Double-flow biomass gasified gas purification device

A purification device and biomass technology, applied in the manufacture of combustible gas, bulk chemical production, petroleum industry, etc., can solve the problems of unscientific structure design of gasifier, low reaction temperature of gasifier, and more tar and waste water. , to achieve the effect of reducing tar content, good gas quality and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

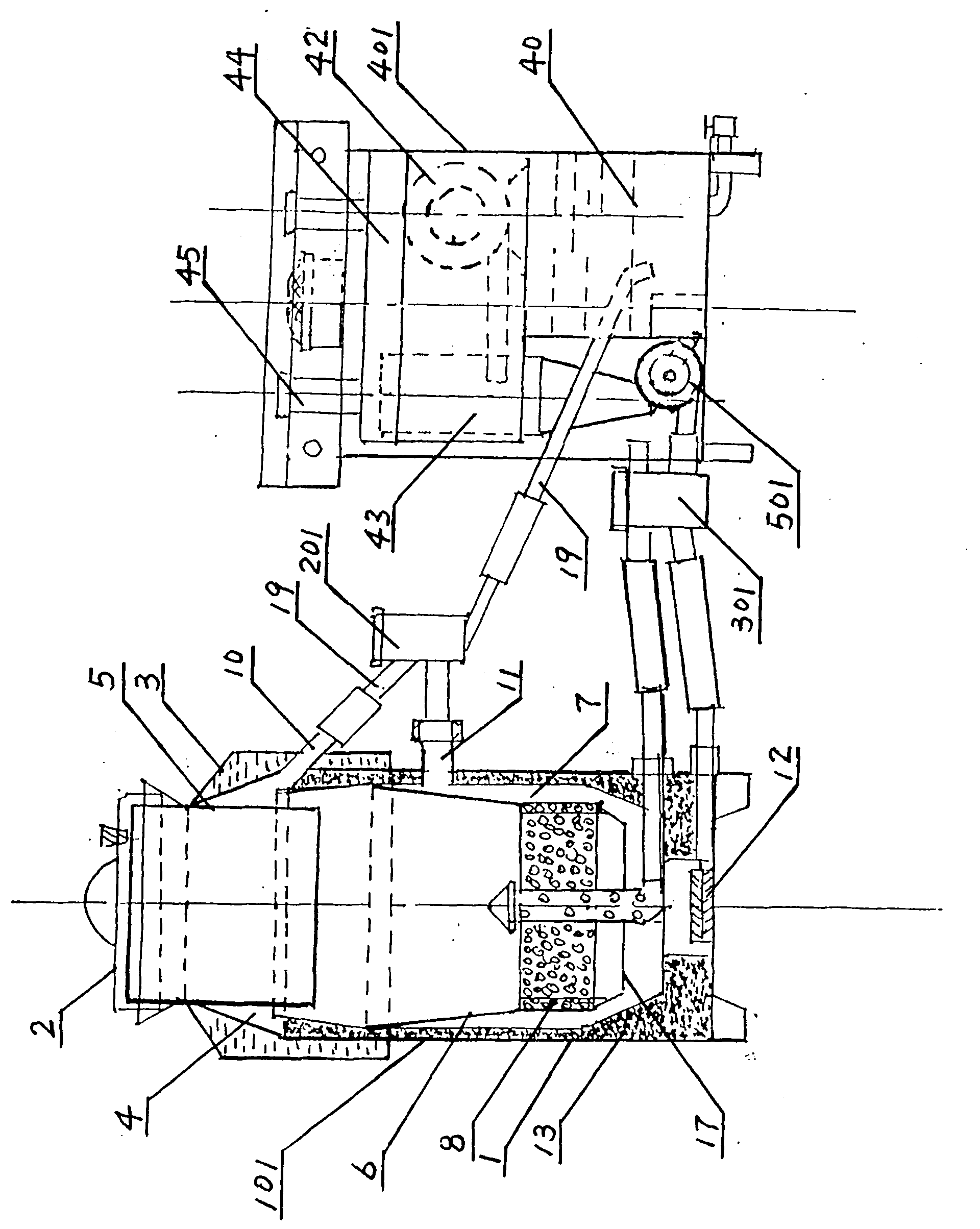

[0010] Specific implementation mode one: combine figure 1 , figure 2 , image 3 The present embodiment will be described. This embodiment consists of a gasifier 101, a gas flow control valve 201, a vortex oxygen-supporting control valve 301, a gas purifier 401, and a fan 501. The gasifier 101 consists of a furnace body 1, a sealing cover 2, a condenser 3, and an upper ring Composed of gas condensation chamber 4, feeding cylinder 5, dry distillation cracking cylinder 6, lower annular gas channel 7, catalytic cracker 8, vortex air distributor 9, infrared electric starter 12 and insulation layer 13, condenser 3 is located in the furnace body 1. The upper part, the upper annular gas condensation chamber 4 is arranged between the inner wall of the condenser 3 and the outer wall of the feeding cylinder 5, and the dry distillation cracking cylinder 6 is arranged below the feeding cylinder 5. The dry distillation cracking cylinder 6 is in an inverted trapezoidal shape. A catalytic...

specific Embodiment approach 2

[0011] Specific implementation mode two: combination figure 1 , Figure 4 The present embodiment will be described. The gas flow control valve 201 described in this embodiment is composed of an outer valve body 20, an inner valve body 21, an inner valve body rotary knob 22, a mesh cylinder 29 and a dry filter material 61, and the inner valve body 21 is provided with an upper gas inlet hole 23 and evacuation and the lower gas inlet 24, the outer valve body 20 is provided with an evacuation port 25, a lower gas interface 27, an upper gas interface 26 and a gas output interface 28, and the upper gas inlet 23 is connected with the evacuation and lower gas inlet. The centerlines of the circular ends of the adjacent ends of the hole 24 are on the same vertical line, the centerlines of the circular ends of the non-adjacent ends are on the 180-degree angle line of the vertical line, and the upper gas inlet hole 23 and the upper gas interface 26 are on the same vertical line. On the ...

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 , Figure 5The present embodiment will be described. The vortex oxygen-assisted control valve 301 described in this embodiment is composed of an outer valve body 30 , an inner valve body 31 , an inner valve body rotary knob 32 and an oxygen-enriched integrated area 39 , and the outer valve body 30 is provided with a vortex air distributor interface 33 , gas purifier oxygen increasing interface 34, infrared electric starter air distribution interface 35 and fan interface 36, the inner valve body 31 is provided with eddy current air distribution device hole 37, infrared electric heating starter distribution air hole 38 and purifier oxygen increasing The hole 60, the vortex air distribution device hole 37 on the inner valve body 31, the infrared electric starter air distribution hole 38 and the purifier oxygenation hole 60 are oval, and the eddy current air distribution device hole 37 and the purification oxygenatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com