Method for extracting crystals of urease in canavalia ensiformis

A technology of urease and extraction method in soybeans, applied in the direction of hydrolytic enzymes, etc., can solve the problems of insufficient purification factor, low purity of urease, complex process flow, etc., to solve the problem of operation time and production, improve purity and extraction rate, without affecting The effect of protein activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

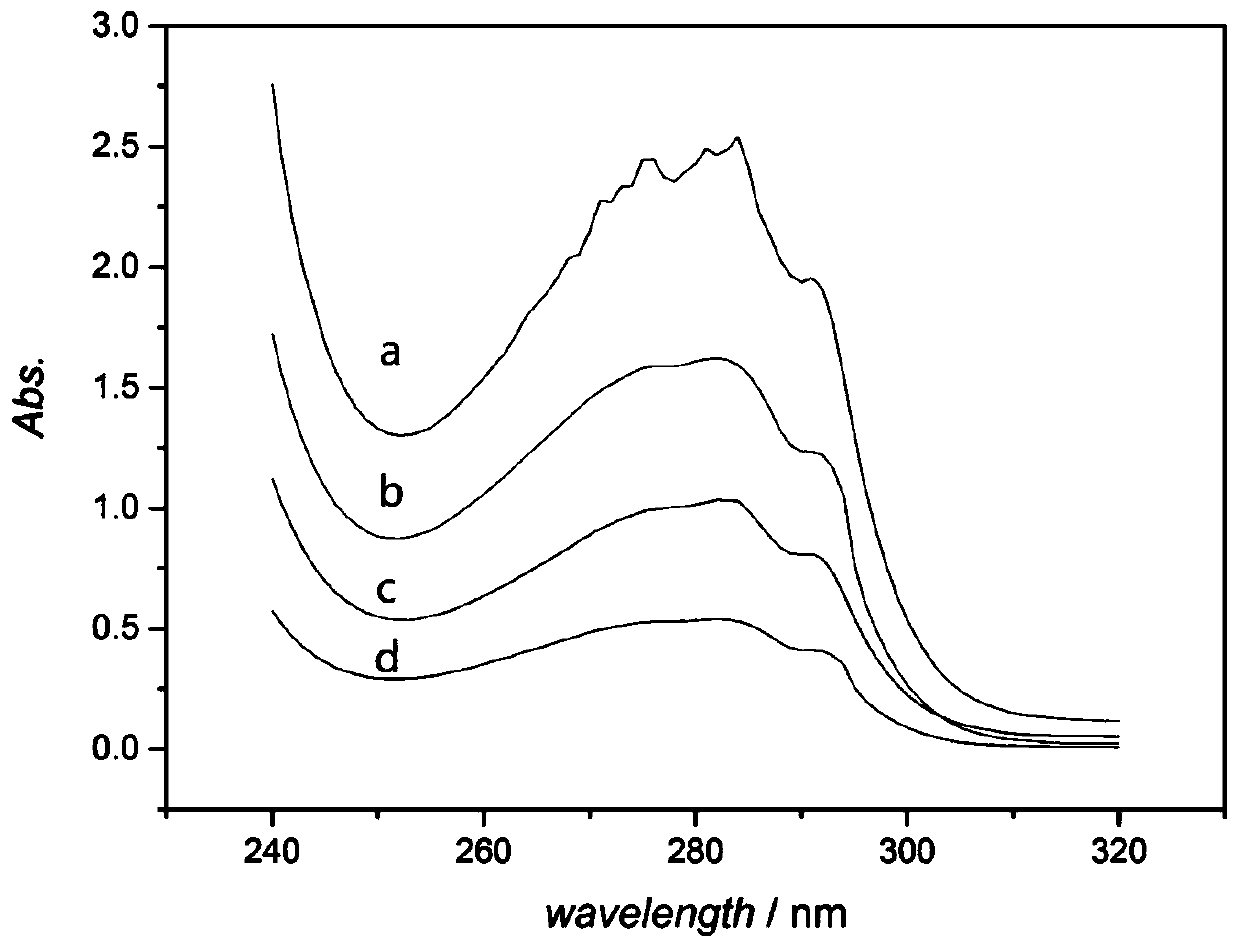

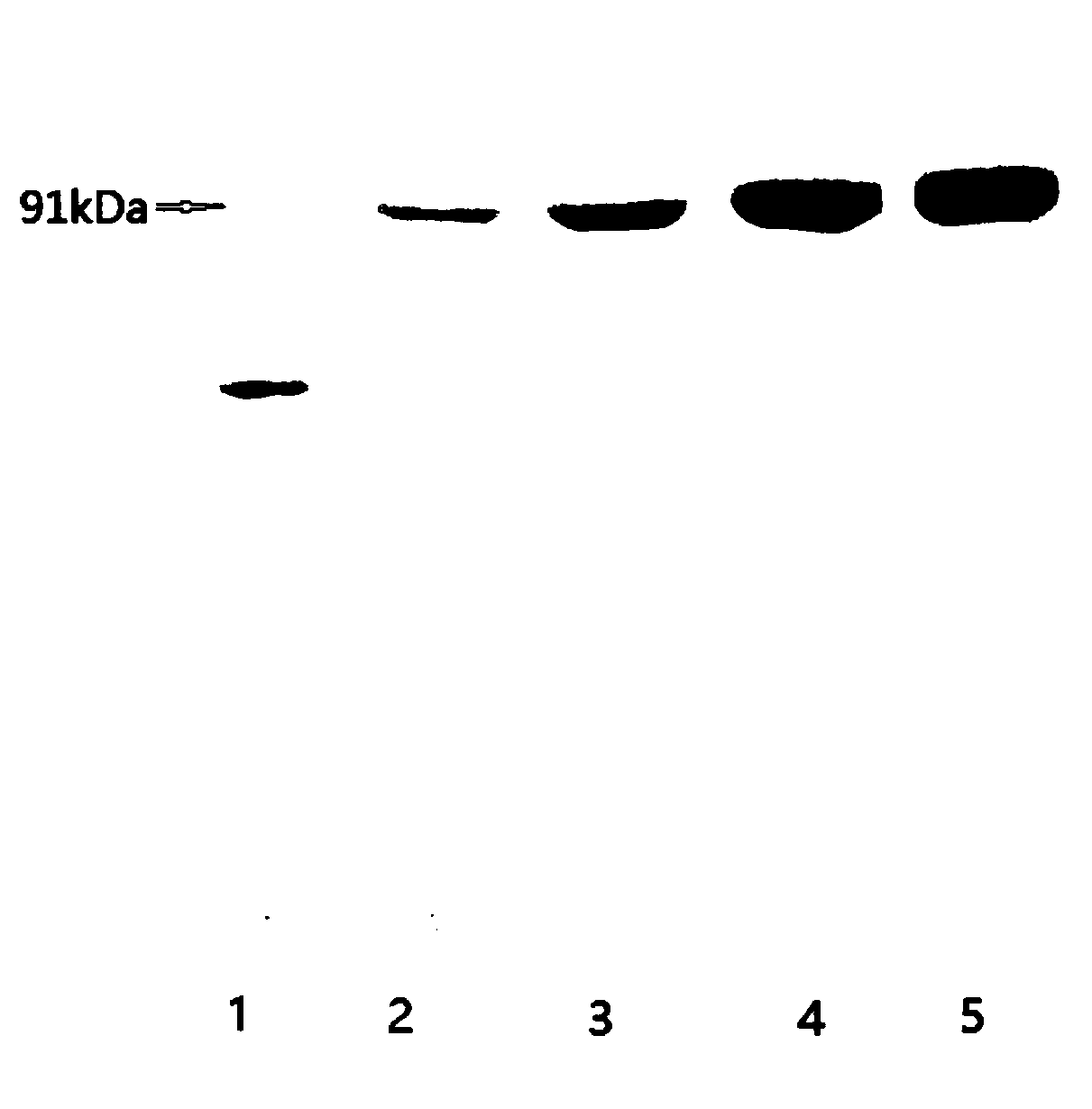

Image

Examples

Embodiment 1

[0031] Take by weighing 2 kg of pineapple powder, sieve to remove large particles of impurities, add 2L of ethanol solution containing 35% mass fraction, wherein the solvent is a sodium citrate buffer solution with an ionic strength of 0.025mol / L at pH=6.0, at room temperature at 700rpm Stir for 10 minutes to obtain a urease extract, and the stirring paddle is made of glass to prevent metals from affecting the urease activity. The resulting extract was centrifuged at 8000 rpm for 30 min, and the supernatant was collected. After the supernatant was refrigerated at 6° C. for 4 h, a suspension containing urease precipitate was obtained. The suspension was centrifuged at 4000 rpm to obtain a crude precipitate of urease. Add 2L of sodium citrate buffer solution with an ionic strength of 0.025mol / L pH=6.0 to the crude precipitate of urease obtained, fully stir and dissolve at room temperature, centrifuge at 2000rpm for 20min to discard insoluble impurities, collect the supernatant,...

Embodiment 2

[0036] Take 2 kg of jack bean powder, sieve to remove large particles of impurities, add 2 L of ethanol solution containing 25% mass fraction, wherein the solvent is a sodium citrate buffer solution with an ionic strength of 0.025 mol / L and pH=6.5, and stir for 15 min at room temperature at 700 rpm , to obtain the leaching solution of urease, and the stirring blade is made of glass. The resulting extract was centrifuged at 8000 rpm for 30 min, and the supernatant was collected. After the supernatant was refrigerated at 5° C. for 4 h, a suspension containing urease precipitate was obtained. The suspension was centrifuged at 4000 rpm to obtain a crude precipitate of urease. Add 2L of sodium citrate buffer solution with an ionic strength of 0.025mol / L pH=6.5 to the crude precipitate of urease obtained, fully stir and dissolve at room temperature, centrifuge at 2000rpm for 20min to discard insoluble impurities, collect the supernatant, and obtain a concentration of urease of Add...

Embodiment 3

[0041] Take 2 kg of jack bean powder, sieve to remove large particles of impurities, add 2 L of acetone solution containing 25% mass fraction, wherein the solvent is a sodium citrate buffer solution with an ionic strength of 0.025 mol / L and pH=7.0, stir at room temperature for 20 min at 700 rpm , to obtain the leaching solution of urease, and the stirring blade is made of glass. The resulting suspension was centrifuged at 8000 rpm for 30 min, and the supernatant was collected. After the supernatant was refrigerated at 4° C. for 4 h, a suspension containing urease precipitate was obtained. The suspension was centrifuged at 4000 rpm to obtain a crude precipitate of urease. Add 2L of sodium citrate buffer solution with an ionic strength of 0.025mol / L pH=7.0 to the crude precipitate of urease obtained, fully stir and dissolve at room temperature, centrifuge at 2000rpm for 20min to discard insoluble impurities, collect the supernatant, and obtain a concentration of urease of Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com