Regeneration method of butene oxidative dehydrogenation catalyst

A technology of oxidative dehydrogenation and catalyst, which is applied in the direction of catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. It can solve the problem of shortened service life, long induction period, and decreased activity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 1.5-liter adiabatic two-stage reactor, the iron-based spinel oxidative dehydrogenation catalyst was used, the conversion rate was 78.5%, and the selectivity was 92.6%. After the catalyst was used for 4000 hours, the conversion rate dropped to 73.2%, and the selectivity 90.4%.

[0025] At 440°C, oxygen / water vapor volume ratio = 0.03, water vapor volume space velocity 1200h -1 Carry out charcoal burning under the same conditions, and after 8 hours, the bed temperature will no longer drop; then control the reaction temperature to 380°C, the oxygen / water vapor volume ratio to 0.03, and the water vapor volume space velocity to 800h -1 , dimethyl disulfide concentration of 20ppm, and system pressure of 0.1MPa for 60 hours. The specific treatment conditions are shown in Table 1.

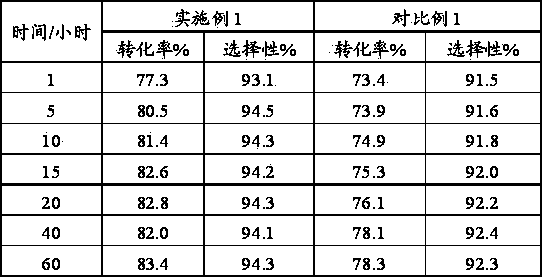

[0026] Stop the feeding of dimethyl disulfide, wait until the system reaches the reaction conditions, the butene feed starts to react, at 380°C, the volume space velocity of butene is 400 hour...

Embodiment 2

[0029] The catalyst after deactivation is the same as [Example 1], at 380°C, oxygen / water vapor volume ratio=0.04, water vapor volume space velocity 600h -1 Carry out charcoal burning under the same conditions, and after 6 hours, the bed temperature will no longer drop; then control the reaction temperature to 340°C, the oxygen / water vapor volume ratio to 0.05, and the water vapor volume space velocity to 1600h -1 , Methyl ethyl disulfide concentration 10ppm, system pressure 0.05MPa condition and process 70 hours, all the other are the same as [embodiment 1].

[0030]

Embodiment 3

[0032] The catalyst after deactivation is the same as [Example 1], at 380°C, oxygen / water vapor volume ratio=0.05, water vapor volume space velocity 800h -1 Carry out charcoal burning under the same conditions, and after 5 hours, the bed temperature will no longer drop; then control the reaction temperature to 420°C, the oxygen / water vapor volume ratio to 0.03, and the water vapor volume space velocity to 1600h -1 , dimethyl disulfide concentration 50ppm, system pressure 0.15MPa under the conditions of 72 hours, all the other with [embodiment 1].

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com