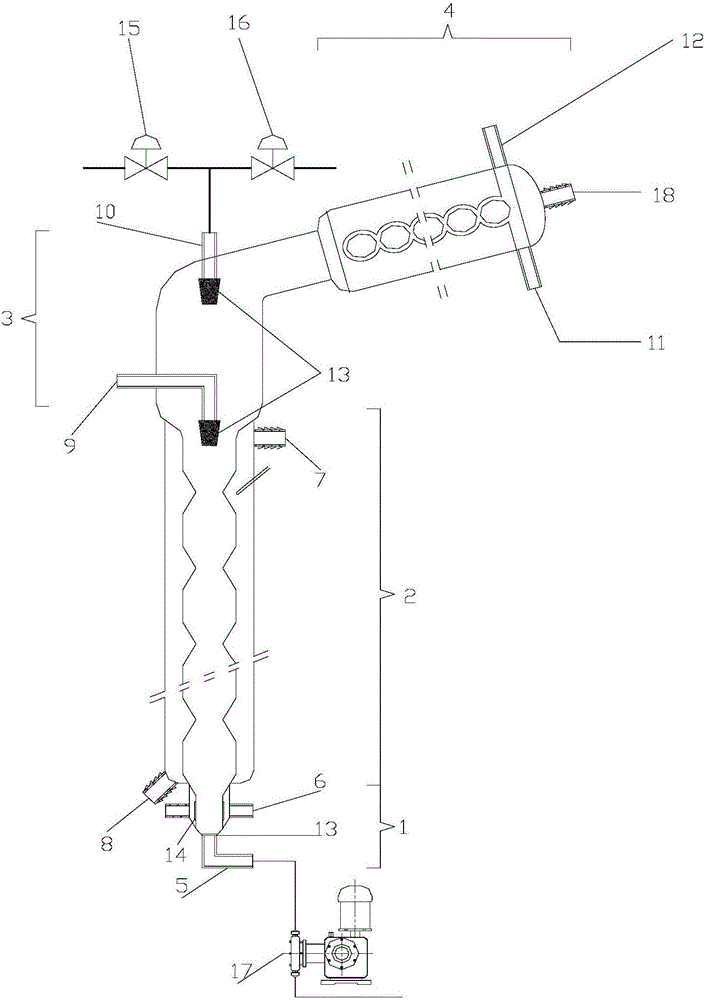

Oscillatory flow reactor used for preparing cumene hydroperoxide (CHP) in catalytic oxidation of cumene and method for preparing cumene hydroperoxide in catalytic oxidation of cumene

A technology for preparing cumene by catalytic oxidation of cumene and hydrogen peroxide, which is applied in the reaction of liquid and gas under a catalytic active body, chemical instruments and methods, and chemical methods for reacting liquid and gas medium, etc. Solve the problems of difficult activation of oxygen molecules, slow reaction speed and high reaction temperature, and achieve the effect of reducing the easy violent decomposition and explosion, fast reaction speed and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The main body of the reaction section of the bellows type oscillating flow reactor consists of 15 sections, each section is 0.7m in height, the diameter of the convex part is 0.4m, and the diameter of the concave part is 0.2m. Add powdered molecular sieve catalyst to the reactor, operate under normal pressure, and the reaction temperature is 50°C. After the gas / liquid material is injected from the bottom, it goes up with the reaction oscillation. The total residence time of the material in the main body of the reaction section is 16h, and the reaction product passes through the liquid After being separated by the solid separator, it is extracted from the discharge port. After analysis, the CHP concentration in the reaction product is 30.68%, and the CHP selectivity is 99.65%.

Embodiment 2

[0034] The main body of the reaction section of the bellows type oscillating flow reactor consists of 10 sections, each section is 1m in height, the diameter of the convex part is 0.6m, and the diameter of the concave part is 0.3m. Add powdery modified MgO catalyst to the reactor, operate under normal pressure, and the reaction temperature is 60°C. After the gas / liquid material is injected from the bottom, it will move up with the reaction oscillation. The total residence time of the material in the main body of the reaction section is 12h, and the reaction product After being separated by a liquid-solid separator, it is extracted from the discharge port. The CHP concentration in the reaction product is analyzed to be 34.05%, and the CHP selectivity is 99.11%.

Embodiment 3

[0036] The main body of the reaction section of the bellows type oscillating flow reactor consists of 8 sections, each section is 1.2m in height, the diameter of the convex part is 0.5m, and the diameter of the concave part is 0.25m. Add powdery modified MgO catalyst to the reactor, operate under normal pressure, and the reaction temperature is 70°C. After the gas / liquid material is injected from the bottom, it moves upward with the reaction oscillation. The total residence time of the material in the main body of the reaction section is 8h, and the reaction product After being separated by a liquid-solid separator, it is withdrawn from the discharge port. After analysis, the CHP concentration in the reaction product is 32.74%, and the CHP selectivity is 98..46%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com