A steaming machine using two-phase process

A steaming machine and process technology, applied in the field of steaming machines, can solve the problems of difficult sewage treatment, uneven and incomplete coloring, etc., and achieve the effect of reducing the difficulty of sewage treatment, uniform coloring, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

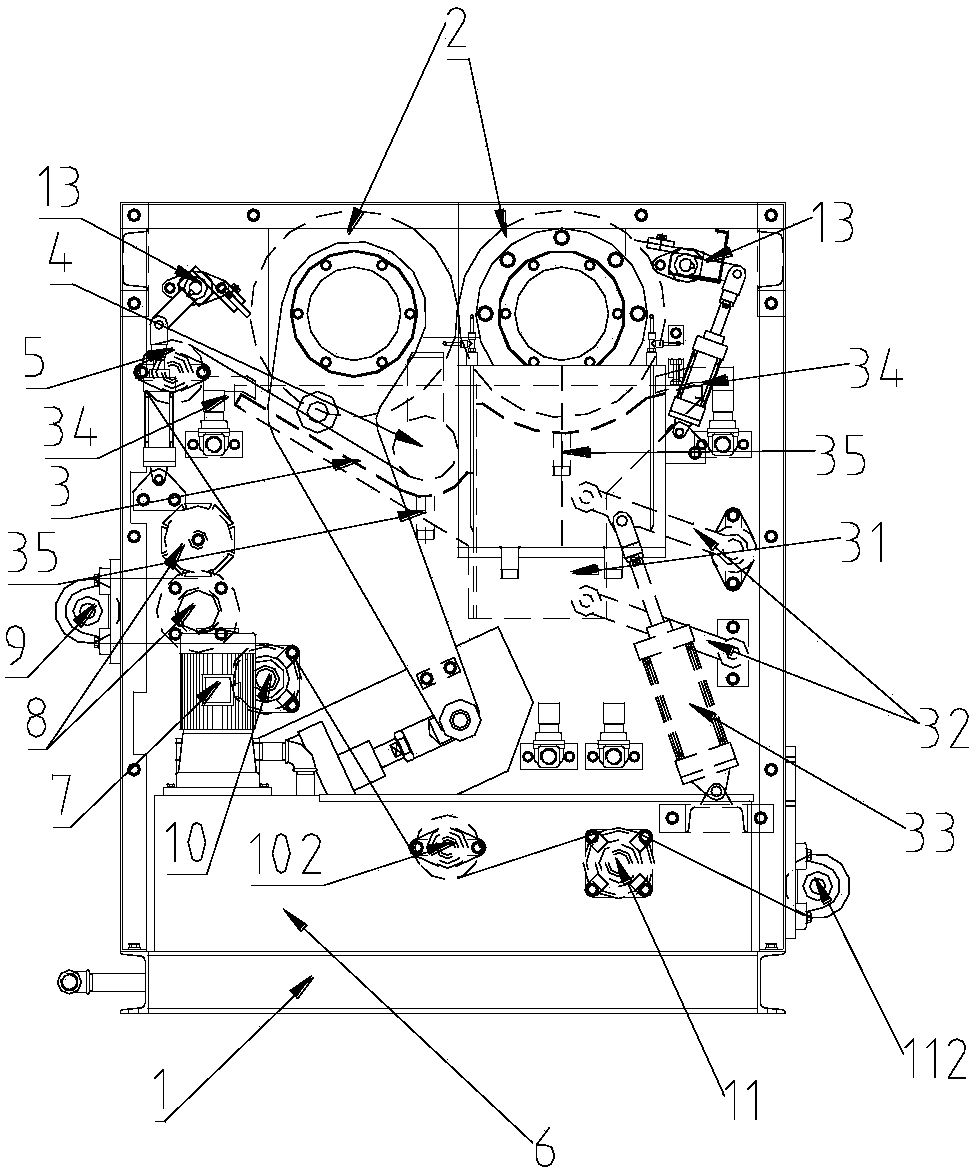

[0050] Such as figure 1The shown steamer of the present invention using a two-phase process includes a steamer box 22, and the cloth feeding end of the steamer box 22 is sequentially provided with a cloth feeding device 20 and a wet padding car 21. The cloth outlet end of the steaming box 22 is provided with a cloth delivery device 27, and a looping system 26 is arranged in the steaming box 22, and the looping system 26 and the described wet padding car and the cloth delivery device 27 form a Cloth circulation, after the cloth is transported from the cloth delivery device 27 to the wet padding car, the cloth passes through the wet padding car and the loop forming system 26 in turn, and finally is transported out from the cloth delivery device 27 to complete the entire processing process.

[0051] The steaming box 22 is also provided with an automatic temperature control device 23, the automatic temperature control device 23 is connected to the heat exchange device 25 in the st...

Embodiment 2

[0055] On the basis of a steamer using a two-phase process described in Embodiment 1, the wet rolling car includes a frame 1; a pair of rolls 2 with the same outer diameter and opposite rotation are arranged on the frame 1 Above: the auxiliary agent tank 3 is arranged under the pair of rolls 2 to contain the auxiliary agent; the auxiliary agent roller 4 is arranged in the auxiliary agent groove 3 and its two ends are arranged in the auxiliary agent groove 3 The inner two ends of the first turning roller 5, the two ends of which are set on the frame 1, to turn the fabric onto the auxiliary roller 4.

[0056] The above-mentioned technical solution is the core technical solution of the present invention. By setting a pair of rollers 2 with the same outer diameter and rotating in opposite directions on the frame 1, the fabric passing through the auxiliary agent tank 3 is squeezed through the pair of rollers 2, and the excess The additives and moisture are removed to ensure the con...

Embodiment 3

[0068] On the basis of a steamer using a two-phase process described in the above embodiments, the ring forming system 26, such as Figure 7 with Figure 8 As shown, a driving roller 41 is horizontally arranged in the steamer 1, and the driving roller 41 drives the translation chain assembly and the conveying chain assembly at the same time, so that the translation chain assembly and the conveying chain assembly are fixed Synchronization without any other links in the middle, so the entire looping system 26 is stable and reliable. The conveyor chain assembly includes a plurality of driven rollers 42 and two groups of conveyor chains that wrap around the plurality of driven rollers 42 in a closed loop 43, wherein one of the driven rollers 42 is driven by the driving roller 41, the translation chain assembly includes two sets of translation chains 44 arranged side by side, and one end of the translation chain 44 is set on the driving wheel on the driving roller 41 The other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com