Three-dimensional calibration device for curve flexible touch sensor array

A tactile sensor and three-dimensional calibration technology, which is applied in the field of sensor applications, can solve problems such as the inability to calibrate the tactile information of the three-dimensional tactile sensor array, the inability to realize the three-dimensional calibration of the flexible tactile sensor array, and the inability to calibrate the flexible sensor array, etc., to achieve automation and intelligence , Fast calibration speed and precise structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

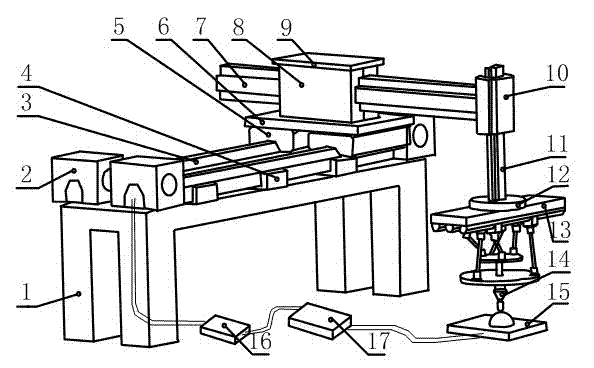

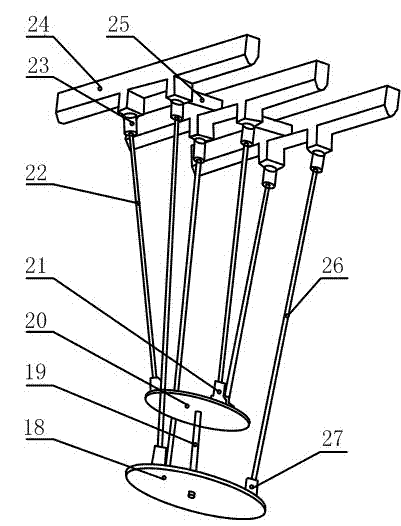

[0028] figure 1It is an experimental calibration device for a curved surface tactile sensor array, and the configuration of the device includes a three-coordinate guide rail robot, a three-dimensional force loading mechanism, an array platform and a control part electrically connected to it. Among them, the three-coordinate guide rail robot is used to adjust the spatial operation positioning of the three-dimensional force loading device, and the three-dimensional force loading mechanism is used to adjust the magnitude and direction of the applied force.

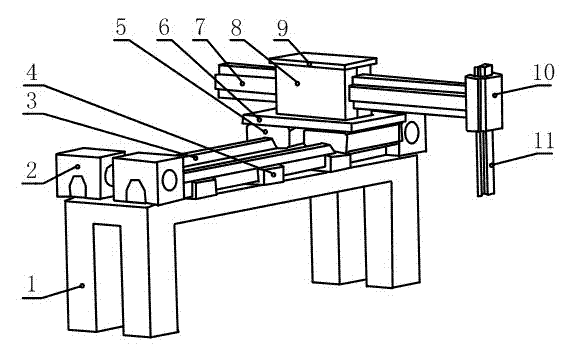

[0029] figure 2 yes figure 1 The three-coordinate guide rail robot described in . The entire calibration platform is supported by the bearing support 1; during the calibration operation, it is driven by the motor installed on the DC servo motor mounting flange 2, and the dovetail guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com