A kind of manufacturing method of matte marble tile

A manufacturing method and marble technology, applied in the field of ceramic building decoration materials, can solve the problems of inflexible gloss adjustment, high technical requirements, high labor intensity, etc., and achieve uniform glaze color development effect, simple process and controllable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

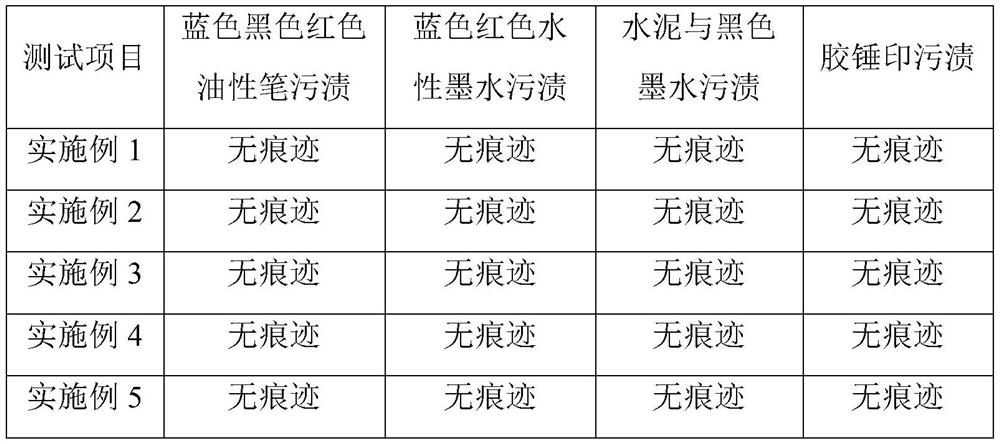

Examples

Embodiment 1

[0023] The preparation of matte marble tiles, the steps are as follows:

[0024] S1. Green body preparation; purchase ceramic raw materials into the warehouse, test the physical and chemical properties of the raw materials, and enter the ball mill according to the formula to form glaze slurry, the glaze slurry is made into powder by spray drying tower, and the powder is pressed into The green body is put into the drying kiln to obtain the green body.

[0025] S2. The body is covered with marble surface glaze; the chemical composition content of the marble surface glaze is: SiO 2 63%, Al 2 O 3 24%, Fe 2 O 3 0.3%, TiO 2 0.15%, ZrO 2 0.15%, CaO 1.5%, MgO 1.6%, K 2 O 1.7%, Na 2 O3.2%, ZnO 0.6%, P2 O 5 0.2%, the loss on ignition is 3.6%; the specific gravity of the marble glaze is 1.7g / cm 3 , the flow rate is 35 seconds, the glaze amount is 400g / m 2 .

[0026] S3. After being conveyed to the inkjet printing machine by the belt for inkjet printing, the matte polishi...

Embodiment 2

[0031] The preparation of matte marble tiles, the steps are as follows:

[0032] S1. Green body preparation; purchase ceramic raw materials into the warehouse, test the physical and chemical properties of the raw materials, and enter the ball mill according to the formula to form glaze slurry, the glaze slurry is made into powder by spray drying tower, and the powder is pressed into The green body is put into the drying kiln to obtain the green body.

[0033] S2. The body is covered with marble surface glaze; the chemical composition content of the marble surface glaze is: SiO 2 69%, Al 2 O 3 20% Fe 2 O 3 0.1%, TiO 2 0.05%, ZrO 2 0.05%, CaO 1.0%, MgO 1.3%, K 2 O 1.3%, Na 2 O2.8%, ZnO 0.4%, P 2 O 5 0.1%, the loss on ignition is 3.9%; the specific gravity of the marble glaze is 2.0g / cm 3 , the flow rate is 40 seconds, the glaze amount is 800g / m 2 .

[0034] S3. After being conveyed to the inkjet printing machine by the belt for inkjet printing, the matte polish...

Embodiment 3

[0039] The preparation of matte marble tiles, the steps are as follows:

[0040] S1. Green body preparation; purchase ceramic raw materials into the warehouse, test the physical and chemical properties of the raw materials, and enter the ball mill according to the formula to form glaze slurry, the glaze slurry is made into powder by spray drying tower, and the powder is pressed into The green body is put into the drying kiln to obtain the green body.

[0041] S2. The body is covered with marble surface glaze; the chemical composition content of the marble surface glaze is: SiO 2 66.68%, Al 2 O 3 22.14%, Fe 2 O 3 0.22%, TiO 2 0.10%, ZrO 2 0.11%, CaO 1.26%, MgO 1.46%, K 2 O 1.50%, Na 2 O 3.08%, ZnO 0.49%, P 2 O 5 0.18%; loss on ignition 2.78%; glaze specific gravity of marble glaze 1.9g / cm 3 , the flow rate is 38 seconds, the glaze amount is 600g / m 2 .

[0042] S3. After being conveyed to the inkjet printing machine by the belt for inkjet printing, the matte po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com