Thermal printing device with dual thermal printing heads

A technology of thermal printing device and thermal printing head, which is applied in printing, typewriters, etc., can solve the problems of low service life of needles of dot matrix printers, slow printing speed of dot matrix printers, and low resolution of dot matrix printers, etc., and achieves Longer lifespan, less energy load, even hair color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

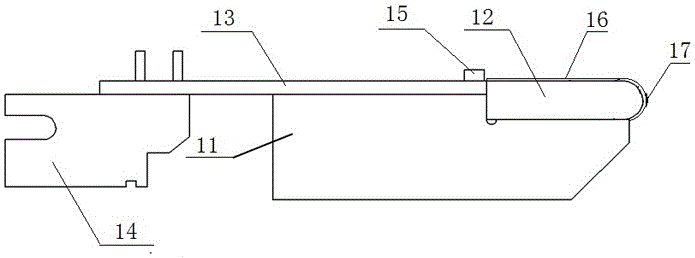

[0020] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0021] The thermal printing device with dual thermal print heads related to the present invention includes a thermal print head and a printer body matched with the thermal print head, wherein the thermal print head adopts two oppositely arranged end surface thermal Sensitive print head, and the heating resistors of the two end-face thermal print heads are arranged oppositely, such as figure 1 As shown, on the paper feeding side and the paper output side of the end face thermal print head, a driven paper roller mechanism 3 and an active paper roller mechanism 4 are respectively provided. The end face thermal print head and the driven side The paper rubber roller mechanism 3 and the active paper-feeding rubber roller mechanism 4 are both arranged in the casing of the printer body. During printing, the thermal medium 5 passes through the driven paper roller me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com