Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Strong retardation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

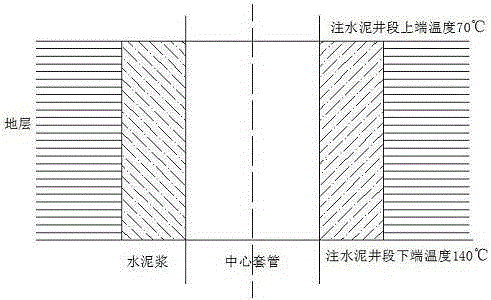

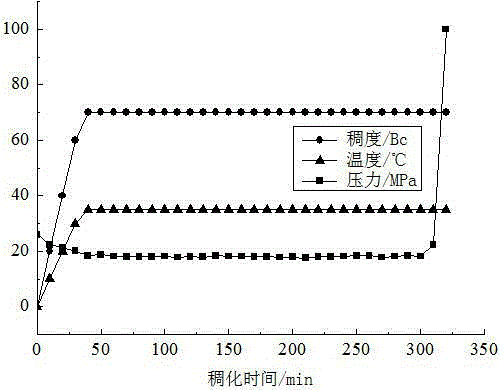

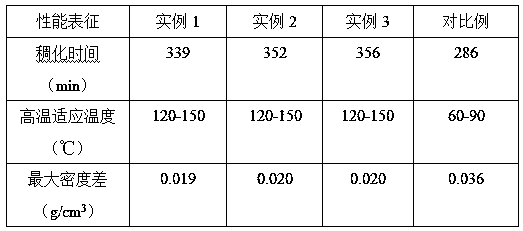

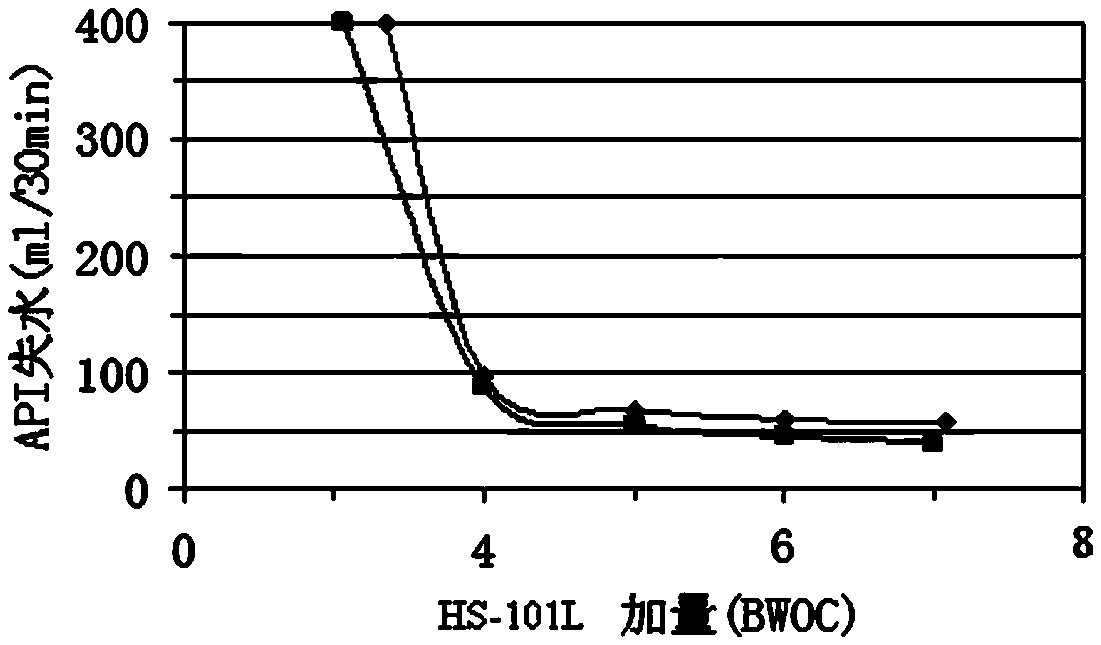

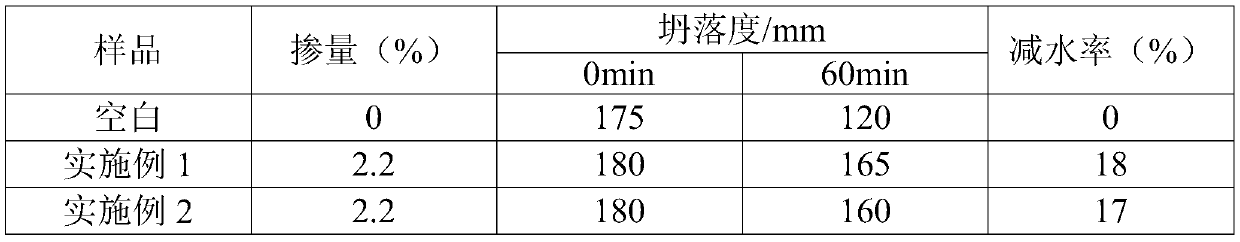

High-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in oil field

ActiveCN105694832AExcellent dehydration performanceGood adaptabilityDrilling compositionSolid phasesSilica fume

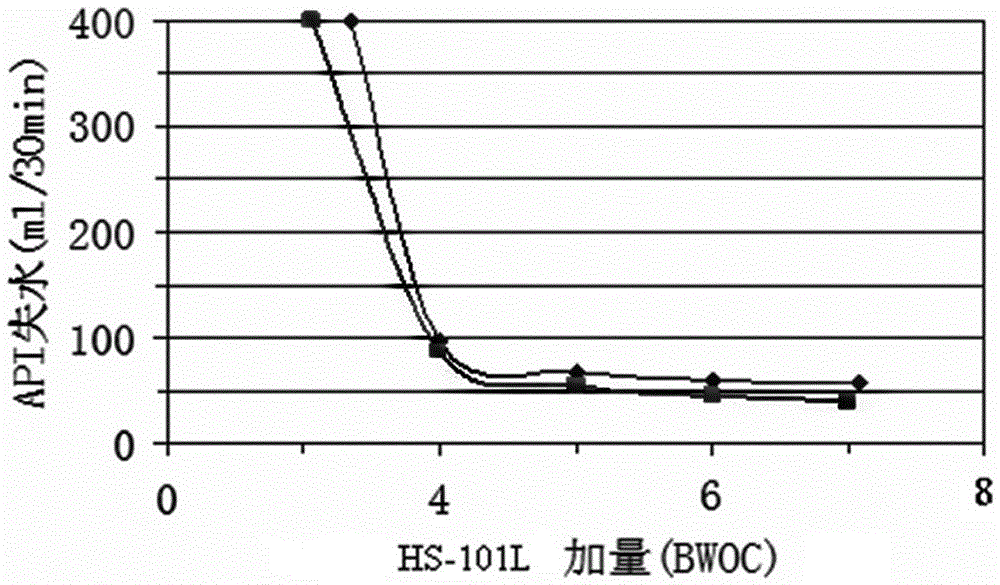

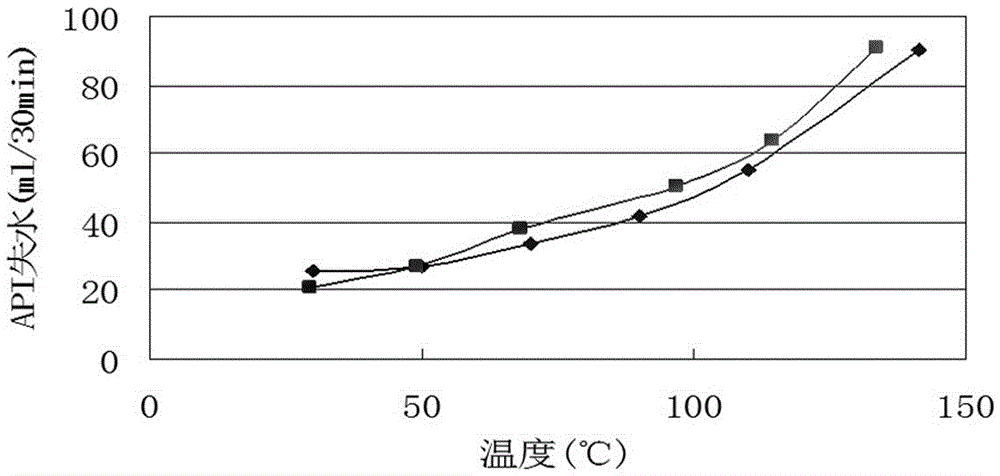

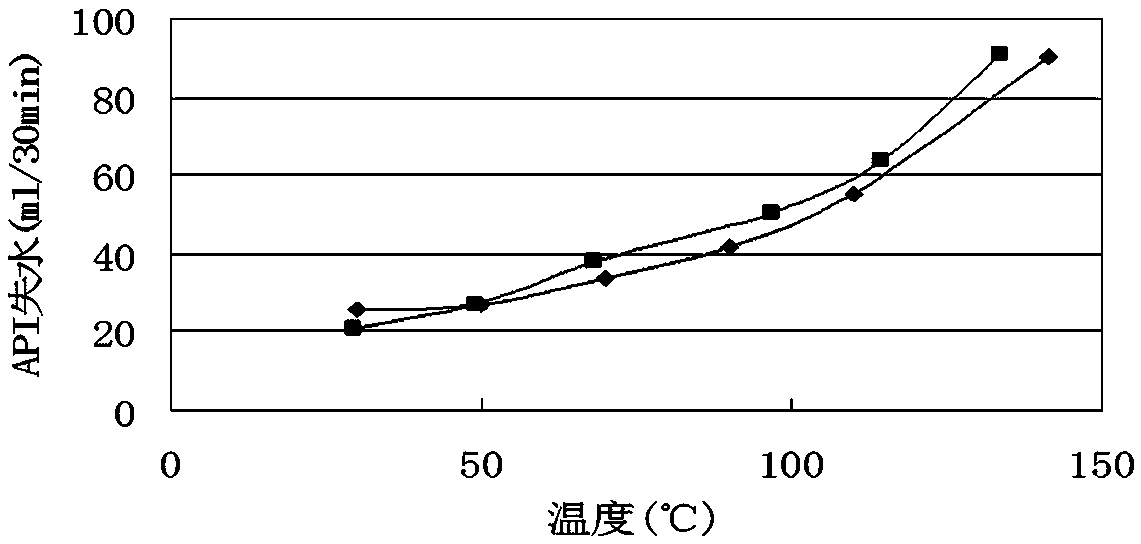

The invention relates to high-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in an oil field. The cement grout is prepared from components of raw materials in parts by weight as follows: 600 parts of G-grade oil well cement, 30-36 parts of an HS101L fluid loss agent, 8-20 parts of an HS201L retarder, 1.8 parts of an HS-301S dispersant, 150 parts of quartz sand, 30 parts of silica fume, 1.8 parts of an HS-XF1S suspension stabilizer, 280-300 parts of water and 1 part of bis(2-ethylhexyl) sulfosuccinate sodium salt, wherein the grain size of the quartz sand is 80-120 meshes, the grain size of the silica fume is 300-400 meshes, and the content of silicon dioxide is 90% or higher. Liquid-phase raw materials are added to a grout mixing container and mixed uniformly; solid-phase substances are added to a solid-phase container and stirred uniformly, the solid-phase mixture is added to the grout mixing container, finally, a defoaming agent is added, and the mixture is stirred uniformly. The cement grout can be used under the condition of 50-180 DEG C, has prominent large-temperature-difference-resistant performance and can effectively avoid a super-retarding phenomenon caused by large temperature difference.

Owner:CHINA PETROCHEMICAL CORP +2

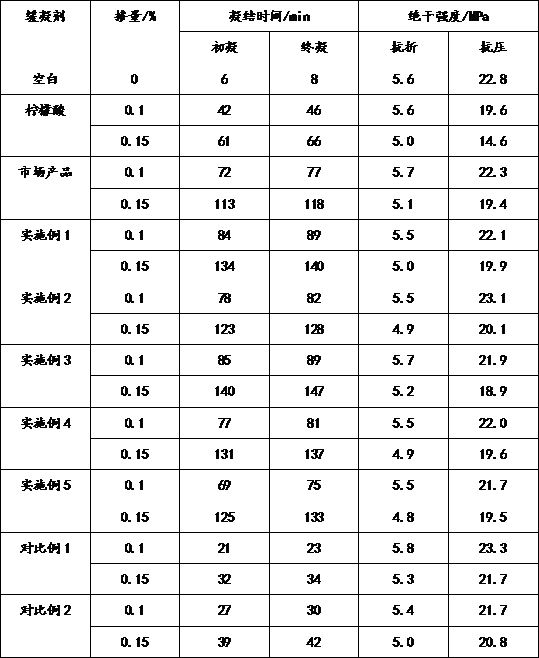

Protein gypsum retarder and preparation method thereof

ActiveCN114315202AImprove uniformityGood retarding effectSolid waste managementProtein solutionPhysical chemistry

The invention provides a protein gypsum retarder and a preparation method thereof, and the preparation method comprises the following steps: pretreatment of a protein component: dissolving an alkali substance and water to form an alkali solution, heating, adding the protein component into the alkali solution, stirring, and cooling to room temperature to obtain a protein liquid; preparing a mixed solution, namely adding an acid substance into the protein solution, stirring until the acid substance is completely dissolved, and cooling to room temperature to obtain the mixed solution; and preparing the powder retarder: adding the anti-blocking agent into a reaction kettle, stirring and heating at the same time, uniformly spraying the prepared mixed solution into the kettle through an atomizer, continuously stirring, taking out the material, and sieving with a 100-mesh sieve to obtain the powder retarder. The protein gypsum retarder disclosed by the invention is strong in retarding effect, small in side effect on the strength of gypsum, relatively simple in raw material components and preparation process, and free from generation of harmful substances in the whole preparation process.

Owner:湖北兆佳材料有限公司

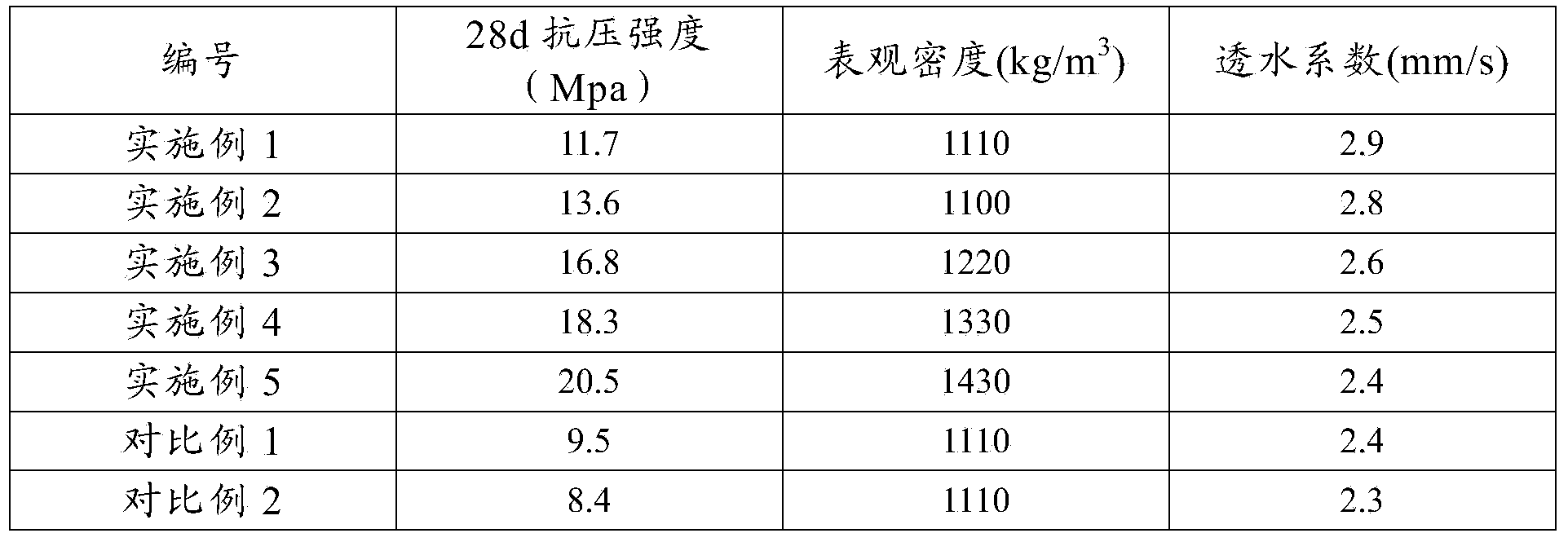

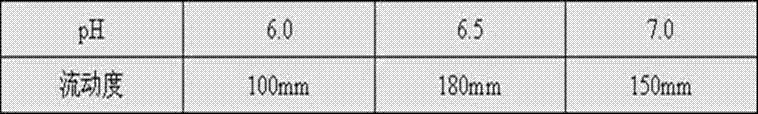

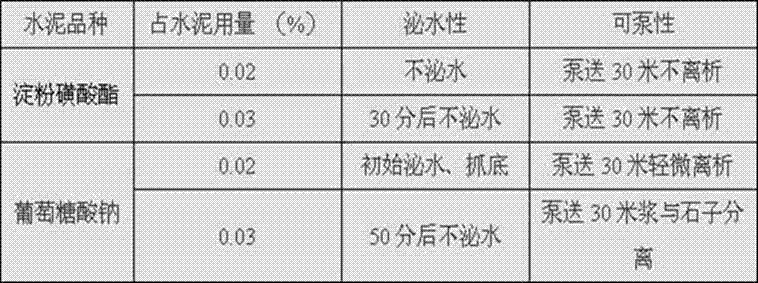

Macroporous concrete containing low grade recycled aggregates and preparation method of concrete

ActiveCN104072061AStrong retardationLower pHSolid waste managementCeramicwareLow gradedConstruction aggregate

The invention discloses macroporous concrete containing low grade recycled aggregates. The macroporous concrete containing low grade recycled aggregates is prepared from the following raw materials: cement, water, low grade recycled aggregates, modified starch and a sugar retarder, wherein the grain size of the low grade recycled aggregates is 5-16mm, and the bulk density is 700-900kg / m<3>. The macroporous concrete containing low grade recycled aggregates is further prepared from additional water, the use level of which is calculated according to the follow formula: delta W=mgr*wgr, wherein delta W is the use level of the additional water of the macroporous concrete containing low grade recycled aggregates; mgr is the use level of the low grade recycled aggregates and wgr is 1h water absorption of the low grade recycled aggregates. According to the invention, the grade recycled aggregates are applied to preparation of the macroporous concrete, so that the mixture state satisfies the using demand under the condition that an additive in an extra amount is not added by virtue of adjusting the raw materials and matching with the sugar retarder and modified starch.

Owner:北京东方建宇混凝土科学技术研究院有限公司

Retarder for high-temperature-resistant cement paste system

InactiveCN107418534AExtend thickening timeReduced hydration rateDrilling compositionItaconic acidCement paste

The invention discloses a retarder for a high-temperature-resistant cement paste system. The retarder comprises the following components: monomers consisting of 2-acrylamido-2-methylpropanesulfonic acid, acrylamide, maleic acid and itaconic acid in a mass ratio of (18-24): (9-21): (6-12): (6-12); an initiator accounting for 6%-8% of the total mass of the monomers; and monomer borax accounting for 3%-5% of the total mass of the monomers. A polymer formed by the above components is a quadripolymer which solves the problem of rapid hydration of cement paste at a high temperature; and the quadripolymer synthesized by using a simple synthetic process has better retarding effect compared with the same mass of a terpolymer or bipolymer.

Owner:四川宏升石油技术开发有限责任公司

Concrete retarder and preparation method thereof

ActiveCN111662037AImprove dispersion characteristicsGood compatibilityPolymer sciencePolyvinyl chloride

The invention belongs to the technical field of building materials, and particularly relates to a concrete retarder and a preparation method thereof. The concrete retarder is prepared from the following raw materials: 3-6 parts of modified microcrystalline cellulose, 1-3 parts of acrylic acid, 8-12 parts of modified glass fiber, 5-10 parts of borax, 6-10 parts of polyvinyl chloride resin, 2-4 parts of anhydrous sodium sulfate, 3-5 parts of quartz sand, 8-12 parts of sodium tripolyphosphate and 1-3 parts of carboxymethyl cellulose. The concrete retarder has good heat absorption property and heat dissipation property, and can absorb hydration heat produced by concrete; a good heat exchange effect is formed between the concrete and the external environment so that hydration heat energy generated in the concrete is dissipated; hydration of cement in the concrete is inhibited, and a strong retarding effect is achieved; meanwhile, the concrete retarder has good strength, and the influence onthe strength and the anti-scouring performance of the concrete is low.

Owner:贵州凯襄新材料有限公司

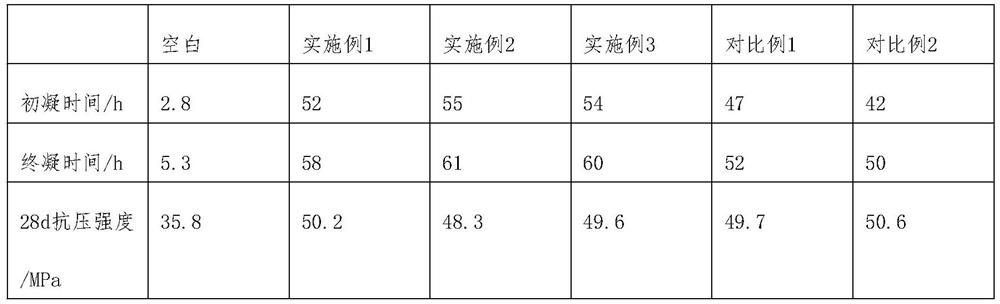

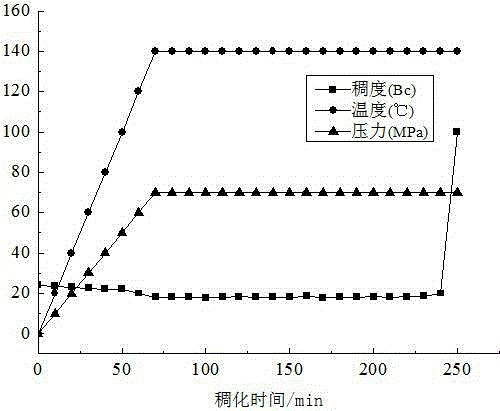

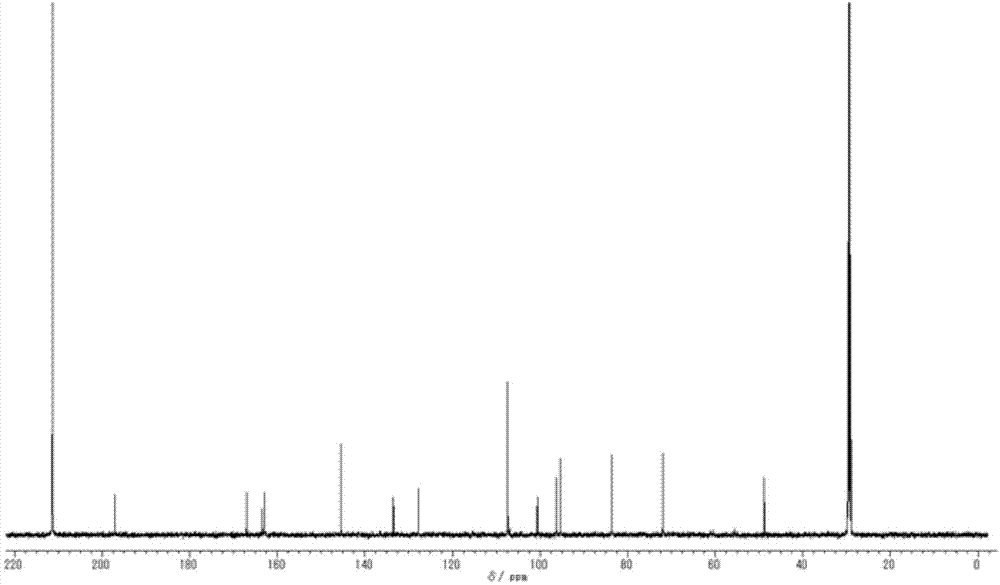

Temperature response type amphoteric polymer retarder and preparation method thereof

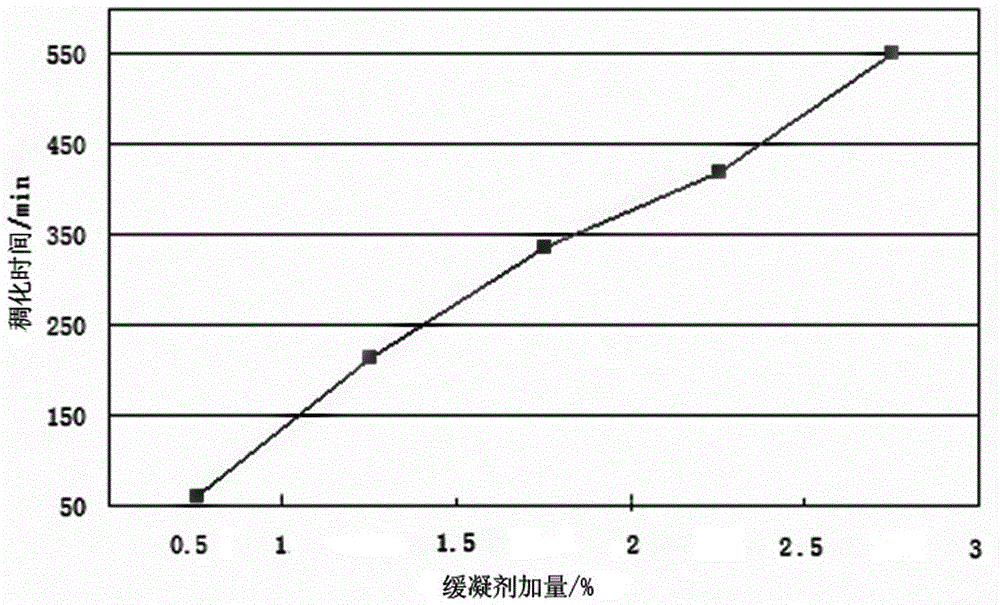

InactiveCN105273135AStrong retardationGood adjustabilityDrilling compositionMaleic anhydride2-Methyl propane

The invention relates to an oil well cement retarder in the field of oil gas well exploration and development and a preparation method of the oil well cement retarder. The amphoteric polymer retarder is prepared from, by mass, 10-20% of dimethyldiallylammonium chloride (DMDAAC), 20-30% of 2-acrylamide-2-methyl propane sulfonic acid (AMPS), 30-50% maleic anhydride (MA) and 10-30% of acrylic amide (AM). Due to lateral groups in an amphoteric polymer structure, a self-response type response can be made for the temperature of surroundings, and the temperature adaptability is high. The delayed coagulation of cement paste within the whole temperature region with 70 DEG C and 140 DEG C as the upper and lower end temperatures of a cementing well section is achieved, the thickening time of the cement paste and the retarder added amount are in the good linear relation, the right-angled thickening effect is obvious, the temperature and the added amount sensitivity are low, and the cement paste comprehensive performance can meet the requirement for well cementation construction; in addition, the retarder is simple in synthesis technology, low in cost, high in operability and capable of achieving large-scale production and application.

Owner:SOUTHWEST PETROLEUM UNIV

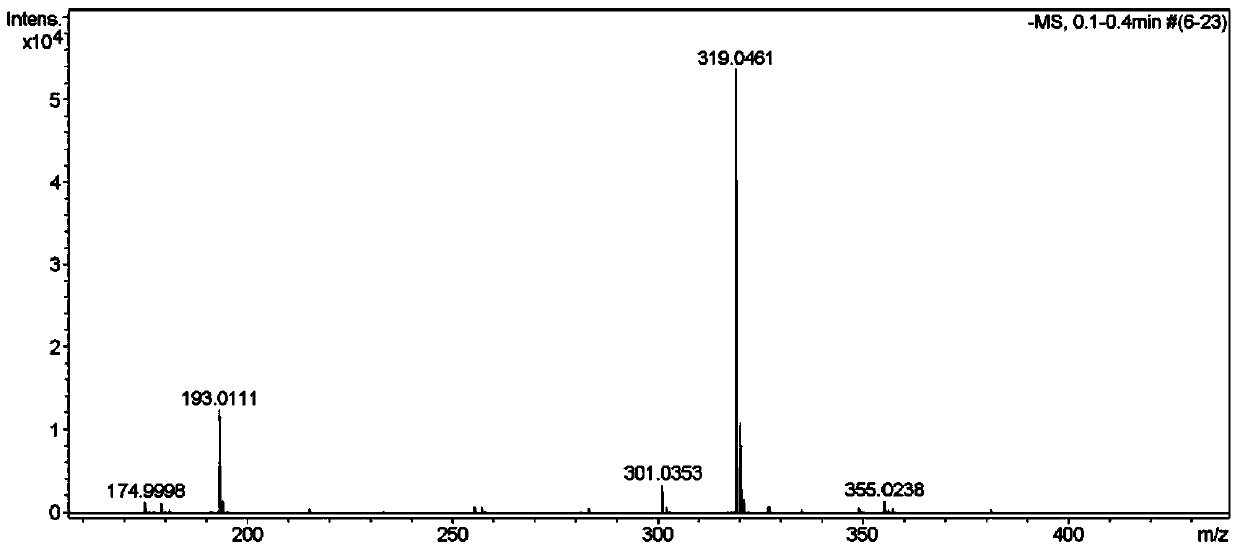

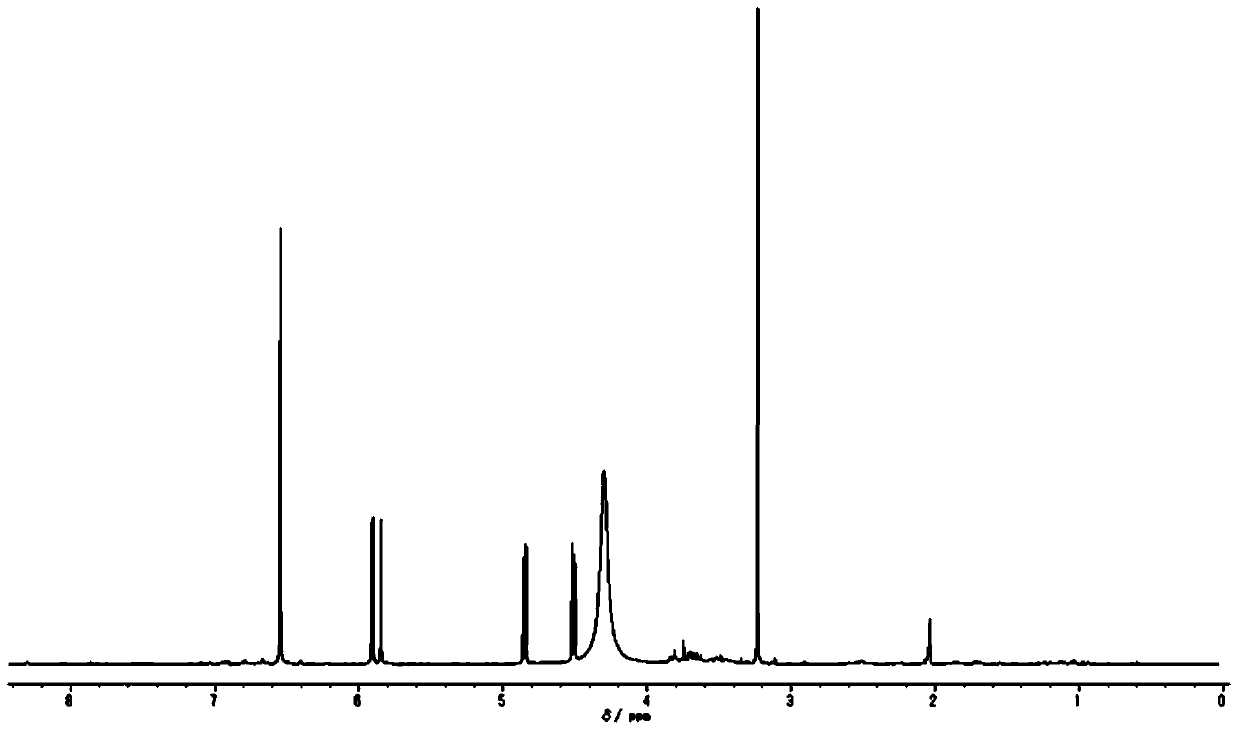

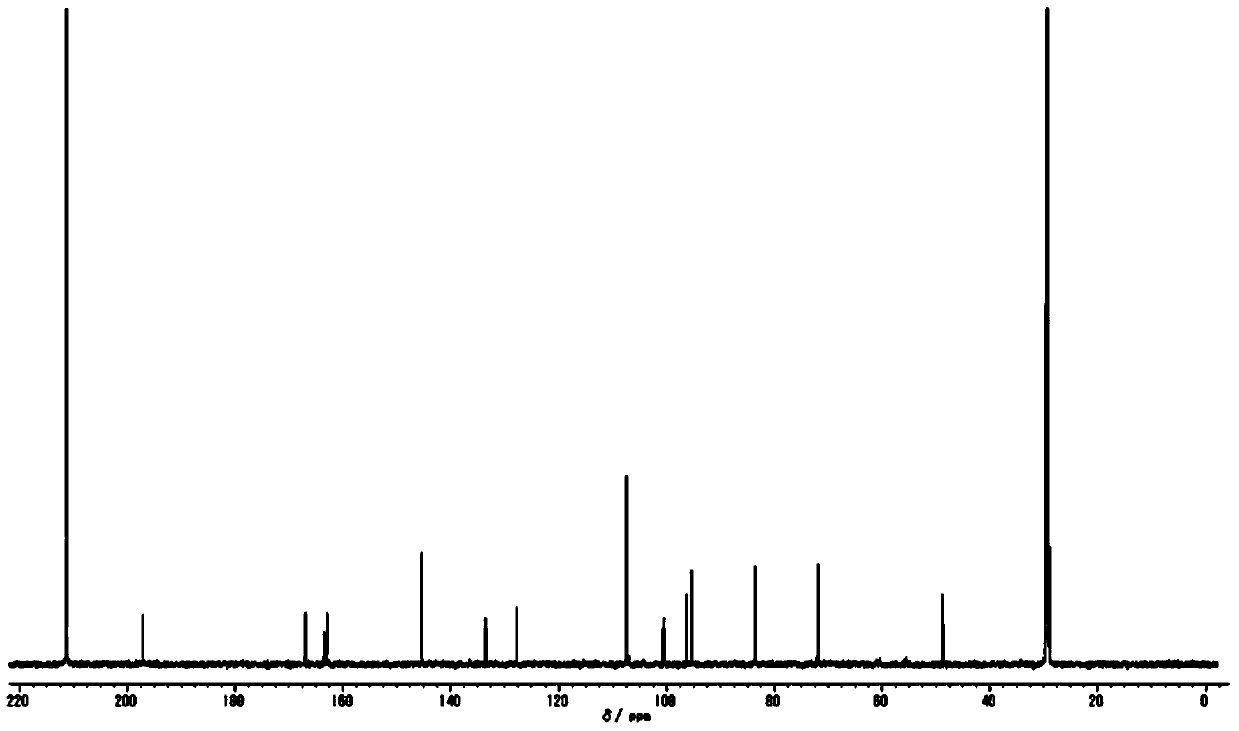

Method for preparing food browning inhibitor from cedar pine needles

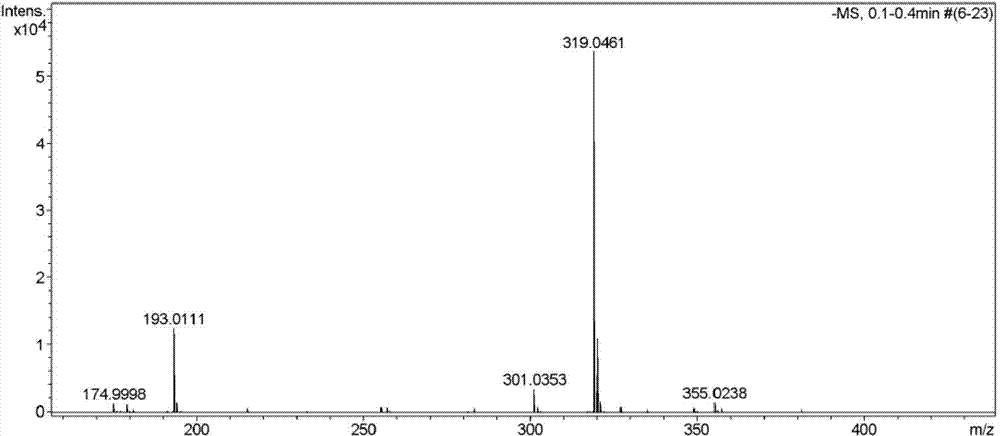

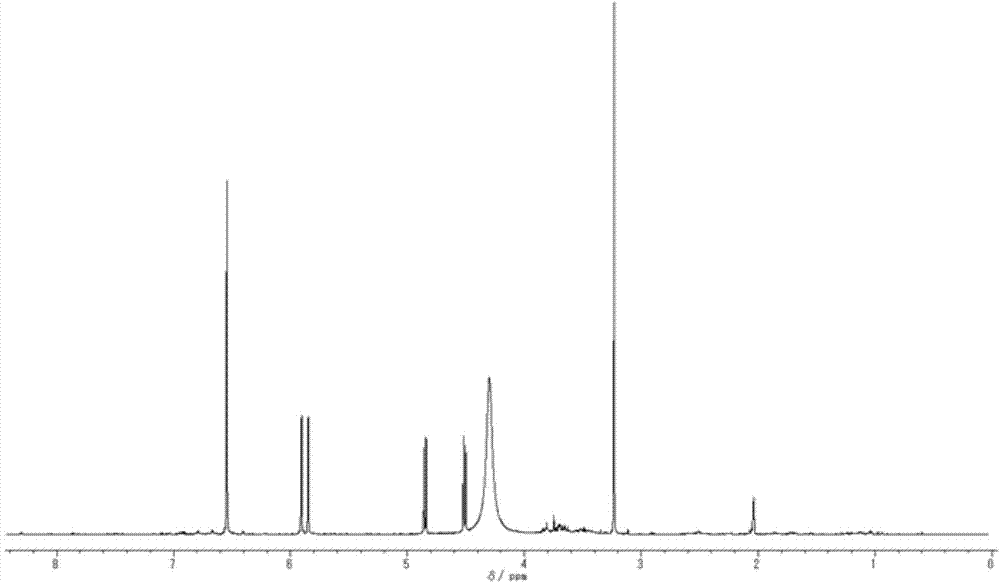

InactiveCN103739582AEnhanced inhibitory effectImproves antioxidant activityOrganic chemistryFood ingredient functionsBiotechnologyGradient elution

The invention discloses a method for preparing a food browning inhibitor from cedar pine needles. The method is characterized by comprising the following steps: smashing dried cedar pine needles, adding normal hexane according to the material-to-liquid ratio of 1g: (10-20mL), vibrating at room temperature for 12-24h and filtering to separate a normal hexane extracting liquid; recovering the degreased pine needles, adding 50-70wt% methanol as an extracting agent according to the material-to-liquid ratio of 1g: (10-30mL), vibrating at room temperature for 24-48h, separating a supernatant, concentrating and drying the supernatant to obtain a methanol extract with the yield of 15-22%; suspending the methanol extract into 20-30mL of 50wt% methanol, carrying out chromatography by using a macroporous adsorption resin DiaionHP-20 chromatographic column, carrying out gradient elution at the flow speed of 3-5mL / min by using water and methanol with the concentrations being respectively 0wt%, 15wt%, 30wt%, 40wt%, 60wt% and 100wt%, collecting the 40wt% methanol eluant, concentrating and drying to obtain the food browning inhibitor, separating and purifying by using a high performance liquid chromatography; and obtaining the effective component, i.e., 2R, 3R-dihydromyricetin of the food browning inhibitor.

Owner:SICHUAN UNIV

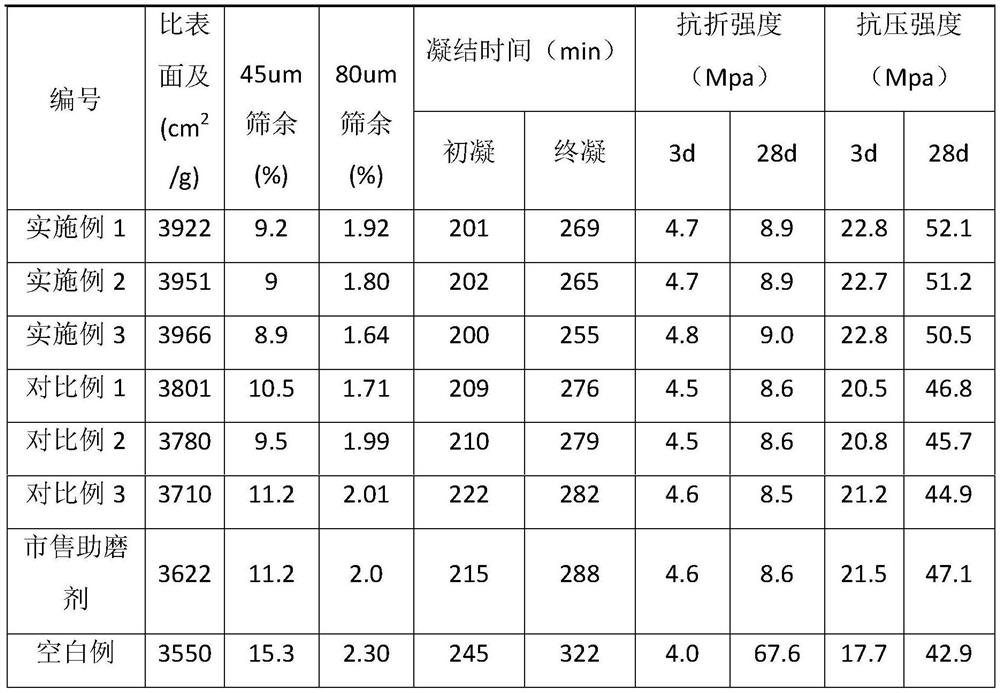

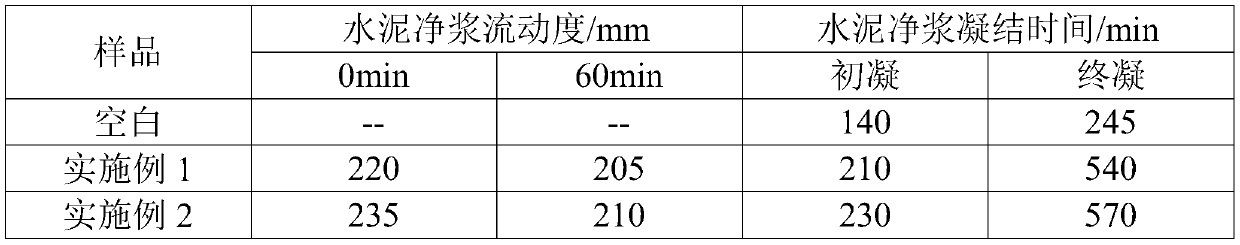

Modified triethanolamine grinding aid

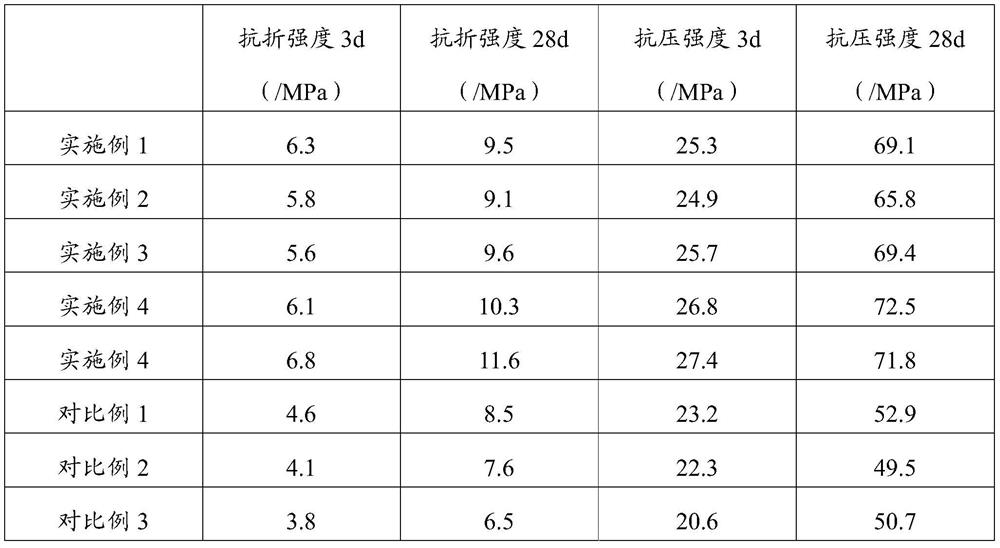

The invention relates to a modified triethanolamine grinding aid. The modified triethanolamine grinding aid comprises the following components: first modified triethanolamine, second modified triethanolamine, molasses, silicone emulsion, sodium pyrophosphate and water. The modified triethanolamine grinding aid is absorbed on surfaces of solid particles, changes the structural property of particlesurfaces, prevents particle agglomeration, improves the flowability of materials, can effectively prevent closure of new cracks, accelerates expansion of material cracks, can rapidly eliminate or weaken aggregation and adhesion among particles, and ensures that the grinding efficiency is improved by 12 percent or more, the 3d strength is improved by greater than or equal to 5MPa, 28d strength is improved by greater than or equal to 6MPa, the initial setting time is greater than or equal to 200min, and the final setting time is smaller than or equal to 300min.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Composite cement admixture

The invention discloses a composite cement admixture, and belongs to the technical field of cement process admixtures. The grinding aid is prepared from the following raw materials in parts by weight:20-30 parts of a compound alcohol amine component, 10-15 parts of isooctyl alcohol phosphate, 4-8 parts of molasses, 4-8 parts of an emulsifying dispersant, 5-10 parts of triethylene glycol, 3-5 parts of an accelerant and 50-70 parts of water. The isooctanol phosphate and the composite alkylol amine component are in synergistic interaction, so that the grinding aid is small in mixing amount and good in grinding aid effect, and the 3d and 28d compressive and flexural strength of cement can be remarkably improved under the mixing amount of 0.01%; in addition, the raw materials are easy to obtain, and the preparation method is simple and suitable for popularization and application.

Owner:安徽海螺材料科技股份有限公司 +1

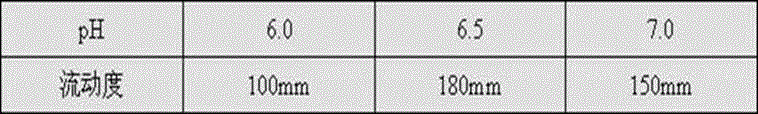

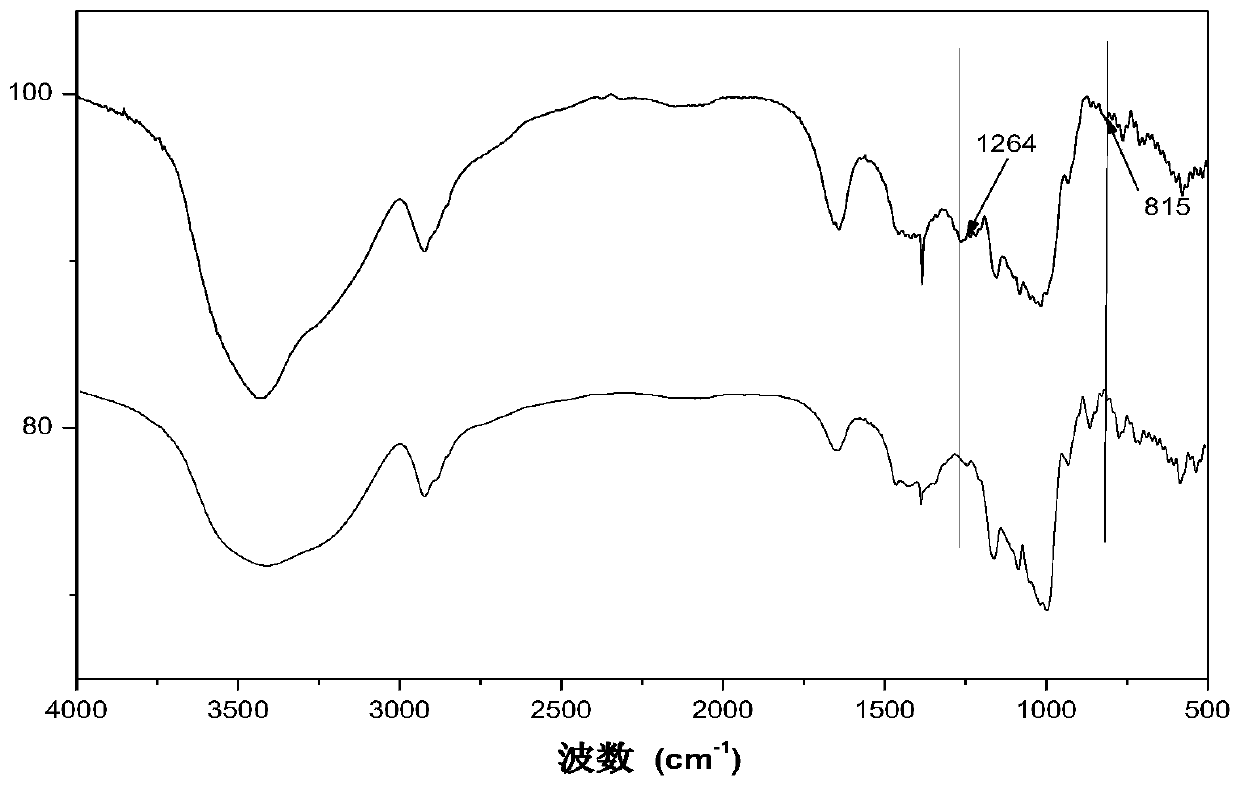

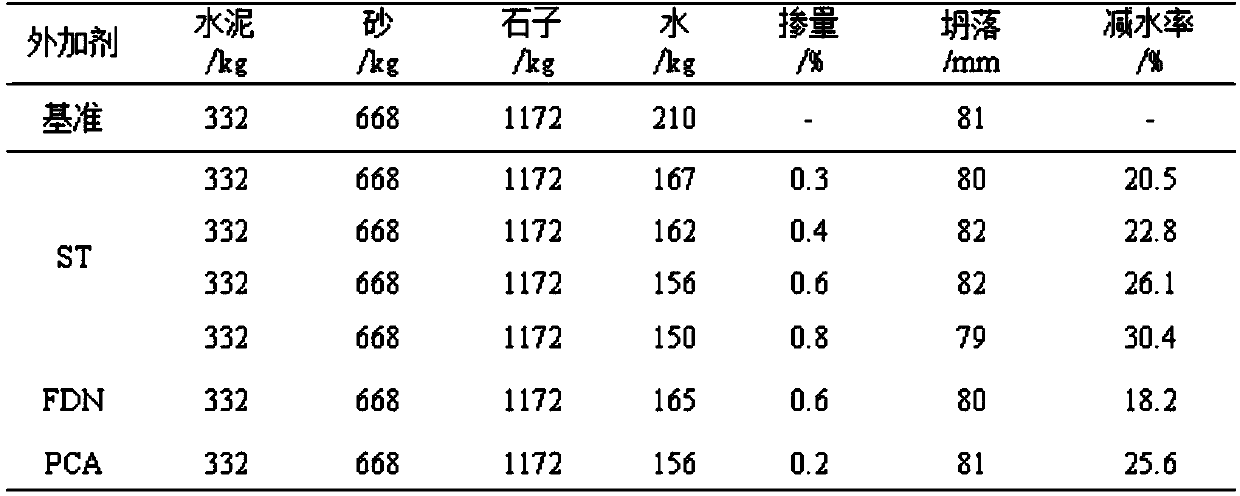

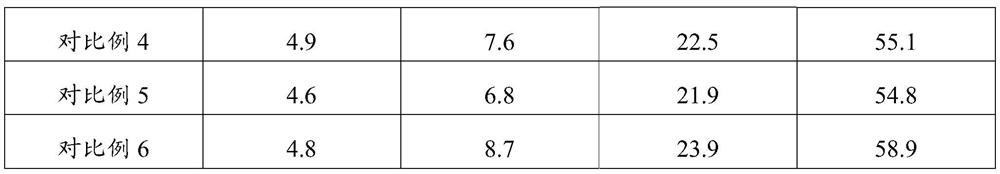

Preparation method of starch sulfonate

The invention belongs to the technical fields of chemical industry and concrete construction materials. In order to solve the problems of high slump constant time loss and lower flowability in the concrete, the invention provides a preparation method of starch sulfonate. The preparation method comprises the following steps: dissolving dextrin prepared from starch or directly purchased dextrin in water, heating to react by using water as a dispersing agent and sodium bisulfite as a sulfonating agent, and regulating the pH value to 7 with sodium hydroxide to obtain a liquid which is the starch sulfonate. The invention uses the method for preparing starch sulfonate by using water as the medium and sodium bisulfite as the sulfonating agent for the first time, which is different from the preparation method by using dichloromethane or any other organic solvent as the medium in the prior art. The method has the advantages of simple technique, environment friendliness and no pollution emission, and is beneficial to industrial production. The product has favorable synergic dispersion properties for cement particles, solves the problems of poor slump retaining effect and poor workability in the existing retarder for concrete, use of toxic solvents in the preparation process, and difficulty in treating sulfonating agent byproduct chlorine ions. The invention provides a novel preparation method of starch sulfonate.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

Phosphorus slag based environmentally-friendly building material and preparation method thereof

ActiveCN108117348AReduced hydration rateStrong retardationSolid waste managementSlagBuilding material

The invention discloses a phosphorus slag based environmentally-friendly building material and a preparation method thereof. The phosphorus slag based environmentally-friendly building material comprises the following components in parts by mass: 14.61 to 44.08 parts of phosphorus slag powder, 1.11 to 18.72 parts of building waste residue powder, 1.11 to 6.24 parts of sialic sphere powder, 1.11 to3.12 parts of nanometer silex, 2.10 to 8.46 parts of an alkaline activator, 20.81 to 66.51 parts of sand, 11.08 to 16.53 parts of water and 0.22 to 1.17 parts of an efficient polycarboxylate superplasticizer. The phosphorus slag based environmentally-friendly building material is low in cost, simple in preparation technology and short in maintenance time.

Owner:中建西部建设贵州有限公司

Preparation method of high-temperature-resistant modified retarder

The invention relates to a preparation method of a high-temperature-resistant modified retarder, belonging to the technical field of sealing materials. According to the technical scheme, a silicon carbide whisker is utilized for modification, and a laminar matrix material is prepared through coating, so that on one hand, a polymer is endowed with the rigidity and thermal stability of an organic material, namely a laminar matrix substance, through the addition of the laminar matrix substance; on the other hand, the partial polymer is inserted among laminar inorganic material slice layers, the partial thermal decomposition effect is effectively shielded by the slice layer structures, and the micromolecule motion caused during the thermal decomposition is impeded, so that the polymer represents good heat stability. According to the retarder prepared by virtue of the scheme, polar groups are effectively released to the surface of cement particles to form an adsorption layer, and the adsorption layer is capable of preventing the contact between the cement and water so as to decrease the cement hydration speed and achieve a retarding effect, so that the heat stability of the material isimproved.

Owner:蒋留平

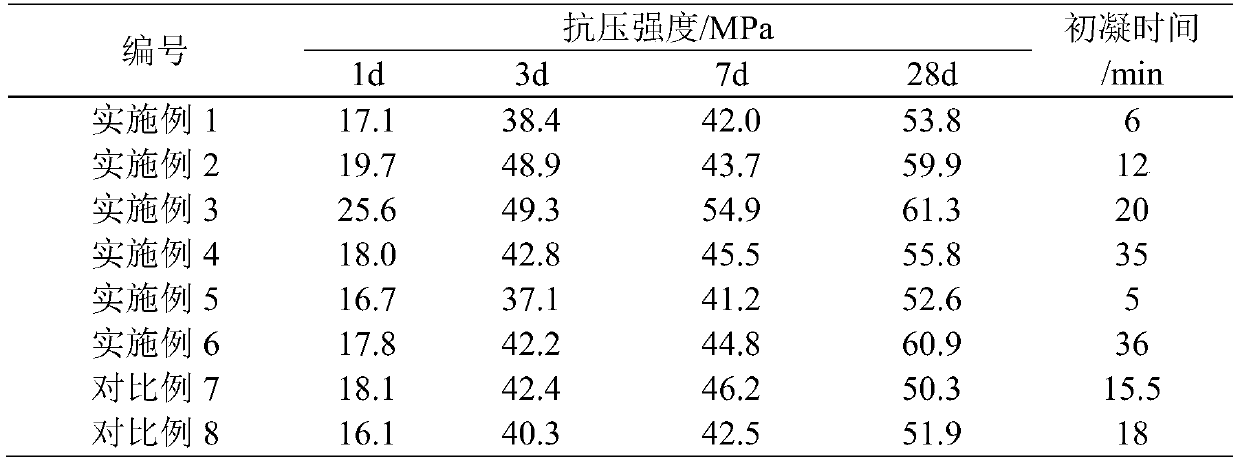

Quick repairing material for magnesium phosphate cement and preparation method thereof

The invention discloses a quick repairing material for magnesium phosphate cement and a preparation method thereof. The quick repairing material for magnesium phosphate cement, as a composite, is mainly made from, by weight, 25 parts of magnesium oxide, 15-20 parts of monopotassium phosphate, 0.5-1.5 parts of ethylenediamine tetraacetic acid dipotassium salt dihydrate, and 5-10 parts of water. Theethylenediamine tetraacetic acid dipotassium salt dihydrate is used herein as a retardant to replace borax used in the traditional magnesium phosphate cement. The quick repairing material has good retarding effect; setting time of the magnesium phosphate repairing system is greatly extended; the magnesium phosphate repairing system ensures early strength of a magnesium phosphate cement sample, and late strength of the magnesium phosphate repairing system is improved to certain extent.

Owner:SOUTHEAST UNIV

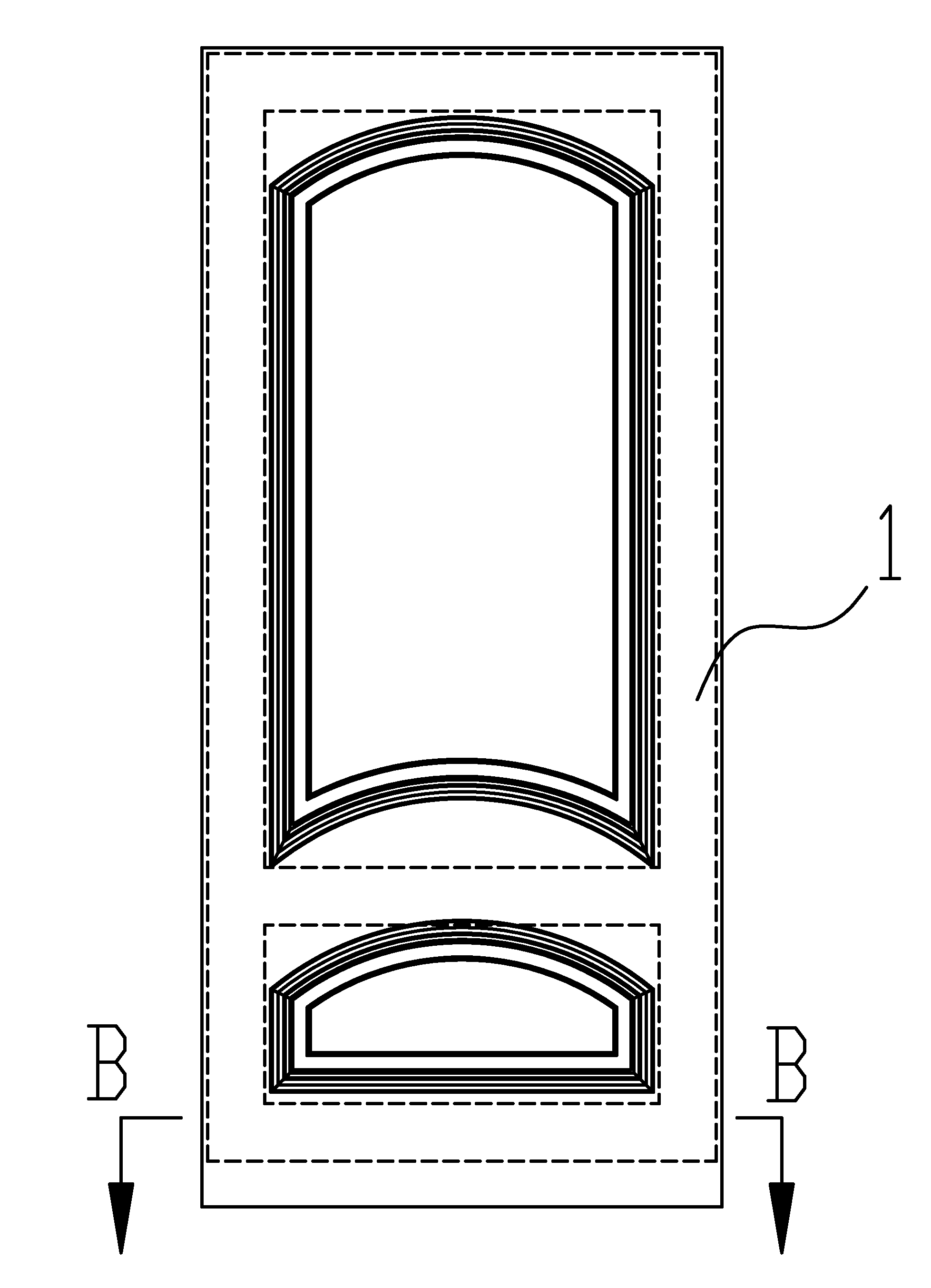

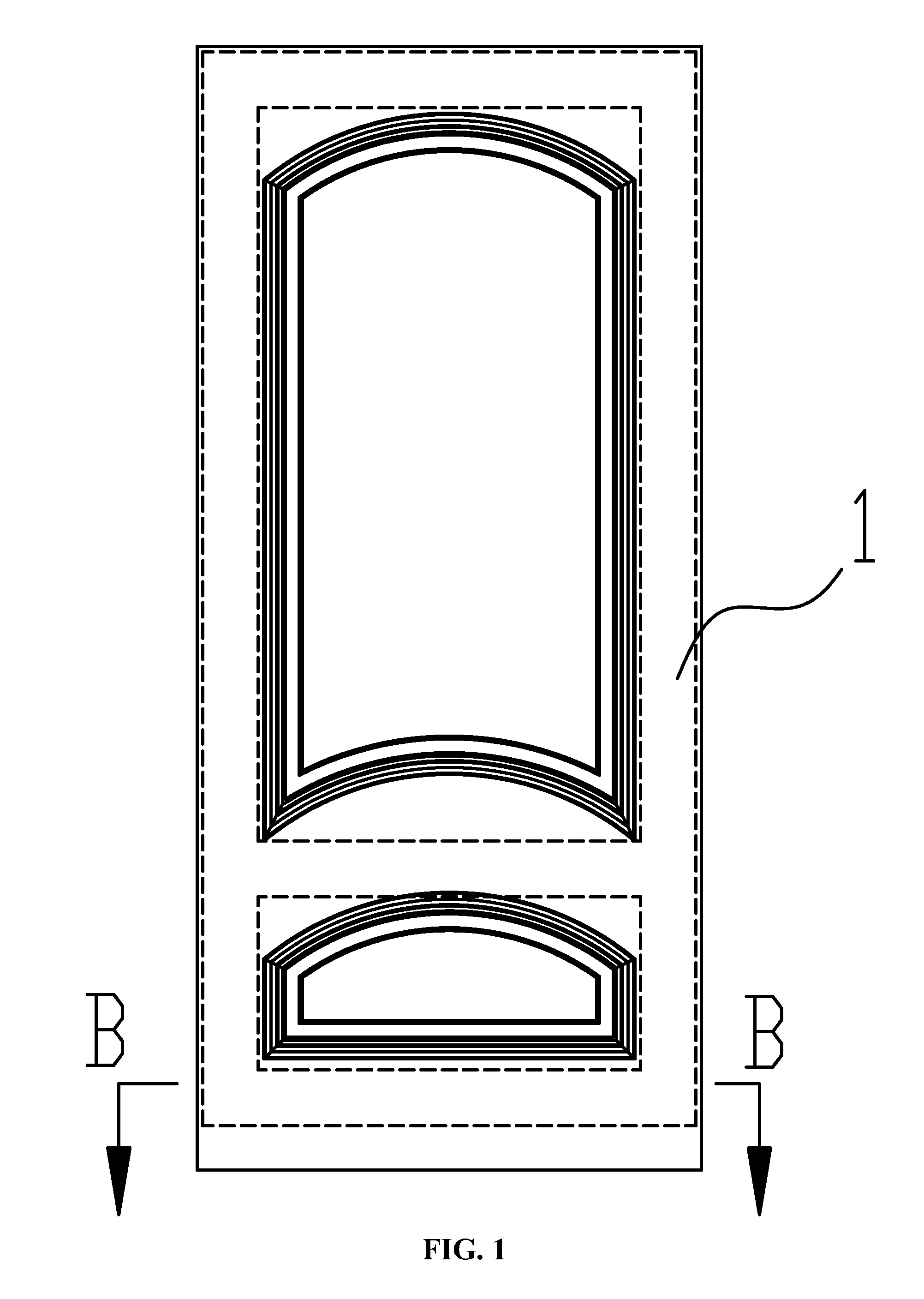

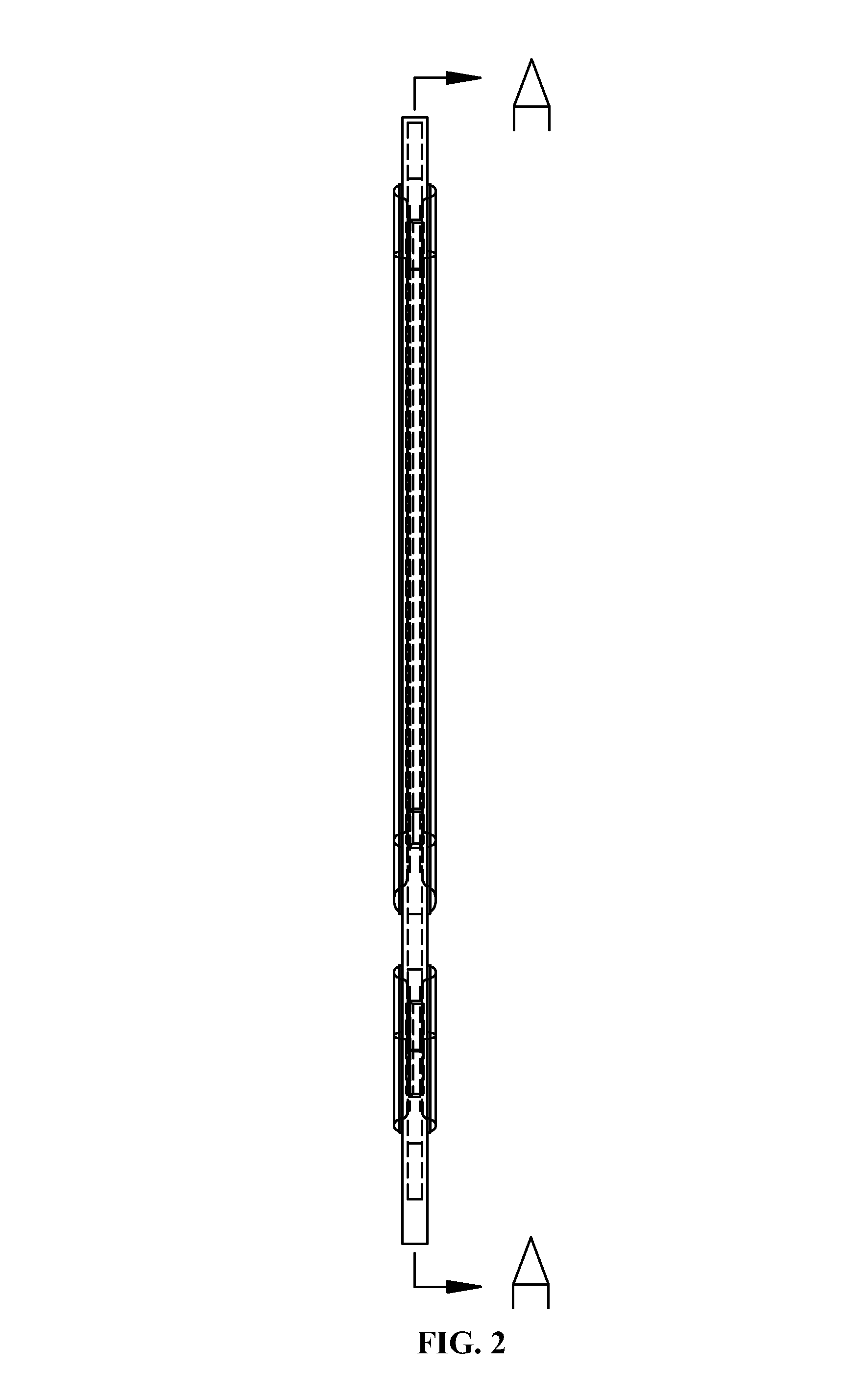

Door made of polyurethane and method for manufacturing the same

InactiveUS8997417B2Low swell factorImprove consistencyLaminationLamination apparatusPolymer scienceEngineering

A door made of polyurethane, including a door body, the door body including a plurality of integrated plates stacked on one another for supporting. A method for preparing the door includes providing a mold, and spraying a parting agent inside the mold; heating the mold to a temperature of 30-70° C., spraying the parting agent, and placing a plurality of plates or a metal skeleton in the mold; mixing raw materials to obtain a mixture; injecting the mixture into the mold to cover the stacked plates, and curing for 30-90 min; demolding, transferring a product from the mold to a thermostatic chamber for shaping at a constant temperature; trimming uneven edges and surfaces of the product; and spraying a paint on the product.

Owner:WANG ZHONGPING

Door made of polyurethane and method for manufacturing the same

InactiveUS20140024732A1Waterproof propertyLow swell factorPretreated surfacesCoatingsEngineeringMechanical engineering

A door made of polyurethane, including a door body, the door body including a plurality of integrated plates stacked on one another for supporting. A method for preparing the door includes providing a mold, and spraying a parting agent inside the mold; heating the mold to a temperature of 30-70° C., spraying the parting agent, and placing a plurality of plates or a metal skeleton in the mold; mixing raw materials to obtain a mixture; injecting the mixture into the mold to cover the stacked plates, and curing for 30-90 min; demolding, transferring a product from the mold to a thermostatic chamber for shaping at a constant temperature; trimming uneven edges and surfaces of the product; and spraying a paint on the product.

Owner:WANG ZHONGPING

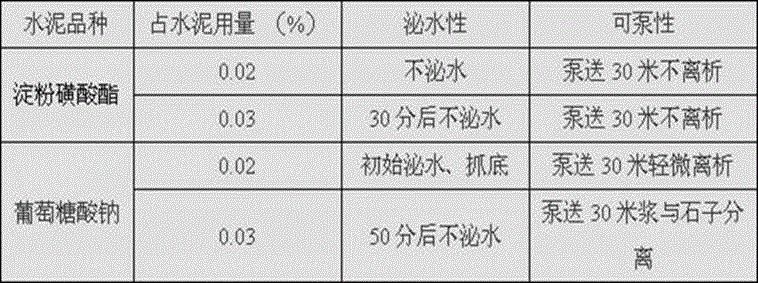

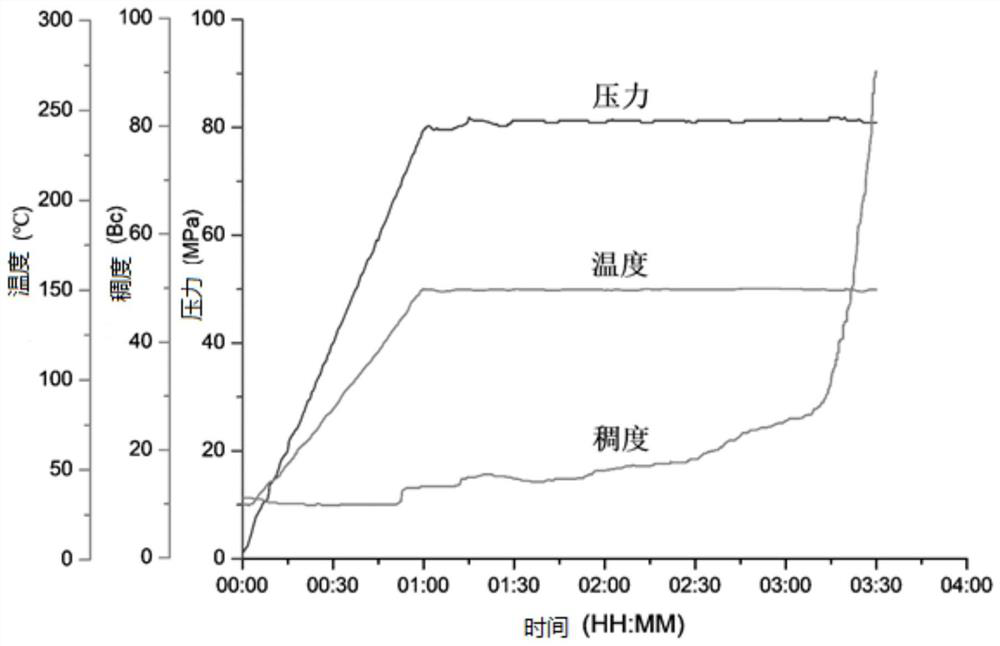

Preparation method of starch sulfate and application of starch sulfate as cement additive

The invention relates to a preparation method of starch sulfate and application of the starch sulfate as a cement additive. The invention relates to the technical field of fine chemical engineering and concrete admixtures. For the first time, the starch sulfate is prepared by taking sodium hydrogen sulfate or sulfuric acid or a composition aqueous solution of sodium hydrogen sulfate and sulfuric acid as a sulfonating agent by a semi-dry method, and synthesis raw materials comprise starch, the sulfonating agent and an inorganic alkali. The synthesis process comprises the following steps: preparing the sulfonating agent; mixing the sulfonating agent with the starch; heating and esterifying the mixture; and performing esterification product base neutralization. The method disclosed by the invention is different from a method for preparing the starch sulfate by taking concentrated sulfuric acid, chlorosulfonic acid, sulfur trioxide and the like as sulfonating agents in the prior art; the method has the advantages of simple preparation process, no emission of three wastes, low raw material cost, low equipment requirements and the like. The product prepared by the invention can be directly used as a super-retarding superplasticizer or retarder, and has the advantages of high water reducing rate, good retarding effect, strong cohesiveness, bleeding resistance, segregation resistance and the like; and if the starch sulfate is compounded with polycarboxylate superplasticizers and the like, an obvious synergistic effect can be generated.

Owner:殷鸽

Concrete curing agent and preparation process thereof

The invention discloses a concrete curing agent and a preparation process thereof. The concrete curing agent is prepared from the following raw materials in parts by weight: 40-60 parts of lithium silicate, 10-20 parts of a silane coupling agent, 6-12 parts of nano titanium dioxide, 10-30 parts of a modified water reducing agent, 10-20 parts of an expanding agent and 50-80 parts of water. According to the concrete curing agent and the preparation process thereof, a modified naphthalene water reducer and an oxidized etherified starch water reducer are introduced into a stirrer to be mixed and stirred uniformly to obtain a composite naphthalene water reducer, the modified naphthalene water reducer contains a large number of hydroxyl groups (-OH) and carboxyl groups (-COOH), the hydroxyl groups (-OH) and calcium ions on the surfaces of cement particles are adsorbed to form a film, hydroxyl groups can form hydrogen bonds with the surface of cement to prevent hydration, a retarding effect on cement hydration is achieved, and an oxidized etherified starch water reducing agent and a naphthalene water reducing agent are compounded, so that the purposes of increasing the water reducing rate, improving the slump retaining property and improving the later strength of concrete are achieved.

Owner:深圳市凯涂科技有限公司

Concrete admixture for roads

The invention aims to provide an admixture for roads, wherein the admixture comprises the following substances in parts by weight: 5-15 parts of triethanolamine, 8-16 parts of ethylene glycol, 2-9 parts of an organic silicon defoamer, 15-35 parts of an organic silicon impermeable waterproof agent, 15-25 parts of an antiwear agent, 3-19 parts of sodium nitrate, 1-10 parts of polyalcohol amine, 12-18 parts of isooctyl alcohol phosphate, 13-15 parts of an emulsifier and 10-25 parts of triethylene glycol. The admixture can prevent concrete cracks from closing and accelerate crack propagation, can form an unstable complex with calcium ions in cement, reduces the calcium concentration, has a strong retarding effect, improves the flowing property of cement paste, and plays a role in improving the compatibility of cement and a water reducing agent; and finally, after the concrete is added, the slump degree and the abrasion rate are reduced, the compressive strength, the flexural strength and the shrinkage rate are improved, and the admixture is more suitable for road concrete.

Owner:江西富创新材料有限公司

A kind of preparation method of starch sulfonate

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

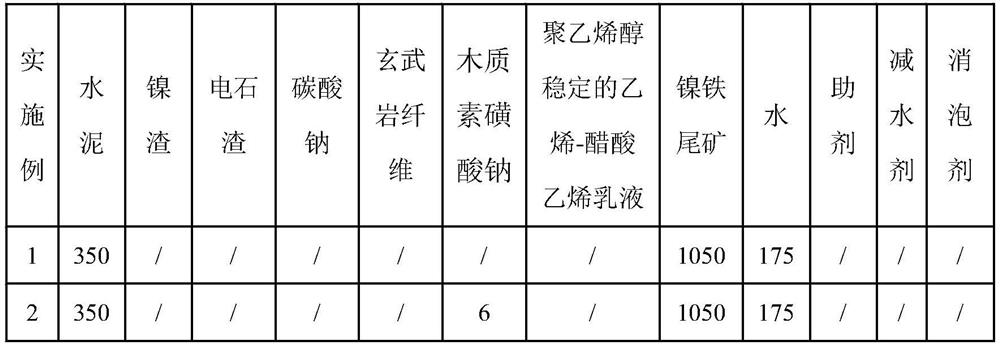

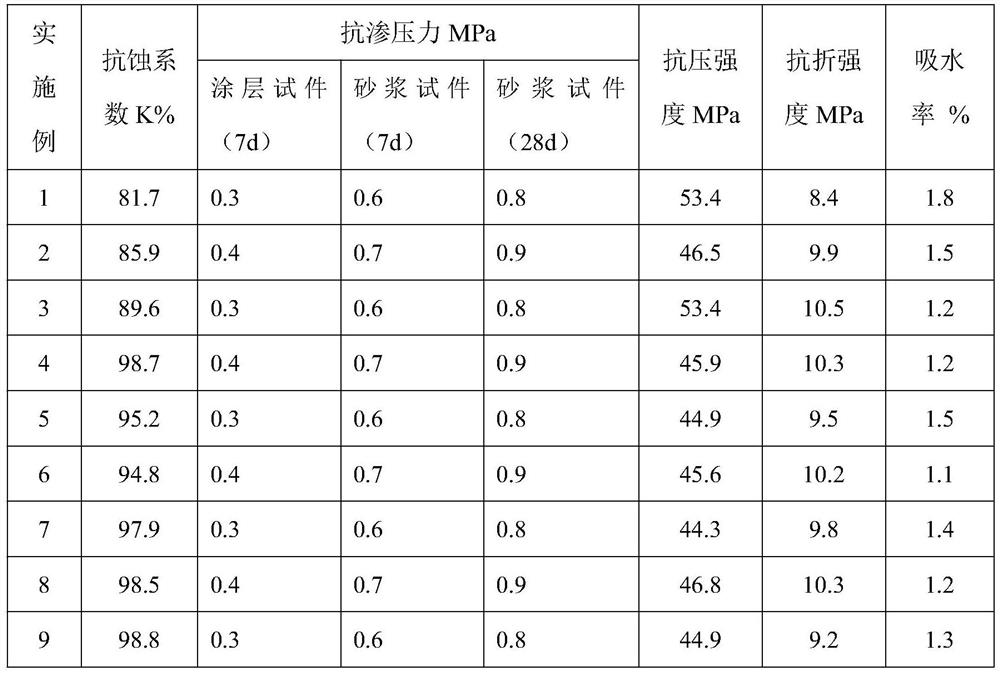

Sulfate-corrosion-resistant waterproof mortar and preparation method thereof

The invention discloses sulfate-corrosion-resistant waterproof mortar and a preparation method thereof. Comprising the following raw materials in parts by weight: 250-350 parts of nickel slag, 20-30 parts of carbide slag, 25-35 parts of sodium carbonate, 4-6 parts of basalt fiber, 5-7 parts of sodium lignin sulfonate, 40-50 parts of polyvinyl alcohol stabilized ethylene-vinyl acetate emulsion, 750-1050 parts of ferronickel tailings, 35-45 parts of water, 4-6 parts of an auxiliary agent, 1-6 parts of a water reducing agent and 1-2 parts of a defoaming agent. According to the sulfate-erosion-resistant waterproof mortar prepared by adopting a wet-grinding ultrafine mode and the preparation method, sulfate erosion of concrete can be effectively prevented, the mortar has excellent self-repairability and impermeability, coordination of body deformation is guaranteed, the materials are low in cost, easy to obtain and environmentally friendly, the operation process is simple and convenient, the preparation cost is effectively reduced, and the method is suitable for industrial production. And the method has obvious practicability and economical efficiency.

Owner:HUBEI UNIV OF TECH

High temperature and large temperature difference cement slurry for oil field cementing

The invention relates to high-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in an oil field. The cement grout is prepared from components of raw materials in parts by weight as follows: 600 parts of G-grade oil well cement, 30-36 parts of an HS101L fluid loss agent, 8-20 parts of an HS201L retarder, 1.8 parts of an HS-301S dispersant, 150 parts of quartz sand, 30 parts of silica fume, 1.8 parts of an HS-XF1S suspension stabilizer, 280-300 parts of water and 1 part of bis(2-ethylhexyl) sulfosuccinate sodium salt, wherein the grain size of the quartz sand is 80-120 meshes, the grain size of the silica fume is 300-400 meshes, and the content of silicon dioxide is 90% or higher. Liquid-phase raw materials are added to a grout mixing container and mixed uniformly; solid-phase substances are added to a solid-phase container and stirred uniformly, the solid-phase mixture is added to the grout mixing container, finally, a defoaming agent is added, and the mixture is stirred uniformly. The cement grout can be used under the condition of 50-180 DEG C, has prominent large-temperature-difference-resistant performance and can effectively avoid a super-retarding phenomenon caused by large temperature difference.

Owner:CHINA PETROCHEMICAL CORP +2

A kind of concrete retarder and preparation method thereof

Owner:贵州凯襄新材料有限公司

A kind of composite cement admixture

ActiveCN111646727BHigh compressive and flexural strengthImprove liquidityIsooctyl alcoholPhosphoric Acid Esters

The invention discloses a composite cement admixture, which belongs to the technical field of cement process admixtures. The grinding aid of the present invention is composed of 20-30 parts of composite alcohol amine components, 10-15 parts of isooctanyl phosphate, 4-8 parts of molasses, 4-8 parts of emulsifying dispersant, 5-10 parts of triethylene glycol, It is prepared from 3-5 parts of accelerator and 50-70 parts of water as raw materials. The synergistic effect of the isooctyl phosphate ester and the compound alcohol amine component of the present invention makes the grinding aid dosage small, and the grinding aid effect is good, and the 3d and 28d compressive and flexural strength of cement can be significantly improved at the dosage of 0.01%. , and the raw materials are easy to obtain, the preparation method is simple, and it is suitable for popularization and use.

Owner:安徽海螺材料科技股份有限公司 +1

A macroporous concrete containing low-quality recycled aggregate and its preparation method

ActiveCN104072061BProlong clotting timeExtended construction periodSolid waste managementCeramicwareLower gradeLow graded

The invention discloses macroporous concrete containing low grade recycled aggregates. The macroporous concrete containing low grade recycled aggregates is prepared from the following raw materials: cement, water, low grade recycled aggregates, modified starch and a sugar retarder, wherein the grain size of the low grade recycled aggregates is 5-16mm, and the bulk density is 700-900kg / m<3>. The macroporous concrete containing low grade recycled aggregates is further prepared from additional water, the use level of which is calculated according to the follow formula: delta W=mgr*wgr, wherein delta W is the use level of the additional water of the macroporous concrete containing low grade recycled aggregates; mgr is the use level of the low grade recycled aggregates and wgr is 1h water absorption of the low grade recycled aggregates. According to the invention, the grade recycled aggregates are applied to preparation of the macroporous concrete, so that the mixture state satisfies the using demand under the condition that an additive in an extra amount is not added by virtue of adjusting the raw materials and matching with the sugar retarder and modified starch.

Owner:北京东方建宇混凝土科学技术研究院有限公司

A kind of phosphorus slag-based environment-friendly building material and preparation method thereof

Owner:中建西部建设贵州有限公司

A kind of rapid repair material for magnesium phosphate cement and preparation method thereof

ActiveCN109796147BProlong clotting timeGood retarding effectMagnesium phosphateMagnesium orthophosphate

The invention discloses a novel rapid repair material for magnesium phosphate cement and a preparation method thereof. The composite material is mainly made of the following raw materials in parts by weight: 25 parts of magnesium oxide, 15-20 parts of potassium dihydrogen phosphate, Diamine tetraacetic acid dipotassium salt dihydrate 0.5-1.5 parts, water 5-10 parts. The invention uses dipotassium ethylenediaminetetraacetic acid dihydrate as a setting retarder, replacing the borax used in traditional magnesium phosphate cement. The invention has excellent retarding effect. On the one hand, the setting time of the magnesium phosphate repair system is greatly prolonged; on the other hand, the system can not only ensure the early strength of the magnesium phosphate cement sample, but also improve its later strength to a certain extent.

Owner:SOUTHEAST UNIV

Method for preparing food browning inhibitor from cedar pine needles

InactiveCN103739582BEnhanced inhibitory effectImproves antioxidant activityOrganic chemistryFood ingredient functionsLiquid ratioRoom temperature

The invention discloses a method for preparing a food browning inhibitor from cedar pine needles. The method is characterized by comprising the following steps: smashing dried cedar pine needles, adding normal hexane according to the material-to-liquid ratio of 1g: (10-20mL), vibrating at room temperature for 12-24h and filtering to separate a normal hexane extracting liquid; recovering the degreased pine needles, adding 50-70wt% methanol as an extracting agent according to the material-to-liquid ratio of 1g: (10-30mL), vibrating at room temperature for 24-48h, separating a supernatant, concentrating and drying the supernatant to obtain a methanol extract with the yield of 15-22%; suspending the methanol extract into 20-30mL of 50wt% methanol, carrying out chromatography by using a macroporous adsorption resin DiaionHP-20 chromatographic column, carrying out gradient elution at the flow speed of 3-5mL / min by using water and methanol with the concentrations being respectively 0wt%, 15wt%, 30wt%, 40wt%, 60wt% and 100wt%, collecting the 40wt% methanol eluant, concentrating and drying to obtain the food browning inhibitor, separating and purifying by using a high performance liquid chromatography; and obtaining the effective component, i.e., 2R, 3R-dihydromyricetin of the food browning inhibitor.

Owner:SICHUAN UNIV

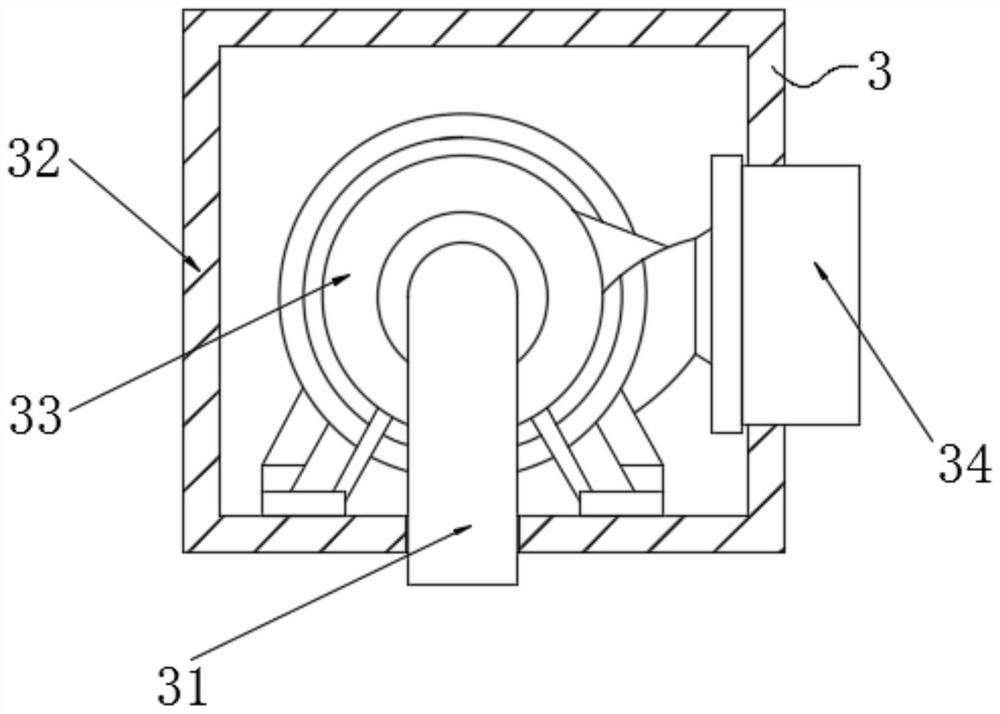

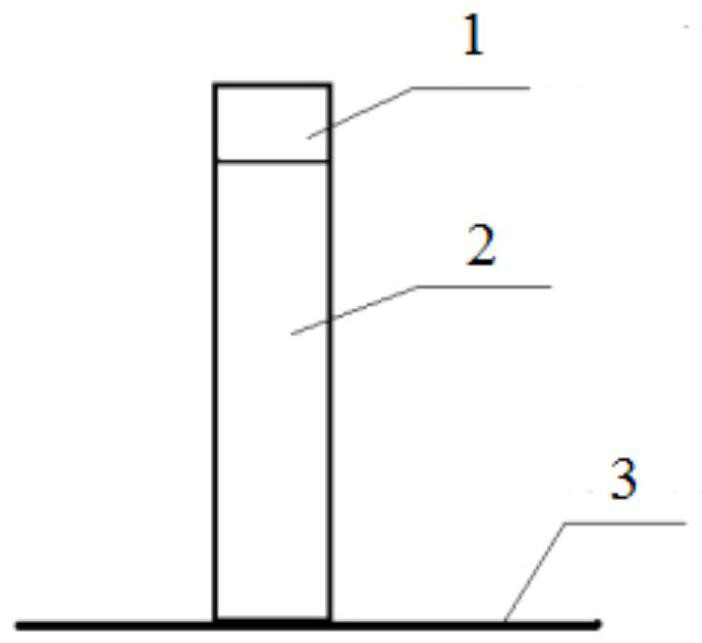

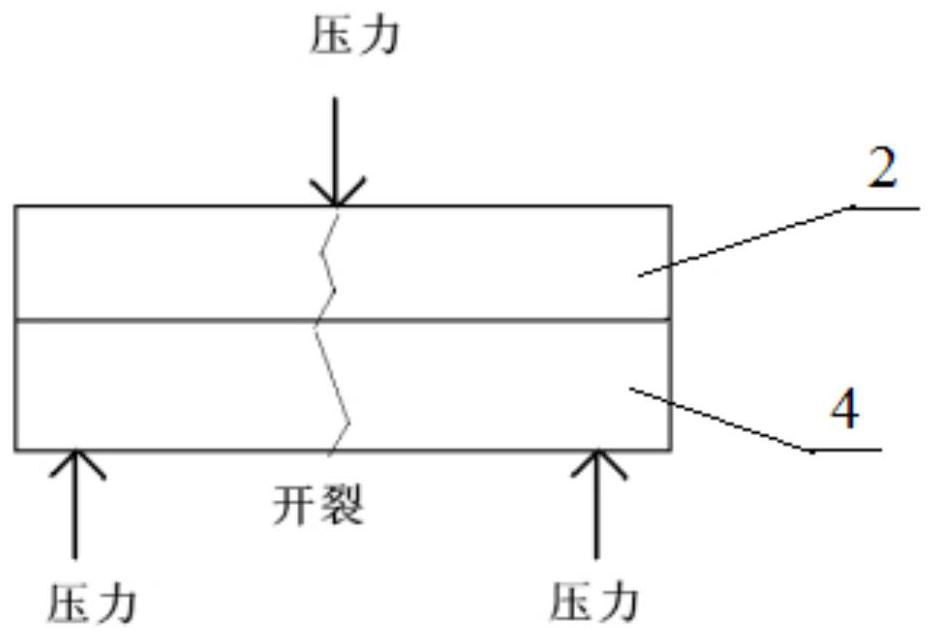

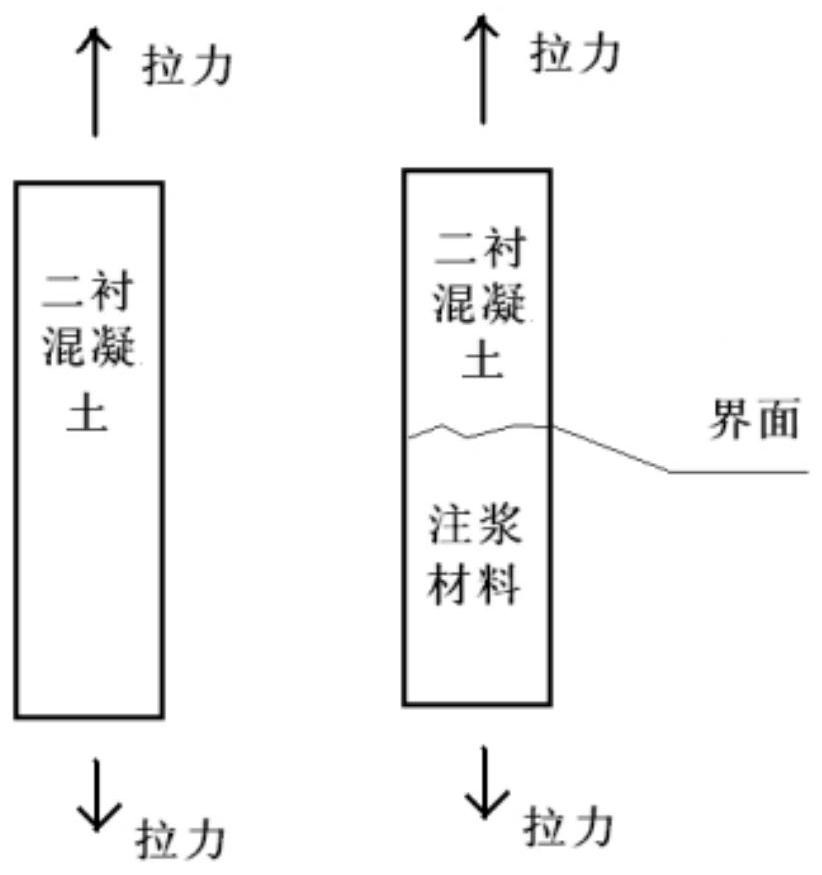

Grouting Binder and Its Performance Parameter Testing Method

ActiveCN108439905BImprove early strengthGood retarding effectUsing mechanical meansMaterial analysisFiberStructural engineering

Owner:北京鸿锐嘉科技发展有限公司

Preparation method of delayed coagulation type water reducing agent

The invention discloses a preparation method of a delayed coagulation type water reducing agent, and mainly relates to the field of concrete admixtures. The preparation method comprises the followingsteps: adding metered water, a formula amount of sulfanilic acid or sodium sulfanilate, salicylic acid or sodium salicylate and glucose into a four-neck flask, adjusting to be alkaline by using sodiumhydroxide, heating to 90 DEG C, starting to dropwise add a formaldehyde solution, and reacting at a constant temperature until the end. The method has the beneficial effects that materials with different functional groups are used for condensation reaction, and the delayed coagulation type water reducing agent has the characteristics of high water reduction, controllable retarding time, good adaptability to sandstone materials and the like.

Owner:山东恒丰天利新材料科技有限公司

Temperature-adaptive high-temperature retarder suitable for oil and gas well cementing, preparation method thereof and cementing cement slurry

ActiveCN109824823BIncrease success rateImprove conversion rateDrilling compositionWell cementingCement slurry

The invention belongs to the technical field of oil and gas well development, and discloses a temperature self-adaptive high-temperature retarder suitable for oil and gas well cementing, a preparation method thereof and well cementing cement slurry. This high-temperature retarder contains structural unit A shown in (I), structural unit B shown in (II), structural unit C shown in (III) and structural unit D shown in formula (IV); wherein, structural unit A, The structure percentages of B, C and D p=7.18‑10.76%, q=40.22‑64.66%, m=25.86‑46.25%, n=1.05‑3.8%; this high temperature retarder can avoid the deterioration of the stability of cement slurry At the same time, the early strength of the cement slurry is high at low temperature, which can avoid the problem of slow or even super retarded cement strength formation in the upper part of the long sealing section;

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com