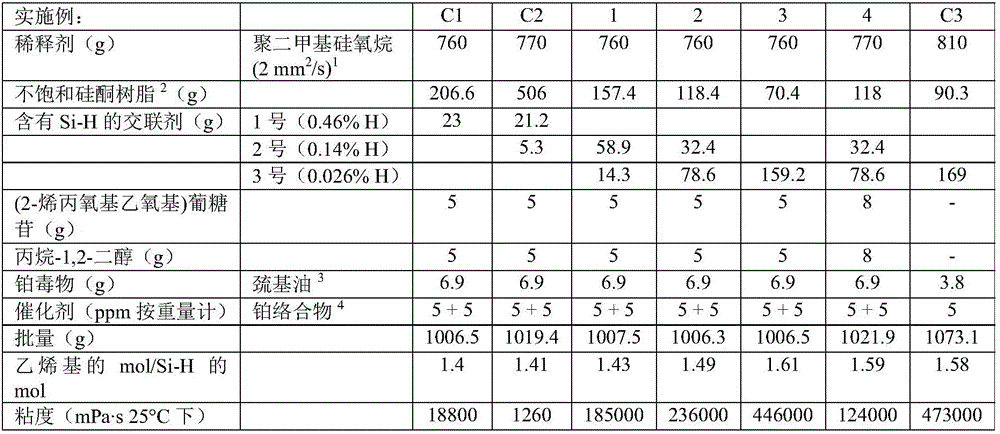

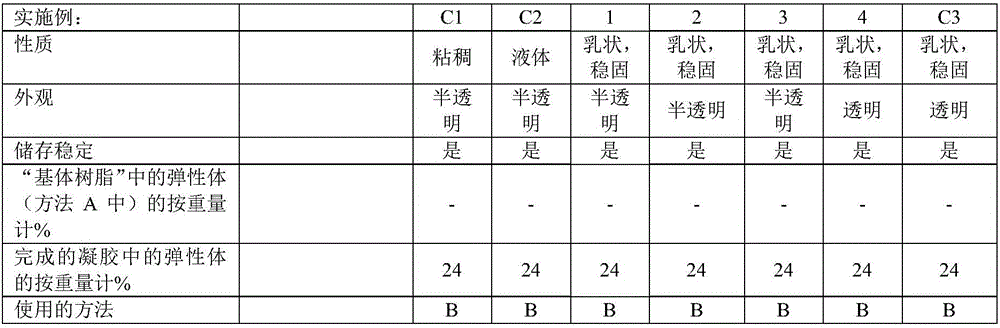

Polyorganosiloxane gels having glycoside groups

InactiveCN105829405AHas a thickening effectGood compatibilityCosmetic preparationsToilet preparationsGlycosidePolymer science

The invention discloses a polyorganosiloxane gels glycoside groups. The invention relates to novel polyorganosiloxane gels, produced by reacting (1a) unsaturated polyorganosiloxane resins and (1b) compounds having a glycoside group and a terminal group that can be hydrosilylated, with (2) Si-H functional polyorganosiloxanes of general formula: HcR3-cSiO(R2SiO)a(RHSiO)bSiR3-cHc, where c represents 0 or 1, R can be identical or different and stands for a monovalent, optionally substituted hydrocarbon group comprising 1 to 8 carbon atoms per group, a and b are whole numbers, with the proviso that the sum of a+b is from 66 to 248, that the polyorganosiloxanes (2) contain Si-bonded hydrogen in amounts of between 0.011 and 0.044 wt. % and that the number of Si-H groups per molecule is on average greater than 2 and less than 5, or by reacting mixtures of (2) Si-H functional polyorganosiloxanes (2') with Si-H functional polyorganosiloxanes of general formula: HcR3-cSiO(R2SiO)a(RHSiO)bSiR3-cHc, where R and c have the definitions given above, a and b are whole numbers, with the proviso that the sum of a+b is from 8 to 248, that the polyorganosiloxanes (2') contain Si-bonded hydrogen in amounts of between 0.045 and 0.35 wt. %, preferably between 0.045 and 0.156 wt. %, in the presence of (3) the attachment of Si-bonded hydrogen to catalysts that promote aliphatic multiple bonds, wherein (1a), (1b) and (2) or mixtures of (2) and (2') are dispersed in (4) diluents, preferable polyorganosiloxanes with 2 to 200 Si-atoms, or in organic diluents.

Owner:WACKER CHEM GMBH

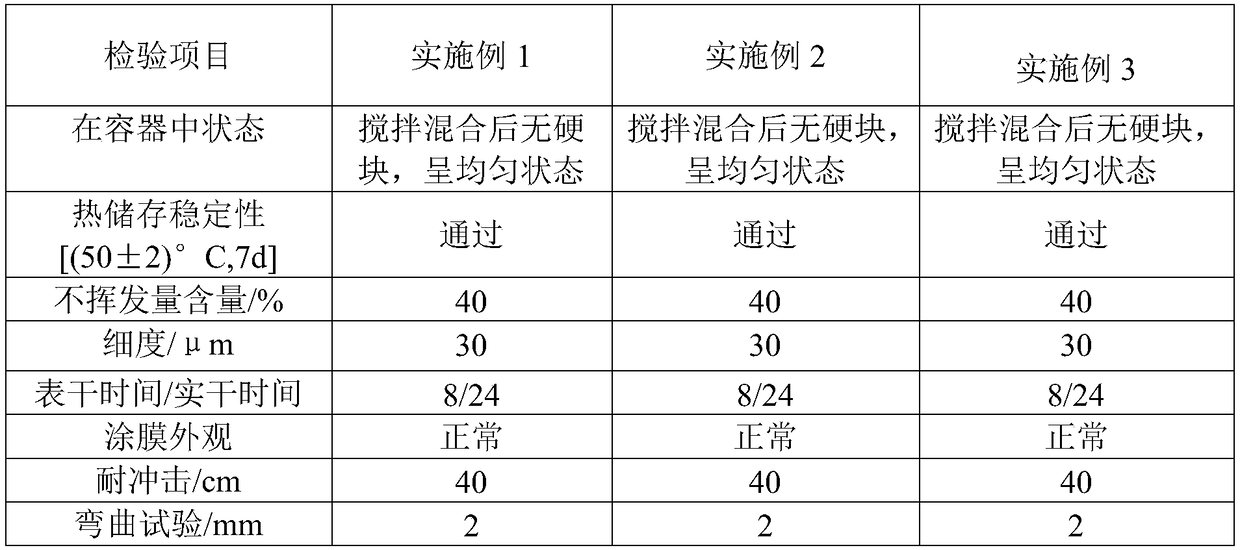

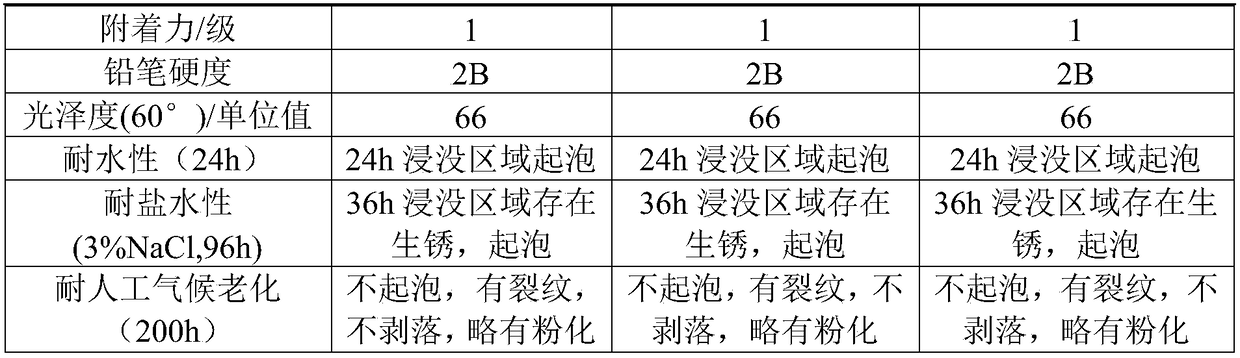

Water-based acrylic finish paint

InactiveCN109439112AEasy constructionImprove hydrophilicityAnti-corrosive paintsWater basedSodium Bentonite

The invention provides water-based acrylic finish paint. The water-based acrylic finish paint comprises, by weight, 24.0-31.0 parts of water-based acrylic acid, 0.4-1.1 parts of dry mixtures, 21.0-30.0 parts of deionized water, 2.2-3.4 parts of ethylene glycol butyl ether, 0.1-0.5 part of dispersing agents, 0.1-0.4 part of defoaming agents, 1.2-3.7 parts of titanium dioxide, 6.0-13.0 parts of 2% EW bentonite pre-adhesive, 2.1-5.4 parts of attapulgite, 2.3-8.8 parts of light chrome yellow, 3.7-9.5 parts of medium chrome yellow, 0.6-3.4 parts of iron oxide yellow, 1.5-3.4 parts of pH (potentialof hydrogen) regulators, 2.27-5.64 parts of coalescing agents, 0.05-0.3 part of base material wetting agents, 0.14-0.3 part of leveling agents, 0.4-0.9 part of flash rust inhibitors, 0.3-0.9 part of thickeners and other 2.0-8.0 parts of deionized water. The water-based acrylic finish paint has the advantages of excellent anti-settling performance, corrosion resistance, weather resistance and scratch resistance.

Owner:TIANJIN MEISHIBANG PAINT CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com