Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

249results about "Pulp liquors combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalytic Gasification Process with Recovery of Alkali Metal from Char

ActiveUS20090169449A1Quantity minimizationThermal non-catalytic crackingMuffle furnacesParticulatesSlurry

Processes are described for the extraction and recovery of alkali metal from the char that results from catalytic gasification of a carbonaceous material. Among other steps, the processes of the invention include a hydrothermal leaching step in which a slurry of insoluble particulate comprising insoluble alkali metal compounds is treated with carbon dioxide and steam at elevated temperatures and pressures to effect the conversion of insoluble alkali metal compounds to soluble alkali metal compounds. Further, processes are described for the catalytic gasification of a carbonaceous material where a substantial portion of alkali metal is extracted and recovered from the char that results from the catalytic gasification process.

Owner:SURE CHAMPION INVESTMENT LTD

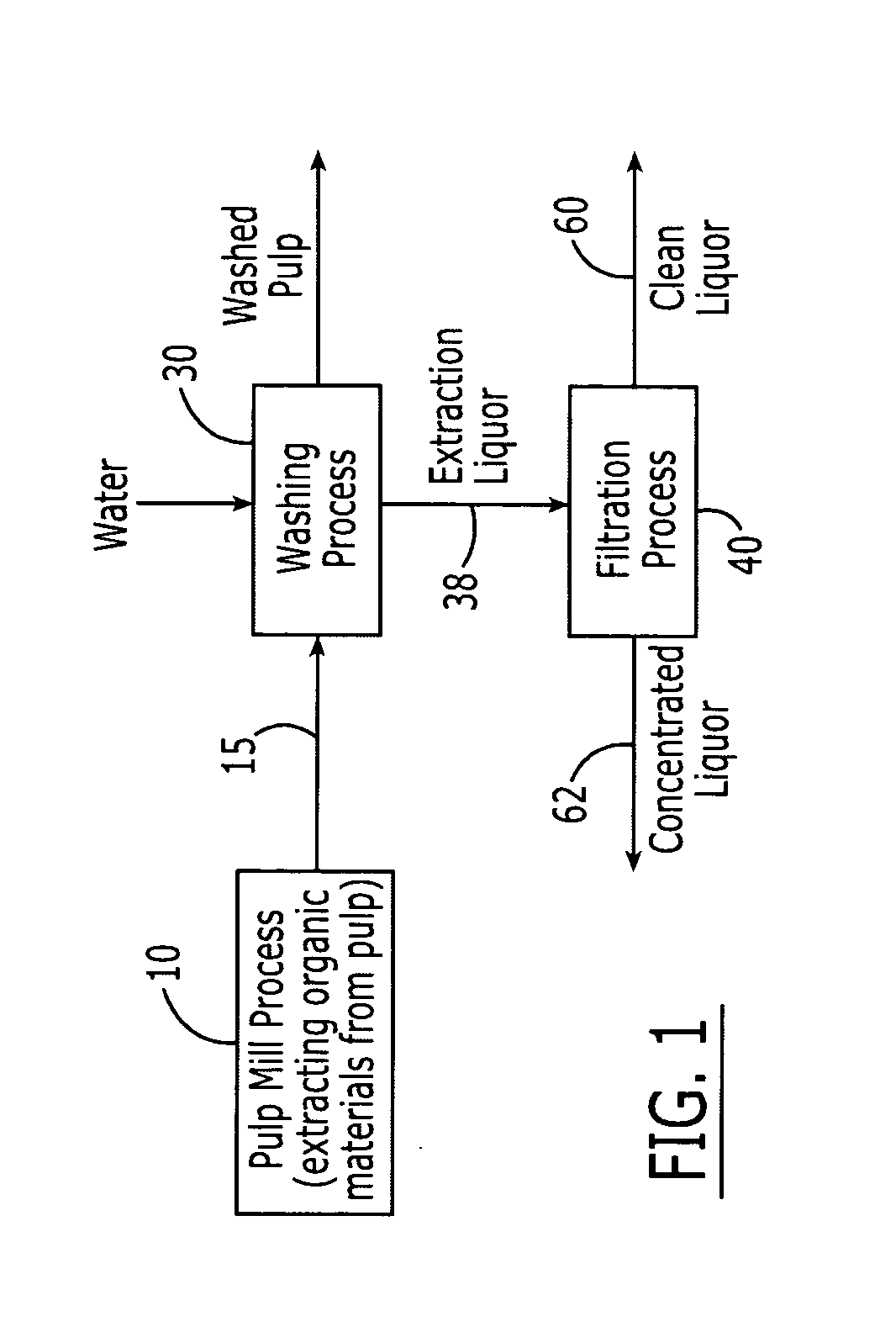

Method of concentrating pulp mill extracts

InactiveUS20060016751A1Reduce loadReduce processMembranesPulp liquors combustionWaste streamPulp mill

A process for separating organic components from a pulp mill waste stream comprising the steps of washing a cellulose pulp to obtain an aqueous extraction liquor containing organic components, and separating at least a portion of said organic components from the extraction liquor by passing the extraction liquor through at least one nanofiltration membrane. The process may be used in conjunction with a variety of pulp mill processes, including kraft cooking processes, hot caustic extraction processes, sulfite cooking processes, and bleaching processes.

Owner:RAYONIER PRODUCTS AND FINANCIAL SERVICES COMPANY

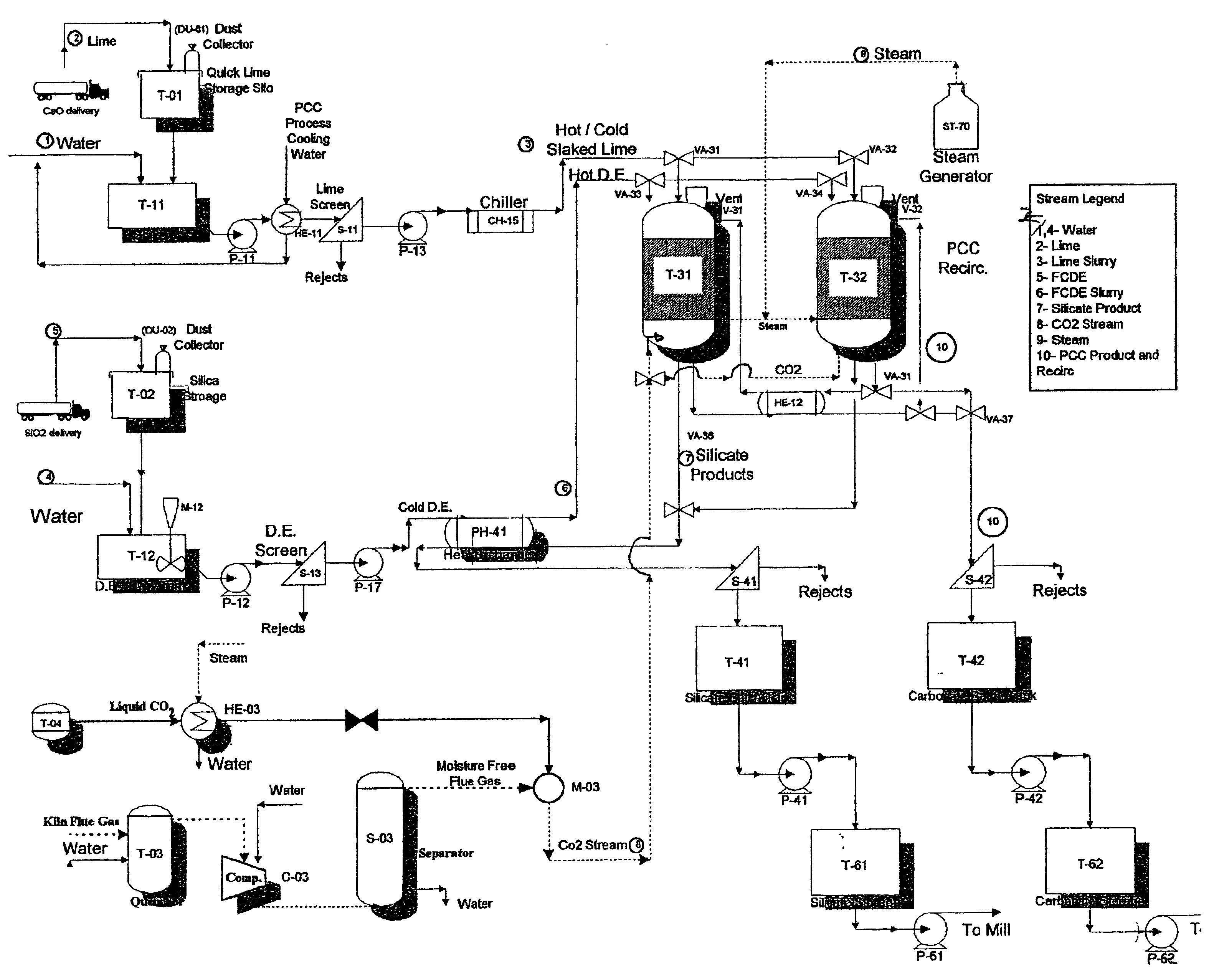

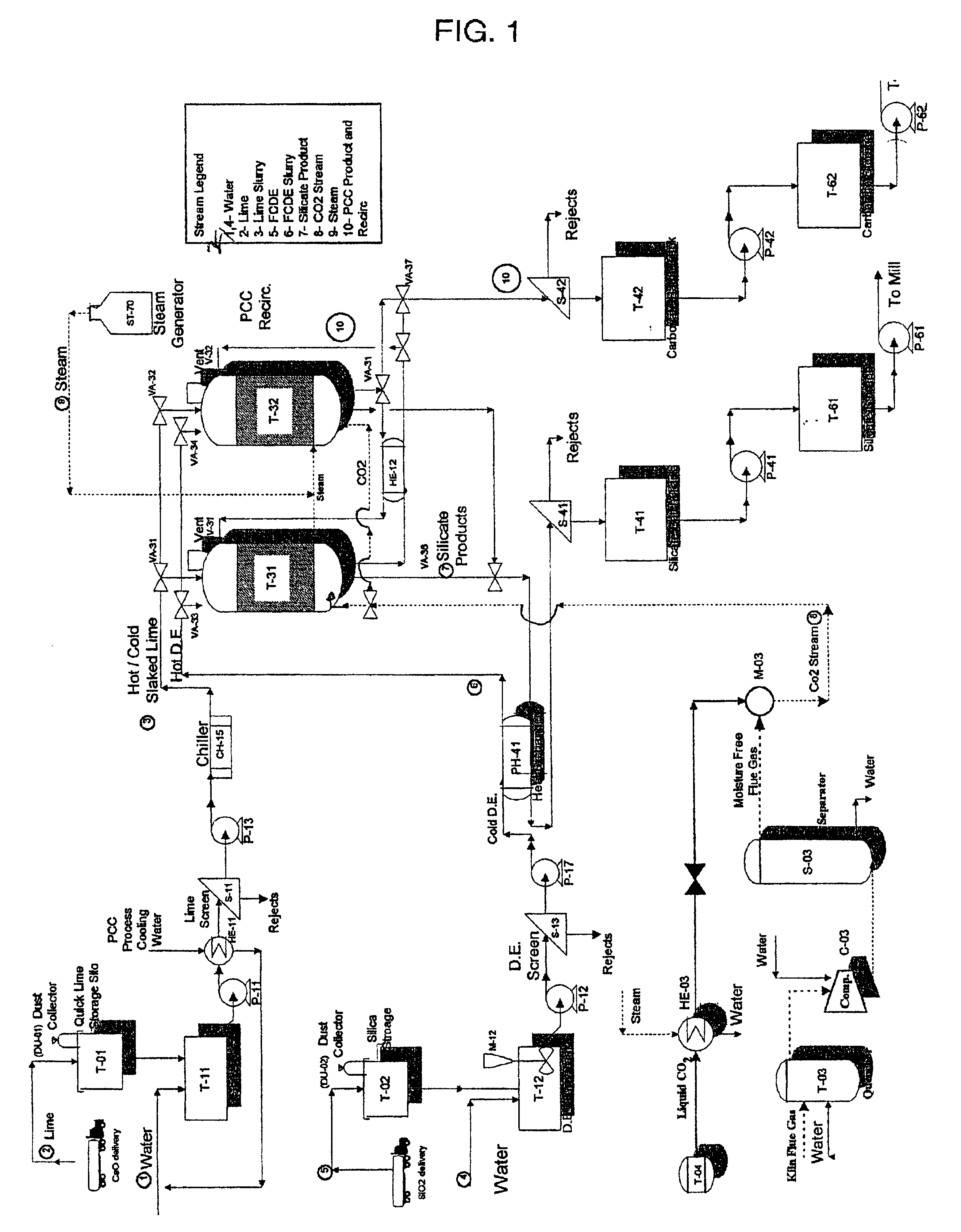

Method and apparatus for production of precipitated calcium carbonate and silicate compounds in common process equipment

InactiveUS7048900B2Increase brightnessHigh opacityCalcium/strontium/barium carbonatesPulp liquors combustionCalcium silicateProcess equipment

A method and apparatus for the production of calcium carbonate and calcium silicate in common superatmospheric reactors. Multiple reactors can be provided for switching production between reactors, and advantageously utilizing process waste heat. On site production of both PCC and Calcium Silicate Hydrates is thus achieved in a paper mill.

Owner:PACIFIC NANO PROD

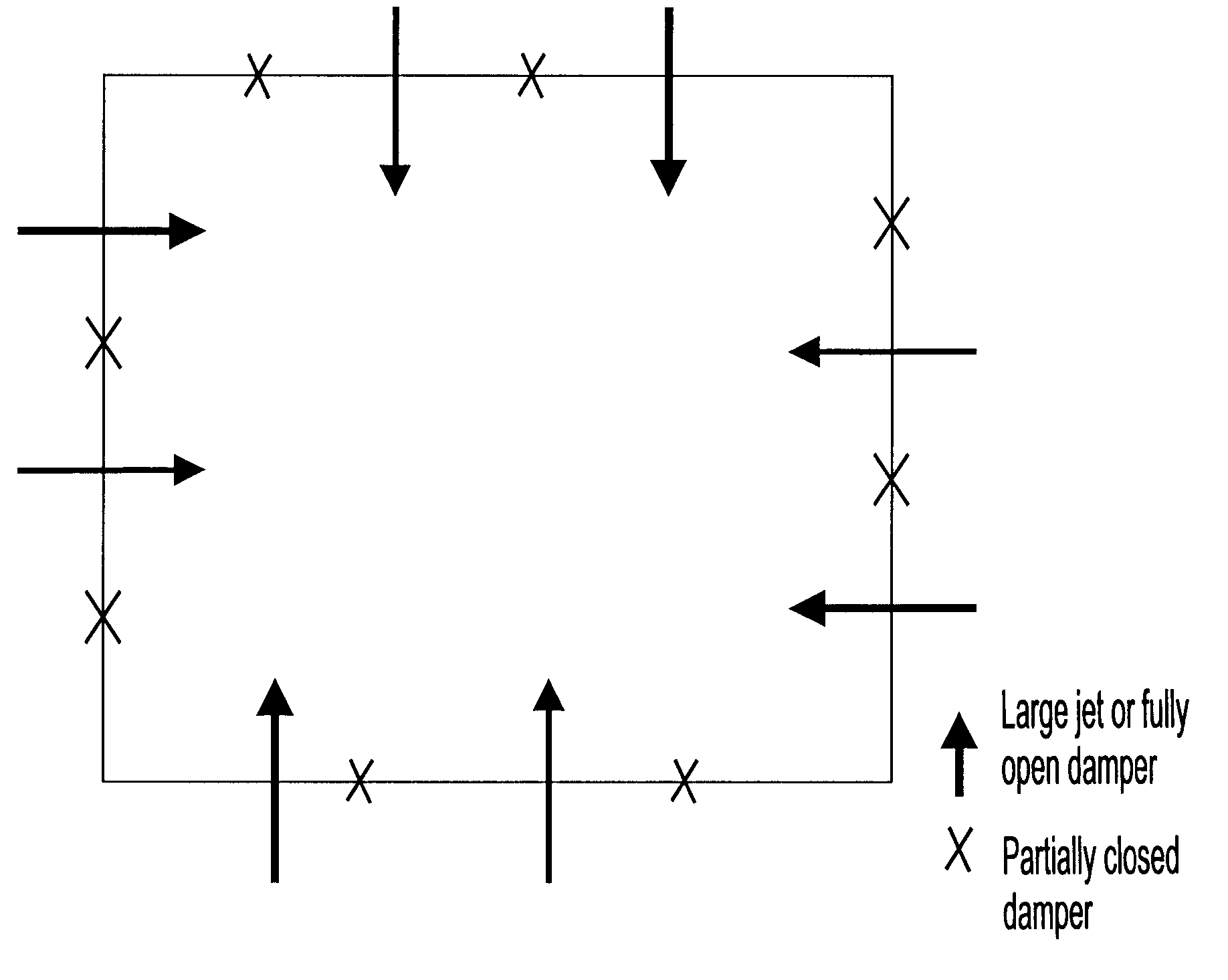

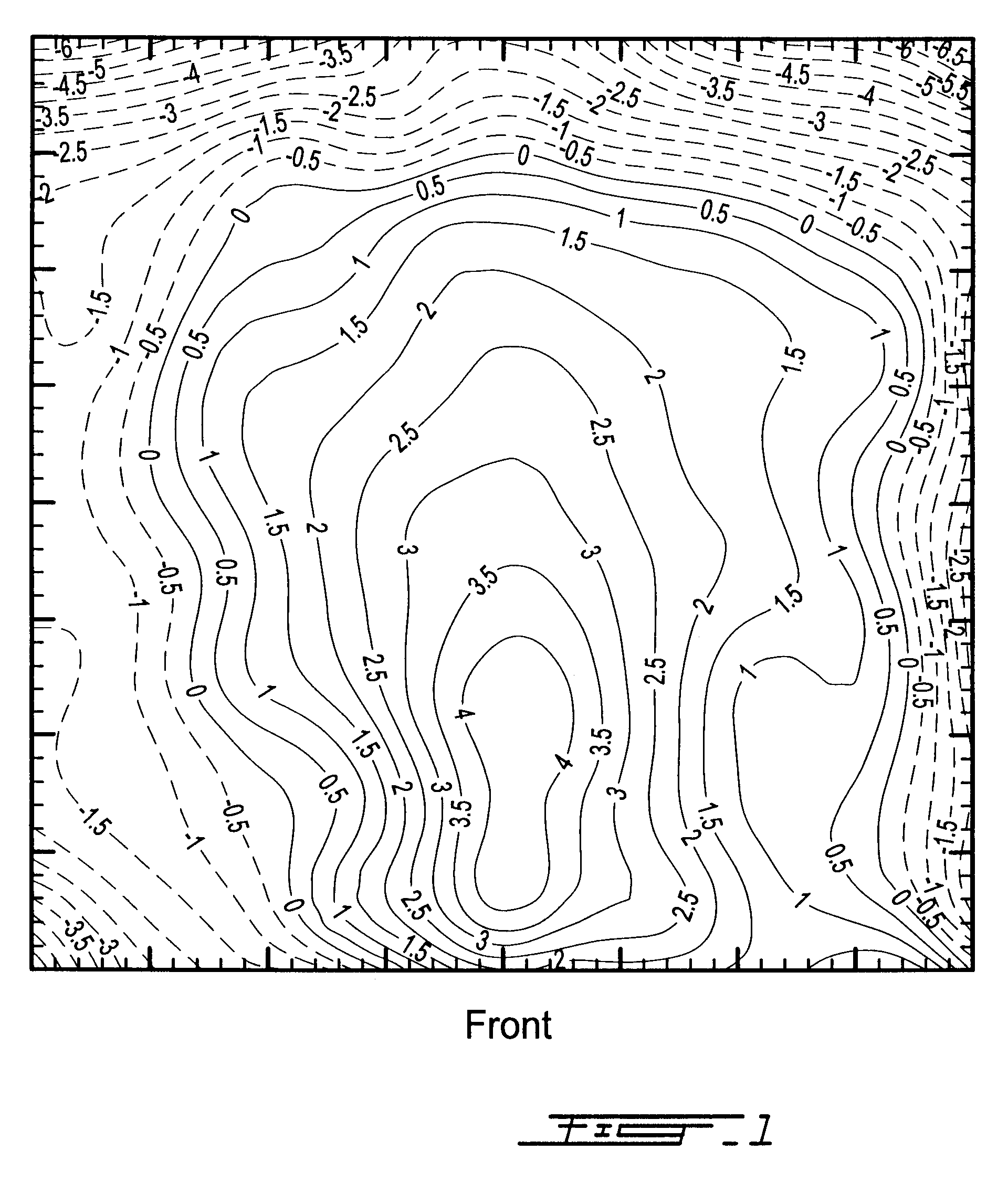

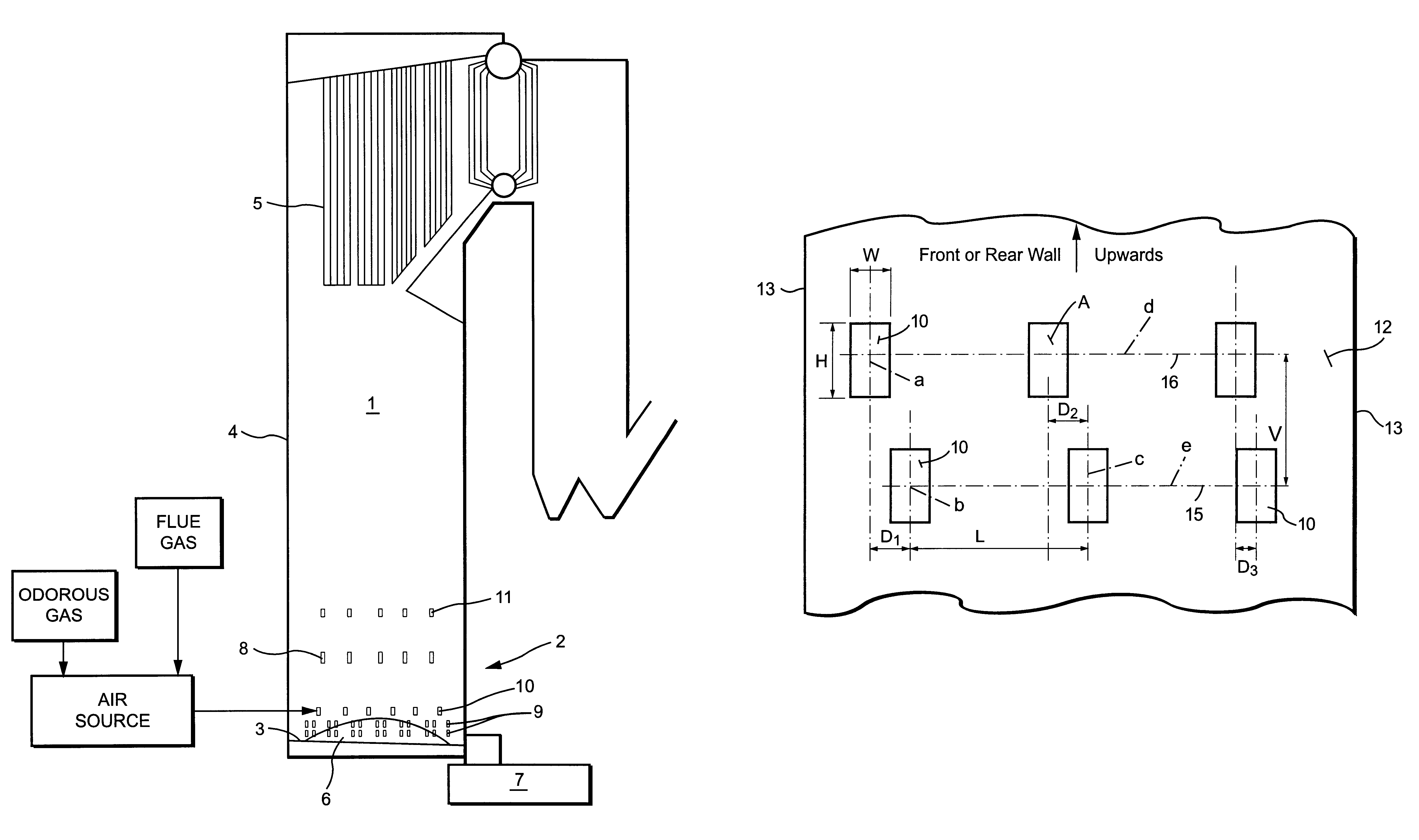

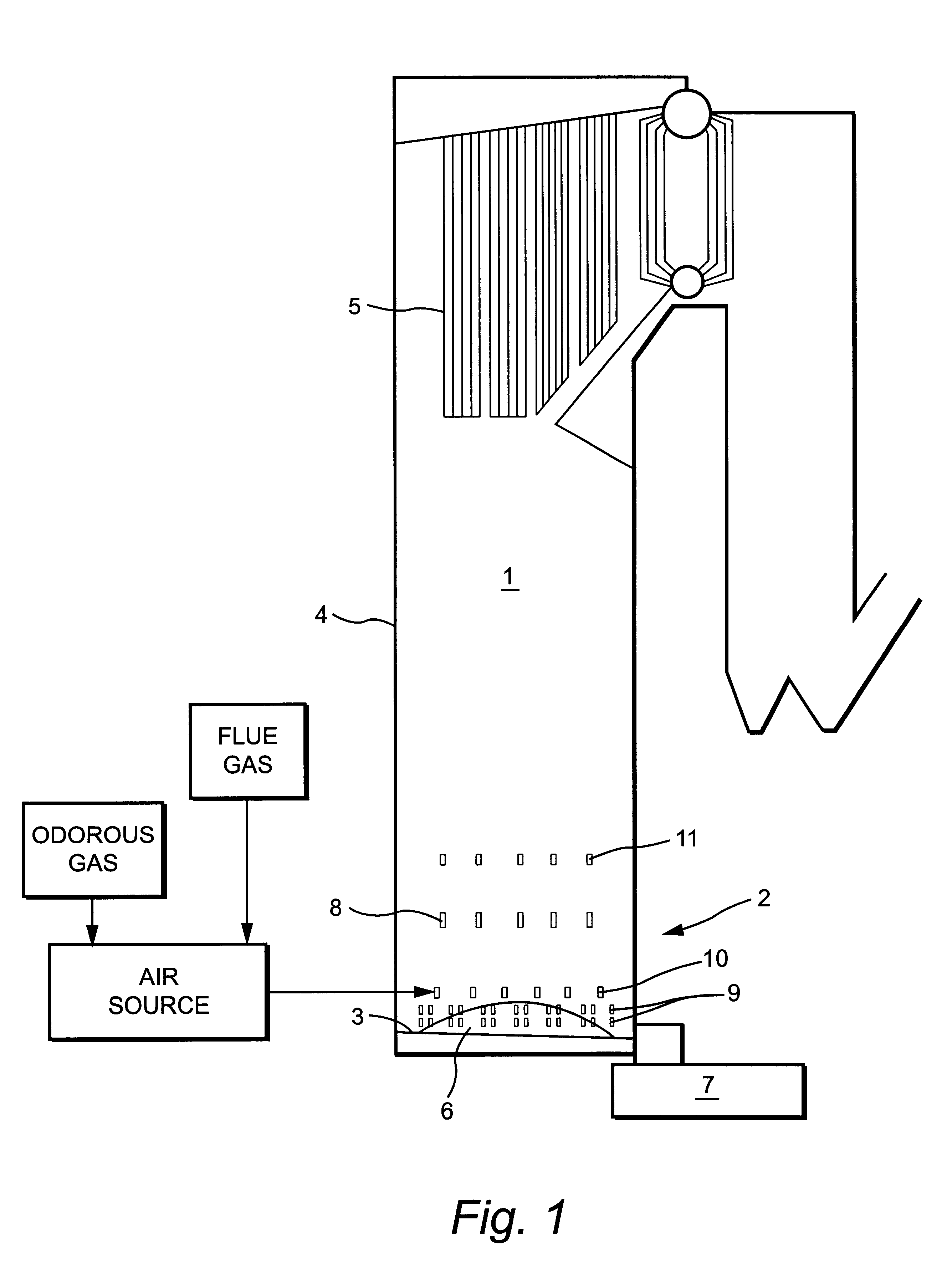

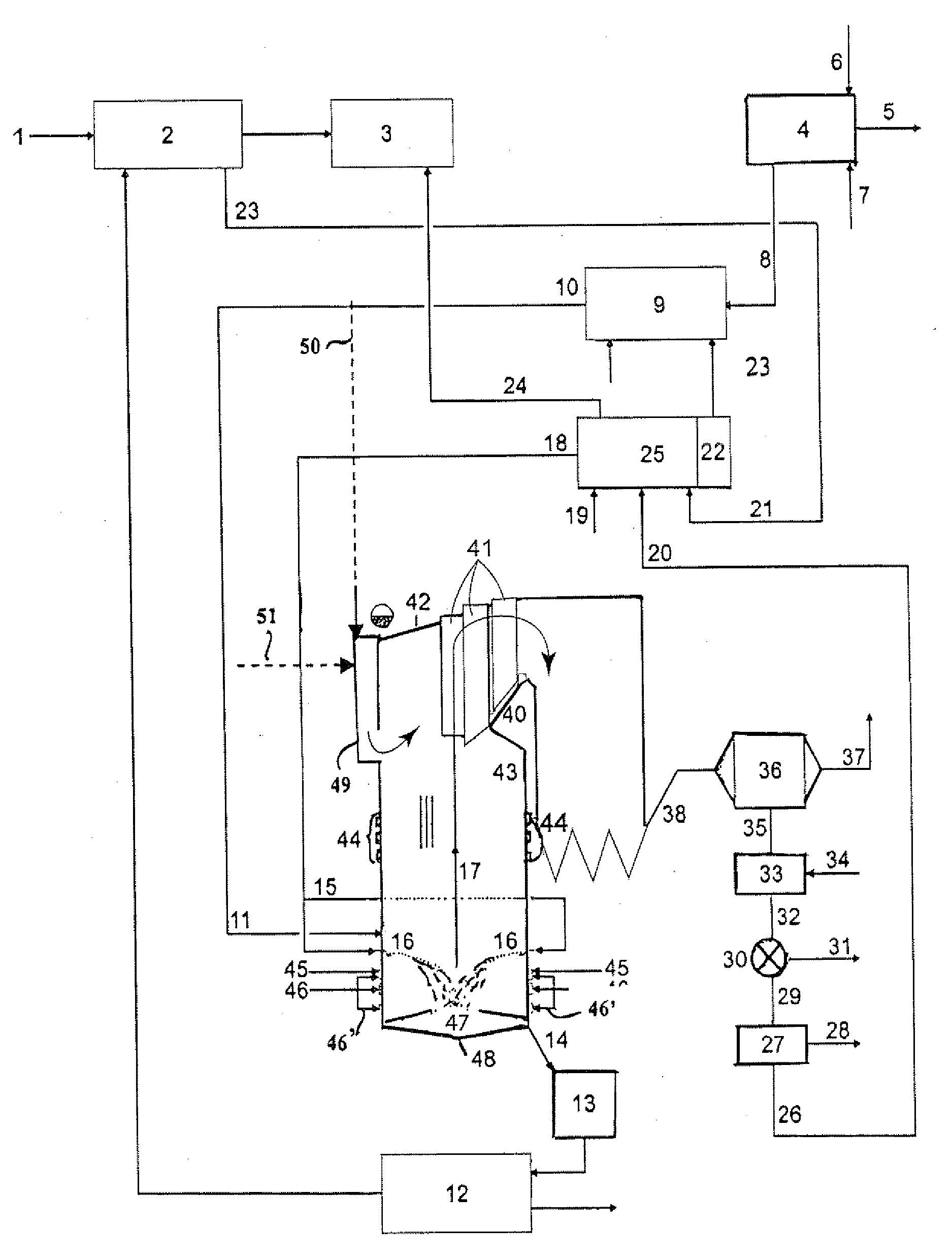

Method and apparatus for optimizing the combustion air system in a recovery boiler

InactiveUS6279495B1Improve boiler efficiencyAvoid costly modificationPulp liquors combustionSolid fuel combustionParticulatesChemical recovery

A method and an apparatus for optimizing the combustion air system in a power boiler or chemical recovery boiler by improving fluid flow and gas mixing are disclosed, whereby one can increase boiler capacity and combustion uniformity and reduce particulate and gaseous emissions. The method involves interlacing of the secondary and, where applicable, the tertiary air supply through opposing air ports on all four walls of the boiler, and is implemented by alternately opening wide or partially closing a port damper on one side, while partially closing or opening wide a port damper on the opposite side, such that a 70-100% open damper on one side opposes a partially closed (10-40% open) damper on the other and vice versa in an alternating fashion, along opposing walls. In a preferred embodiment, the optimization is further enhanced by balancing primary air flow, achieved by adjusting port dampers and windbox pressures so that the primary air flow is evenly distributed between opposite walls, between all four walls of the boiler and between individual airports on each wall. Windbox pressure and other key measurements of boiler operation ensure proper balancing and an adequate interlacing of air flows at the primary, secondary and tertiary elevations, respectively.

Owner:FPINNOVATIONS INC

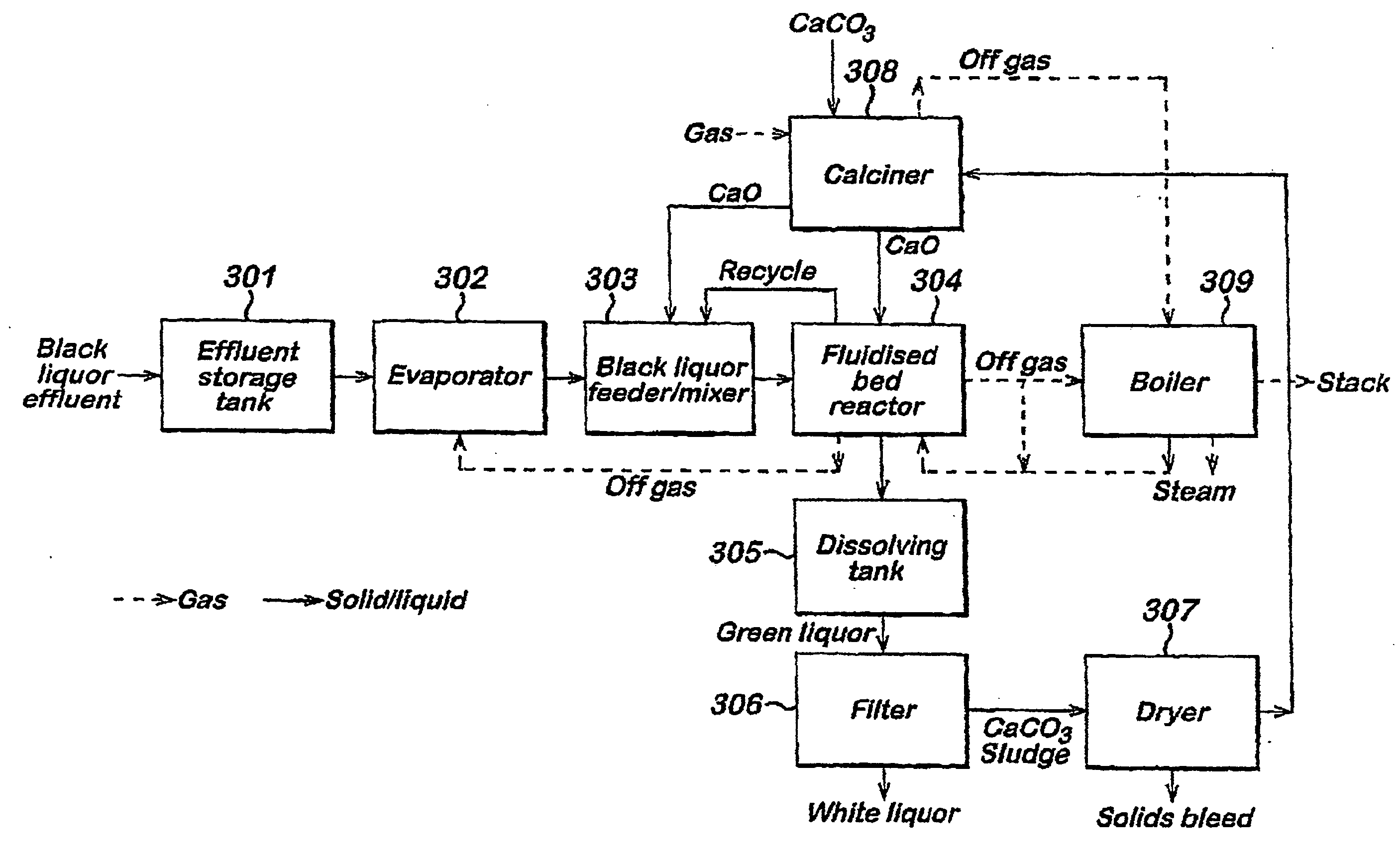

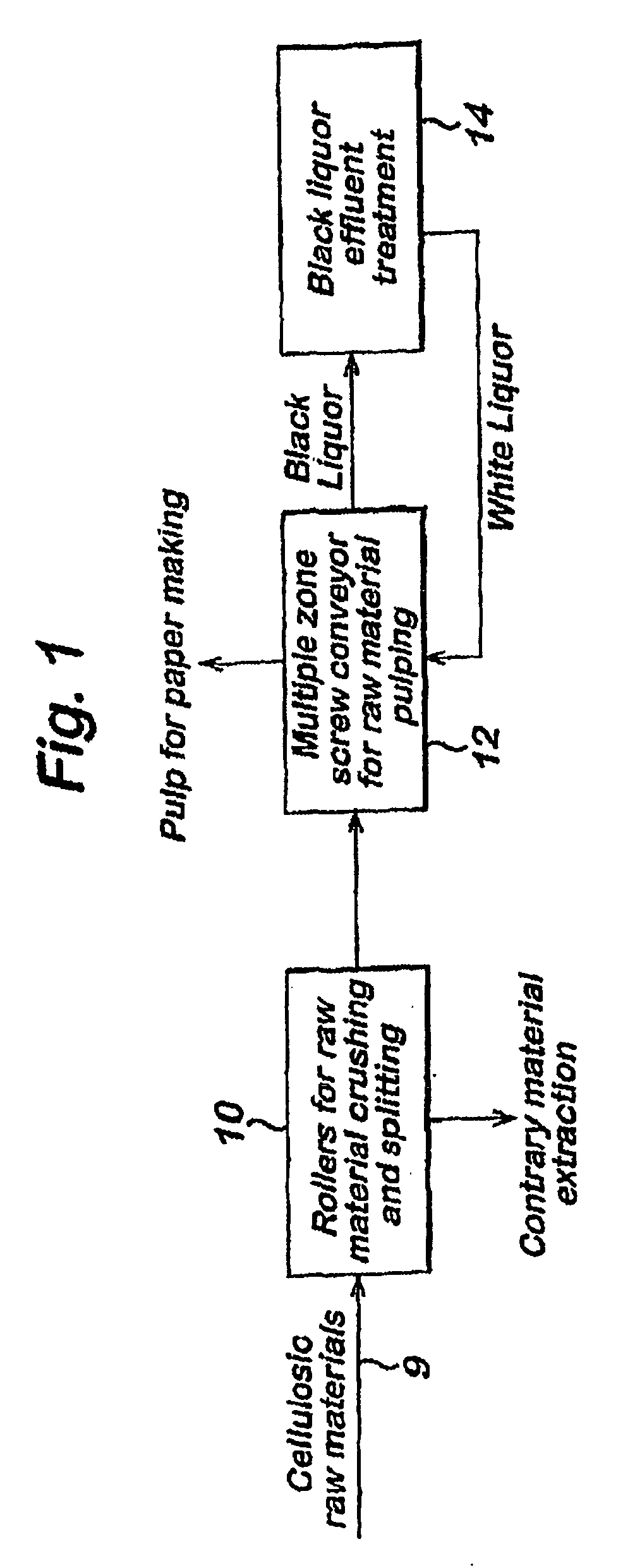

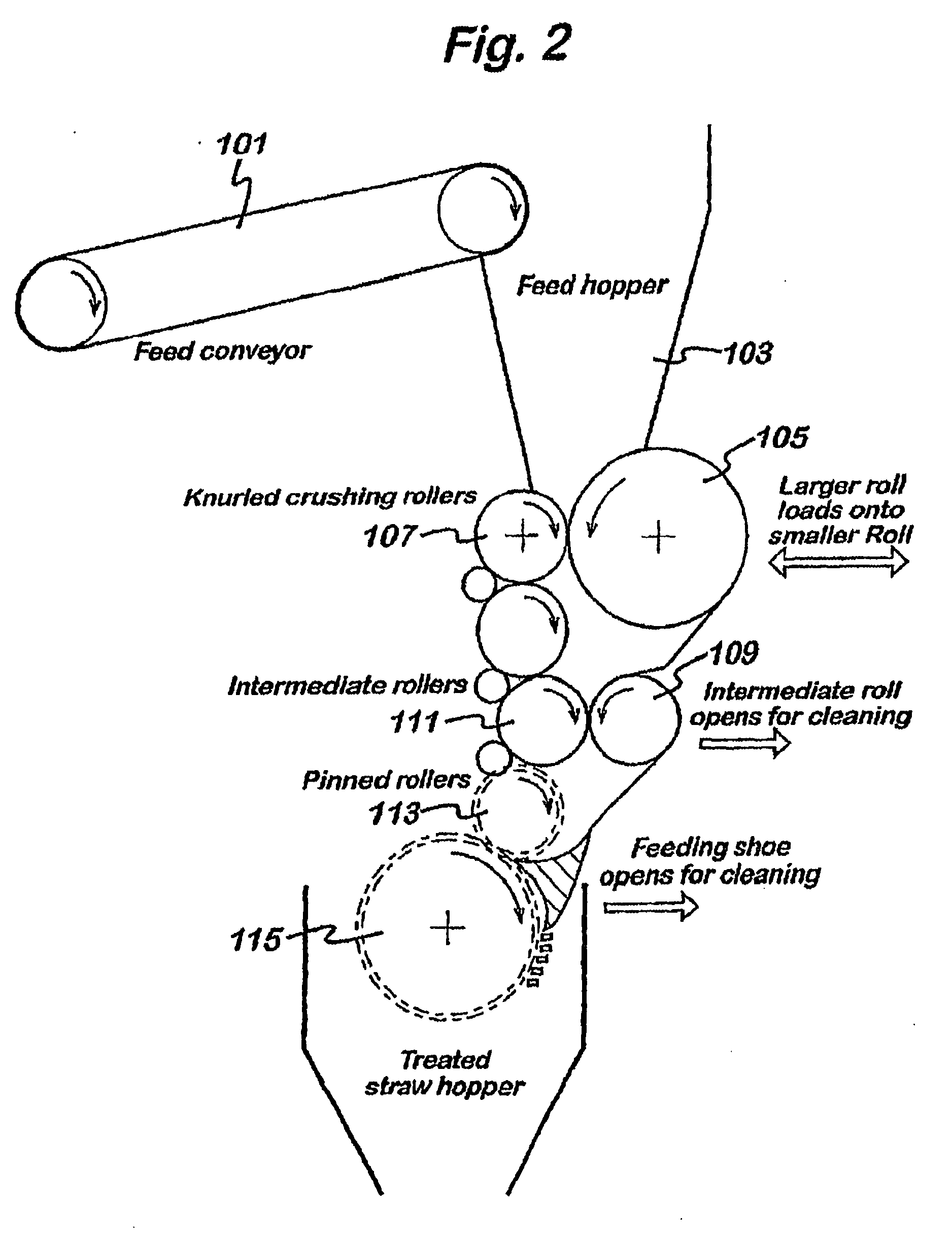

Methods for producing pulp and treating black liquor

InactiveUS20060201641A1Maintaining output qualityRaise the reaction temperaturePretreatment with water/steamPulp liquors combustionCalcium silicateOrganic content

A method is provided for treating black liquor particularly derived from non-wood pulp, by heating with an alkaline earth metal oxide in a toroidal fluidised bed reactor at a temperature of above 650° C. The method may be used alone or as part of a method of converting graminaceous raw material to pulp for paper or board, said method comprising (a) digesting said raw material with a white liquor based on sodium hydroxide and further comprising calcium hydroxide in an amount effective to substantially convert silica of said raw material to calcium silicate; (b) recovering pulp and black liquor substantially free of uncombined silica; (c) heating the black liquor in a fluidized bed reactor containing calcium oxide for catalysing conversion of organic content of said black liquor to gas and for providing recovered solids including sodium values of said white liquor and calcium oxide; and regenerating said white liquor using said recovered solids. The use of the above mentioned white liquor permits treatment of wheat straw, rice straw and other high-silica materials without resulting in a black liquor that is difficult to treat.

Owner:BIOREGIONAL MINIMILLS UK

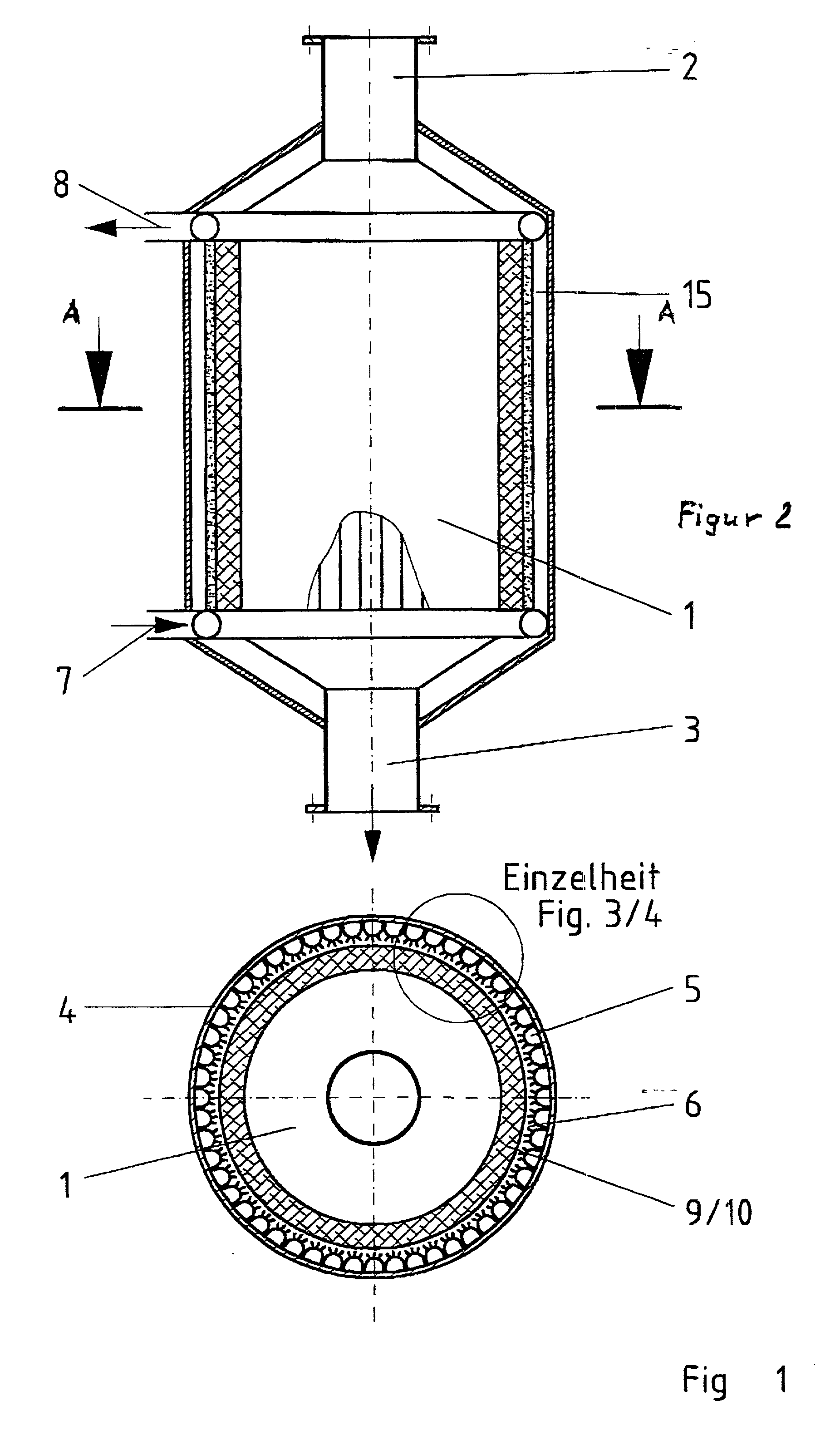

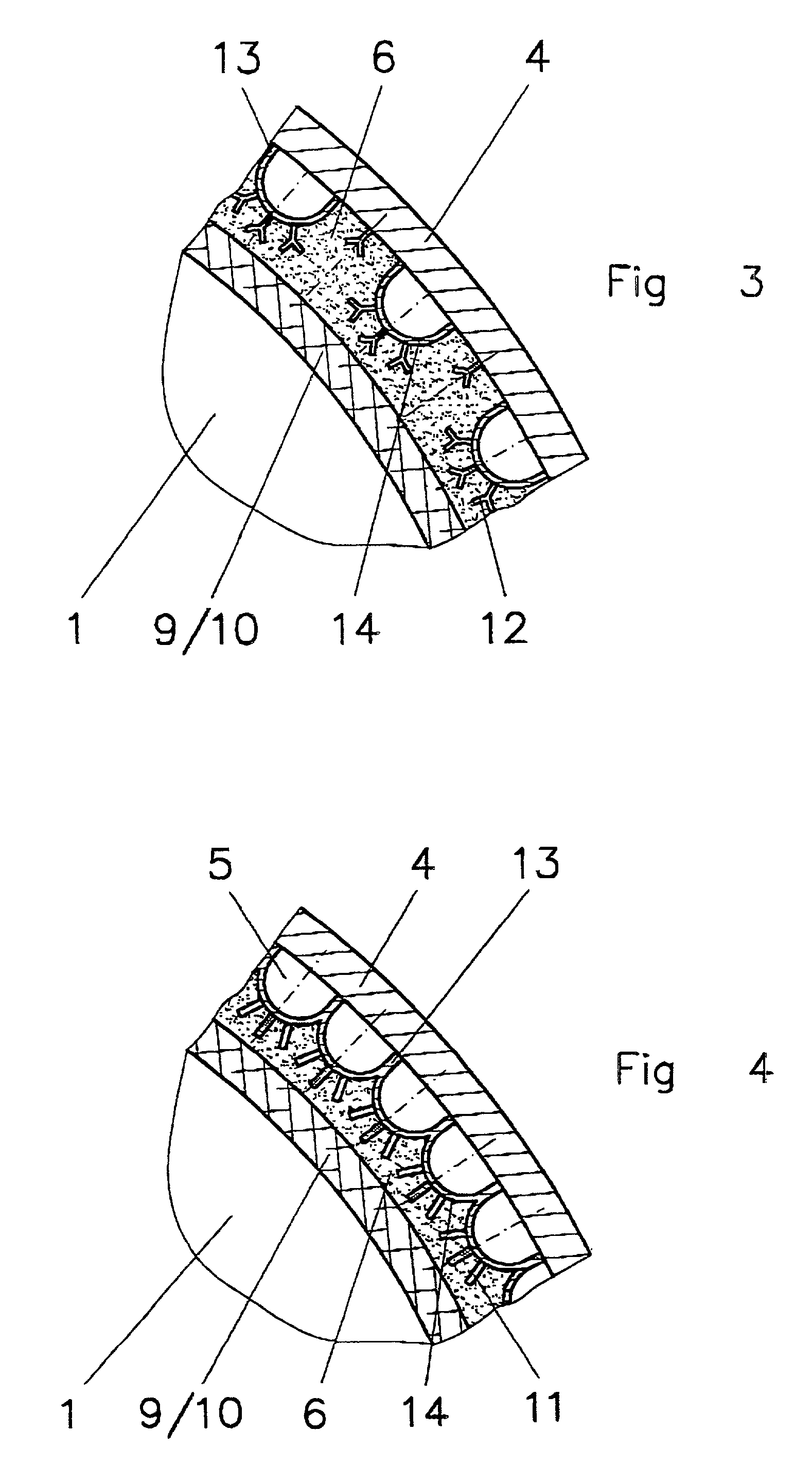

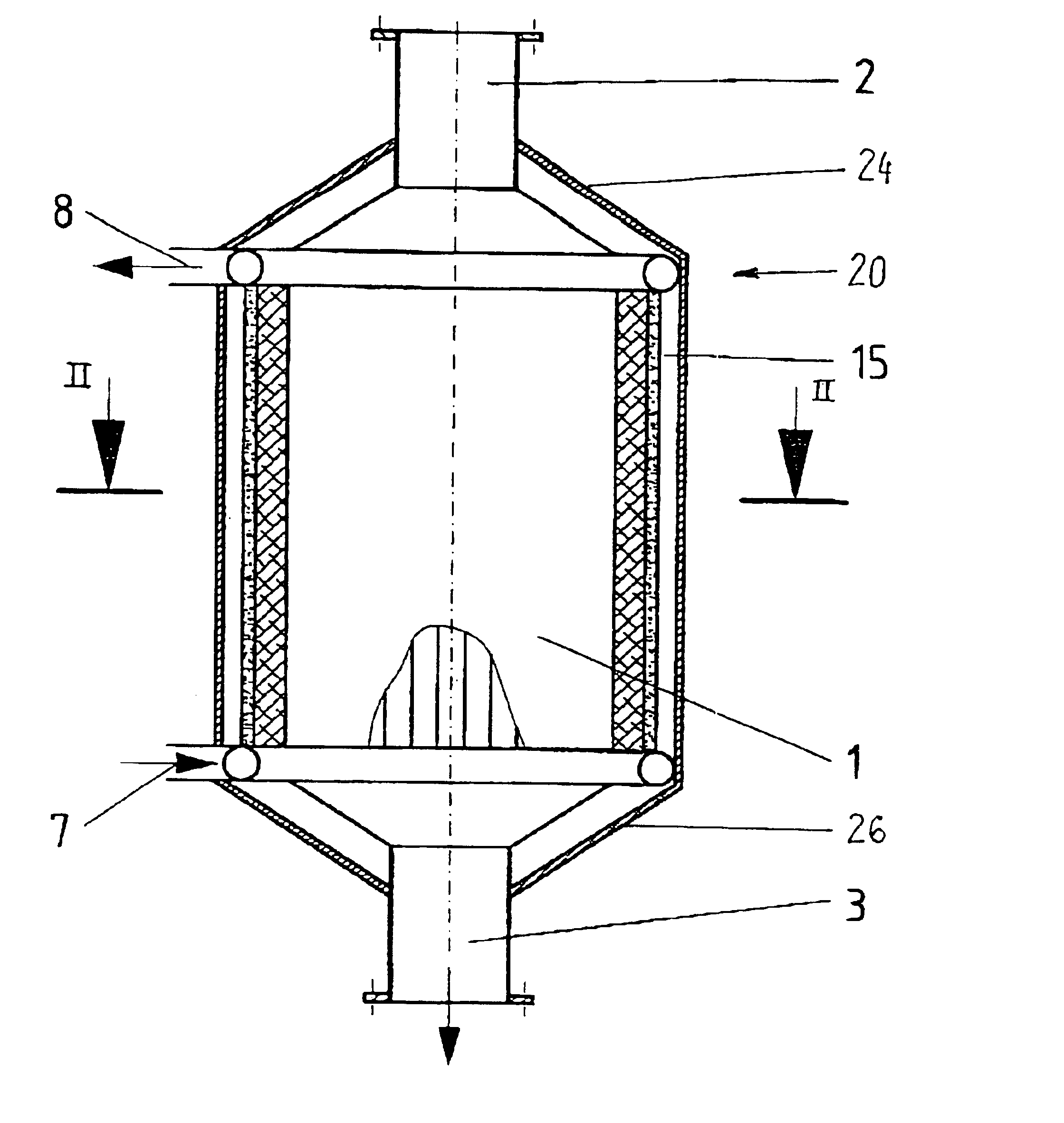

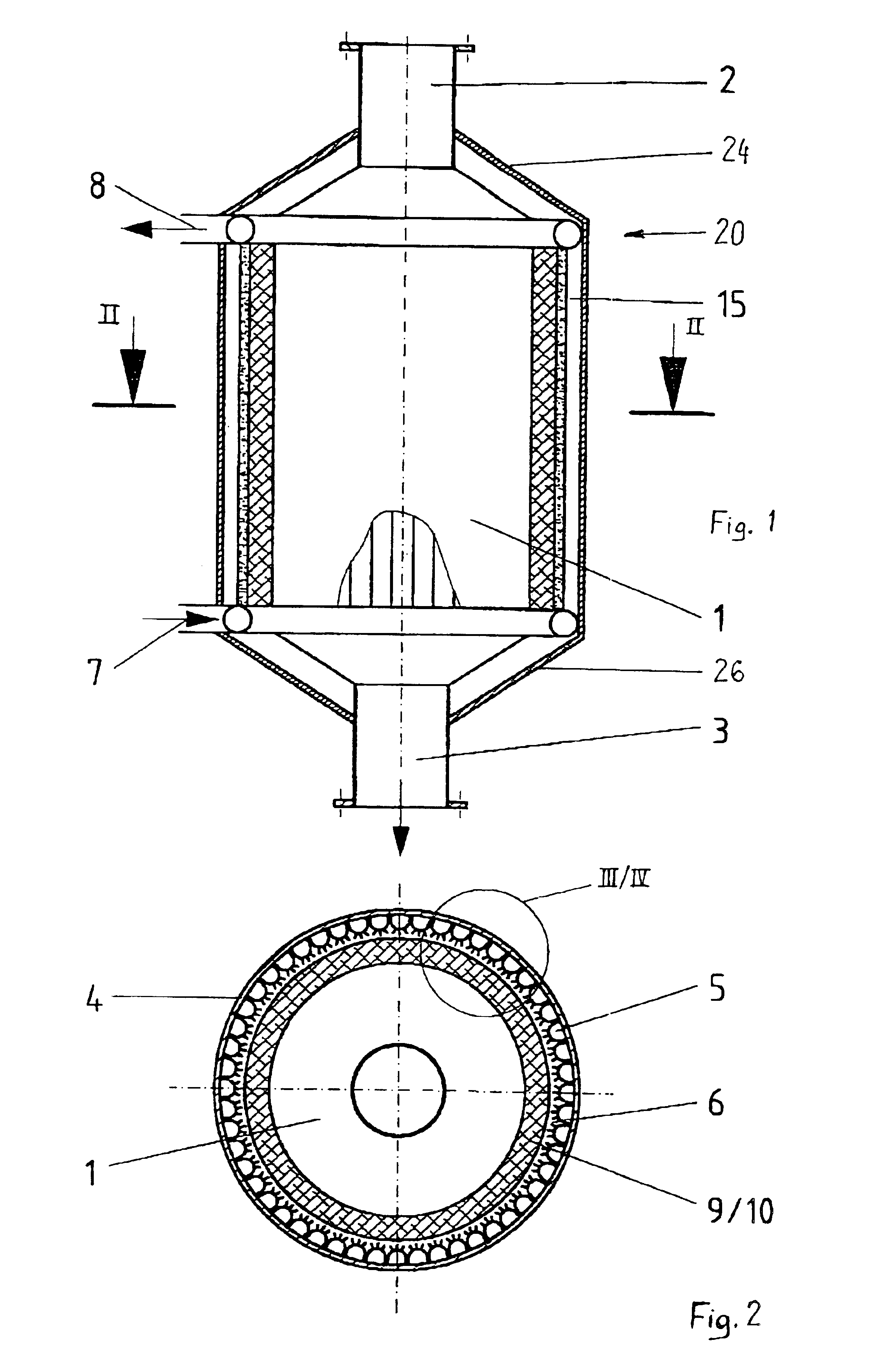

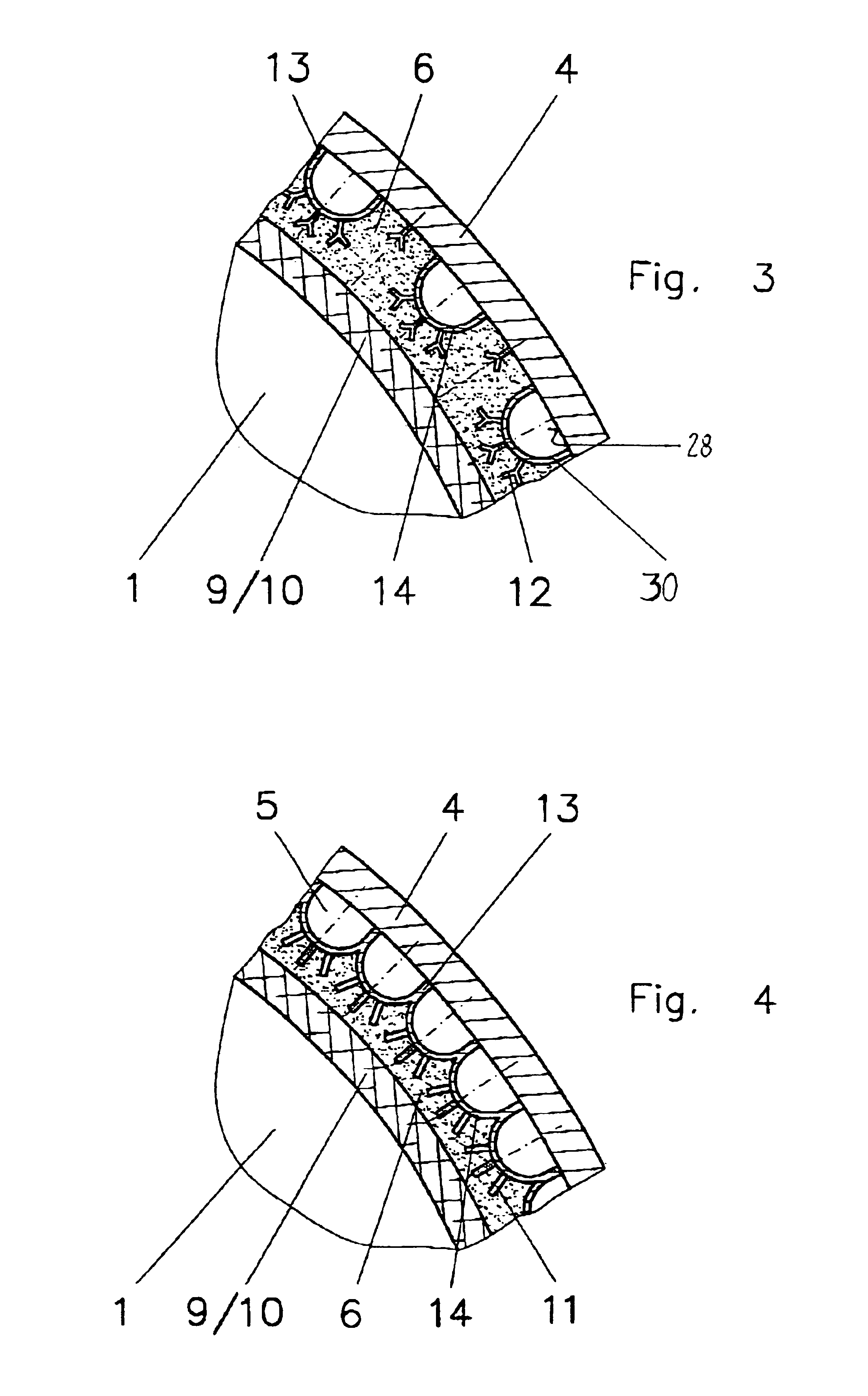

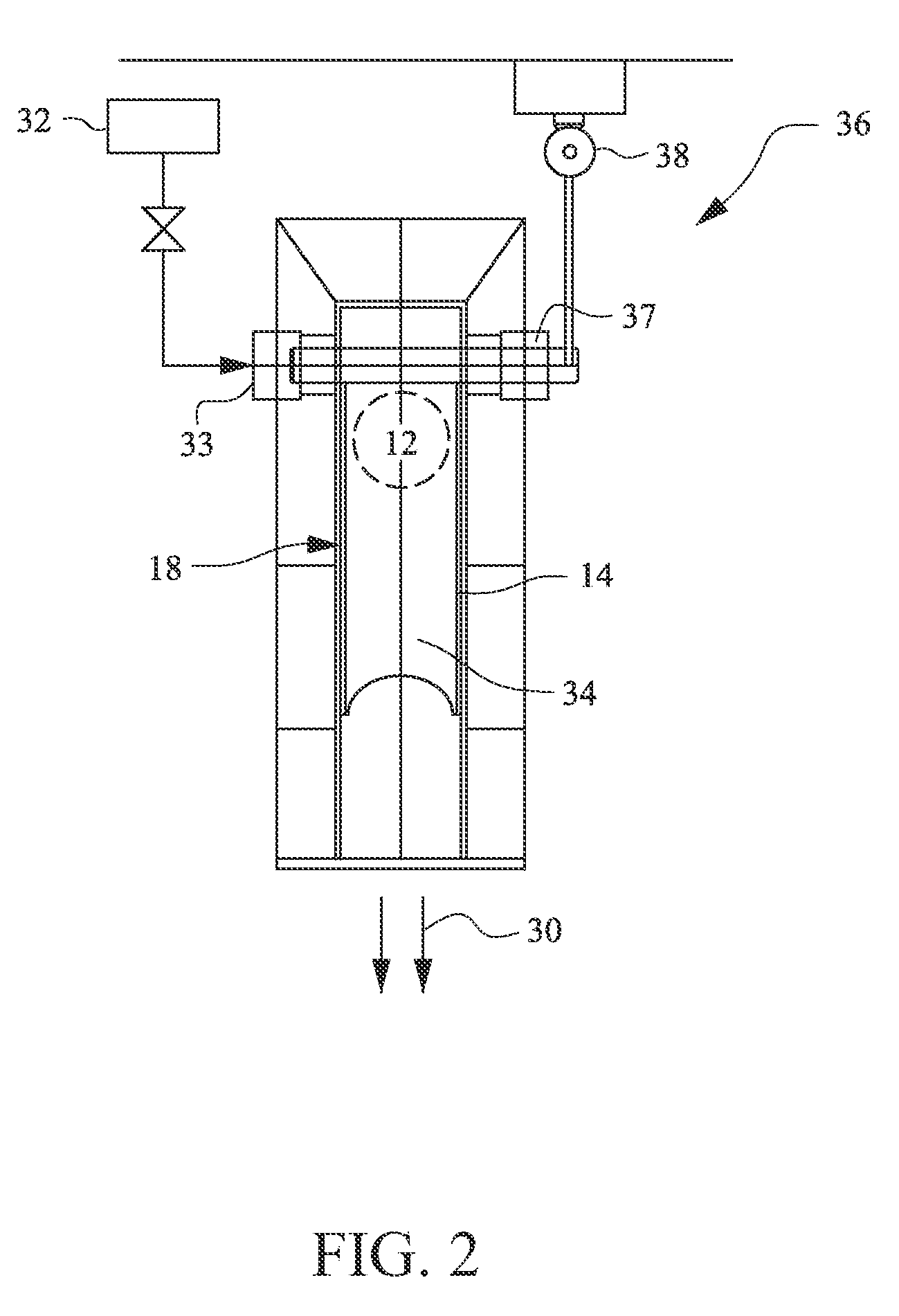

Gasification reactor vessel

InactiveUS20010020346A1Significant differencePressurized chemical processPulp liquors combustionAmbient pressureEngineering

The invention relates to a reactor vessel and method for the gasification of carbon-containing fuel, residual and waste materials using an oxygen-containing oxidizing agent and in a reaction chamber which is designed as an entrained-bed reactor, at pressures between ambient pressure and 80 bar, preferably between ambient pressure and 30 bar, the contour of the reaction chamber being delimited by a cooling system, and the pressure in the cooling system always being held at a higher level than the pressure in the reaction chamber, and the cooling system withstanding the maximum possible pressure difference with respect to the reaction chamber, which has been depressurized to atmospheric pressure, which reactor vessel is distinguished by the fact that cooling channels are formed by webs which are in contact both with a refractory protective layer and with the pressure shell.

Owner:NOELL KRC ENERGIE & UMWELTTECHN GMBH +1

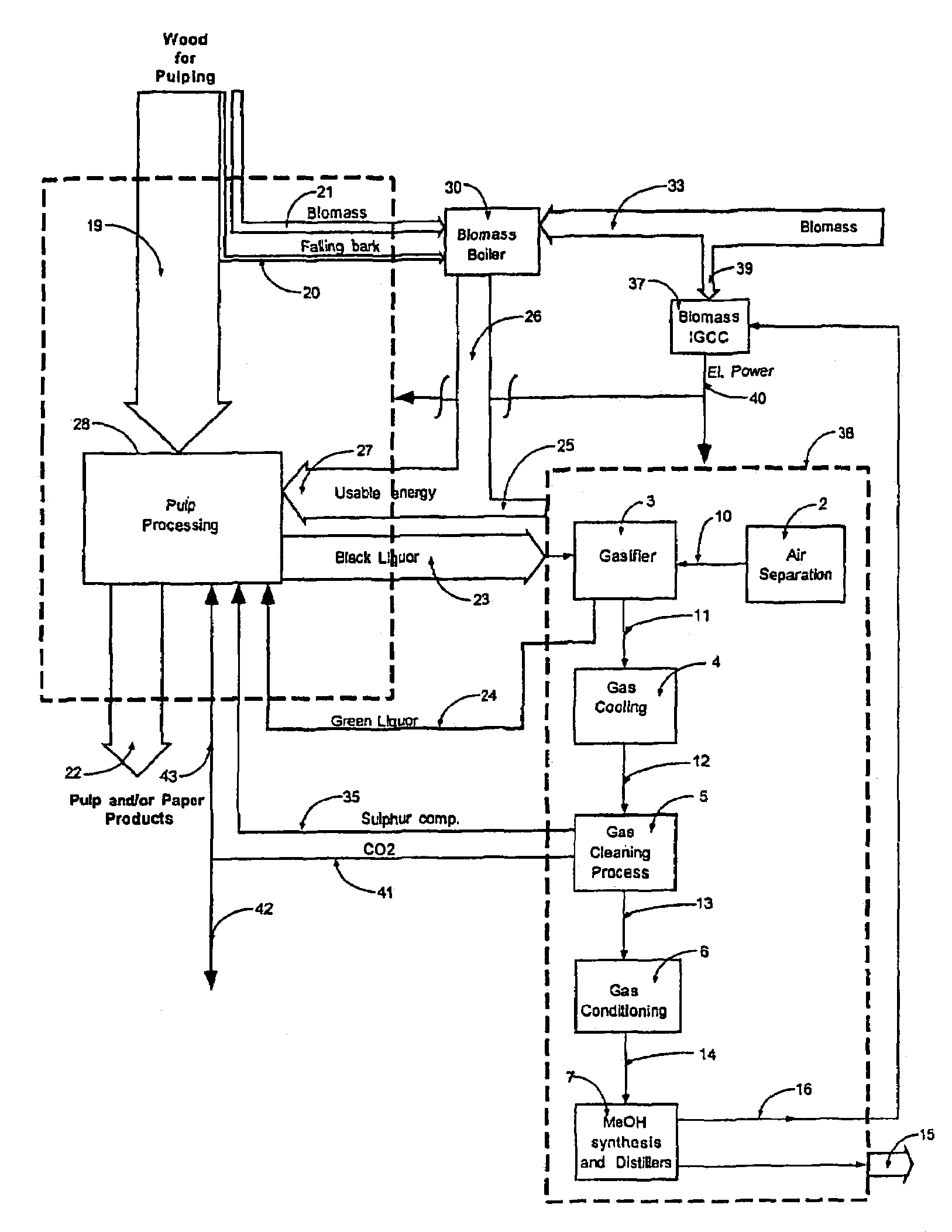

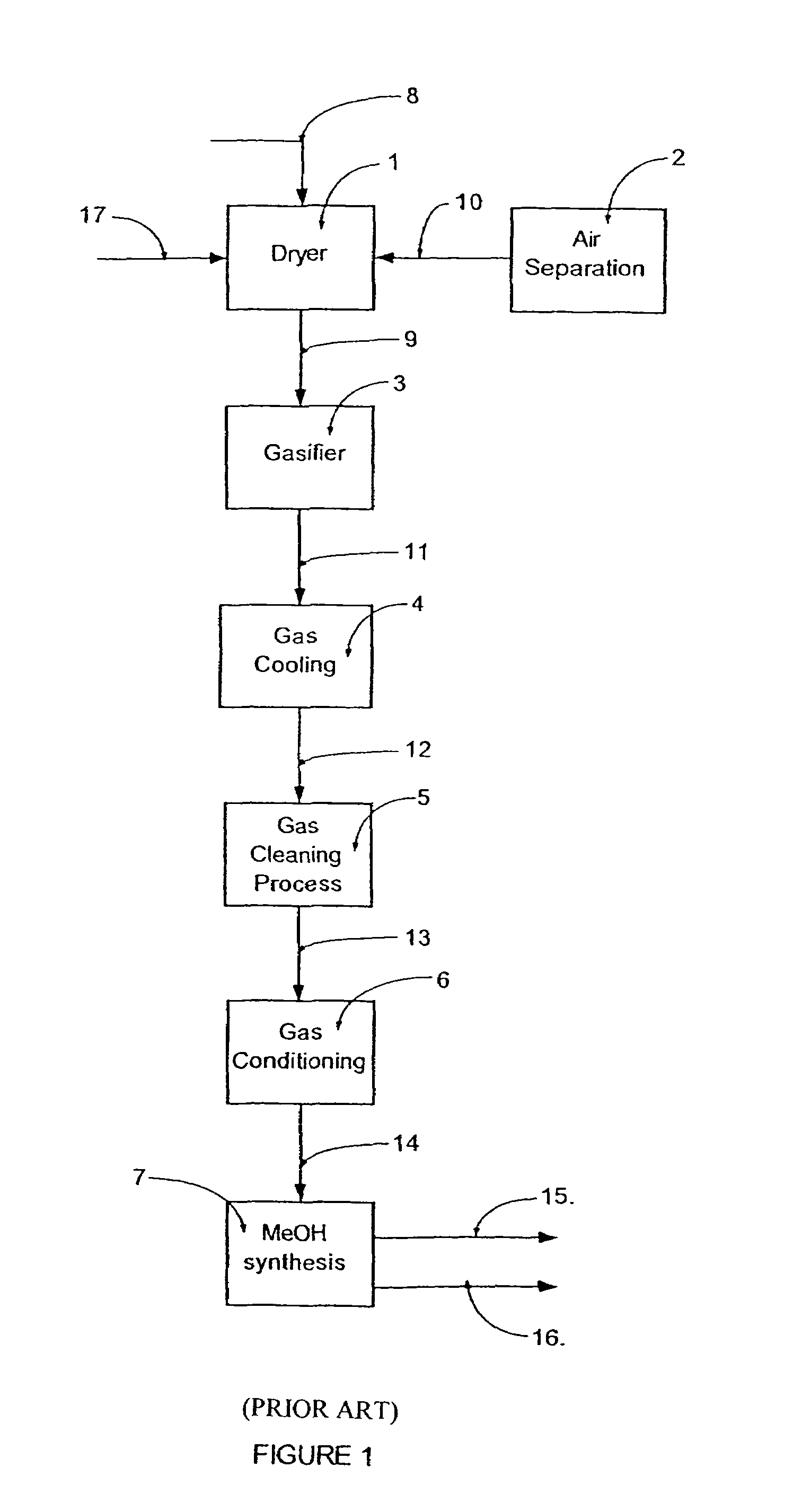

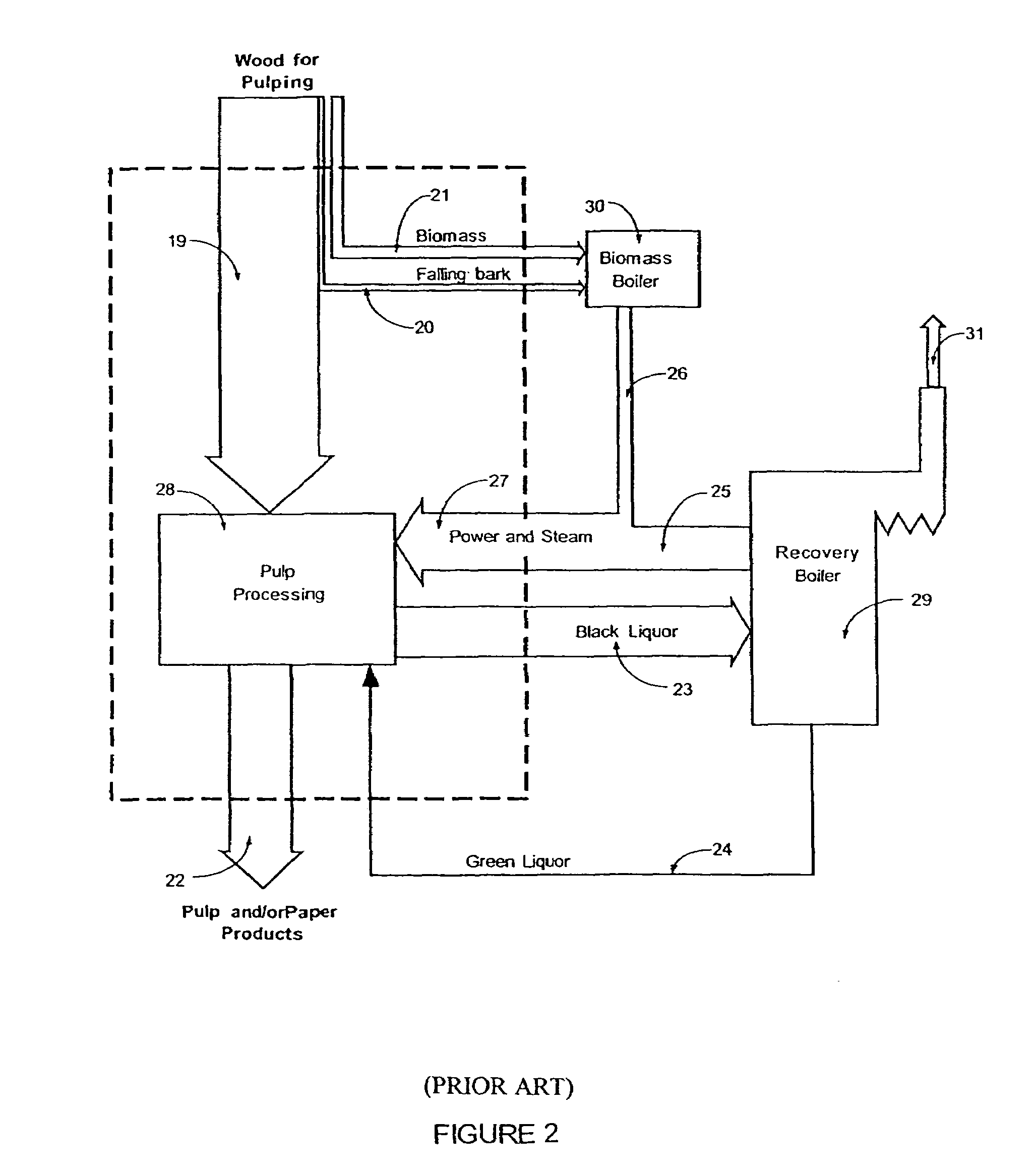

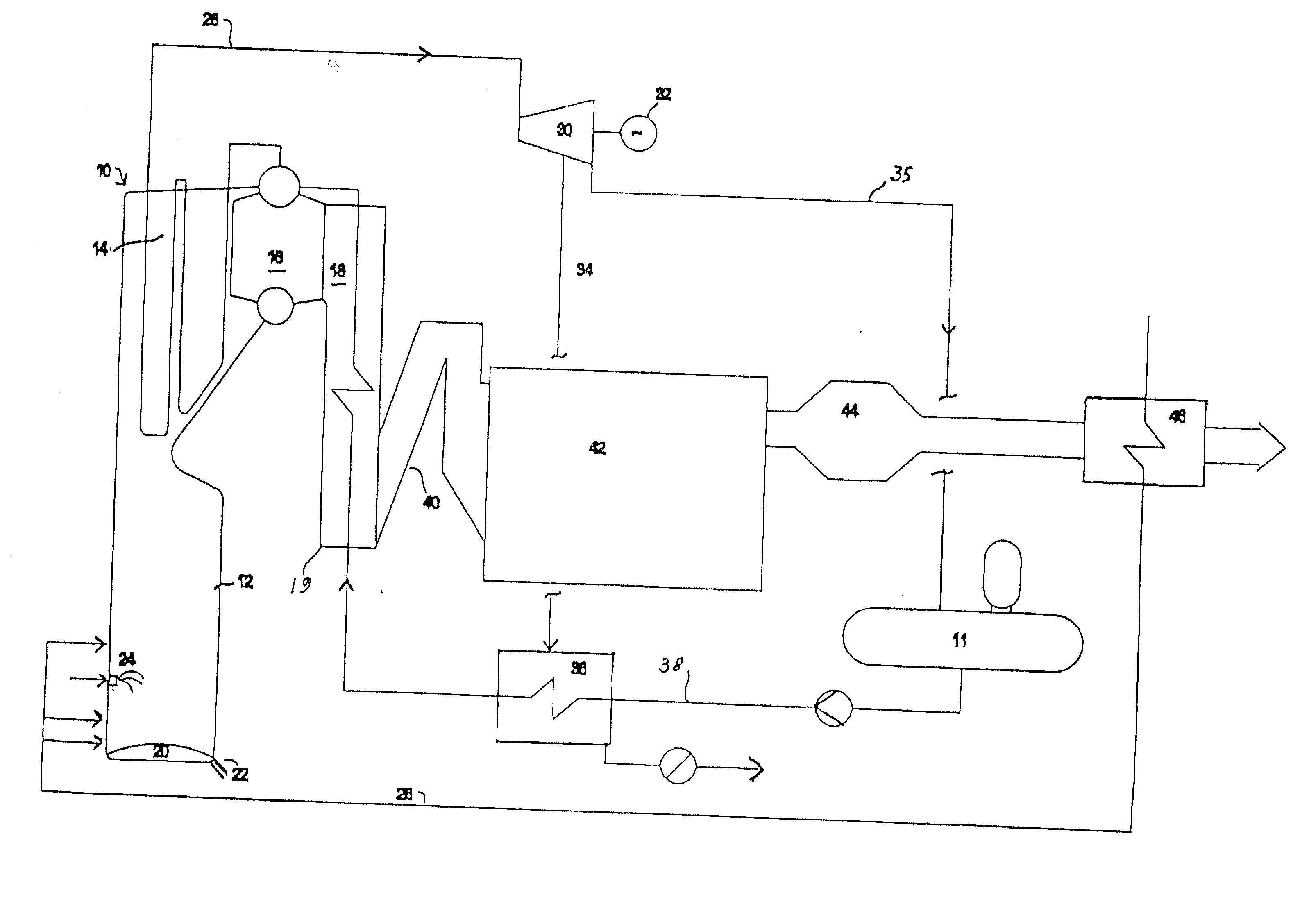

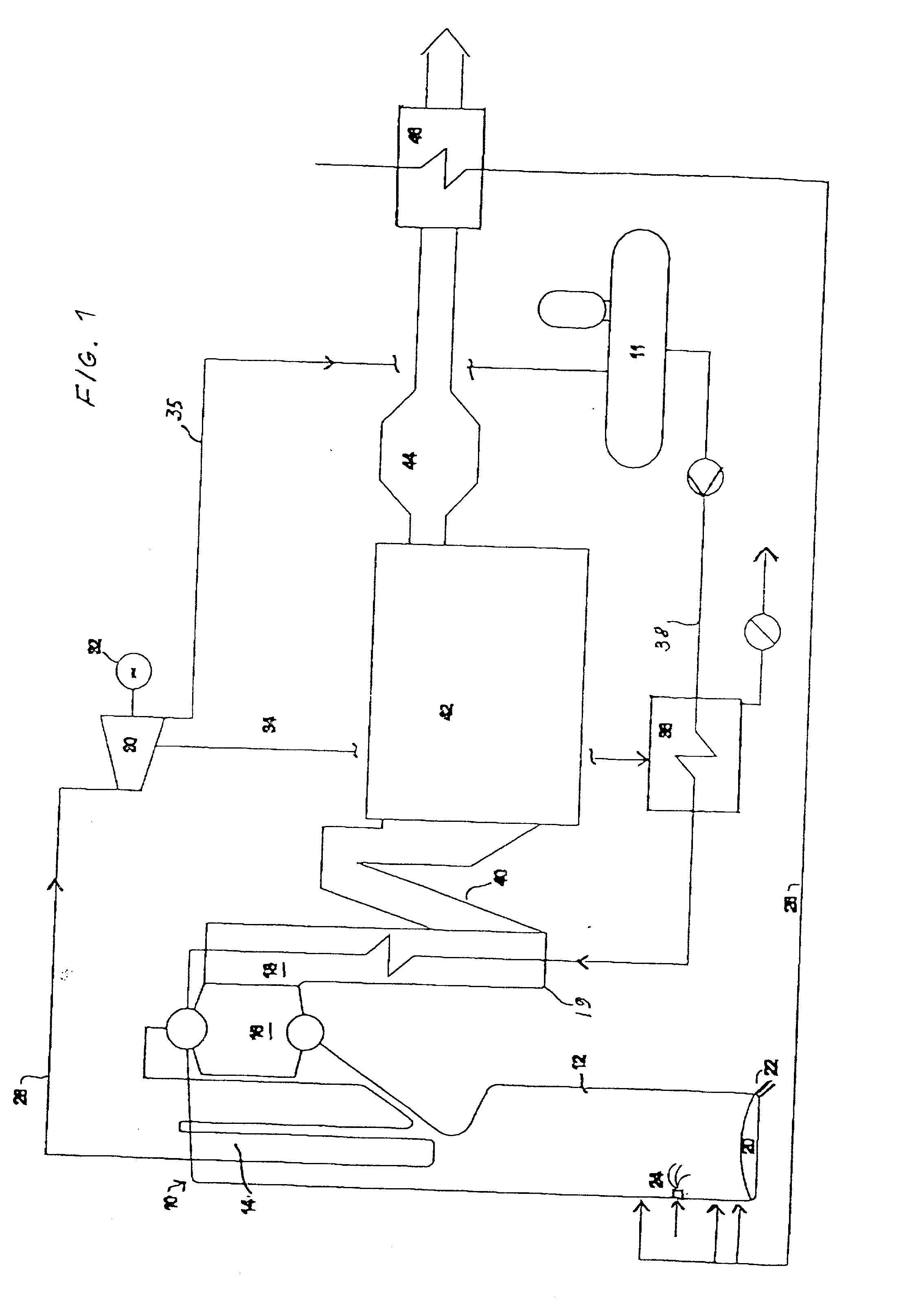

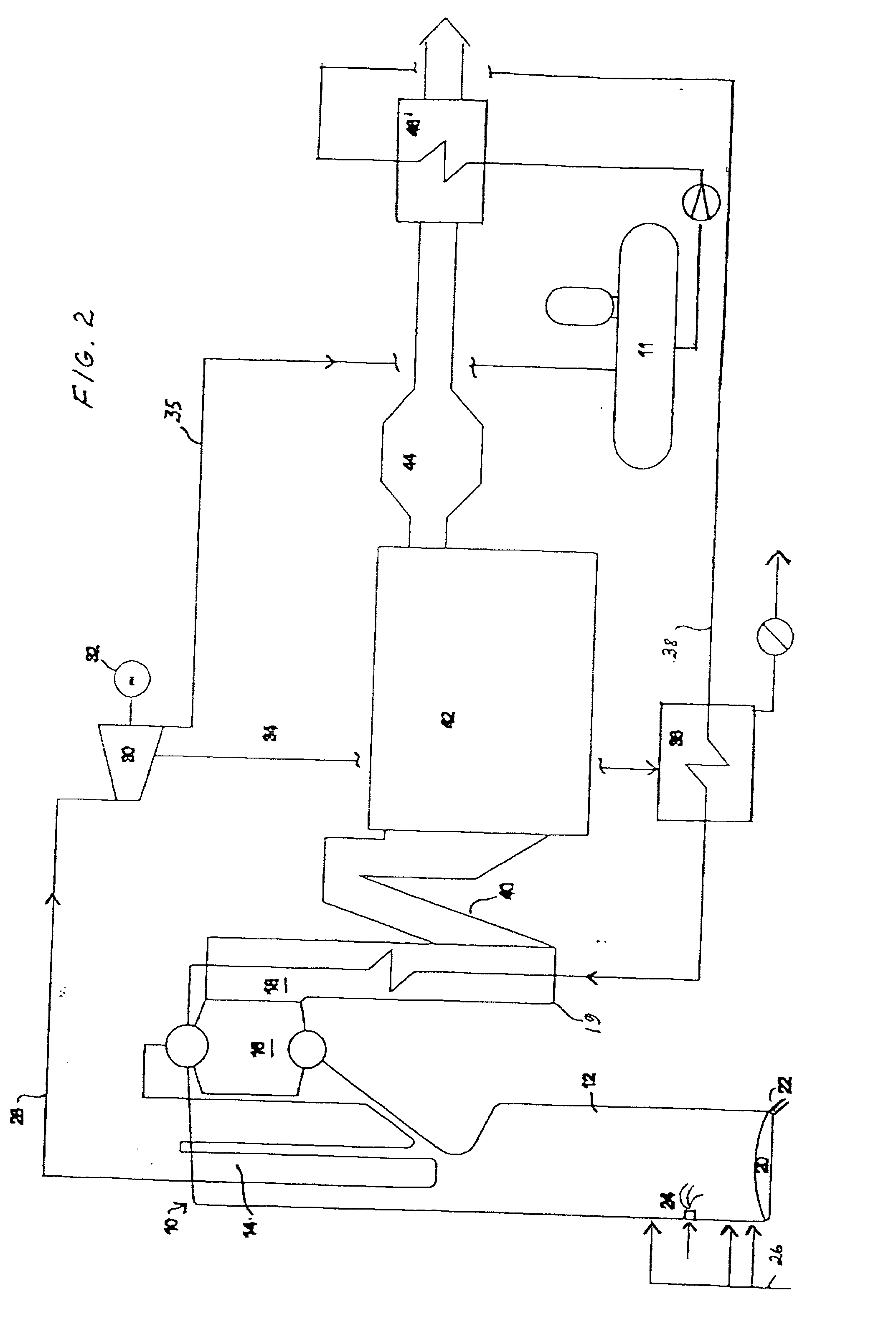

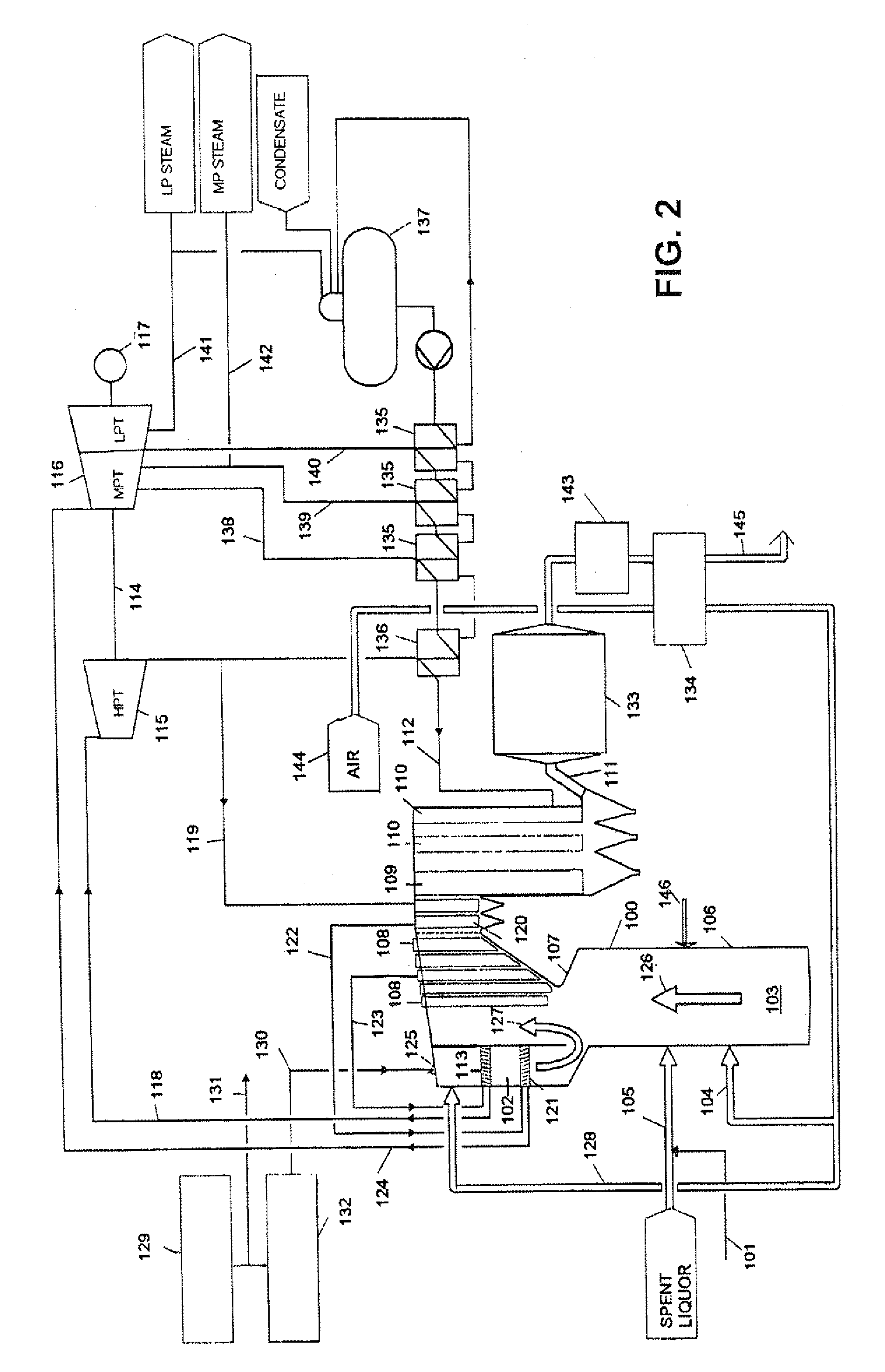

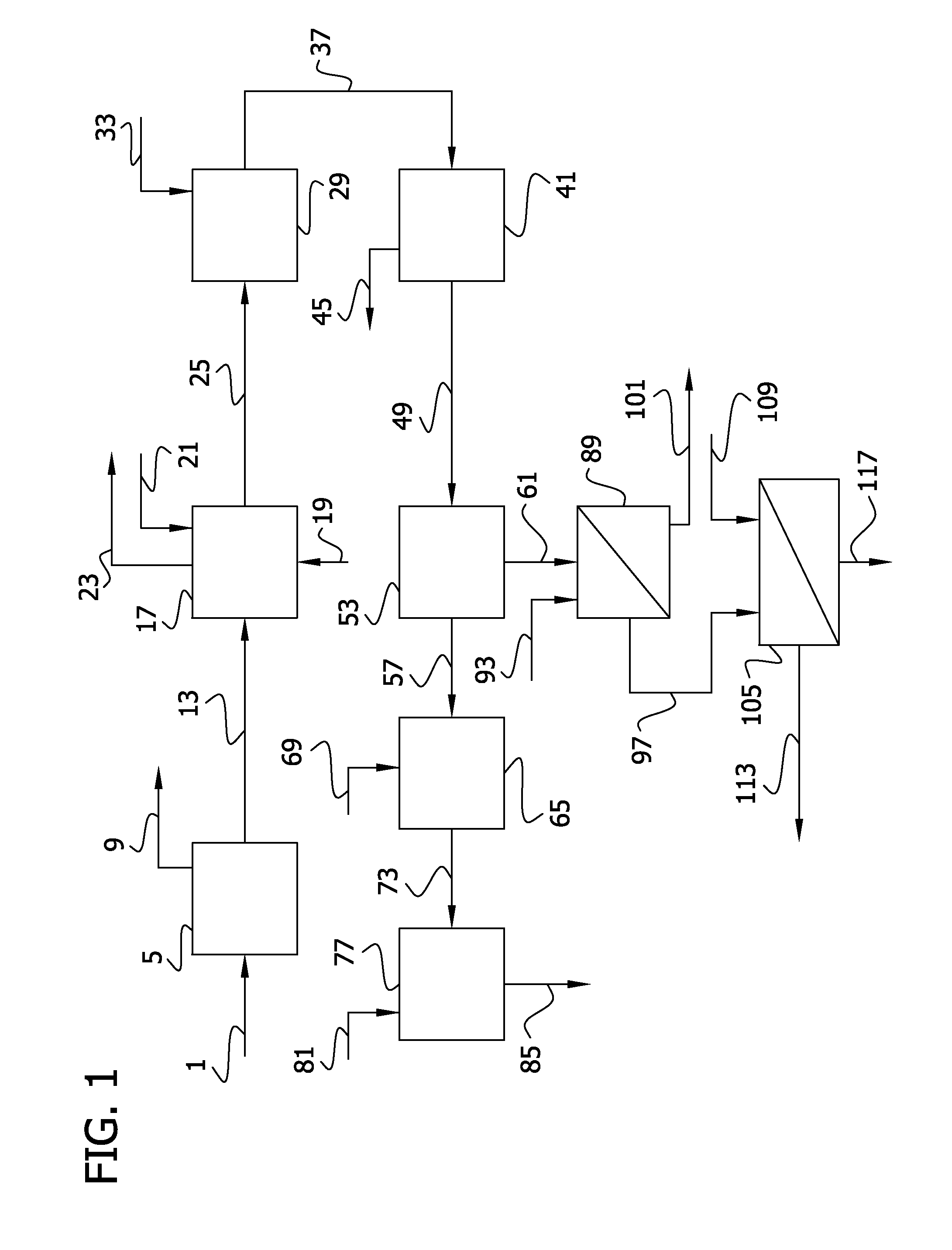

Process for production of synthesis gas in combination with the maintenance of the energy balance for a pulp mill

InactiveUS7294225B2Simpler andImprove energy savingPulp liquors combustionHydrocarbon from carbon oxidesEnergy balancingCombustion

A process (44) for the production of pulp and paper (28), recycling of cooking chemicals (3, 29), combustion of biomass (30, 37) and generation of heat and electric energy (27, 40) comprising a pulp and paper mill (28), in that the part of the process which is recycling cooking chemicals is adjusted from combustion (29) to gasification (3) to generate synthesis gas (14); and that biomass is added (33, 39) in an amount sufficient for compensating of the decrease in heat and electricity generation as a consequence of the generation of synthesis gas (14).

Owner:CHEMREC AB

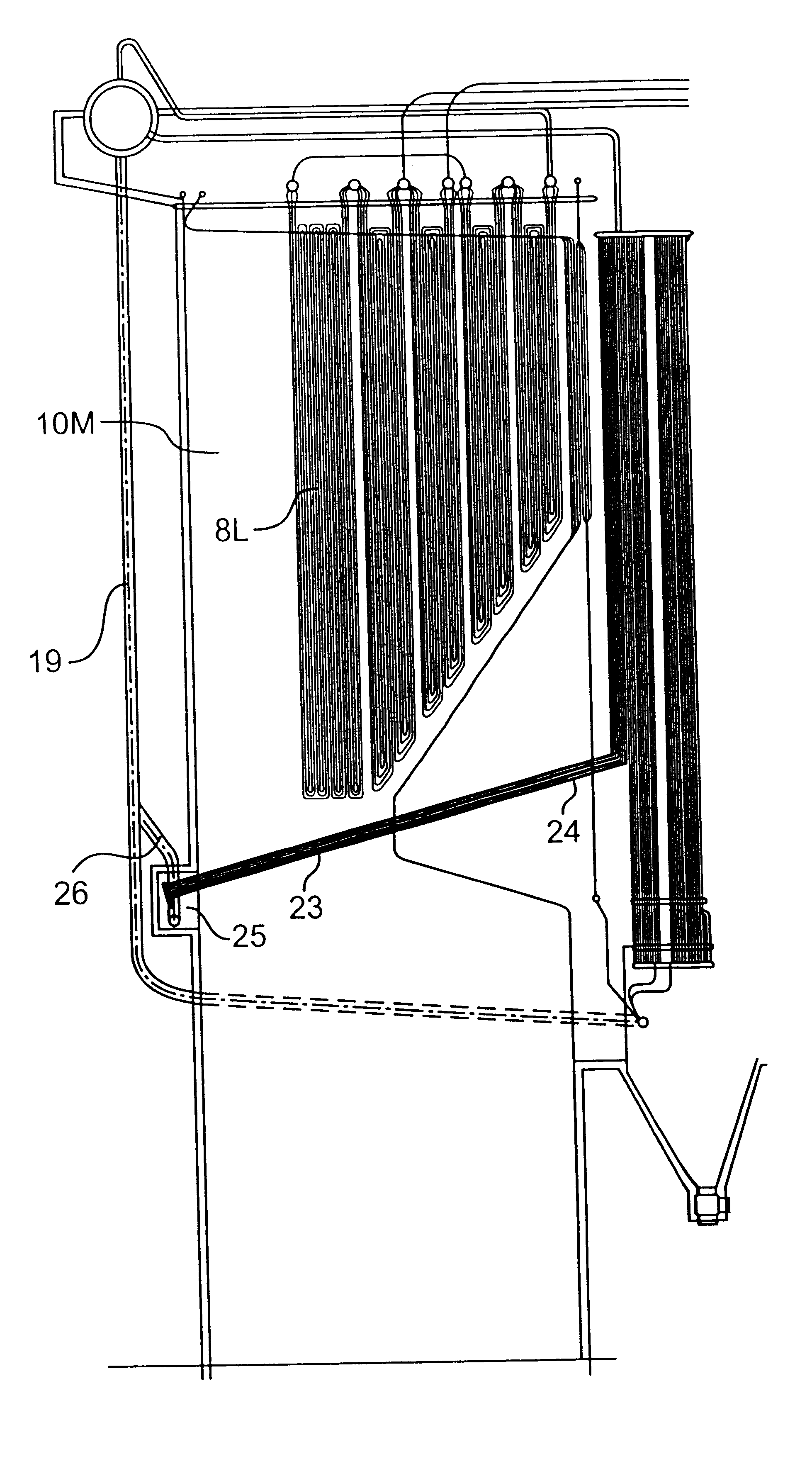

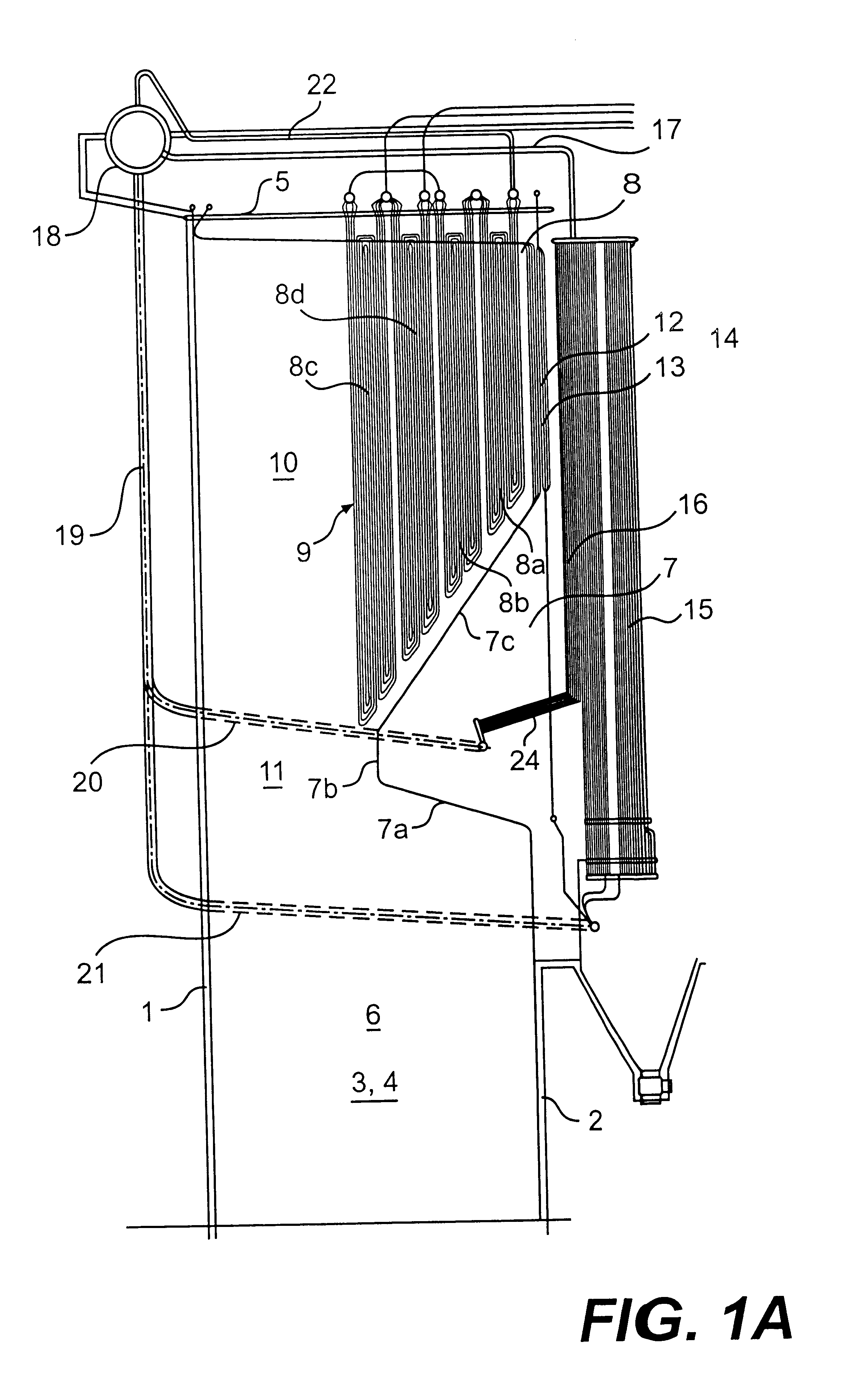

Method for upgrading a boiler

InactiveUS6178924B1Increase capacityImprove efficiencyFluidized bed combustionPulp liquors combustionEngineeringSuperheater

A method for upgrading a boiler is provided. When operating at a first capacity, the boiler is used such that an open space is kept in radiation communication with a firebox. The open space is also kept as empty. A first set of water circulation tubes are connected to the boiler cylinder in connection with the ascending tubes. When the boiler is operated at a second capacity, which is higher than the first capacity, at least one additional part is arranged in the open space to expand the basic super heater arrangement. Additionally, or alternatively at the second capacity, a second set of water circulation tubes may be connected to the boiler cylinder in connection with the ascending tubes. The second set of water circulation tube has a capacity exceeding that of the first set of water circulation tubes.

Owner:KVAERNER POWER OY

Treatment of Pulp Stocks Using Oxidative Enzymes to Reduce Pitch Deposition

InactiveUS20070261806A1Lower energy requirementsImprove paper strengthPulp liquors combustionFats/resins/pitch/waxes removal in pulpTime rangeResin acid

Methods of treating pulp stocks with an enzyme formulation containing one or more oxidative enzymes, to reduce pitch deposition, control pitch related problems, modify the physical and / or chemical properties of tri, di-, and mono-glycerides, fatty acids, resin acids, esters of fatty acids and resin acids, and metal soaps of fatty acids and resin acids, or change the concentration of triglycerides, fatty acids, resin acids, and esters of fatty acids and resin acids, have been developed. The pulp stock is treated with an enzyme formulation containing laccases, peroxidases, esterases, and / or combinations thereof. The enzyme formulations may also contain a laccase mediator and / or a dispersant. The enzyme formulation can be applied at any of several locations during the pulping and / or papermaking process. The enzyme formulation is typically applied as a solution to the pulp stock. The enzyme treatment is effective at a temperature of between about 30° C. to about 95° C., more preferably from about 50° C. to about 80° C. The pH of the pulp stock is from about 4.0 to about 7.0, more preferably from about 4.5 to 5.5. The stock can be treated for a period of time ranging from about 5 minutes to about 10 hours.

Owner:ENZYMATIC DEINKING TECH LLC

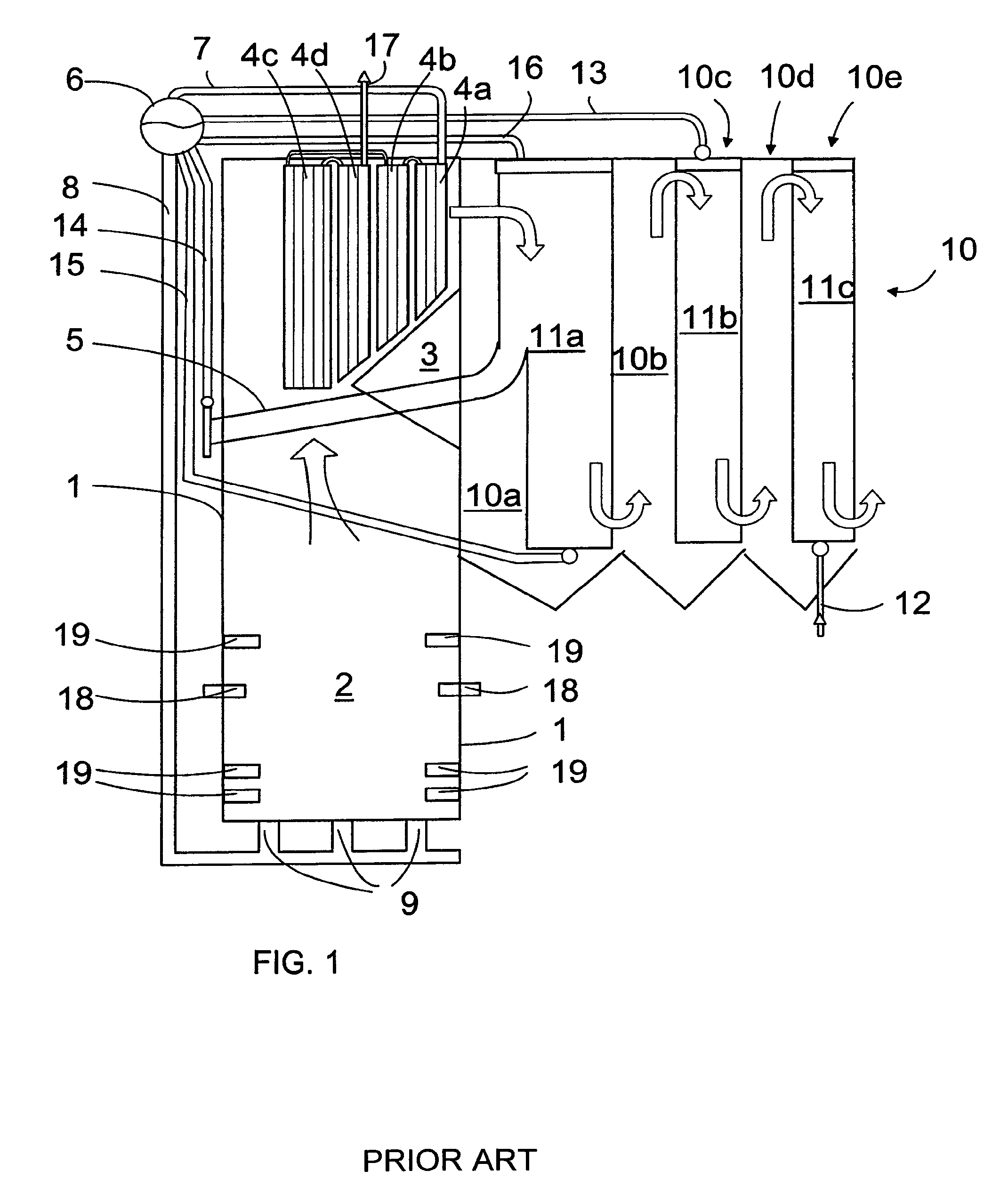

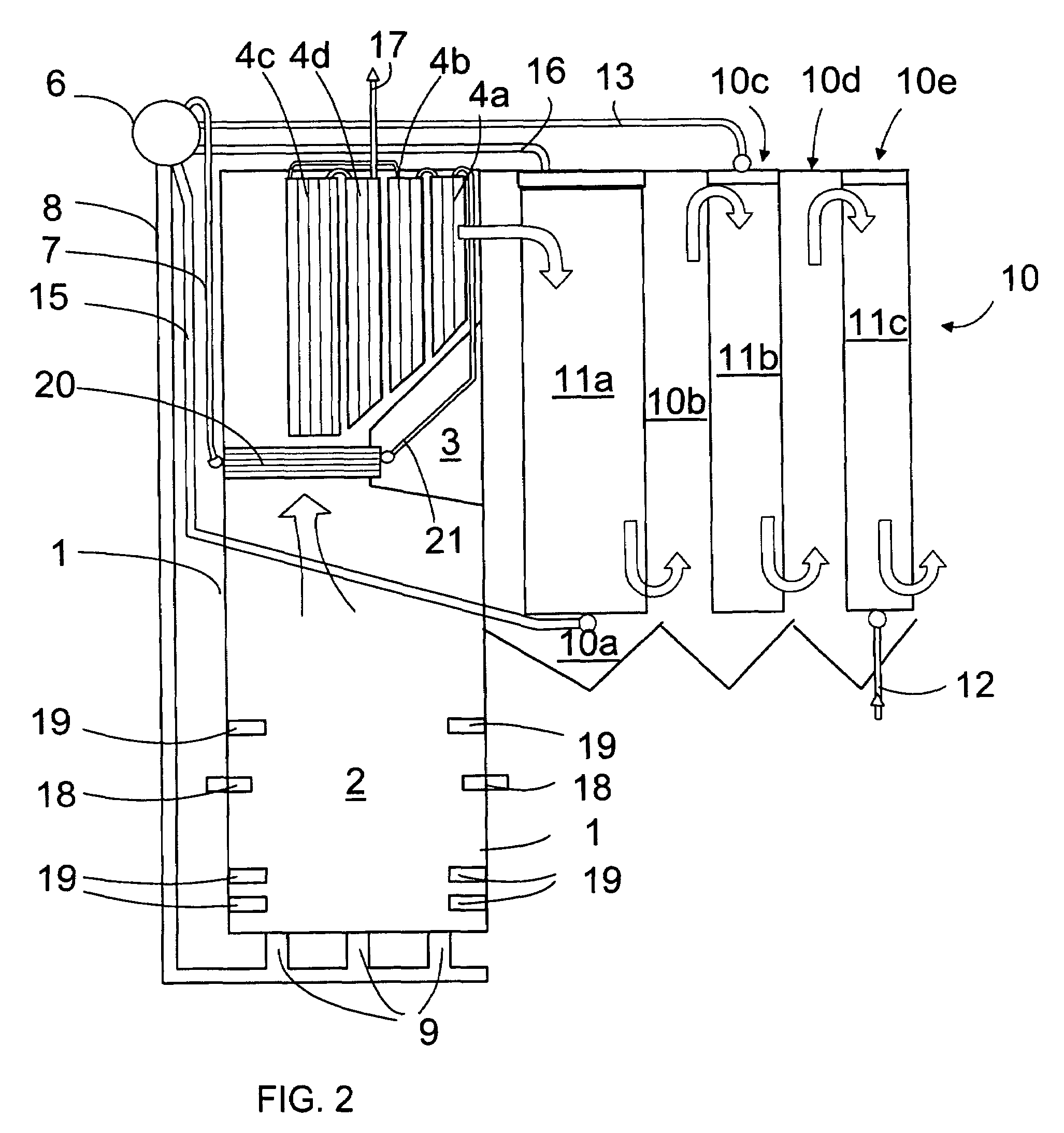

Arrangement in recovery boiler

ActiveUS7434543B2Increase heatFine surfacePulp liquors combustionSteam engine plantsSuperheaterPulp and paper industry

The invention relates to an arrangement in a recovery boiler, into which spent liquor to be combusted and combustion air are fed, the arrangement comprising superheaters in the upper part of the recovery boiler for recovering heat. Instead of screen tubes the invention is provided with a superheater formed of horizontal elements.

Owner:KVAERNER POWER OY

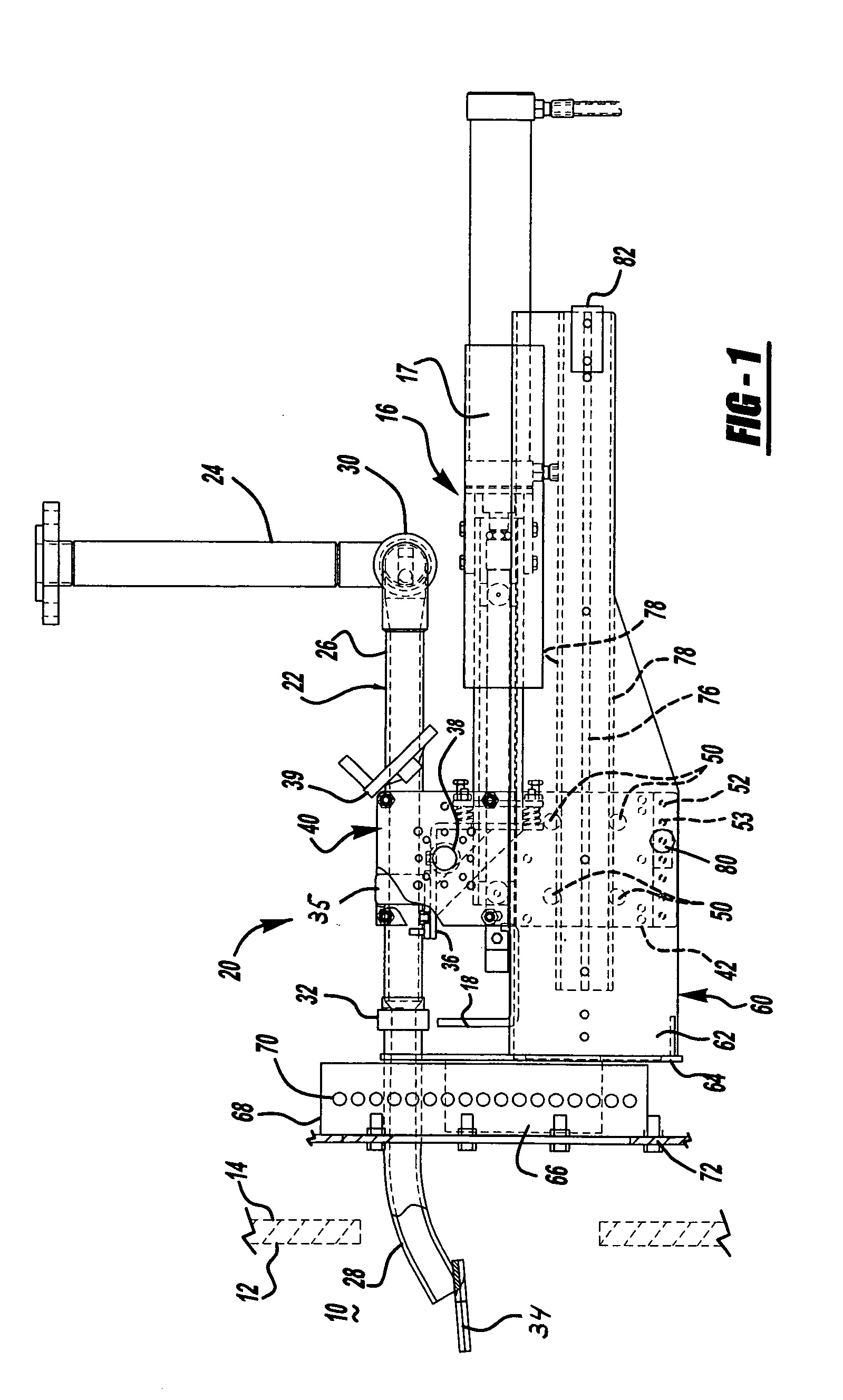

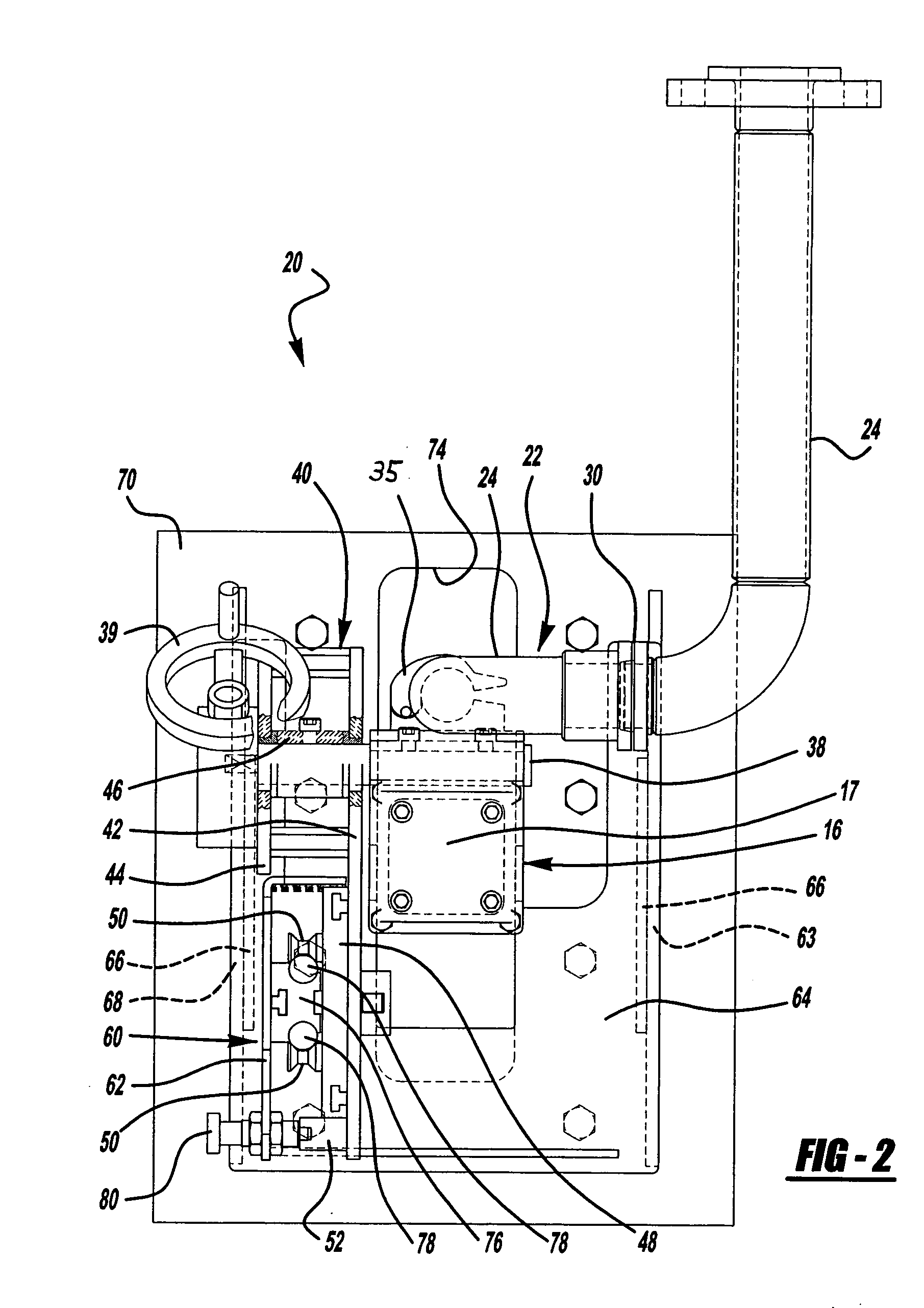

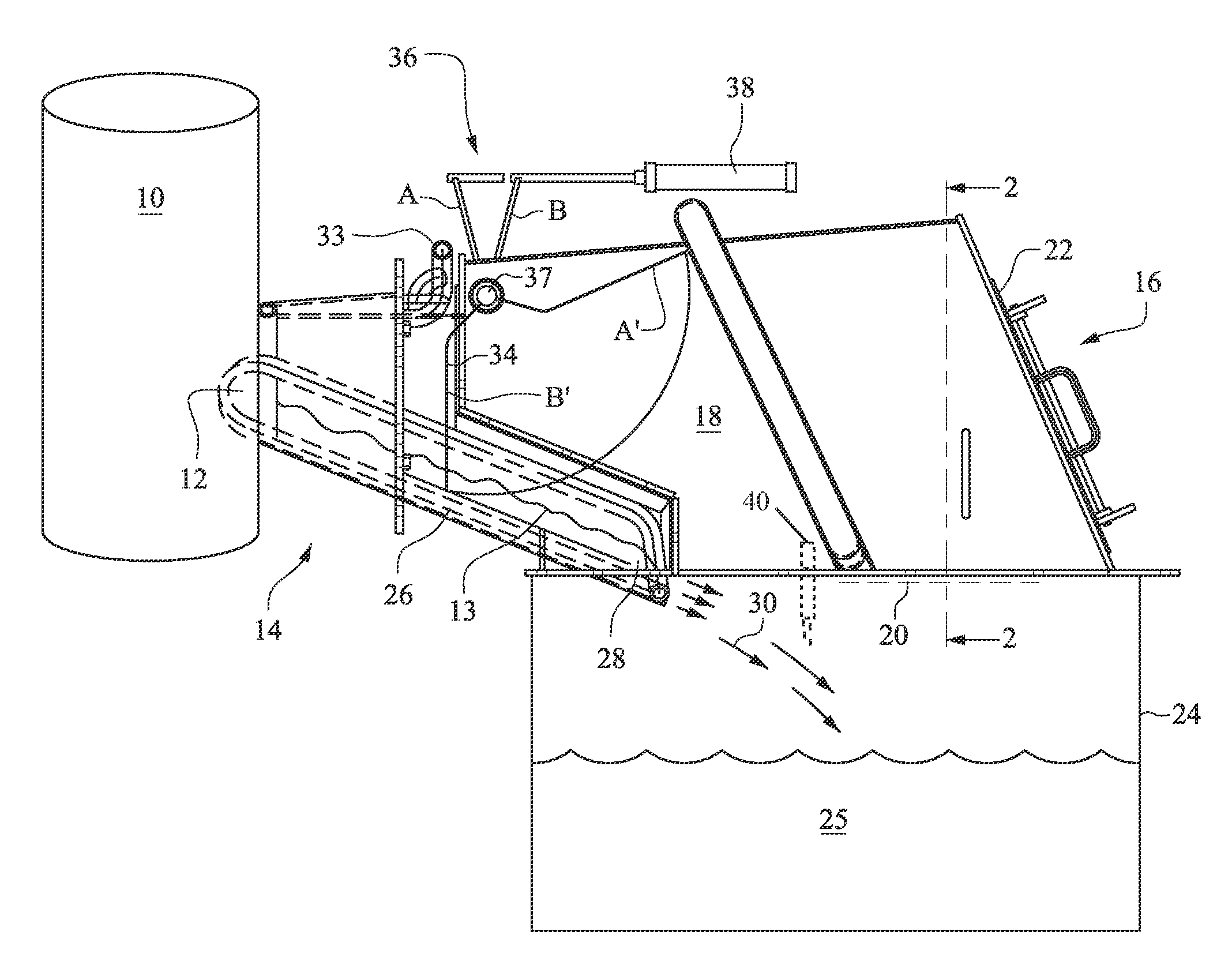

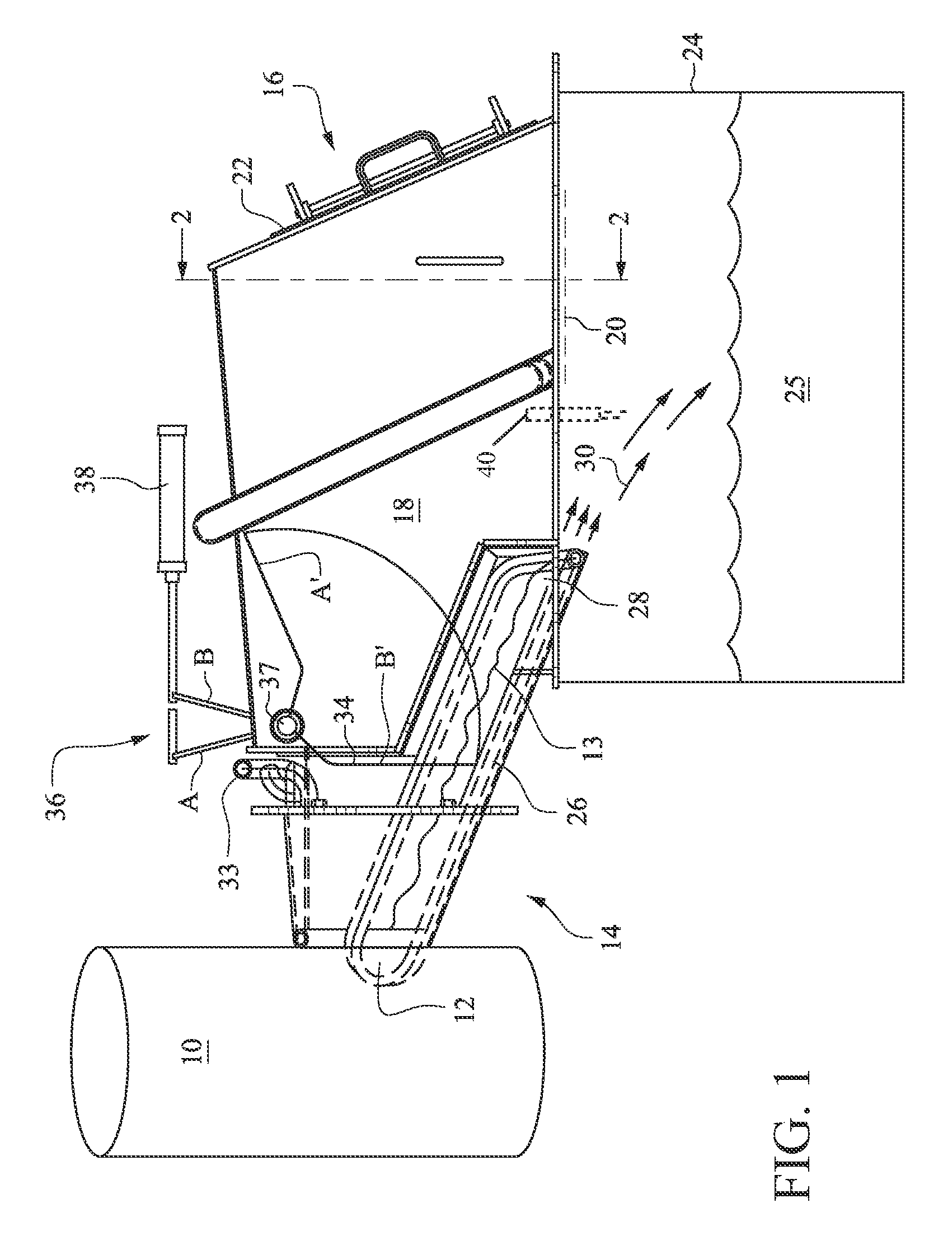

Retractable liquor gun holder for a recovery furnace

A liquor gun holder for a recovery furnace includes a rail assembly, a carriage assembly moveably mounted onto the rail assembly such that the carriage assembly is moveable longitudinally along the rail assembly, a pivot pin supported by a bearing and extending laterally from the carriage assembly, and a cleaning assembly pivotally mounted onto the pivot pin such that the cleaning assembly is rotatable about a horizontal axis extending longitudinally through the pivot pin and is positioned laterally from the carriage assembly and the rail assembly, the cleaning assembly including a clamp adapted to secure a liquor gun thereon such that the liquor gun is rotatable with the cleaning assembly and is positioned laterally from the carriage assembly.

Owner:DIAMOND POWER INT

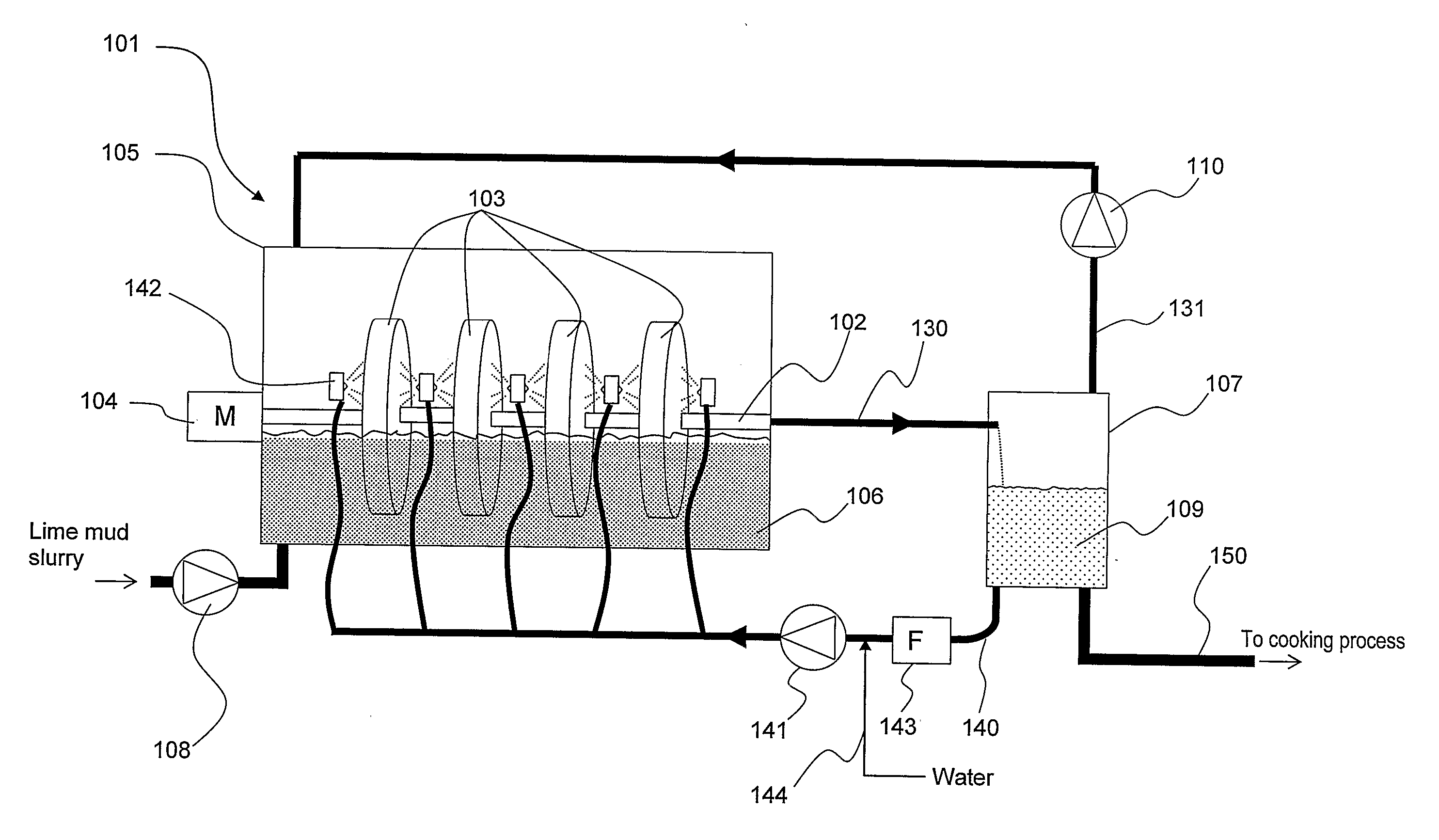

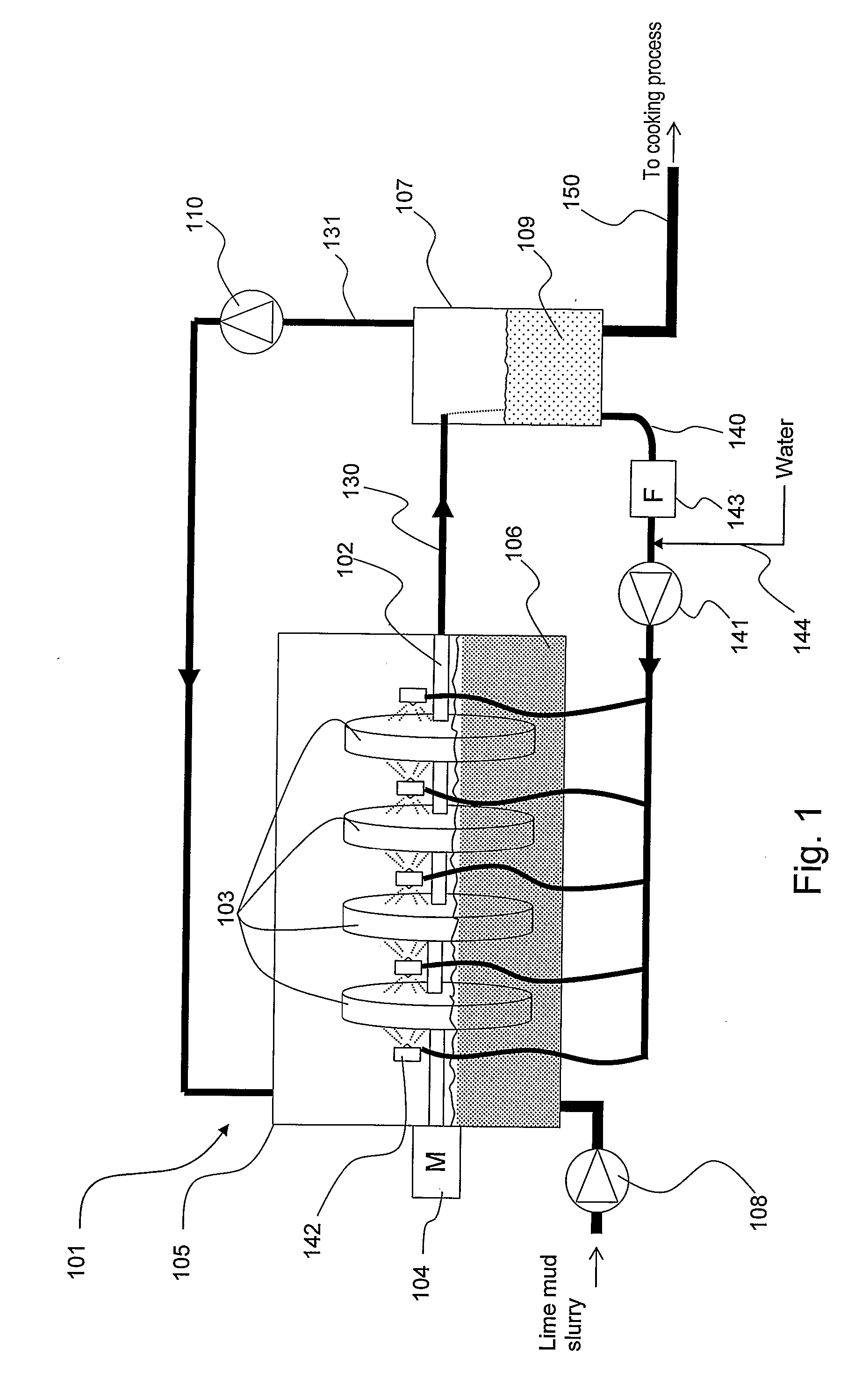

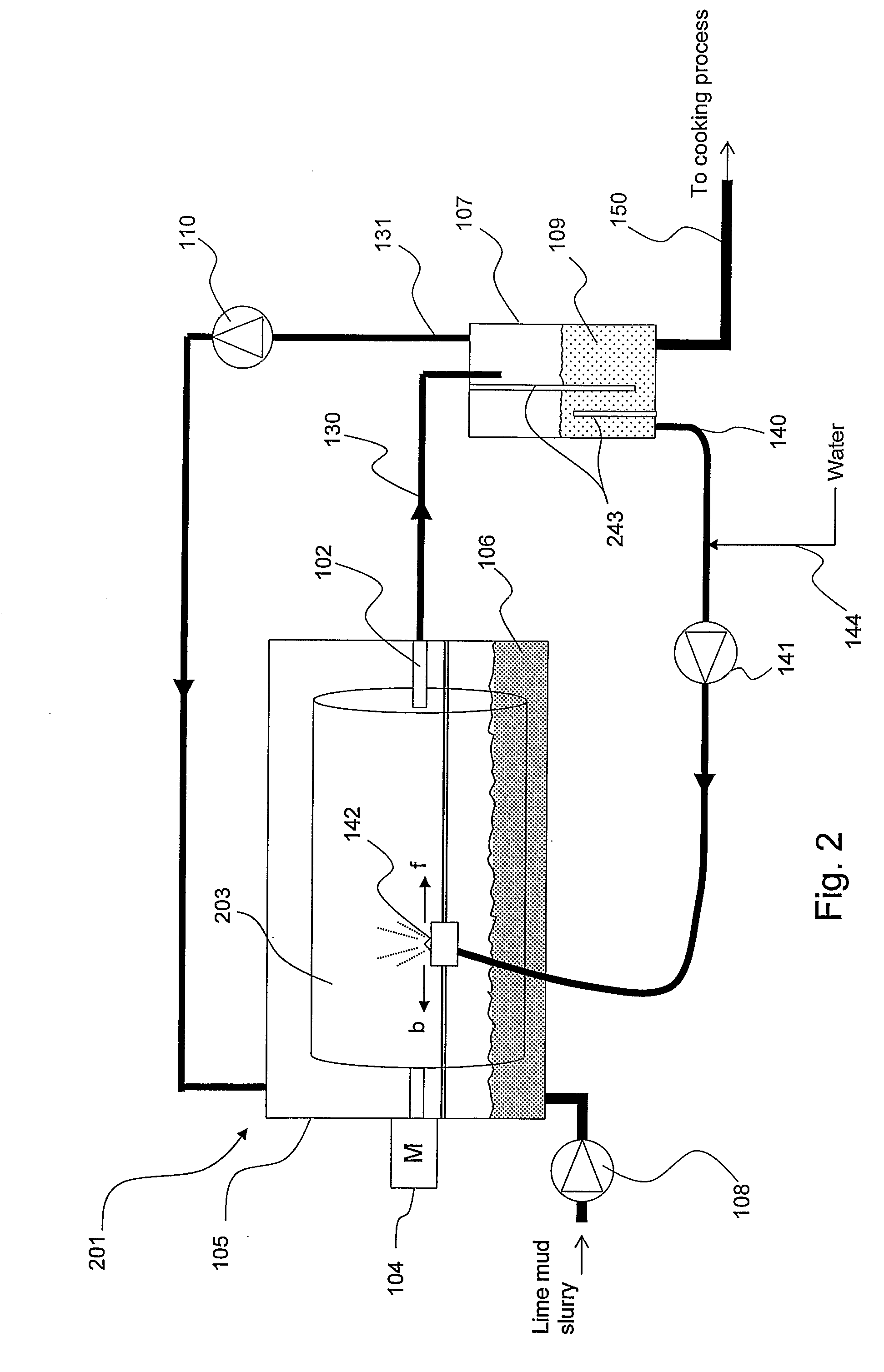

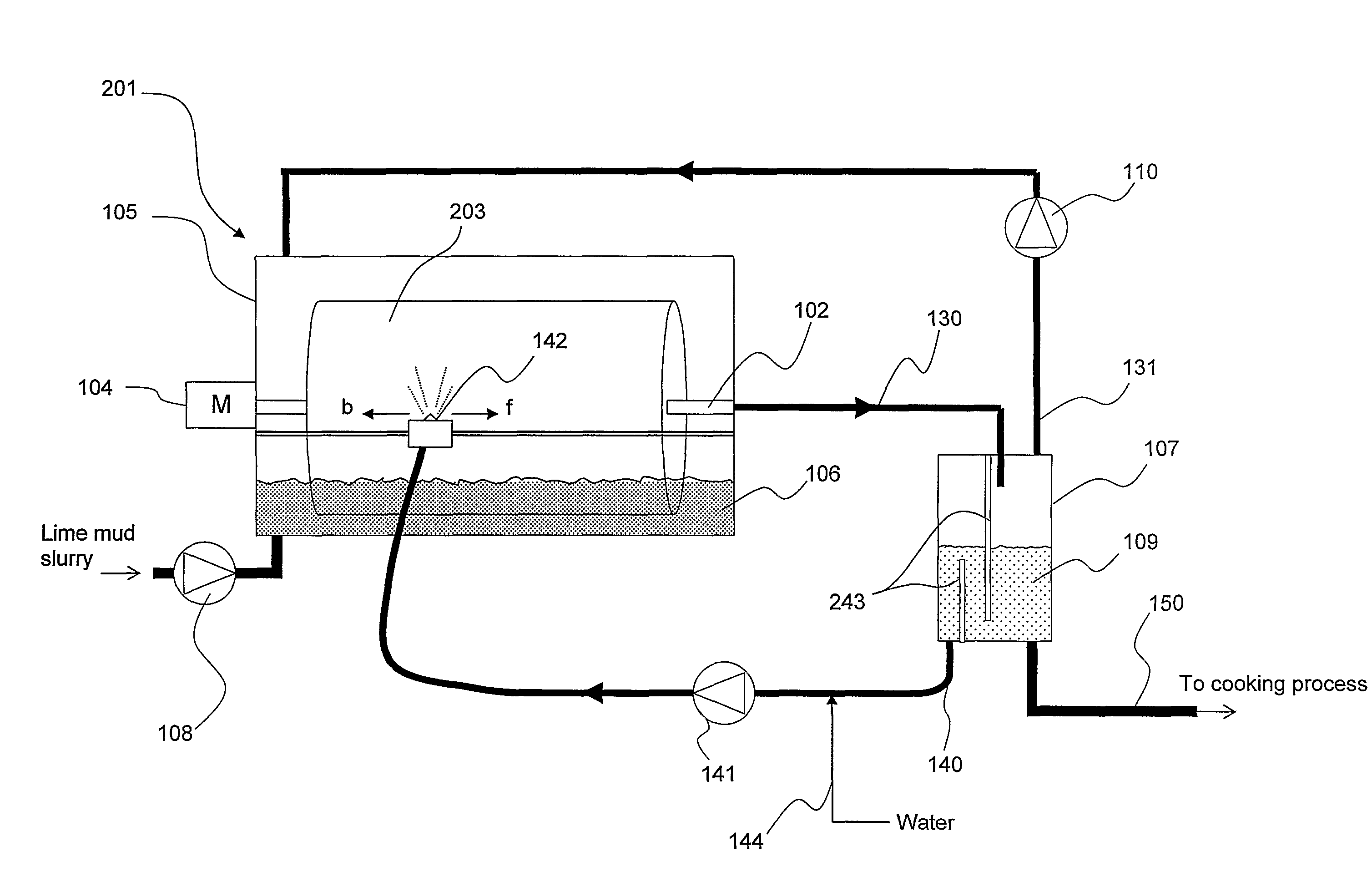

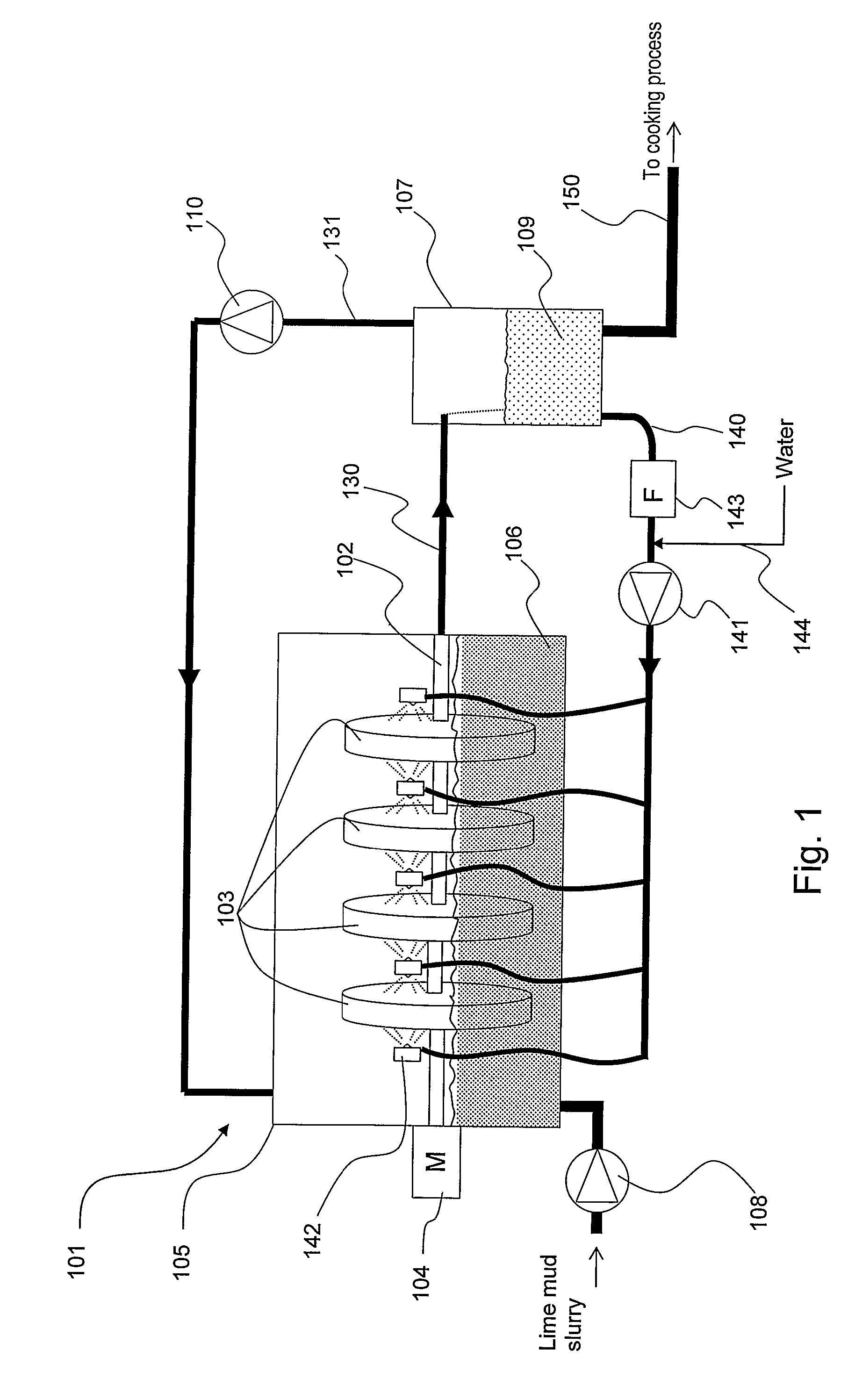

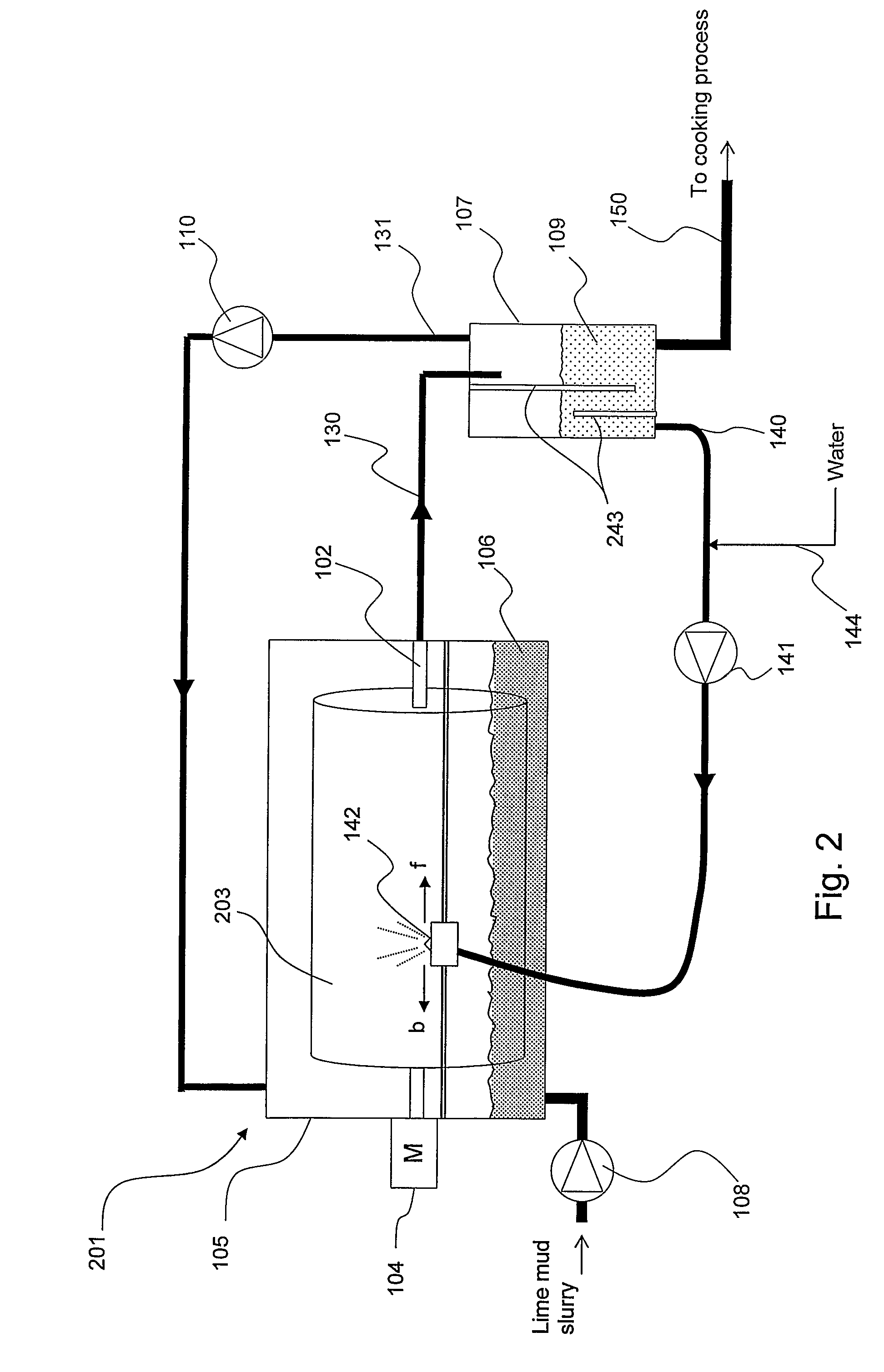

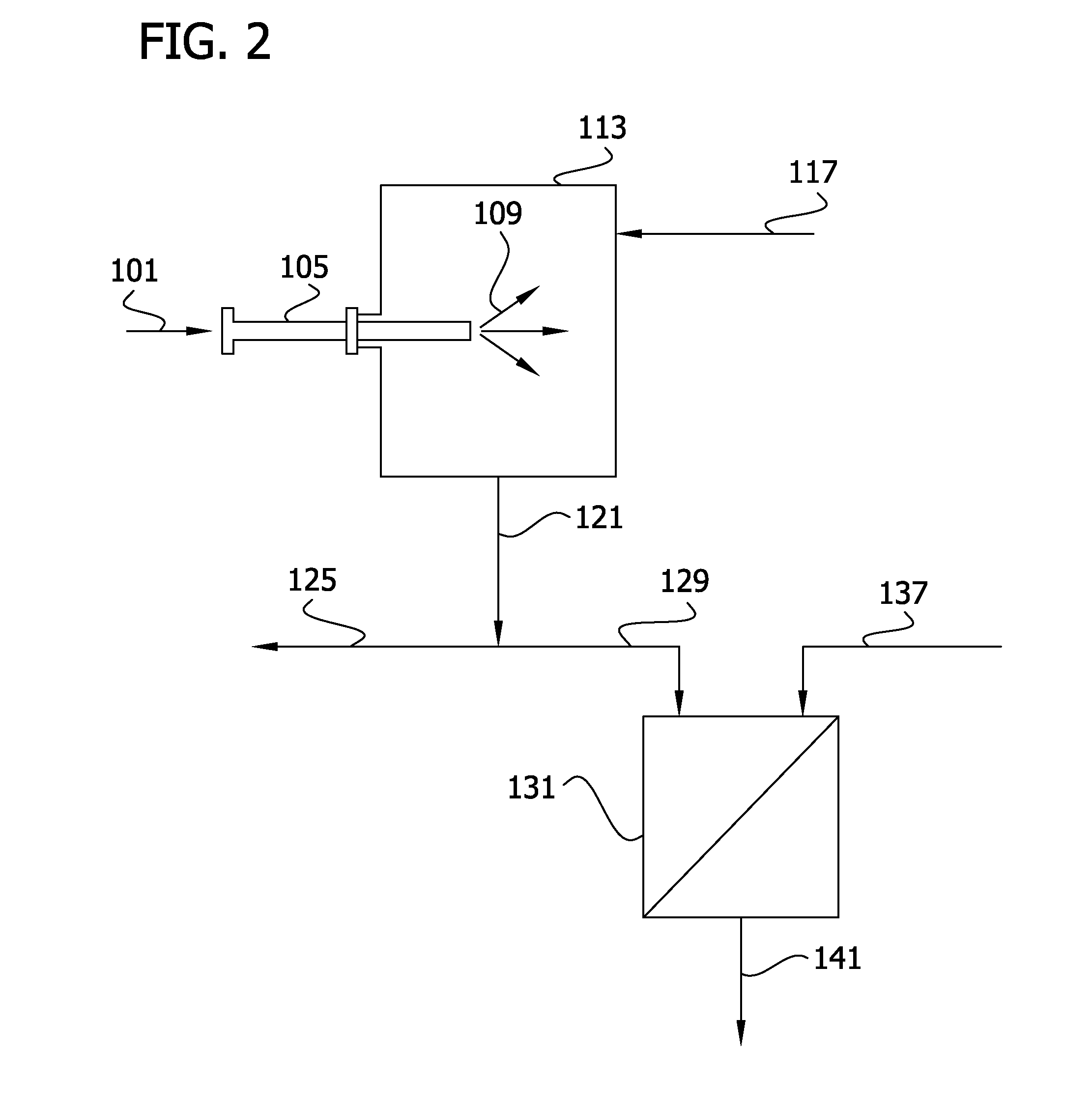

Method and Device for Cleaning of Filter

InactiveUS20070251891A1Pulp liquors combustionLoose filtering material filtersSpray nozzleWhite liquor

The method and arrangement is for cleaning at least one of filter sheets and filter cakes in a pressurized white liquor filter with spray nozzles and driving fluid. The white liquor filter is used in a causticizing process in which green liquor is causticized before the white liquor filter by the addition of lime and in which it forms during the process a lime mud slurry. The white liquor filter 101 is used to separate white liquor from the lime mud. The driving fluid for the spray nozzle is constituted principally by the filtrate that is obtained from the filter.

Owner:METABO PAPER SWEDEN

Shaped cellulose manufacturing process combined with a pulp mill recovery system

ActiveUS20120000621A1Low capital intensityImprove the environmentNon-fibrous pulp additionPulp liquors combustionFiberUnit operation

Provided is a process for manufacturing shaped cellulose materials from lignocellulose where a dissolving grade pulp is manufactured and dissolved in an aqueous alkaline or acidic solvent system forming a solution suitable for shaping new cellulose structures including fibers, films and cellulose derivatives. At least a part of the spent cellulose dissolving or cellulose shaping chemicals are recovered in one or more unit operations in a pulp mill chemical recovery cycle.

Owner:TREETOTEXTILE AB

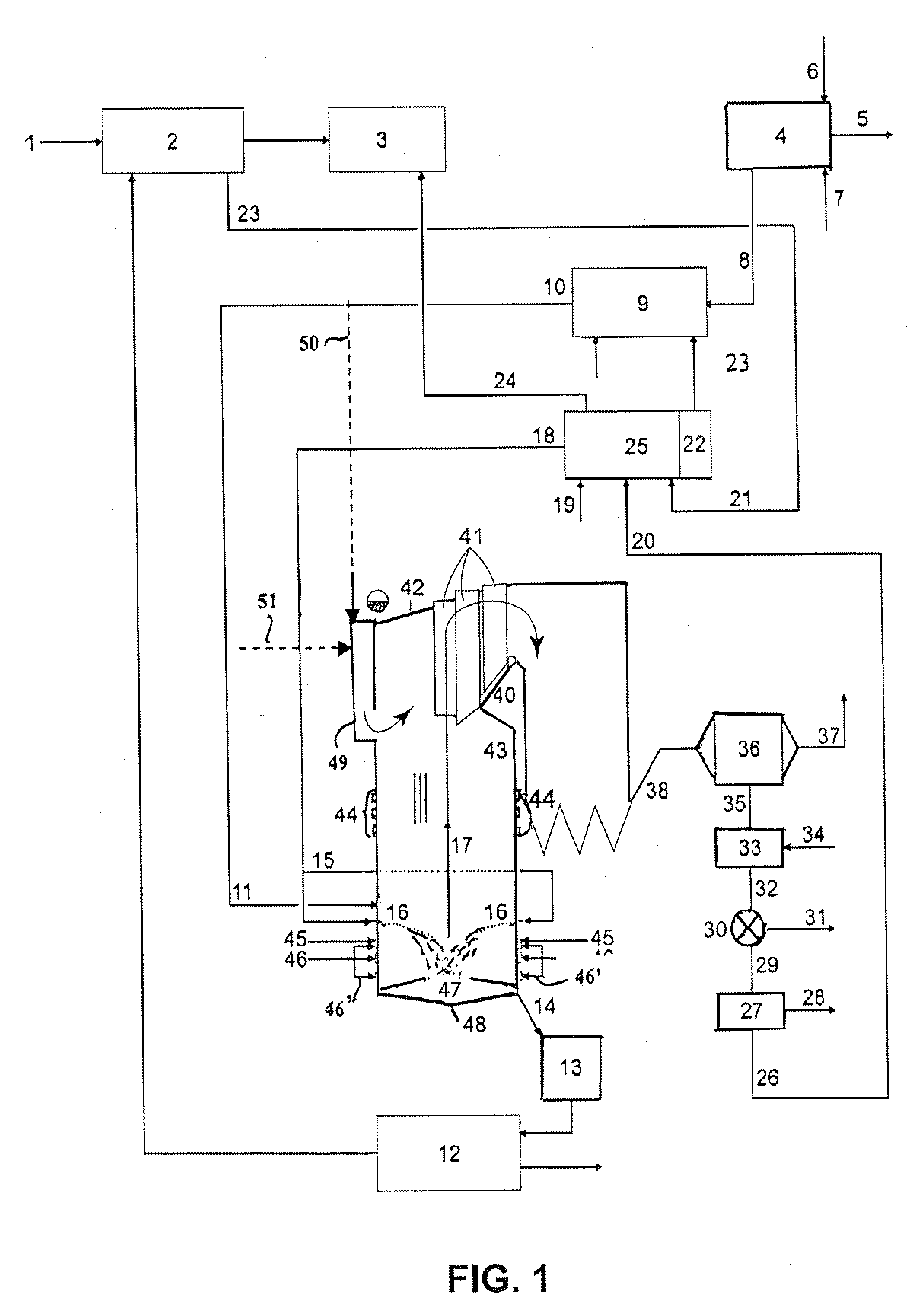

Method and arrangement for producing electrical energy at a pulp mill

InactiveUS20020194849A1Improve power production efficiencyElectrical efficiencyPulp liquors combustionSteam generation using steam absorptionSuperheaterEconomizer

The invention relates to a method and an arrangement in the production of electric energy in a boiler plant of a pulp mill. Black liquor having a dry solids content of more than 80% and combustion air are fed into a furnace of a recovery boiler for combusting black liquor and recovering chemicals contained therein. The flue gases generated in the combustion are led into an economizer of the recovery boiler, in which economizer the feed water for the boiler is heated, and after the economizer to gas cleaning. The feed water is led from the economizer onto the steam-generating bank at a temperature below the saturation temperature and further into a superheater to produce steam having a pressure of more than 80 bar. The steam is led from the recovery boiler to a steam turbine to produce electricity. The temperature of the feed water being led into the economizer is regulated by means of bleed steam of the turbine so that the flue gases exit the economizer at a temperature of more than 250° C. and that after the economizer the flue gases are cleaned in at least a hot electrostatic precipitator and the cleaned flue gases are cooled by the combustion air or the feed water.

Owner:ANDRIZ OY

Methods of improving productivity of black liquor recovery boilers

InactiveUS20020043192A1Improve throughputImprove boiler efficiencyPulp liquors combustionSolid fuel combustionProduction rateBlack liquor

Methods of increasing the throughput of recovery boilers equipped with at least two levels of injection of air are presented, the methods improving the thermal efficiency of the boiler with oxygen enrichment of the air in at least one level of the combustion air system, at or above the secondary air level. One embodiment is a method to retrofit black liquor recovery boilers having a two level air injection system with a third level of oxidant injection below or at the same level as the original secondary air, and oxygen enrichment applied to at least the original secondary air stream and said third level. A preferred method is for the third level to be placed at or close to the same level as black liquor injector ports.

Owner:AIR LIQUIDE IND US LP

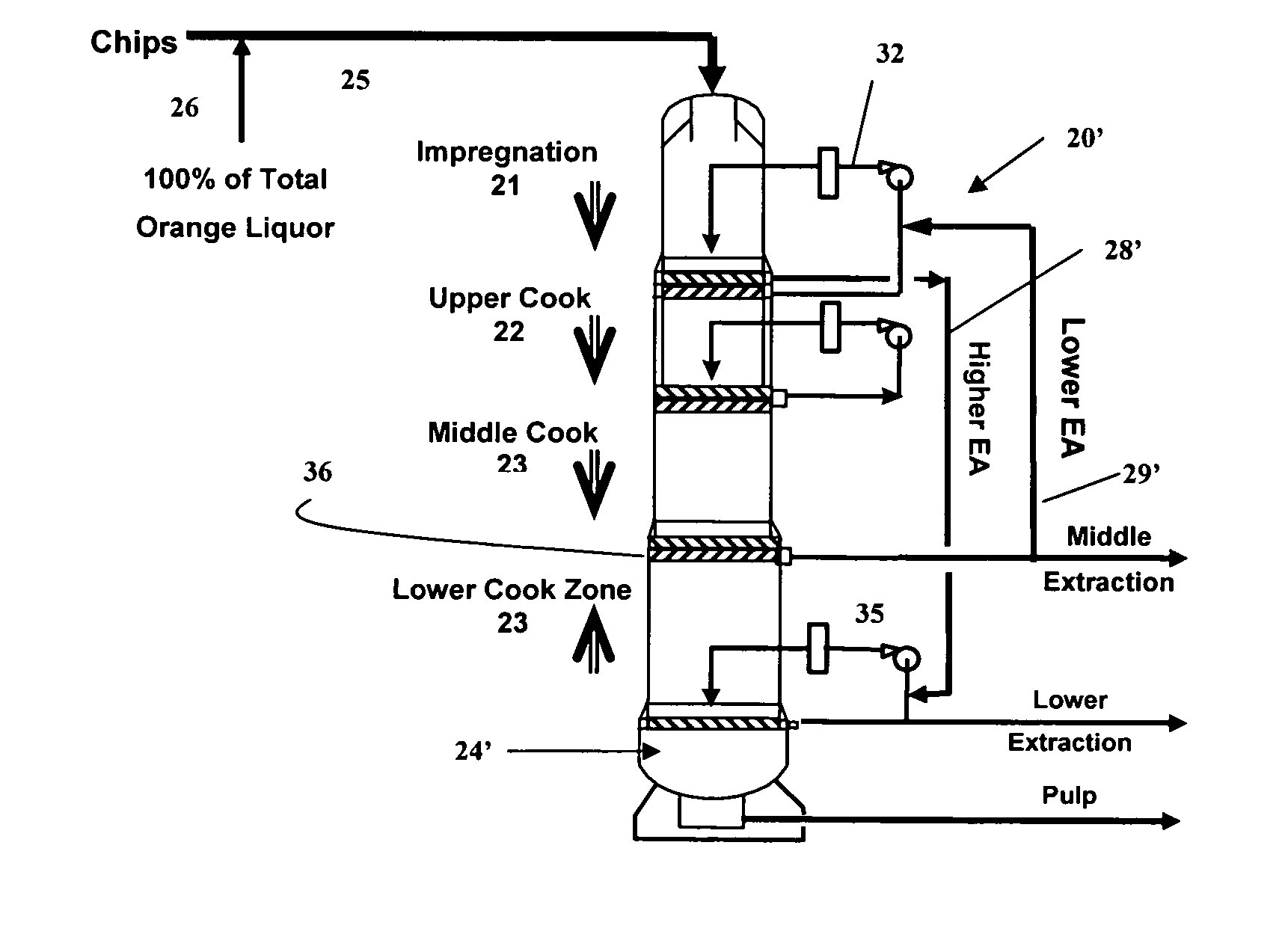

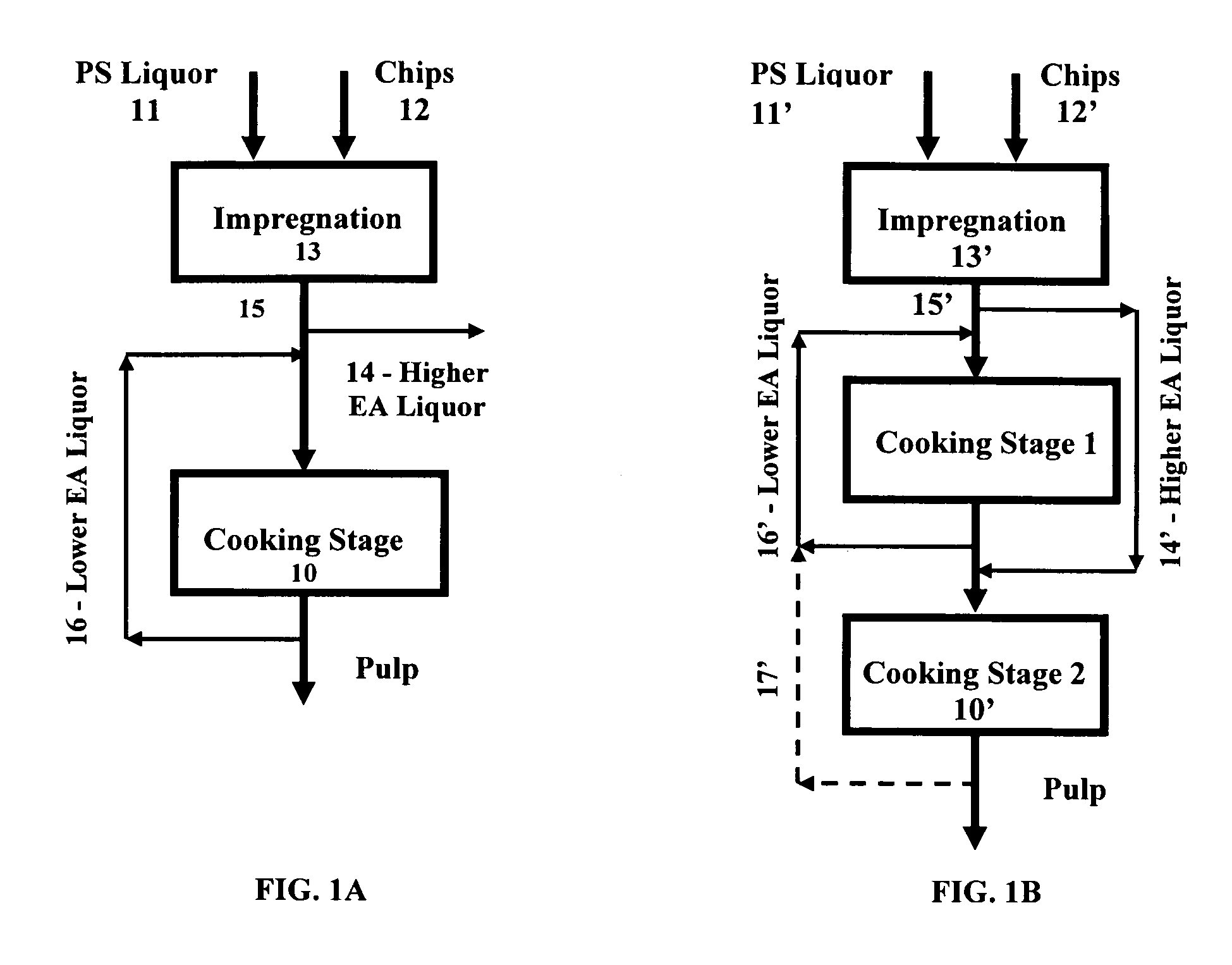

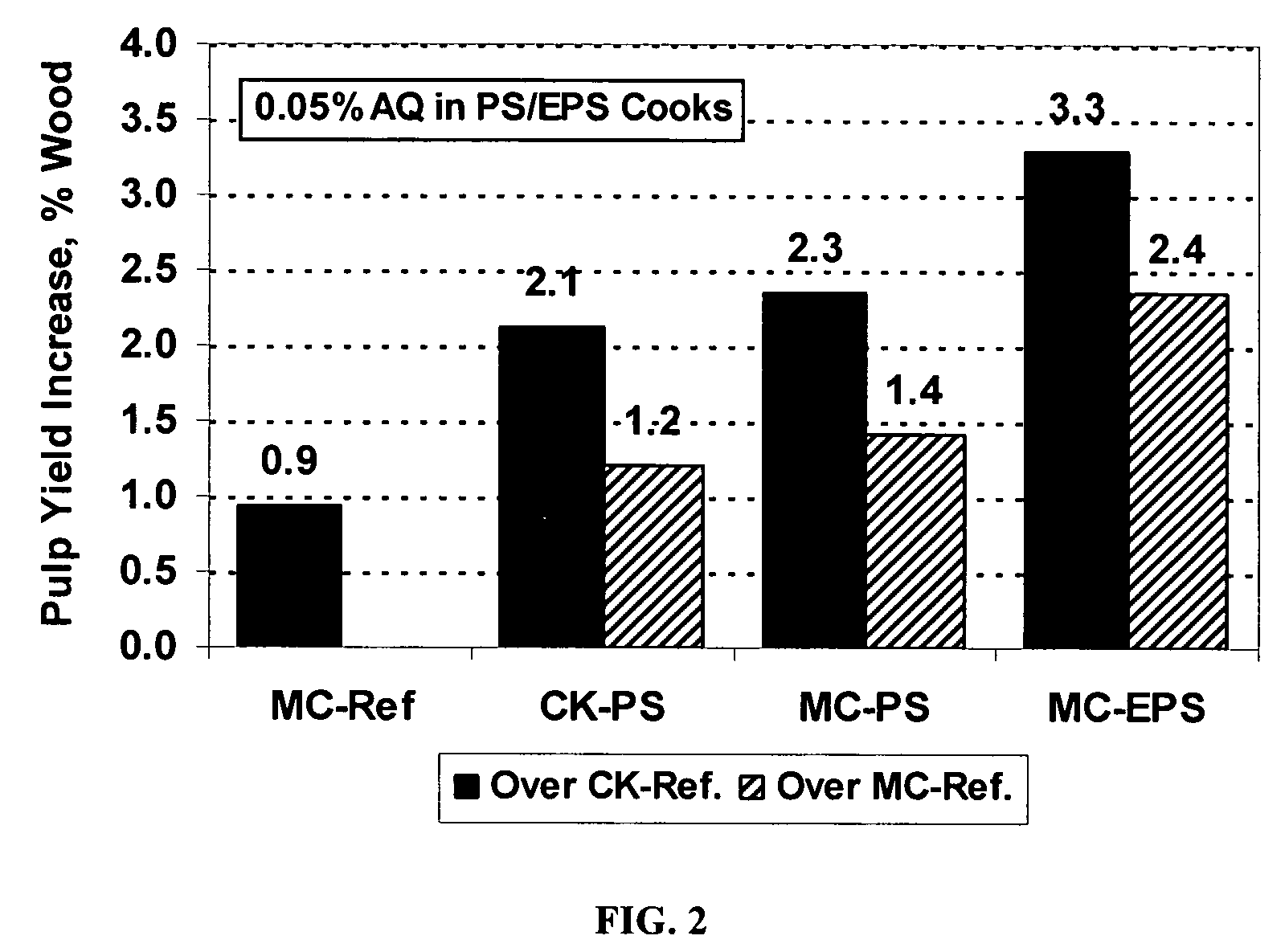

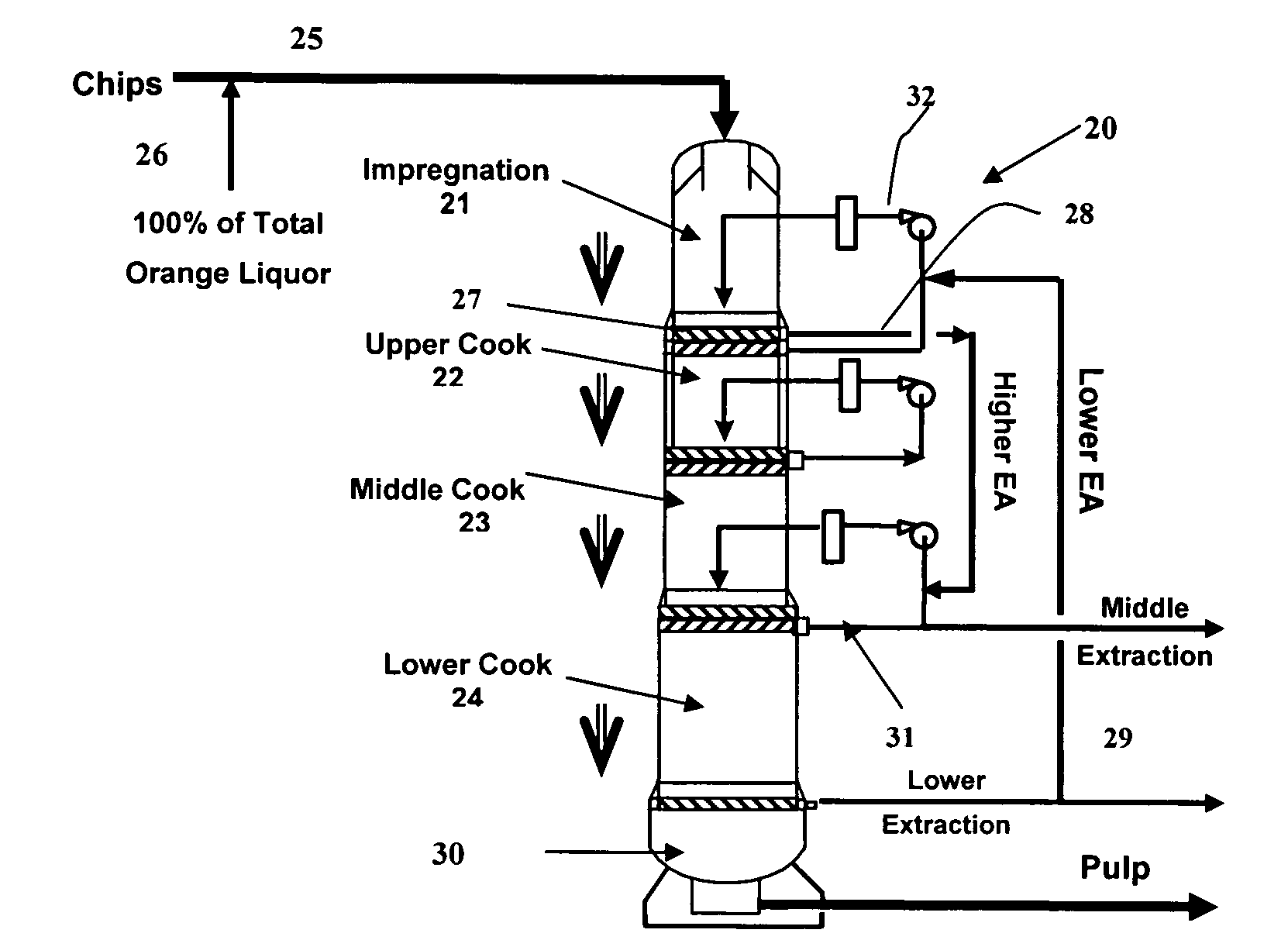

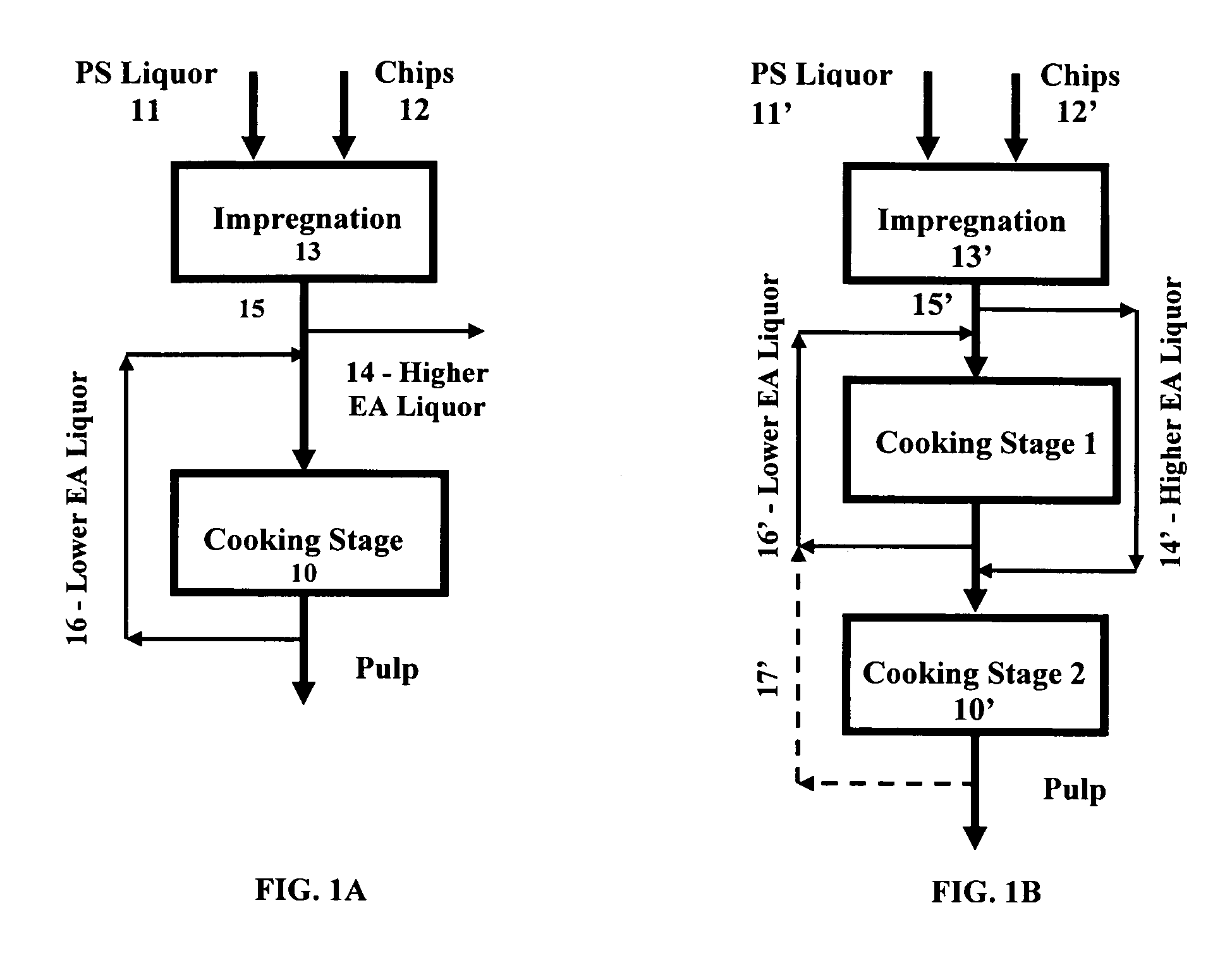

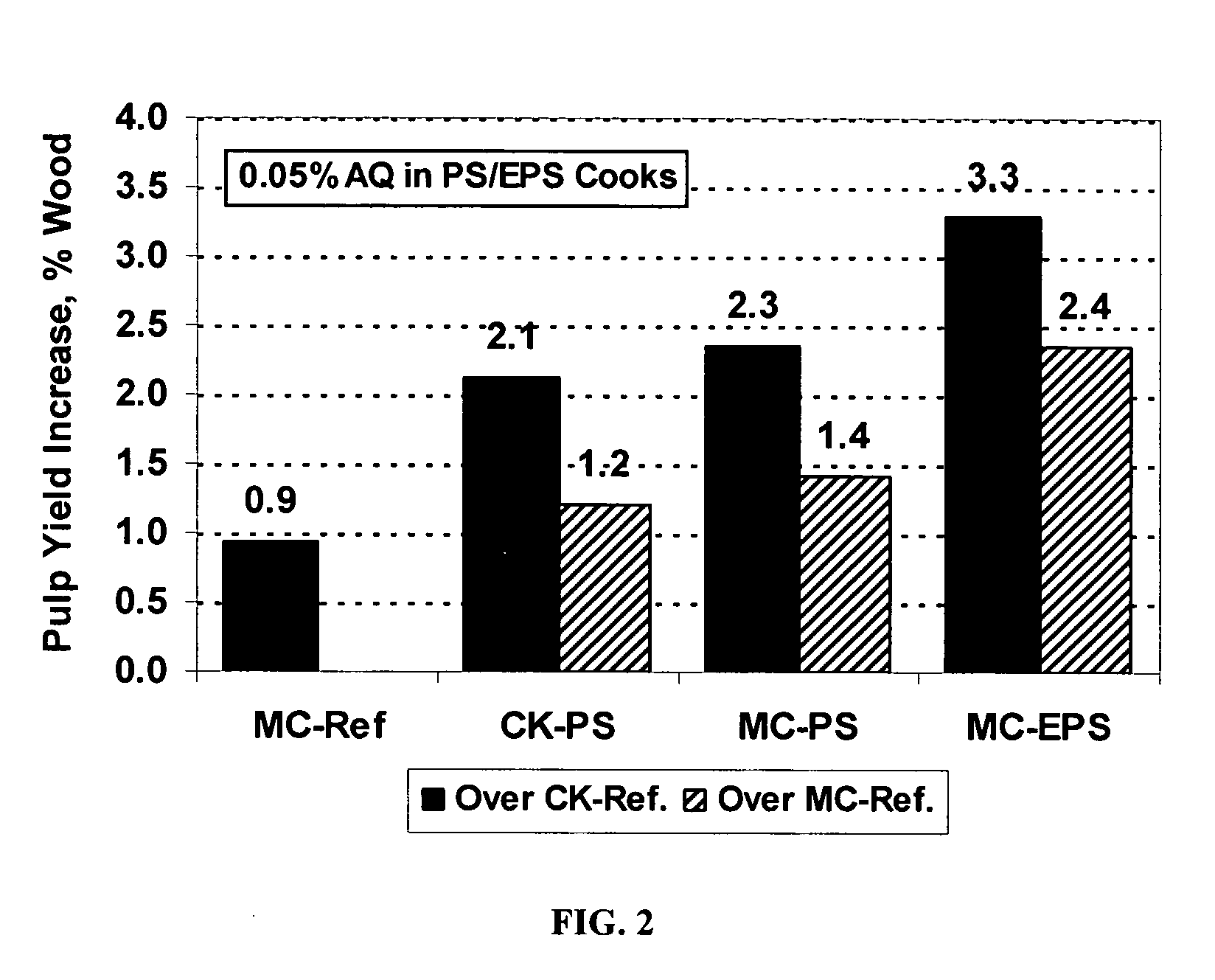

Use of polysulfide in modified cooking

A method for Kraft pulping employing a modified cooking process in conjunction with polysulfide pulping technologies to obtain higher pulping yields than obtained in the prior art. The total required alkali charge (polysulfide liquor) is added to the beginning of a cook, and after all polysulfide has essentially reacted with lignocellulosic material at temperature below that at which no significant carbohydrate degradation occurs, a first quantity of the cooking liquor high in effective alkali (EA) concentration is removed from a first point in the pulping process and replaced with a cooking liquor low in EA concentration removed from another process point. The first quantity is then added elsewhere in the pulping process, where the EA concentration is low. This cooking liquor “exchange” obtains the full yield benefit from polysulfide pulping and a more uniform EA concentration profile to retain the major benefits of modified cooking.

Owner:INT PAPER CO

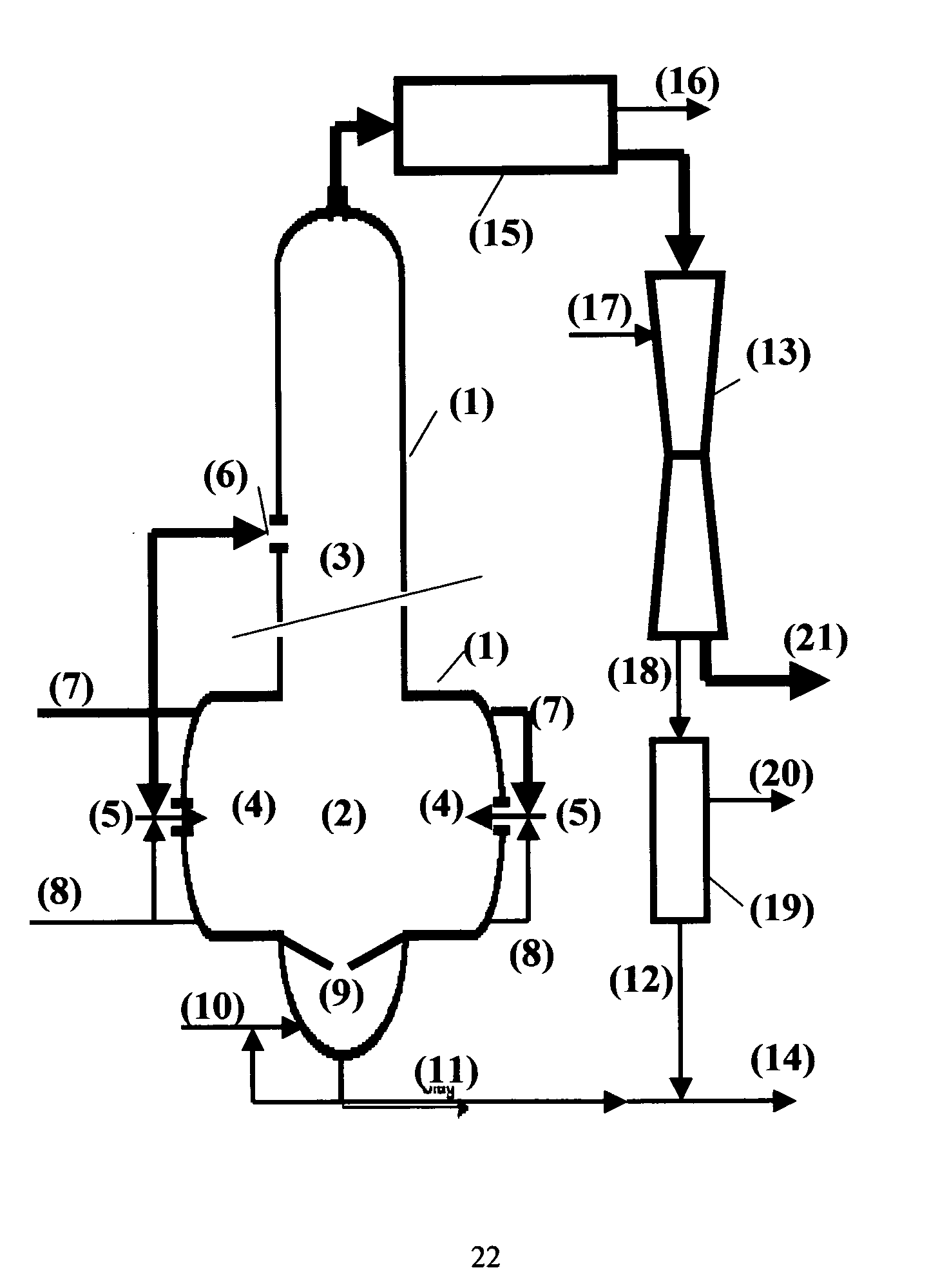

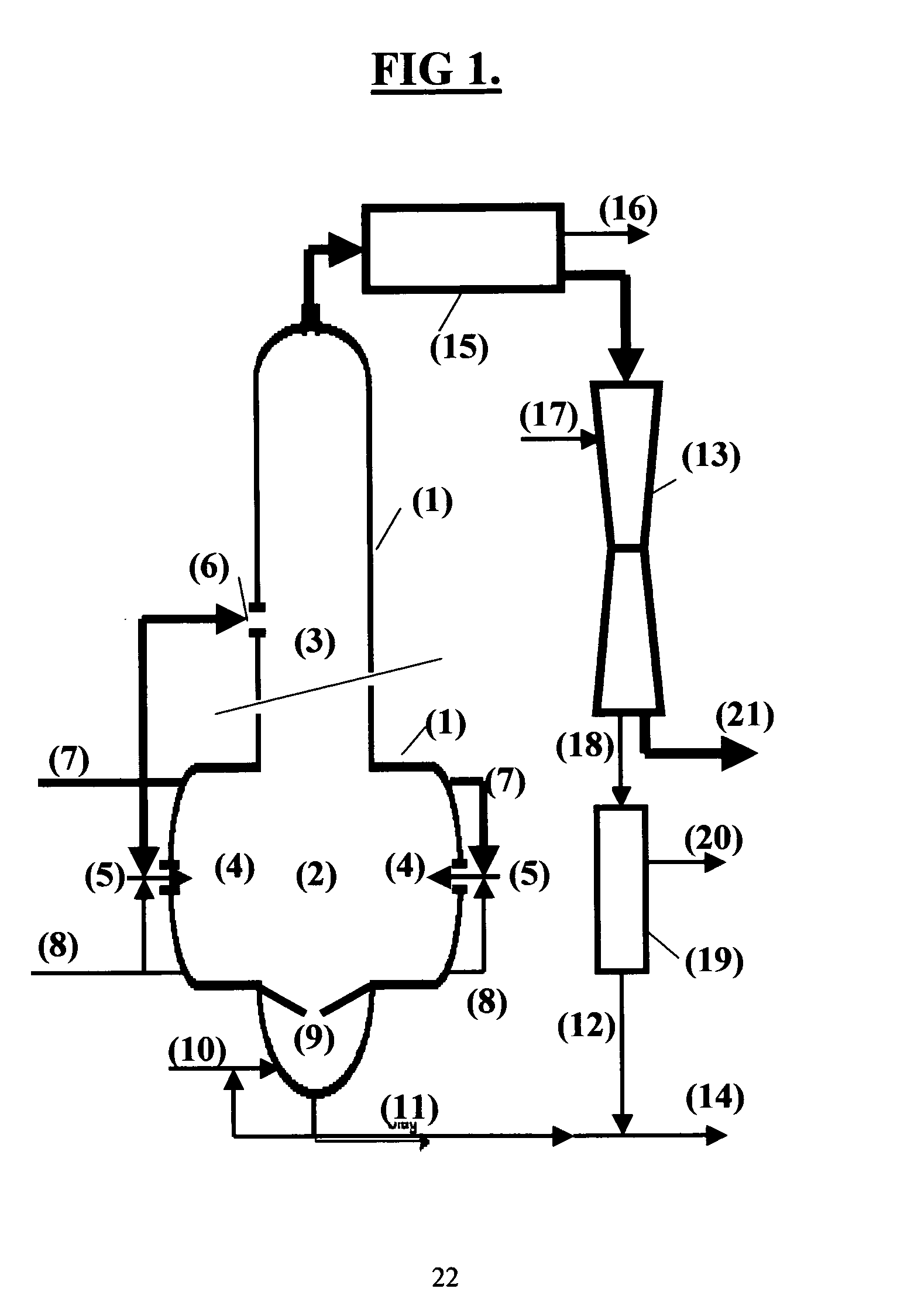

Partial oxidation of cellulose spent pulping liquor

InactiveUS20050076568A1Sulfur contentEasy to cleanPressurized chemical processPulp liquors combustionCellulosePartial oxidation

The present invention relate to a two-stage gasification process using a gas generator for the recovery of strongly alkaline chemicals and energy value from a cellulose spent liquor. The temperature in the first reaction zone of the gas generator is maintained between 1000 C. and 1400 C. by the controlled addition of an oxygen containing gas. A strongly alkaline smelt comprising alkali oxide, alkali hydroxide, alkali carbonate and alkali borate's corresponding to at least 75% by weight of the smelt is recovered from below the first reaction zone of the gas generator. A gaseous components stream formed by exothermal reactions in the first reaction zone are directed to a second reaction or gas transfer zone of substantially of updraft or up-flow design, wherein the gaseous stream is cooled to a temperature below about 1000 C, said cooling preferably achieved by endothermal decomposition of cellulose spent liquor injected into the gaseous stream.

Owner:STIGSSON LARS LENNART

Gasification reactor vessel

InactiveUS6827912B2Significant differencePressurized chemical processPulp liquors combustionAmbient pressureEngineering

The invention relates to a reactor vessel and method for the gasification of carbon-containing fuel, residual and waste materials using an oxygen-containing oxidizing agent and in a reaction chamber which is designed as an entrained-bed reactor, at pressures between ambient pressure and 80 bar, preferably between ambient pressure and 30 bar, the contour of the reaction chamber being delimited by a cooling system, and the pressure in the cooling system always being held at a higher level than the pressure in the reaction chamber, and the cooling system withstanding the maximum possible pressure difference with respect to the reaction chamber, which has been depressurized to atmospheric pressure, which reactor vessel is distinguished by the fact that cooling channels are formed by webs which are in contact both with a refractory protective layer and with the pressure shell.

Owner:NOELL KRC ENERGIE & UMWELTTECHN GMBH +1

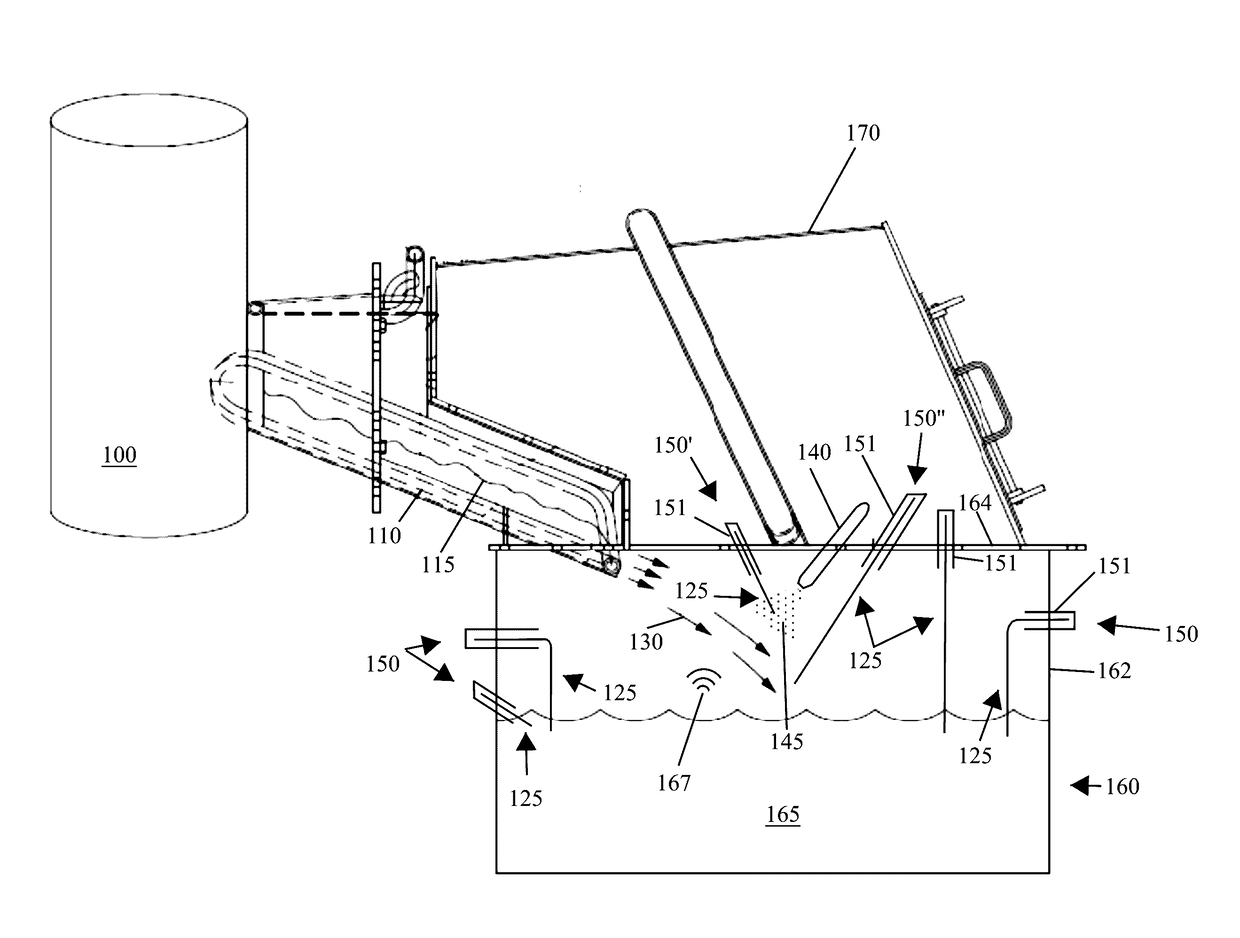

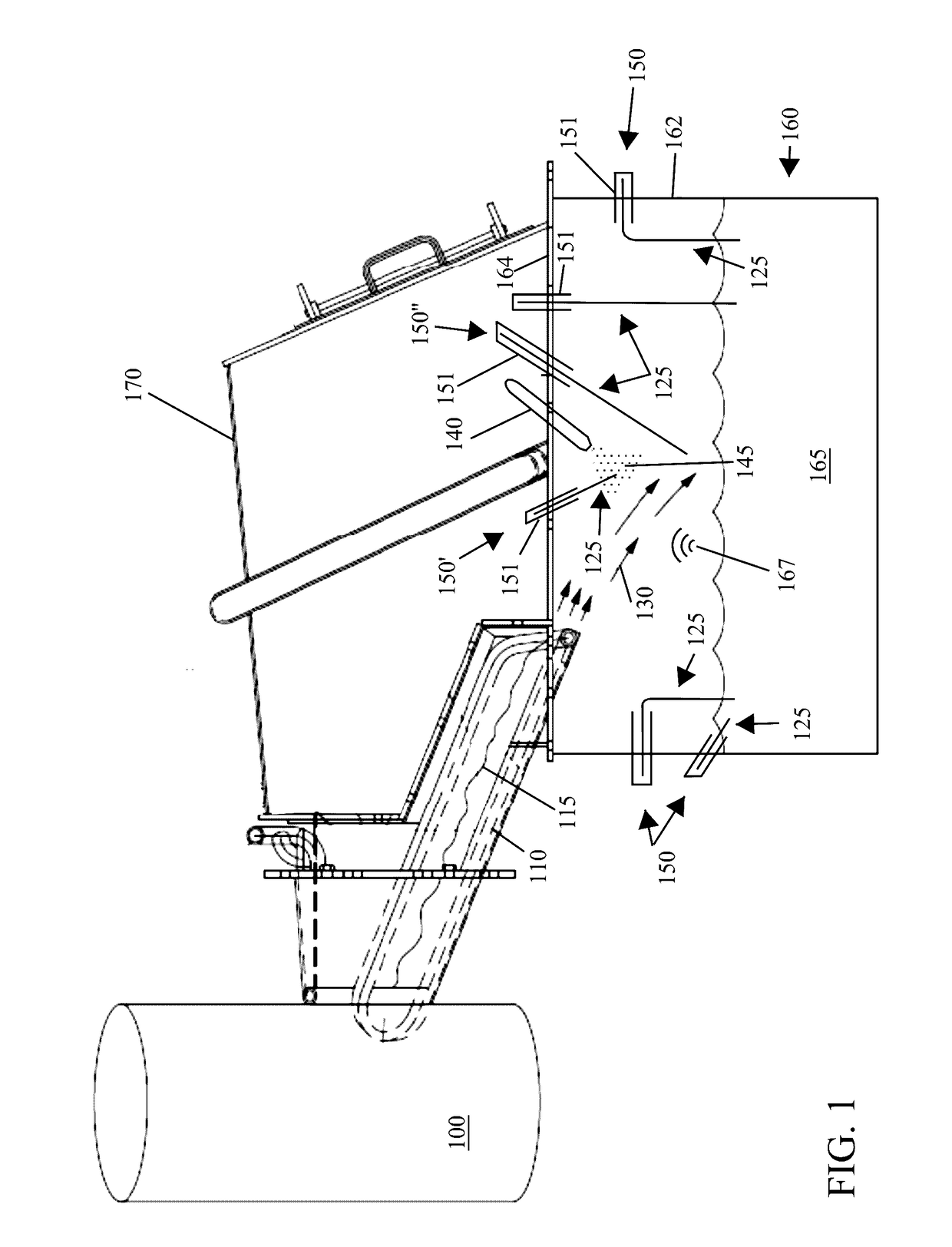

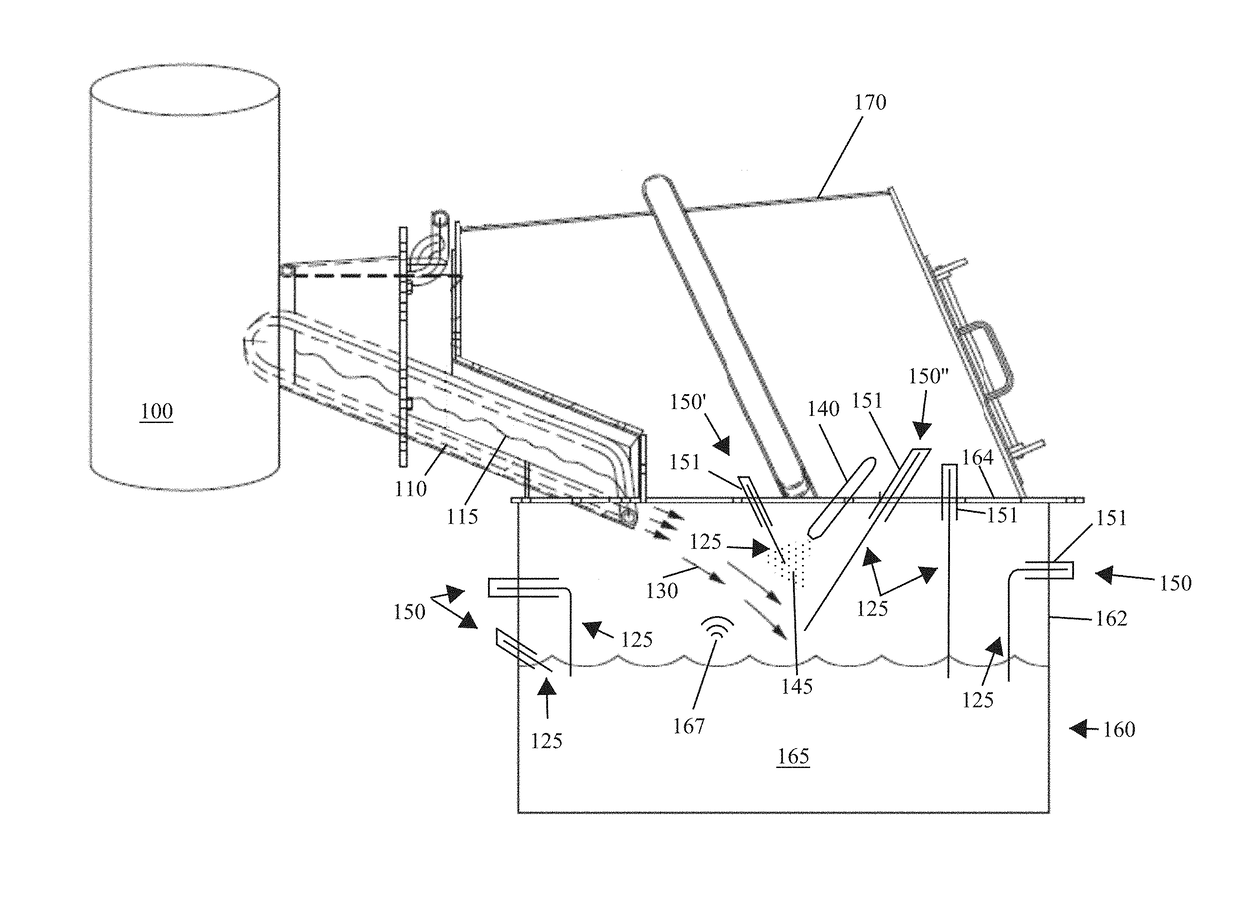

Acoustic emission system and method for predicting explosions in dissolving tank

ActiveUS20170131240A1Prevent and mitigate conditionAnalysing fluids using sonic/ultrasonic/infrasonic wavesPulp liquors combustionAcoustic emissionEngineering

The present disclosure describes a system for predicting explosions in a dissolving tank. The system includes acoustic emission sensors placed in or around the dissolving tank. By filtering the recorded frequencies to the range which is most sensitive for desired explosions “fingerprints,” it is possible to predict a smelt influx before the smelt influx occurs as well as program response actions to prevent compromising explosions.

Owner:ANDRITZ INC

Use of polysulfide in modified cooking

A method for Kraft pulping employing a modified cooking process in conjunction with polysulfide pulping technologies to obtain higher pulping yields than obtained in the prior art. The total required alkali charge (polysulfide liquor) is added to the beginning of a cook, and after all polysulfide has essentially reacted with lignocellulosic material at temperature below that at which no significant carbohydrate degradation occurs, a first quantity of the cooking liquor high in effective alkali (EA) concentration is removed from a first point in the pulping process and replaced with a cooking liquor low in EA concentration removed from another process point. The first quantity is then added elsewhere in the pulping process, where the EA concentration is low. This cooking liquor “exchange” obtains the full yield benefit from polysulfide pulping and a more uniform EA concentration profile to retain the major benefits of modified cooking.

Owner:INT PAPER CO

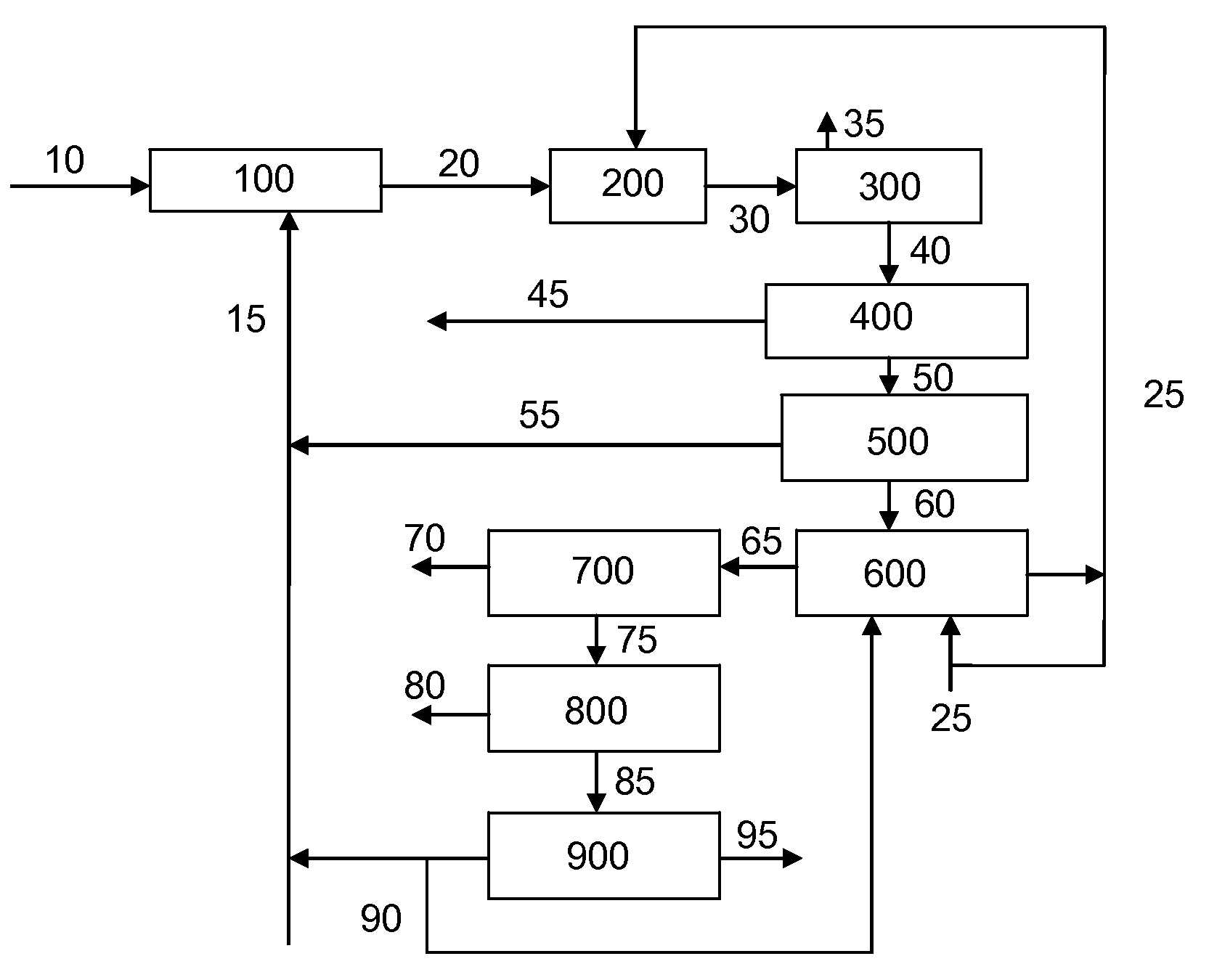

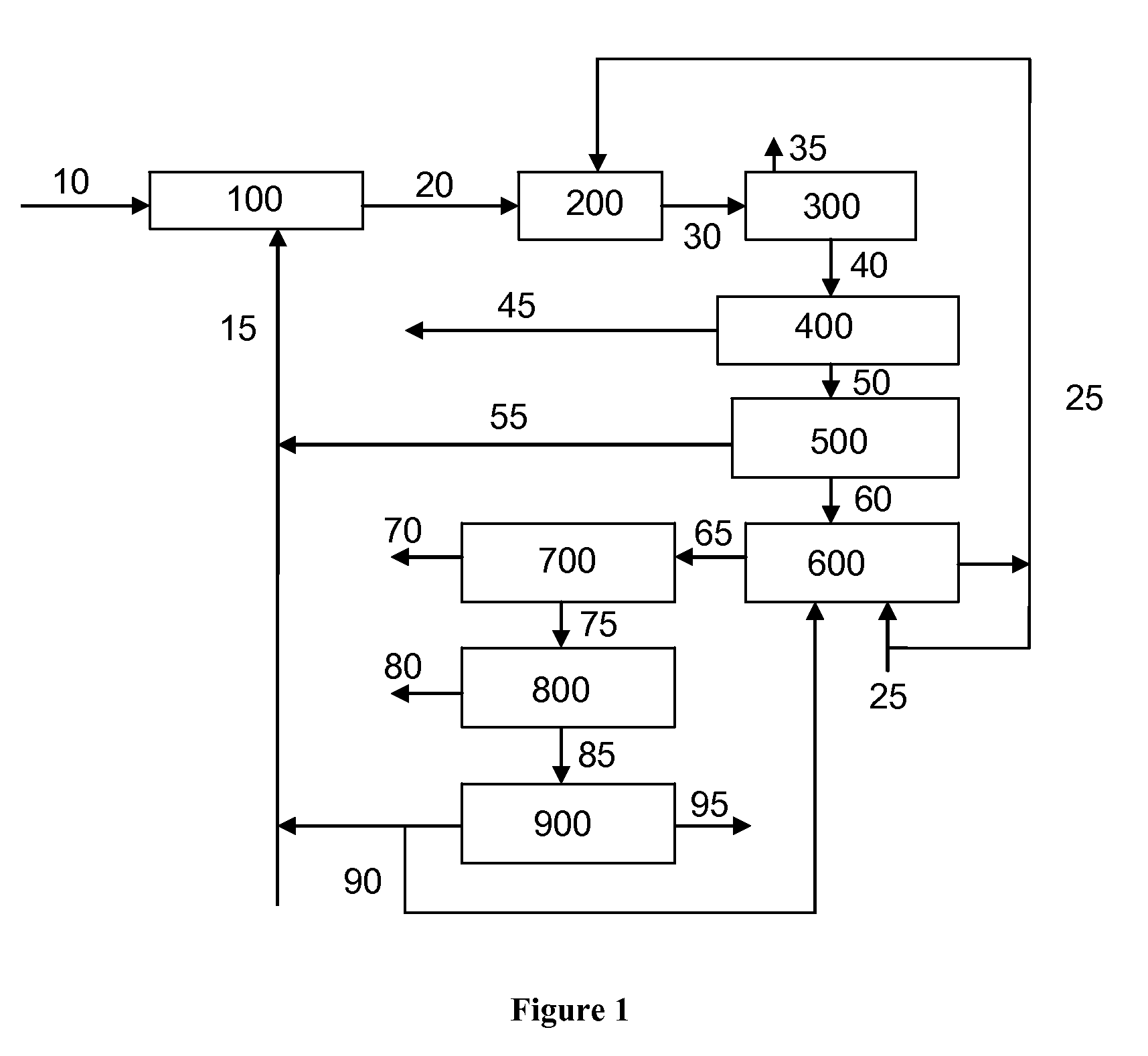

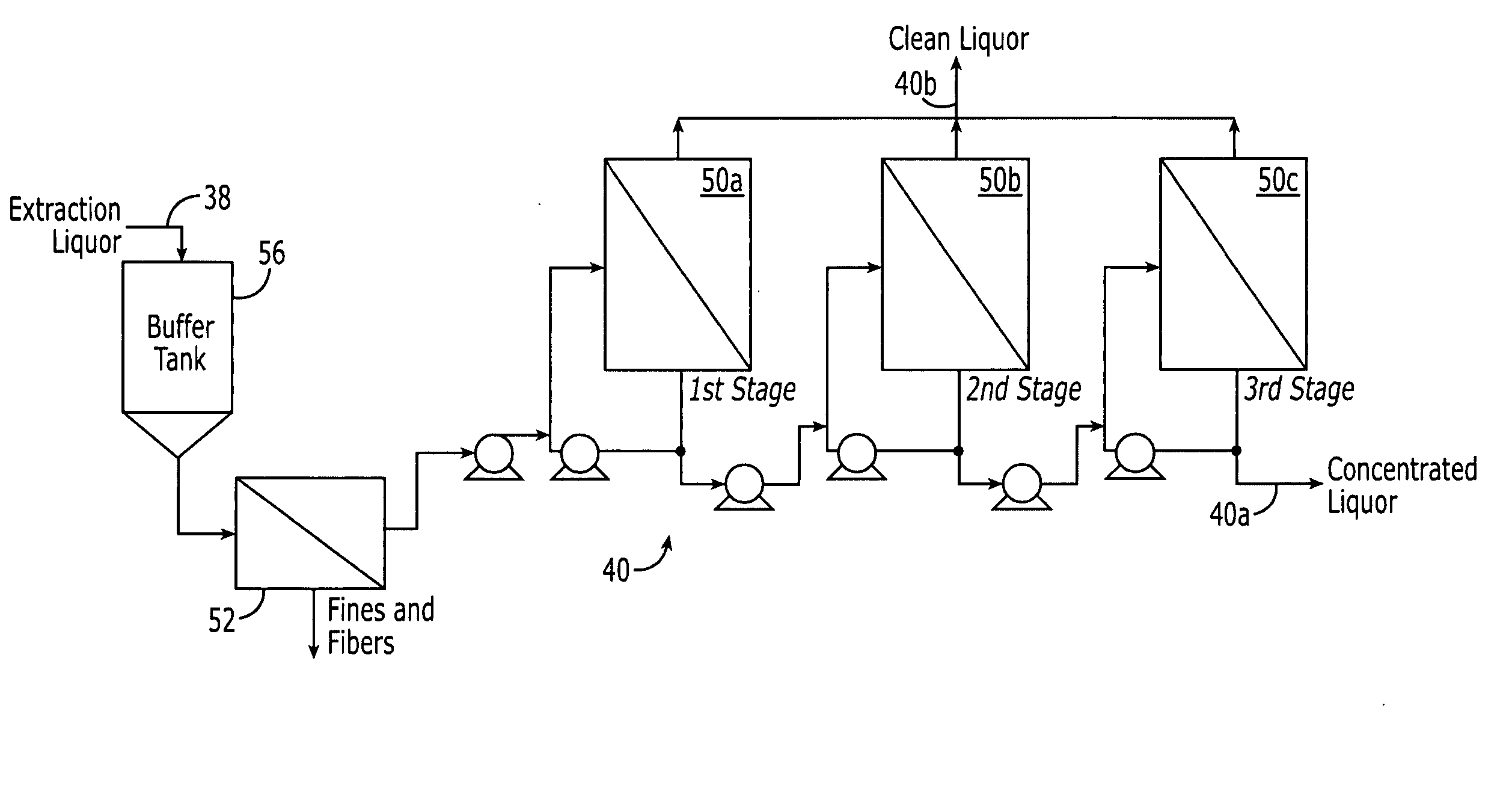

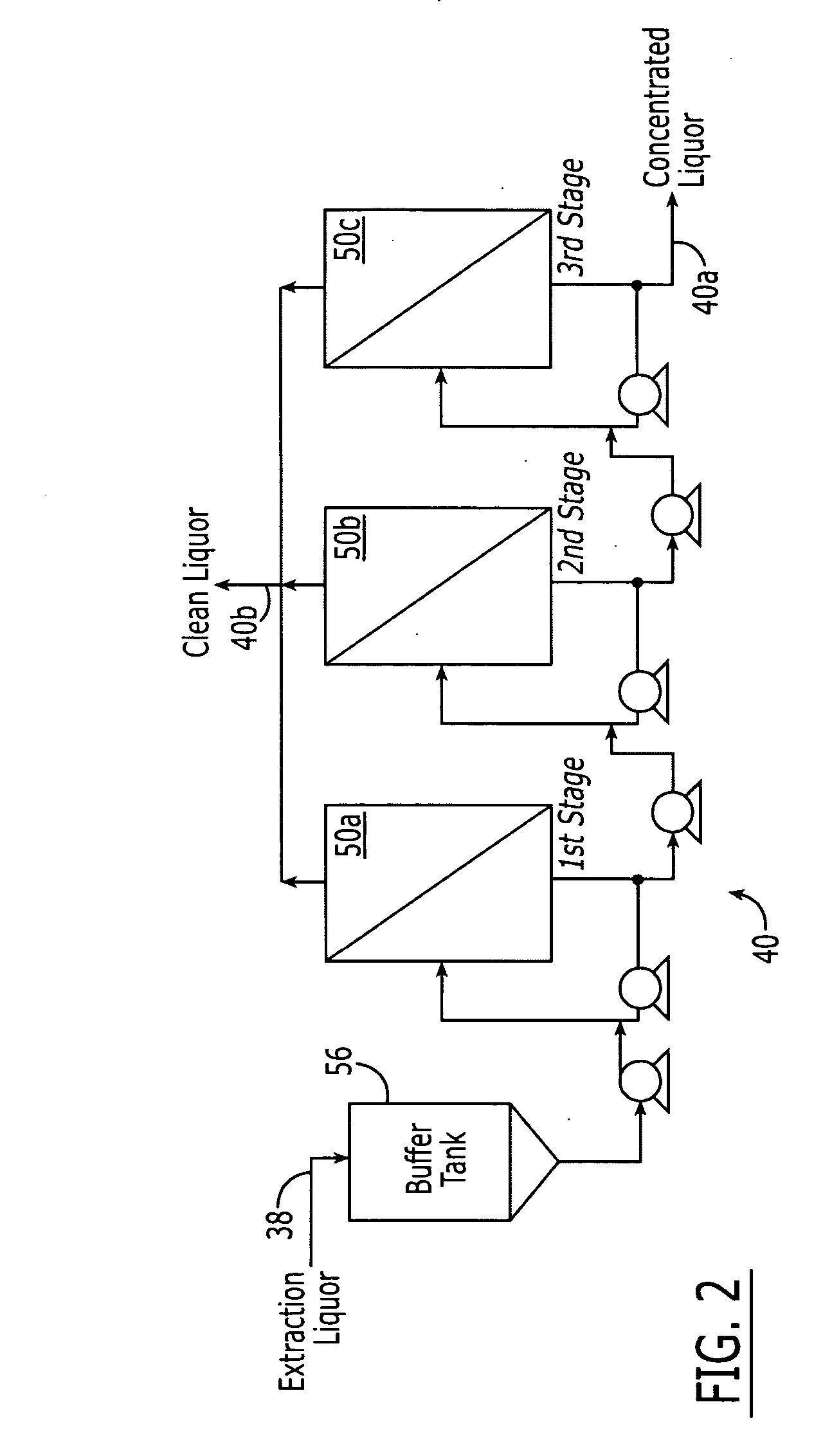

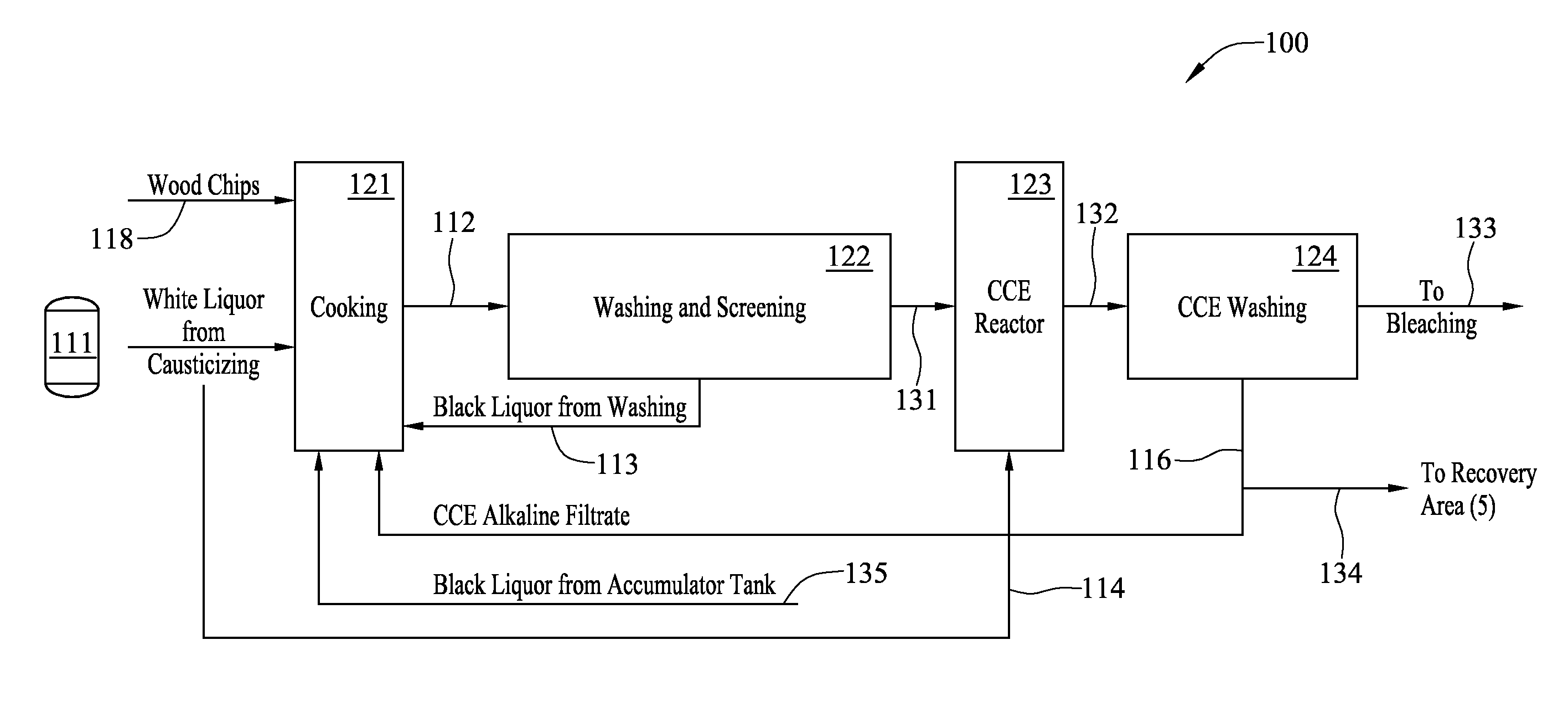

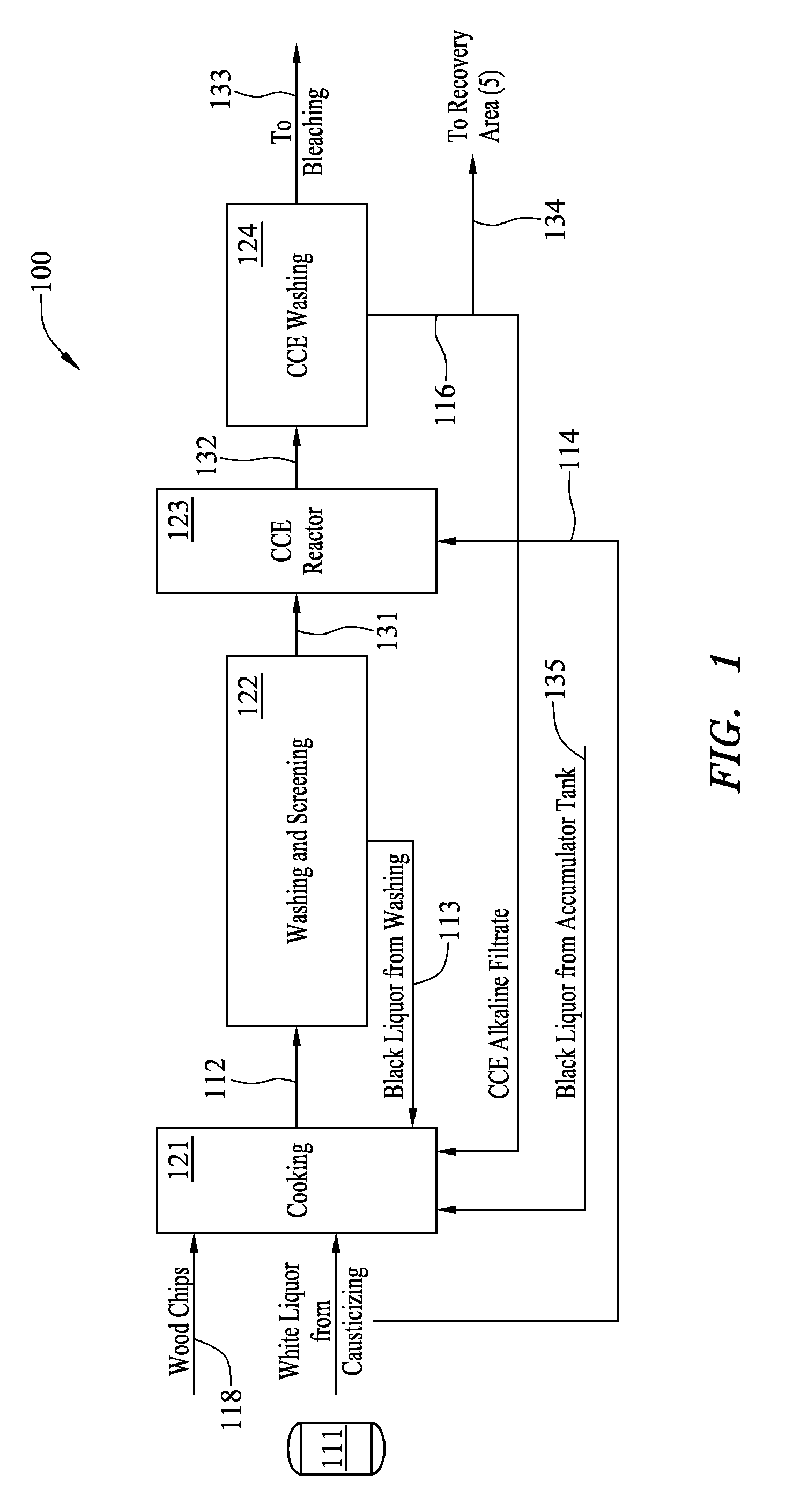

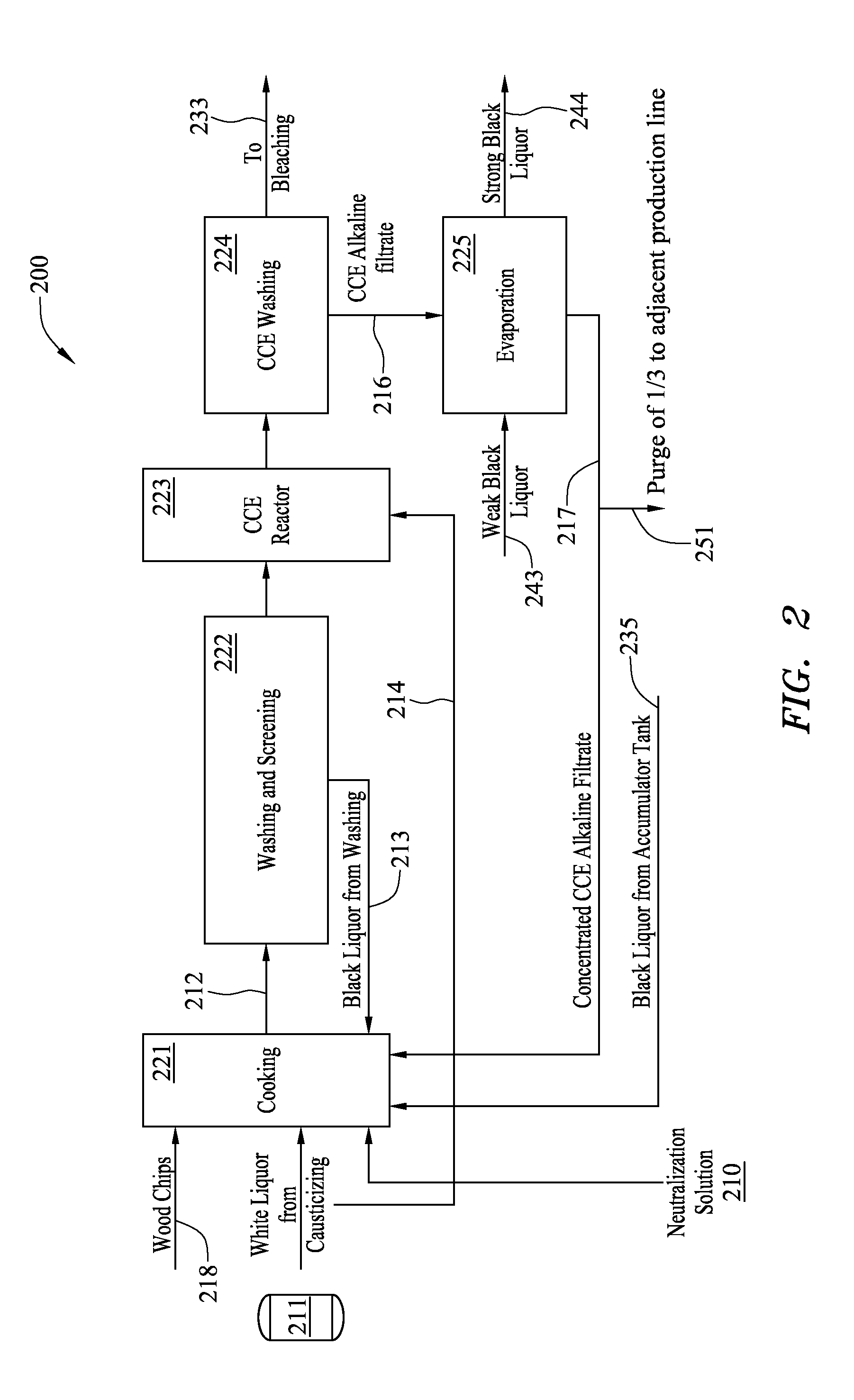

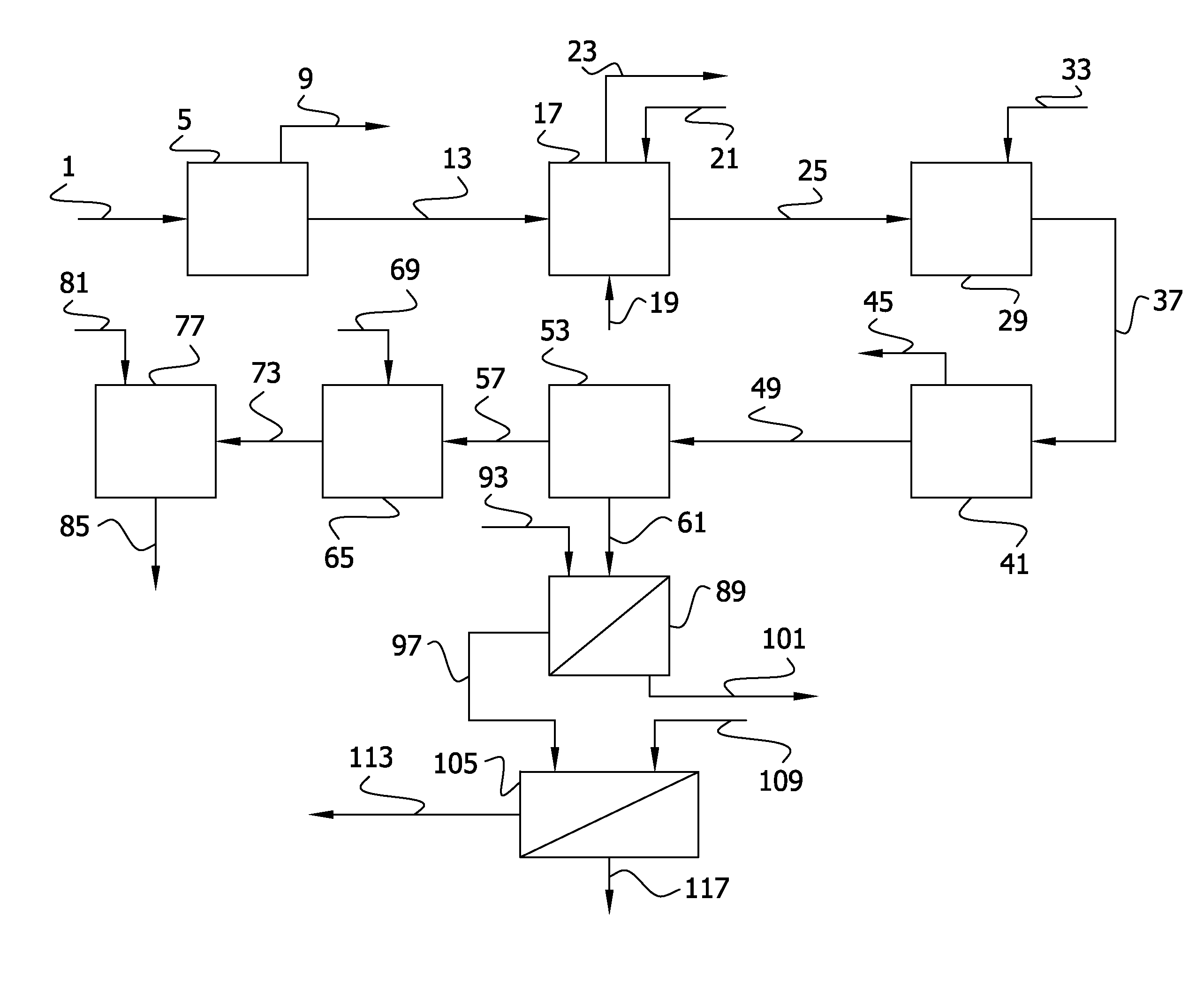

Method and system for pulp processing using cold caustic extraction with alkaline filtrate reuse

ActiveUS20110272109A1Improve efficiencyHigh purityPretreatment with water/steamNatural cellulose pulp/paperWood fibreEvaporation

A method for pulp processing includes a cold caustic extraction stage in which the spent cold caustic solution and the spent liquid used to wash the extracted pulp are concentrated by an evaporation system. The concentrated liquid can be used as part of the neutralization and cooking liquor in the pulp process, leading to increased efficiency without significant reduction in pulp quality. Highly concentrated filtrate from the cold caustic extraction stage may help reduce hemicellulose deposition on wood fiber during the cooking step.

Owner:BAHIA SPECIALTY CELLULOSE

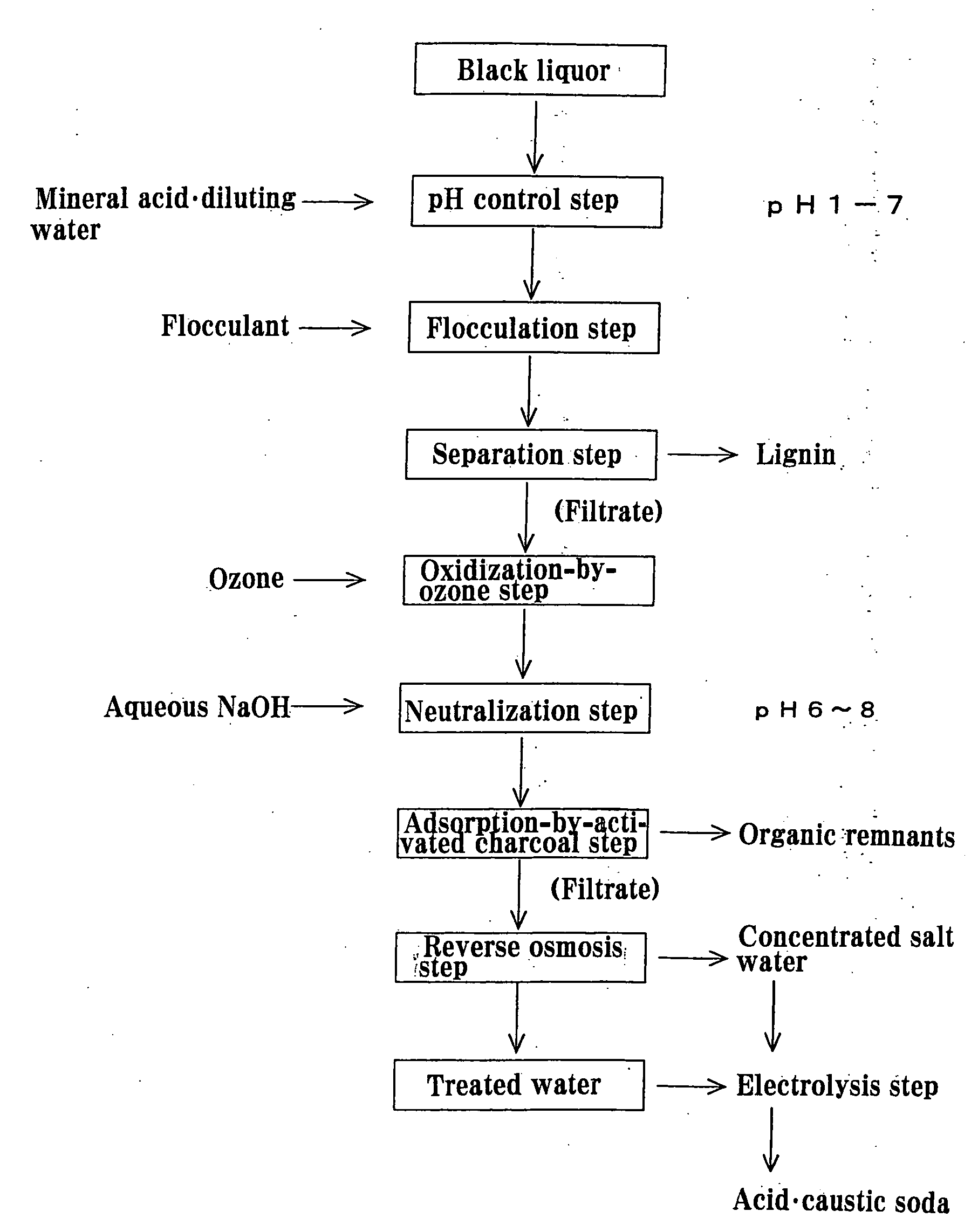

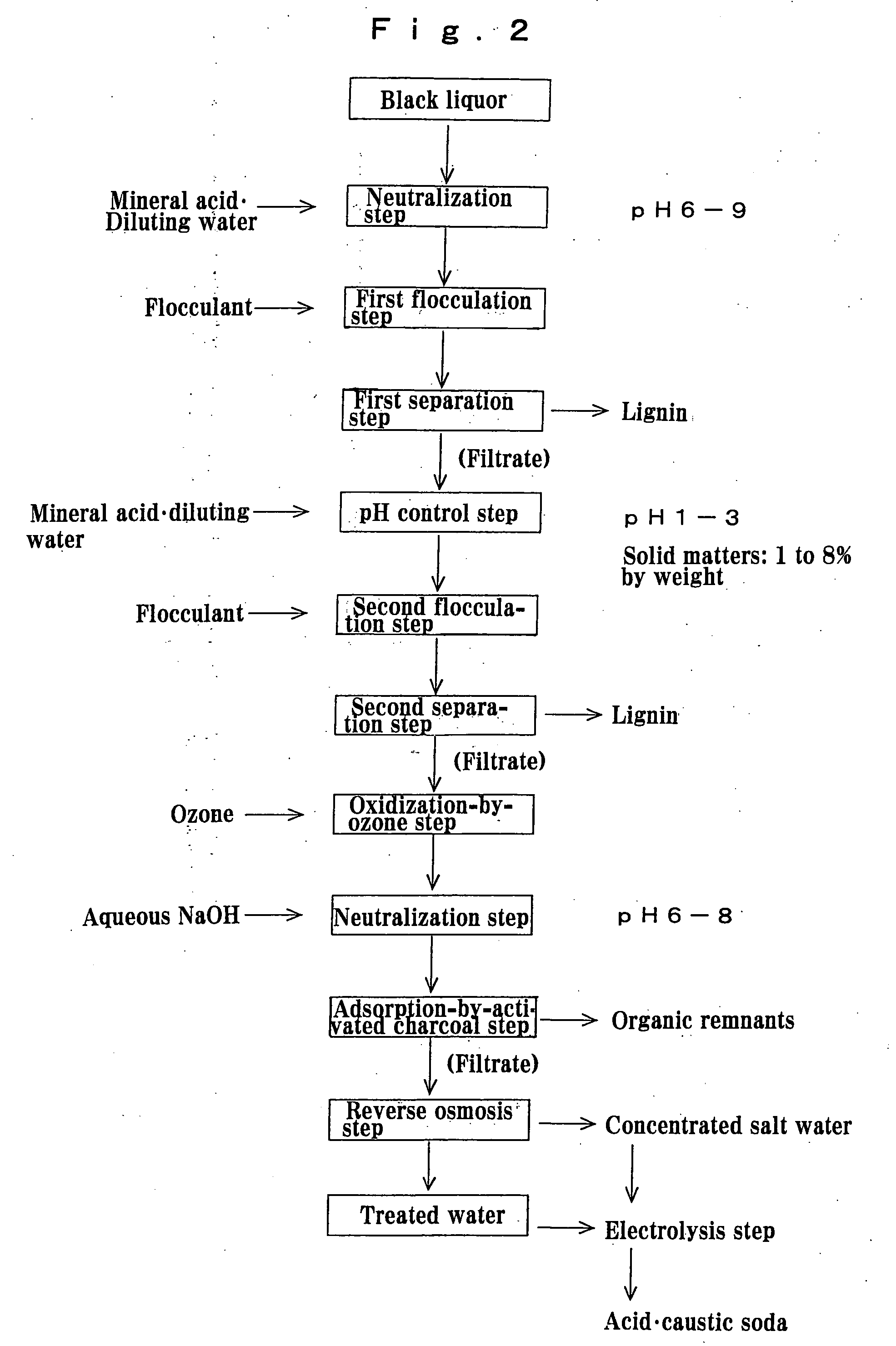

Disposal process for sulfide-free black liquors

InactiveUS20100108274A1Facilitating black liquor disposalHigh removal rateMembranesPulp liquors combustionActivated carbonBlack liquor

Lignin is flocculated and batched off from a sulfide-free black liquor discharged out of a pulp digestion step by water disposal techniques, and organic matters remaining in the filtrate are removed to recover water, acids and caustic soda.A mineral acid and, if necessary, diluting water is added to the black liquor to control its pH to 1 to 7, and a flocculant is added to the black liquor to filtrate out flocculating lignin. Further, ozone is brought into contact with the filtrate to oxidize and break down organic matters in the filtrate and remaining organic matters are adsorbed onto activate charcoal for removal.

Owner:NIHON CELLULOSE CO LTD +1

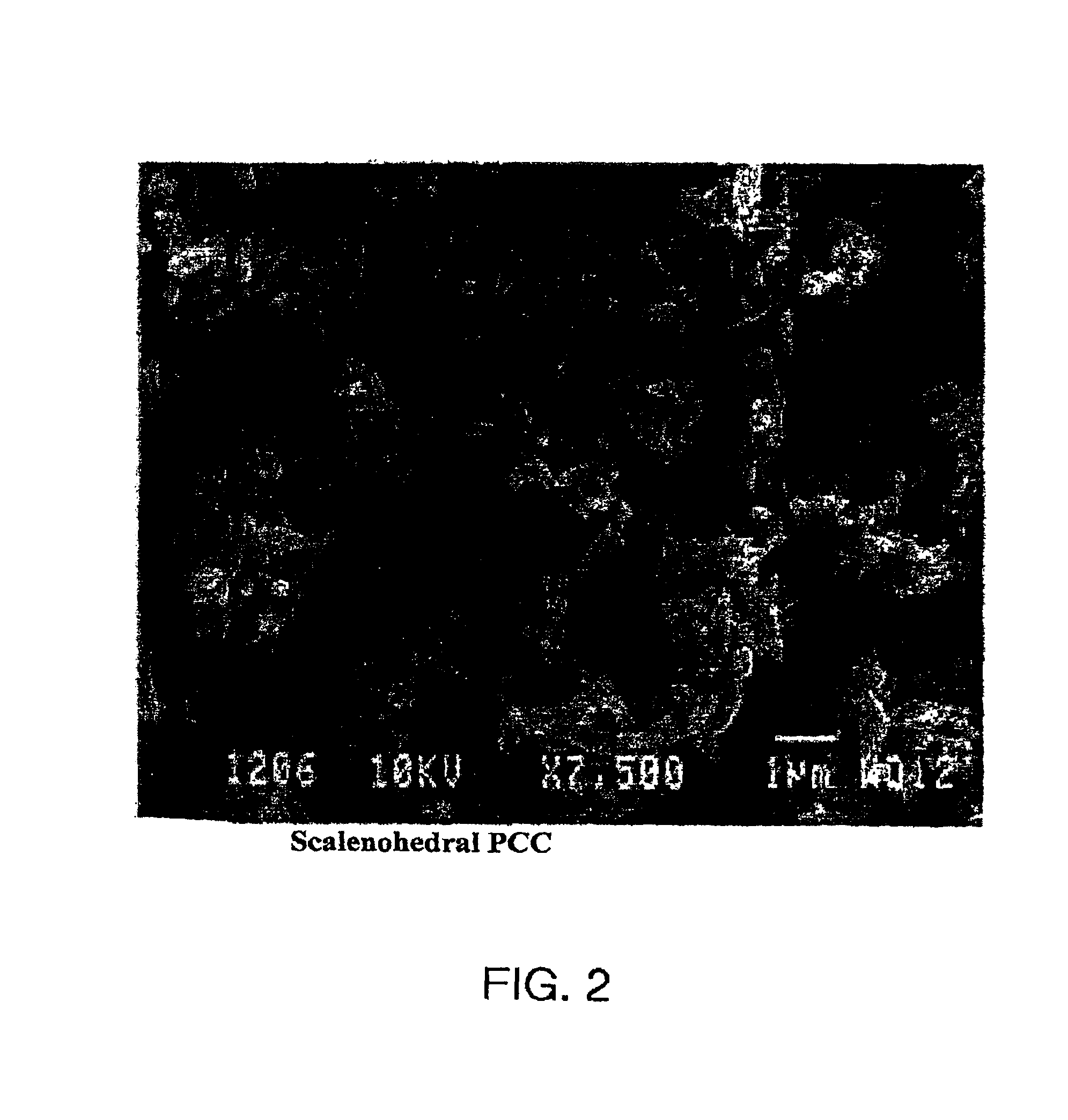

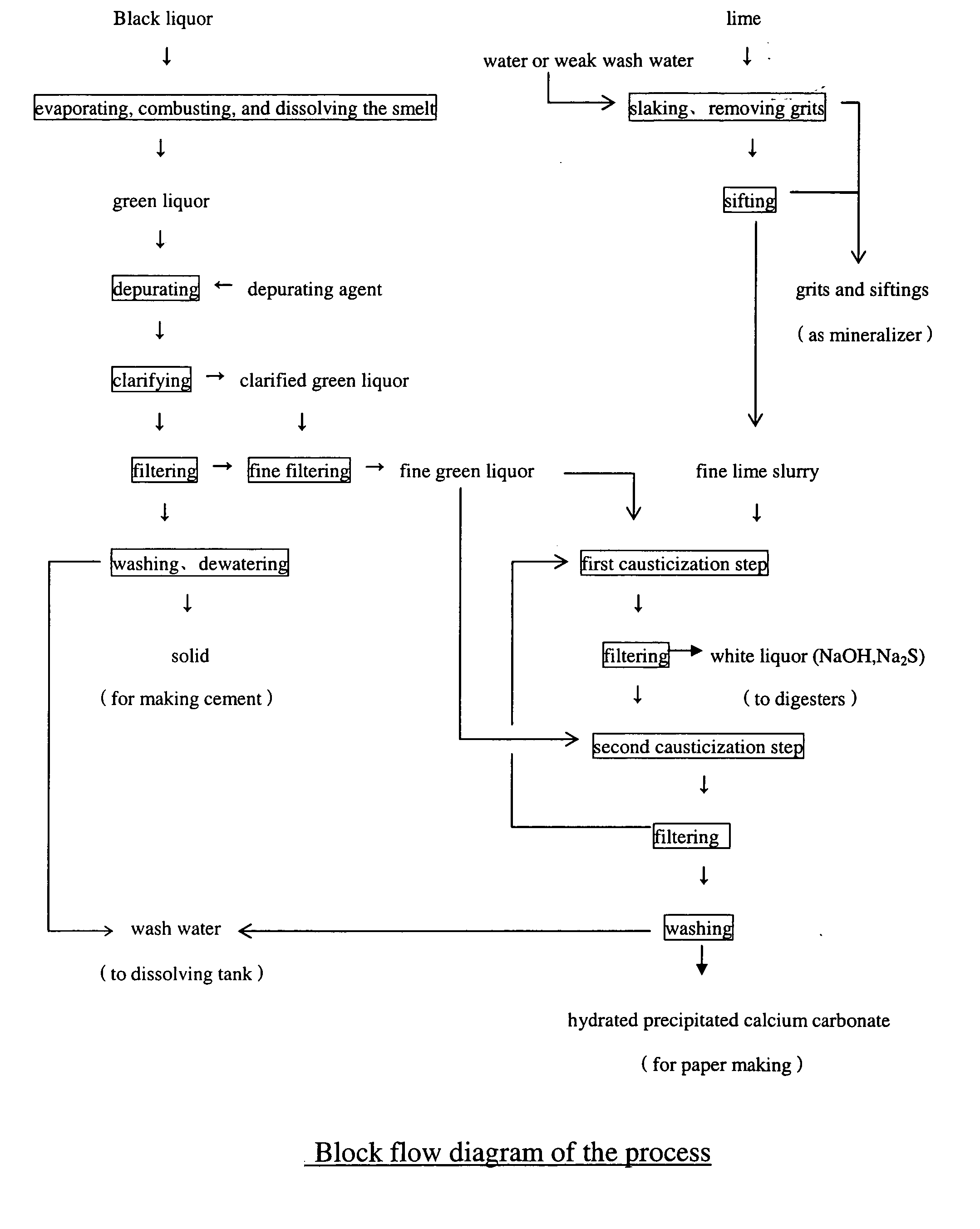

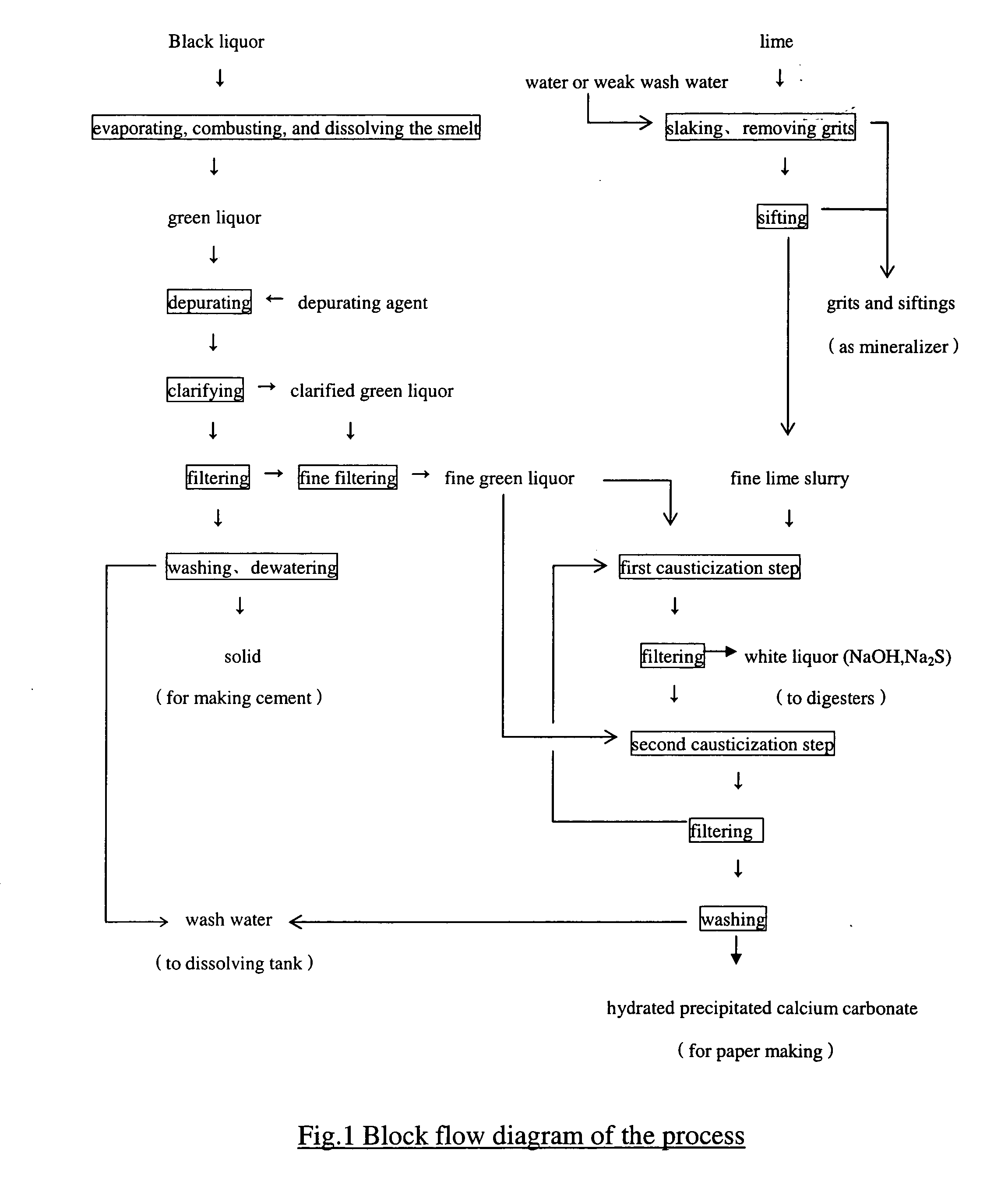

Process of recovering alkali from black liquor of papermaking

InactiveUS20050199358A1Equipment investmentReduce energy consumptionCalcium/strontium/barium carbonatesPulp liquors combustionBlack liquorPrecipitated calcium carbonate

This invention provides an improved process for recovering chemicals from black liquor in alkaline pulping, which is achieved by introducing depuration treatments of green liquor and lime before causticization reaction and a two-step-causticization procedure in the causticization procedure of the conventional chemical recovery process. The process of this invention not only avoids the generation of the waste residue (lime mud) from the beginning and saves the recovery and treatment of lime mud, but also can directly produce a series of precipitated calcium carbonate products with various particle sizes by regulating process conditions while the alkali is recovered, said CaCO3 products including a CaCO3 suitable for making coated paper, wherein >=50% of the CaCO3 has a particle size below 2 mum; a CaCO3 suitable for making neutral sized paper, wherein >=90% of the CaCO3 have a particle size below 2 mum; a superfine CaCO3 having an average particle size <1 mum. The present invention can be used for treatment of pollution of black liquor in the alkaline pulping.

Owner:AI TIANZHAO +3

Combustion air system for recovery boilers, burning spent liquors from pulping processes

InactiveUS6742463B2Reduce the amount requiredIncrease supplyPulp liquors combustionIncinerator apparatusLiquid wasteBlack liquor

Owner:ANDRIZ OY

Method and device for cleaning of filter

The method and arrangement is for cleaning at least one of filter sheets and filter cakes in a pressurized white liquor filter with spray nozzles and driving fluid. The white liquor filter is used in a causticizing process in which green liquor is causticized before the white liquor filter by the addition of lime and in which it forms during the process a lime mud slurry. The white liquor filter 101 is used to separate white liquor from the lime mud. The driving fluid for the spray nozzle is constituted principally by the filtrate that is obtained from the filter.

Owner:METABO PAPER SWEDEN

Recovery process and system for a pulp mill

InactiveUS20080289782A1Efficient productionImprove reusePulp liquors combustionFlue gasChemical recovery

A method for burning chlorine-containing liquors in a chemical recovery boiler at a pulp mill, wherein the recovery boiler includes spent liquor sprayers for feeding spent liquor and a number of combustion air levels including: increasing a combustion temperature in the recovery boiler in a burning zone where a chlorine-containing liquor or a chlorine-containing effluent is burned; while burning the liquor or effluent, volatilizing the chlorine in the liquor or effluent to produce chloride-containing salts in flue gases in the boiler, and removing the chloride-containing salts from the flue gases.

Owner:ANDRIZ OY

Recovery of phosphorus values and salt impurities from aqueous waste streams

The present invention generally relates to processes for recovery of phosphorus values and salt impurities from aqueous waste streams. In particular, the present invention relates to processes for recovery of phosphorus values and salt impurities from aqueous waste streams generated in the manufacture of phospho-herbicides, including N-(phosphonomethyl)glycine and glufosinate.

Owner:MONSANTO TECH LLC

Method for the production of high yield chemical pulp from softwood

InactiveUS20050155730A1Increase pulp yieldHigh yieldPulp liquors combustionPulp by-products recoveryChemical managementWhite liquor

The present invention relates to a novel method for the production of a high yield chemical pulp from softwood in a pulp mill by the application of a delignification catalyst in a wood impregnation step and by using alkaline pulping liquors comprising boron compounds at a white liquor sulfidity level below about 25%. The method is practiced concurrently with a controlled sulfur chemicals management in the pulp mill thereby providing a pulping process which have low emission of odorous pollutants, low rate of corrosion in mill equipment and which has a rate of delignification and selectivity sufficient to produce softwood pulp in higher yield and at a quality at least on a par with a kraft pulping alternative.

Owner:STIGSSON LARS LENNART

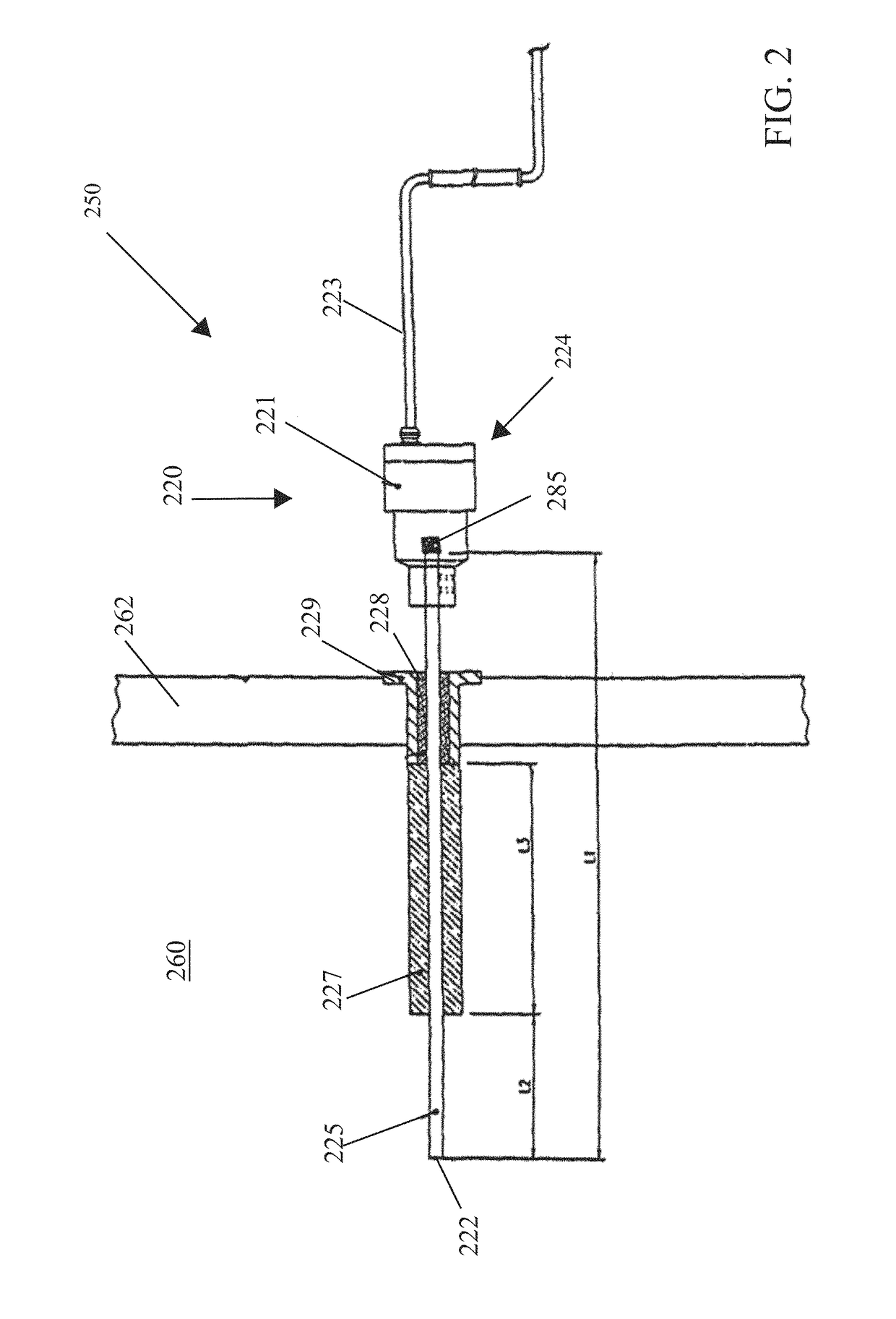

Cooled smelt restrictor at cooled smelt spout for disrupting smelt flow from the boiler

ActiveUS9206548B2Reduce the temperatureReduced and blocked flowPulp liquors combustionPipeline systemsHot meltEngineering

The amount or extent of expositions as a result of hot smelt from a pulp mill recovery boiler impacting cool liquid in a dissolving tank is reduced more effectively by regulating the smelt flow via a restrictor assembly. The restrictor assembly may be positioned to permit the smelt to flow, unrestricted, from the recovery boiler to the dissolving tank, or the restrictor assembly may be positioned so as to fully or partially block the smelt flow from the boiler to the dissolving tank. In some embodiments, a source of cooling fluid may be coupled to the restrictor assembly so as to assist in cooling parts of the restrictor assembly when hot smelt is in contact with the assembly.

Owner:ANDRITZ INC

Acoustic emission system and method for predicting explosions in dissolving tank

ActiveUS10012616B2Prevent and mitigate conditionAnalysing fluids using sonic/ultrasonic/infrasonic wavesPulp liquors combustionAcoustic emissionEngineering

The present disclosure describes a system for predicting explosions in a dissolving tank. The system includes acoustic emission sensors placed in or around the dissolving tank. By filtering the recorded frequencies to the range which is most sensitive for desired explosions “fingerprints,” it is possible to predict a smelt influx before the smelt influx occurs as well as program response actions to prevent compromising explosions.

Owner:ANDRITZ INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com