Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

125results about How to "Shorten the induction period" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogen storage material hydrolysis and hydrogen releasing system taking monodispersed or supported phosphorus-containing metal compound as catalyst

ActiveCN108525685ASave raw materialsHigh catalytic efficiencyPhysical/chemical process catalystsHydrogen productionHydrolysisAqueous solution

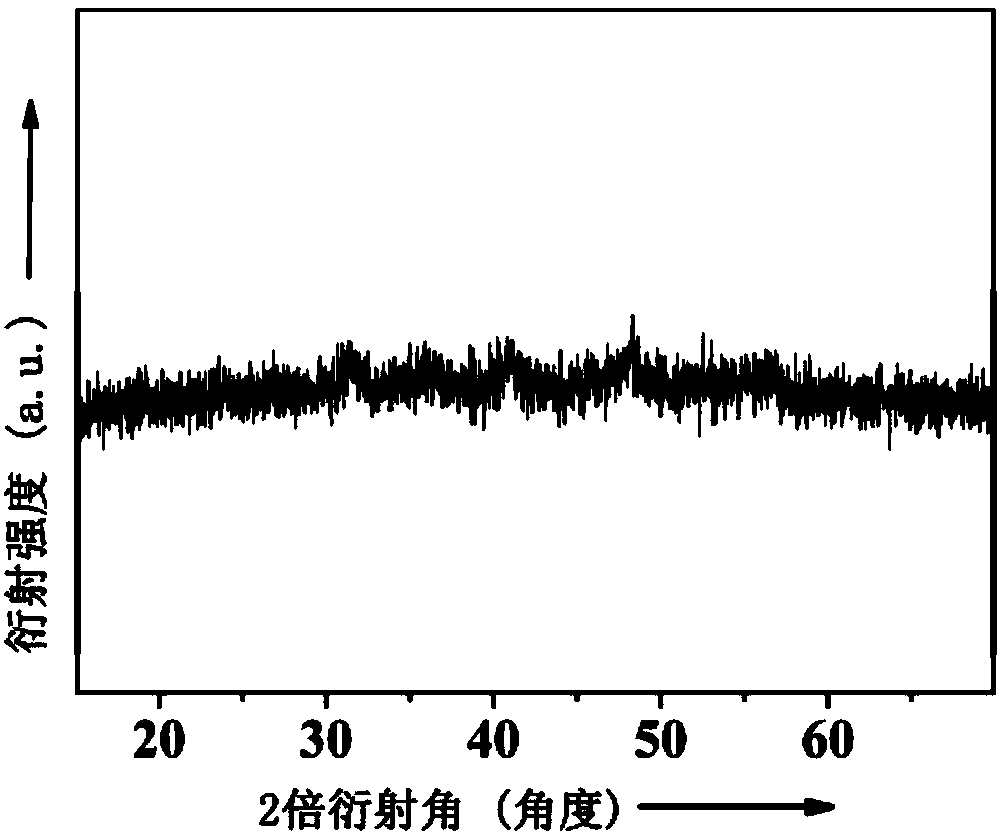

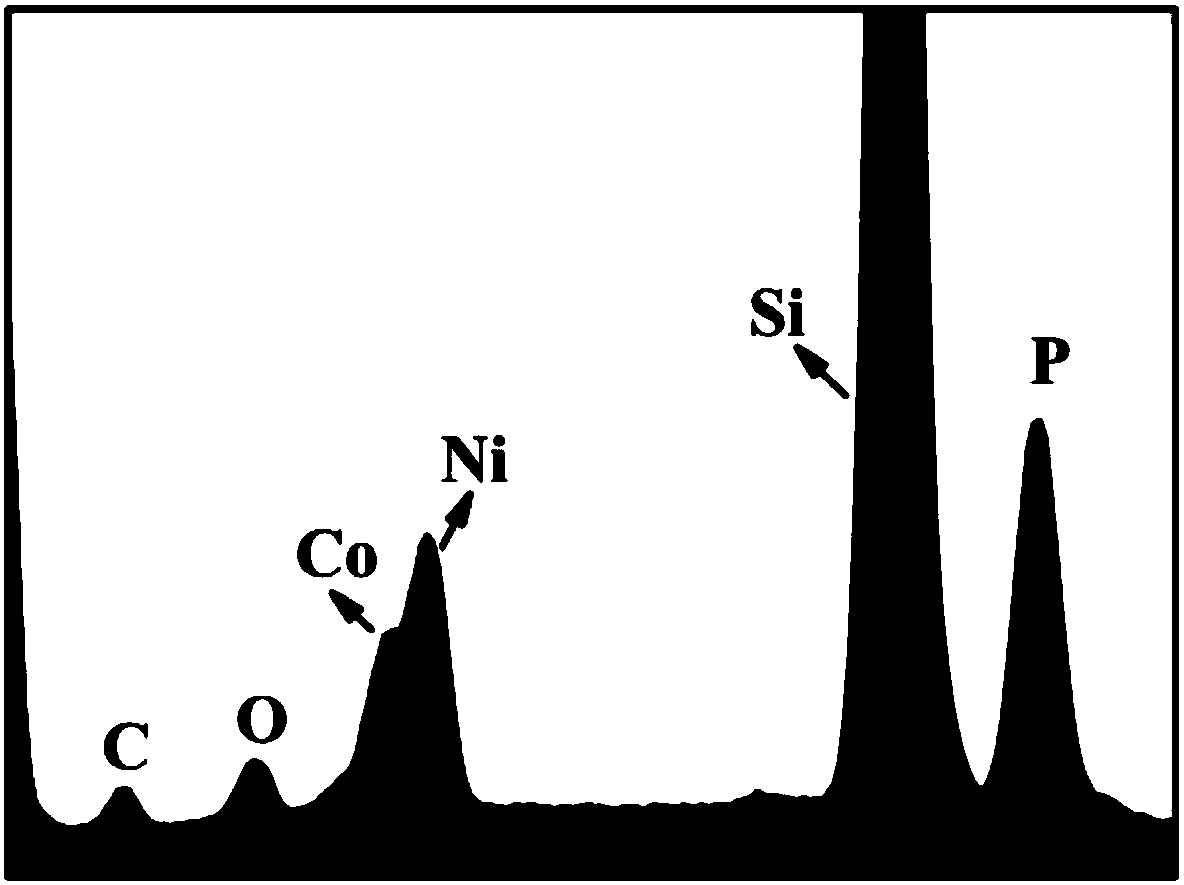

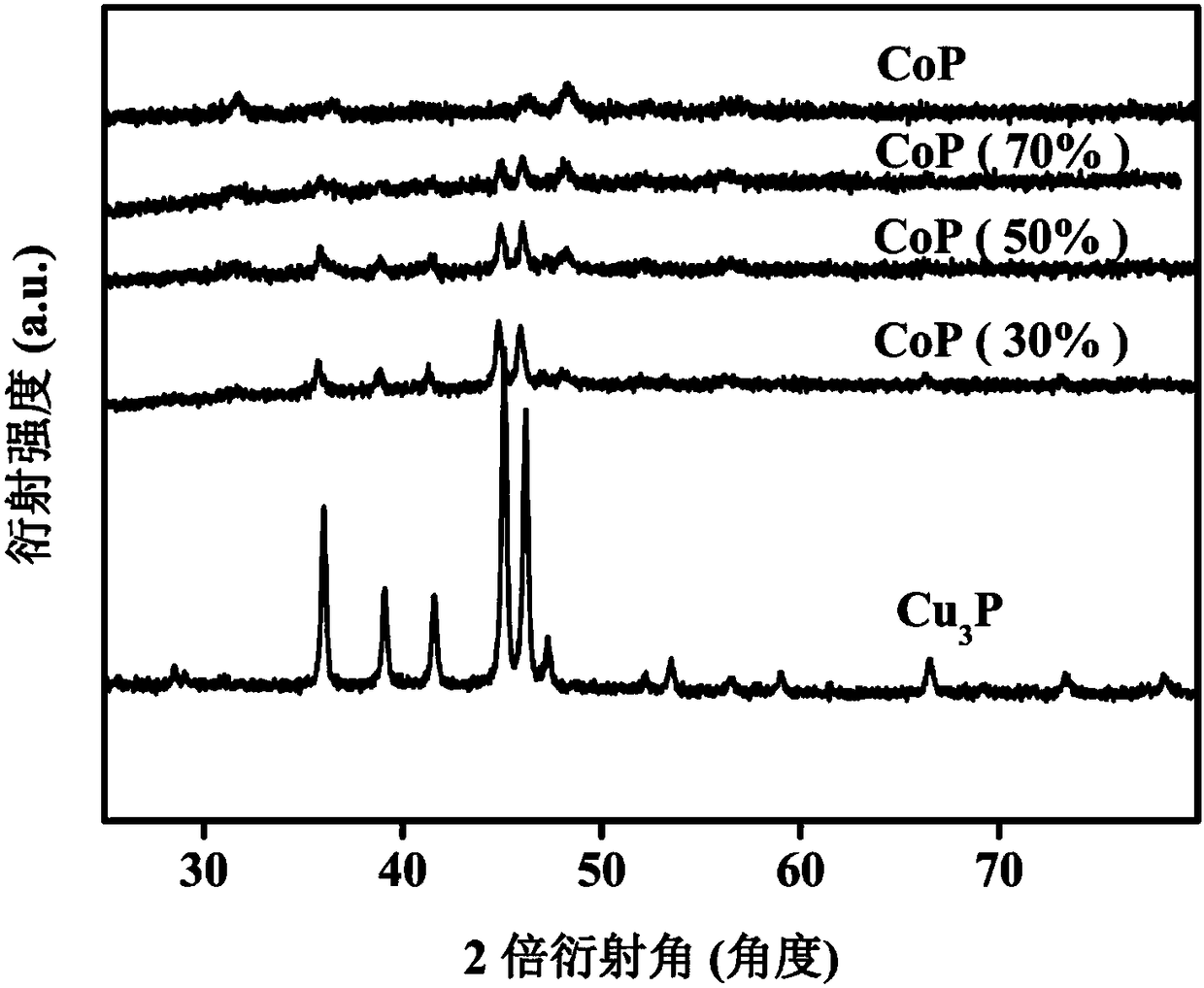

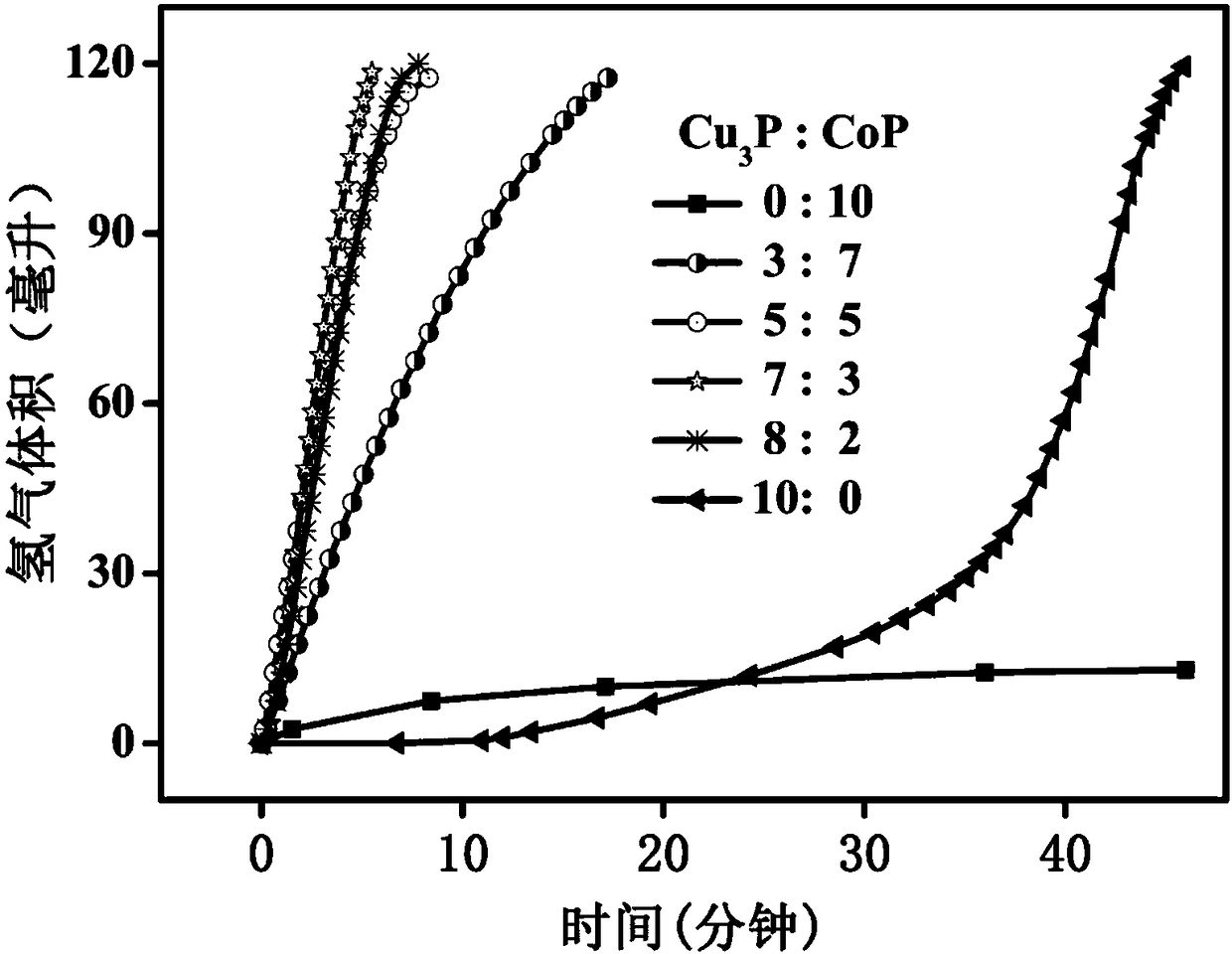

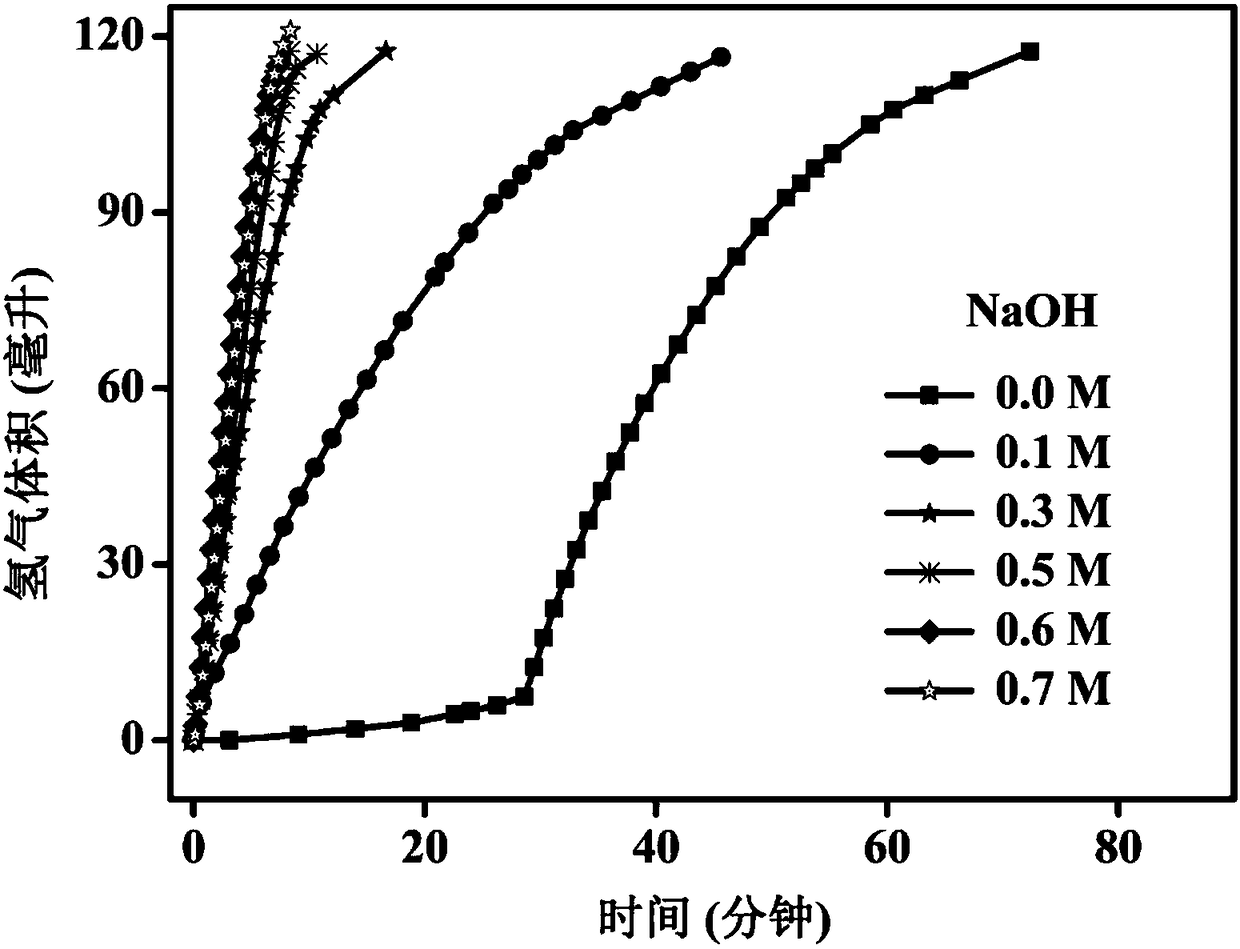

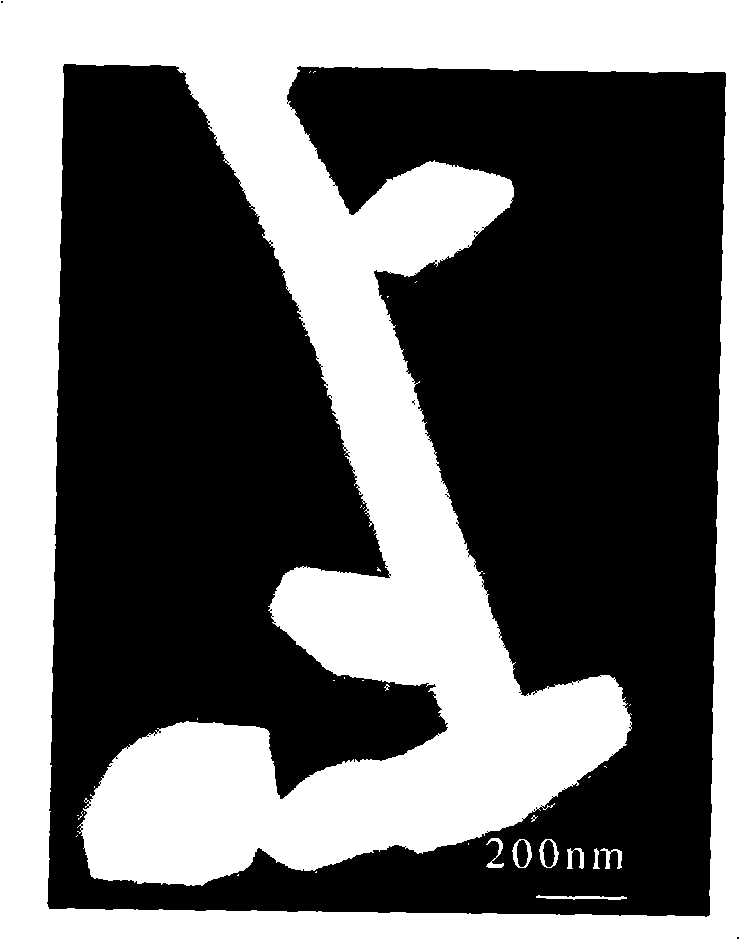

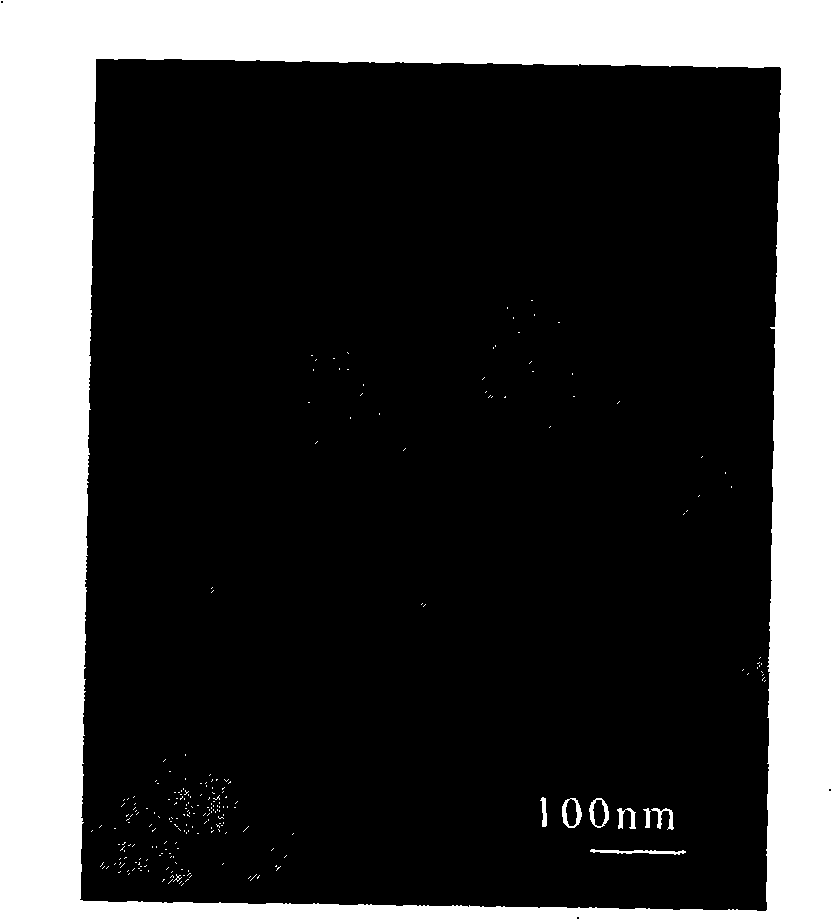

The invention discloses a hydrogen storage material hydrolysis and hydrogen releasing system taking a monodispersed or supported phosphorus-containing metal compound as a catalyst. The system comprises a hydrogen storage material and water, and further comprises a catalyst, wherein the catalyst is one or multiple of a monodispersed multi-metal phosphide, a supported multi-metal phosphide, a monodispersed single-metal and multi-non-metal phosphorus-containing compound, a supported single-metal and multi-non-metal phosphorus-containing compound, a monodispersed multi-metal multi-non-metal phosphorus-containing compound and a supported multi-metal multi-non-metal phosphorus-containing compound. Alkali is added into an aqueous solution of the monodispersed or supported phosphorus-containing metal to improve the catalytic rate of the catalyst and shorten the induction period. The catalysis efficiency of the supported catalyst is higher than that of the monodispersed catalyst. The system provides a batch of efficient novel catalysts for hydrolysis and hydrogen releasing of the hydrogen storage material, and provides a method for increasing the hydrolysis rate of the hydrogen storage material under the catalysis of the phosphorus-containing metal compound.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Hydrogen storage material decomposing and hydrogen release system

ActiveCN109225284ASave raw materialsIncrease catalytic rateReversible hydrogen uptakeChemical recyclingOrganic solventSolvent

The invention discloses a hydrogen storage material decomposing and hydrogen release system. The system comprises a hydrogen storage material, a catalyst and a solvent, wherein the catalyst is a mixture of two or more of metal compounds mixed in any proportion. The invention provides the cheap and stable catalytic hydrogen storage material decomposing and hydrogen release system, and the raw materials for catalyst preparation are cheap. The catalyst has stable properties and high hydrogen release efficiency when applied to catalysis of a hydrogen storage material; the catalytic hydrogen release system is heterogeneous catalytic reaction, and the catalyst is convenient to recycle; if the catalytic hydrogen release system is conducted in an organic solvent, the catalytic reaction can be conducted at a temperature of 273 K or lower; in the catalytic hydrogen release system, when the hydrogen storage material is ammonia borane and methanol is used as a solvent, ammonia borane can be obtained again from NH4B(OCH3)4 obtained after alcoholysis under certain conditions.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Abrasive grain CeO2 for chemical and mechanical buffing and method for preparing same

ActiveCN101284952AReduce surface roughnessImprove flatnessPigmenting treatmentSemiconductor/solid-state device manufacturingCrystal systemInorganic salts

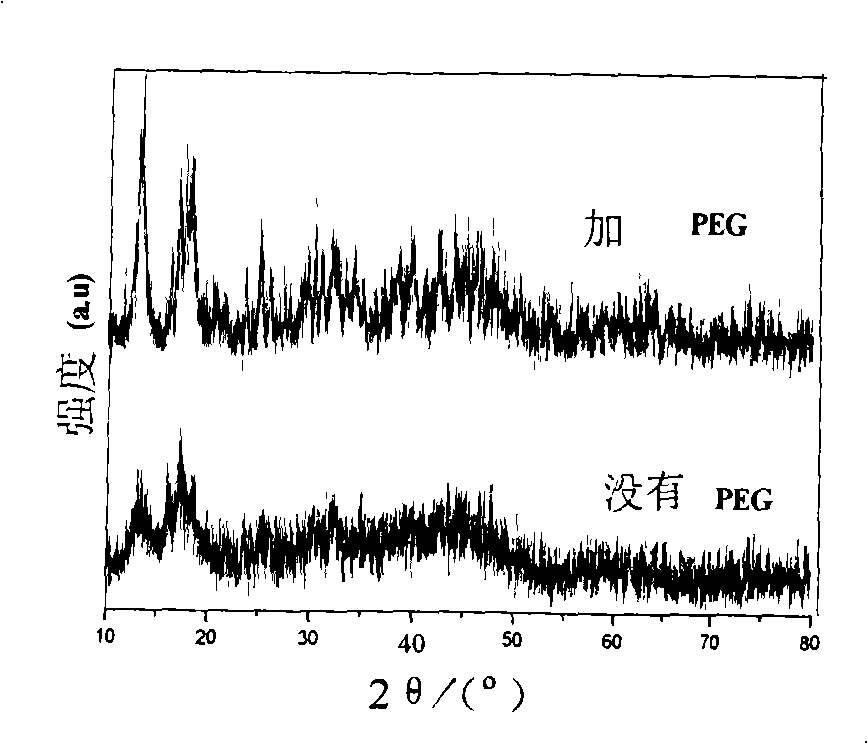

The invention relates to a chemical mechanical polishing abrasive particle CeO2 and a method for preparing the same, belonging to the rare earth powder material chemical preparation technical field. The invention is to prepare the CMP abrasive particle by utilization of cerous inorganic salt solution and homogeneous precipitation agent. The method comprises the following steps that: the cerous inorganic salt and the precipitation agent are prepared into solution with certain proportion; the solution is uniformly mixed through ultrasonic vibration; deposits are generated after the solution is heated to a certain temperature; serum is kept stand, aged, filtered and calcined, and then the CeO2 abrasive particle is prepared. The method also accelerates the nucleation rate through addition of surface active agent so as to reduce the reaction temperature, and simultaneously the nodulizing degree of the abrasive particle obtained is also good. The method prepares the CMP abrasive particle, wherein, the CMP abrasive particle belongs to the single-phase cubic crystal system; the space group is O<5>H-FM3M; the dispersibility is good; the grain fineness distribution is uniform; the shape is similar to a sphere; and the specific surface area BET is more than 0 and less than 50m<2> / g.

Owner:GRIREM ADVANCED MATERIALS CO LTD

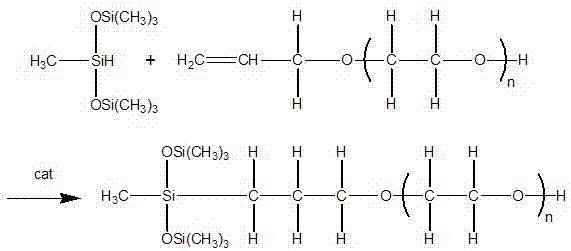

Preparation method of polyether modified siloxane

InactiveCN102225947AHigh activityImprove the mixing effectSilicon organic compoundsTransportation and packagingHydrogenOrganic solvent

The invention discloses a synthesis of organosilicon surfactant (polyether modified siloxane), comprising a solvent-free reaction of terminal allyl polyoxyethylene ether (molecular weight: 456-500) with heptamethyl trisiloxane by using chloroplatinic acid (speier catalyst) as catalyst. The catalyst used in the invention has high reactive activity for catalyzing organosilicon, and active hydrogen has high conversion rate, the use of benzene organic solvent is prevented, so that the preparation process is nontoxic and no pollution. The prepared polyether modified siloxane is clear and transparent, and has good wetability and spreadability.

Owner:南通德益化工有限公司

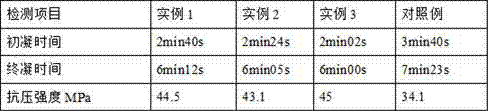

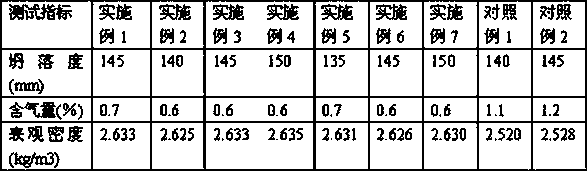

Green alkali-free liquid concrete setting accelerator and preparation method thereof

The invention relates to a green alkali-free liquid concrete setting accelerator and a preparation method thereof, and belongs to the technical field of concrete processing. According to the method, aluminum sulphate, calcium hydroxide, organic acid and deionized water are taken and are charged into a three-opening flask; stirring is performed under the condition of constant-temperature water bath; setting accelerator mother liquid is obtained; sodium fluoroaluminate is taken and is added into the deionized water; heating and stirring are performed; then, organic alcohol amine is added; continuous stirring is performed; then, the setting accelerator mother liquid is dripped; after the dripping is completed, ethylene diamine tetraacetic acid is added; heat insulation stirring is performed;after the materials are cooled to the room temperature, stabilizing agents are added; stirring is performed; the green alkali-free liquid concrete setting accelerator is obtained. The setting accelerator provided by the invention has the advantages of no alkali, non-toxicity, no smell and no corrosion; the environment is protected in the construction process; almost no harm is caused on the body health of construction personnel and ecological environment in the spraying process; the production process is simple; the preparation is easy; the storage is easy; the stability in the storage processis high.

Owner:常州琨瑶纺织品有限公司

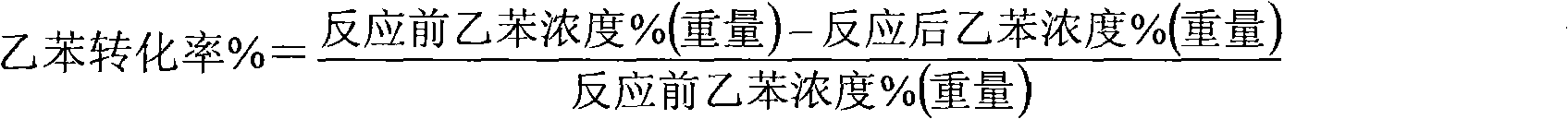

Method for preparing styrene catalyst by ethyl benzene dehydrogenation

ActiveCN102039204AHigh activityHigh initial activityCatalyst activation/preparationHydrocarbonsCeriumDehydrogenation

The invention relates to a method for preparing a styrene catalyst by ethyl benzene dehydrogenation, which mainly solves the problems of low initial activity and long induction period of the catalyst in the prior art. The method comprises the following steps of: mixing a required amount of cerium source, a required amount of iron source, potassium source, molybdenum source or tungsten source and mixture thereof, alkaline earth metal oxide and pore forming agent uniformly, and molding, drying and roasting to obtain a catalyst precursor I; and carrying the rest cerium source on the catalyst precursor I by adopting a dipping method, and drying and roasting to obtain the required catalyst. According to the technical scheme, the problems are well solved, and the method can be used for industrial production of preparing the styrene by ethyl benzene dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing low-unsaturation-degree polyether polylol

The invention relates to the preparation of a kind of low unsaturation polyether polyols. It's mainly used to solve the problem in previous technology that it has long catalyst inductive period and the concentration of catalyst in initiator is high, which is that it has a high catalyst cost in the preparation of unsaturation polyether polyols. The invention excellently solves the said problem through adopting catalyst components containing double metal cyanide (DMC) mixture, C4 - C10 organic mellow with tertiary alcohol structure, adding bronsted acid, and adopting the technology project of inert gas frothing to degasificate. So it can be used in the industrial production of low unsaturation polyether polyols.

Owner:SINOPEC SHANGHAI GAOQIAO PETROCHEM CORP +1

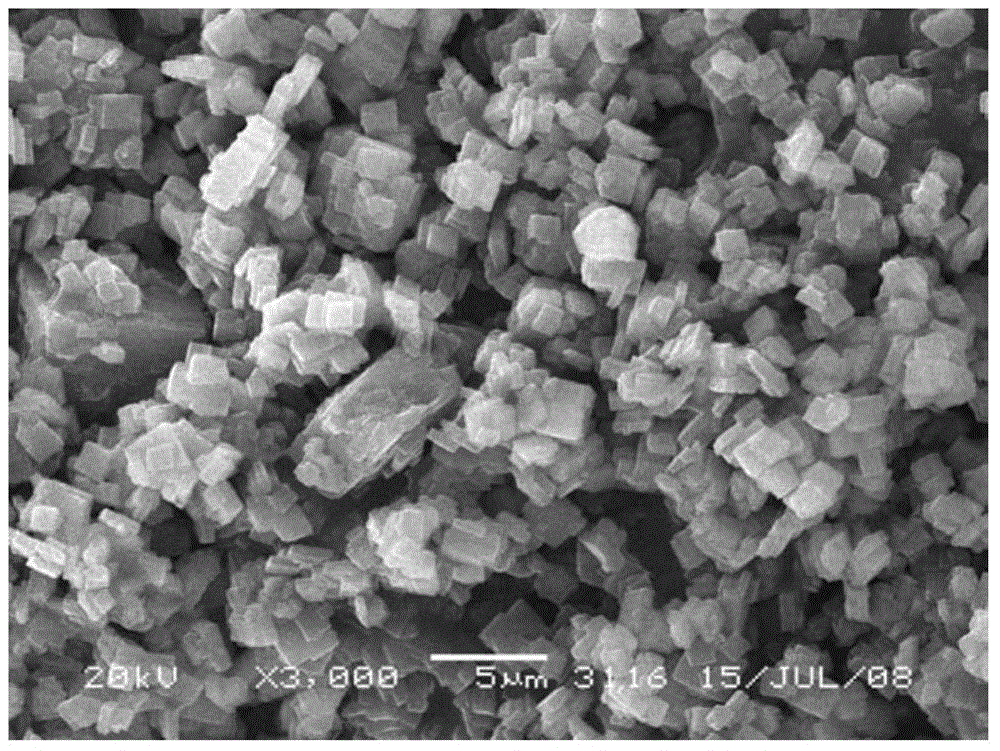

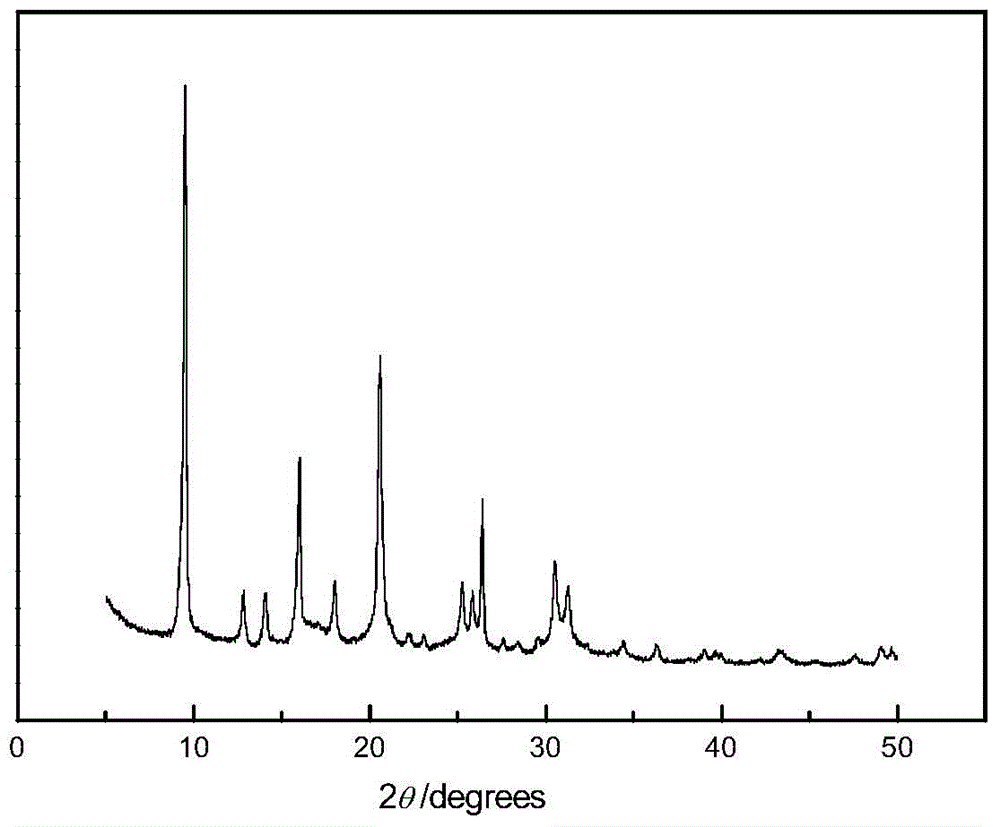

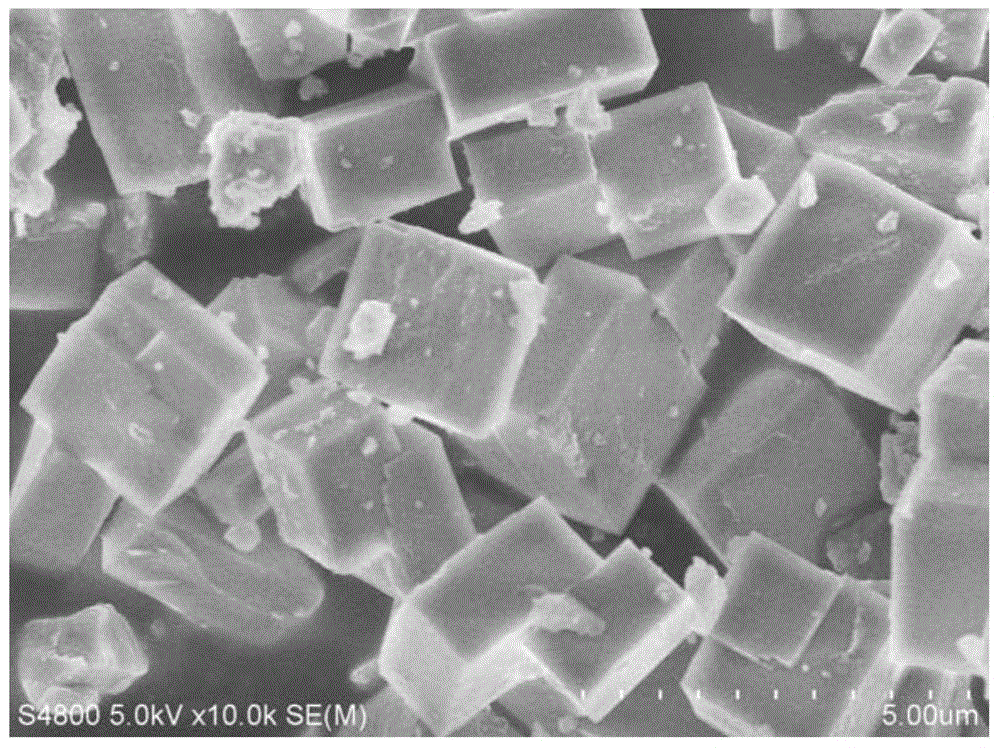

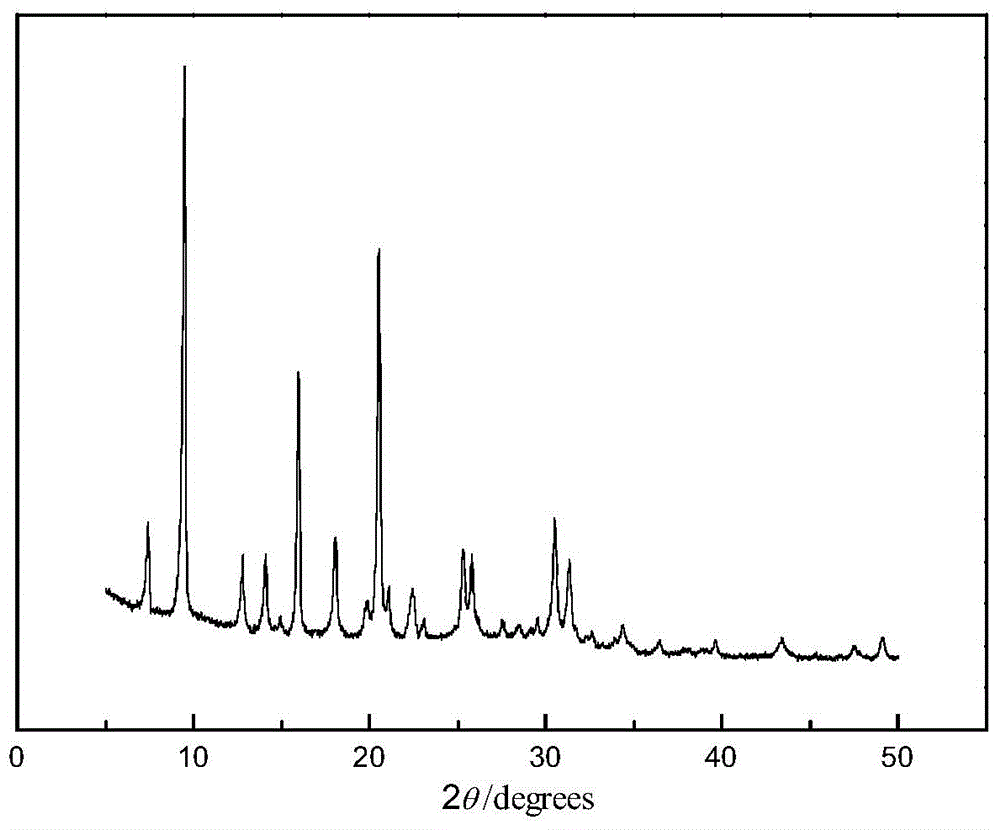

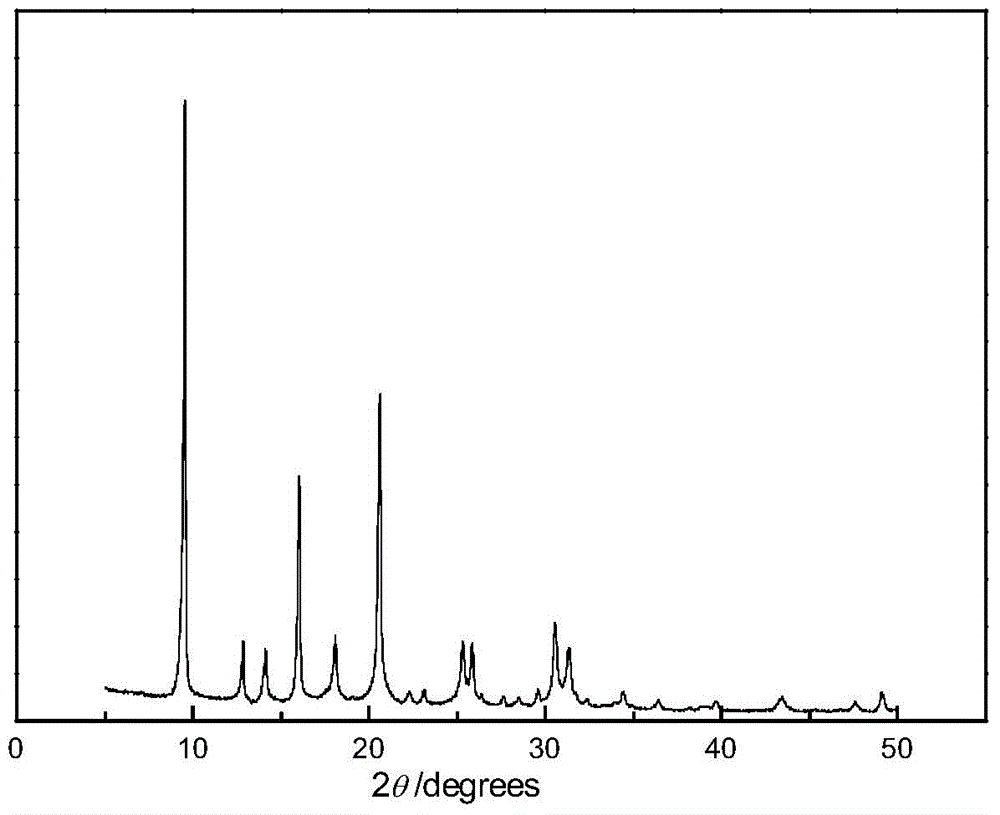

Preparation method of SAPO-34 molecular sieve

ActiveCN104556091APromote generationShorten the induction periodMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveSolid content

The invention discloses a preparation method of a SAPO-34 molecular sieve, which is characterized by comprising the following steps: (1) uniformly mixing a phosphorus source and an aluminum source according to the mol ratio of (0.6-1.2)P2O5:Al2O3:(20-60)H2O, and drying to obtain phosphorus aluminum dry glue A with the solid content of not lower than 60%; (2) uniformly contacting and mixing the phosphorus aluminum dry glue A with a template and a silicon source to obtain a mixture B, wherein the addition amount of the template agent is 1-2.5 mol on the basis of 1 mol of Al2O3 in the phosphorus aluminum dry glue A, and the addition amount of the silicon source is 0.1-1 mol on the basis of SiO2; and (3) putting the mixture B in a closed reaction kettle, sectionally crystallizing under autogenous pressure, and recovering the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

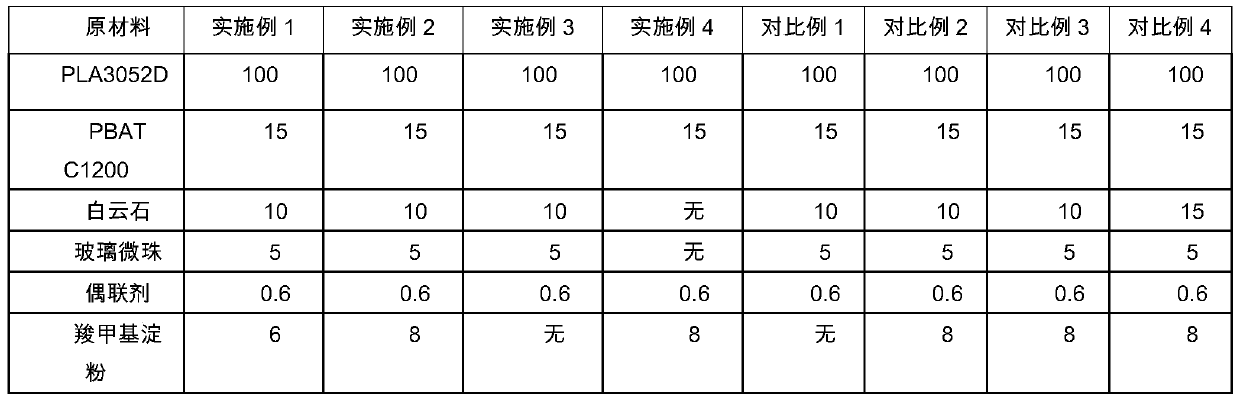

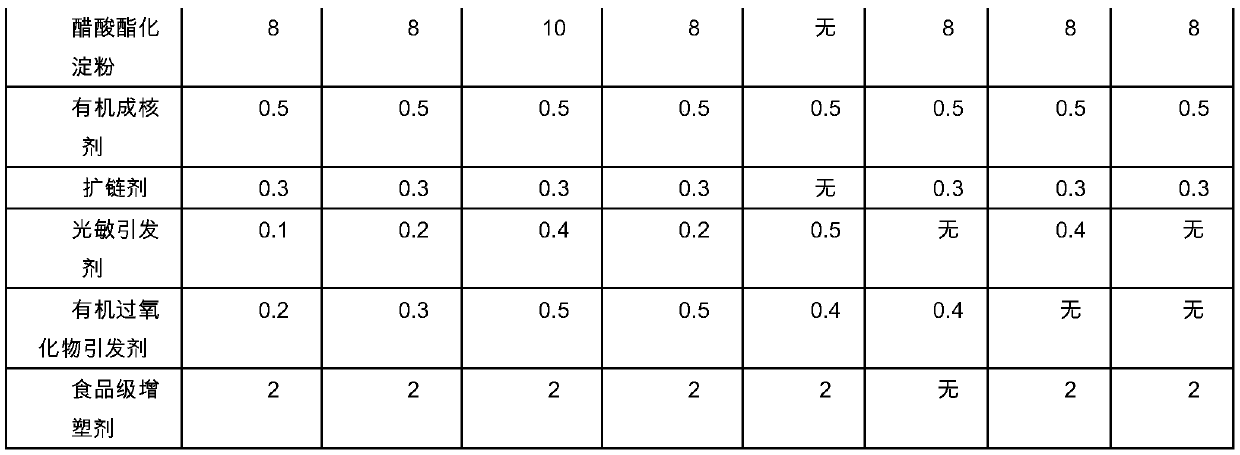

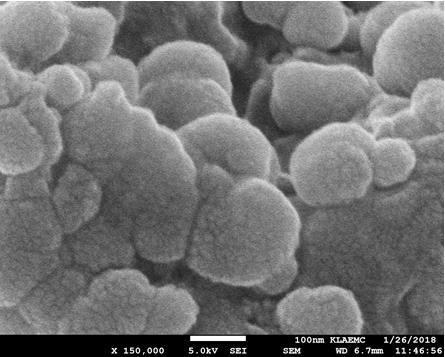

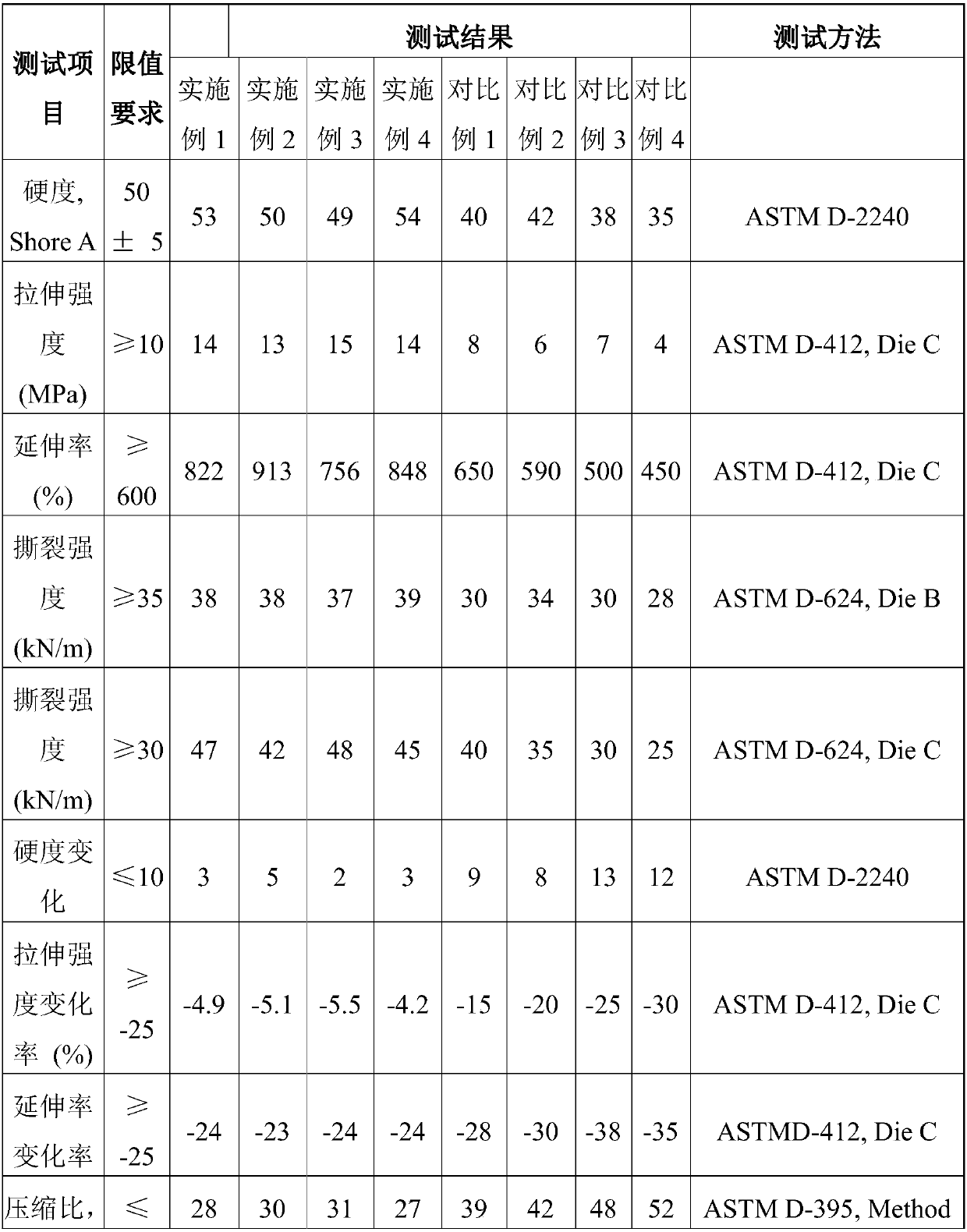

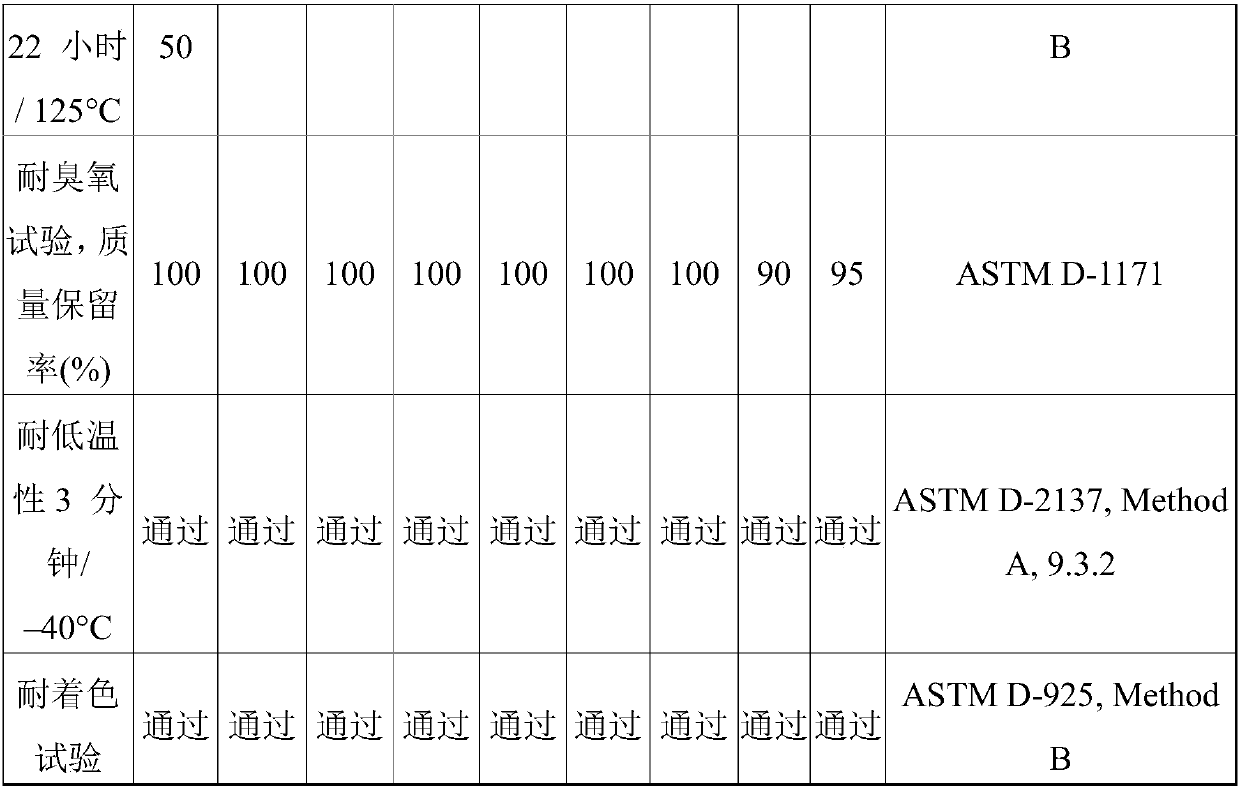

Heat-resistant polylactic acid composite material with short degradation cycle and preparation method of composite material

InactiveCN110128806AAchieve controlled degradationGood compatibilityFlexible coversWrappersOxygenHydrolysis

The invention discloses a polylactic acid (PLA) composite material with a high degradation speed and a preparation method of the composite material. The composite material provided by the invention isprepared by adopting polylactic acid resin, PBAT resin, an inorganic filler, modified starch, an organic nucleating agent, a coupling agent, a chain extender, a compound photosensitive initiator, a thermal oxygen degradation initiator and a food-grade plasticizer, the heat resistance of the polylactic acid material is improved, and the use range of polylactic acid products is expanded; thermal degradation, photodegradation and hydrolysis speeds of wasted PLA products are increased, harsh conditions that require industrial composting are avoided, and the degradation speed faster than that of ordinary polylactic acid can be realized under natural conditions; the auxiliary agents used in the method are all food-grade raw materials and can be applied to food packaging; and the preparation method of the polylactic acid composite material with the high degradation speed provided by the invention employs simple equipment and is low in investment.

Owner:中山市正合色彩资源有限公司

Preparation method and use method of core-shell catalyst for carbon dioxide hydrogenation

ActiveCN109569695ASimple manufacturing methodHigh catalytic activityCatalyst activation/preparationCarbon monoxideEtchingZinc alloys

The invention provides a preparation method and a use method of a core-shell catalyst for carbon dioxide hydrogenation. The method includes the steps: firstly, synthesizing a copper-oxide-containing and zinc-oxide-containing mixed metal oxide precursor with catalytic activity; secondly, preparing a copper nano-particle composite material coated by MOFs of ZIF-8 in a solid phase etching manner; performing procedure heating roasting to obtain a copper-zinc alloy core-shell catalyst coated by nitrogen-doped carbon materials. The method is characterized in that a MOFs material ZIF-8 is prepared bya solid-phase etching method without solvents, carbon material shell layer containing a lot of pyridine nitrogen is acquired in a high-temperature calcination manner, a copper zinc alloy core is acquired, a novel preparation technique of a pyridine nitrogen-doped carbon material and a copper zinc alloy is developed, the core-shell catalyst is applied to carbon monoxide reaction prepared by carbondioxide hydrogenation, the core-shell catalyst has excellent catalytic activity, and catalytic effects of the copper zinc alloy are greatly facilitated in the presence of a lot of pyridine nitrogen.

Owner:NANKAI UNIV

Process for producing polyether polyols with low degree of unsaturation

The invention relates to a process for producing polyether polyols with low degree of unsaturation, wherein the catalyst composition comprises bimetallic cyanide mixture, C4-C10 organic alcohol having a tertiary alcohol structure and selected from silicon acid esters or aliphatic esters, aromatic diester and organic esters of their mixtures, the catalyst can be applied into the industrial production of polyether polyols.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low smell EPDM for automobile wire harness and preparation method thereof

The invention relates to a low smell EPDM (ethylene propylene diene monomer) for an automobile wire harness and a preparation method thereof. The EPDM is prepared by the method of: (1) firstly addingEPDM into an open mill, then adding zinc oxide, stearic acid and an antioxidant RD in order, mixing the substances evenly, then further adding carbon black and paraffin oil, mixing the substances evenly, finally adding an environment-friendly accelerator and sulfur, and conducting mixing to obtain mixed compound; (2) placing the mixed compound in a die and conducting primary vulcanization to obtain a section of vulcanized EPDM; and (3) taking out the section of vulcanized EPDM for secondary vulcanization, thus obtaining the target product EPDM. Compared with the prior art, the low smell EPDM provided by the invention meets the characteristics of rubber itself in the aspects of strength, compression set and the like, at the same time also can meet the requirements of low emission and low smell, also takes into account the low pollution characteristic, and is especially suitable for making automobile parts and the like.

Owner:DELPHI PACKARD ELECTRIC SYST

Nano-based early strength type compound polycarboxylate water reducer and preparation method thereof

The invention provides a nano-based early strength type compound polycarboxylate water reducer. The nano-based early strength type compound polycarboxylate water reducer is prepared from following raw materials in percentage by mass through heating and complexing: 18%-25% of an early strength type polycarboxylic superplasticizer, 2%-5% of a nano-based early strength agent, 0.05%-0.1% of a workability regulator, 1%-3% of a reactive activator, 0.5%-1.5% of a complexing stabilizer, 0.04%-0.1% of a defoaming agent and the balance of water. The invention further provides a preparation method of the nano-based early strength type compound polycarboxylate water reducer. The preparation method is simple, low in raw material cost and widely sourced, the prepared nano-based early strength type compound polycarboxylate water reducer is good in stability, avoids layering, is free of chlorine or sulfate radicals, contains no formaldehyde and has high early strength, air content of concrete is low, water-reducing rate is high, workability and construction performance are good, and effects are remarkable.

Owner:唐山市筑业新材料有限公司

Non-steam autoclaved PHC tubular pile concrete

Owner:浙江沪嘉住宅工业股份有限公司

Method for shortening induction time during catalysis of ring opening polymerization of epoxide in discontinuous method

ActiveCN103360595AReduce dosageShorten the induction periodPolymer scienceRing-opening polymerization

The invention discloses a method for shortening induction time during the catalysis of ring opening polymerization of an epoxide in a discontinuous method. The method comprises the following steps of: adding a certain amount of PO (Propylene Oxide) or a mixture of PO and EO (Ethylene Oxide) in the presence of a DMC (Dimethyl Carbonate) catalyst by taking low-molecular weight polyether glycol as an initiator when the polyether glycol is synthesized through the DMC catalyst by adopting the discontinuous method; inducing and activating, and then continuously introducing surplus PO or EO / PO. The method is characterized in that a part of the low-molecular weight polyether glycol initiator is previously added in order to add the surplus part of the low-molecular weight polyether glycol initiator after induction is completed at relatively high catalyst concentration. The method disclosed by the invention can be used for realizing that a user is easier to implement the application of the DMC catalyst by being used for actual production and preventing the helpless measure of catalyst supplement from being often adopted during former adverse reaction condition, thereby reducing the excessive worry of a polyether manufacturer on the raw material quality.

Owner:HUAIAN BUD POLYURETHANE SCI & TECH CO LTD

Method for producing food-grade copper sulfate by smelting byproduct-copper sulfate

The invention discloses a method for producing food-grade copper sulfate by a smelting byproduct-copper sulfate. The method comprises the following steps of: dissolving the industrial smelting byproduct-copper sulfate in ultrapure water, heating to 70-80 DEG C, slowly dropwise adding acid for adjusting the pH value of a solution to be 1.00, stirring for dissolving, and slowly adding an oxidant; mixing polymeric ferric sulfate and basic cupric carbonate according to a mass ratio of 1:(2.0-5.0) to prepare a deposition complexing agent, slowly adding the deposition complexing agent which is 0.6-2.8% of the weight of the solution into the insulation solution, using basic cupric carbonate to adjust the pH value of the solution to be 3.0-4.0, slowly adding an adsorbing agent which is 1.0-2.5% of the weight of the solution, stirring and insulating for 6-8 hours, cooling to room temperature, and standing for a day; and carrying out vacuum filtration on the solution, filtering by using a microporous filter membrane of 0.2-0.3mu m, carrying out ultrasonic-assisted rotary evaporation and concentration on filter liquor for crystallization, and carrying out spray-drying to obtain the food-grade copper sulfate.

Owner:JIANGXI UNIV OF SCI & TECH

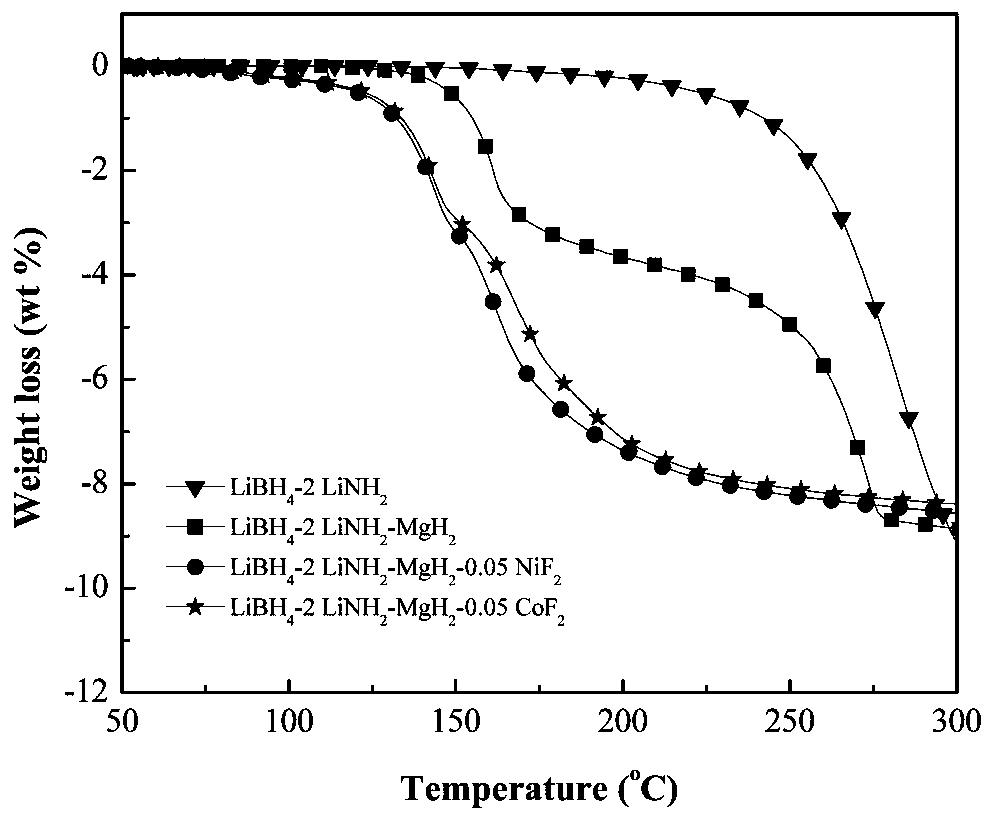

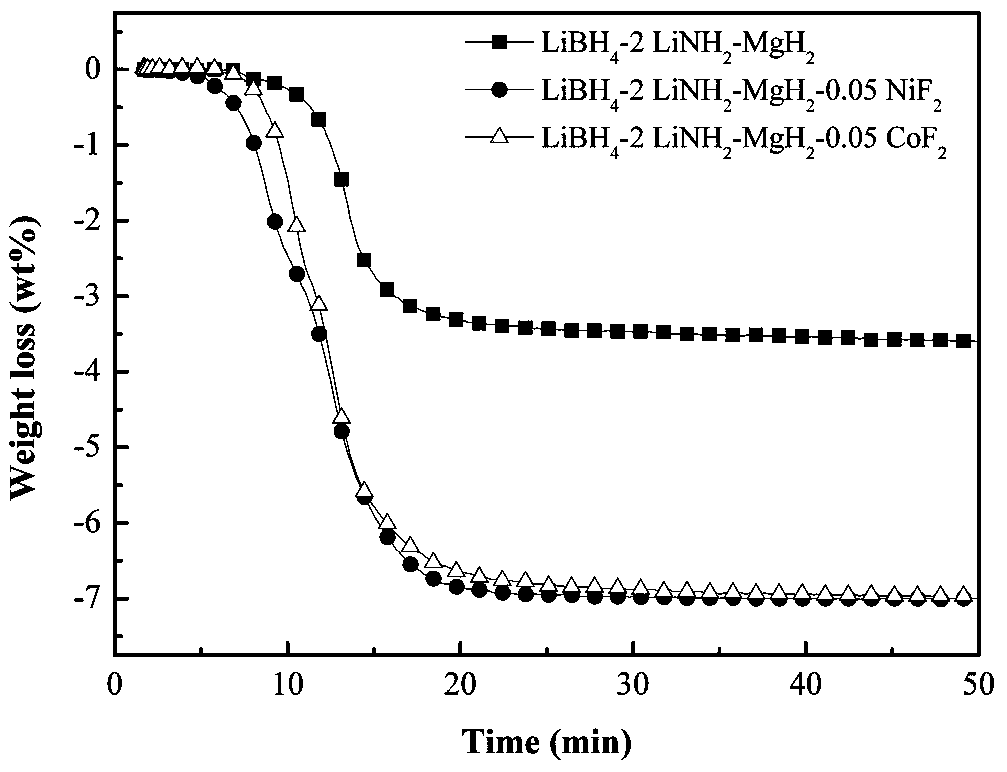

Preparation method of transition metal fluoride-doped composite hydrogen storage material, and application thereof in hydrogen storage material

ActiveCN107934913ALow hydrogen release temperatureShorten the induction periodReversible hydrogen uptakeSynthesis methodsReaction rate

The invention discloses a transition metal fluoride-doped composite hydrogen storage material. The material is prepared through mixing and mechanically ball-milling LiBH4, LiNH2, MgH2 and transition metal fluoride. The initial hydrogen desorption temperature of the material is 90-100 DEG C, the second-step hydrogen desorption temperature is about 150 DEG C, hydrogen desorption is mainly completedat 180-200 DEG C, and the composite hydrogen storage desorbs 6.5-7.0 wt% of hydrogen when heated to 200 DEG C. A preparation method of the material comprises the following steps: 1, weighing raw materials; and 2, carrying out a ball-milling process to prepare the composite hydrogen storage material. The composite hydrogen storage material has the following advantages: 1, the hydrogen desorption temperature is low, and the amount of hydrogen desorption heat is large; 2, the hydrogen desorption quantity is large; 3, the induction period in a second-step hydrogen desorption process used as the speed control step in the hydrogen desorption process is greatly shortened, the second-step hydrogen desorption temperature is reduced, the hydrogen desorption processes in two steps are coordinated, the hydrogen desorption reaction rate is fast, and the dehydrogenation kinetics performance is good; and 4, the cost of raw materials is low, and the synthesis method has a simple process. The preparation method has a certain application prospect in the field of hydrogen storage materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Preparation method of low-silicon SAPO-34 molecular sieve

ActiveCN104556142ALow depolymerization rateConcentration controllableMolecular sieve catalystsHydrocarbon from oxygen organic compoundsMolecular sieveSolid content

The invention discloses a preparation method of a low-silicon SAPO-34 molecular sieve, which is characterized by comprising the following steps: (1) uniformly mixing a silicon source, a phosphorus source and an aluminum source according to the mol ratio of (0.7-2)P2O5:(0.01-0.2)SiO2:Al2O3:(20-100)H2O, and drying to obtain silicon phosphorus aluminum dry glue with the solid content of not lower than 60%; (2) uniformly contacting and mixing the silicon phosphorus aluminum dry glue with a template and a silicon source to obtain a mixture, wherein the addition amount of the template is 1-2.5 mol on the basis of 1 mol of Al2O3 in the silicon phosphorus aluminum dry glue; and (3) putting the mixture in a closed reaction kettle, sectionally crystallizing under autogenous pressure, and recovering the product.

Owner:CHINA PETROLEUM & CHEM CORP +1

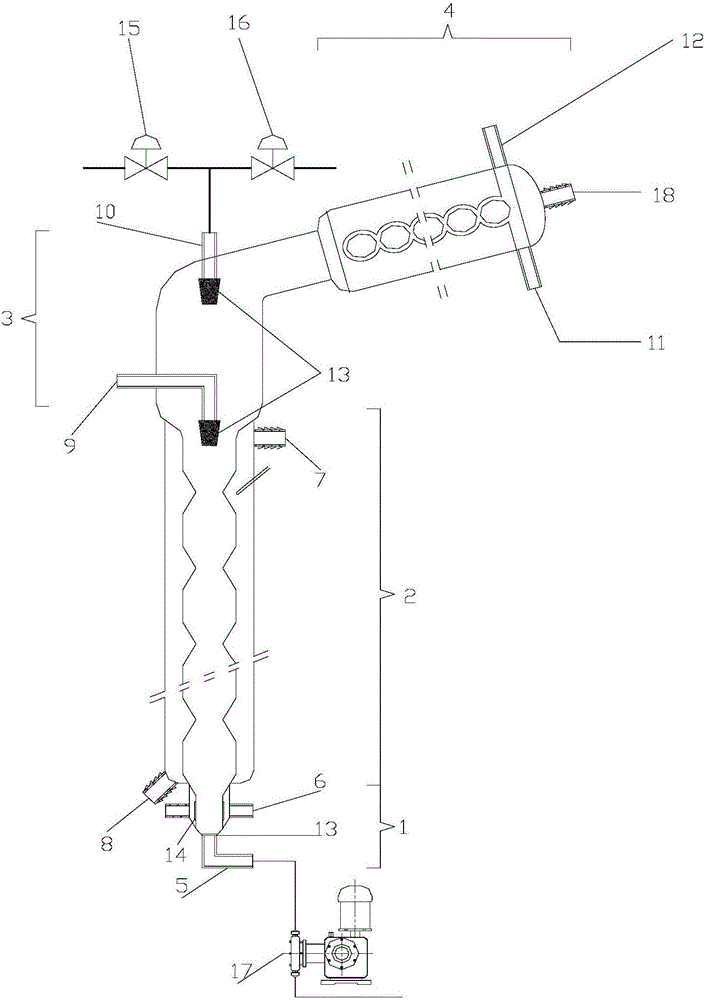

Oscillatory flow reactor used for preparing cumene hydroperoxide (CHP) in catalytic oxidation of cumene and method for preparing cumene hydroperoxide in catalytic oxidation of cumene

ActiveCN106475020AIncrease in sizeReduce sizeOrganic compound preparationCatalytic liquid-gas reactionReaction temperatureCatalytic oxidation

The invention relates to an oscillatory flow reactor used for preparing cumene hydroperoxide (CHP) in catalytic oxidation of cumene and a method for preparing CHP in catalytic oxidation of the cumene. The oscillatory flow reactor comprises a feed distribution section, a reaction section, a gas-liquid separation section and a condensation section; the feed distribution section comprises gas inlets, a gas distributor, a liquid inlet and a liquid-solid separator, and the liquid-solid separator is connected with an oscillation pump; the main body of the reaction section comprises a corrugated reaction tube with multiple sections which are in sectoral arc connection to form a concave-convex corrugated shape integrally, a heat tracing layer is arranged on the outer side of the corrugated reaction tube, and heat tracing medium enters from a heat tracing liquid inlet and flows out from a heat tracing liquid outlet; each of the upper, middle and lower section of the main body of the reaction section is provided with a temperature measuring point; the gas-liquid separation section is provided with a discharge hole with the liquid-solid separator, a safe injection hole and an electromagnetic valve and an electrically operated valve which are connected with the safe injection hole; the condensation section is of a double-layer tube shell structure, a gas exit is arranged in the tube layer, and a condensate inlet and a condensate outlet for the condensate medium are arranged in the shell layer. By the arrangement, quick reaction under lower reaction temperature and pressure is achieved, and meanwhile, higher CHP selectivity is acquired.

Owner:CHINA PETROLEUM & CHEM CORP

Catalyst for preparing aromatic aldehyde and aliphatic aldehyde and its prepn process

InactiveCN1608729ALarge specific surface areaHigh catalytic activityPreparation by hydrogenolysisMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureNitrogen

The present invention relates to catalyst for preparing aromatic aldehyde and aliphatic aldehyde and its preparation process. The catalyst is decorated nanometer composite oxide comprising MnO2 and ZnO, and has great specific surface area, high reaction activity, high acid transformation rate and aromatic aldehyde selectivity, low reaction and long service life. The preparation process includes the steps of adding decorating element, dissolving, forming precipitate, decomposing precipitate to obtain composite oxide comprising MnO2 and ZnO, extruding into strip and calcination. The catalyst may be reduced and activated via introducing nitrogen in pressurizing or decompressing process.

Owner:XIAMEN UNIV +1

Cyanide complex catalyst, and its preparing method and use

InactiveCN1640544AImprove performanceThe synthesis process is stableOrganic-compounds/hydrides/coordination-complexes catalystsKetoneCarboxylic acid

The present invention relates to a cyanide complex compound catalyst, its preparation method and application in polyether. Said catalyst is made up by means of common coordination of three ligands of organics small molecule, functional compound and functional polymer which are introduced into cyanide complex compound. Said organic small molecule ligand is one or several kinds of alcohol, ether, aldehyde, ketone, ester or acidamine, its molecular weight is less than 200; the functional compound is aromatic carboxylic acid ester compound, its molecular weight is less than 500, and the functional polymer is macromolecular compound containing oxygen, nitrogen, phosphorus and sulfur, and its molecular weight is greater than 500.

Owner:LIMING RES INST OF CHEM IND

Preparation method and application of composite catalyst for synthesis of carbon dioxide copolymer

The invention discloses a preparation method and application of a composite catalyst for synthesis of carbon dioxide copolymer, in particular a novel composite catalyst for synthesis of the carbon dioxide copolymer, which is prepared by compounding double metal cyanide and zinc carboxylate according to a certain ratio. The double metal cyanide shortens the induction period of the zinc carboxylate and improves the conversion rate of epoxy compounds; the catalysis efficiency of the catalyst is more than 550g polymer / g catalyst; the molecular weight of the obtained polymer is 40,000 to 100,000; the content of carbonic ester chain element is over 68 percent; the carbon dioxide fixation rate reaches 30 percent; the conversion rate of epoxypropane reaches 95 percent; and the selectivity is over 99 percent. Compared with the single double metal cyanide or single zinc carboxylate, the composite catalyst has obvious advantages; the synthesis process is simple; and the composite catalyst is stable in air, has lower cost, and is particularly applied to industrial production of the carbon dioxide copolymer.

Owner:GUANGXI ACAD OF SCI

Preparation method of acetylacetone triphenylphosphine carbonyl rhodium (I)

InactiveCN104370972AReduce the temperatureHigh strengthRhodium organic compoundsBenzeneAcetylacetone

The invention discloses a synthetic method of acetylacetone triphenylphosphine carbonyl rhodium (I). The method comprises the following steps: (1) mixing rhodium trichloride hydrate and N,N-dimethylfomamide (DMF), heating to 130-150 DEG C under the protection of nitrogen, adding acetylacetone after rhodium trichloride is completely dissolved, heating until reflux reaction is performed for 0.5-1.5 hours, then putting the reaction solution in a power ultrasound area in a room temperature state, adding a precipitation enhancer in a low temperature state, and performing precipitation after-treatment, thereby preparing acetylacetone dicarbonyl rhodium (I); and (2) dissolving the acetylacetone dicarbonyl rhodium (I) prepared in the step (1) by using an organic solvent, adding triphenylphosphine which causes generation of bubbles, performing reflux reaction for 0.5-1 hour until no bubble is generated, putting the reaction solution in the power ultrasound area in the room temperature state to perform crystallization and precipitation, and treating to obtain acetylacetone triphenylphosphine carbonyl rhodium (I). By adopting the method disclosed by the invention, the total yield of acetylacetone triphenylphosphine carbonyl rhodium (I) is obviously improved, and the production cost is reduced; and a relatively environment-friendly solvent is adopted, so that benzene and toluene which are harmful to human bodies are avoided, environmental pollution is reduced, and safety is improved.

Owner:BEIJING GAOXIN LIHUA TECH CO LTD

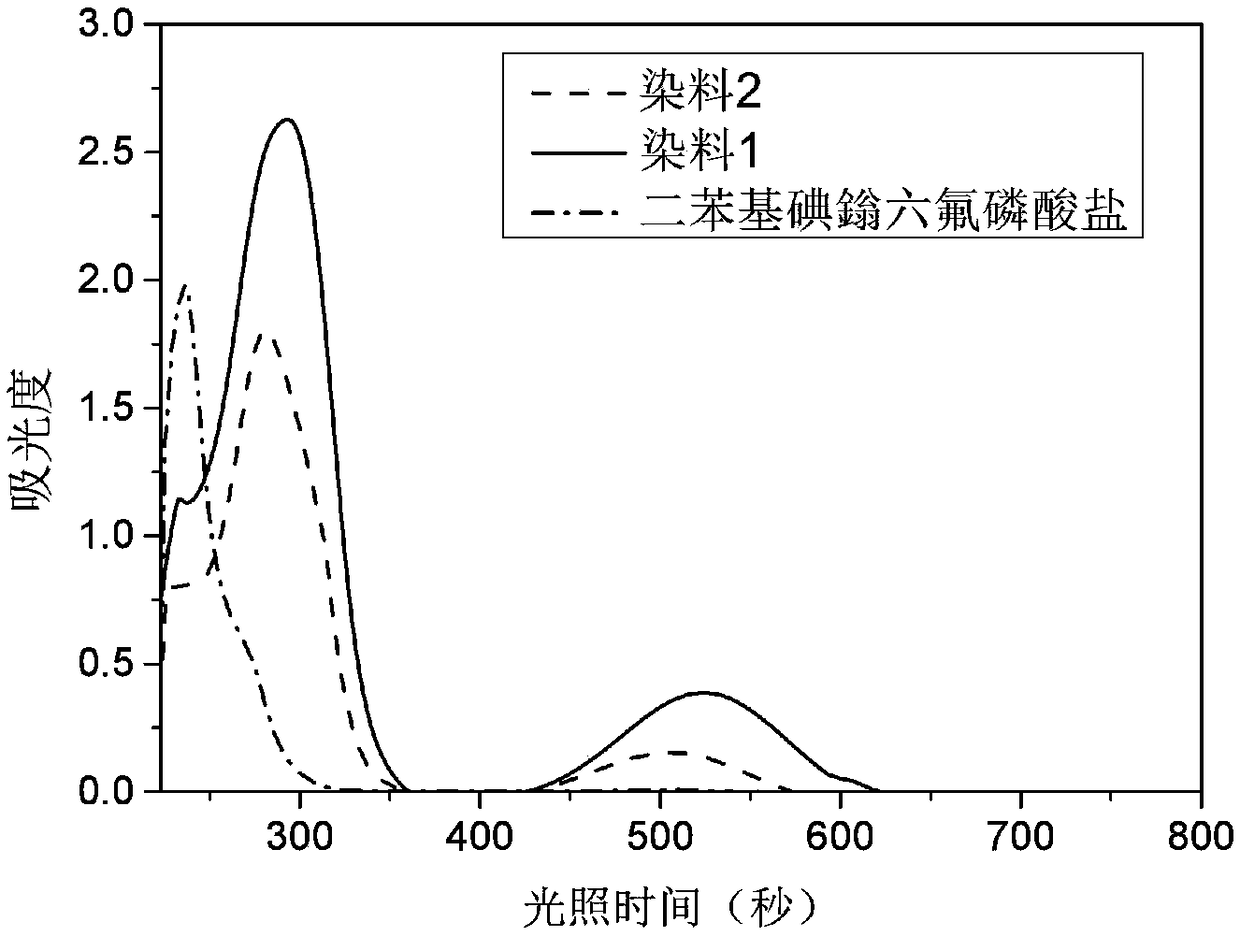

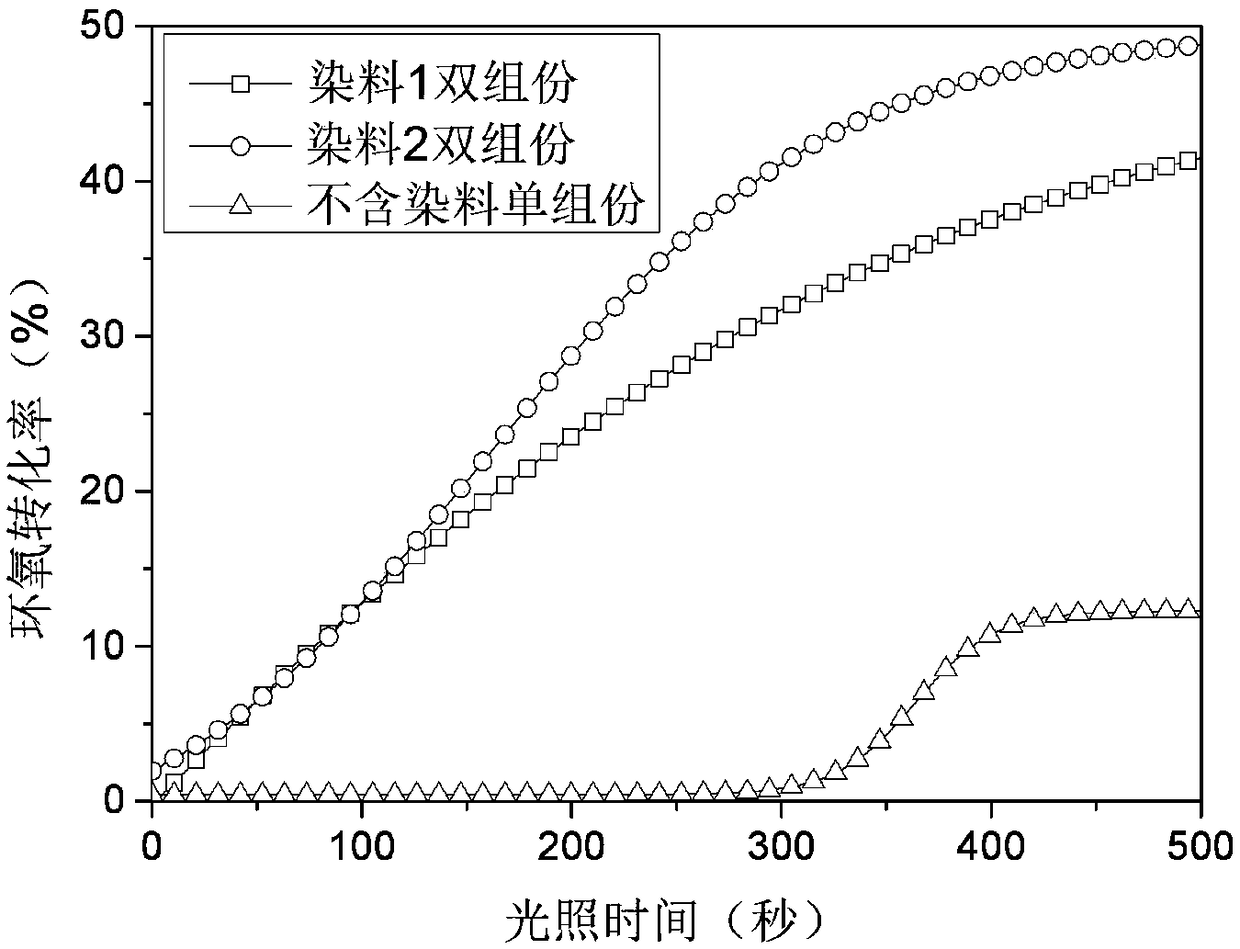

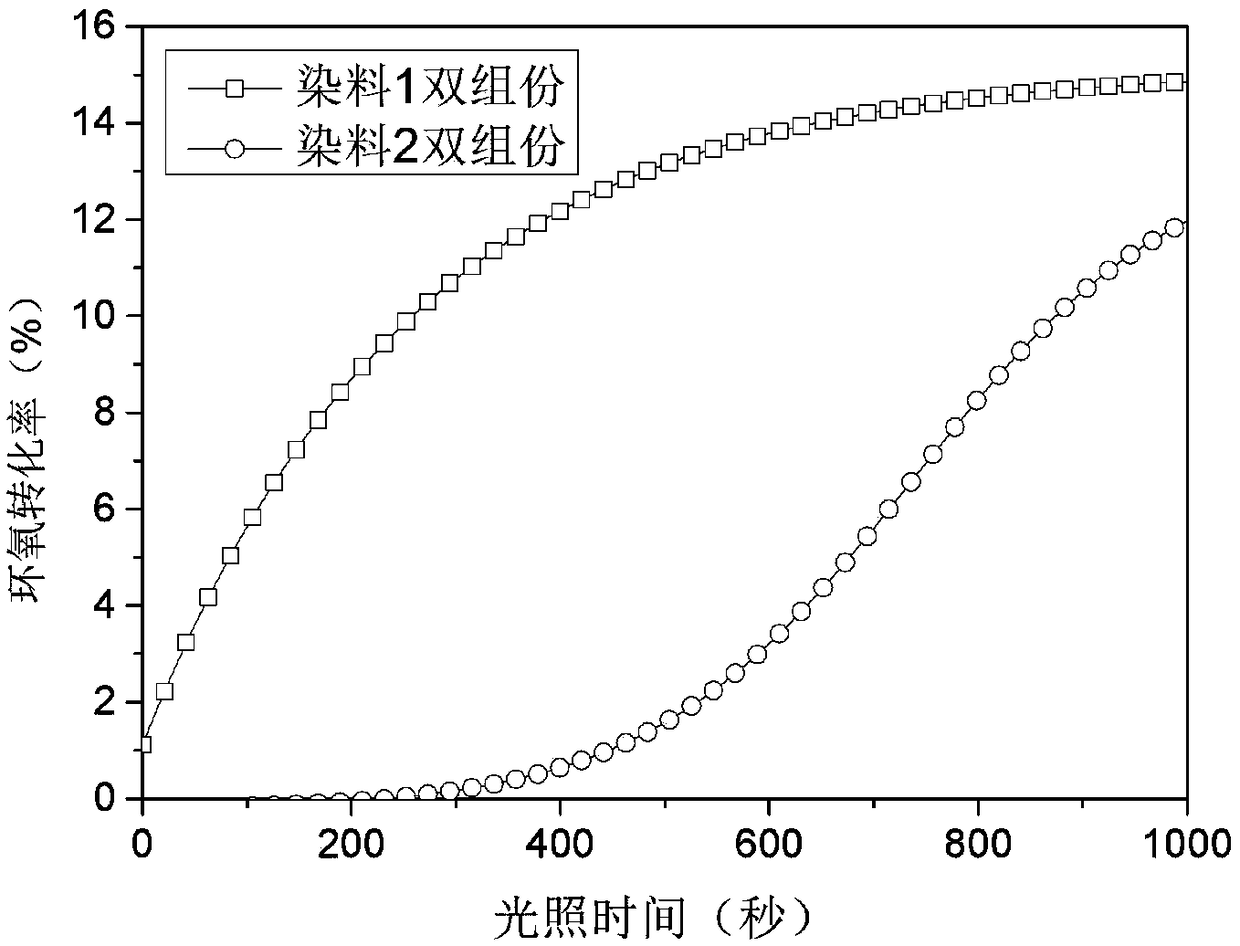

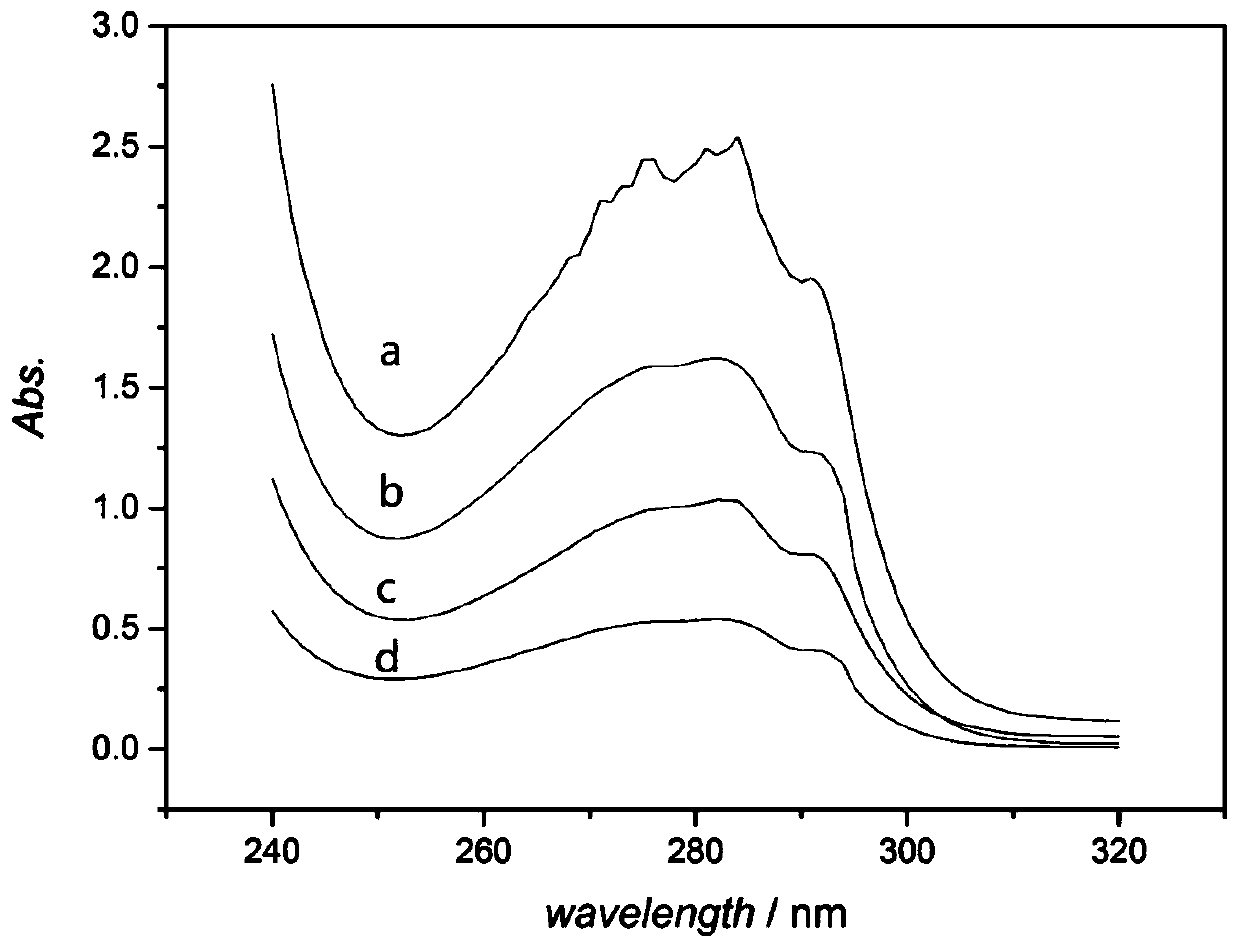

Two-component cationic visible-light initiator and application of two-component cationic visible-light initiator in photocuring technology

The invention discloses a two-component cationic visible-light initiator and application of the two-component cationic visible-light initiator in the photocuring technology. The two-component cationicvisible light initiator comprises diphenyl iodonium hexafluorophosphate and benzothiadiazole structural unit-based organic dye at a weight ratio of 1:(0.02-1), wherein diphenyl iodonium hexafluorophosphate with a CAS No. Of 58109-40-3) is a commercial ultraviolet photoinitiator, and the benzothiadiazole structural unit-based organic dye is adopted as a sensitizer of diphenyl iodonium hexafluorophosphate. The two-component cationic visible-light initiator has a wide absorption spectrum, curing molding of epoxide can be initiated under irradiation of a visible light source, and rapid curing canbe performed under low illumination of less than 30 mW / cm<2>, so that adoption of a traditional UV source with high energy consumption and large radiation is avoided; in addition, the benzothiadiazole structural unit-based organic dye has small synthesis difficulty, few steps and low-cost raw materials.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Preparation method of foaming modifier for foaming PVC (poly vinyl chloride) wood-plastic composite

The invention relates to the field of foaming PVC (poly vinyl chloride) wood-plastic composites and relates to a preparation method of a foaming modifier for a foaming PVC wood-plastic composite. The preparation method of the foaming modifier for the foaming PVC wood-plastic composite is characterized by comprising the following steps: weighing copolymerization monomer, deionzed water and emulsifier in mass ratio of 1.0:(0.5-1.0):(0.02-0.05); weighing copolymerization monomer, oxidant and reducing agent in mass ratio of 1:(0.015-0.005):(0.015-0.005); dropwise adding the rest two thirds of seed emulsion after blue lights appear in the emulsion, reducing temperature of a heating sheath to be 60-65 DEG C, and adding the same amount of initiator every half hour for five times. By virtue of adoption of the technical scheme, an oxidation-reduction system is taken as an initiator, multi-stage emulsion polymerization is adopted, a core-shell structure is prepared, viscosity of a polymerization product is greatly improved, and finally a reaction temperature is increased for increasing conversion rate of a monomer; meanwhile, the monomer is dropwise added and the initiator is added in stages, so that gel content can be greatly reduced.

Owner:湖北福云居智能建筑股份公司

Titanium gypsum high-performance concrete building material and preparation method therefor

The invention discloses a titanium gypsum high-performance concrete building material and a preparation method therefor. The titanium gypsum high-performance concrete building material comprises cementing material slurry S1 and aggregates S2, wherein the aggregates S2 are one or a combination of a random ratio of two of light aggregates and normal aggregates, and the ratio of volume of the cementing material slurry S1 to stacked volume of the aggregates S2 is (1: 1) to (1: 3). An acidic excitant is adopted in a titanium gypsum based cementing material system, so that an induction period of reaction is shortened, and the early strength is improved; during batching, a method that other powder ingredients are premixed firstly except for wet titanium gypsum slag is adopted, so that original-condition titanium gypsum slag can be directly adopted in case of relatively high moisture content; the speed of uniform stirring of slurry powder is accelerated, so that a dehydration link for the titanium gypsum slag is avoided, and the stirring rate is increased; and a vacuumizing mode is adopted during slurry powder stirring, so that the mechanical strength, softening coefficient and durability of the titanium gypsum based building material prepared by the preparation method are further improved.

Owner:MAANSHAN MCC17 ENG TECH CO LTD

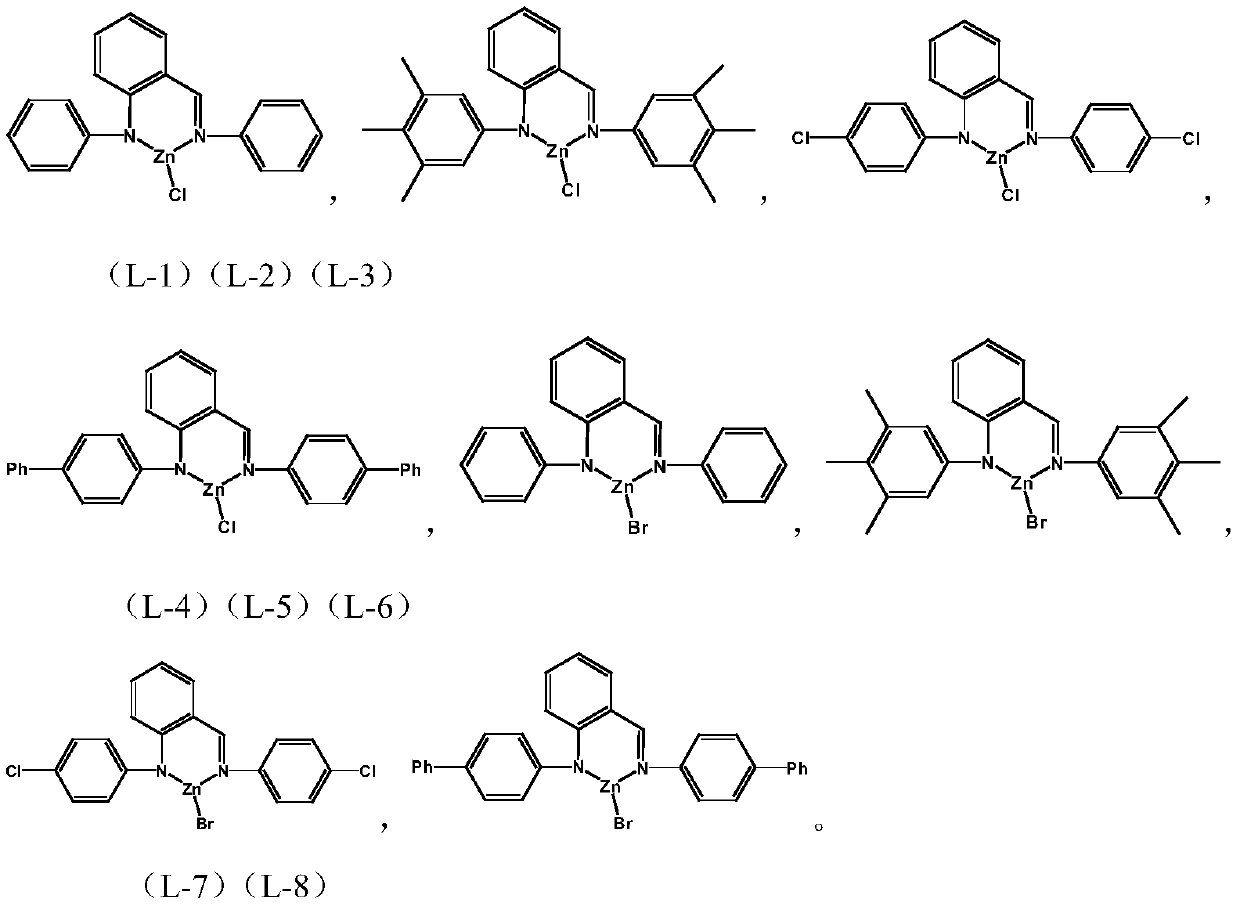

Double-metal cyanide catalyst for copolymerization of carbon dioxide and epoxide and preparation method of double-metal cyanide catalyst

The invention provides a double-metal cyanide catalyst for copolymerization of carbon dioxide and epoxide. The structural formula is M1a [M2 (CN) bLc] dXi, and the catalyst is obtained by mixing a complex M1LX of metal M1, cyanide of metal M2 and metal salt M1eXf and performing reaction under mechanical ball milling, wherein M1LX is a compound with a structure as shown in the following formula (II) which is described in the specification, M2 is selected from one of Co<2+>, Co<3+>, Fe<2+>, Fe<3+>, Cd<2+> and Mn<3+>, and X is selected from one or more of F<->, Cl<->, Br<->, I<->, NO3<->, SO4<2->or organic carboxylate anions. The preparation method of the catalyst is simple, convenient and green, the catalyst is high in catalytic efficiency, good in activity and good in stability, and in a carbon dioxide / epoxide copolymerization reaction, higher catalytic activity and higher selectivity of a polymer product and polycarbonate chain links on a polymer main chain can be embodied in a polymerization reaction under the conditions of relatively lower catalyst concentration and higher initiator concentration.

Owner:合肥普力先进材料科技有限公司

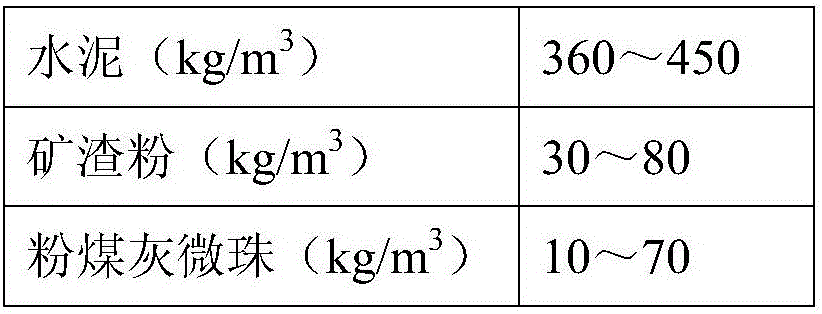

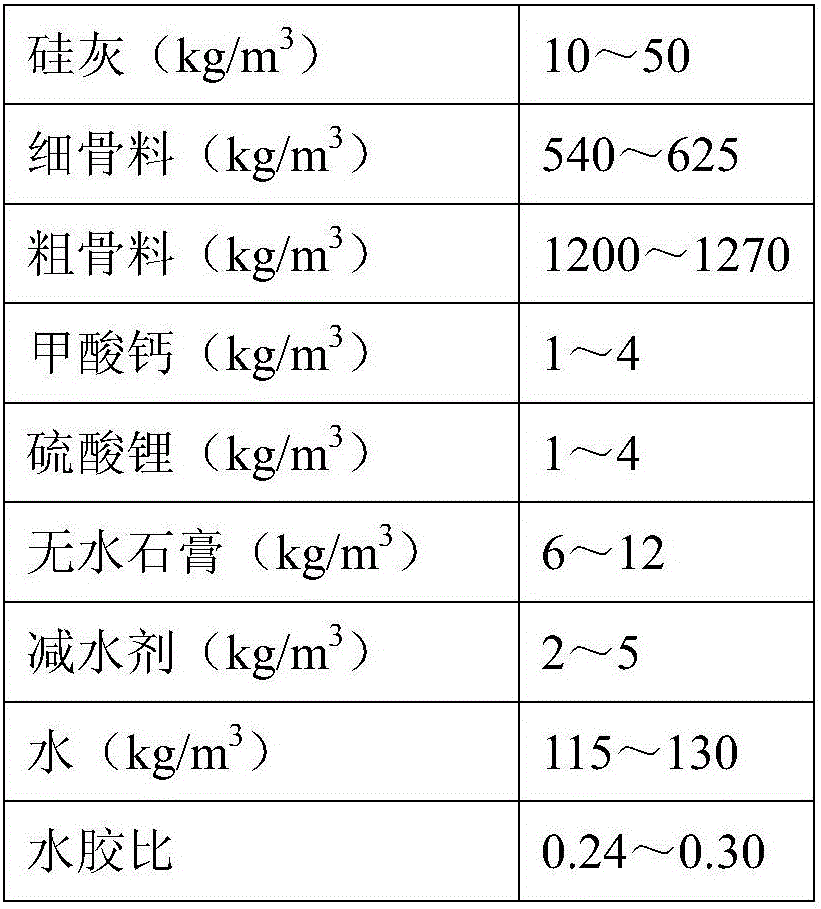

Concrete for large tubular pile of autoclaving-free process

The invention belongs to the technical field of concrete materials, and in particular relates to concrete for a large tubular pile of an autoclaving-free process. Each cubic meter of preparation materials of the concrete comprise the following components: 360-450kg of cement, 30-80kg of slag powder, 10-70kg of coal ash microbeads, 10-50kg of silicon ash, 540-625kg of fine aggregate, 1200-1270kg of coarse aggregate, 1-4kg of calcium formate, 1-4kg of lithium sulfate, 6-12kg of anhydrite, 2-5kg of a water reducing agent and 115-130kg of water. A series of tests and studies on the proportioning ratio of the concrete provided by the invention are implemented, and an optimal concrete proportioning ratio which can meet the requirement of large tubular pile demolding strength and strength of C60 concrete within a relatively short time at a normal temperature can be obtained.

Owner:CCCC THIRD HARBOR ENG +2

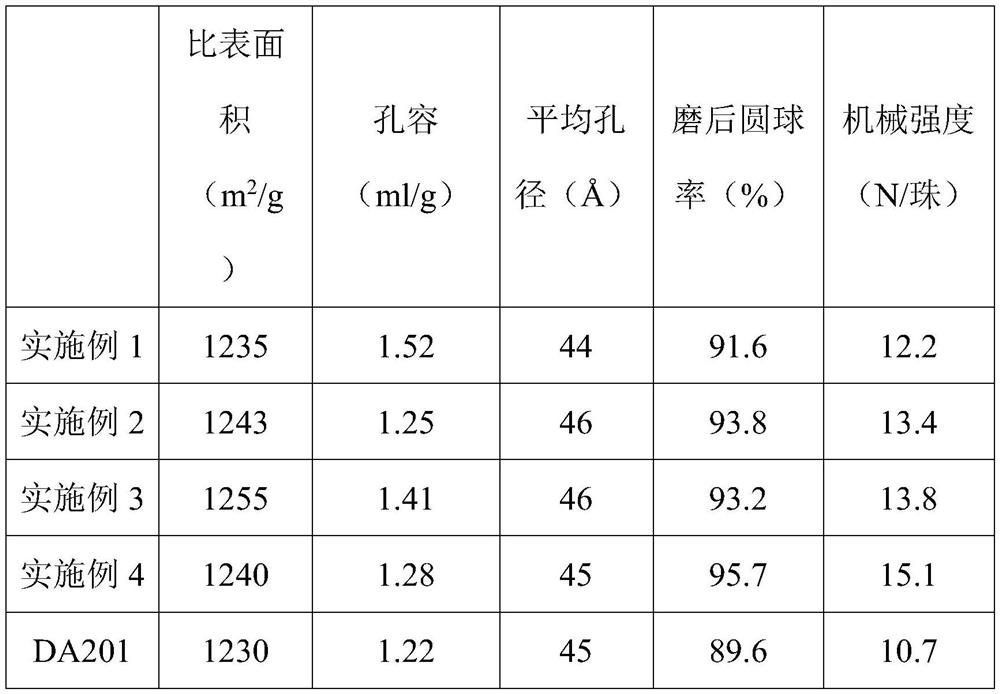

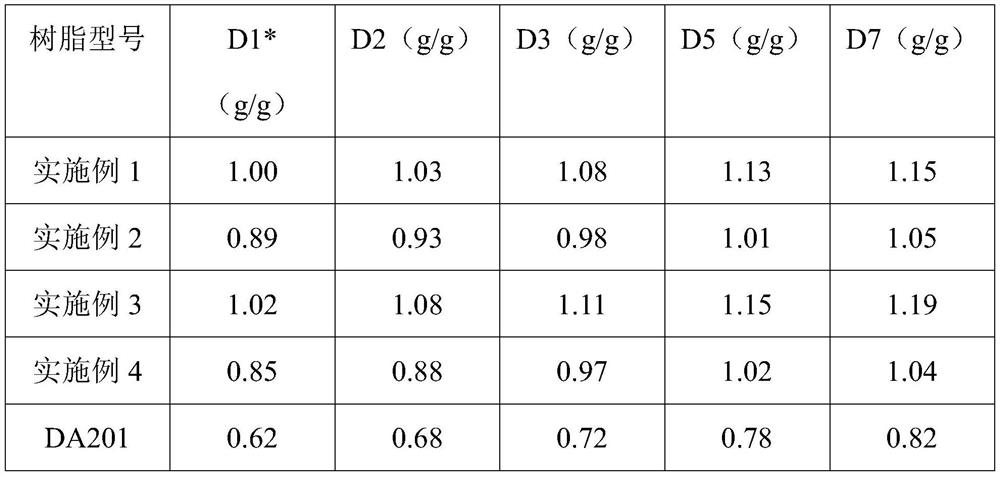

Macroporous adsorption resin and synthesis method thereof

The invention discloses macroporous adsorption resin and a synthesis method thereof. The synthesis method comprises the following steps of preparing a dispersant, a polymerization inhibitor and tap water into a water phase, mixing a monomer, a pore-foaming agent and an initiator to prepare an oil phase, adding the oil phase into the water phase, standing, then stirring at a constant speed, carrying out heating and heat preservation treatment, obtaining white balls after the reaction is finished, and washing and drying the white balls to obtain dry white balls, adding a solvent into dry white balls, stirring for swelling, then adding a catalyst in two times for heating reaction, after the reaction is finished, adding tap water into a system for heating azeotropic recovery of the solvent, then washing the resin with water until the resin is neutral, and screening to obtain the macroporous adsorption resin with the particle size of 0.315-1.25 mm. The resin is simple in process, low in production cost, green, environment-friendly and pollution-free, and the synthetic resin has the advantages of high mechanical strength, large specific surface area, relatively high adsorption performance on small molecular substances (such as ethyl acetate) and the like.

Owner:SHAANXI LANSHEN SPECIAL RESIN

Method for extracting crystals of urease in canavalia ensiformis

The invention discloses a method for extracting crystals of urease in canavalia ensiformis. The method comprises the following steps of 1, extraction, wherein canavalia ensiformis is ground into powder, an extracting solution is added after screening is carried out, full stirring is carried out, urease in the canavalia ensiformis powder is all digested, the leaching liquor is centrifugalized at room temperature, and the supernate is collected; 2, rough precipitating, wherein the supernate stands and refrigerated, centrifugalization is carried out, precipitate is collected, and rough urease precipitate is obtained; 3, cooling crystallization, wherein the rough urease precipitate is dissolved in a sodium citrate solution and stirred to be fully dissolved, centrifugalization is carried out, supernate is collected, a protein solution is obtained, a precipitator solution is slowly added to the protein solution, crystallization starts to be carried out after the materials are mixed to be uniform, a crystal solution is obtained, the crystal solution is subjected to centrifugal separation, urease crystal precipitate is collected and freeze-dried, and a urease product with the purity exceeding 96% is obtained. The method is easy to operate, short in technological process and low in energy consumption, a conventional solid-liquid separation means is adopted in the preparation process, and the urease gross activity recovery rate reaches 60% or above.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com