Ceramic polished brick and production method and production line of ceramic polished brick

A production method and a technology of polishing bricks, which are applied in the field of building ceramic materials, can solve the problems of rigid and single decorative pattern texture, blurred and unsmooth lines, and poor decorative effects, and achieve clear colors, random textures without solidification, and strong three-dimensional effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

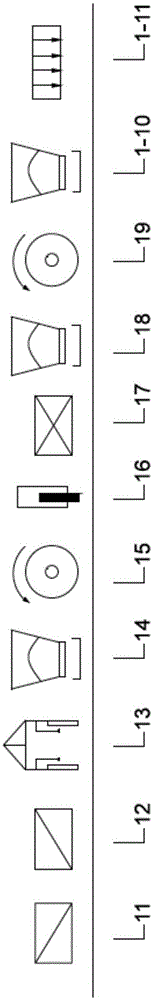

Method used

Image

Examples

Embodiment 1

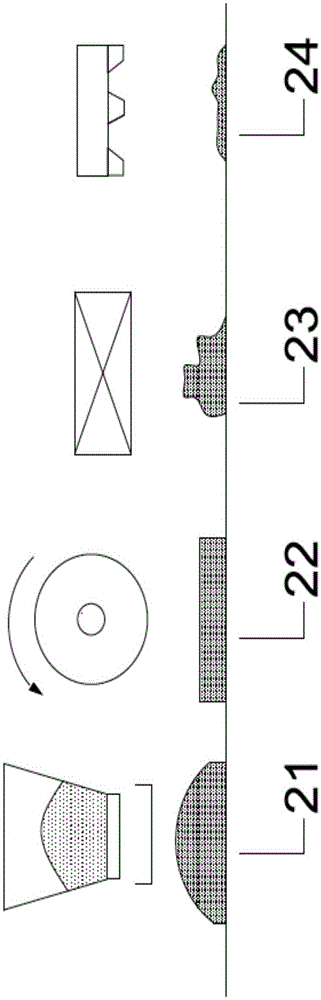

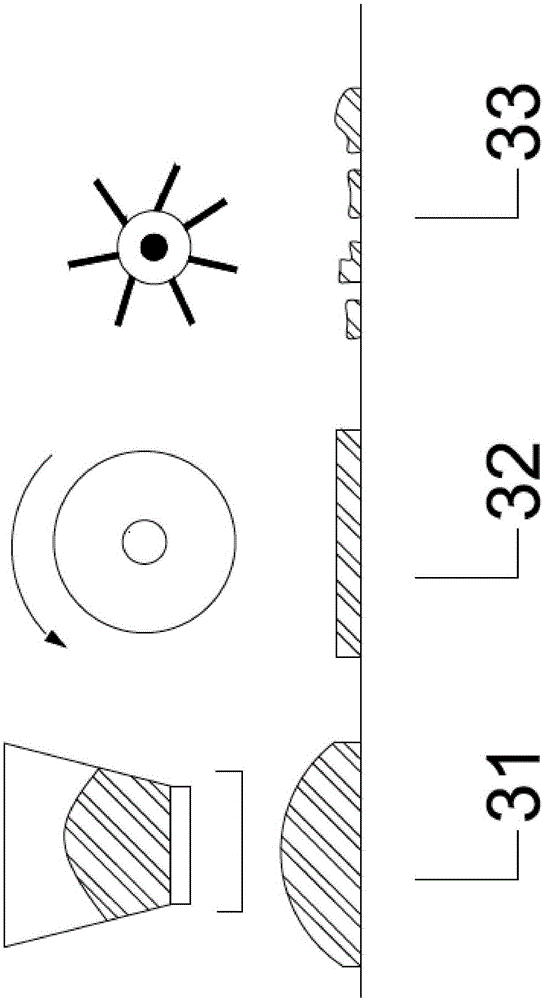

[0051] A production method of porcelain polished tiles, the steps are as follows:

[0052] 1) Formation of mountain-like texture: choose ordinary polished brick body powder through the preparation process of ordinary porcelain tile fabric, and lay out the mixture through the first distributing device 21, and the mixture is pressed into 20mm premixed powder by the first pre-pressing device 22 The material layer is pushed into a strip-shaped material pile by the pushing device 23 along the moving direction of the main belt, and then the corrugation device 24 applies a force of 90N vertically and twists 30° to form a mountain-like textured material belt with a length of 1m. , by changing the rotation angle and applied pressure of the corrugated grain maker, the squeezed band-shaped material pile is formed into mountain-like textures with different lengths, widths, angles, and layers, so that the detailed stripes are various, The pattern of the brick surface is richer and more var...

Embodiment 2

[0062] A production method of porcelain polished tiles, the steps are as follows:

[0063] 1) Mountain-like texture formation: choose ordinary polished brick body powder through the preparation process of ordinary porcelain tile fabric, and lay out the mixture through the first distributing device 21, and the mixture is pressed into 23mm premixed powder by the first pre-pressing device 22 The material layer is pushed into a strip-shaped material pile by the pushing device 23 along the moving direction of the belt, and then a 100N force is applied vertically by the corrugated graining device 24 and twisted by 45° to form a mountain-shaped textured material belt with a length of 1.1m. Change the rotation angle and applied pressure of the corrugated grain maker, and form mountain-like textures with different lengths and widths, different angles, and different levels on the pile of strips that have been squeezed, so that the details of the stripes are various, and the brick surface...

Embodiment 3

[0072] A production method of porcelain polished tiles, the steps are as follows:

[0073] 1) Mountain-like texture formation: choose ordinary polished brick body powder through the preparation process of ordinary porcelain tile fabric, and lay out the mixed material through the first distributing device 21, and the mixed material is pressed into 21mm premixed powder by the first pre-pressing device 22 The material layer is squeezed and pushed into a strip-shaped material pile by the pushing device 23 along the moving direction of the belt, and then a 94N force is applied vertically by the corrugated graining device 24 and twisted by 40° to form a mountain-shaped textured material belt with a length of 1.05m. Change the rotation angle and applied pressure of the corrugated grain maker, and form mountain-like textures with different lengths and widths, different angles, and different levels on the pile of strips that have been squeezed, so that the details of the stripes are var...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com