Preparation method of mannose

A technology of mannose and mannose, which is applied in the field of mannose preparation, can solve the problems of increasing the complexity of operation, easily remaining organic solvents, increasing energy consumption costs, etc., achieving less separation column consumption, realizing the separation of ternary components, The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

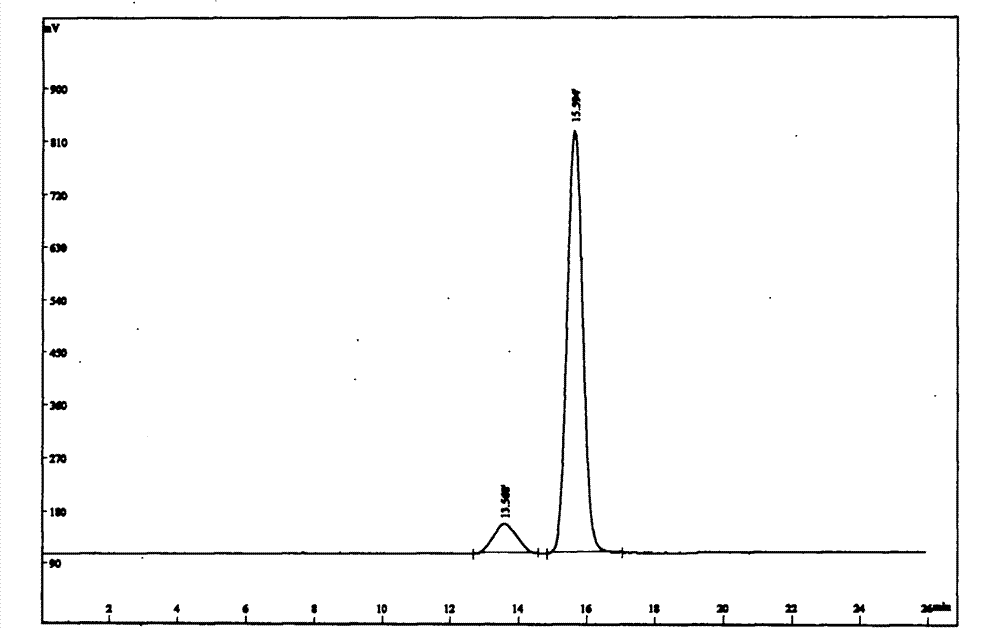

Embodiment 1

[0036] Dilute 5kg of crystalline glucose with purified water to a solid mass percentage concentration of 50wt.%, add 15g of catalyst ammonium molybdate, and carry out epimerization under the conditions of 0.2MPa and 110 ° C for 2h, and the obtained isomerized mixed solution contains manna The mass percentage concentration of sugar was 15.2 wt.%. After decolorizing, desalting and refining the above-mentioned heterogeneous mixed solution, it enters into a six-column sequential simulated moving bed 1 (the filler is calcium-type cationic resin) for separation and purification to obtain a mannose-rich component A and a glucose-rich component B, The purity of mannose in component A was 88.3%. Then, component A enters the six-column sequential simulated moving bed 2 (the filler is calcium molecular sieve) for secondary separation to obtain mannose-rich component C and glucose-rich component D. The purity of mannose in component C is obtained. is 99.5%. Component B is filtered throu...

Embodiment 2

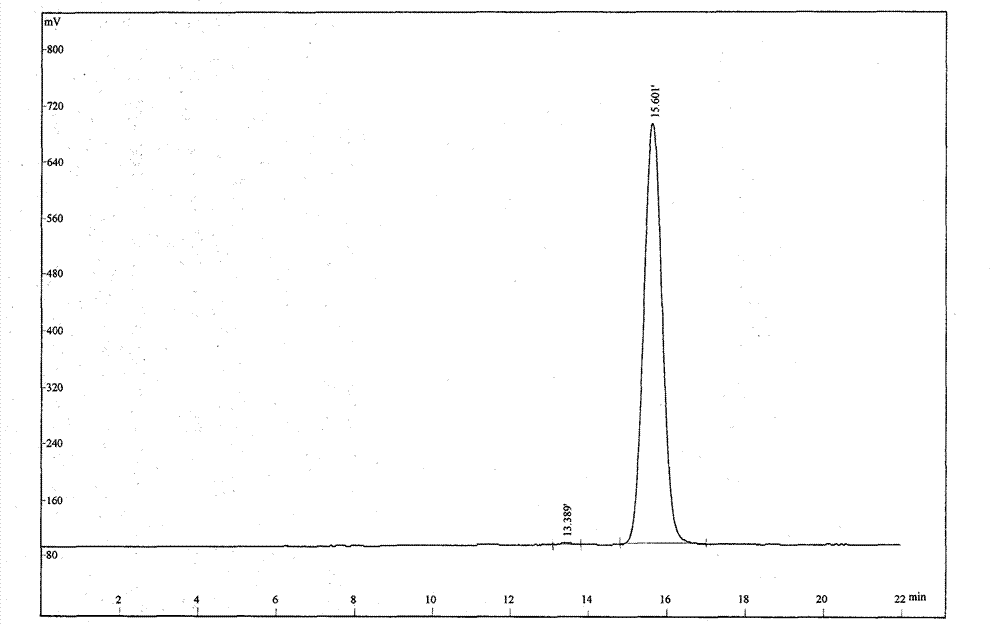

[0038] Dilute 5kg of crystalline glucose with purified water to a solid mass percentage concentration of 50wt.%, add 15g of catalyst ammonium molybdate, and carry out epimerization under the conditions of 0.15MPa and 105°C for 2h, and the obtained isomerized mixed solution contains manna The sugar mass percentage concentration was 14.5 wt.%. After decolorizing, desalting and refining the obtained isomerized mixed solution, it enters into a six-column sequential simulated moving bed 1 (the filler is calcium-type cation resin) for separation and purification to obtain a mannose-rich component A and a glucose-rich component B, The purity of mannose in component A was 87.2%. Then, component A enters the six-column sequential simulated moving bed 2 (the filler is calcium molecular sieve) for secondary separation to obtain mannose-rich component C and glucose-rich component D. The purity of mannose in component C is obtained. was 99.2%. Component B is filtered through the membrane...

Embodiment 3

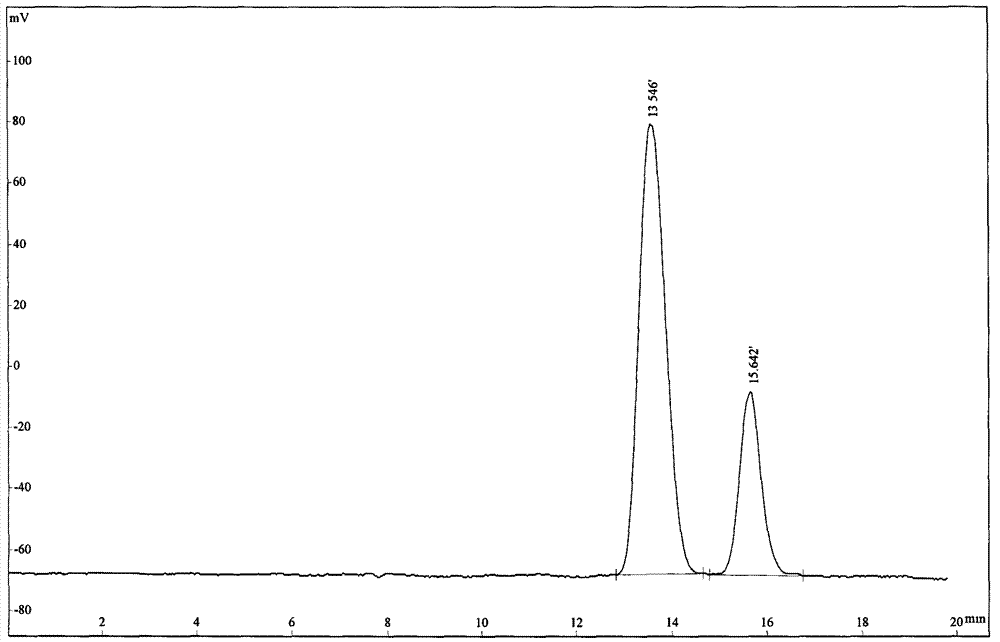

[0040]Dilute 5kg of crystalline glucose with purified water to a solid mass percentage concentration of 50wt.%, add 15g of catalyst ammonium molybdate, and carry out epimerization for 2h under the conditions of normal pressure and 100 ℃, and the obtained isomerized mixed solution contains manna The sugar mass percentage concentration was 13.6 wt.%. After decolorizing, desalting and refining the obtained isomerized mixed solution, it enters into a six-column sequential simulated moving bed 1 (the filler is calcium-type cation resin) for separation and purification to obtain a mannose-rich component A and a glucose-rich component B, The purity of mannose in component A was 86.2%. Then, component A enters the six-column sequential simulated moving bed 2 (the filler is calcium molecular sieve) for secondary separation to obtain mannose-rich component C and glucose-rich component D. The purity of mannose in component C is obtained. was 99.1%. Component B is filtered through the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com