Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1189results about How to "Raise the reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

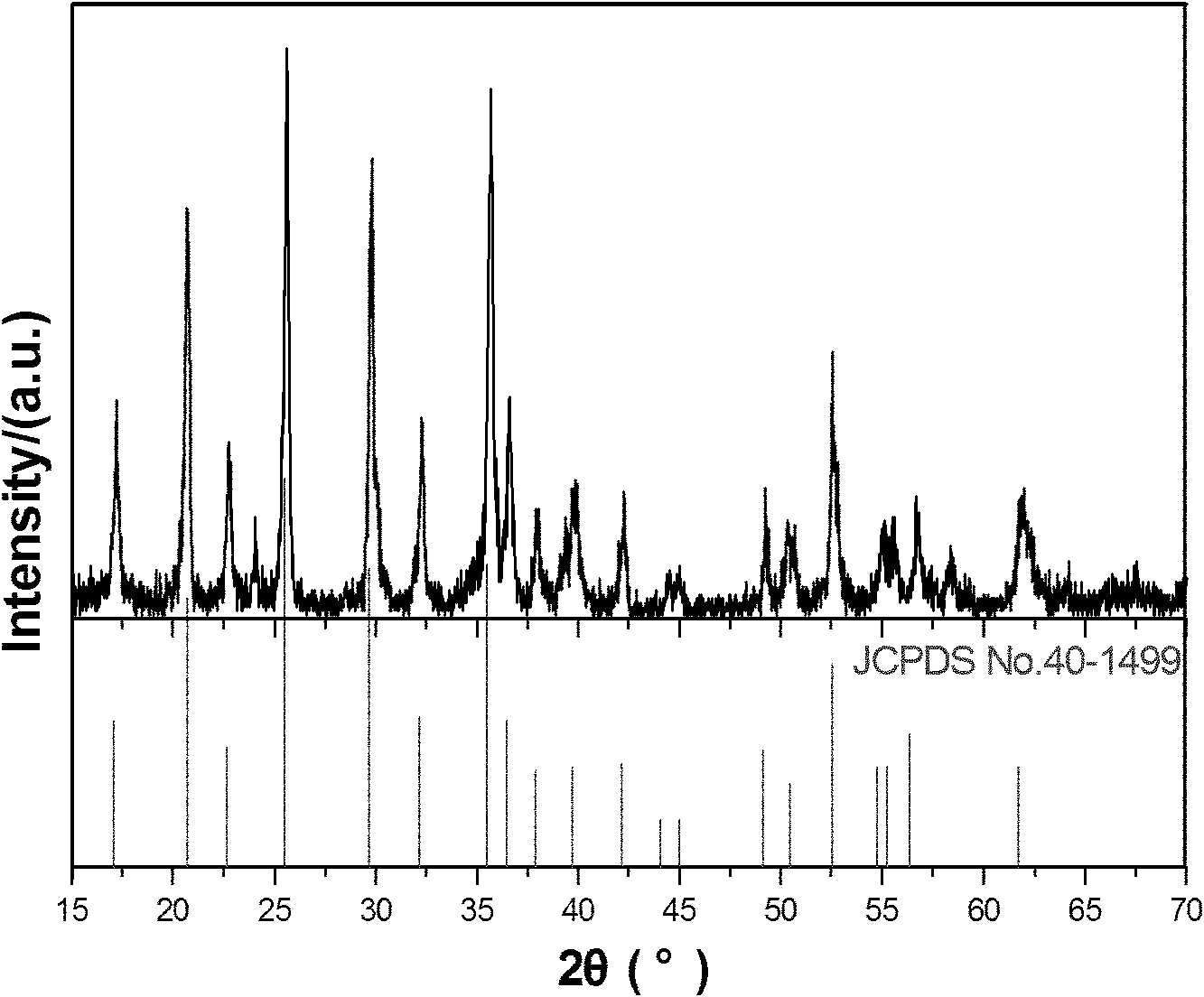

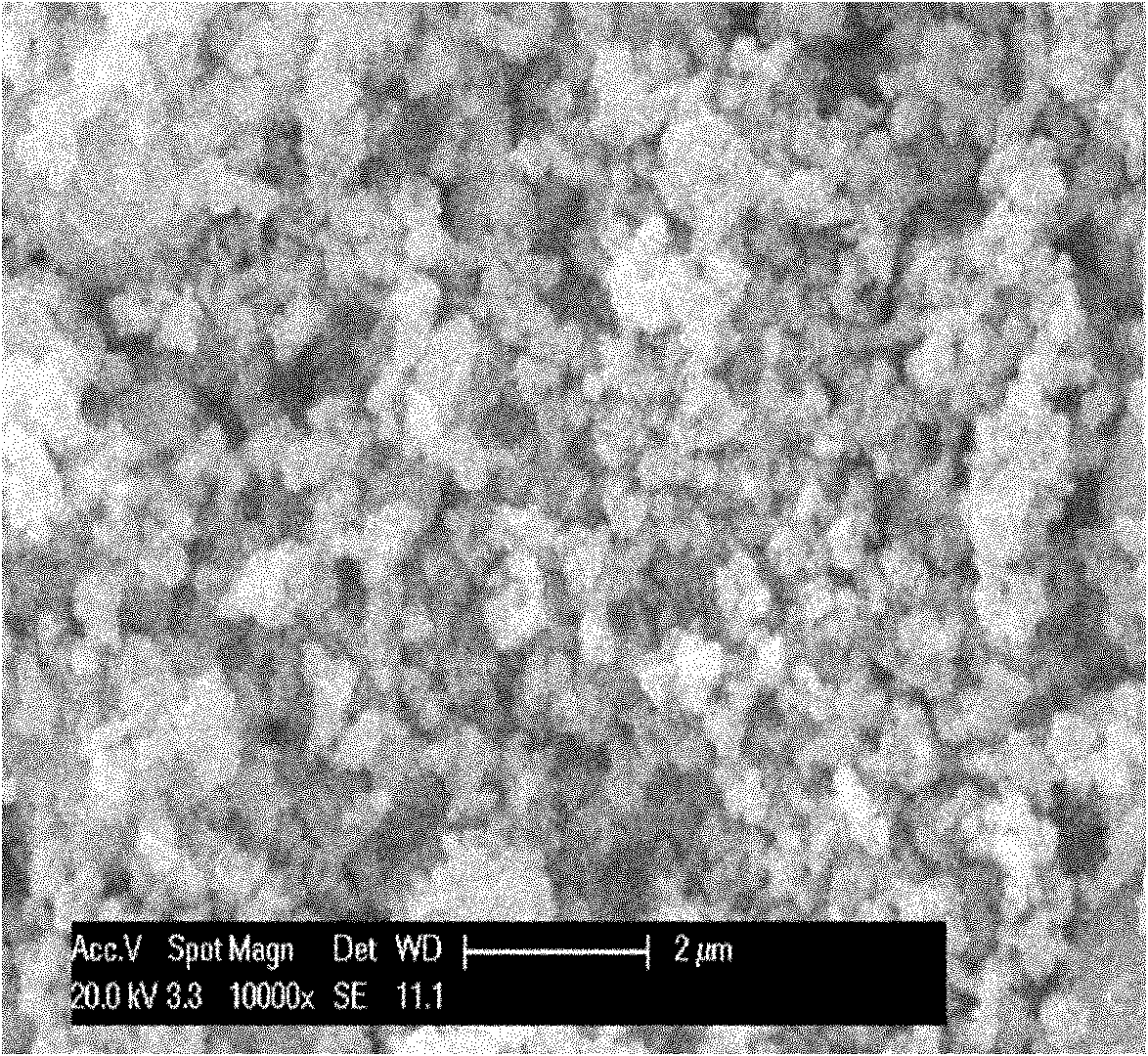

Low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst and preparation method

ActiveCN102114424ARich pore structureLarge specific surface areaDispersed particle separationCatalyst activation/preparationSilicon-controlled rectifierManganese oxide

The invention relates to a low-temperature smoke denitration SCR (silicon controlled rectifier) catalyst, which comprises a carrier, a manganese oxide, and composite oxide of one or more of Ce, Zr, Ti, Co, Fe and Cu, the mass content of manganese is 0.1-66 percent, and the total mass content of the Ce, Zr, Ti, Co, Fe or / and Cu is 0-50 percent; and glass fiber and / or kieselguhr is used as the carrier, wherein the glass fiber of the carrier is calcined for 2-4 hours at temperature of 400-600 DEG C, then placed in a nitric acid, sulfuric acid or hydrochloric acid solution with mass concentration of 5-40 percent for acidizing for 1-8 hours, washed by distilled water to be neutered, dried at temperature of 80-120 DEG C, and crushed to have the fineness of 20-325 meshes. The catalyst uses the glass fiber and the kieselguhr as the carriers, so that the dispersion effect of nanoparticles and specific surface area of the catalyst are increased, the high adsorptive capacity and strong heat resistance and corrosion resistance capacity are achieved, stronger toxic resistance capacity to sulfur dioxide and stream contained in the smoke is realized, the invention can be used for 10-200 DEG C of low temperature smoke denitration, and has strong water resisting and sulphur toxic resisting capacities.

Owner:GUODIAN SCI & TECH RES INST +1

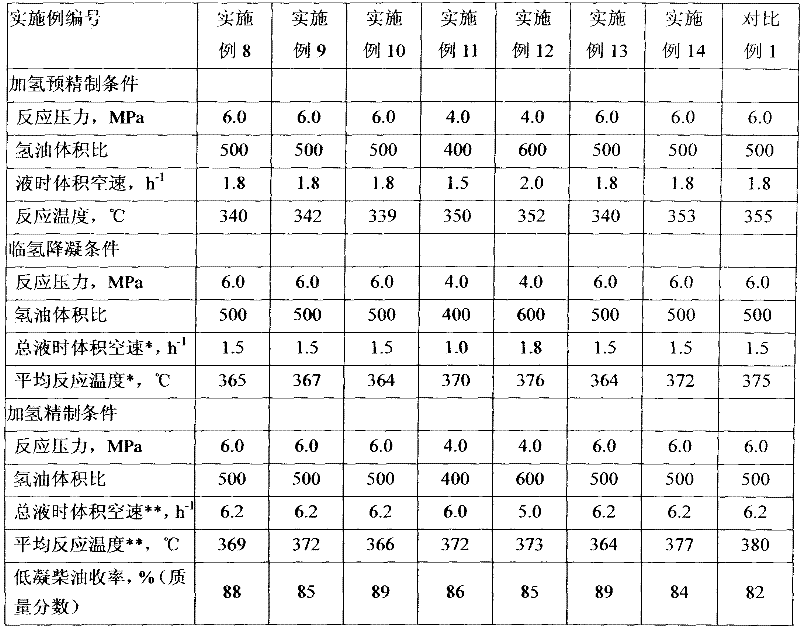

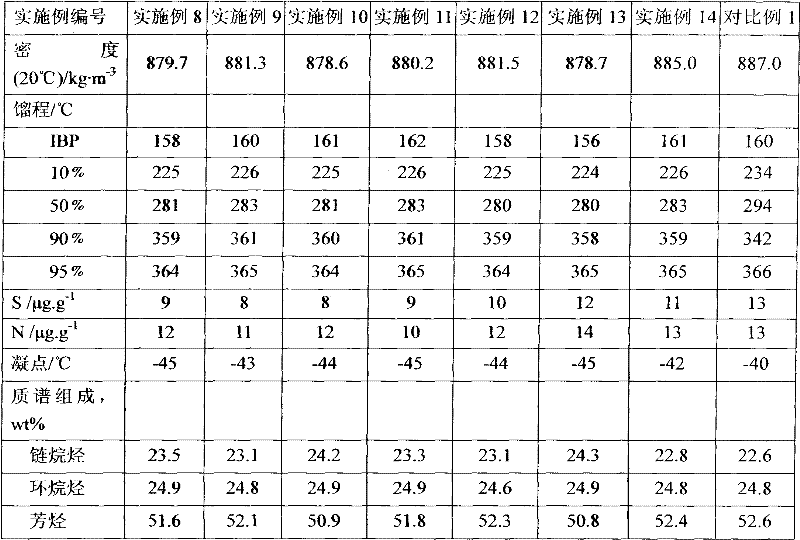

Hydrodewaxing method for diesel fraction

ActiveCN102453531ARaise the reaction temperatureIncrease profitTreatment with hydrotreatment processesWaxDiesel fuel

The invention discloses a hydrodewaxing method for diesel fraction. The method is as follows: a raw material of wax-containing diesel oil sequentially passes through alternatively cascaded hydrodewaxing catalyst beds and hydrofining catalyst beds, and a finally obtained hydrofining product is subjected to separation so as to obtain a product of diesel oil. The method enables average reaction temperature of the hydrodewaxing catalyst beds to be increased, thereby improving the utilization rate of a hydrodewaxing catalyst, prolonging the on-stream period of an apparatus and enhancing yield of the target product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Non-aqueous electrolyte and lithium secondary battery including the same

ActiveCN102569886AHigh decomposition voltageRaise the reaction temperatureSecondary cellsStable stateOrganic solvent

A non-aqueous electrolyte including a lithium salt, an organic solvent, and an electrolyte additive is provided. The electrolyte additive is a meta-stable state nitrogen-containing polymer formed by reacting Compound (A) and Compound (B). Compound (A) is a monomer having a reactive terminal functional group. Compound (B) is a heterocyclic amino aromatic derivative as an initiator. A molar ratio of Compound (A) to Compound (B) is from 10:1 to 1:10. A lithium secondary battery containing the non-aqueous electrolyte is further provided. The non-aqueous electrolyte of this disclosure has a higher decomposition voltage than a conventional non-aqueous electrolyte, such that the safety of the battery during overcharge or at high temperature caused by short-circuit current is improved.

Owner:IND TECH RES INST

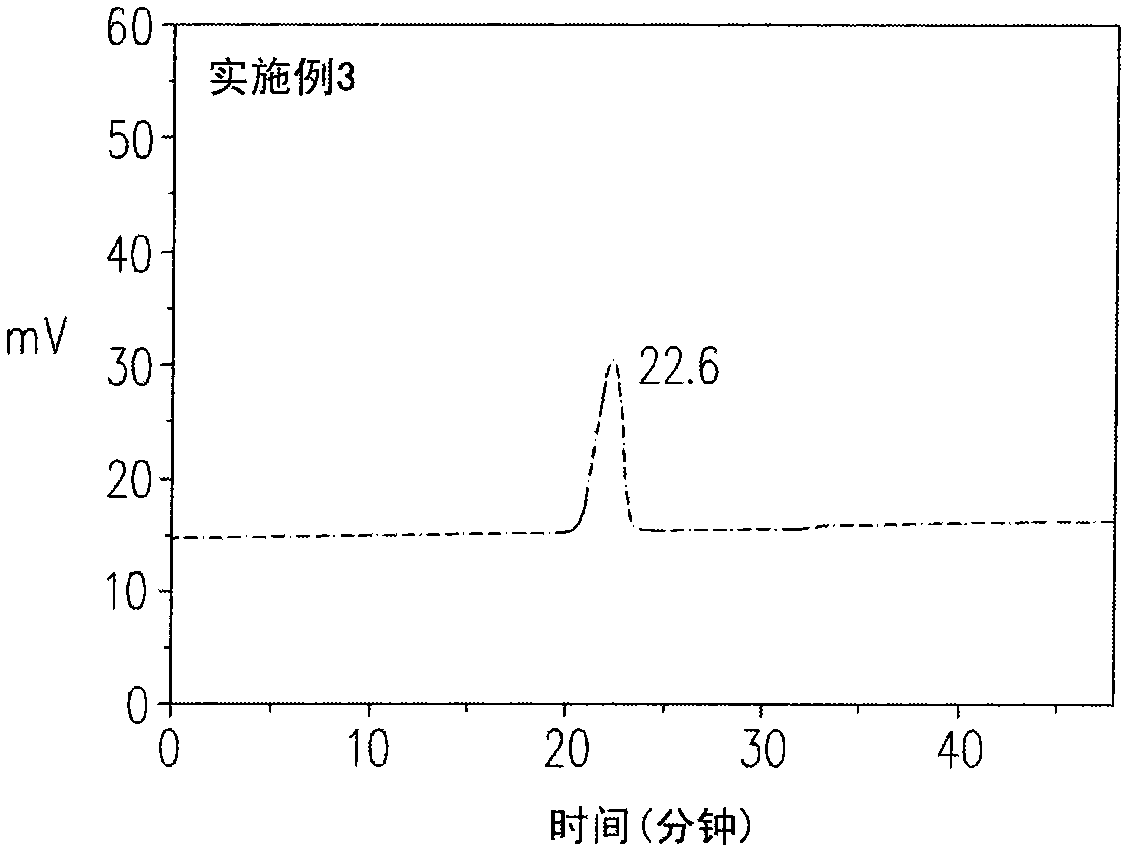

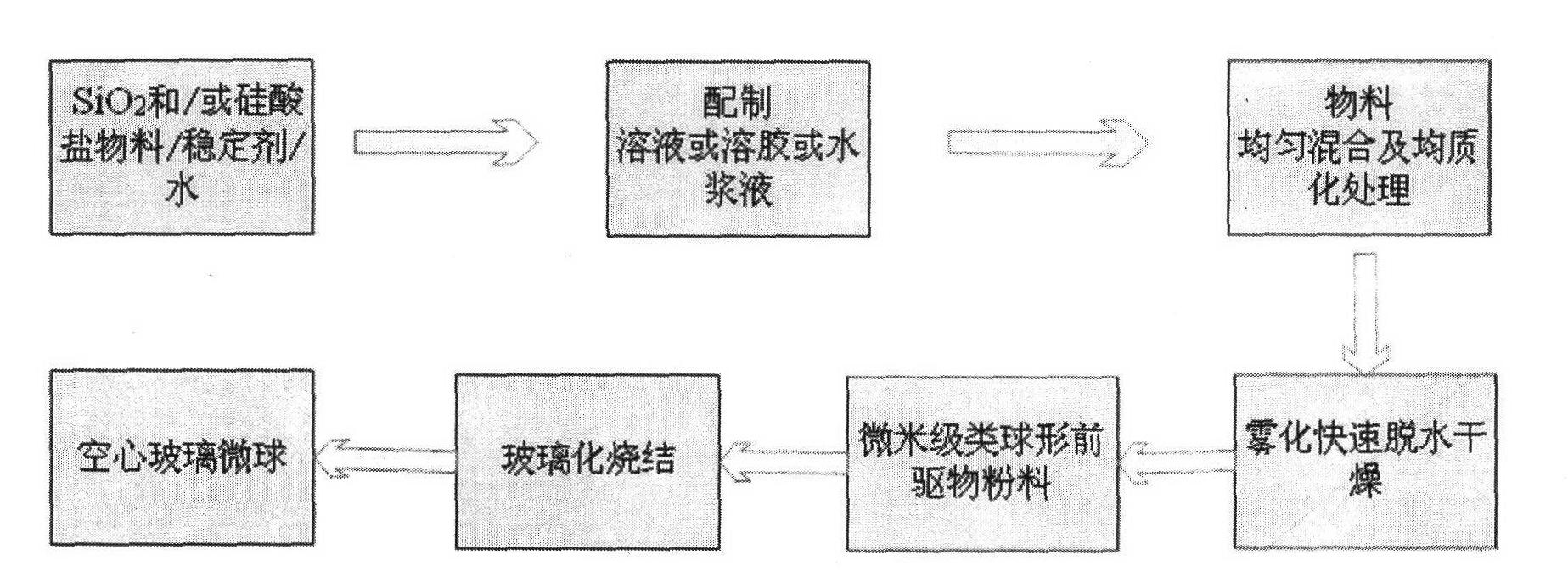

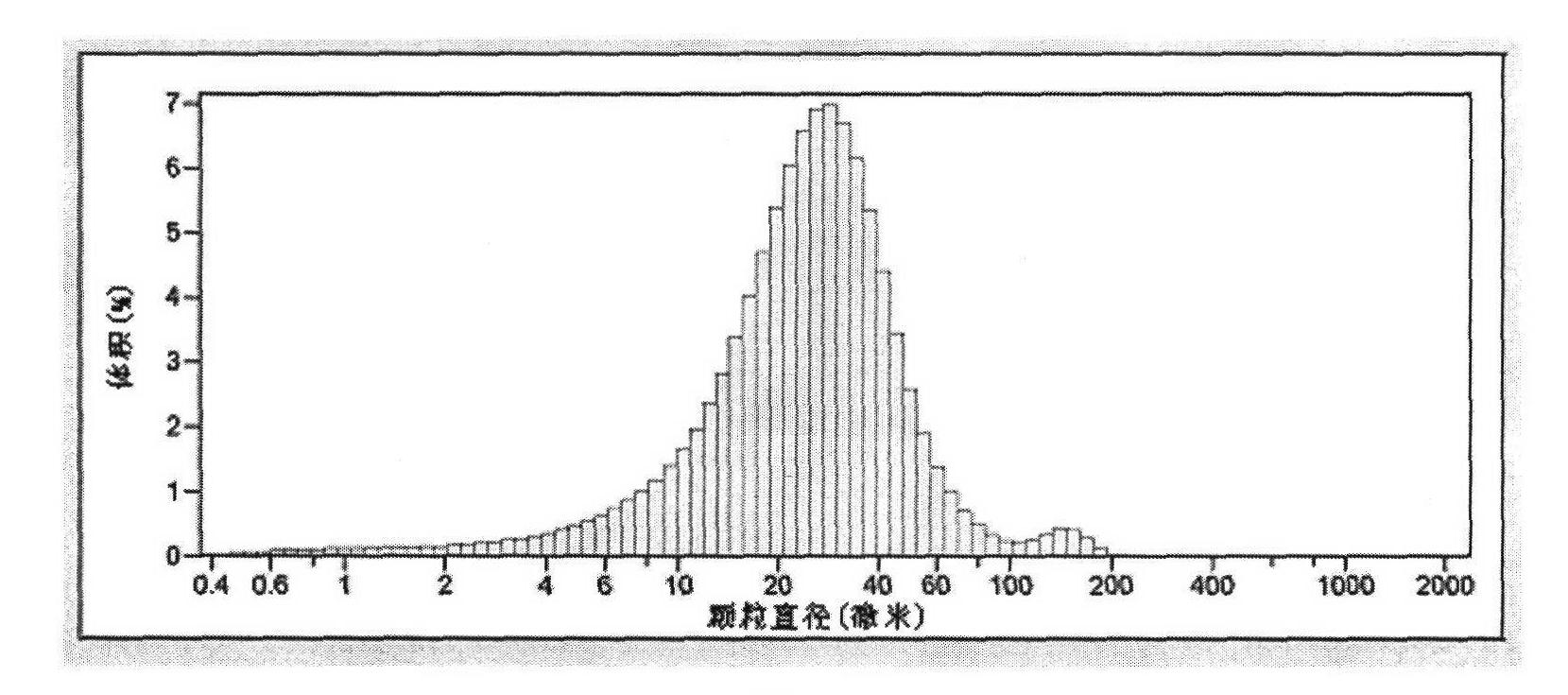

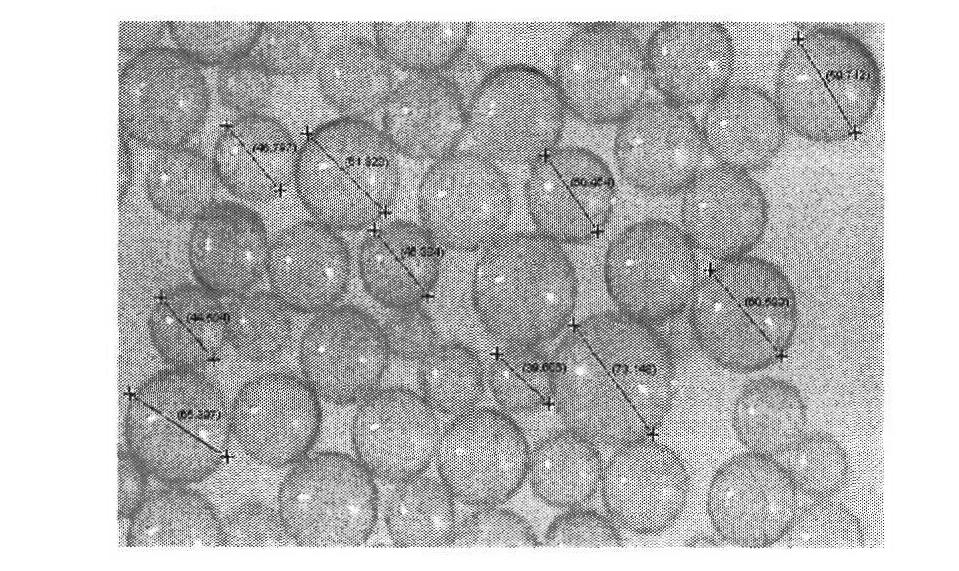

Soft chemical preparation method for hollow glass micro-balloon, prepared hollow glass micro-balloon and application thereof

ActiveCN102583973AHigh strengthHigh compressive strengthGlass shaping apparatusMicron scalePolymer science

The invention belongs to the technical field of a soft chemical method. According to the invention, the method is used for overcoming the defects that the traditional solid-phase glass powder method for preparing a hollow glass micro-balloon is high in energy consumption, long in technical process and difficult in controlling grain size distribution and the hollow glass micro-balloon prepared according to a liquid-phase atomizing method is high in alkalinity, easy to absorb water, high in strength and easy to break, and the like. A liquid material system is compounded through a chemical reaction; after the system is homogenized, the system is quickly atomized, dewatered and dried, thereby obtaining approximate spherical precursor powder with required grain size and corresponding distribution; and the powder is treated under high temperature at 600-1100 DEG C, thereby obtaining a micron-scale hollow glass micro-balloon with the volume floating rate being above 90%, the SiO2 content (weight) being 55-88%, the true density being 0.1-0.7g / cm<3> and the compression strength being 1-50MPa. The method is low in energy consumption, free from fusion and sintering, and high in yield. The prepared hollow glass micro-balloon is high in compression strength, light in weight, low-alkali, waterproof, excellent in fluidity and dispersibility, and suitable for various high-performance light compound materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

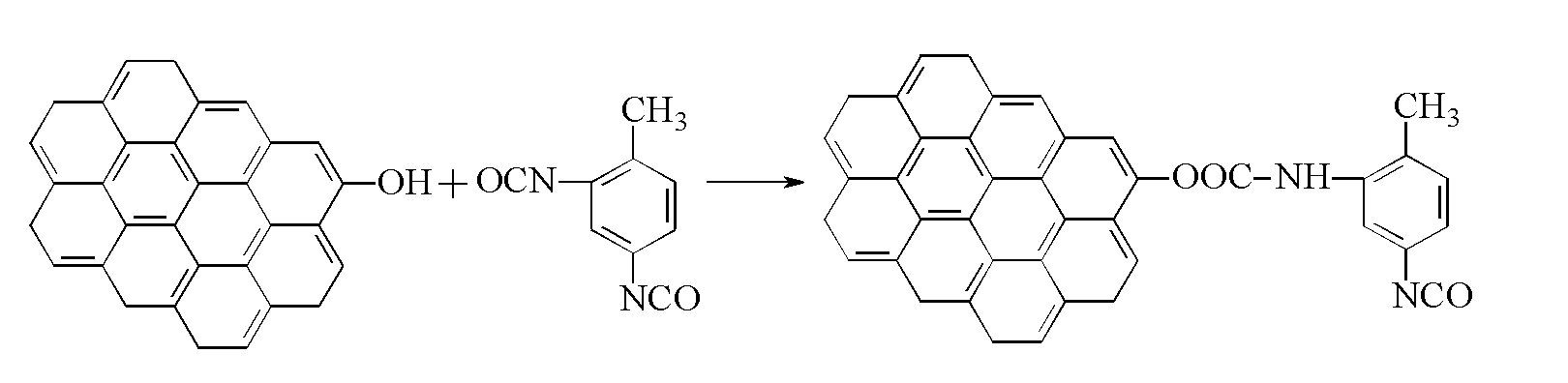

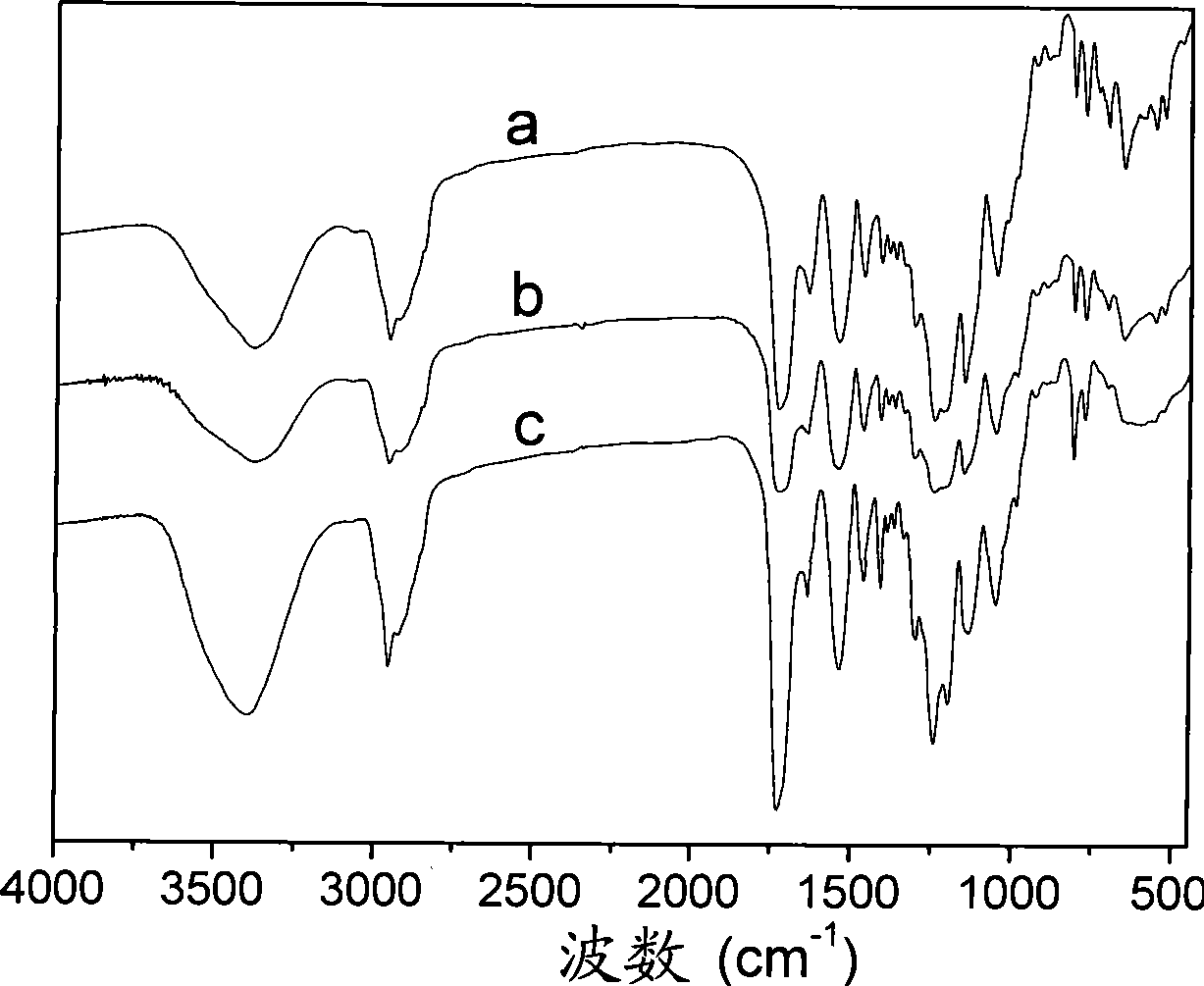

Modified graphene/epoxy resin composite material and preparation method thereof

The invention provides a modified graphene / epoxy resin composite material and a preparation method thereof. The modified graphene / epoxy resin composite material has a two-phase structure, wherein an epoxy resin substrate serves as a main body, and black modified graphene serves as a wild phase. A preparation process comprises the following steps of: preparing graphite oxide; preparing graphene oxide; and preparing a modified graphene / epoxy resin composite material. The modified graphene / epoxy resin composite material has higher toughness compared with epoxy resin and a graphene / epoxy resin composite material, the interface bonding performance between graphene and epoxy resin is greatly enhanced, and the utilization of the performance of graphene is facilitated. By adopting the preparationmethod of the modified graphene / epoxy resin composite material, provided by the invention, the reaction temperature for the preparation of graphite oxide serving as an intermediate product is raised,thus the reaction speed is increased.

Owner:BEIHANG UNIV

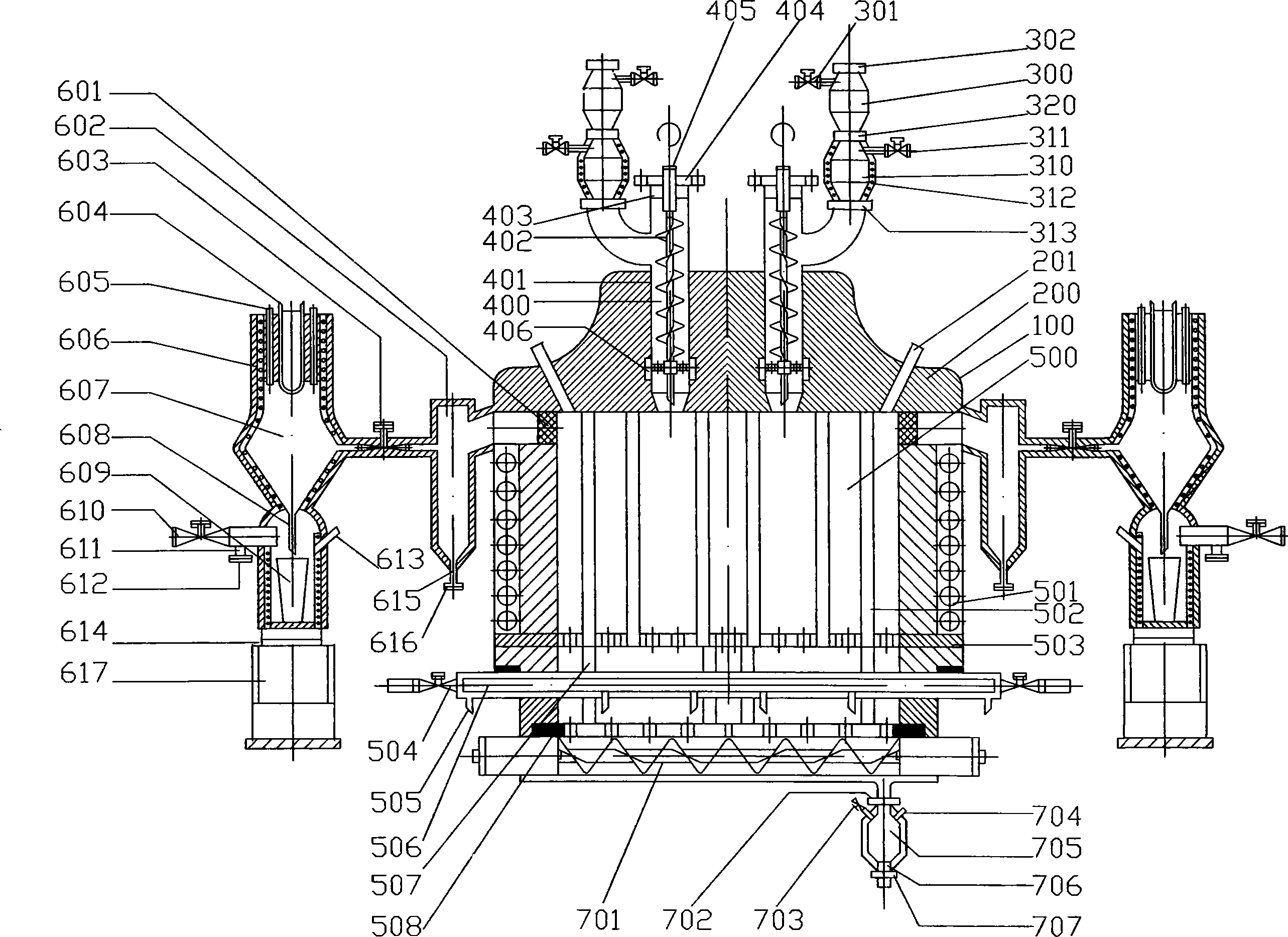

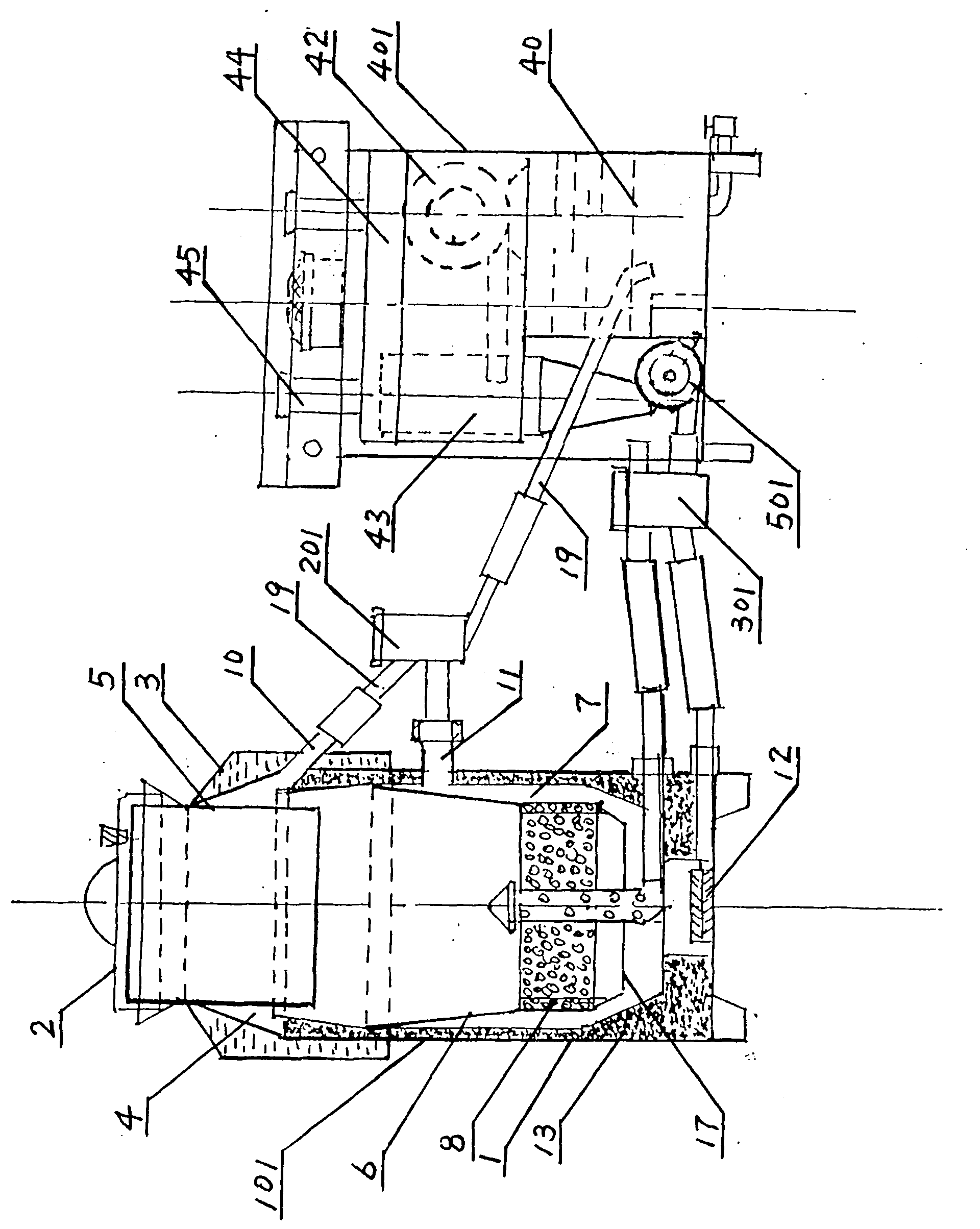

Induction heating continuous magnesium-smelting system and continuous magnesium-smelting technique

The invention discloses a system of inductive heating continuous magnesium smelting and a continuous magnesium smelting technique. The system comprises a continuous feeding device, an inductive heating reaction chamber, a magnesium steam condensing device and a continuous discharging device; wherein the feeding device consists of a feeding housing and a spiral feeding mechanism, the reaction chamber comprises an inductive heating winding, a heating element, a clapboard with holes and a slag cooling device, the condensing device consists of a mesh clapboard, a dust deposition chamber, the magnesium steam condensing chamber, the continuous discharging device comprises spiral slag discharging mechanism and slag housing. The continuous magnesium smelting technique consists of the processes of the continuous feeding of reacting burden into the reaction chamber, the continuous condensation of the magnesium steam and the discharge of liquid magnesium, and also comprises steps of the continuous feeding of reacting slag into the slag housing and slag discharging. The invention has high heat energy utilization rate, and can realize the low cost continuous production of the metal magnesium.

Owner:CENT SOUTH UNIV

Modified urea-formaldehyde resin adhesive and production method thereof

ActiveCN103450832AHigh viscosityViscosity increases relatively gentlyNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer sciencePhosphoric acid

The invention provides a modified urea-formaldehyde resin adhesive low in formaldehyde residue and a production method thereof. The modified urea-formaldehyde resin adhesive is characterized by being prepared from the following raw materials in parts by weight: 100 parts of modified urea-formaldehyde resin, 20-25 parts of reinforcing agent and 0.1-0.2 part of defoamer, wherein the reinforcing agent is any one or a composition of several of white carbon black, titanium dioxide, calcium carbonate and kaolin having the particle size greater than 300 meshes; the defoamer is polydimethylsiloxane or tributyl phosphate. The formaldehyde residue of the modified urea-formaldehyde resin adhesive provided by the invention is less than 0.1 mg / L; the modified urea-formaldehyde resin adhesive is used as an adhesive for an artificial board; as the modified urea-formaldehyde resin adhesive is low in release amount of formaldehyde, the health of customers is protected.

Owner:广西横州丽冠环保材料有限公司

Process for production of an olefin oxide

ActiveUS7507845B1Loss in selectivityImprove productivityOrganic chemistryMolecular sieve catalystsRheniumProduction rate

The invention relates to a process for the epoxidation of an olefin, wherein the concentration of the olefin oxide in the outlet is greater than about 2.2% by volume. More particularly, the invention relates to a process for the epoxidation of ethylene by contacting a feed including at least ethylene and oxygen with an improved epoxidation catalyst. The catalyst which has improved selectivity in the epoxidation process at high productivities, includes a solid support having a surface, which has a first mode of pores that have a diameter ranging from about 0.01 μm to about 5 μm and having a differential pore volume peak in the range from about 0.01 μm to about 5 μm. The surface also has a second mode of pores, which is different from the first mode of pores, having a diameter ranging from about 1 μm to about 20 μm and have a differential pore volume peak in the range from about 1 μm to about 20 μm. On the bimodal pore surface is a catalytically effective amount of silver or a silver-containing compound, a promoting amount of rhenium or a rhenium-containing compound, and a promoting amount of one or more alkali metals or alkali-metal-containing compounds.

Owner:SD LIZENZVERWGMBH

Catalyst for Catalytic Cracking Fluidized Bed

InactiveUS20090288990A1Good effectHigh yieldCatalytic crackingMolecular sieve catalystsNaphthaFluidized bed

The present invention relates to a catalyst for catalytic cracking fluidized-bed, and the technical problems to be primarily solved by the present invention are high reaction temperature, low cryogenic activity of catalysts and worse selectivity during the preparation of ethylene-propylene by catalytically cracking naphtha. The present invention uses the composition having the chemical formula (on the basis of the atom ratio): AaBbPcOx, so as to magnificently solve said problems. The present invention therefore can be industrially used to produce ethylene and propylene by catalytically cracking naphtha.

Owner:CHINA PETROCHEMICAL CORP +1

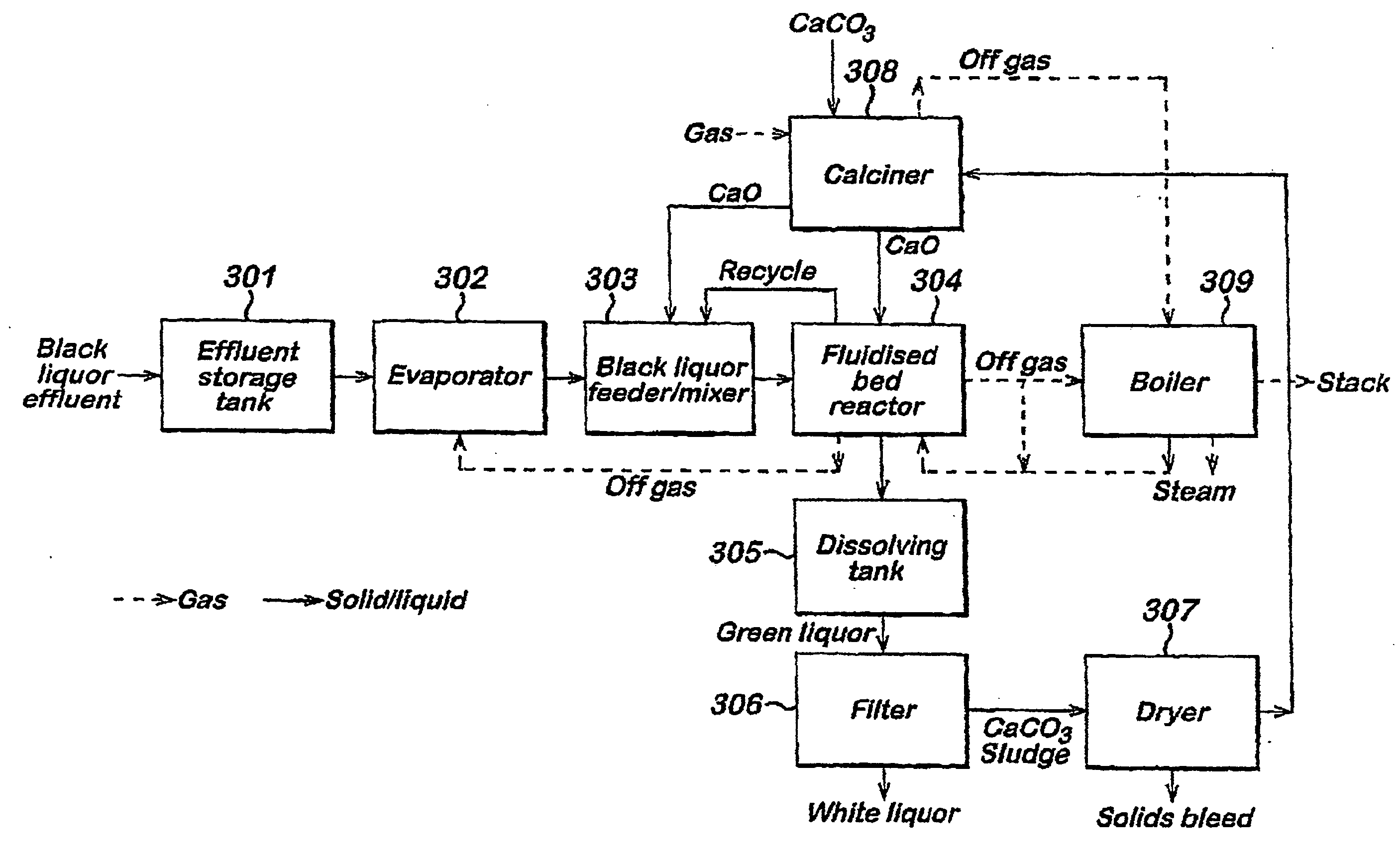

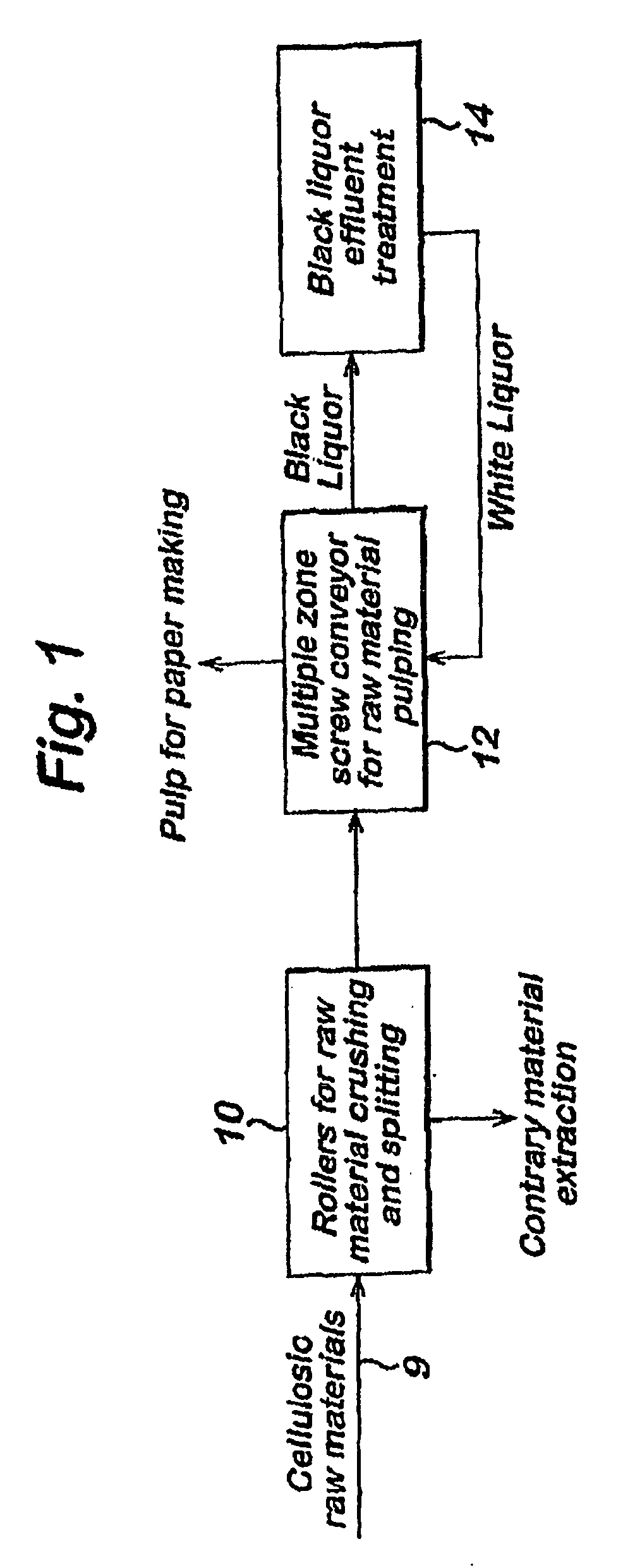

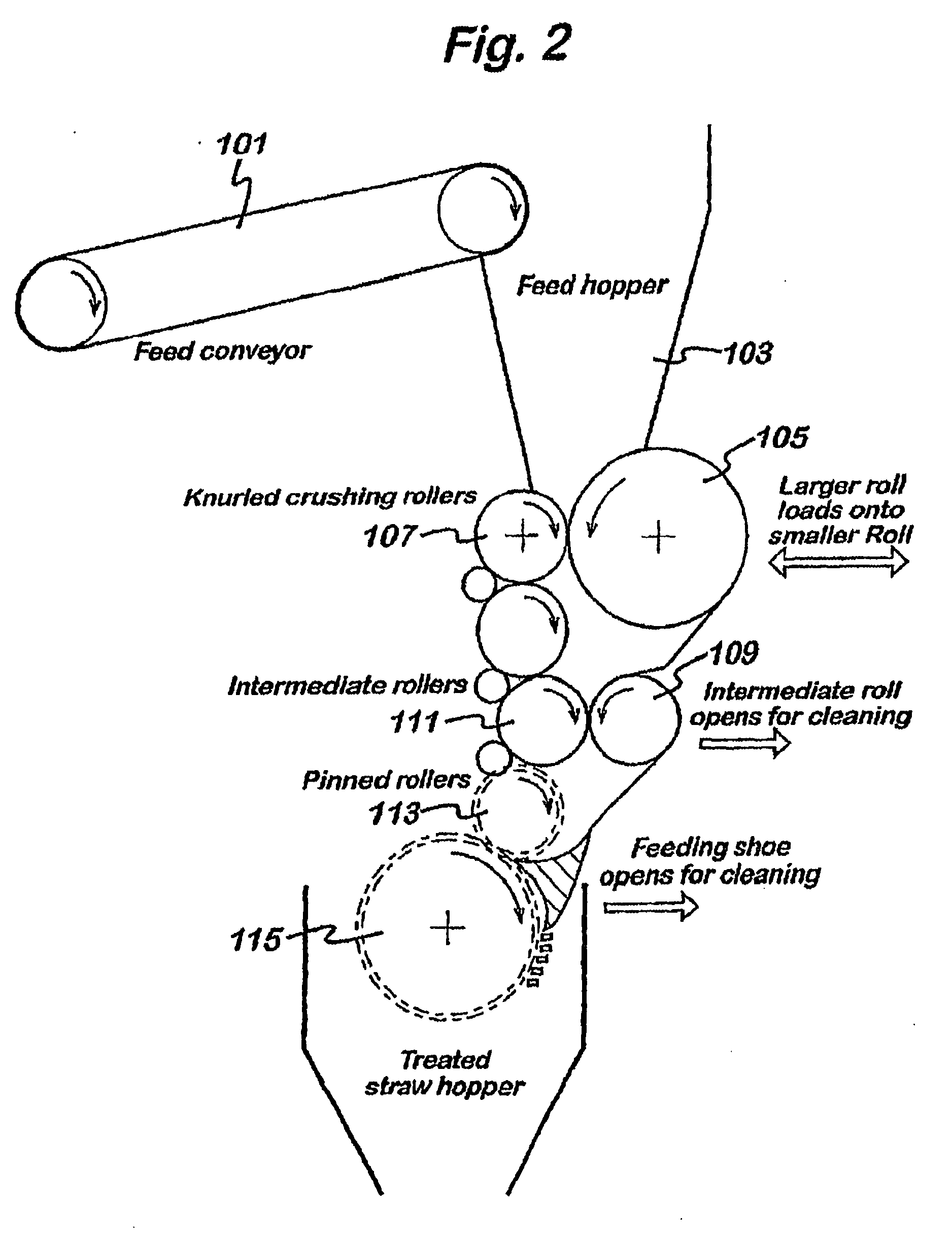

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

Glycol catalyst synthesized by hydrogenating oxalic ester and preparation method and application thereof

InactiveCN101524646AImprove hydrogenation activityLow investment costOrganic compound preparationHydroxy compound preparationHigh activityMetal

The invention discloses a glycol catalyst synthesized by hydrogenating oxalic ester and a preparation method and an application thereof. The catalyst has the chemical formula of CuO-AOx / Al2O3, wherein A is one or more than one metallic element of Zn, Mn, Mg and Cr, x is half of the valence number of A, the content of CuO accounts for 40 percent to 80 percent of the catalyst mass, the content of AOx accounts for 5 percent to 40 percent of the catalyst mass and the content of Al2O3 accounts for 5 percent to 30 percent of the catalyst mass. The catalyst has high activity and selectivity at low temperature and under low pressure, the energy and power consumption in production can be reduced greatly and the catalyst has good stability and long service life. The preparation method of the catalyst is simple and raw materials as industrial products are easily obtained and have low price.

Owner:DANYANG DANHUA COAL CHEM

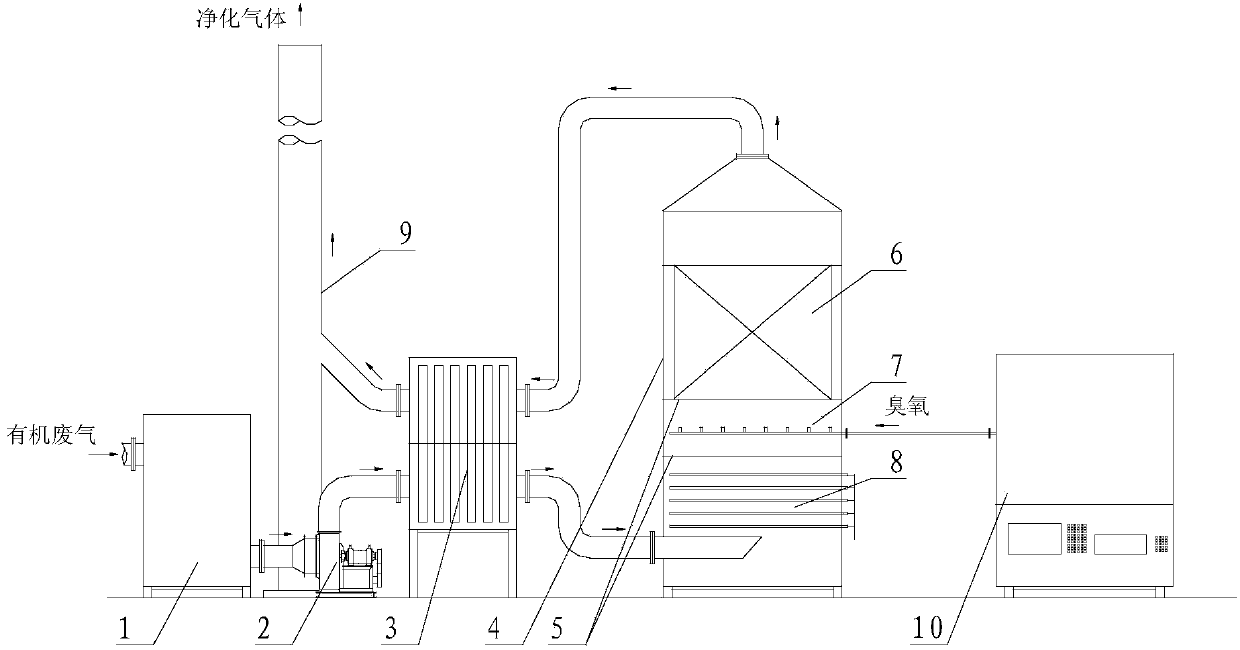

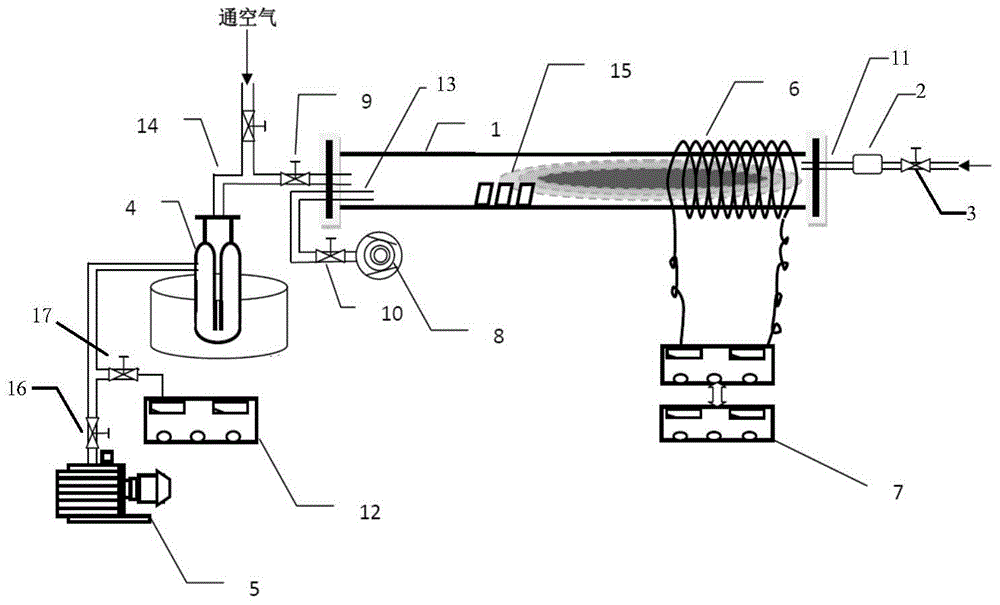

Device and method for treating organic waste gas by catalysis and ozonation

ActiveCN103721563AReduce energy consumptionWith processing efficiencyDispersed particle separationCatalytic oxidationPre treatment

The invention discloses a device and a method for treating organic waste gas by catalysis and ozonation. The method comprises the following steps: (1) the organic waste gas is collected and enters a pretreater, the waste gas is pretreated and oil drops, particulate matter, acid etchant gas and fog drops in the waste gas are intercepted; (2) after the pretreated organic waste gas is pressurized by an induced draft fan, the organic waste gas enters the cold end of a heat exchanger to be preheated; (3) the preheated organic waste gas enters a catalytic oxidation device, the organic waste gas entering the catalytic oxidation device is warmed up and then is mixed with ozone fed into the catalytic oxidation device, and the mixed gas enters a catalytic oxidation reaction region of the catalytic oxidation device to be subjected to the catalytic oxidation reaction so as to remove organic pollutants; (4) the purified gas serving as a heat source enters the hot end of the heat exchanger in the step (2) to be subjected to heat exchange and the gas subjected to heat exchange is discharged by an exhaust pipeline. When being combined with the treatment device disclosed by the invention, the treatment method disclosed by the invention has a better purifying effect on the waste gas and not only ensures purifying efficiency of the waste gas, but also is energy-saving and environment-friendly.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

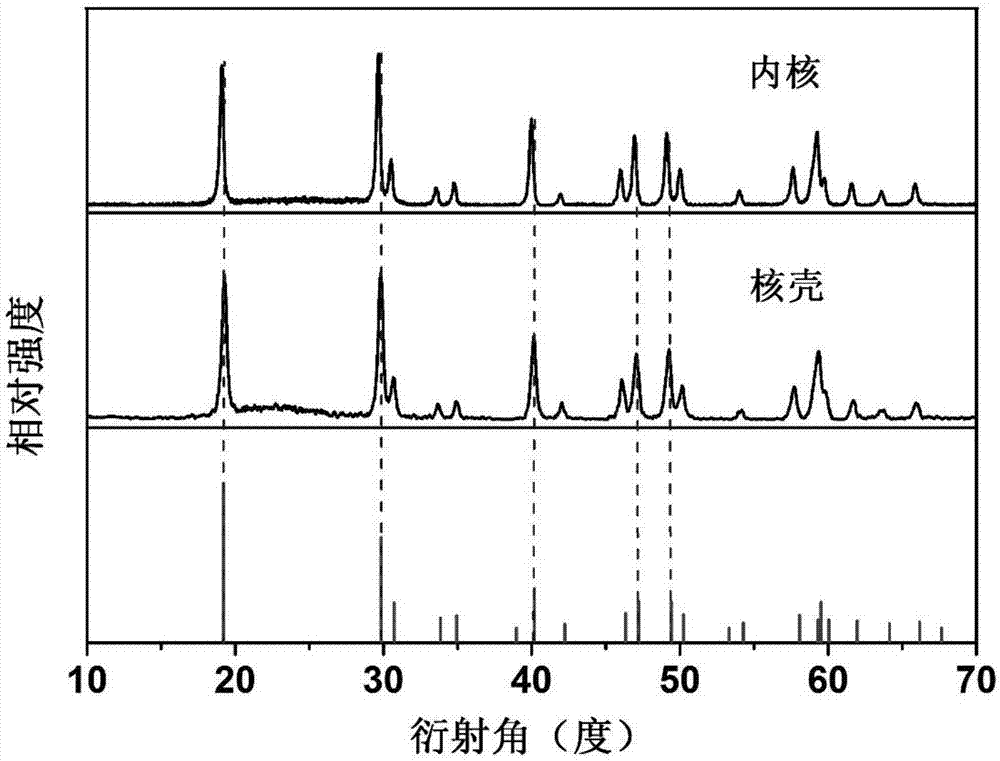

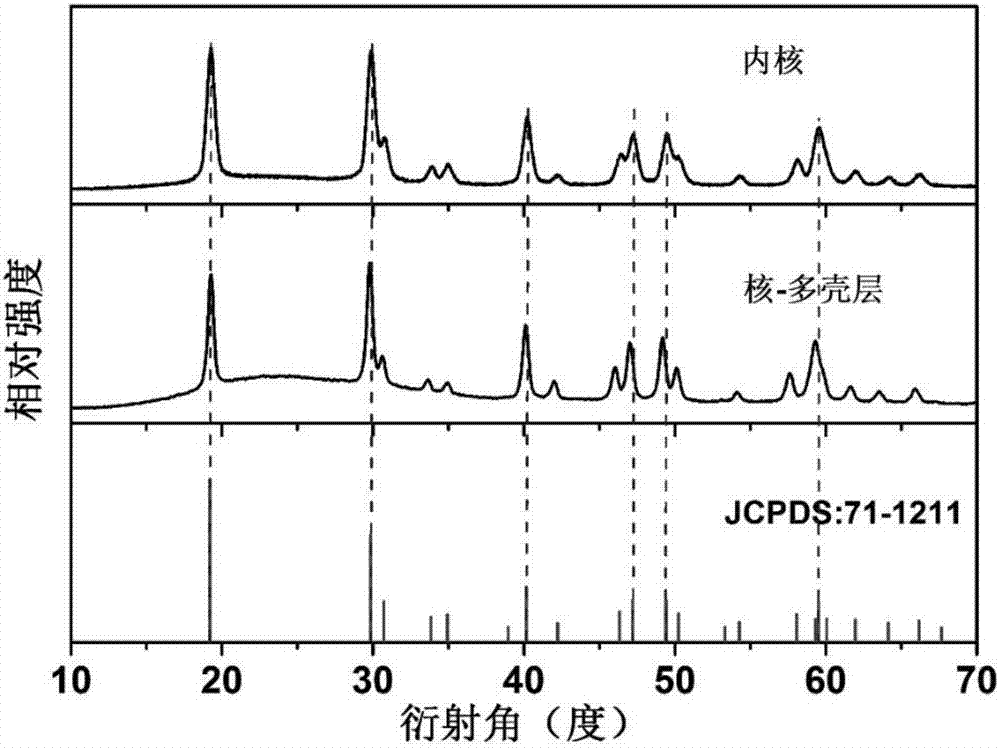

Rare earth doped lithium yttrium fluoride nanometer material and preparation method and application thereof

InactiveCN107033905AGood monodispersityImprove luminous efficiencyNanoopticsLuminescent compositionsBiological imagingRare earth

The invention relates to a rare earth doped lithium yttrium fluoride nanometer material and a preparation method and application thereof. A modified high-temperature coprecipitation method is adopted to synthesize the rare earth doped lithium yttrium fluoride nanometer material with upper conversion / lower transfer luminescence, at the same time, epitaxial growth is conducted on the basis of a core, a mono-layer core-shell structure nanometer material which is uniformly covered can be obtained, and a lithium yttrium fluoride based multi-layer core-shell nanometer material is further prepared. The three prepared and obtained materials are good in monodispersity, uniform in particle size and excellent in luminescent property, after acid pickling treatment, water-soluble nanometer particles can be used for biological detection and biological imaging.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

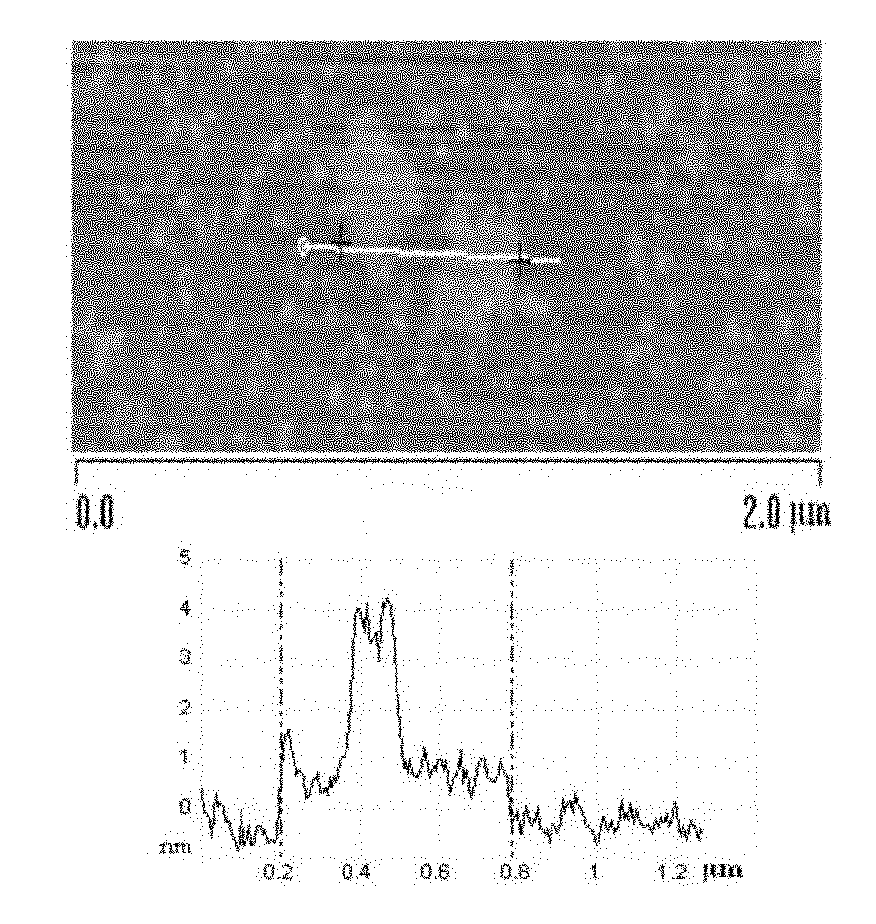

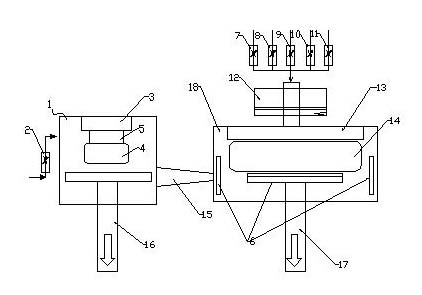

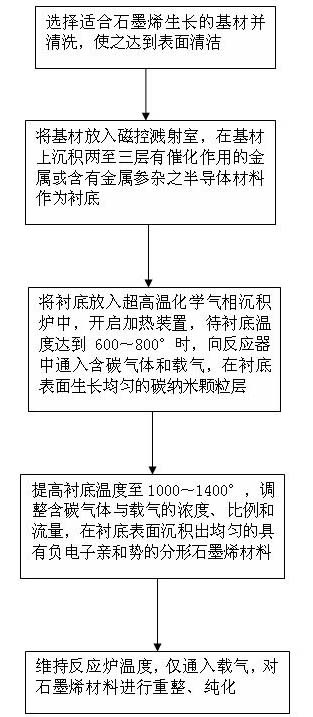

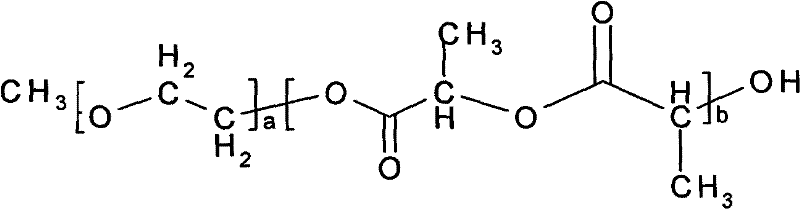

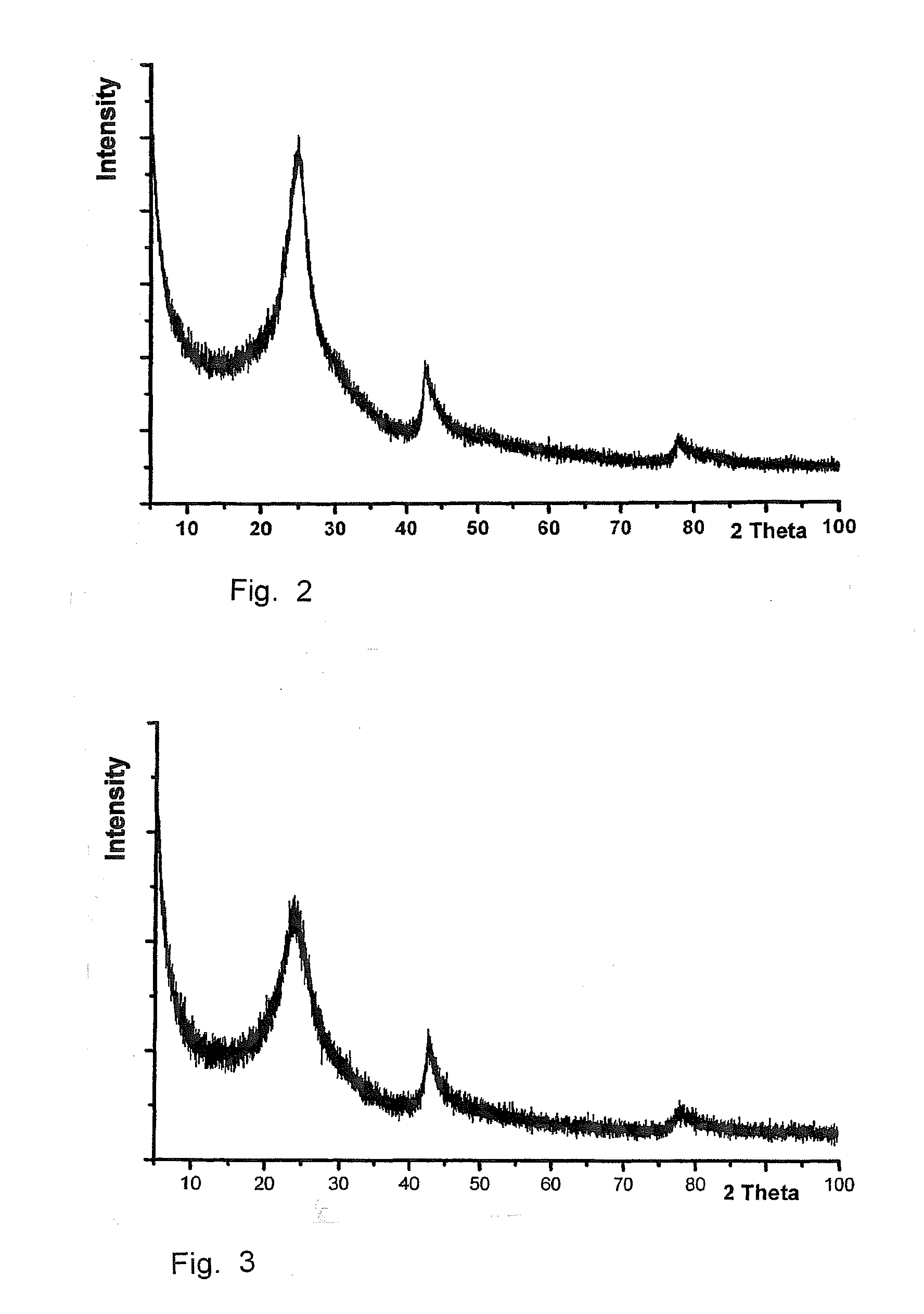

Fractal graphene material with negative electron affinity as well as preparation method and application thereof

ActiveCN101966987APromote escapeExcellent electron field emission capabilityField emission deviceChemical vapor deposition

The invention relates to a fractal graphene material with negative electron affinity as well as a preparation method and application thereof. The fractal graphene material is prepared by adopting a superhigh temperature chemical vapor deposition process and comprises monolayer fractal flake graphene and multilayer fractal flake graphene which are deposited on a substrate and vertically grow in a staggered way; along with the increase of the temperature of the substrate, the crystal state of a graphene nanosheet trends to vertical growth, which directly decides the electrical property orientation of the graphene nanosheet; and the negative electron affinity is generated due to the existence of a large-curvature strip-shaped bulging structure of the flake graphene so that the local field is enhanced, therefore, the fractal graphene material has stronger field electron emission capacity and high structure stability, is very suitable for manufacturing a cathode material of a field emission device and has wide application prospects in the fields of field emission display, cold cathode electric light sources, X-ray sources, electron beam welding and cold cathode electron source devices, and the like.

Owner:CHONGQING QIYUEYONGYANG MICROELECTRONICS SCI&TECH DEV

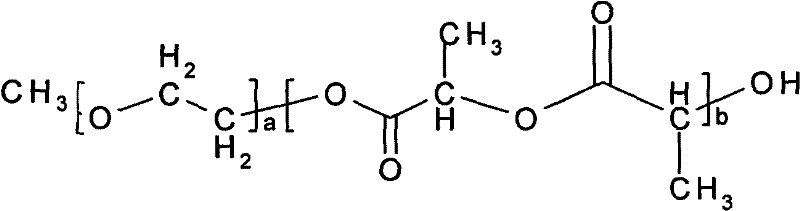

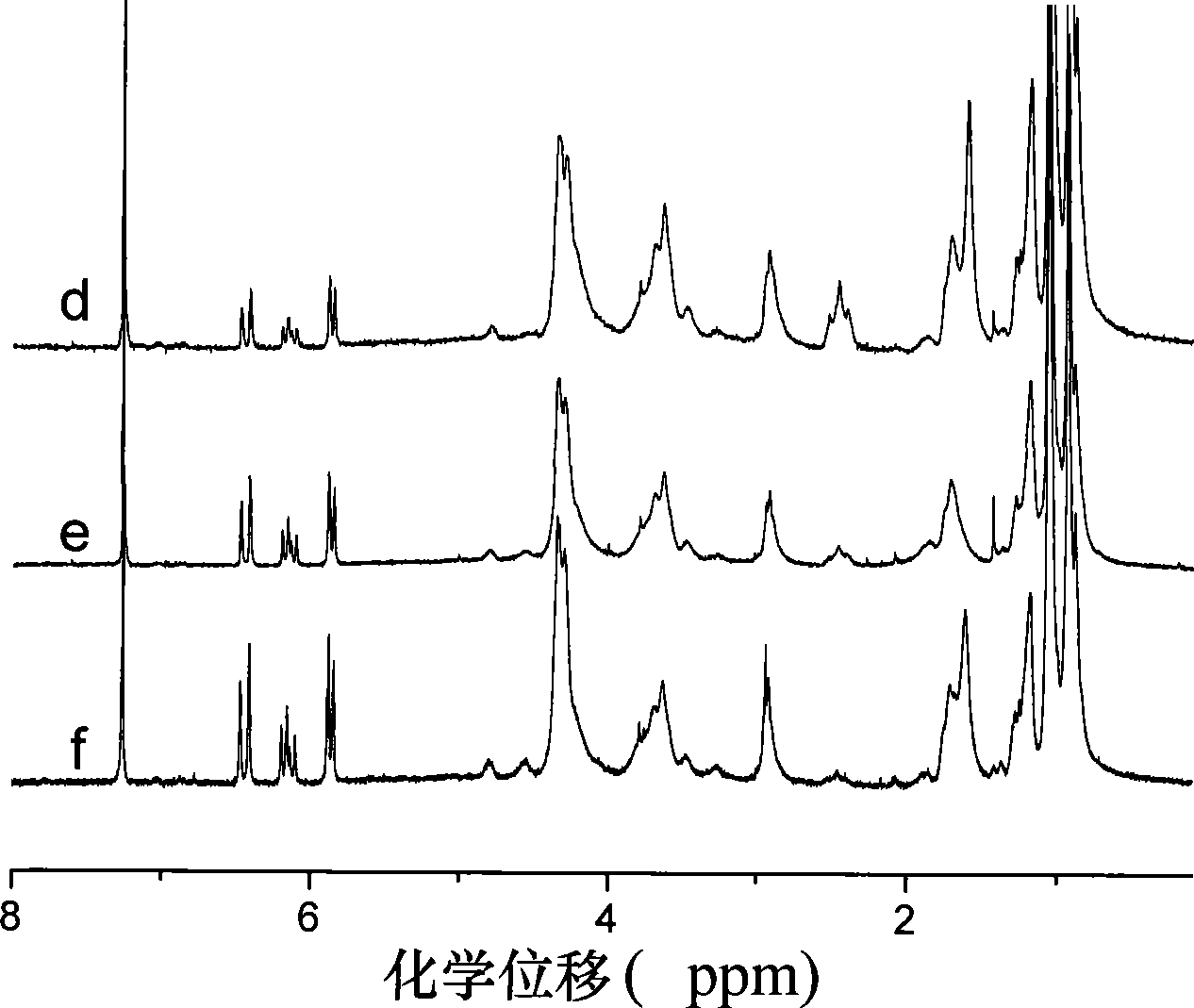

Preparation method of polyethylene glycol monomethyl ether-dl-polylactic acid block copolymer

The invention belongs to the filed of biopolymer material synthesis, relates to a preparation method of a polyethylene glycol monomethyl ether-dl-polylactic acid block copolymer. The method includes the following steps of: adding a solvent with volume more than 3-6 times of total weight of reagents into a dried reactor, adding stannous octoate as a catalyst, and polyethylene glycol monomethyl ether and dl-lactide whose weight ratio is in the range of 65:35 to 20:80, introducing nitrogen, removing air, then heating and reacting, pouring a product into a compound of petroleum ether-carbon dioxide dry ice, simultaneously, violently stirring, obtaining the needed product after drying a white filtered solid in a vacuum drying oven. The new-type solvent is used in the invention, and a novel purification processing method is provided and is simple and easily controlled, the copolymer with a certain amount of molecular weight can be synthesized according to the specified requirement, and the requirement of further producing a pharmaceutical preparation is met.

Owner:上海谊众药业股份有限公司

Catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, preparation method and applications thereof

InactiveCN106582652AHigh activityImprove overall lifespanOrganic compound preparationHeterogenous catalyst chemical elementsSal ammoniacCopper salt

The present invention relates to a catalyst for ethylene glycol synthesis through gas phase hydrogenation of dimethyl oxalate, a preparation method and applications thereof. The catalyst comprises CuO, a metal auxiliary agent oxide and silica, wherein the Cu element accounts for 10-50% of the total weight of the catalyst, and the metal auxiliary agent element accounts for 1-10% of the total weight of the catalyst. The invention further discloses the preparation method of the catalyst. According to the present invention, a soluble copper salt and a metal auxiliary agent soluble salt are used and are added with ammonia water to form an ammonia complex aqueous solution, aging-ammonia evaporation and co-precipitating are performed, and the obtained material and silica form the gel so as to form the stable chemical structure, such that the stability of the catalyst is substantially improved; during the preparation process, the organic modifier is added so as to effectively improve the pore structure and the specific surface area of the catalyst, and improve the activity of the catalyst and the ethylene glycol selectivity; and with the application of the catalyst in the dimethyl oxalate hydrogenation reaction, the service life is more than one year, the average conversion rate of dimethyl oxalate is more than 99.9%, and the ethylene glycol selectivity is more than 95%.

Owner:SHANGHAI HUAYI ENERGY CHEM

Stable dispersions of single and multiple graphene layers in solution

ActiveUS9045346B2Rapid productionKeep for a long timeMaterial nanotechnologyFinal product manufactureCvd grapheneLithium-ion battery

A method for producing colloidal graphene dispersions comprises the steps of: (i) dispersing graphite oxide in a dispersion medium to form a colloidal graphene oxide or multi-graphene oxide dispersion, and (ii) thermally reducing the graphene oxide or multi-graphene oxide in dispersion. Depending on the method used for the preparation of the starting dispersion, a graphene or a multi-graphene dispersion is obtained that can be further processed to multi-graphene with larger inter-planar distances than graphite. Such dispersions and multi-graphenes are, for example, suitable materials in the manufacturing of rechargeable lithium ion batteries.

Owner:BELENOS CLEAN POWER HLDG

Process for methanol coupled catalytic cracking reaction of naphtha using a modified zsm-5 molecular sieve catalyst

ActiveUS20140051900A1Improving catalytic cracking efficiencyLow carbon olefinsCatalytic crackingLiquid hydrocarbon mixture productionCyclic alkaneNaphtha

The present invention provides a process for methanol coupled catalytic cracking reaction of naphtha using a modified ZSM-5 molecular sieve catalyst, comprising performing a co-feeding reaction of methanol and naphtha on the modified ZSM-5 molecular sieve catalyst to produce low carbon olefins and / or aromatic hydrocarbons. In the process, the modified ZSM-5 molecular sieve catalyst comprises, in term of weight percent, 25-80 wt % of a ZSM-5 molecular sieve, 15-70 wt % of a binder, and 2.2-6.0 wt % of lanthanum and 1.0-2.8 wt % of phosphorus loaded on the ZSM-5 molecular sieve. The naphtha comprises 63.8-89.5 wt % of saturated chain alkanes and 5.6-29.8 wt % of cyclic alkanes. The naphtha and methanol concurrently pass through the catalyst bed, which are reacted during contacting with the catalyst under a reaction condition of a reaction temperature of 550-670° C., a mass ratio of methanol to naphtha of 0.05-0.8, and a total mass space velocity of naphtha and methanol of 1.0-5 h−1.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Hydrogenating and demetalization catalyst and its prepn

InactiveCN1417300AHigh activityImprove activity stabilityCatalyst activation/preparationHydrocarbon oils refiningPore distributionHigh activity

The hydrogenating and demetalization catalyst contains a alumina carrier and hydrogenating group VIB and group VIII metal component carried on the carrier, where the alumina carrier is gamma-alumina,which has such pore distribution that the pore volume of pores of 10-20 nm diameter accounts for 70-98 % of the total pore volume. The catalyst has high activity and high activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

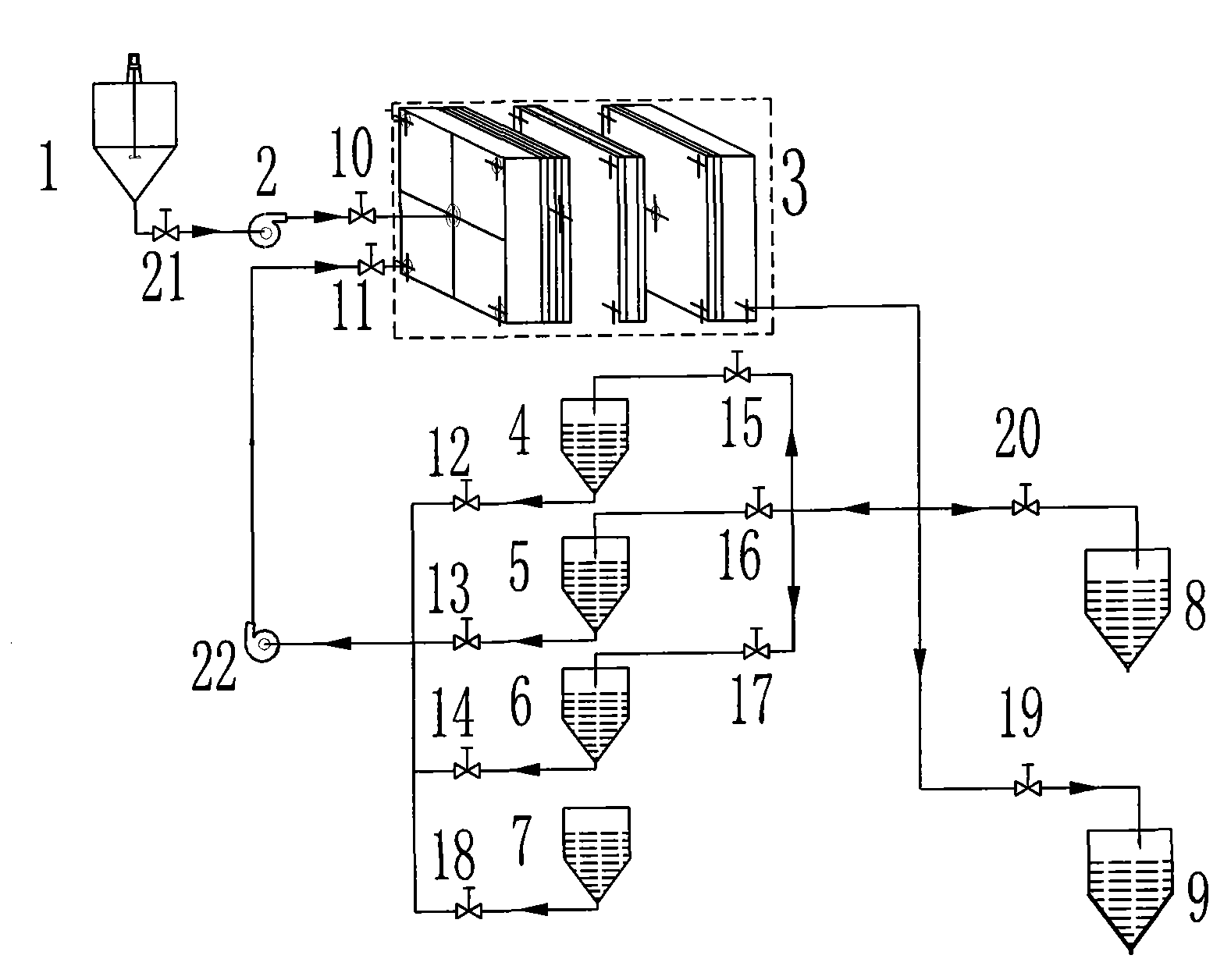

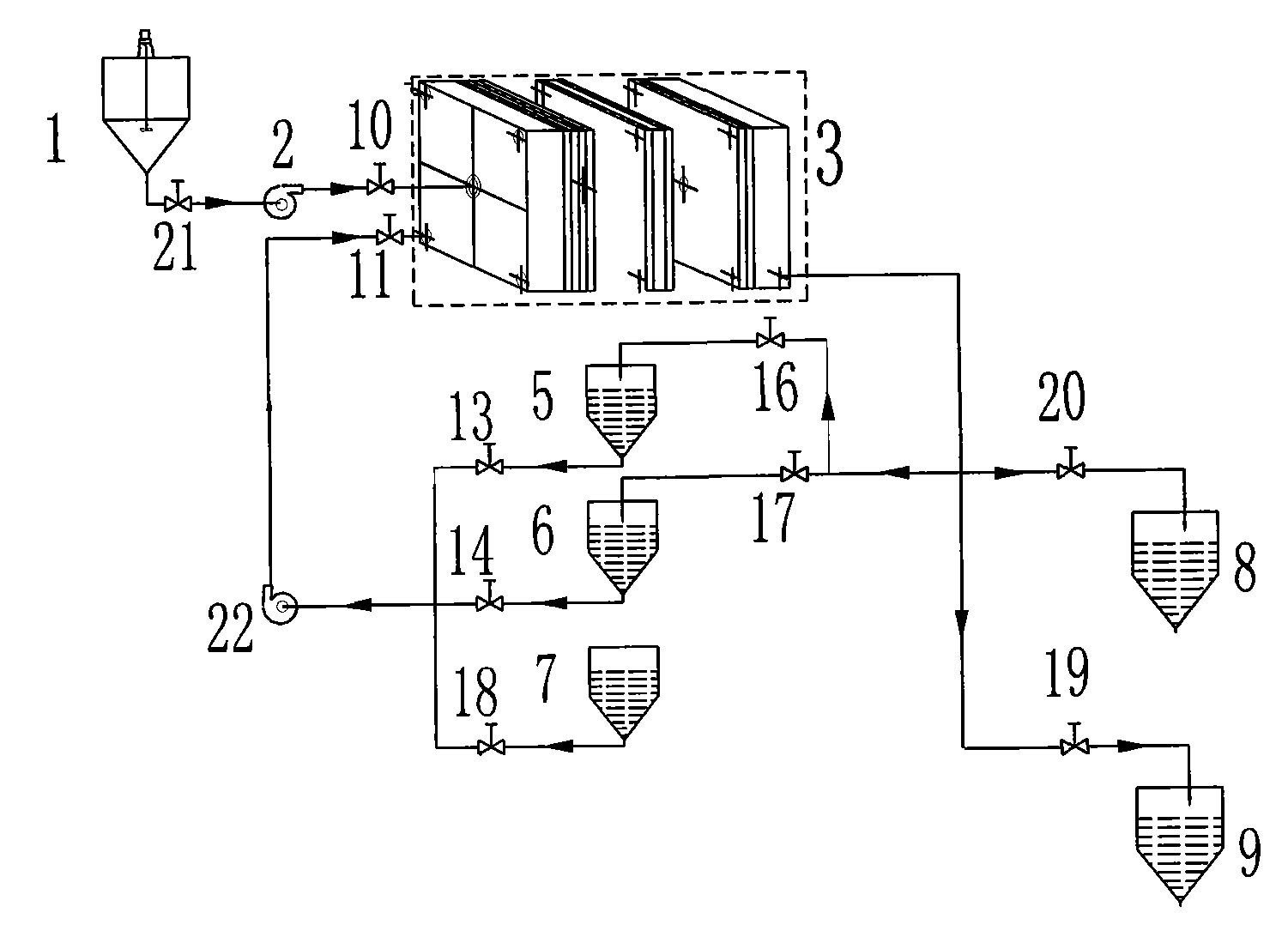

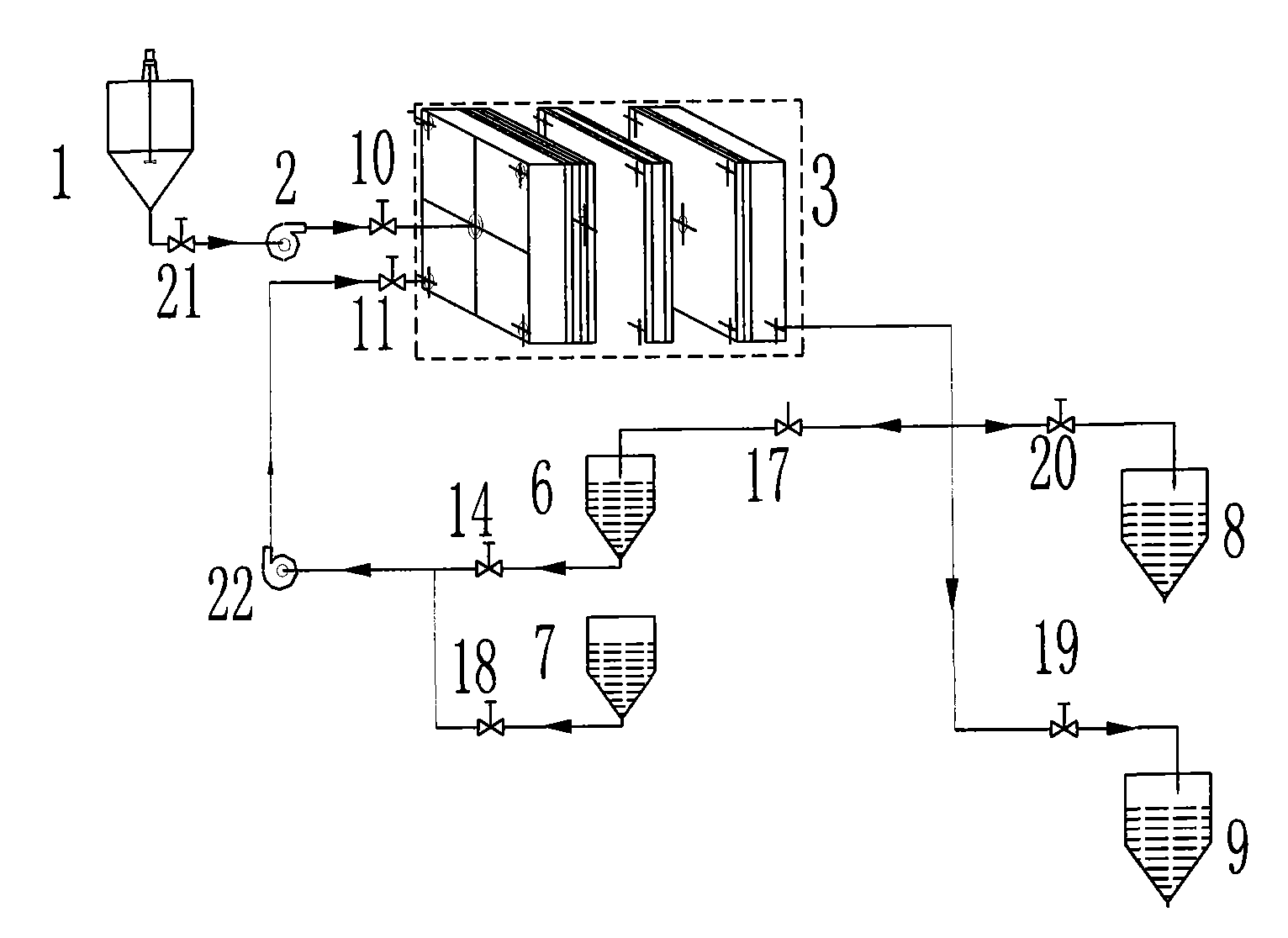

Multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method

InactiveCN102071311AWater-soluble zinc content is reducedReduce environmental risksFiltration separationProcess efficiency improvementElectrolysisSlag

The invention relates to a multisection acid leaching, multistage countercurrent washing and filter pressing integrated system and method which are applicable to industries such as the metallic zinc electrolysis industry, hydrometallurgy and the like. The system provided by the invention comprises a membrane filter press, wherein the feed port end of the membrane filter press is connected with a zinc calcine acid leaching liquor feed pool, and the discharge port end of the membrane filter press is respectively connected with a filtrate pool and a collection liquor pool; and a waste electrodeposit liquor circulation pool, a circulation washing pool and a clean washing water pool are connected in parallel between the feed port end and discharge port end of the membrane filter press. The method provided by the invention comprises the following steps: (1) feeding materials; (2) carrying out multisection acid leaching by using the waste electrodeposit liquor at different temperature gradients; (3) carrying out multistage countercurrent washing by using zinc-containing washing water of different concentrations; and (4) carrying out filter pressing on the filter cake. According to the invention, the content of water-soluble zinc (in terms of Zn) in zinc waste slag in the mainstream technique in metallic zinc electrolysis industry at present can be reduced from 3.5-6.0% to below 0.5%; and the acid leaching and washing efficiency are greatly enhanced, and the acid leaching recovery rate of zinc ore can be higher than 97%.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

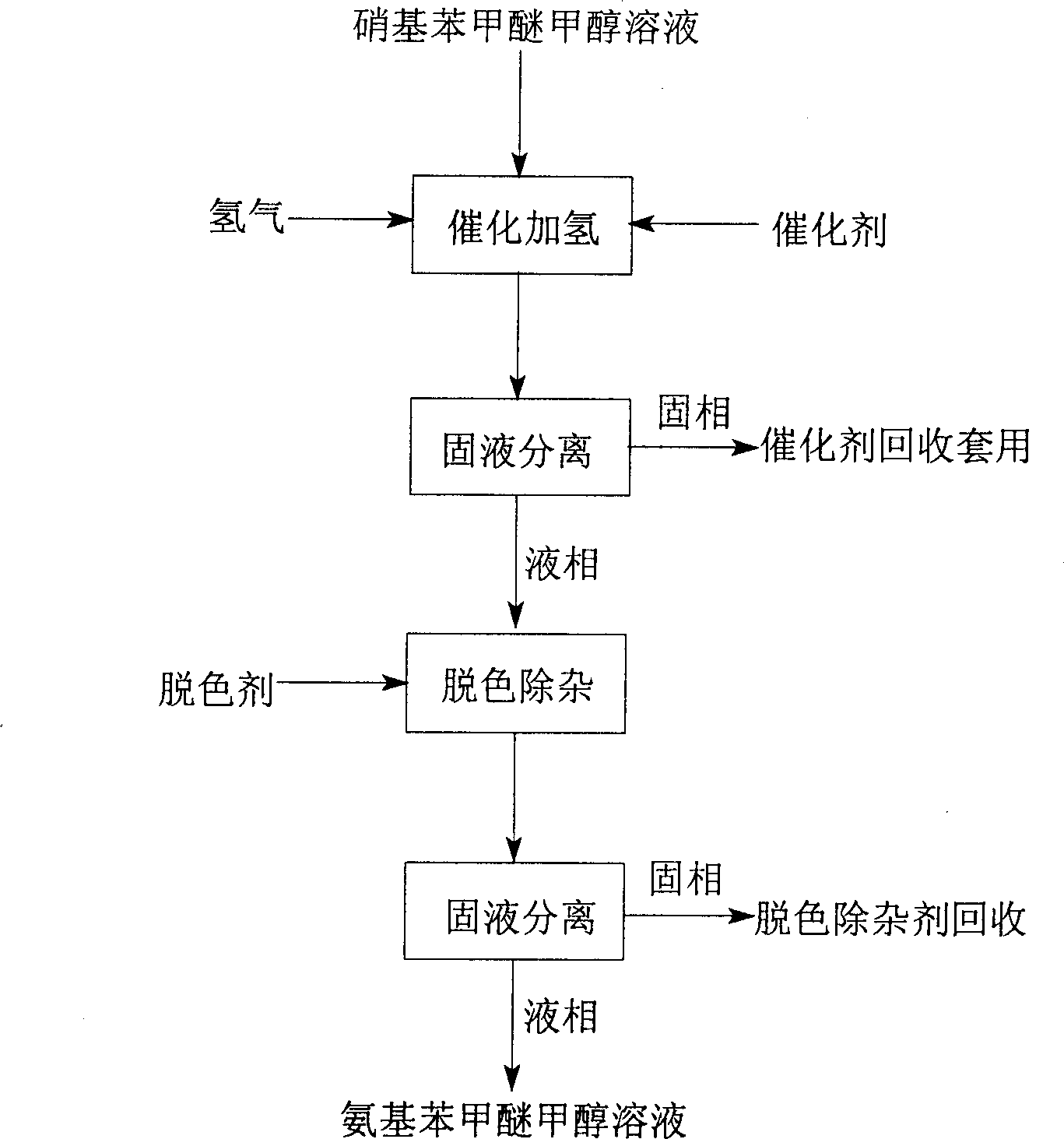

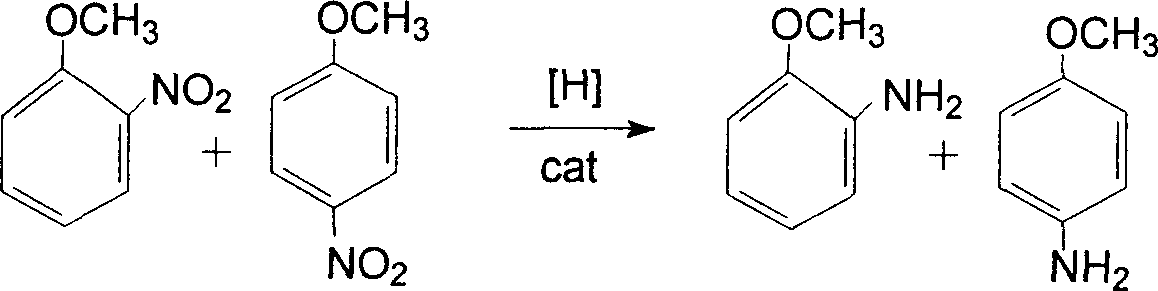

Tech. of preparing amino benz methyl-phenoxide by nitro methyl-phenoxide mixture catalyzing hydrogenation

InactiveCN1861570AImprove dispersionImprove recycling efficiencyOrganic compound preparationAmino-hyroxy compound preparationSolventImpurity

A process for preparing amino phenylmether from nitro phenylmether mixture by catalytic hydrogenating includes such steps as catalytic hydroreducing reaction between methanol, nitro phenylmether mixture and catalyst, recovering catalyst, decoloring, removing impurities, filtering to obtain liquid phase (the solution of amino phenylmether, methanol and water), separation and refining.

Owner:CHANGZHOU JIASEN CHEM +1

Method for oxidizing fluorene to 9-fluorenone

ActiveCN1754867AIncrease profitHigh yieldOrganic compound preparationCarbonyl compound preparationWastewaterOxygen

The invention discloses a method to prepare 9-fluorenone with fluorene. Wherein, using dimethyl sulfoxide as solvent, sodium hydroxide as catalyst, oxygen as oxidant and tower filling reactor; cooling and filtering the reacted liquid to obtain 93% coarse fluorenone; distilling liquid and recycling 94% solvent and some coarse fluorenone; refining with oriented crystallization method and obtaining yellow piece 99.8% fluorenone. This method is simple, needs short reaction time, produces no waste water, and convenient to produce in industry.

Owner:SHANGHAI HUAYI ENERGY CHEM

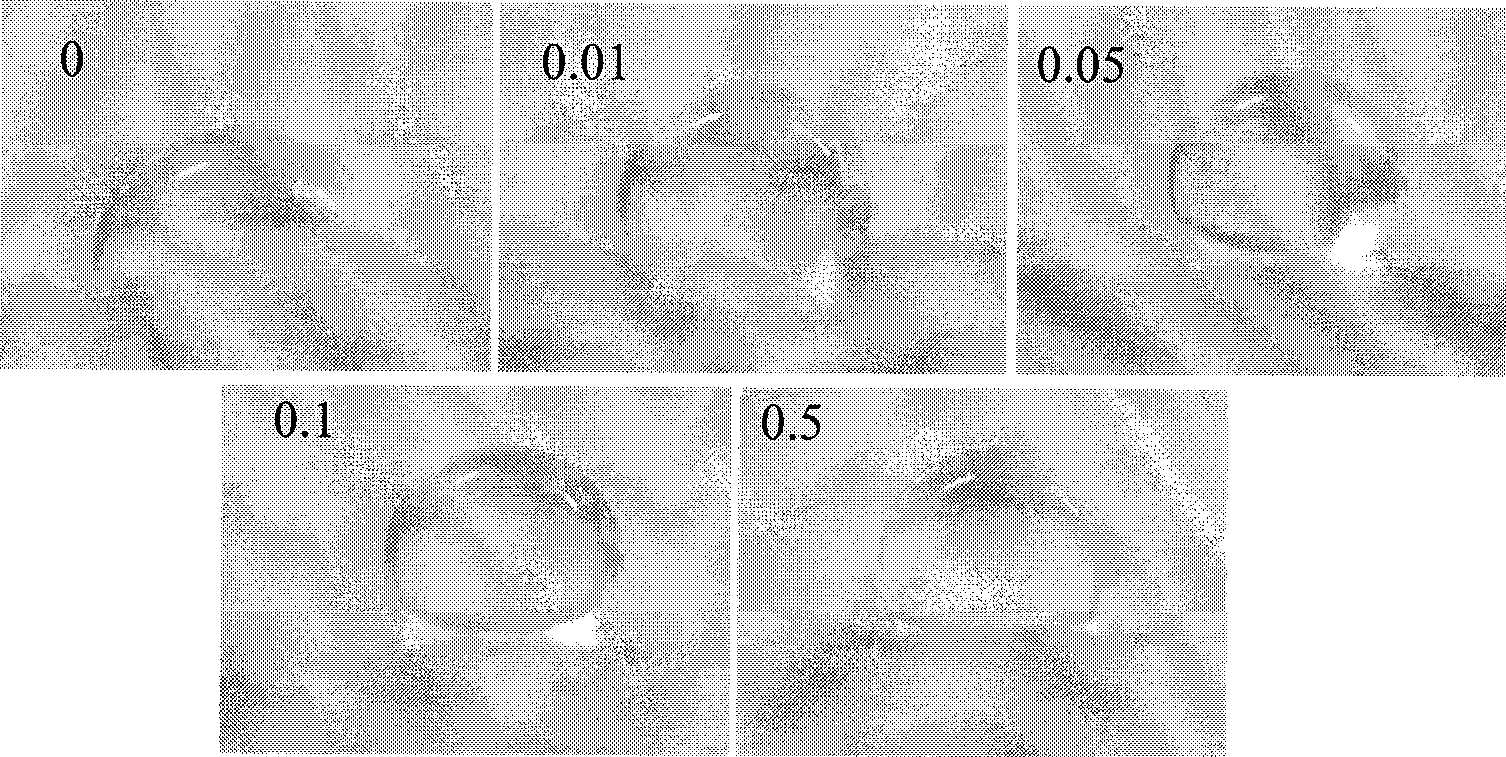

Hetero atom-doped hollow spherical grapheme composite material, and preparation method and applications thereof

The invention belongs to the technical field of carbon material and electrochemistry, and discloses a hetero atom-doped hollow spherical grapheme composite material, and a preparation method and applications thereof. The preparation method comprises following steps: styrene, polyvinyl pyrrolidone, and 2,2'-azobis(2-methylpropionamidine) dihydrochloride are mixed with water, and positively charged polystyrene spheres are prepared under certain conditions; a graphene oxide aqueous dispersion and a positively charged polystyrene sphere aqueous dispersion are stirred for reaction so as to prepare a graphene oxide@polystyrene sphere compound; a hetero atom-doped sourced compound and a solvent are added into the graphene oxide@polystyrene sphere compound, and an obtained mixture is subjected to mixing, coating, and freeze drying so as to obtain solid thin films; a substrate loaded with the solid thin films is delivered into a plasma high-temperature tubular reactor for reaction so as to obtain the hetero atom-doped hollow spherical grapheme composite material. The hetero atom-doped hollow spherical grapheme composite material possesses relatively high specific surface area and relatively excellent electrical properties, and can be applied to the field of supercapacitor.

Owner:SOUTH CHINA UNIV OF TECH

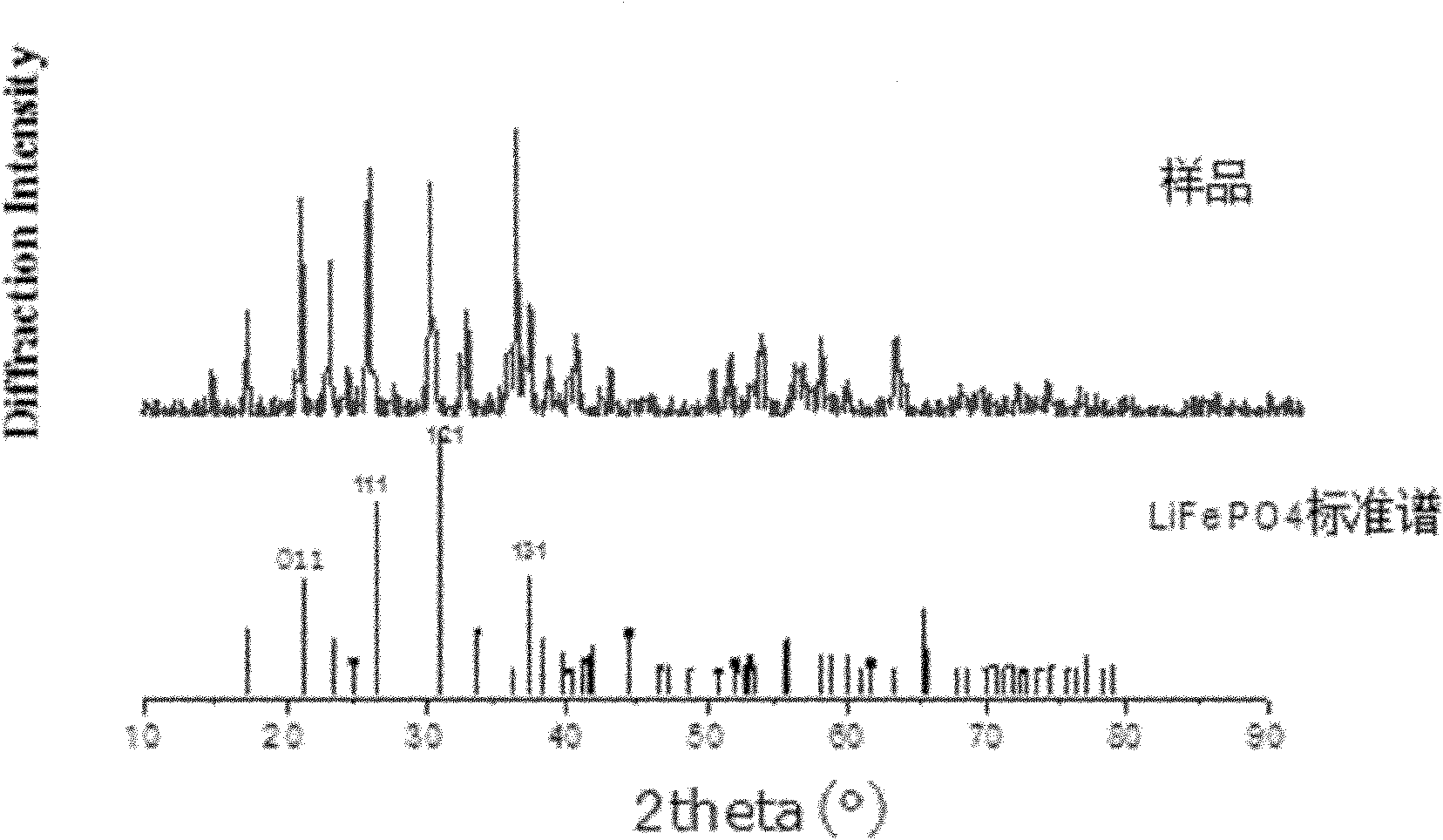

Hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate

InactiveCN102074687AShort tripIncrease the speed of diffusionCell electrodesReaction temperatureMolecular level

The invention discloses a hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate, which belongs to the field of lithium-ion battery anode materials and comprises the following steps of: sequentially adding a phosphorus-source solution, an iron-source solution, a carbon source, a lithium-source solution and a boiling-point elevator into a reaction device in sequence, mixing, then heating to the temperature of 60-180 DEG C for reaction under inert gas, cooling after the reaction, filtering precipitates to obtain a nano-scale lithium iron phosphate precursor, and then sintering the nano-scale lithium iron phosphate precursor at the temperature of 400-600 DEG C under the protection of the mixed gas of the inert gas and hydrogen gas. The combination of lithium, iron, phosphorus and the like on a molecular level is realized by the method, and the grains of a product are quite fine and are uniformly distributed; because the boiling-point elevator is adopted, the reaction temperature and pressure of the reaction kettle are decreased; and the hydrothermal synthesis method has the advantages of simple preparation process, short flow, easiness in operational control, low reaction temperature, short time, low energy consumption and easiness in realizing large-scale industrialized production.

Owner:JIANGSU DELI CHEM

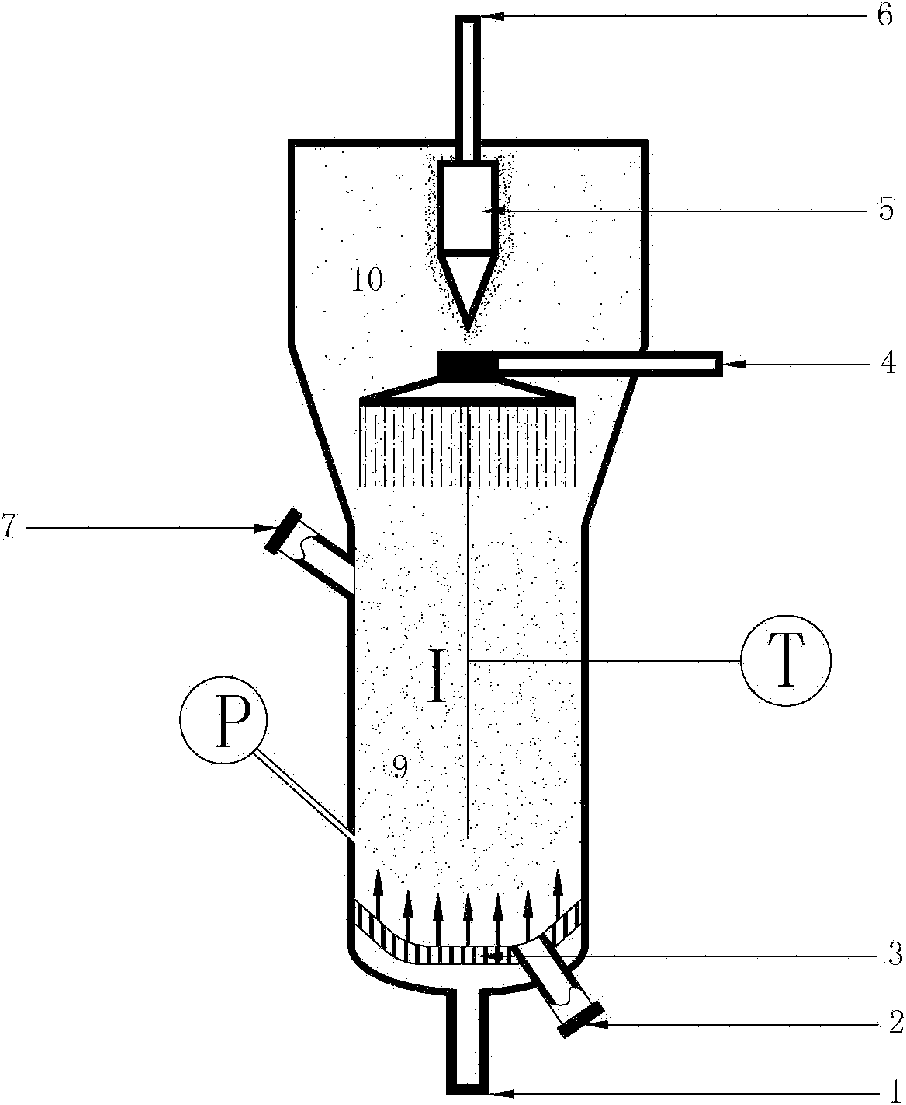

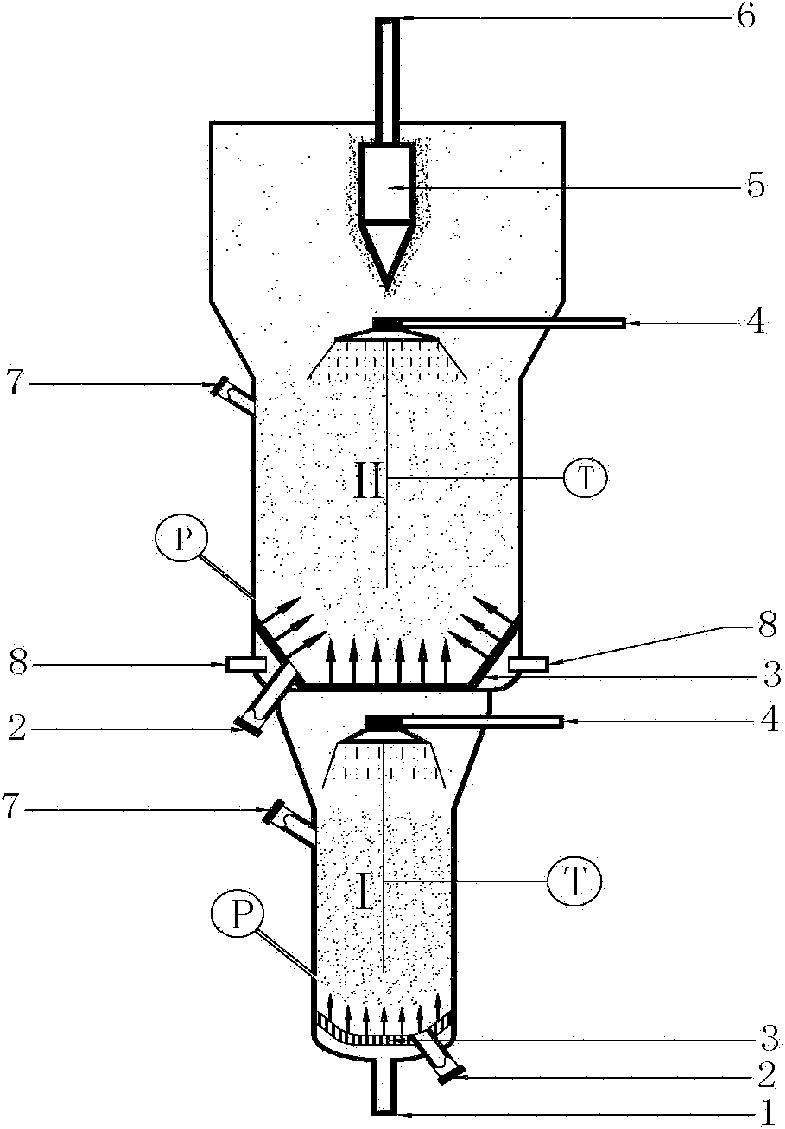

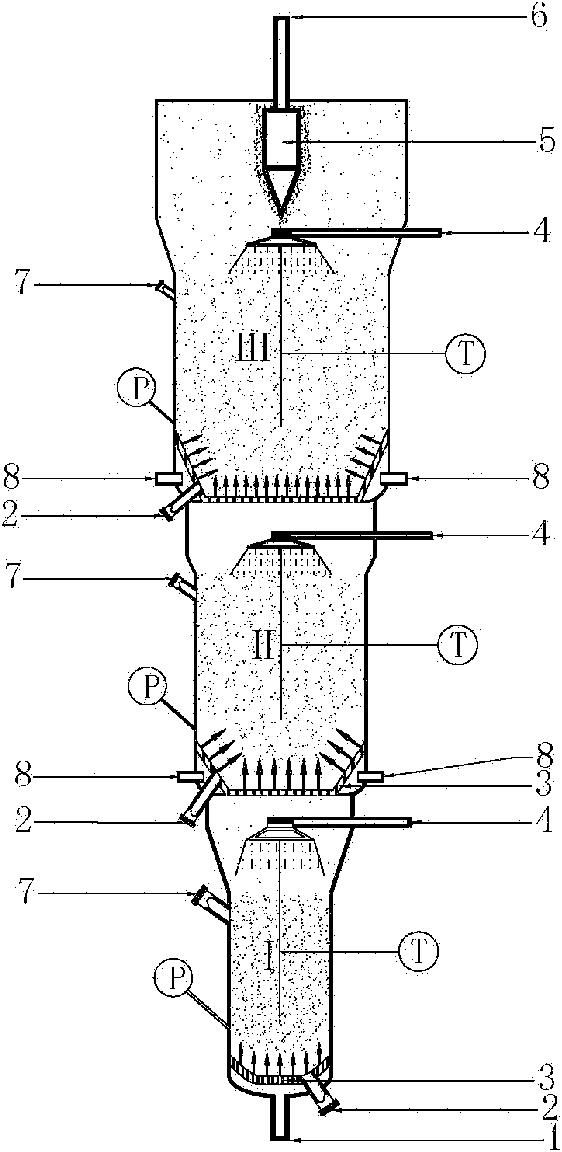

Fluidized bed reactor and method for methanation of gas mixture containing H2 and CO

ActiveCN102600771AReduce the numberExtend your lifeHydrocarbon from carbon oxidesChemical/physical processesGas solidContact high

The invention relates to a fluidized bed reactor and a method for methanation of gas mixture containing H2 and CO. The fluidized bed reactor of the invention comprises a material gas inlet 1, a catalyst outlet 2, a gas-solid separator 5, a product gas outlet 6, a catalyst inlet 7 and a material gas lateral line inlet, wherein one or more gas distribution plate 3 is arranged in the fluidized bed reactor in order to divide the reactor into several fluidized bed layers to form several catalyst dense-phase zones; a cooling water spraying device 4 is arranged above each layer of the catalyst dense-phase zone in order to control temperature of the reactor. Because the circulating cooling water directly contacts high-temperature product gas, the reactor of the invention strengthens heat transfer, is easy to control reaction temperature, reduces heat loss during the heat transfer and improves heat utilization rate during the reaction. The reactor has the advantages of large production flux, big operation elasticity, high CO conversion rate, high selectivity of produced methane, less catalyst dosage, high utilization rate of heat quantity and so on, so that the reactor has good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Double-flow biomass gasified gas purification device

InactiveCN102079998AHigh calorific valueIncrease contact areaBulk chemical productionCombustible gas productionReaction temperatureMoisture

The invention relates to a gasified gas purification device, in particular to a double-flow biomass gasified gas purification device, which solves the problems of low reaction temperature of a gasification furnace, abundant generated tar and wastewater, low gas-producing efficiency and abundant impurities and low heat value of output gas, resulted from unscientific structure of the gasification furnace. The gasified gas purification device comprises a gasification furnace, a gas flow control valve, a vortex flow oxidation-assisted control valve, a gas purifier and a fan. The gasified gas purification device provided by the invention has the advantages of increasing the reaction temperature of the furnace, wherein the temperature in oxidation, reduction and pyrolysis cylinders is between 1,300 and 1,600 DEG; increasing the gasification intensity; being capable of quickly separating moisture in biomass combustible gas so that gas quality is better; ensuring greatly reduced tar content in the combustible gas, less wastewater generated, high gas-producing efficiency and low environmental pollution due to the adoption of a mesh-type catalytic cracking device; and removing tar, moisture and ash in the gas through the gas purifier so that the heat value of the gas is improved. The gasified gas purification device is widely applied in industrial and civil fields.

Owner:林口信安建材板业有限公司

Fluorine-containing hyperbranched polyester acrylic ester and method of preparing the same

The invention discloses fluorinated hyperbranched polyester acrylate and a preparation method thereof. Fluoride-alcohol and hydroxy acrylate are chosen to react with diisocyanate respectively to achieve two semi-additive products, and the two semi-additive products in proper proportions are used to react with hydroxyl-terminated hyperbranched polymer, to achieve hyperbranched polymer fluorine terminated bases with acrylic acid ester base groups and halothane base groups linked to the hyperbranched molecular framework through carbamate base groups as well as acrylic acid modified hyperbranched polymer. The iso-cyan acid radical reaction of the method has high activity, the Fluoro-alcohol conversion rate is high, the raw materials are cheap and easy to obtain, the operation is easy, and capable of facilitating industrial production. The fluoric hyperbranched polyester acrylate achieved by the method can be applied to ultraviolet-light solidification coating, the achieved coating has sound hydrophobic and oleophobic performances, and the industrial application is very broad.

Owner:UNIV OF SCI & TECH OF CHINA

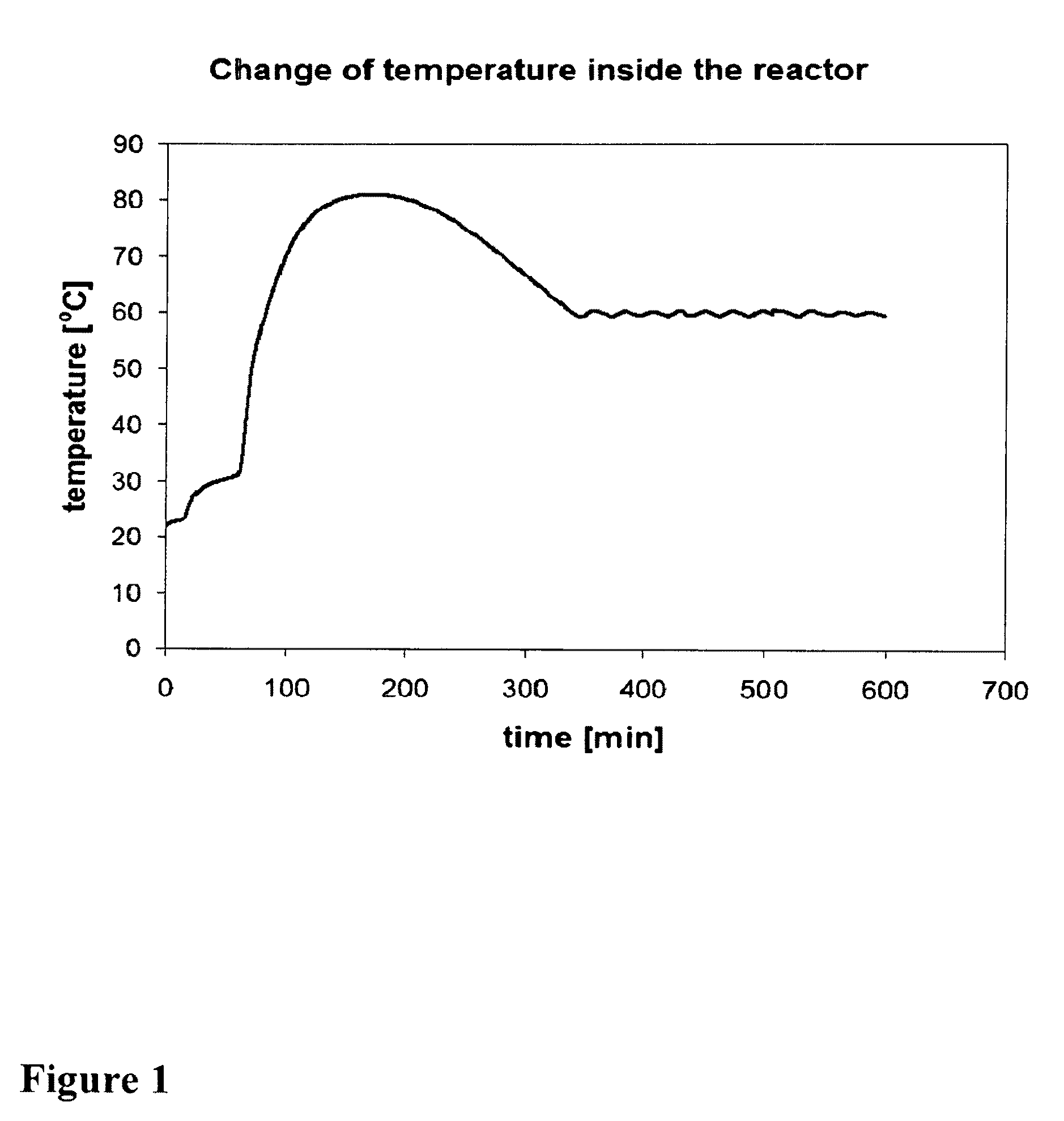

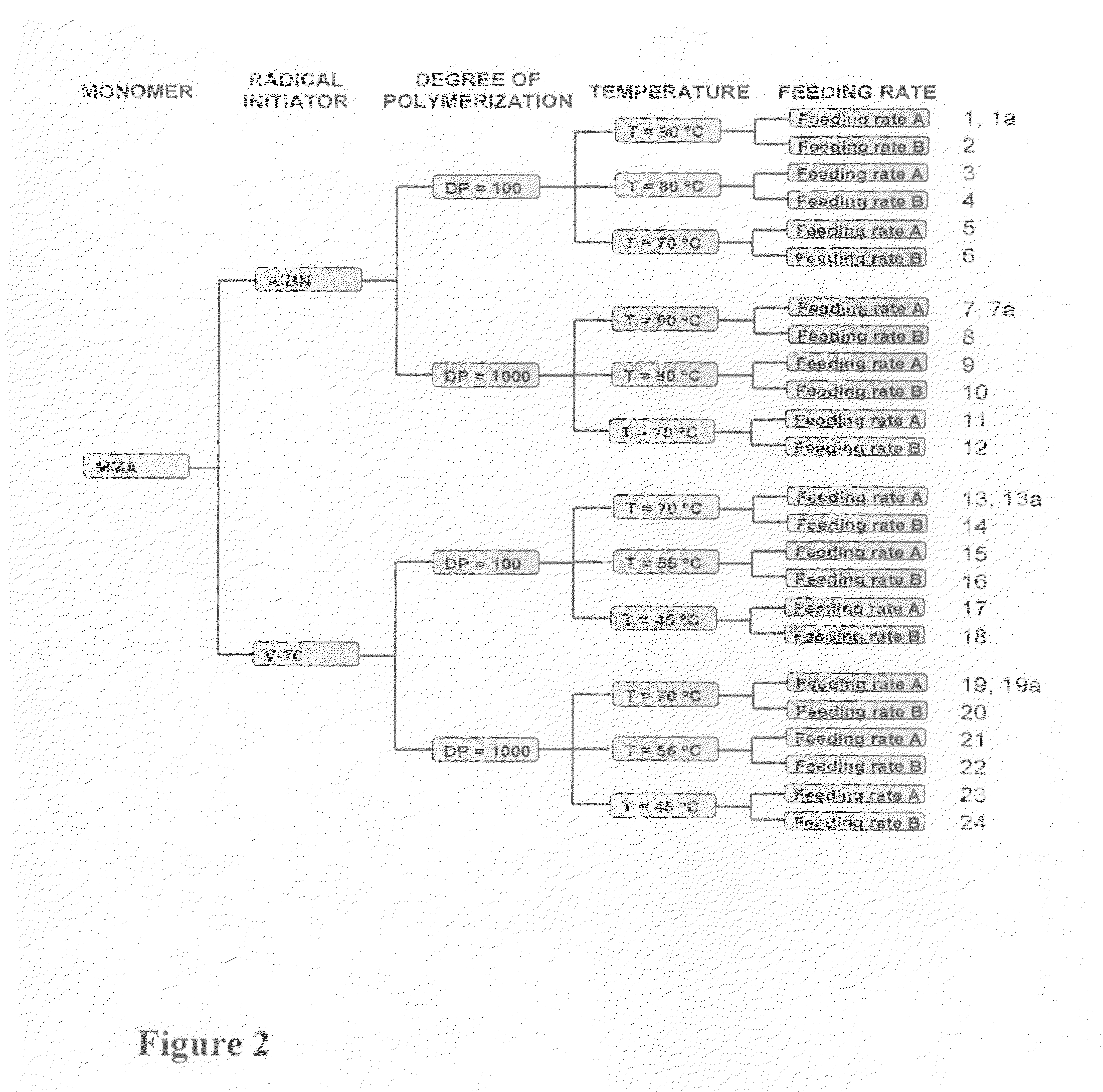

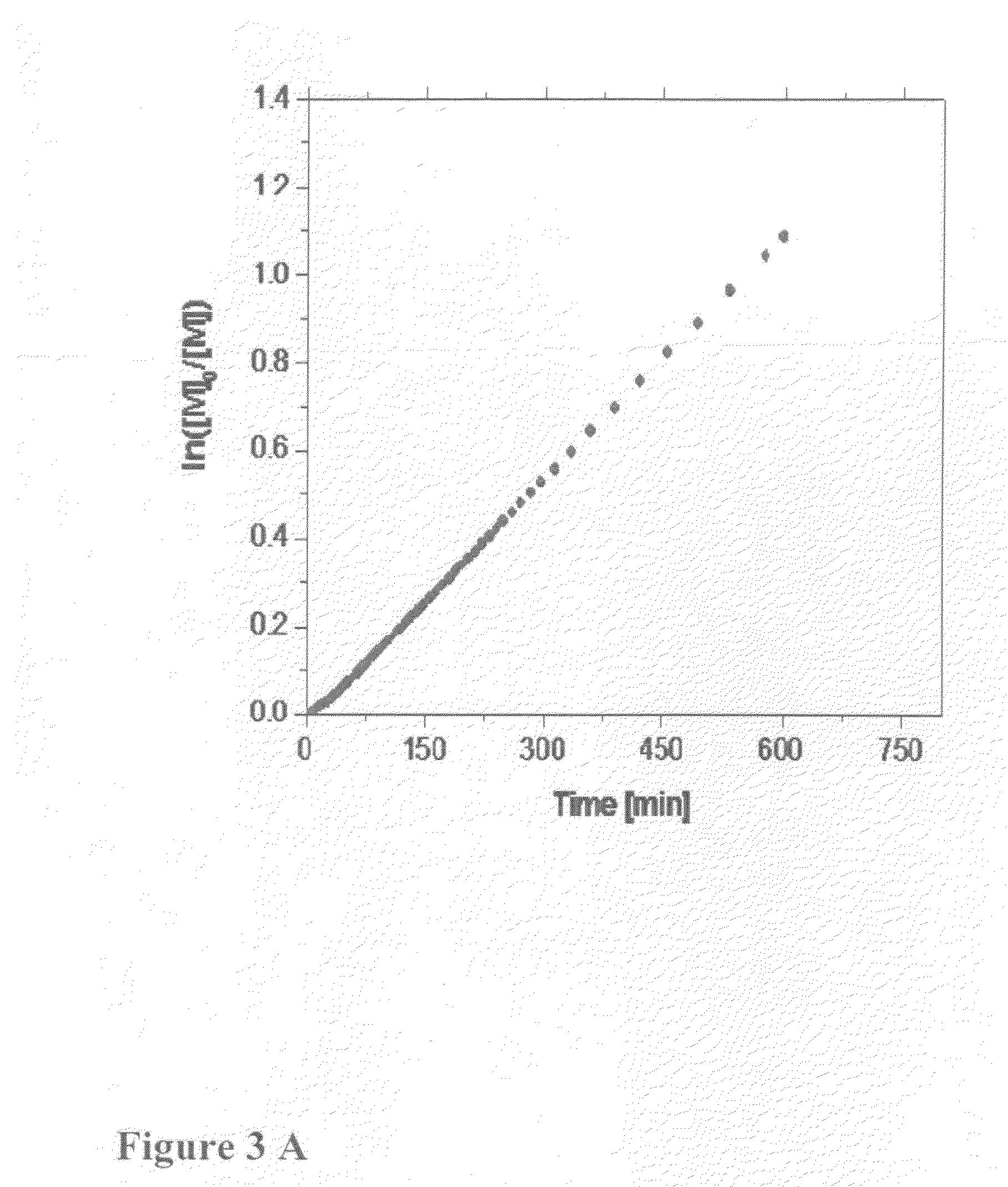

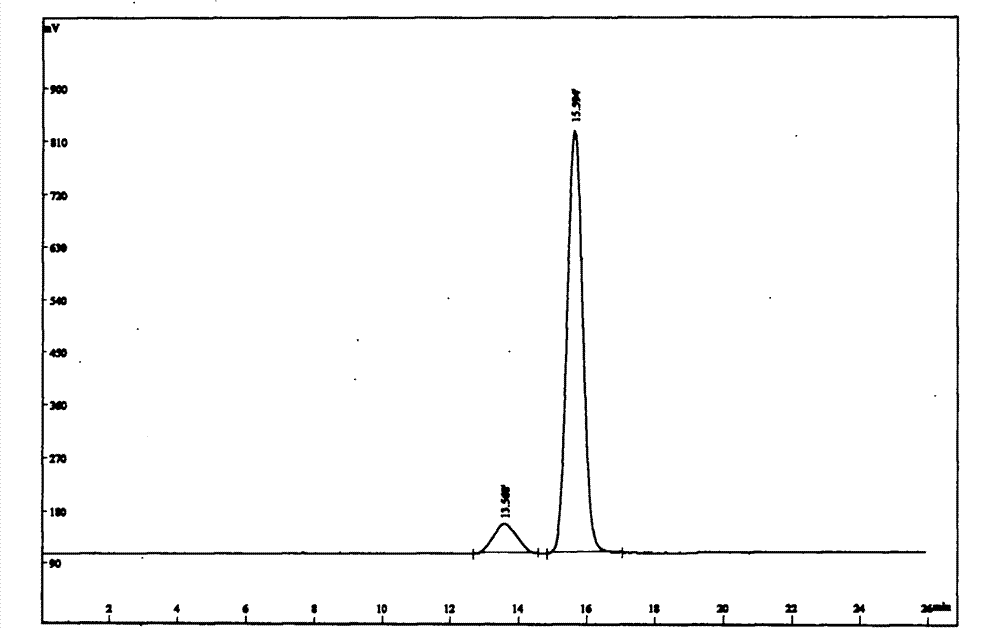

Control over controlled radical polymerization processes

A procedure for improved temperature control in controlled radical polymerization processes is disclosed. The procedure is directed at controlling the concentration of the persistent radical in ATRP and NMP polymerizations procedures and the concentration of radicals in a RAFT polymerization process by feeding a reducing agent or radical precursor continuously or intermittently to the reaction medium through one of more ports.

Owner:PILOT POLYMER TECHNOLGIES INC

Preparation method of mannose

InactiveCN102807593AReduce viscosityOvercome the disadvantage of easy moisture absorptionSugar derivativesSugar derivatives preparationSimulated moving bedD-Glucose

The invention discloses a preparation method of D-mannose, which comprises the following steps that glucose is epimerized under a normal pressure or pressurized condition by using ammonium molybdate as catalyst to obtain mixed solution of glucose and mannose; the mixed solution is discolored, desalted and refined and then enters a simulated moving bed 1 for separation and purification to obtain a component A rich in mannose and a component B rich in glucose; the component A enters a simulated moving bed 2 for separation to obtain a component C rich in mannose and a component D rich in glucose; the component B is filtered through a membrane and then enters the step of epimerization; the component D is filtered through a membrane and then enters the simulated moving bed 1 for cyclic separation; and the component C is centrifugally spray-dried to obtain D-mannose finished products. The preparation method of the D-mannose has the advantages of simple steps and easiness in operation. The purity of the D-mannose finished products prepared by adopting the method reaches more than 99 percent and the total yield reaches 53-60.4 percent.

Owner:白心亮

High-viscosity modified asphalt material and preparation method thereof

InactiveCN110041720AReduce manufacturing costOptimizing the distribution of ingredientsBuilding insulationsBituminous materialsWaste rubber

The invention discloses a high-viscosity modified asphalt material. The asphalt material is prepared from the following raw materials in parts by mass: 100 parts of matrix asphalt, 4-7 parts of a thermoplastic elastomer, 4-10 parts of waste rubber powder or an ethylene-vinyl acetate copolymer, 1-3 parts of a plasticizer, 2-4 parts of thermoplastic resin, 3-5 parts of a solubilizer, 0.2-2 parts ofa stabilizer, 0.5-1.5 parts of a chemical modifier and 0.2-0.7 part of polypropylene glycol. Through the high-viscosity modified asphalt material, the storage stability of high-viscosity modified asphalt is improved; meanwhile, high-temperature viscosity of the high-viscosity modified asphalt is reduced; when the high-viscosity modified asphalt material is applied to mixing of asphalt mixture, themixing temperature is low; the high-viscosity modified asphalt material is easy to construct, low in cost and simple in preparation method.

Owner:无锡市城市道桥科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com