Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Uniform hair color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

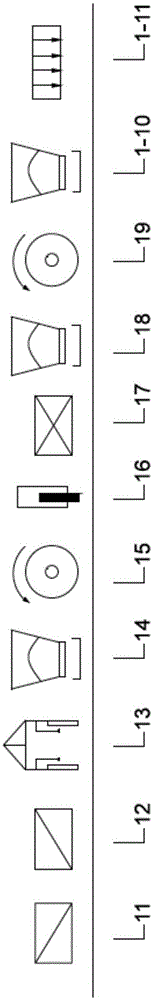

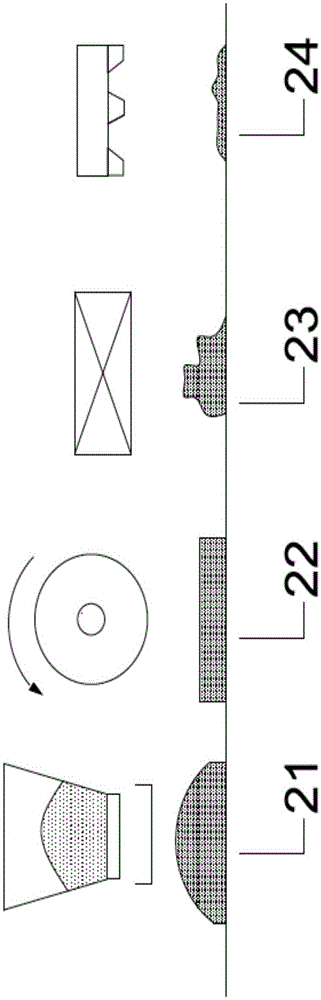

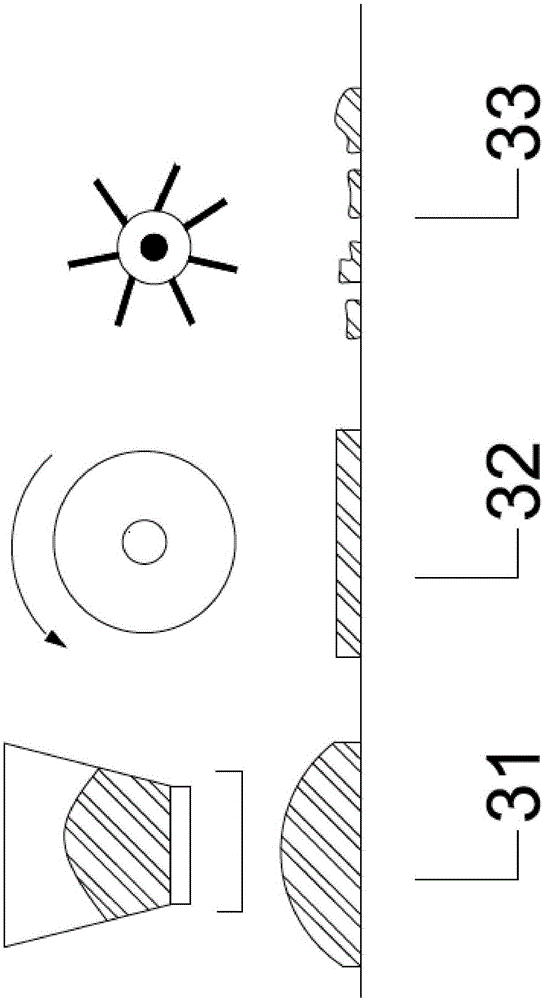

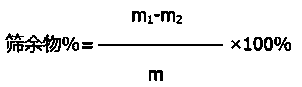

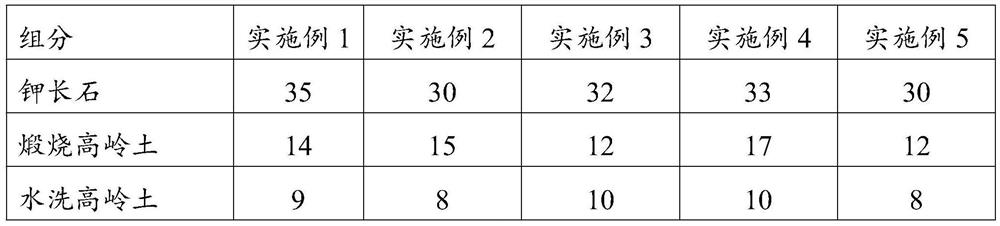

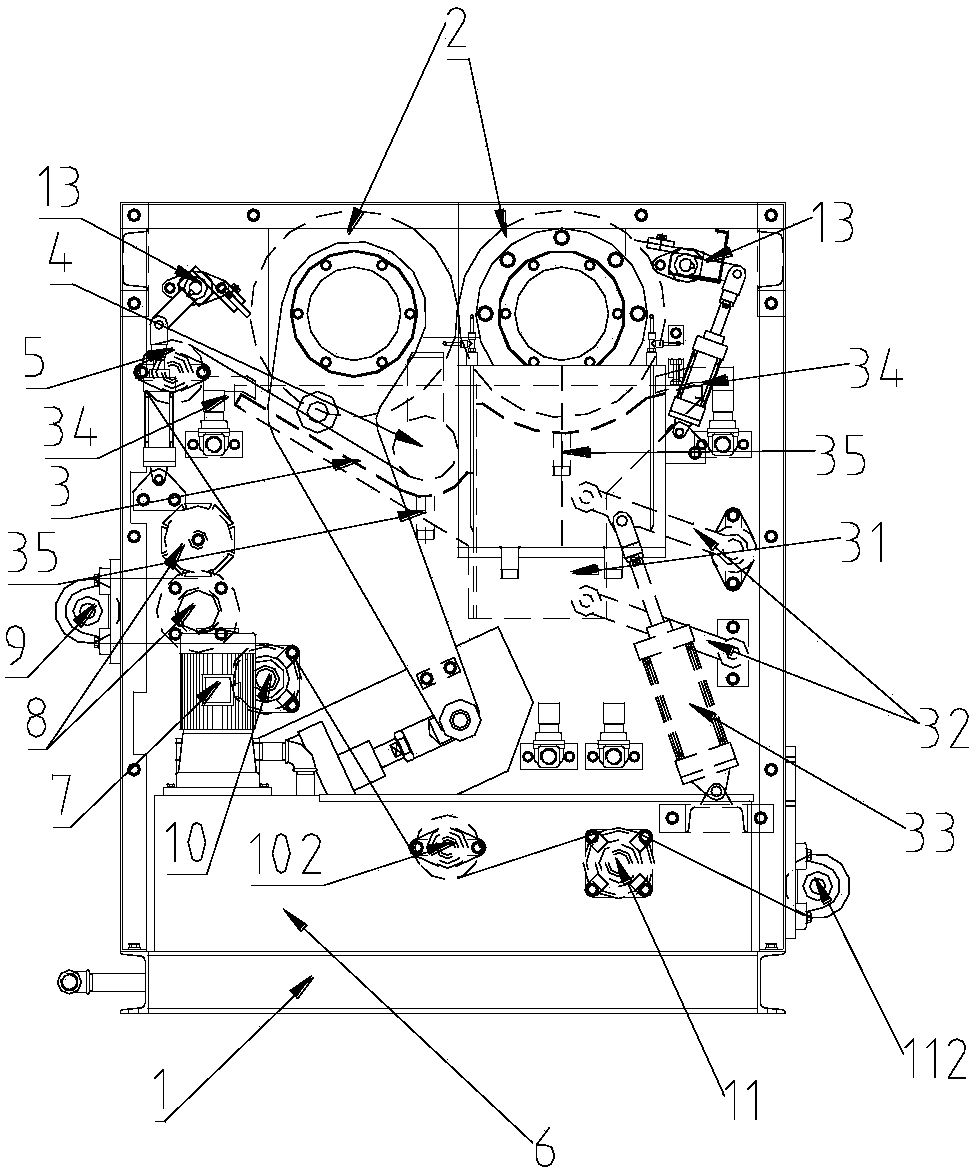

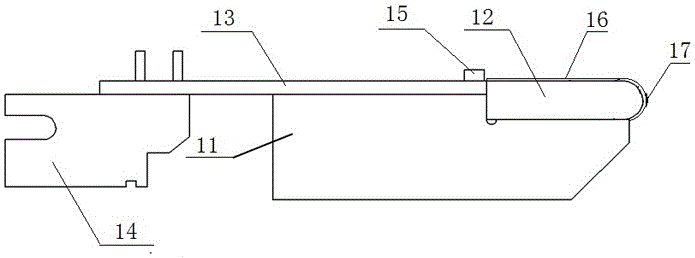

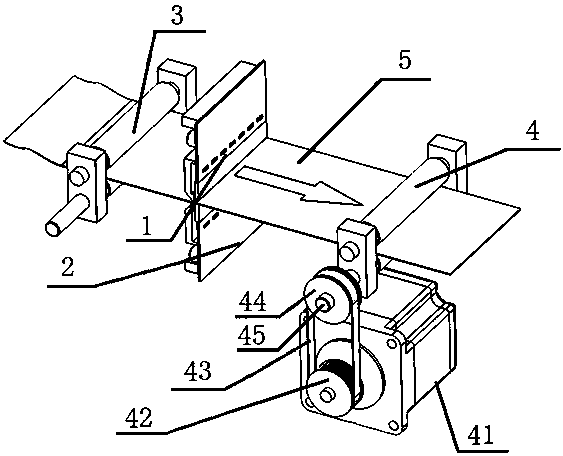

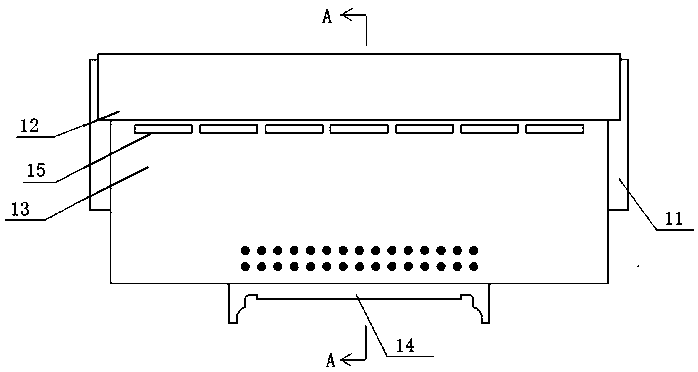

Ceramic polished brick and production method and production line of ceramic polished brick

ActiveCN105328782ASmooth transitionClear and smooth textureCovering/liningsCeramic shaping plantsYarnBrick

The invention discloses a ceramic polished brick and a production method and a production line of the ceramic polished brick. The production line comprises a range-shaped texture forming set, a material block forming set, an atomization spraying system, a third material distributing device, a first roll pressing device, a cutting device, a gorge-shaped texture forming set, a sixth material distributing device, a second roll pressing device, a seventh material distributing device and a press device, all of which are sequentially connected through a belt. According to a preparing method, color attaching pulp is attached to a micro powder stack jointly formed by material blocks formed by a range-shaped texture material belt subjected to the action of a texture manufacturing device and tooth roller crushing, the poking operation and super-through line material filling procedures are carried out on pressed powder through two sets of different mechanical arm combinations, wherein the pressed powder is formed through material supplementing, prepressing and cutting and edge removing. The polished brick obtains the polished brick decoration texture jointly composed of the range-shaped texture, the lava-shaped texture and the gorge-shaped texture. The range-shaped texture is smooth and natural, the edge of the lava-shaped texture has color lines fine like silk yarn, the texture is infinitely close to the difference texture of natural stone, and the stone imitating effect is extremely good.

Owner:GUANGDONG WINTO CERAMICS +3

Pigment pencil for underglaze painting of ceramics and application method of pigment pencil

The invention relates to a pigment pencil for underglaze painting of ceramics and an application method of the pigment pencil. The pigment pencil for the underglaze painting of the ceramics is made up of a penholder and a refill, wherein the refill is prepared from the materials in percentage by weight: 70% to 90% of high-temperature underglaze painting pigment for ceramics, 5% to 30% of paraffin and 2% to 8% of clay. According to the pigment pencil for the underglaze painting of the ceramics, provided by the invention, the traditional underglaze painting pigment for ceramics is processed into a pencil refill structure which is convenient to operate, and a writing-brush underglaze painting mode, which is hard to master, is improved into a pencil painting mode which is common in daily lives, so that the material category and mode of expression of the underglaze painting of the ceramics are enriched. According to the pigment pencil for the underglaze painting of the ceramics, provided by the invention, the use in basic instruction of the ceramics is better facilitated, the popularization rate is high, the pigment pencil is simple and convenient in operation, is smooth and clear, is not prone to falling and is durable in stability, and the transition of a ceramics underglaze painting process to the pigment-pencil-for-the-underglaze-painting-of-the-ceramics, i.e., hard-pen convenient operating process from a writing-brush-dipping-pigment soft-pen tedious operating process is achieved.

Owner:上海满意文化传播有限公司

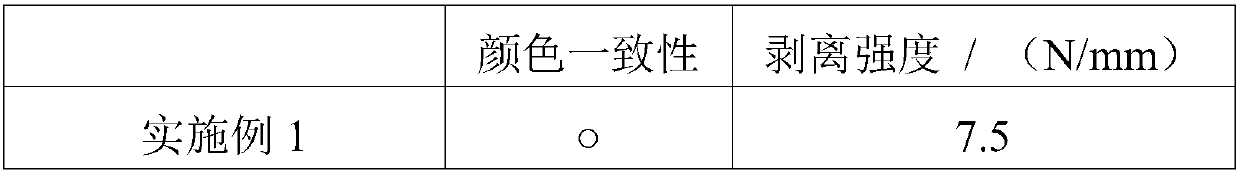

Environmentally-friendly color-changing packaging leather and preparation method thereof

InactiveCN107604684ANo pollution in the processUniform hair colorPolyurea/polyurethane coatingsTextiles and paperVanadium dioxideSurface layer

The invention relates to the technical field of synthetic leather, in particular to environmentally-friendly color-changing packaging leather and a preparation method thereof. The environmentally-friendly color-changing packaging leather comprises a packaging leather base body, wherein a thermochromic layer and a waterborne polyurethane surface layer are arranged on the packaging leather base bodyin sequence; the thermochromic layer is prepared from the following substances in parts by weight: 34 to 52 parts of waterborne polyurethane, 8 to 19 parts of a chromic material, 0.1 to 1.2 parts ofa dispersant, 0.2 to 1.4 parts of a defoaming agent, 2 to 13 parts of an adhesive force accelerant and 30 to 45 parts of water. According to the chromic packaging leather disclosed by the invention, the thermochromic layer taking the waterborne polyurethane as a carrier and taking vanadium dioxide as the color-changing material is adopted, so that no organic solvent is used, and no pollution is caused; therefore, the environmentally-friendly color-changing packaging leather is prepared; after being subjected to modification treatment, the vanadium dioxide can be stably dispersed in the waterborne polyurethane base body, and the uniformity of a chromophoric group is guaranteed; therefore, the chromophoric uniformity of the thermochromic leather is guaranteed; no phenomenon of obvious patchcolors is caused; the quality of the color-changing packaging leather is improved.

Owner:江西省新天汇实业有限公司

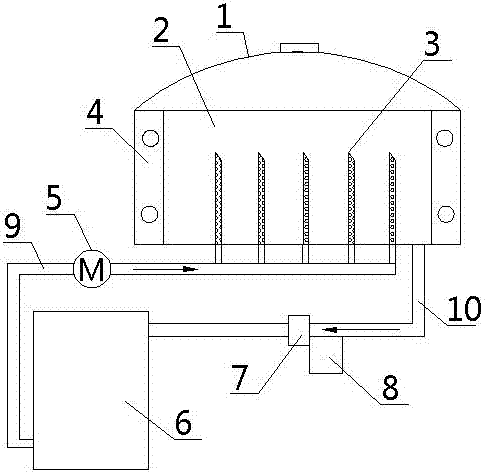

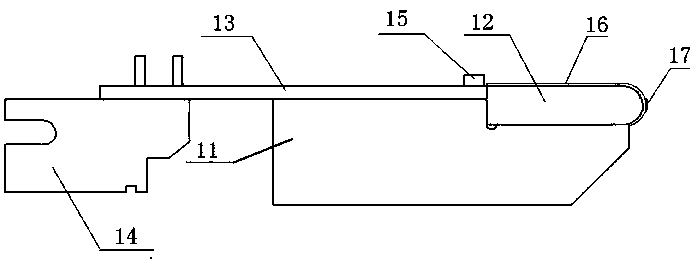

Making method of stewed beef and injection pickling device for making method

InactiveCN107410929AUniform hair colorConsistent flavor inside and outsideFood scienceBiotechnologyNutrition

The invention belongs to the technical field of meat food processing, and in particular relates to a method for preparing stewed beef and an injection curing device used therefor. A method for making stewed beef, the process steps of which are: 1. pretreatment of beef; 2. preparation of cured meat soup; 3. injection marinating; the beef is put into an injection curing device, and the soup is controlled at 10 ℃~15℃, marinating for 6 hours; 4. marinade penetration; The beneficial effect of the present invention is that it is green, healthy, rich in nutrition, uniform in color of stewed beef, consistent inside and outside flavor, soft and tender meat, strong aroma, excellent taste, high quality, high degree of process integration, and the device combines traditional dry pickling The combination of method and wet pickling method, the use of needles reduces the pickling time, which is beneficial to the realization of industrial production.

Owner:山东省阳信广富畜产品有限公司

Novel copper-iron colored glaze and method for manufacturing household porcelain through using novel copper-iron colored glaze

The invention relates to novel copper-iron colored glaze. The novel copper-iron colored glaze comprises, by weight, 20-34 parts of quartz, 5-14 parts of kaolin, 12-17 parts of calcite, 0-3 parts of bone powder, 2-8 parts of barium carbonate, 30-50 parts of albite, 2-2.5 parts of stannic oxide, 0.5-0.8 part of copper oxide, 0-2 parts of talc and 0-4 parts of glass powder. The invention further provides a method for manufacturing household porcelain through using the copper-iron colored glaze. The glaze color of the household porcelain manufactured through the method is bright, color development is even, glassiness and brightness are good, few defects exist in the glaze, and cracks will not occur.

Owner:GUANGDONG SONGFA CERAMICS

Chromophoric method for java tilapia sheet processing

InactiveCN1836575AFast color developmentUniform hair colorFood preparationProduct gasWatering trough

The tilapia fillet coloring process includes the following steps: filling water into water trough, regulating the water temperature to basically the same as that in cultivating environment, and setting tilapia inside the water trough; introducing CO and air successively through a gas-water mixing pump to mix homogeneously for 13-20 min; and cutting tilapia, sterilizing and making tilapia fillet. The said coloring process adopts live body coloring technology, and has reduced excessive CO gas on the worker, decreased sterilizing times, and raised coloring effect.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Jun porcelain sapphire blue glaze and preparing method thereof

The invention discloses jun porcelain sapphire blue glaze. The jun porcelain sapphire blue glaze is prepared from, by weight, 40-48 parts of melilite, 14-18 parts of quartz, 12-18 parts of calcite, 12-18 parts of Ben drug, 3-5 parts of copper ore, 3-5 parts of zinc oxide, 0.5-1.5 parts of stannic oxide, 0.5-1.5 parts of copper oxide, 0.2-0.4 part of cobaltous oxide. The preparing method of the junporcelain sapphire blue glaze includes the following steps that the raw materials are smashed, mixed and put into a ball grinder to be grinded, water is added so that the mass concentration of the glaze can reach 55-56%, wet grinding is carried out by 8-10 hours, slurry obtained after wet grinding is screened through a screen of 200-300 mesh to obtain glaze slip; a green body is soaked in the glaze 1-2 times; sintering is carried out at the temperature of 1280-1320 DEG C.

Owner:禹州市锦丰源瓷业有限公司

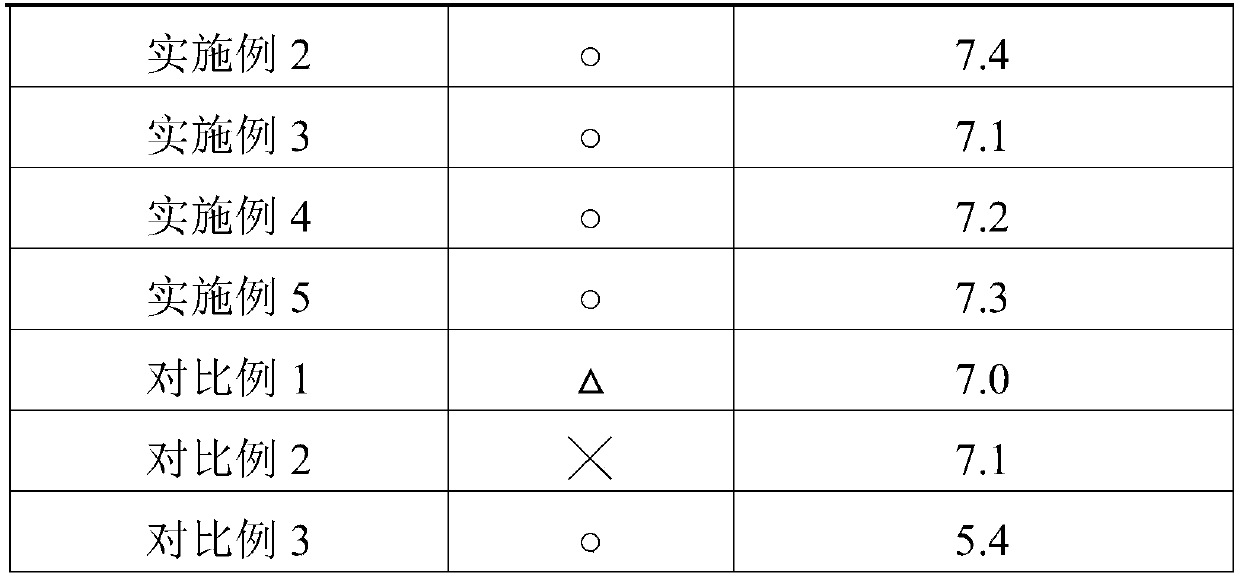

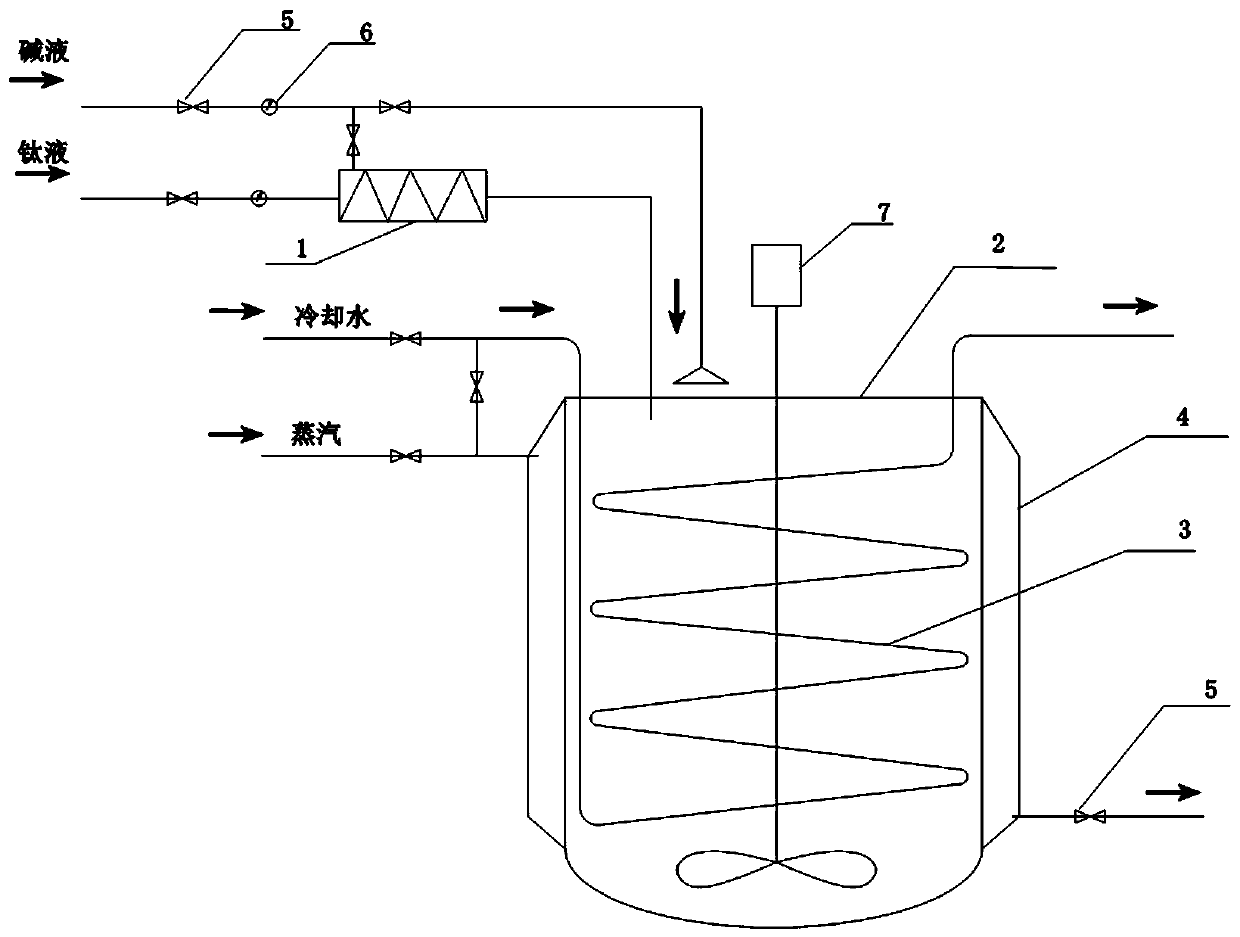

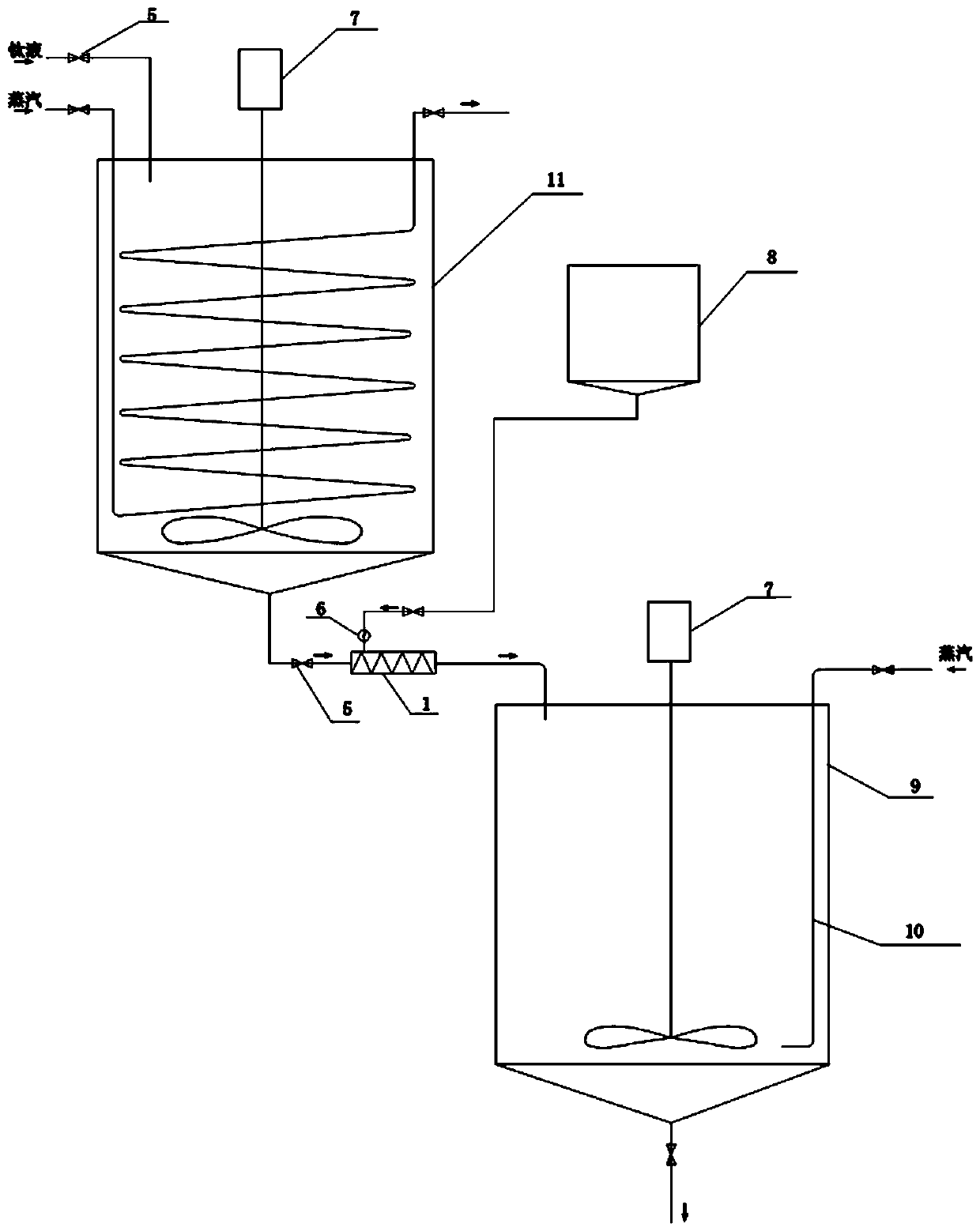

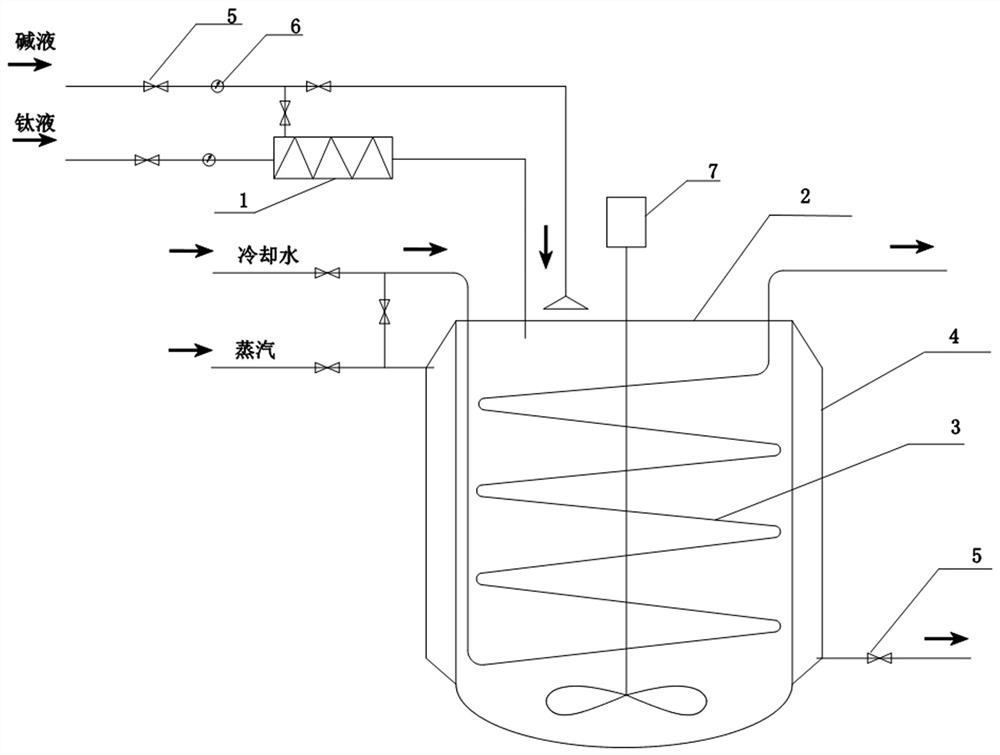

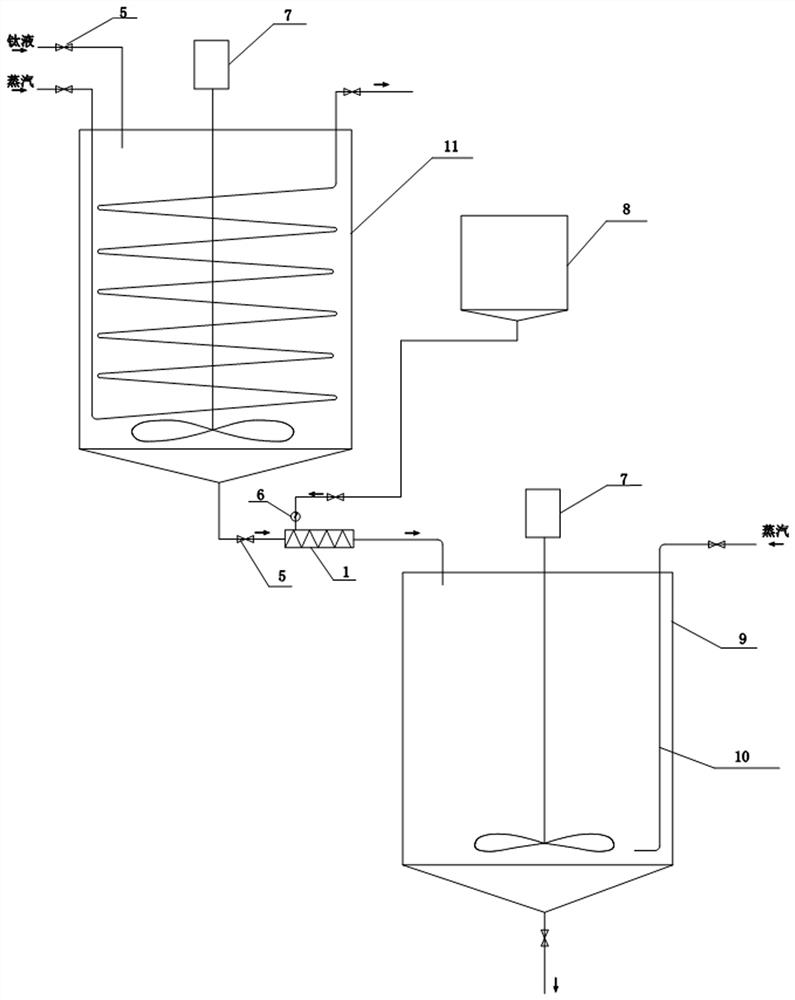

Production method of high-chromogenic-power enamel titanium dioxide for pigment by sulfuric acid method

The invention relates to the field of titanium dioxide preparation and specifically relates to a production method of high-chromogenic-power enamel titanium dioxide for a pigment by a sulfuric acid method. The production method comprises the steps: (1) hydrolyzed crystal seed preparation; (2) hydrolysis; (3) washing; (4) calcining and the like. Titanium dioxide produced by using the production method of high-chromogenic-power enamel titanium dioxide for the pigment by the sulfuric acid method has particles with very uniform particle sizes and is small in particle size and high in specific surface area; the prepared titanium dioxide is very ideal in chromogenic effect after being caked, high in chromogenic rate, stability in chromogenic effect and good in glossiness, is high-quality pigmenttitanium dioxide and has the advantages such as low dosage, strong chromogenic capacity, uniform in chromogenic effect, consistent in color light and hue and stable using effect; and compared with atraditional conventional product, the production method has the advantages such as low production cost and stable quality and is deeply welcomed by customers.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

Urination-promoting and dampness-excreting oxtail and preparation method thereof

InactiveCN105410711AFull of nutritionSoft and tender meatFood ingredient functionsCalcium in biologyDisease

The invention discloses an urination-promoting and dampness-excreting oxtail. The urination-promoting and dampness-excreting oxtail is prepared by the following raw material drugs in parts by weight: 120 parts of oxtails, 6 parts of table salt, 4 parts of white sugar, 4 parts of peanut oil, 3 parts of peels of bunge pricklyash, 2 parts of peppers, 4 parts of garlic, 5 parts of fresh ginger, 1 part of spice-leaves, 2 parts of barks of Japanese cinnamon, 2 parts of anises, 2 parts of cinnamons, 1 parts of amomum fruits, 2 parts of dahurian angelica, 4 parts of common achyranthes herbs, 2 parts of cordate houttuynia, 2 parts of barbed stullcap, 2 parts of leonurus heterophyllus, 2 parts of plantain, 4 parts of cogongras rhizome, 0.1 part of bog rushes, 44 parts of carrots, 18 parts of tomatoes and 8 parts of cider vinegar. Compared with prior art, the urination-promoting and dampness-excreting oxtail prepared according to the invention is developed for young children; the meat of the urination-promoting and dampness-excreting oxtail is rich in nutrition, heavy in aroma, unique in flavor, high in protein content, low in fat and high in calcium; the urination-promoting and dampness-excreting oxtail has the functions of clearing away heat and toxin, promoting urination and excreting dampness. Diseases such as acute and chronic nephritis and urinary tract infection in children can be effectively prevented and treated by long-term taking of the urination-promoting and dampness-excreting oxtail disclosed by the invention.

Jun porcelain cracked celeste glaze and preparation method thereof

The invention discloses a jun porcelain cracked celeste glaze, prepared from the following raw materials in parts by weight: 32 to 40 parts of melilite, 10 to 14 parts of quartz, 10 to 14 parts of calcite, 12 to 18 parts of basic chemical, 6 to 10 parts of monatomic silicon powder, 3 to 5 parts of talcum, 1 to 3 parts of ferric oxide, 0.5 to 1.5 parts of stannic oxide, 6 to 10 parts of wood ash and 1 to 3 parts of black wool soil. A preparation method of the jun porcelain cracked celeste glaze comprises the following steps: (1) crushing the raw materials, then mixing, putting into a ball miller for ball-milling, adding water, so that the mass concenetration of a glaze reaches 54 to 55 percent, wet-milling for 5 to 7 hours, and enabling slurry subjected to wet-milling to pass through a 200-to 300- mesh sieve to obtain glaze slurry; (3) soaking a green body in the glaze for 1 to 2 times; (3) firing at a firing temperature of 1280 to 1300 DEG C.

Owner:禹州市锦丰源瓷业有限公司

Environment-friendly plush fabric dyeing method and residual color paste treatment technology thereof

InactiveCN109355834AHigh uniformity of color brightnessImproved performance of the finished productHeating/cooling textile fabricsLiquid/gas/vapor removalColour fastnessDye absorption

The invention discloses an environment-friendly plush fabric dyeing method and a residual color paste treatment technology thereof. The technology comprises the following steps that 1, a white gray fabric of a plush fabric is pretreated; 2, a high-temperature dye is prepared into color paste and poured into a rolling groove of a padder; 3, the pretreated white grey cloth is guided into the rollinggroove in the padder through a cloth guide roller at the front end of the padder for quick hunger type high-permeability dye absorption to complete dyeing, and the dyed fabric and the residual colorpaste are obtained; 4, drying and primary color development are carried out; 5, drying and high-temperature color development are performed; 6, the fabric is discharged; 7, the fabric is rinsed and softened; 8, shaping is carried out; 9, post-treatment is performed; 10, a finished product is manufactured. The fabric dyed through the method is uniform in color, free of color difference, bright andgood in finished product, and the liquid rate when the padder is used for padding the gray fabric is controlled to be 35-50% so that color development can be fully achieved during color development, the color is bright, and the color fastness is quite good.

Owner:江苏康尼纺织品有限公司

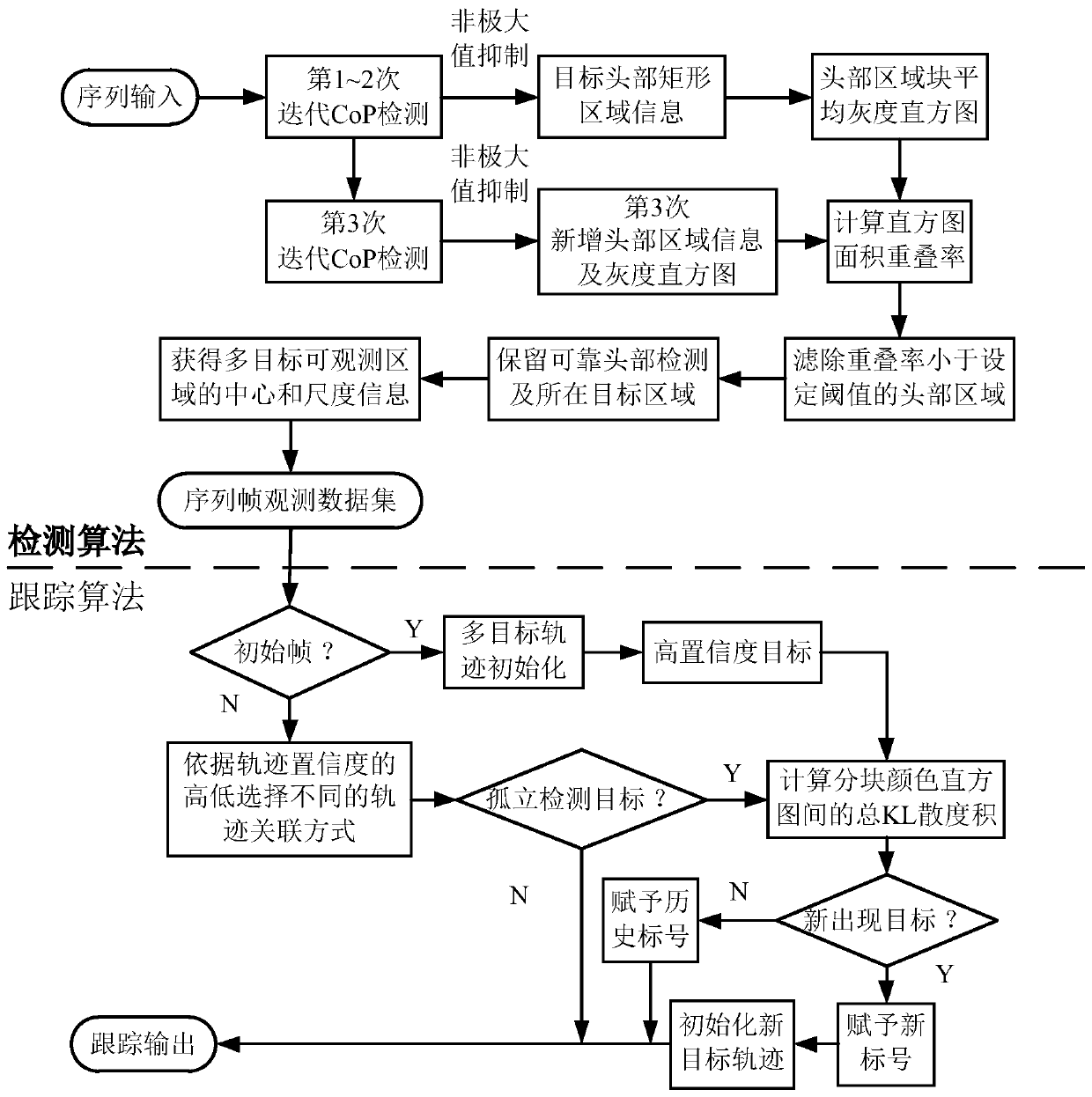

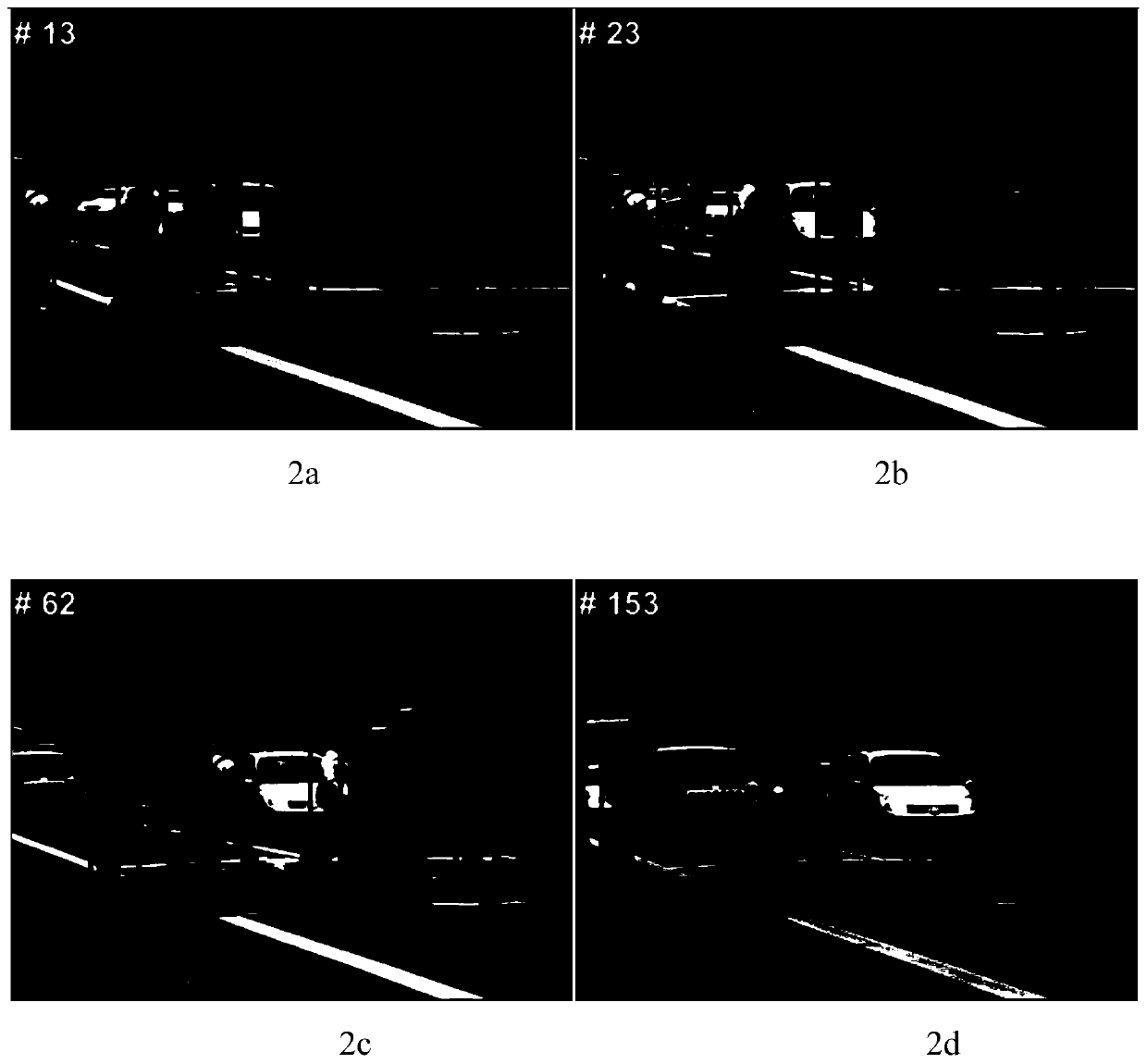

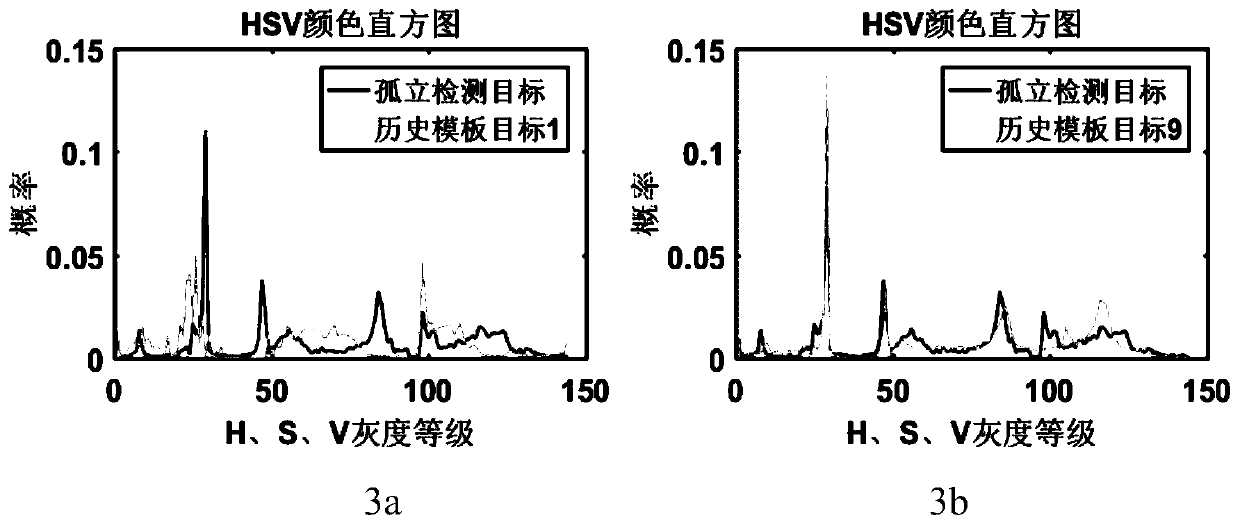

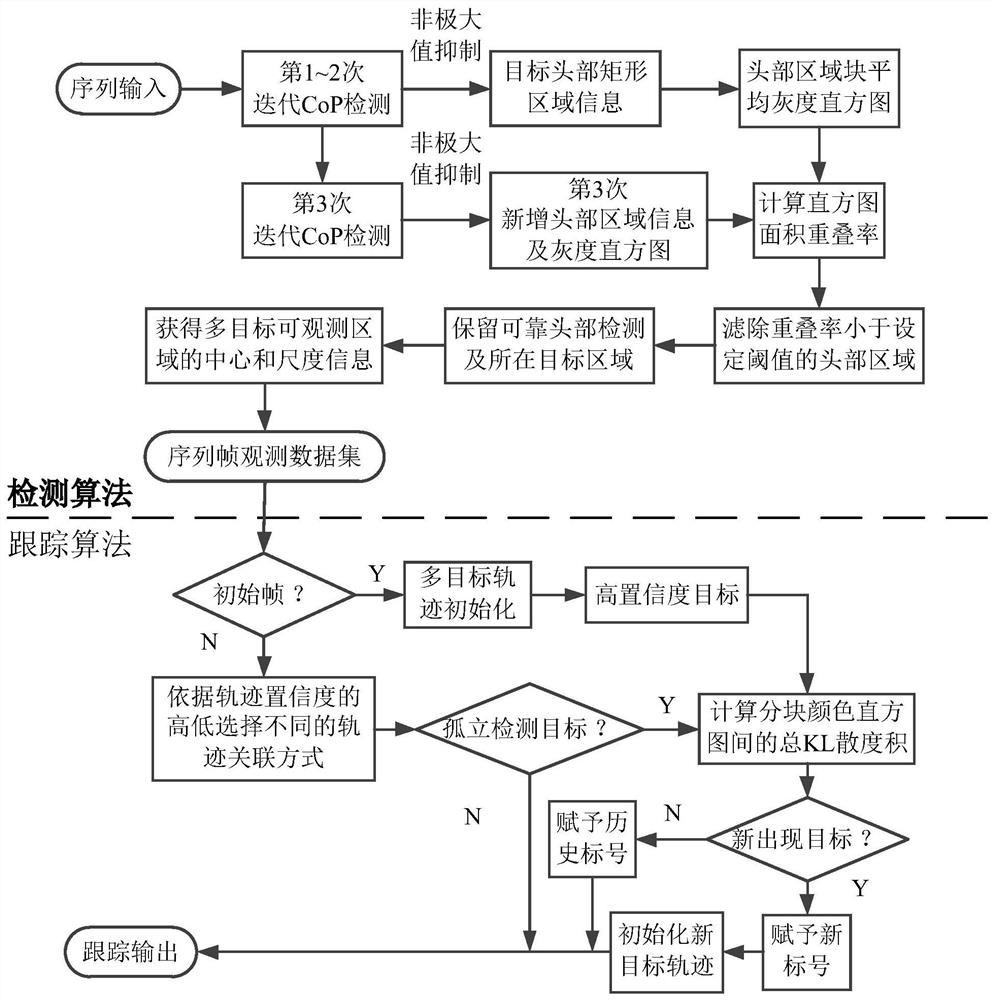

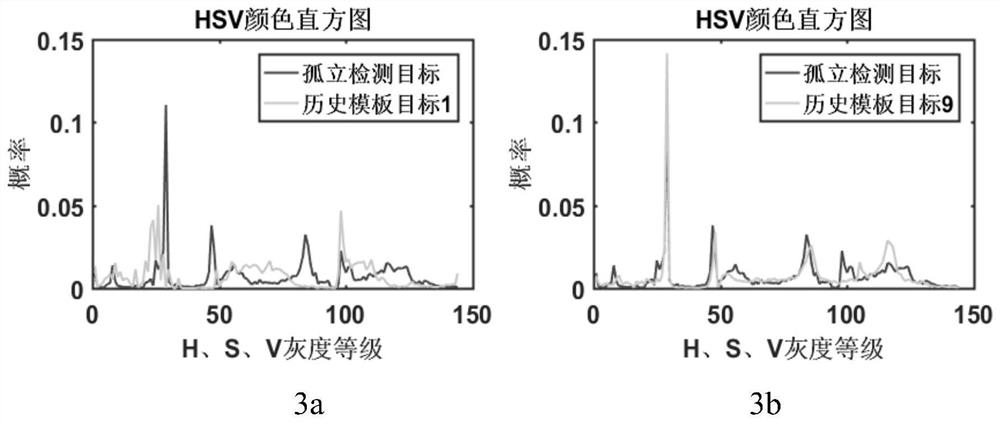

Multi-pedestrian tracking method based on iterative filtering and observation discrimination

ActiveCN110349184AHelps balance hair colorHelps balance skin tone differencesImage enhancementImage analysisData setObservation data

The invention discloses a multi-pedestrian tracking method based on iterative filtering and observation discrimination. Iterative component combination detection is performed on a to-be-detected videoimage three times so as to reduce the omission ratio. A histogram area overlapping ratio is calculated between a newly added target head gray histogram reserved after the third iteration and an average gray histogram of the head image block after the second iteration. The target head detection frame of which the overlapping rate is smaller than a set threshold value is filtered out to effectivelyinhibit the influence of a false detection frame on the detection performance, reserve a reliable target detection frame, and facilitate the improvement of the detection accuracy. A local observablearea of the mutually-shielded or incomplete detection target is extracted. Center and scale information of the multi-target observable area is acquired., An observation data set is established and tracking is realized according to the observation data set and the target trajectory confidence. The method can be applied to the fields of artificial intelligence, intelligent robots, intelligent videomonitoring and the like.

Owner:NANJING INST OF TECH

Preparation method of scratch double-layer reaction glaze

The invention discloses a preparation method of a scratch double-layer reaction glaze, which comprises the following steps of S1, washing a green body with water, glazing with an inner glaze, and drying, S2, applying ground glaze to the green body treated in the step S1, airing for 2-3 min, and then applying surface glaze, S3, after the surface glaze is completely dried, uniformly carving lines corresponding to the scratch patterns on the surface glaze by using a carving knife according to the designed scratch patterns, and S4, firing the green body treated in the step S3 to obtain a finishedproduct. The Baume concentration of glaze slip used by the surface glaze and the bottom glaze is controlled to be 38-42 Baume degrees, the specific gravity is controlled to be 1.2-1.3, and the water content is controlled to be 58-62%. The glaze disclosed by the invention is uniform in color development and good in glaze effect.

Owner:醴陵市和兴瓷业有限公司

Skin carrying beef with qi tonifying and blood activating efficacy and preparation method thereof

InactiveCN105360971AFull of nutritionSoft and tender meatNatural extract food ingredientsFood ingredient functionsCyathula officinalisPEAR

The invention discloses a skin carrying beef with qi tonifying and blood activating efficacy. The product is prepared from the following bulk drugs by weight part: 120 of skin carrying beef, 6 of salt, 3 of white sugar, 4 of soybean oil, 4 of Chinese prickly ash, 2 of black pepper, 6 of garlic, 5 of ginger, 1 of bay leaf, 2 of Cinnamomum tamala, 3 of star anise, 2 of cinnamomum cassia, 1 of Amomum villosum lour, 2 of angelica dahurica, 1 of cortex moutan, 2 of radix paeoniae alba, 2 of astragalus, 1 of Angelica sinensis, 2 of hawthorn, 2 of Ligusticum wallichii, 1 of radix rehmanniae, 3 of Cyathula officinalis, 42 of grapefruit, 38 of snow pear, 17 of lemon, and 8 of apple vinegar. The invention also discloses a preparation method of the skin carrying beef. Compared with the prior art, the skin carrying beef with qi tonifying and blood activating efficacy provided by the invention has the characteristics of rich nutrition, soft and tender meat, strong aroma, appropriate saltiness, unique flavor, high protein, low fat and high calcium, also has health care functions, and has the efficacy of tonifying qi and activating blood, dredging vessel and unblocking meridians.

Owner:JIESHOU HONGLIANG FOOD

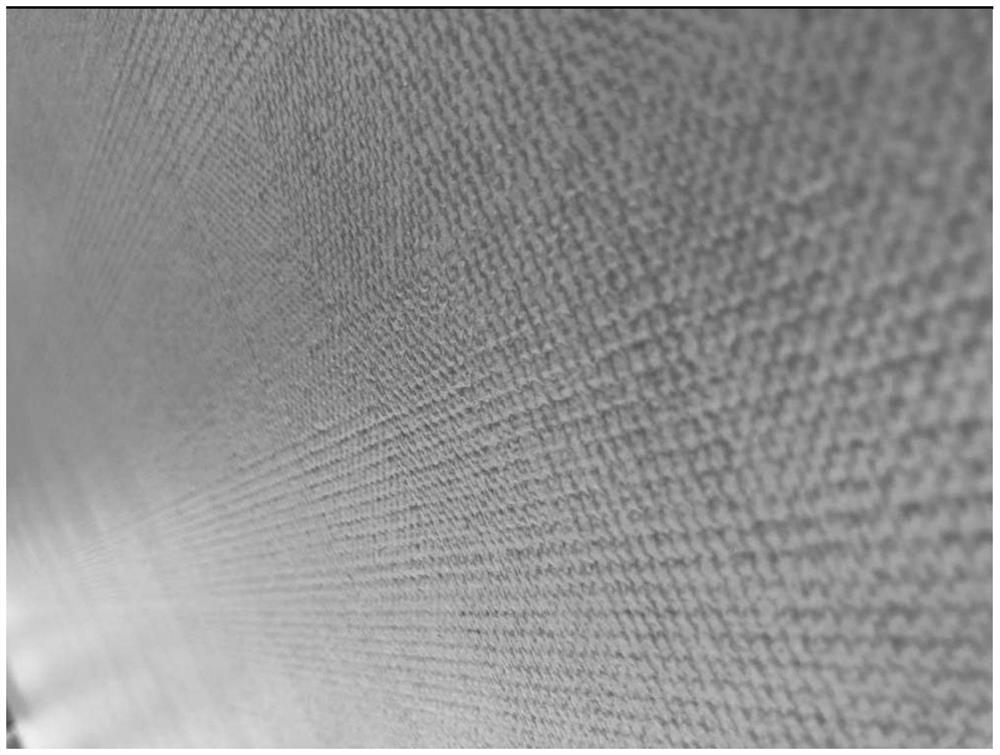

Preparation method of cloth-pattern-imitated rock plate

The invention relates to the technical field of architectural ceramics, and particularly discloses a preparation method of a cloth-pattern-imitated rock plate, which comprises the following steps: S1, applying cover glaze to a green body and drying; S2, printing a pattern by adopting oily matte ink and ceramic ink-jet ink; S3, applying a velvet-like glaze material; S4, applying a particle-like glaze material, and then drying; and S5, firing. According to the invention, the texture pattern with a three-dimensional effect is preliminarily formed on the surface of the green body through the oily matte ink, the unique velvet texture of the cloth grains is reduced by combining the velvet-like glaze, and then the soft fine particle texture of the cloth grains with slight fluctuating particles is reduced by superposing the granular-like glaze, so that the unique texture of the cloth grains is highly reduced; in addition, the velvet-like glaze and the particle-like glaze can make the color development of the ceramic ink-jet ink more uniform, local color difference is avoided, and the manufactured cloth-pattern-like rock plate is high in reduction degree, fine and smooth in hand feeling and good in decoration effect; the velvet-like glaze and the granular-like glaze can also endow the rock plate with high hardness and high wear resistance, and the prepared rock plate is excellent in antifouling property and scratch resistance.

Owner:广东兴辉陶瓷集团有限公司

A Multi-Pedestrian Tracking Method Based on Iterative Filtering and Observation Discrimination

ActiveCN110349184BHelps balance hair colorHelps balance skin tone differencesImage enhancementImage analysisData setVideo image

Owner:NANJING INST OF TECH

Method of using vat dye to dye yarns

The invention relates to a method of using a vat dye to dye yarns. The method includes the steps of pretreating yarns; reducing, to be specific, adding water to the pretreated yarns, controlling pumping speed of a vat to 1160-1450 r / m, adding a vat dye, and adding an alkali and a reducing agent to carry out reducing reaction; oxidizing, to be specific, decreasing the pumping speed to 580-1015 r / mafter the reducing reaction is over, and adding an oxidant to carry out oxidation reaction; post-treating the yarns subjected to oxidation reaction. The method herein helps effectively solve the problems of dyeing defects and inner and outer color differences in the application of a vat dye in yarn dyeing; the yarns dyed have uniform and bright color and are high in soaping fastness and light fastness.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Preparation method of sauced beef

The invention discloses a preparation method of sauced beef. The method comprises the following process steps of pickling raw material of beef cubes, injecting, rolling and prickling, boiling, cooling, sterilizing, packaging, and the like. The method has the advantages that the industrial production of sauced beef is realized, the prickling time is reduced, the quality stability is improved, the color of the prepared sauced beef is uniform, the flavor of the sauced beef is uniform, and the fragrant flavor is heavy and lasting.

Owner:修武县伊赛牛肉有限公司

Production method of high chromogenic power sulfuric acid enamel titanium dioxide for pigment

The present invention relates to the field of titanium dioxide preparation, in particular to a production method of high-color-developing sulfuric acid enamel titanium dioxide for pigments, including (1) making hydrolysis seed crystals, (2) hydrolysis, (3) washing, and (4) calcining. Adopting the production method of high color-developing power sulfuric acid enamel titanium dioxide for the pigment, the produced titanium dioxide has particles with a very uniform particle size, small particle size and high specific surface area, and the color development of the prepared titanium dioxide after being caked It is also very ideal, with high color development rate, stable color development and good gloss. It is a high-quality pigment titanium dioxide. It has the advantages of less dosage, strong color development ability, uniform color development, consistent color tone, and stable use effect. Compared with traditional conventional products, it has the advantages of low production cost and stable quality, and is very popular among customers.

Owner:ALFA FULL GUANGXI TENG COUNTY TITANIUM DIOXIDE

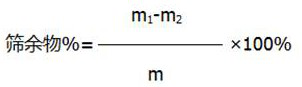

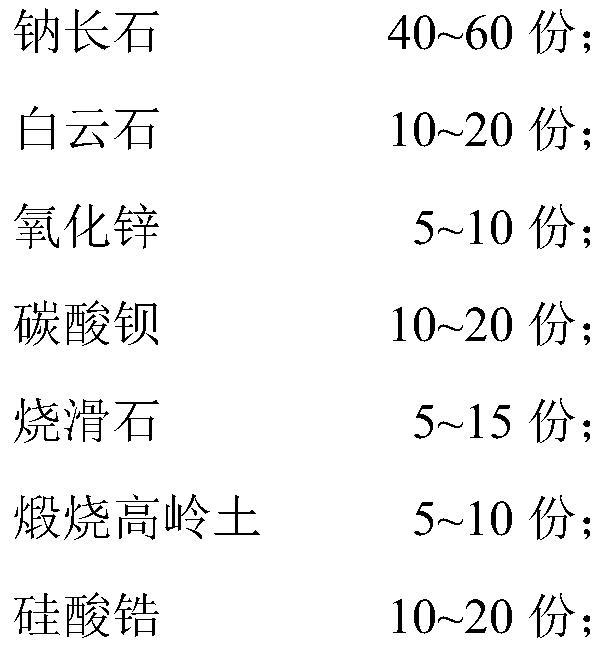

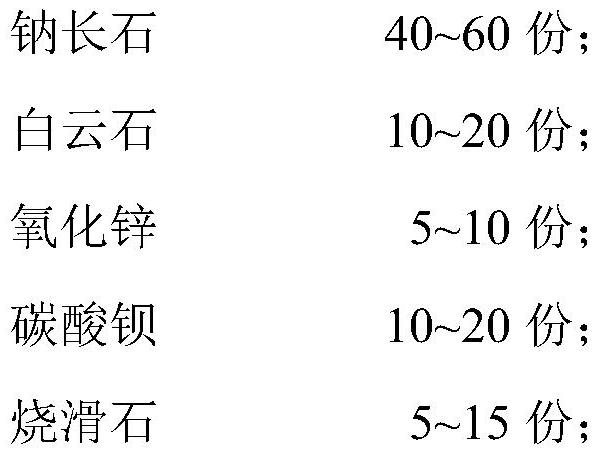

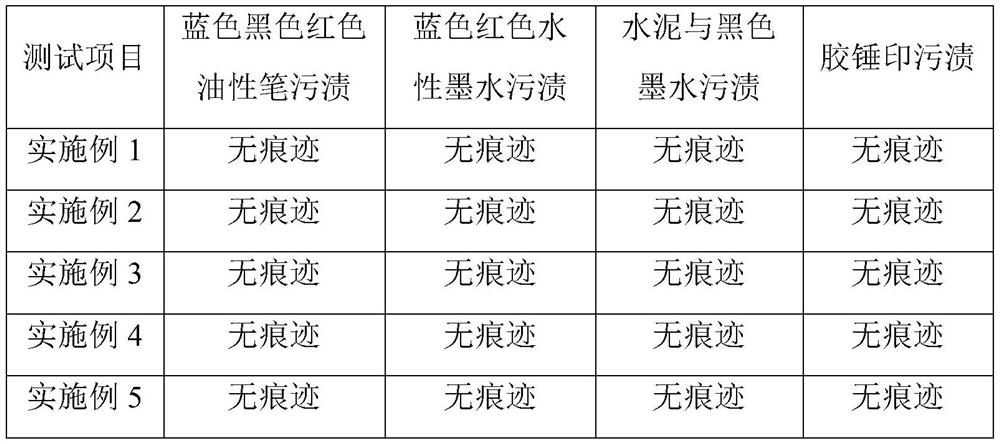

Imitation marble soft light brick surface glaze, imitation marble soft light brick and preparation method thereof

The invention discloses a marble imitation soft light tile surface glaze, which comprises the following components in parts by weight of raw materials: 40-60 parts of albite, 10-20 parts of dolomite, 5-10 parts of zinc oxide, and 10 parts of barium carbonate ~20 parts, calcined talc 5~15 parts, calcined kaolin 5~10 parts, zirconium silicate 10~20 parts, corundum 2~10 parts. The invention optimizes and adjusts the surface glaze components and proportions, and the glaze has a uniform color development effect and stable glaze gloss, thereby endowing the surface of imitation marble tiles with a more delicate soft light effect, making the imitation marble texture decoration and soft light After the effect is combined, it still maintains an excellent simulation degree, and at the same time, the glazed surface has excellent antifouling and wear resistance after firing. The invention also discloses a marble imitation soft light brick applied with the surface glaze and a preparation method thereof.

Owner:广东金牌陶瓷有限公司

A kind of manufacturing method of matte marble tile

The invention provides a method for manufacturing a matte marble tile, which comprises the following steps: S1. preparation of a blank; S2. applying a marble surface glaze; the specific gravity of the marble surface glaze is 1.7-2.0g / cm 3 , the flow rate is 35-40 seconds, the glaze amount is 400-800g / m 2 ; S3. Printing, then drenched with matte polishing glaze; S4. Firing, firing temperature 1050-1200 ℃, firing cycle 40-60 minutes, glossiness after firing is 15-20°; S5. Matt polishing, using The foam elastic polishing module has a polishing mesh of 240 to 300 mesh, and is made into a finished product. The invention obtains marble tiles with excellent simulation degree through the combination of glaze formulation and technology. The marble surface glaze of the invention has a uniform color development effect, and the matte polishing glaze keeps the marble texture decoration and the matte effect combined with excellent simulation degree, and meanwhile, the glazed surface has excellent antifouling and wear resistance performance after firing. Further, with the optimized selection of polishing modules, the matte effect of the marble tile surface is easier to adjust, the process is simple, and the quality is controllable.

Owner:江西新明珠建材有限公司 +1

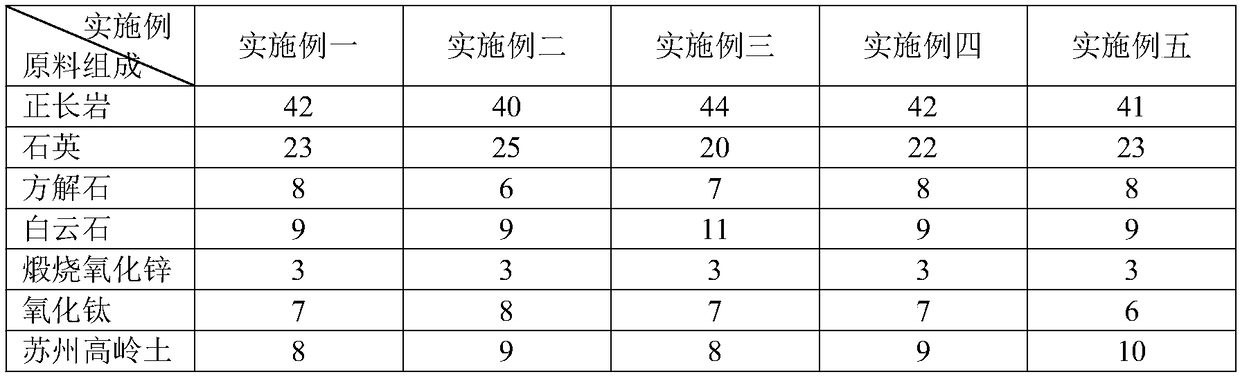

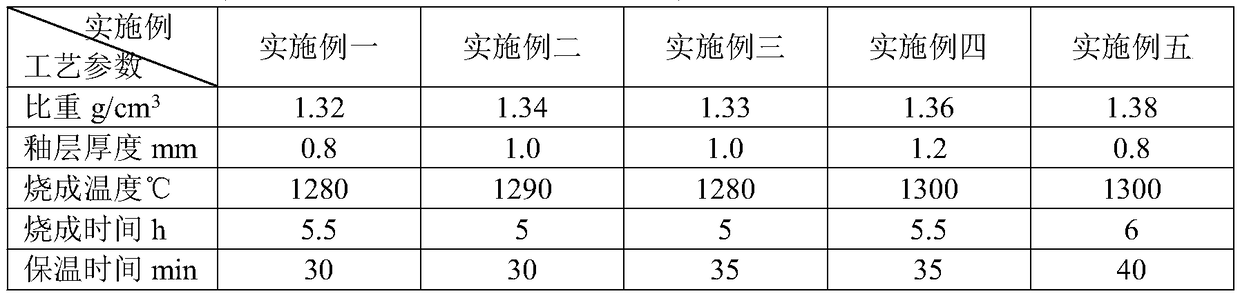

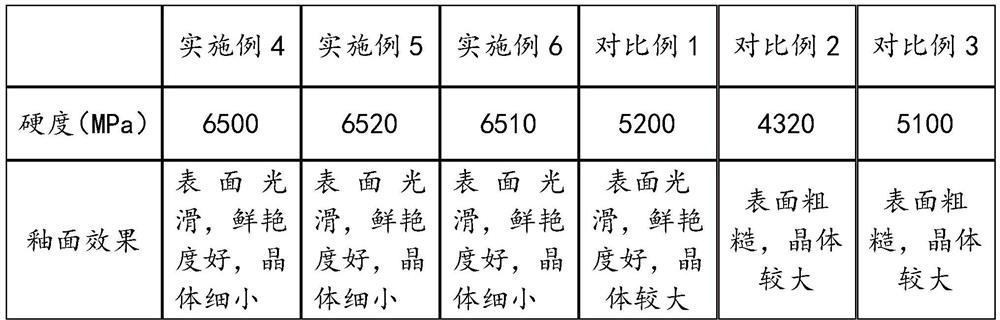

High-content syenite low-cost zirconium-free opaque glaze and preparation method and application thereof

The invention discloses a high-content syenite low-cost zirconium-free opaque glaze, which comprises the following main raw materials (by weight): 40-45 parts of syenite, 20-25 parts of quartz, 6-10 parts of calcite, 9-11 parts of dolomite, 2-5 parts of calcined zinc oxide, 6-9 parts of titanium oxide, and 7-10 parts of Suzhou kaolin. In addition, a preparation method and application of the abovehigh-content syenite low-cost zirconium-free opaque glaze are also disclosed. By replacing high-quality feldspar material with syenite and replacing high-cost zirconium silicate with titanium oxide asan opacifier and through the optimum formula design, the reliance on high-quality mineral raw material resources in the glaze production process is reduced, and the product has advantages of low cost, good opacity effect and high whiteness after burning. Moreover, the preparation method of the invention has simple process, is easy to operate, is easy for promotion and application, and has a broadapplication prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Fast-fired tea dust matt reaction glaze and preparation method thereof

The invention discloses fast-fired tea dust matt reaction glaze, and belongs to the technical field of glaze preparation. The glaze comprises the following raw materials in parts by weight: 25-40 parts of potassium feldspar, 10-25 parts of albite, 10-25 parts of quartz, 3-8 parts of barium carbonate, 5-10 parts of rutile, 3-8 parts of alumina micro powder, 4-8 parts of modified nano zinc oxide, 1-5 parts of talc, 10-18 parts of calcite, 2-6 parts of dolomite, 4-8 parts of soil, 4-8 parts of high-boron frit, 2-8 parts of manganese oxide and 2-8 parts of iron oxide red. The invention further discloses a preparation method of the glaze, a roller kiln is adopted for one-time rapid firing, the obtained tea dust glaze has the advantages of color development, stable character and rich color and luster, large-scale production is more facilitated, the productivity is increased, and the labor cost required by large-scale production is reduced.

Owner:湖南泰鑫瓷业有限公司

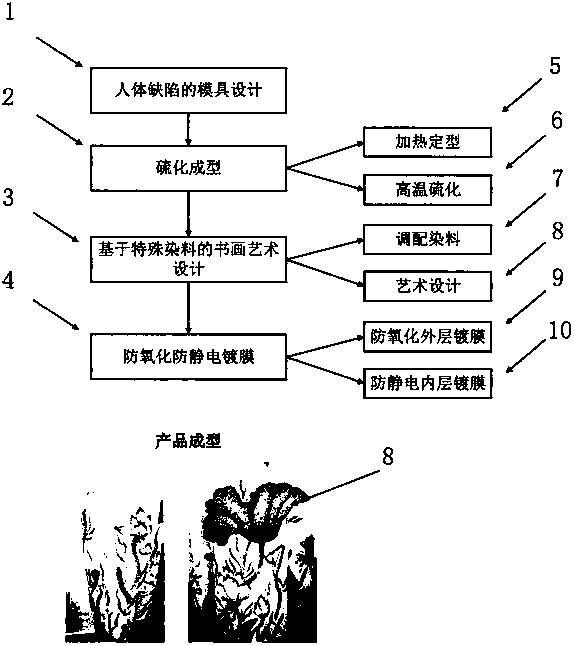

Multifunctional silica gel clothing designed in combination with painting and calligraphy

InactiveCN110810936AGuaranteed integral moldingNo need to adjust positionProtective garmentSpecial outerwear garmentsPolymer scienceEngineering

The invention relates to multifunctional silica gel clothing designed in combination with painting and calligraphy. The multifunctional silica gel clothing mainly comprises mold design based on humanbody defects, vulcanization molding, painting and calligraphy artistic design based on special dyes and an anti-oxidation and anti-static coating; the mold design is that the mold can be thickened andshaped according to different design requirements, various physical properties of the material are improved through vulcanization molding, the calligraphy and painting art design is created on the silica gel clothes by an artist through special dyes, and the anti-oxidation and anti-static coating is used for carrying out outer-layer anti-oxidation and inner-layer anti-static treatment on the silica gel clothing; vulcanization molding on the silica gel solution is performed through a specially designed mold; after the integrated silica gel costume is formed, special mixed dye is adopted for painting and calligraphy creation, and anti-oxidation and anti-static treatment is conducted on the whole costume after air drying, and therefore painting and calligraphy design on the silica gel costume never fades; the whole product is comfortable and attractive to wear, scientific in design and novel in style, and certain artwork collection value is achieved.

Owner:赵寒平

A steaming machine using two-phase process

ActiveCN105862297BFastIncrease productionTextile storage in festooned formTextile treatment carriersTemperature controlAutomatic control

The invention relates to a steaming machine using a two-phase process, which includes a steaming box. The cloth feeding end of the steaming box is provided with a cloth feeding device and a wet padding car in sequence, and the cloth discharging end of the steaming box is provided with a cloth discharging device. device, the steaming box is equipped with a loop system, which forms a cloth circulation with the wet padding car and the cloth discharge device. The steaming box is also equipped with an automatic temperature control device, and the automatic temperature control device is connected to the steamer through a conveying pipe. The heat exchange device and the automatic temperature control device in the steaming box are also connected to the temperature sensor arranged in the steaming box. The steaming box is also equipped with a steam humidification device. The present invention is a two-phase steaming machine that breaks through the traditional process. , single-sided or double-sided rolling aids can be used, and the printed fabric can fully absorb moisture and absorb moisture evenly. After re-rolling by the rolling mill, the residual liquid of the fabric will be small and even, and then enter the steamer for steaming, making the printed fabric 100% hygroscopic and 100% hygroscopic. % uniformity; and then perform steaming in the box to overcome the defects of incomplete and uneven color development.

Owner:JIANGYIN BEIFA PRINTING & DYEING MACHINERY CO LTD

Thermal printing device with dual thermal printing heads

The invention provides a thermal printing device with dual thermal printing heads. The device comprises thermal printing heads and a printer body which is matched with the thermal printing heads. The thermal printing heads are two opposite end face thermal printing heads whose heating resistors are opposite. The paper feed sides and the paper out sides of the thermal printing heads are provided with driven paper feed roller mechanisms and driving paper feed roller mechanisms. The end face thermal printing heads, the driven paper feed roller mechanisms and the driving paper feed roller mechanisms are arranged in the shell of the printer body. According to the thermal printing device, the two end face thermal printing heads are used to print multiple layers of thermal mediums, the energy load of the thermal printing heads can be reduced, the purpose of protecting the thermal printing heads is achieved, the service life of the thermal printing heads are prolonged, the colors of the multiple layers of thermal mediums are more uniform, and the thermal printing device has the advantages of high printing speed and low noise compared with a needle printer.

Owner:SHANDONG HUALING ELECTRONICS

Vat dyeing method

The invention relates to a method for dyeing yarn with a vat dye, which comprises the following steps: pre-treating the yarn; reducing: adding water to the pre-treated yarn, and controlling the pump speed of the dyeing vat to 1160-1450 rpm , add vat dyes, then add alkali and reducing agent to carry out reduction reaction; Oxidation: After the reduction reaction ends, reduce the pump speed to 580‑1015 rpm, add oxidant to carry out oxidation reaction; After the yarn is processed, you can. The yarn dyeing method can effectively solve the problem of the vat dye used in yarn dyeing and the color difference between the inner and outer layers, so that the obtained yarn has uniform color, bright color, and high soaping and light fastness.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Novel copper-iron colored glaze and method for making daily-use porcelain with it

Owner:GUANGDONG SONGFA CERAMICS

Ceramic pigment and production process thereof

PendingCN108948788AUniform hair colorDeep coloringPigment physical treatmentDecompositionHeat resistance

The invention discloses a ceramic pigment including iron oxide, chromium oxide, manganese dioxide, mineral powder, and a catalyst. The five components are added into a stirrer according to ratio and are stirred, homogenized and mixed to form a ceramic pigment mixture; then the mixture is subjected to treatment in a smoke exhaust section at 600 DEG C, a sintering section at 1200 DEG C and a heat insulation zone at 1220 DEG C to form ceramic pigment particles. The ceramic pigment has compact crystal form, stable structure and appearance, and beautiful and homogenous color. The ceramic pigment can reach more than 1300 DEG C in heat resistance. The ceramic pigment is free of decomposition during color development at high temperature, can form a deep color, is free foaming and has a color leaning to blue.

Owner:佛山市天元无机材料有限公司

Thermal printing unit with dual thermal print heads

Owner:SHANDONG HUALING ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com