Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Extended induction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance polycarboxylate water reducing agent and preparation method thereof

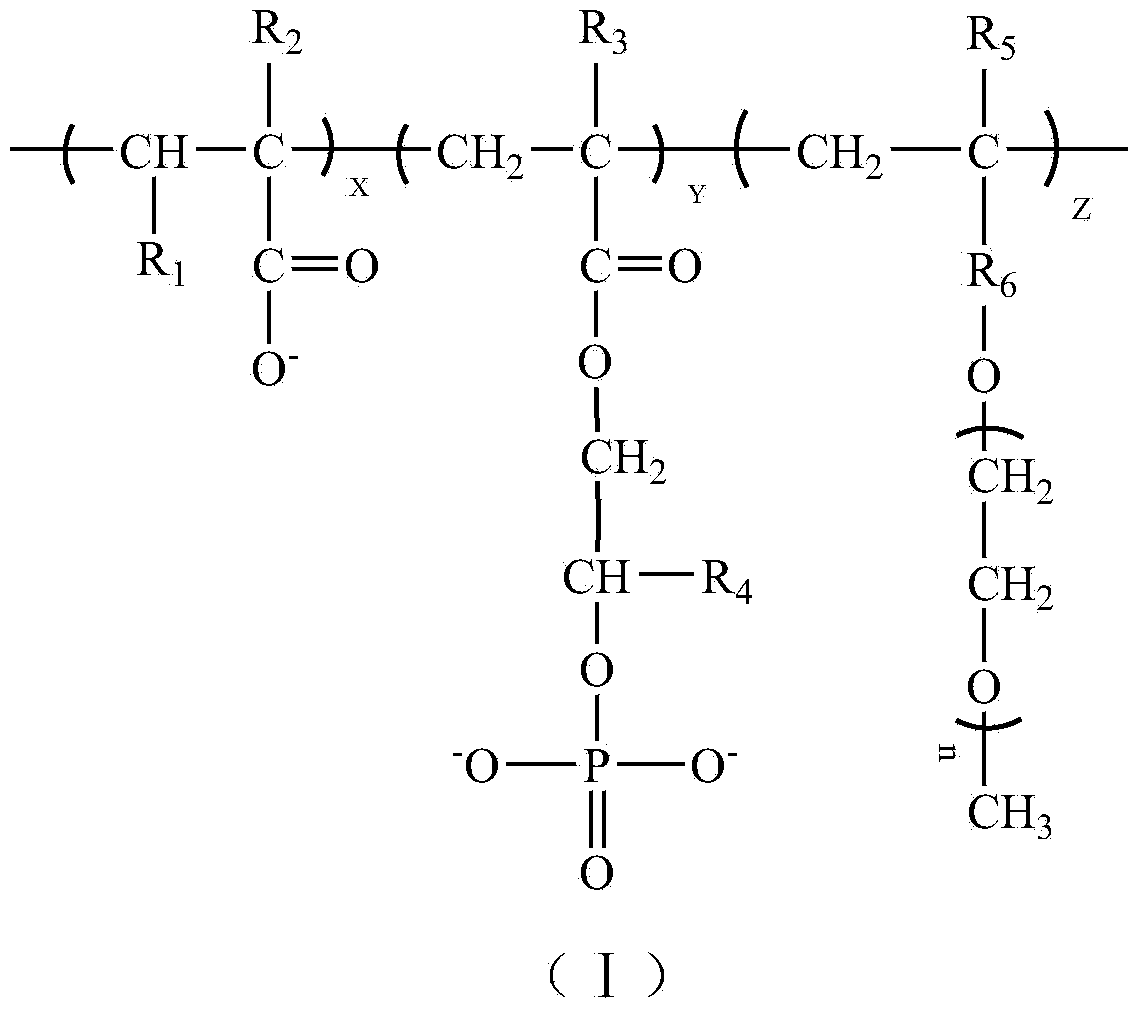

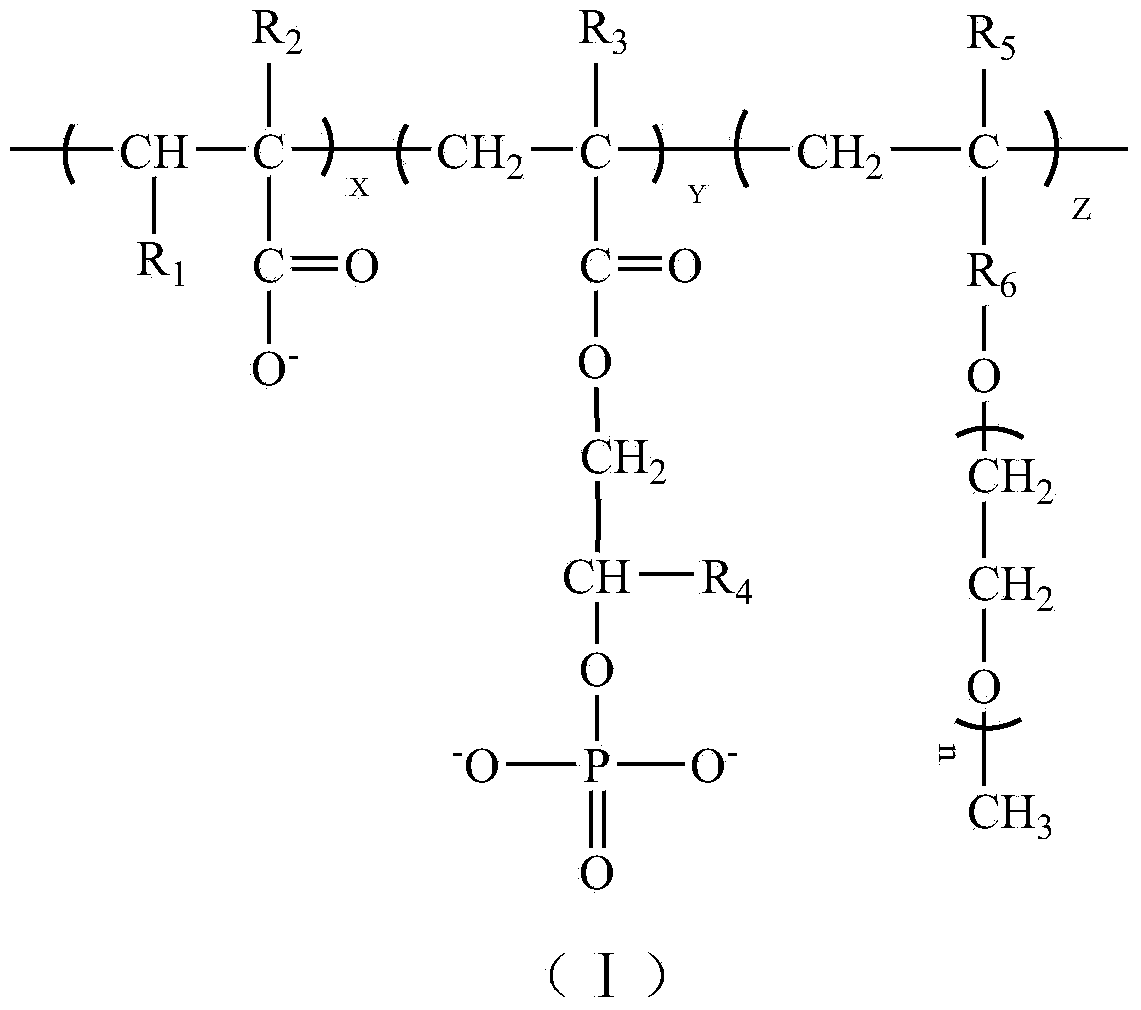

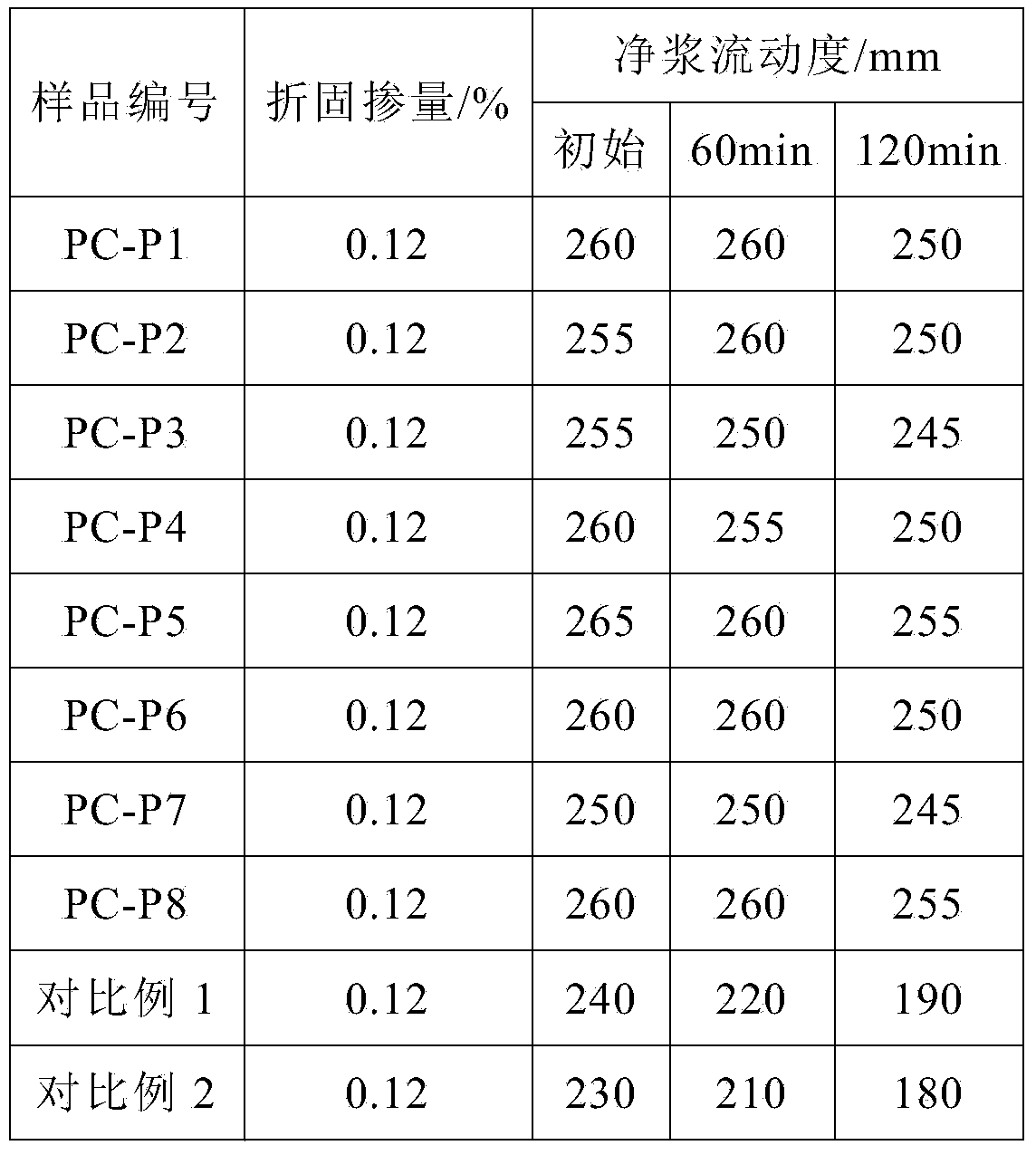

The invention discloses a high-performance polycarboxylate water reducing agent. The polycarboxylate water reducing agent has a structural general formula shown as a structural formula (I). The invention further provides a preparation method of the high-performance polycarboxylate water reducing agent. Apart from a polyether macromonomer and an unsaturated carboxylic acid monomer, an unsaturated phosphate monomer is added to obtain a product, namely, the high-performance polycarboxylate water reducing agent having a phosphate structure. The polycarboxylate water reducing agent disclosed by the invention is safe and simple in preparation process, environmentally friendly, low in energy consumption, low in cost, and suitable for industrial large-scale production. In the structural formula (I), R1 is -H, -COO- or -CH2COO-; R2 is -H or -CH3; R3 is -H or -CH3; R4 is -H or -CH3; R5 is -H or -CH3; R6 is -CH2- or -CH2CH2-; X, Y, Z and n are integers; X=1-100; Y=1-100; Z=1-100; and n=22-53.

Owner:CCCC SHEC WUHAN PORT NEW MATERIALS

Rubber tire tread and milling process thereof

The invention discloses a rubber tire tread and a milling process thereof. The rubber tire tread comprises the following components in parts by weight: 70-110 parts of natural rubber, 0-15 parts of styrene-butadiene rubber, 5-20 parts of tread rubber powder, 1.5-2.5 parts of stearic acid, 1-2 parts of sulfur powder, 2-18 parts of white carbon black, 12-15 parts of carbon block, 2-30 parts of aromatic oil, 1-8 parts of zinc oxide, 4-7 parts of an anti-aging agent, 1-4 parts of pine tar, 1-4 parts of an accelerating agent, 0.2-1 part of an anti-reversion agent and 2-5 parts of a binding agent. A three-section milling process is adopted, and the milling process can improve the abrasive resistance, tear resistance and chunking and chipping resistance of the tire tread.

Owner:SHANDONG YONGTAI CHEM GROUP

Tyre inner liner rubber and preparation method thereof

InactiveCN103435858ALow air permeabilityExtended induction periodSpecial tyresSilane couplingCarbon black

The invention discloses tyre inner liner rubber, which adopts a sulfur-free formula and is prepared from the following components in weight part: 80-120 parts of natural rubber, 20-60 parts of halogenated butyl rubber, 10-15 parts of tread rubber powder, 10-15 parts of white carbon black, 15-25 parts of carbon black, 1-8 parts of zinc oxide, 0.2-1 part of magnesium oxide, 1-15 parts of calcium carbonate, 1-4 parts of stearic acid, 2-15 parts of softening agent, 3-5 parts of anti-aging agent, 1-4 parts of microcrystalline wax, 1-4 parts of pine tar, 1-2 parts of accelerant, 3-10 parts of binding agent and 1-3 parts of silane coupling agent. The two-stage mixing technology is adopted. The air permeability of the rubber is low, and the airtight performance of the tyre is better. As the halogenated butyl rubber is adopted, the pressure can be maintained and the tyre can be prevented from erosion by oxygen and moisture in the air.

Owner:SHANDONG YONGTAI CHEM GROUP

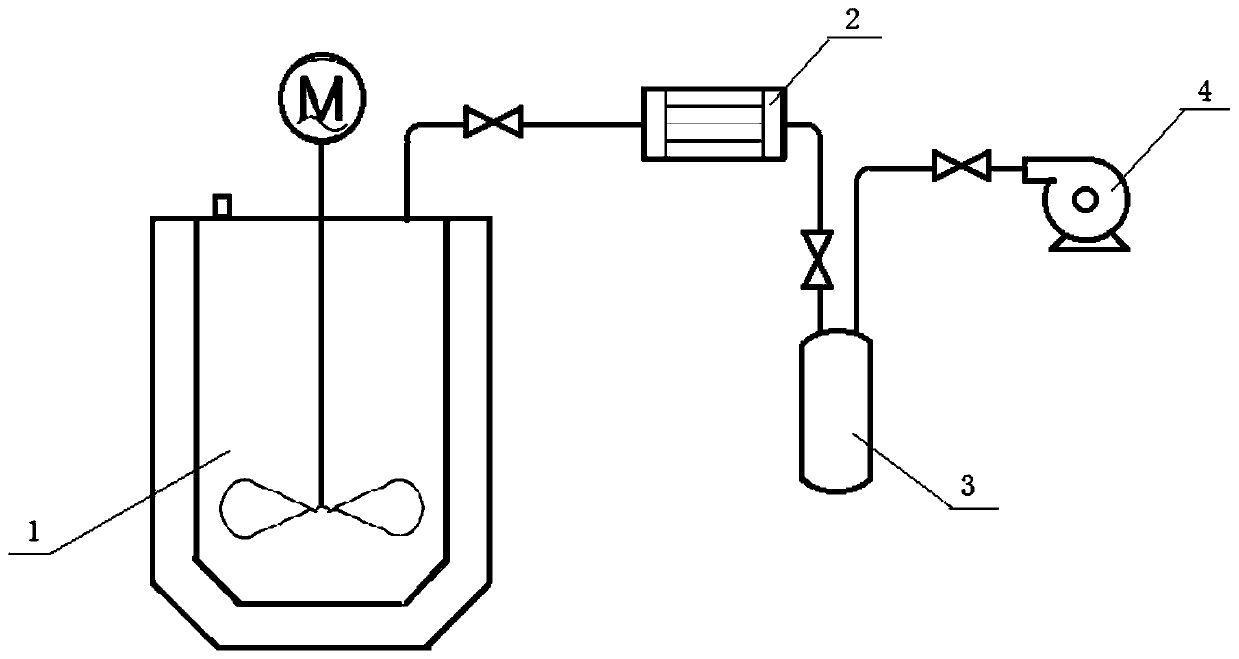

Method for preparing low-unsaturation-degree polyether polylol

The invention relates to the preparation of a kind of low unsaturation polyether polyols. It's mainly used to solve the problem in previous technology that it has long catalyst inductive period and the concentration of catalyst in initiator is high, which is that it has a high catalyst cost in the preparation of unsaturation polyether polyols. The invention excellently solves the said problem through adopting catalyst components containing double metal cyanide (DMC) mixture, C4 - C10 organic mellow with tertiary alcohol structure, adding bronsted acid, and adopting the technology project of inert gas frothing to degasificate. So it can be used in the industrial production of low unsaturation polyether polyols.

Owner:SINOPEC SHANGHAI GAOQIAO PETROCHEM CORP +1

Edible blend oil and its preparation method

InactiveCN107494775AHigh smoke pointExtended shelf lifeEdible oils/fatsNutritive valuesAcute hyperglycaemia

The invention discloses edible blend oil and its preparation method. The edible blend oil is prepared from, by weight, 20-30 parts of corn oil, 20-30g of soybean oil, 10-20 parts of rice oil, 10-20 parts of flaxseed oil, 5-10 parts of peanut oil, 1-2 parts of Vitamin E, 0.5-1 part of hydrolysis plant protein, and 0.5-1 part of green tea extractive. The raw material further comprises lycopene, citric acid and medlar extractive. The edible blend oil is high in nutrition value and good in oxidization stability; after eating for a long time, the edible blend oil has good effect to people with hyperlipidemia, high blood pressure and hyperglycemia, patients with cardia-cerebrovascular disease, fatty liver and obesity.

Owner:宜昌傲海油脂有限公司

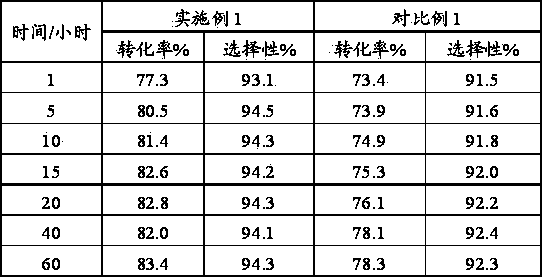

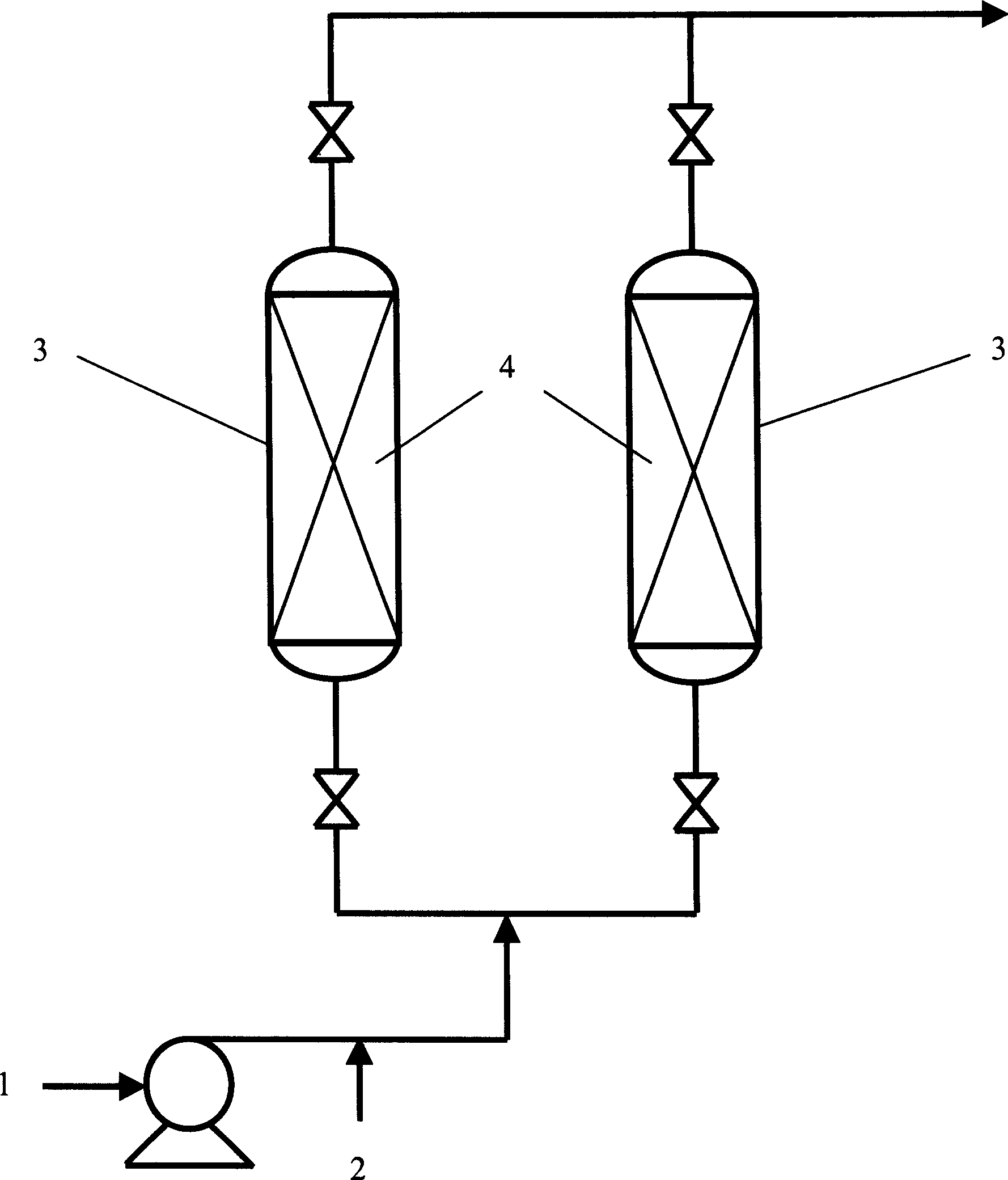

Regeneration method of butene oxidative dehydrogenation catalyst

ActiveCN104226334ARestore activityExtended induction periodCatalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsBurn treatmentGas phase

The invention relates to a regeneration method of a butene oxidative dehydrogenation catalyst, and mainly solves the problems of poor regeneration effect, decreased activity after regeneration, long induction period and shortened service life of the catalyst in the prior art. The method provided by the invention comprises the following steps: a) conducting carbon burning treatment on inactivated iron spinel composite oxide catalyst for butene oxidative dehydrogenation to produce butadiene at 360-480 DEG C under the conditions of oxygen / steam volume ratio of 0.01-0.06 and water vapor airspeed of 400-2000 / h for 2-24 h; b) treating the catalyst subjected to carbon burning at 300-550 DEG C under the conditions of gauge pressure of 0-0.2 MPa, oxygen / steam volume ratio of 0.01-0.1, water vapor volume space velocity of 400-4000 / h and sulfide gas phase concentration of 0-100 ppm for at least 24 h. The technical scheme well solves the problem, and can be used in industrial production of butadiene from butene oxidative dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

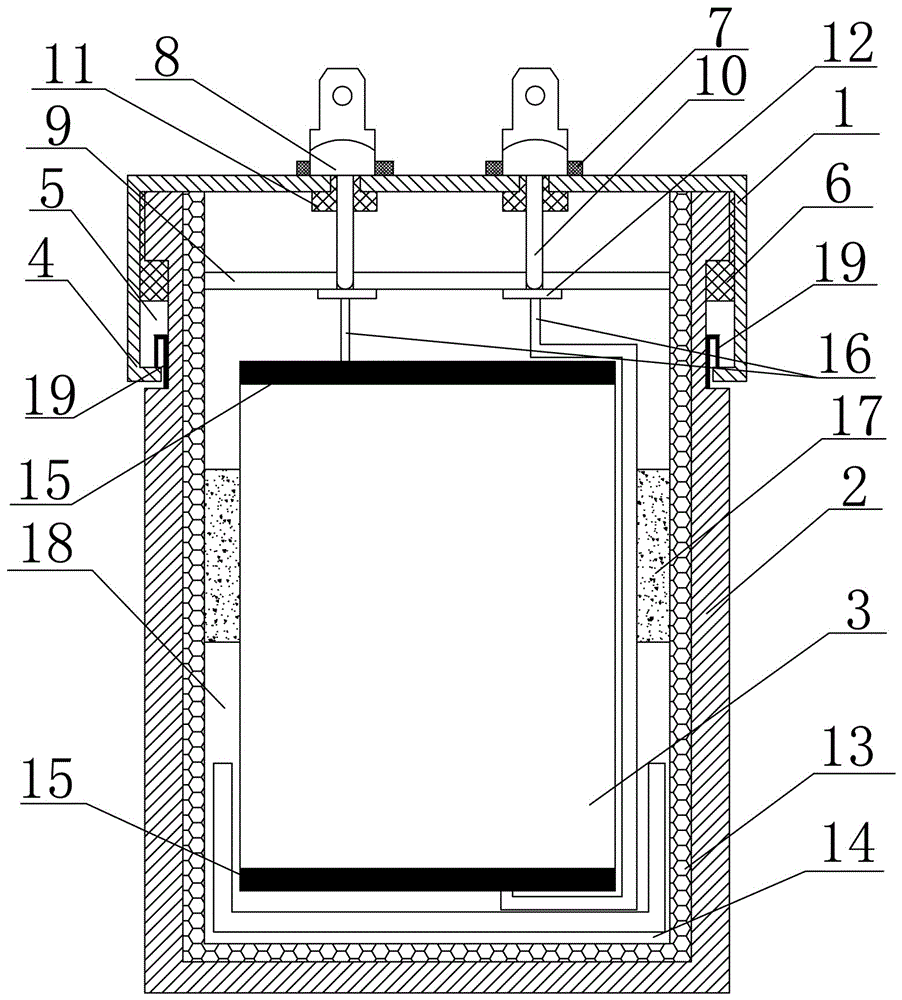

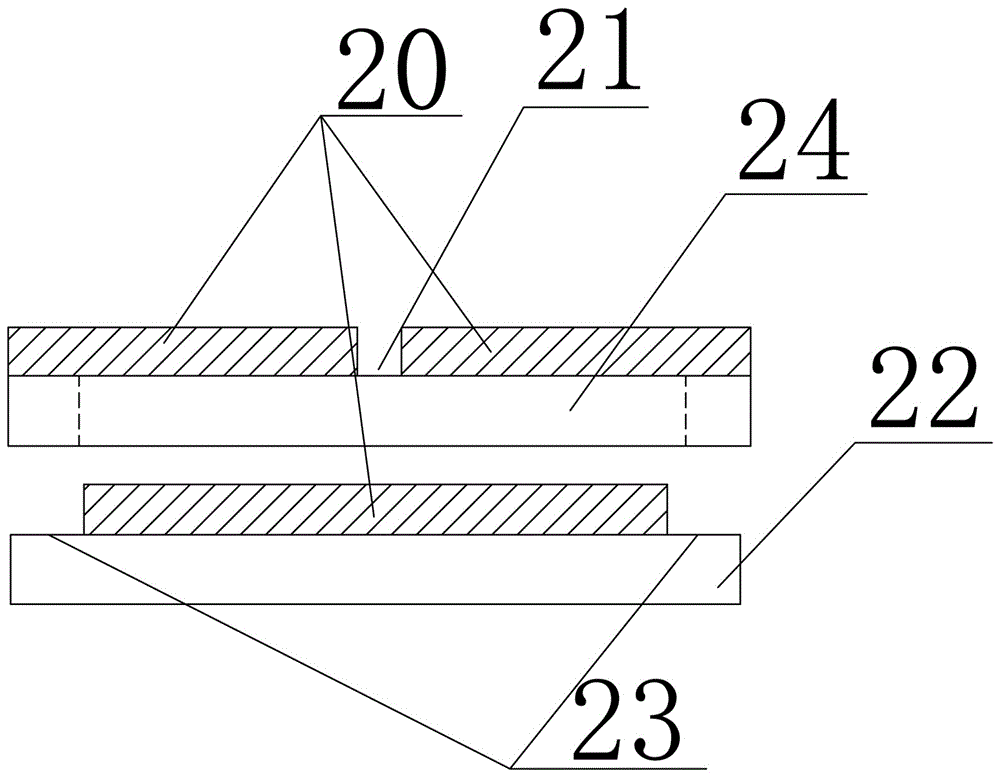

Anti-interference high-voltage metalized polypropylene film capacitor

ActiveCN105869884AImprove securityExtended range of movementThin/thick film capacitorFixed capacitor electrodesRubber ringHeat conducting

The invention discloses an anti-interference high-voltage metalized polypropylene film capacitor, which comprises a cover board (1), a housing (2) and a core body (3), wherein an annular bump (4) is formed in the inner wall of an opening of the cover board (1); an annular groove (5) is formed in the upper part of the housing (2); the annular bump (4) is arranged in the annular groove (5) and can longitudinally move in the annular groove (5); an elastic seal ring (6) is arranged between the inner wall of the lower part of the cover board (1) and the outer wall of the upper part of the housing (2); an elastic rubber ring (19) is fixedly connected between the annular bump (4) and the bottom part of the annular groove (5); a buffer layer (13) is arranged at the inner wall of the housing (2); a core body (3) is arranged in the housing (2); a positioning sleeve (14) is arranged at the bottom part of the core body (3); an elastic washer (17) registered in the middle part of the core body (3); and insulated heat-conducting oil (18) is sealed between the housing (2) and the core body (3). The capacitor is high in breakdown voltage, anti-interference, safe, stable and long in service lifetime.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

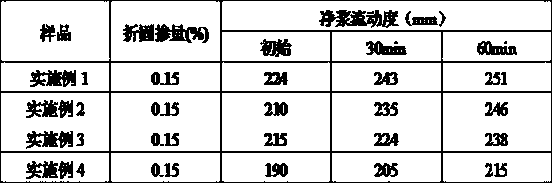

High-temperature-resistant stone powder adsorption-resistant slump-retaining polycarboxylate superplasticizer and preparation method thereof

ActiveCN113461873AImprove water reducing performanceGood slump retention performanceSolid waste managementPhosphateEnvironmental geology

The invention discloses a high-temperature-resistant stone powder adsorption-resistant slump-retaining polycarboxylate superplasticizer and a preparation method thereof. The polycarboxylate superplasticizer is prepared from the following components in parts by weight: 320 to 360 parts of unsaturated polyether macromonomer, 20 to 30 parts of unsaturated monocarboxylic acid, 6 to 10 parts of maleimide alkyl acid, 5 to 8 parts of unsaturated phosphate, 2 to 5 parts of unsaturated amino acid monoester, 2.5 to 5.0 parts of oxidant, 0.5 to 1.0 part of reducing agent and 1 to 3 parts of chain transfer agent. The pH value of the water reducing agent is 5.0-7.0, and the solid content of the water reducing agent is 40%-42%. The polycarboxylic acid water reducing agent can effectively solve the problems of insufficient initial fluidity of concrete, too fast slump loss and poor workability of a concrete mixture caused by incapability of simultaneously meeting high temperature resistance and limestone powder adsorption resistance of the existing water reducing agent, and has great significance in widening the engineering application field of the water reducing agent.

Owner:SICHUAN TONGZHOU CHEM TECH

High-temperature compound polymerization inhibitor used in rectification process of aromatic alkene monomer and application thereof

InactiveCN106554244ANot easy to aggregate and adhereInhibit aggregate adhesionHydrocarbon purification/separationHydrocarbonsSolventAlkene

The invention relates to a high-temperature compound polymerization inhibitor used in a rectification process of an aromatic alkene monomer and an application thereof. The compound polymerization inhibitor includes a component A, a component B and a component C, wherein the component A is a piperidine nitroxyl free radical compound, the component B is an alkoxyphenol compound, and the component C is solvent oil. The polymerization inhibitor has polymerization inhibition effect at high temperature and also has anti-scaling effect, thus solving the problems that polymerization inhibition is achieved only if a polymerization retarder is compounded with a real polymerization inhibitor, and the compound is complex in ingredient, has poor polymerization inhibition effect at high temperature and has no anti-scaling effect. The compound polymerization inhibitor has low toxicity, has good polymerization inhibition effect at high temperature and has the anti-scaling effect, thereby increasing rectification yield of aromatic alkene, reducing pollution and eliminating safety risk.

Owner:CHINA PETROLEUM & CHEM CORP

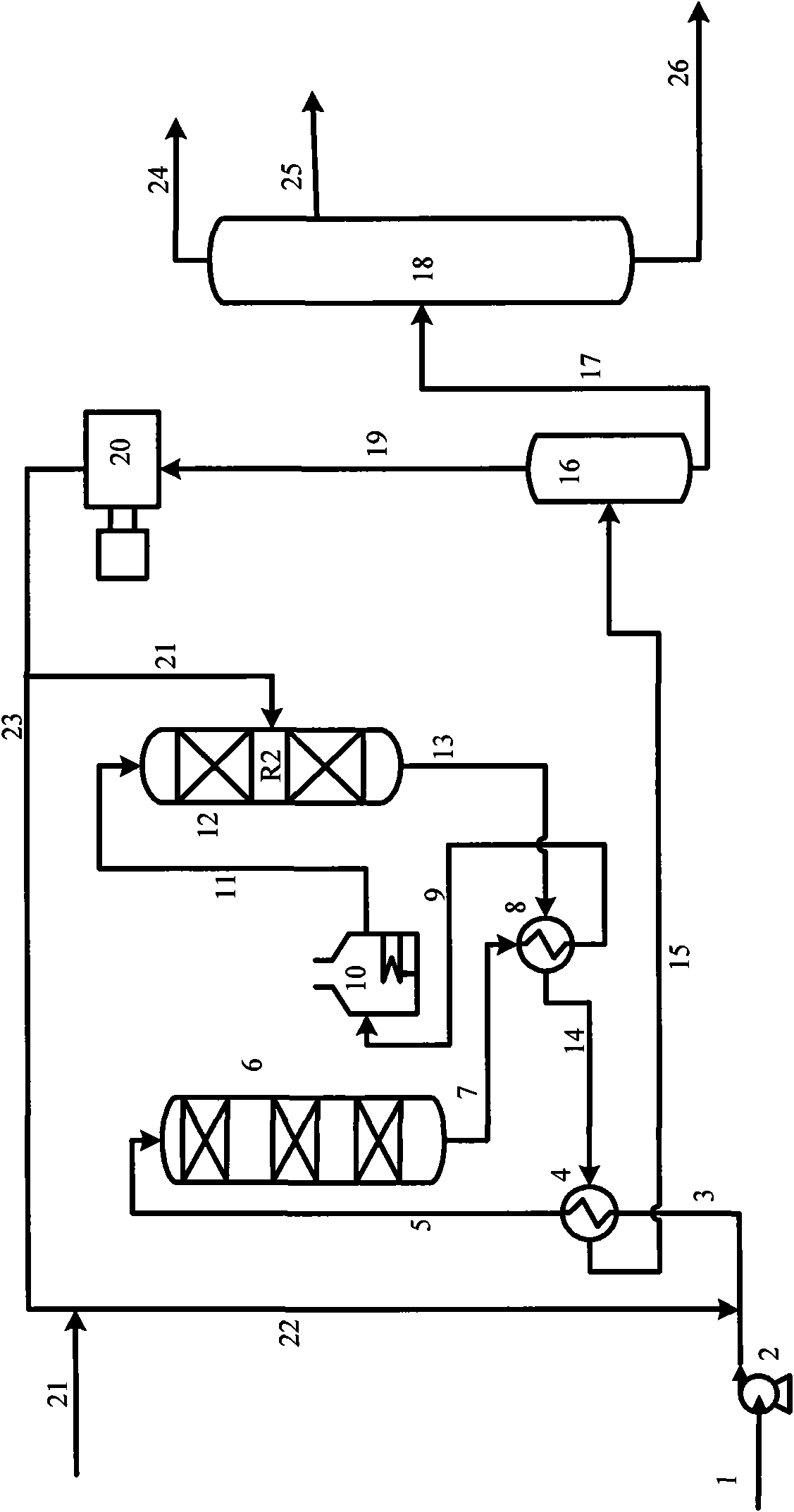

Process for lowering sulfur content in gasoline through hydrogen supply agent

InactiveCN1635055AReduce sulfur contentReduce cracking conversionHydrocarbon oils refiningWater vaporReaction temperature

The invention discloses a process for lowering sulfur content in gasoline through hydrogen supply agent, which comprises mixing raw material petroleum, hydrogen supply agent and catalyst in reactor at the presence of water vapor, charging the reaction oil gas to the subsequent separation system, and circulating the catalyst through recovery, wherein the hydrogen supply agent employs cycloalkyl aromatic hydrocarbons containing 1-3 naphthene. The invention can be applied to substantially reduce the sulfur content in the gasoline.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC

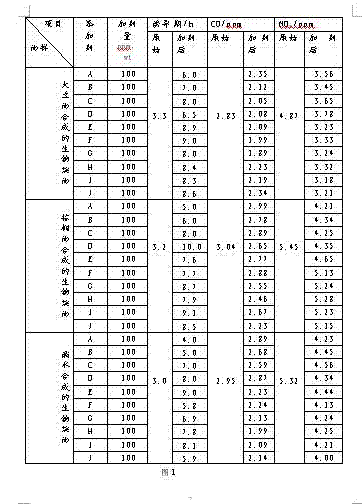

Compound additive applied in biodiesel

ActiveCN102585937AImprove stabilityExtended induction periodLiquid carbonaceous fuelsExhaust fumesProcess engineering

The invention belongs to the technical field of petroleum additives, particularly relates to a compound additive applied in biodiesel. The compound additive applied in biodiesel comprises the following components in parts by weight: 5-20 parts of an antioxidant, 10-20 parts of fire promoting agent, 10-30 parts of a lubricant, 30-50 parts of a heat stabilizer, and 50-80 parts of solvent oil. The compound additive provided by the invention can enable the physical and chemical indictors of biodiesel to meet GB252-2000 standard, has good stability, less exhaust discharge amount, improves environment, and can increase power and reduce carbon residue ash content.

Owner:临沂星火知识产权服务有限公司

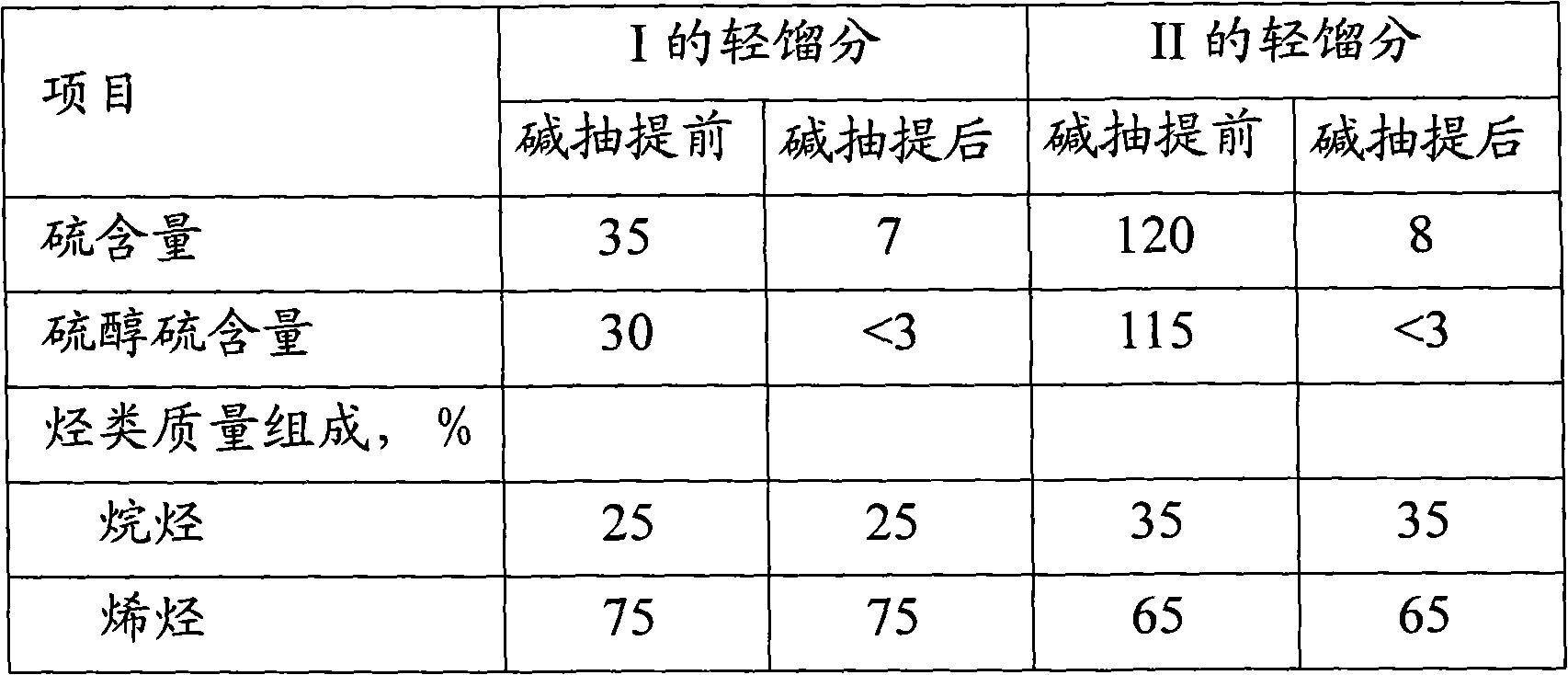

Method for preparing large grain anhydrous sodium sulfate

InactiveCN101007640AExtended induction periodEnhanced interface energyAlkali metal sulfite/sulfate dehydrationPhosphatePolyethylene glycol

The invention discloses a making method of large-particle anhydrous sodium sulfate, which comprises the following steps: adding 0.01%-10% surface activator with one or more of dodecyl phosphate ester, dodecyl sodium benzosulfonate, dodecyl dimethyl amine oxide, phenylethene or carbowax; adding water under 60-260 deg.c; keeping the constant density of solution to react 1.5-3.0h; stopping heating; filtering; drying; obtaining 80% product over 40 order.

Owner:HEBEI UNIVERSITY

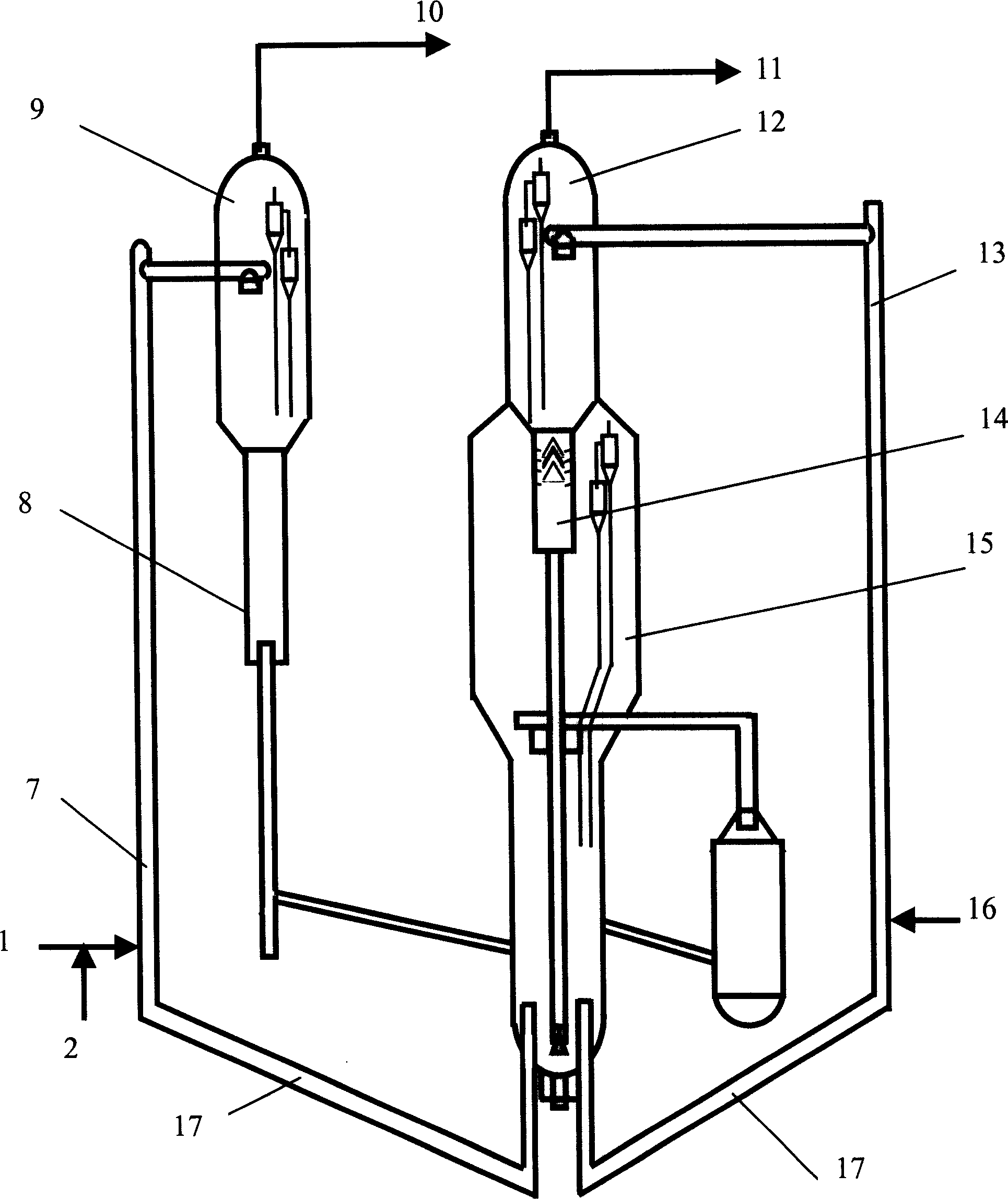

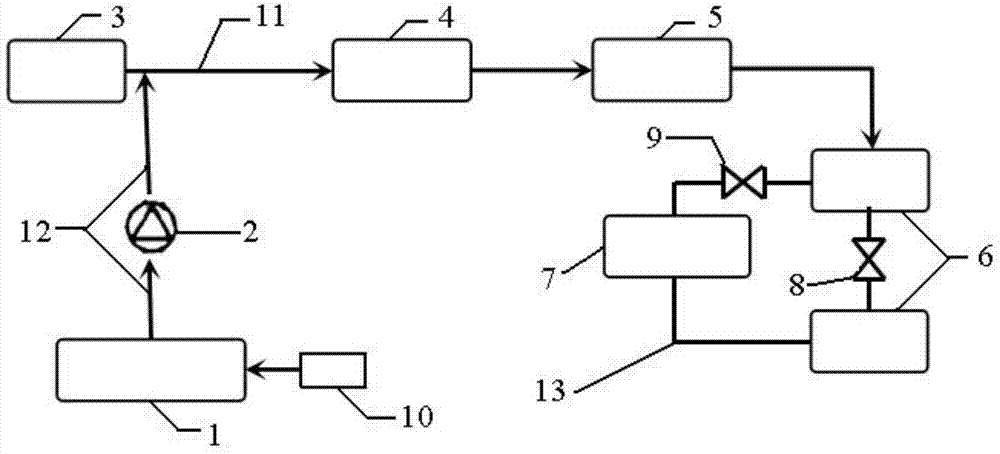

System and method for improving heat efficiency of boiler and removing scale and oxide skin of boiler

PendingCN107420876APrevent supersaturationReduce thermal resistanceBoiler cleaning apparatusProcess engineeringSolid particle

The invention discloses a system and method for improving the heat efficiency of a boiler and removing scale and oxide skin of the boiler, and relates to the field of scale removal of boilers. The system for improving the heat efficiency of the boiler and removing scale and oxide skin of the boiler comprises a feeding chamber. The feeding chamber is connected with a second pipeline, and a pump is arranged on the second pipeline. The second pipeline communicates with a first pipeline, and the first pipeline is connected with the boiler. The boiler is connected with a steam pocket, and the steam pocket is connected with a down pipe. The first pipeline is used for adding boiler water, and the feeding chamber is used for adding inert solid particles. According to the system and method for improving the heat efficiency of the boiler and removing scale and oxide skin of the boiler, the inert solid particles are added into the boiler water, online scale prevention and removal of scale and oxide skin of the boiler are achieved by means of the characteristics of the inert solid particles, and thus the heat exchange efficiency of the boiler is improved.

Owner:北京必可测科技股份有限公司

Super retarding concrete

The invention relates to the technical field of building materials, in particular to super-retarding concrete. The formula comprises the following raw materials in parts by weight: 210-250 parts of cement, 30-50 parts of an admixture, 3-5 parts of basalt fiber, 8-10 parts of an additive, 805-810 parts of river sand, 985-1010 parts of stone and 165-170 parts of water. The additive comprises a waterreducing agent, a retarder, a water retaining agent and a defoaming agent, the weight ratio of the water reducing agent to the retarder to the water retaining agent to the defoaming agent is (6-8): (7-9): (3-5): (1-2), the admixture comprises phosphorus slag, coal ash and microbeads, and the weight ratio of the phosphorus slag to the coal ash to the hollow glass microbeads is (10-20) :(40-50) :(10-15). The super-retarding concrete with higher strength and longer setting time is obtained by reasonably proportioning the cement, the admixture, the basalt fibers, the additive, the river sand, thestone and the water and matching the raw materials, pumping construction can be carried out, segregation and layering are not likely to happen, and the super-retarding concrete has important significance on development of the concrete industry.

Owner:深圳市鸿力健混凝土有限公司

Method for preparing phosphate functional monomer by P2O5 dispersion method and application

InactiveCN107793447AGood dispersionImprove adaptabilityPhosphorus organic compoundsSimple Organic CompoundsFunctional monomer

The invention discloses a method for preparing a phosphate functional monomer by a P2O5 dispersion method and application. The invention relates to a method for synthesizing a phosphate functional monomer by feeding a polymerizable unsaturated organic compound dispersed P2O5, wherein a polymerizable unsaturated organic compound dispersing agent used in a synthesis process can participate in a subsequent polymerization reaction, thereby solving the problems of difficult separation and recovery of a low-boiling-point and toxic organic solvent adopted in a preparation process of an existing phosphate functional monomer and environmental pollution, and simultaneously simplifying the synthesis route of the phosphate functional monomer. The invention also discloses a method for preparing a high-performance polycarboxylate superplasticizer by taking a phosphate functional monomer solution with a polymerizable unsaturated organic compound as a solvent as a third monomer of a polycarboxylate superplasticizer, so that the problem of contradiction between dispersion capacity and slump retention capacity of an existing polycarboxylate superplasticizer is solved, and a method for preparing a high-performance polycarboxylate superplasticizer with high dispersion and slump retention capacity and strong cement adaptability is provided.

Owner:贵州中兴南友建材有限公司

Double metal cyanide catalysts for producing polyether polyols

The invention relates to a double metal cyanide catalysts for producing polyether polyols, wherein the catalyst composition comprises bimetallic cyanide mixture, C4-C10 organic alcohol having a tertiary alcohol structure and selected from silicon acid esters, the catalyst can be applied into the industrial production of polyether polyols.

Owner:CHINA PETROLEUM & CHEM CORP +1

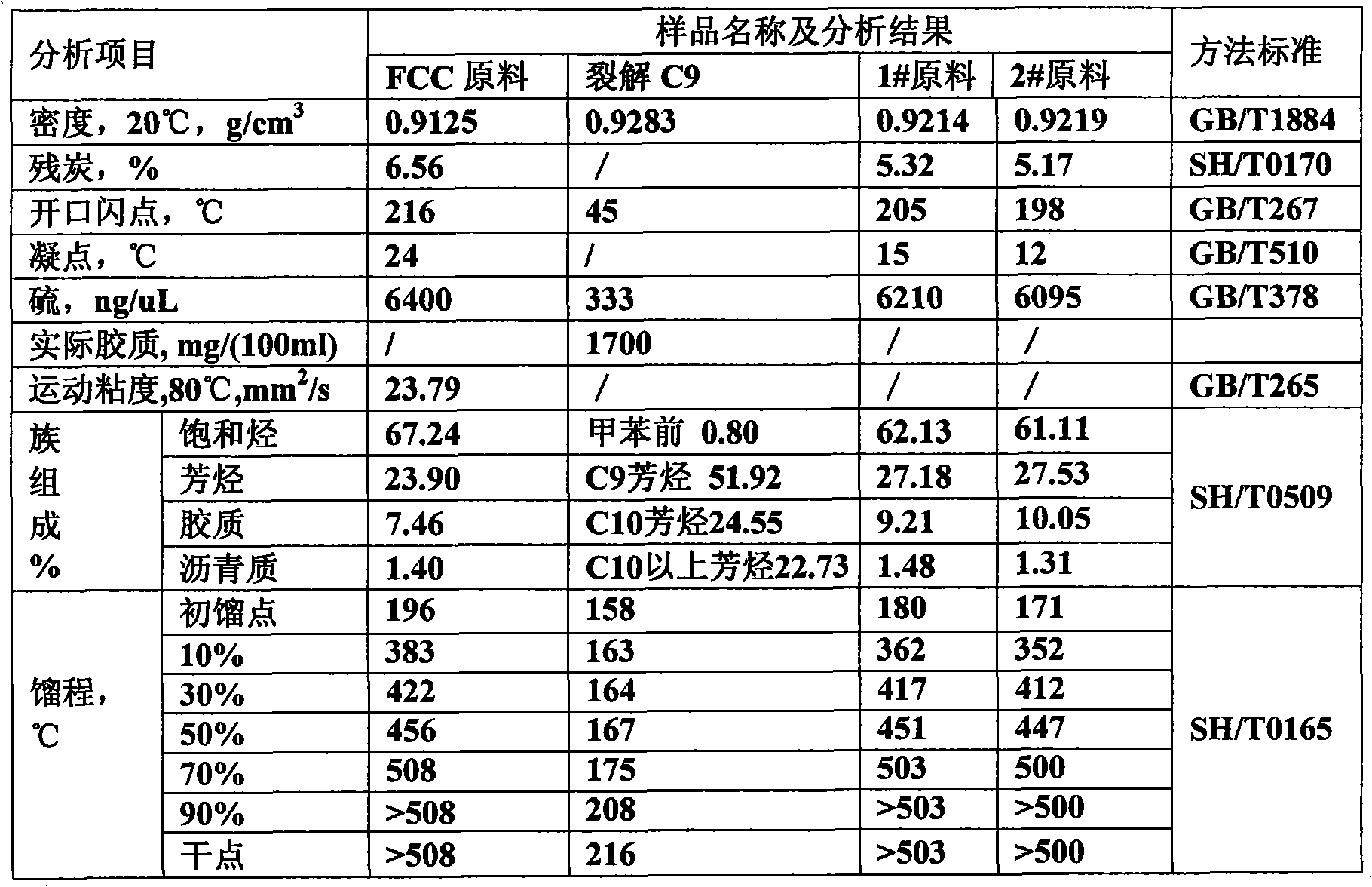

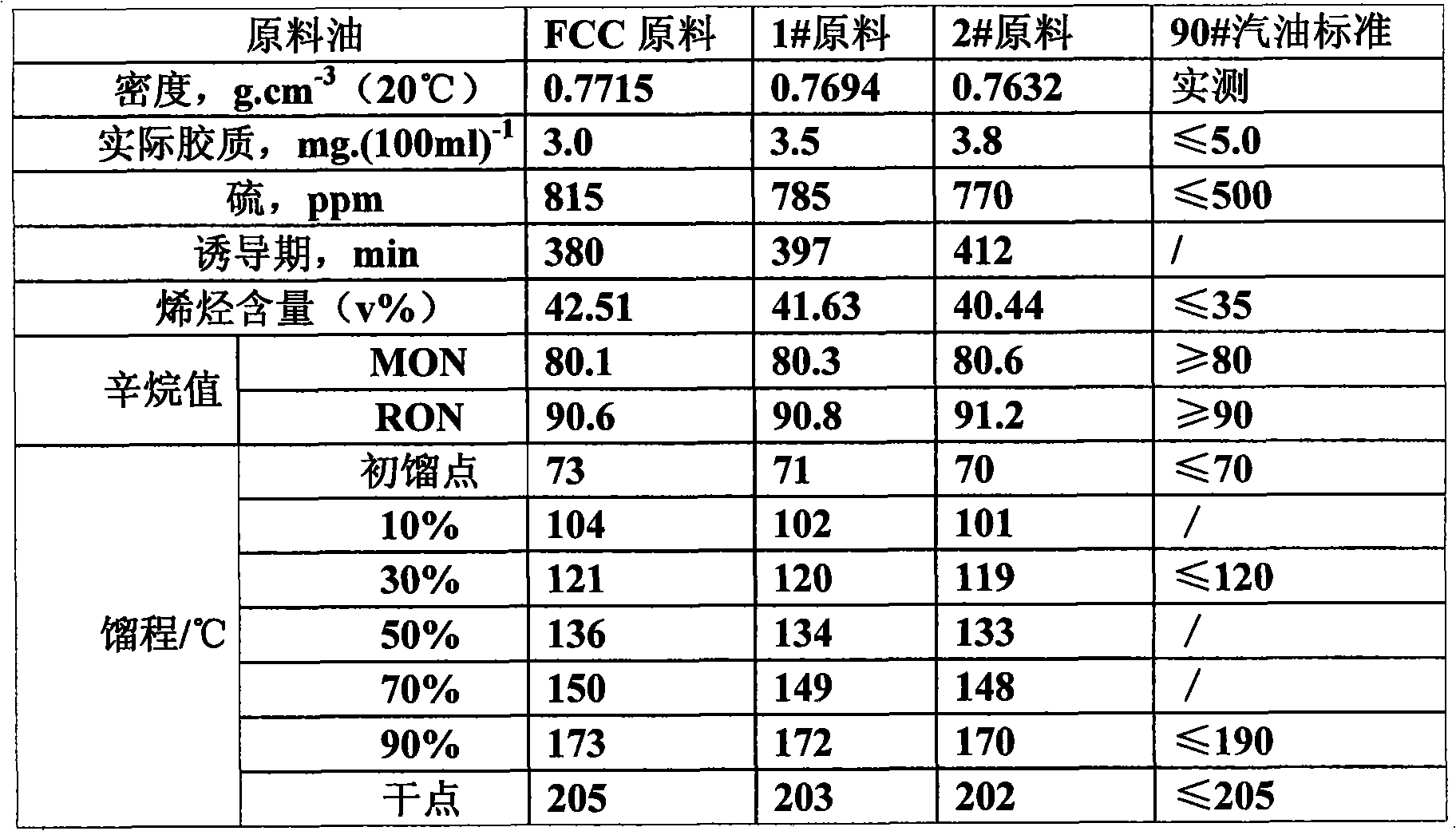

Method for utilizing pyrolysis C9 by performing catalytic reforming

InactiveCN101906314AHigh yieldExtended induction periodCatalytic crackingCatalytic reformingGasoline

The invention relates to a method for utilizing pyrolysis C9 by performing catalytic reforming. The method is mainly technically characterized in that: the pyrolysis C9 is taken as a catalysis raw material by doping or taken as a terminator of a catalytic device; the pyrolysis C9 can react under the pressure of between 0.1 and 0.8MPa and at the temperature of between 450 and 600 DEG C by using the conventional catalytic device; when the pyrolysis C9 is taken as the catalysis raw material by doping, the doping proportion of the pyrolysis C9 is between 2 and 15 weight percent and the pyrolysis C9 is mixed with the catalysis raw materials and fed from a crude oil inlet; and when the pyrolysis C9 is taken as the terminator, the doping proportion is between 2 and 10 weight percent and the pyrolysis C9 is fed from a terminator inlet at the upper middle end of a raising pipe. The catalytic reforming is performed on the pyrolysis C9, so that products (petrol and diesel oil) with high added value are obtained; meanwhile, the product distribution of the catalytic device can be improved, the yield, the overall liquid yield and the transformation ratio of light oil are increased to a certain extent, the yields of the petrol and the diesel oil can be increased and economic benefit is very remarkable.

Owner:CHINA PETROLEUM & CHEM CORP

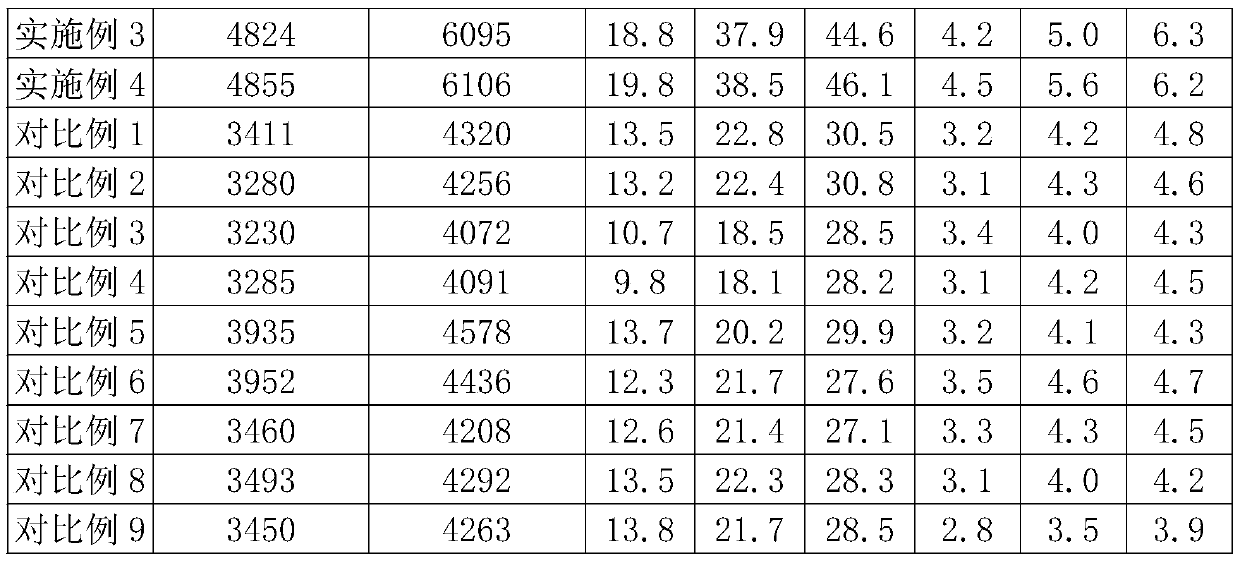

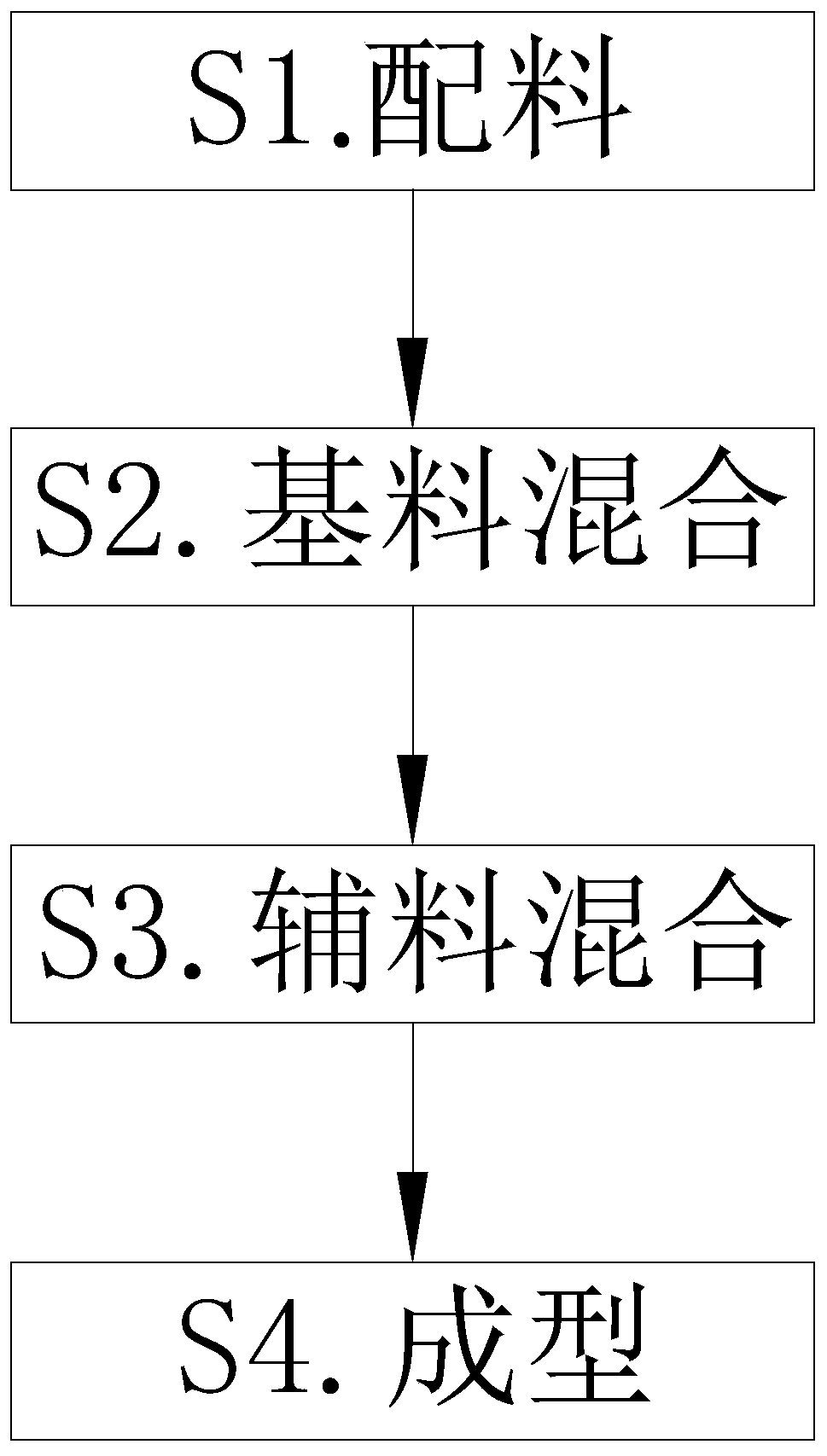

Magnesium phosphate cement repair mortar and preparation method thereof

ActiveCN110776303AExtended induction periodShorten the setting timeMagnesium phosphateMagnesium orthophosphate

The invention relates to magnesium phosphate cement repair mortar and a preparation method thereof. The magnesium phosphate cement repair mortar is prepared from the following components in parts by weight: 20-35 parts of potassium dihydrogen phosphate, 60-75 parts of magnesium oxide, 10-20 parts of fly ash, 10-15 parts of fine sand, 12-30 parts of water, 1-4 parts of zinc gluconate, 1-3 parts ofcopper gluconate, 1-2 parts of a retarder, 5-10 parts of recycled concrete, 4-8 parts of diatomite and 3-6 parts of metal ceramic micropowder. The preparation method for the magnesium phosphate cementrepair mortar specifically comprises the following steps: S1, proportioning the above components in parts by weight; S2, stirring potassium dihydrogen phosphate, magnesium oxide, fly ash and fine sand at a low speed; S3, adding water and the retarder into a base material, continuing to stir, sequentially adding the recycled concrete waste, zinc gluconate, copper gluconate, diatomite and metal ceramic micropowder, and performing stirring to prepare slurry; and S4, subjecting the slurry to pouring, vibrating and curing treatment for forming of the slurry. The method of the invention has the effect of delaying the setting time of the magnesium phosphate cement repair mortar.

Owner:北京建工新型建材有限责任公司

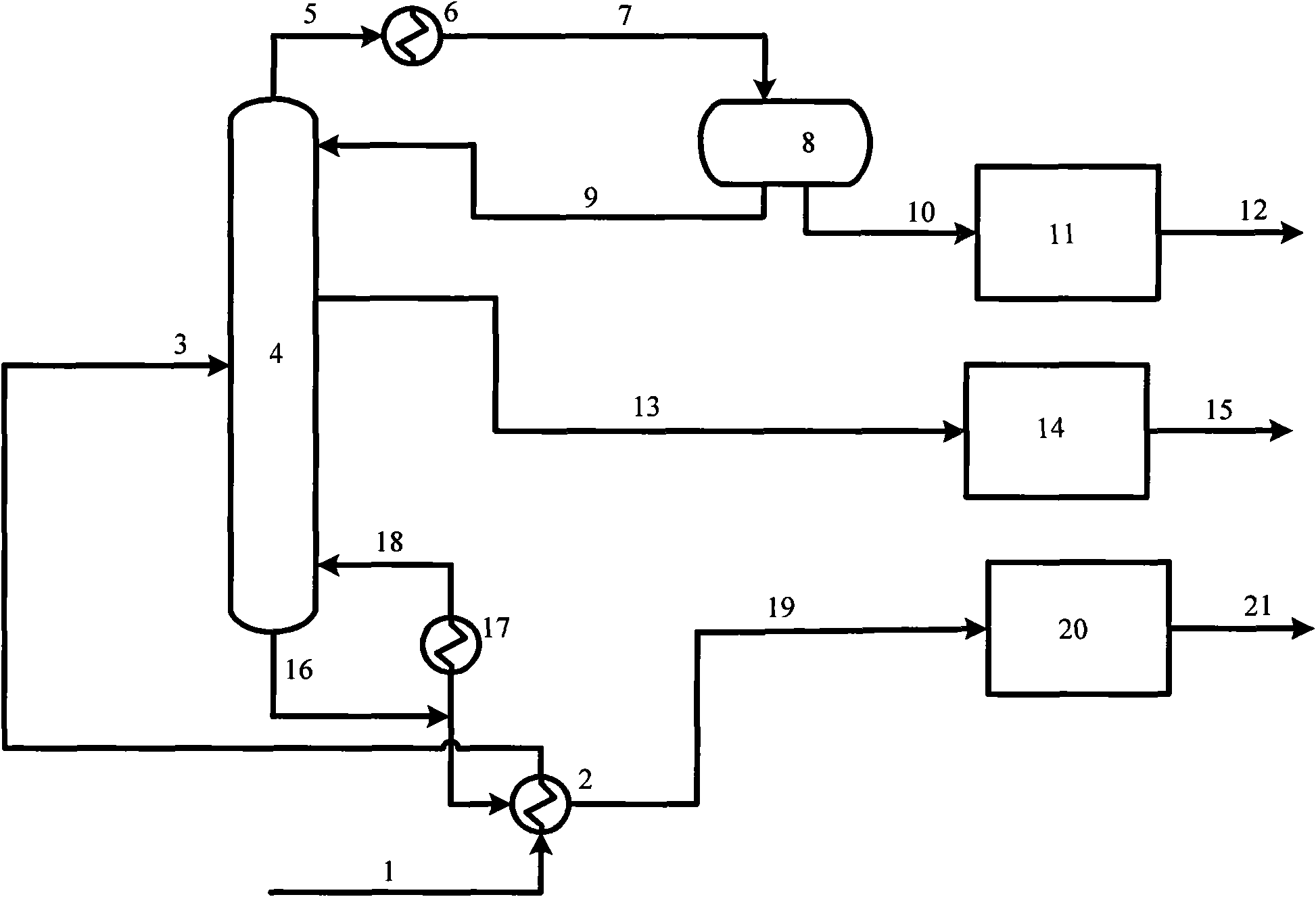

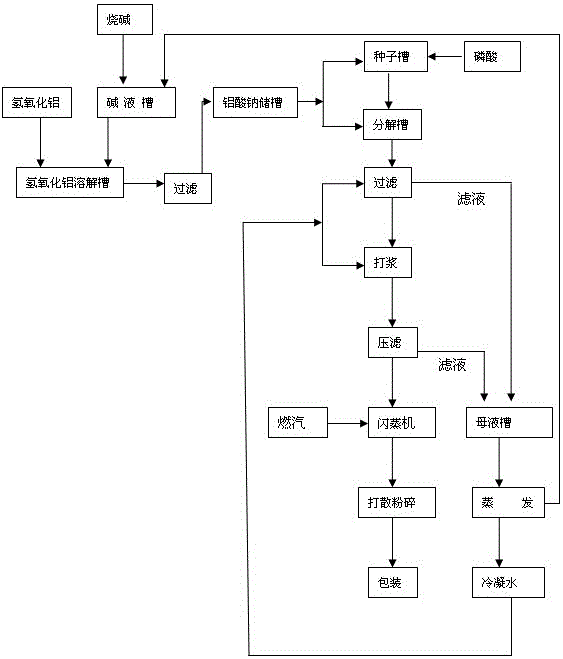

Gasoline processing method

ActiveCN102757817AExpand sourceMeet the requirements of the feedTreatment with hydrotreatment processesBenzeneLiquid product

A gasoline processing method includes: subjecting raw materials of full distillates to a fractionating tower to be fractioned into three fractions, and removing mercaptan sulfur in a light fraction by means of alkali extraction to obtain a liquid product I which is a gasoline blending component; processing an intermediate fraction through a first hydrogenation unit to obtain a liquid product II which is a qualified aromatics extraction raw material; and processing a heavy fraction through a second hydrogenation unit to obtain a liquid product III which is a gasoline blending component. By the gasoline processing method, a qualified aromatic hydrocarbon product and a qualified gasoline product can be obtained simultaneously, sources of the aromatic hydrocarbon product are widened, and compared with raw materials, the obtained gasoline product has the advantages that the induction period is greatly prolonged, sulfur content is greatly reduced, and aromatic hydrocarbon content, especially benzene content is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

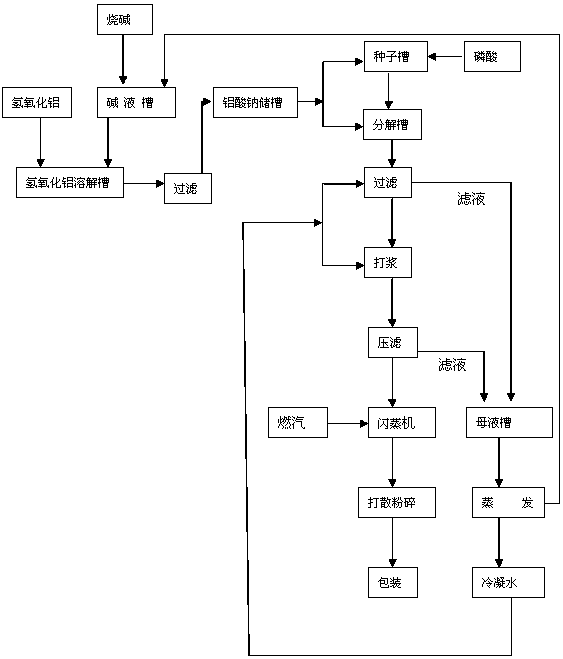

Method for preparing seed crystal by utilizing phosphoric acid and producing superfine aluminum hydroxide

ActiveCN106745126AUniform particle sizeImprove distributionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationGranularityPhosphoric acid

Owner:SHANDONG LUBEI ENTERPRISE GROUP +1

Method for improving gasoline stability

InactiveCN1542097AExtended induction periodImprove stabilityHydrocarbon oils refiningMaleopimaric acidGasoline

The method of raising gasoline stability features that gasoline is made to contact with one of the following reagents or their mixture under temperature higher than 60 deg.c. The said reagents include compound in the general expression of CH2=CHCOOR1 or R2CH=CHCOR3, maleic acid and maleic anhydride, where, R1 is C1-C3 alkyl group, R2 is H or C1-C7 alkyl group, and R3 is H or OH. The volume ratio between the reagent and gasoline is 1 to 10-10000. The said method can increase the induction period of gasoline material obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sound-insulation fireproof building material

ActiveCN111807866AIncreased hydration rateImprove setting timeSolid waste managementCeramicwareAggregate (composite)Fire prevention

The invention relates to the technical field of building materials, and in particular, relates to a sound-insulation fireproof building material comprising the following raw materials in parts by weight: 45-60 parts of composite cement, 30-35 parts of graded aggregate, 15-20 parts of a sound insulation component, 3-5 parts of a fireproof component, 1-2 parts of a water reducing agent, 0.5-1.8 parts of a thickening time control component, 2-4 parts of an expansion component, 0.1-0.2 part of a foaming agent, 0.2-0.4 part of a defoaming agent and 0.02-0.04 part of a water retaining agent, whereinthe thickening time control component consists of sodium sulfate, sodium gluconate and boric acid in a mass ratio of (2-4):(0.5-1):(0.6-0.8). The composite cement, the graded aggregate, the sound insulation component, the fireproof component, the water reducing agent, the thickening time control component, the expansion component, the foaming agent, the defoaming agent and the water retaining agent are reasonably proportioned, and all the raw materials are matched with one another, so that the sound-insulation fireproof building material has the advantages of fire prevention, sound insulation, high mechanical strength and short setting time, and has important significance for development of the concrete industry.

Owner:广东潮威建设工程有限公司

Scale inhibitor for S-Zorb device, preparation method and application thereof

ActiveCN108342221AExtended induction periodImprove heat transfer efficiencyTreatment apparatus corrosion/fouling inhibitionOrganic solventAntioxidant

The invention discloses a scale inhibitor for an SZorb device, a preparation method and application thereof. The scale inhibitor is prepared from the following raw materials in percent by weight: 1-10% of free-radical capturing agent, 5-40% of cleaning dispersant, 1-10% of antioxidant and 30-70% of organic solvent; the scale inhibitor does not contain metal ions. The preparation method comprises the following steps of: taking all the raw materials according to a set proportion, uniformly mixing and stirring under normal temperature and normal pressure to obtain the scale inhibitor. The scale inhibitor disclosed by the invention not only can inhibit coking and scaling, but also has dispersing and cleaning effects for formed cokes; the preparation method of the scale inhibitor is simple andeasy in implementation and low in cost; after the scale inhibitor is added into catalytically-cracked gasoline, no toxicity and harm are caused to the SZorb device and environment, the addition amountis low and the use cost is low.

Owner:金浦新材料股份有限公司

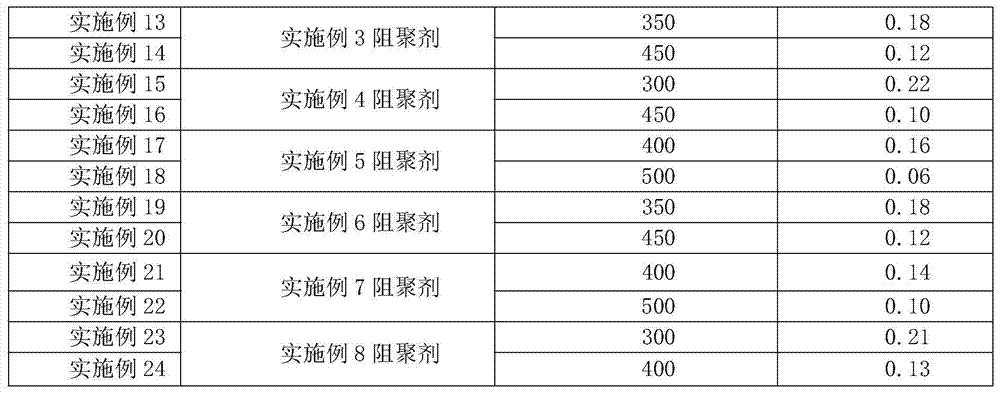

Styrene rectification polymerization inhibitor and preparation and application method thereof

InactiveCN106554245AExtended induction periodGood inhibition effectDistillation purification/separationHydrocarbonsTarChemistry

The invention belongs to the field of chemical production and relates to a styrene rectification polymerization inhibitor and a preparation and application method thereof, in particular to a compound polymerization inhibitor used for styrene rectification in an ethylbenzene dehydrogenation process. The polymerization inhibitor is formed by compounding bis(2,2,6,6-tetramethyl-4-piperidyl)sebate nitrogen oxygen free radicals, triphenylphosphine and sulfolane, the characteristics of all the components are ingeniously used, a synergistic effect is produced, and the polymerization inhibition efficiency is high; the solubility in an ethylbenzene / styrene system is high, and the polymerization inhibition effect is stable; production of styrene high polymers can be inhibited; the risk that a pipeline is blocked by tar is reduced; safe and smooth operation of a styrene device is ensured; and the economic benefits are increased.

Owner:CHINA PETROLEUM & CHEM CORP

Biodegradable agricultural mulching film modified material and preparation method thereof

ActiveCN114854215ALower surface energyImprove water resistanceClimate change adaptationPlant protective coveringsMicroorganismSoil science

The invention provides a biodegradable agricultural mulching film modified material and a preparation method thereof. Graft-modified PBAT resin is oxidized polyethlene wax graft-modified PBAT resin; the modified water-absorbent resin is water-absorbent resin particles for adsorbing the preservative. A hydrophobic polyethylene alkyl chain structure is introduced in a polyethylene wax grafting modification PBAT mode, and the polyethylene alkyl chain structure is easy to migrate to the surface of the material after film blowing, so that the surface energy of the material is reduced, and the water resistance of the material is improved. By introducing the water-absorbent resin, hydrolysis caused by direct contact of ester groups in the mulching film with water can be inhibited, and the water-absorbent resin slowly releases the preservative in a reverse osmosis manner, so that the degradation of microorganisms such as bacteria in soil on the degradable mulching film can be inhibited, and the problem of rapid loss in the use process due to direct addition of the preservative into the material is avoided; the induction period of the degradable mulching film is effectively prolonged.

Owner:WANHUA CHEMICAL (NINGBO) CO LTD

A kind of method that uses phosphoric acid to make crystal seed to produce superfine aluminum hydroxide

ActiveCN106745126BUniform particle sizeImprove distributionAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationGranularityPhosphoric acid

The invention discloses a method for preparing a seed crystal by utilizing phosphoric acid and producing superfine aluminum hydroxide. A semi-product, namely aluminum hydroxide, in a Bayer-process aluminum oxide process is used as a raw material to carry out alkali digestion; the seed crystal is prepared by utilizing the phosphoric acid, and a superfine aluminum hydroxide flame retardant product is produced. According to the method disclosed by the invention, the granularity of the product is uniform, the product is not agglomerated and a dispersant is not needed.

Owner:SHANDONG LUBEI ENTERPRISE GROUP +1

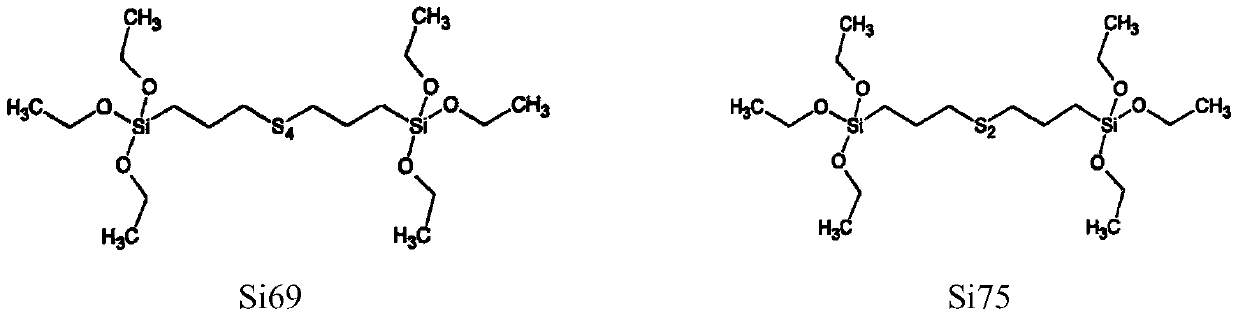

Benzothiazole sulfamino low-volatile sulfur-containing silane coupling agent and synthesis method thereof

ActiveCN111320782AInhibition formationReduce formationGroup 4/14 element organic compoundsPolymer scienceCoupling reagent

The invention relates to a sulfur-containing silane coupling agent and a synthesis method thereof, in particular to a benzothiazole sulfur-amino low-volatile sulfur-containing silane coupling agent and a synthesis method thereof. The problems that an existing sulfur-containing silane coupling agent discharges organic volatile gas and an organic solvent is used in the synthesis process are solved.The molecular formula of the sulfur-containing silane coupling agent is R2NH-C (R1O) 3 Si-R-S x -Y, wherein x is an integer from 1 to 10; when x is equal to 1, Y is H or-R-Si (OR1) 3C-NHR2; when x isgreater than or equal to 2, Y is-R-Si (OR1) 3C-NHR2; R is CH2, CH2CH2 or the like; r1 is CH2, CH2CH2 or the like; r2 is a preparation method which comprises the following steps: preparing a semi-finished product from 2-mercaptobenzothiazole, an amino trihydric alcohol aqueous solution and sodium hypochlorite, and reacting with sulfur-containing silane to obtain the sulfur-containing silane coupling agent. Volatile organic compounds in the rubber are less than 0.1%, and the rubber is suitable for natural rubber and synthetic rubber.

Owner:江西宏柏新材料股份有限公司

Method of preparing phosphate functional monomers in vinyl pyrrolidone medium and application

ActiveCN107880226AExtended induction periodSlow down the rate of hydrationPhosphorus organic compoundsFunctional monomerBoiling point

The invention discloses a method of preparing phosphate functional monomers in a vinyl pyrrolidone medium and application. Vinyl pyrrolidone is used as a reaction medium, after phosphorylation reaction, the final product can be obtained without separation, the phosphate functional monomers serve as third monomers for synthesizing a polycarboxylate superplasticizer, the medium vinyl pyrrolidone canparticipate in polymerization reaction, the step of recovering toxic micromolecular organic solvent with low boiling point is omitted, environment pollution is avoided, and the problem that dispersive capacity and slumps retaining capacity of an existing polycarboxylate superplasticizer contradict is solved. The preparing method of the polycarboxylate superplasticizer which is high in dispersivecapacity, slumps retaining capacity and cement adaptability is provided.

Owner:GUIZHOU TIEJIANHENGFA NEW MATERIAL TECH CO LTD

An Anti-interference High Voltage Metallized Polypropylene Film Capacitor

ActiveCN105869884BImprove securityExtended range of movementThin/thick film capacitorFixed capacitor electrodesRubber ringHeat conducting

The invention discloses an anti-interference high-voltage metalized polypropylene film capacitor, which comprises a cover board (1), a housing (2) and a core body (3), wherein an annular bump (4) is formed in the inner wall of an opening of the cover board (1); an annular groove (5) is formed in the upper part of the housing (2); the annular bump (4) is arranged in the annular groove (5) and can longitudinally move in the annular groove (5); an elastic seal ring (6) is arranged between the inner wall of the lower part of the cover board (1) and the outer wall of the upper part of the housing (2); an elastic rubber ring (19) is fixedly connected between the annular bump (4) and the bottom part of the annular groove (5); a buffer layer (13) is arranged at the inner wall of the housing (2); a core body (3) is arranged in the housing (2); a positioning sleeve (14) is arranged at the bottom part of the core body (3); an elastic washer (17) registered in the middle part of the core body (3); and insulated heat-conducting oil (18) is sealed between the housing (2) and the core body (3). The capacitor is high in breakdown voltage, anti-interference, safe, stable and long in service lifetime.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Styrene water-soluble synergic polymerization inhibitor and preparation method thereof

ActiveCN106928010AGood compatibilityLow viscosityDistillation purification/separationHydrocarbonsSolubilityDistillation

The invention provides a styrene water-soluble synergic polymerization inhibitor. The inhibitor is composed of a solvent and effective components A and B. The solvent is a high-boiling-point alcoholic solution with the dilution effect and high solubility. The effective component A is one of 4-hydroxy-2,2,6,6-tetramethylpiperidinooxy and 4-oxo-2,2,6,6-tetramethylpiperidinooxy compounds; the effective component B is a succinimide compound. The mass content of the solvent is 60-65%, the mass content of the effective components is 35-40%, and the mass ratio of the component A to the component B in the effective components is (4-6):1. The styrene water-soluble synergic polymerization inhibitor is good in inhibition effect, small in kinematic viscosity, low in toxicity and convenient to store and convey, and has the good solubility in the styrene distillation process, the rectification yield of styrene can be effectively increased, and the inhibitor is better suitable for the industrial production requirement.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com