Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

108 results about "Boiler plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Boiler in a power plant has two functions. The Combustion system converts energy in coal to Heat. Water and steam system converts the heat to steam at high pressures and temperatures. This series explains the working of the boiler in modern power plant.

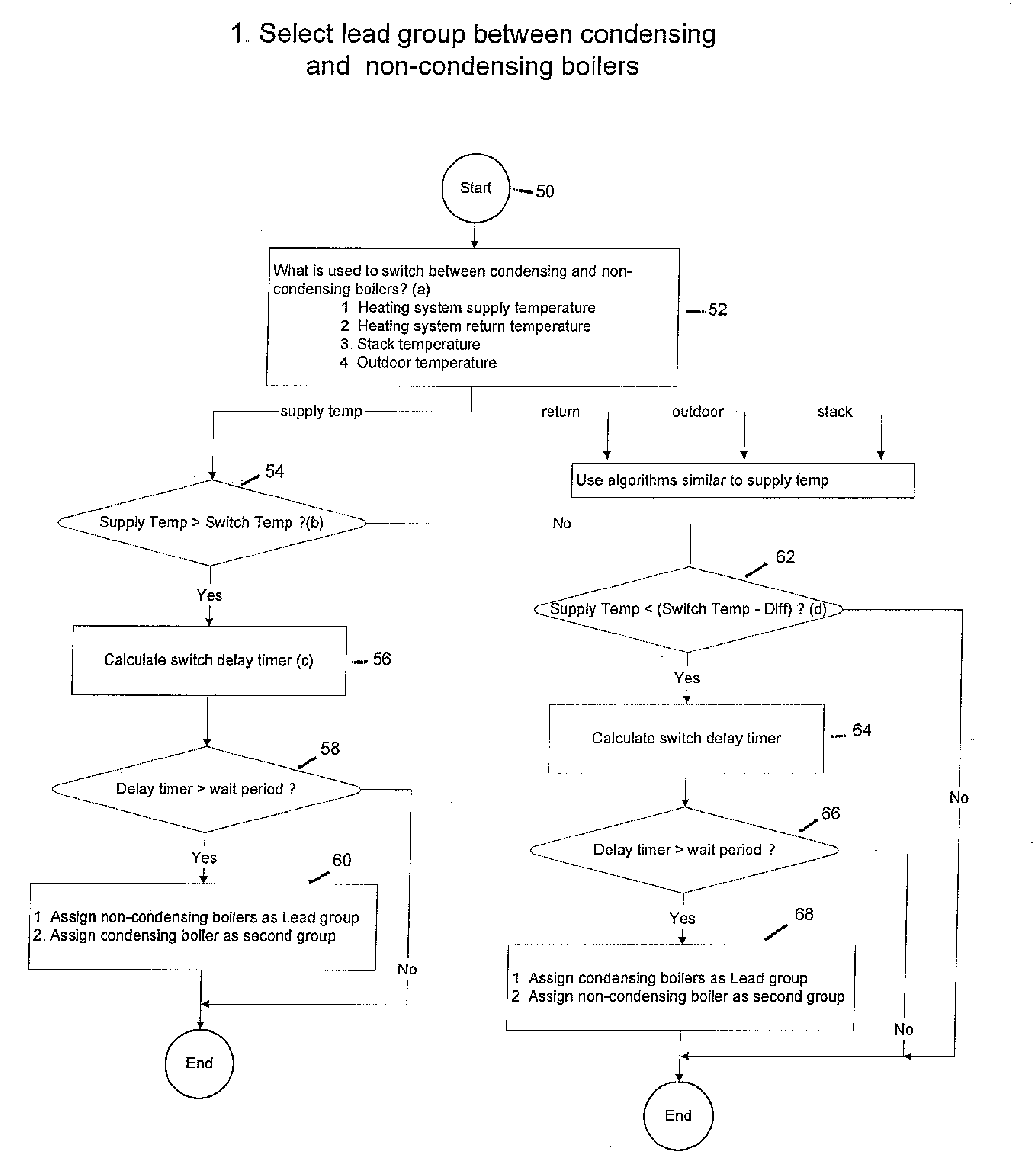

Optimizing multiple boiler plant systems with mixed condensing and non-condensing boilers

ActiveUS20100006042A1Maintaining overall heating plant efficiencyImprove efficiencyBoiler controlSteam generation plantsBoiler plantIndependent group

A system is provided to optimize multiple boiler plant systems having mixed condensing and non-condensing boiler groups. The system advantageously employs the independent groups of boilers depending on preset conditions under control of a system control unit. The preset conditions are checked against operating conditions of the boiler plant, and a system control unit controls which of the groups of boilers is the lead and which is secondary. In some instances, both groups of boilers may be utilized under heavy load. Further, effective switching between groups and within groups is also provided to minimize unnecessary repetitive boiler operation.

Owner:HEAT TIMER

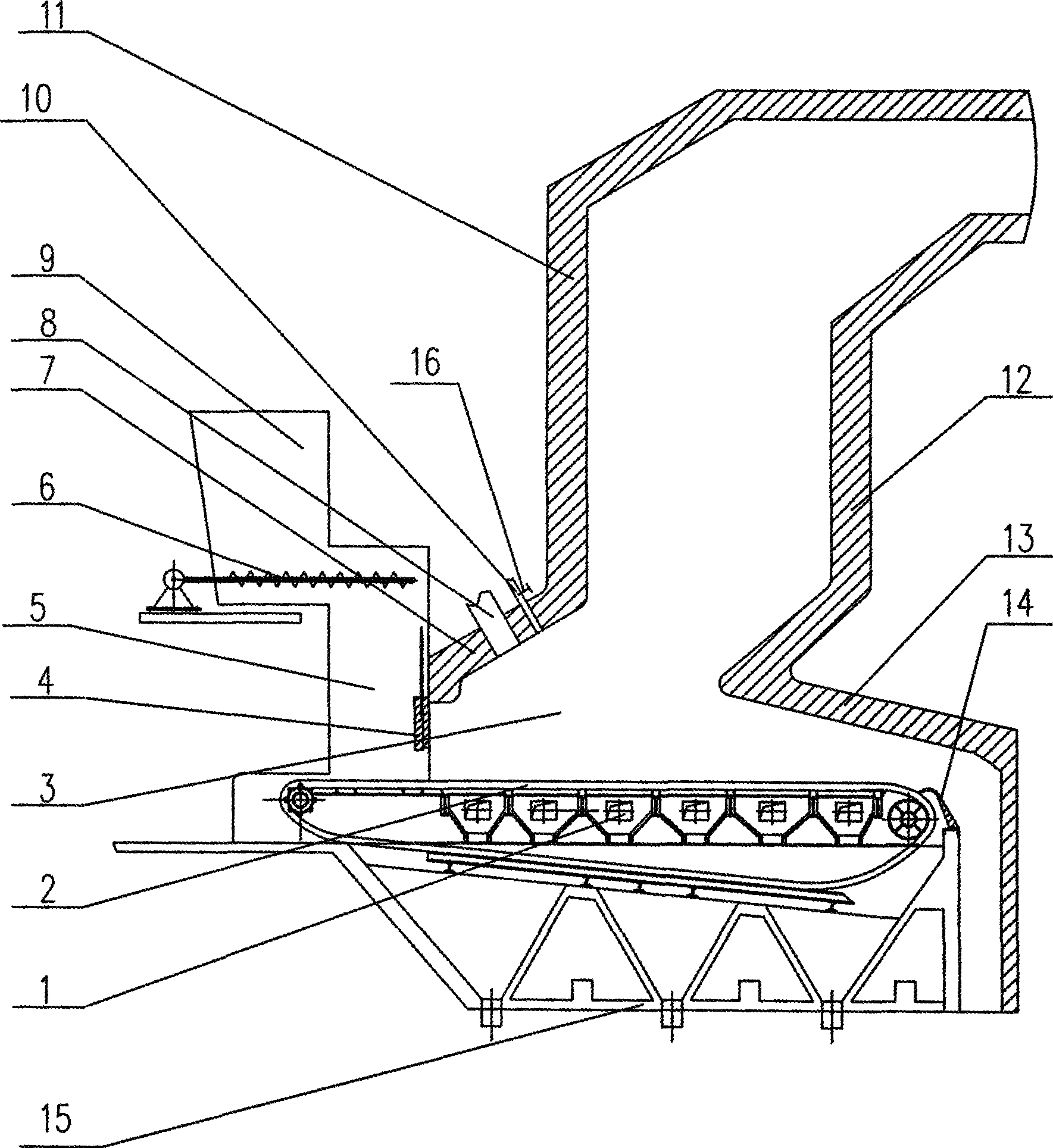

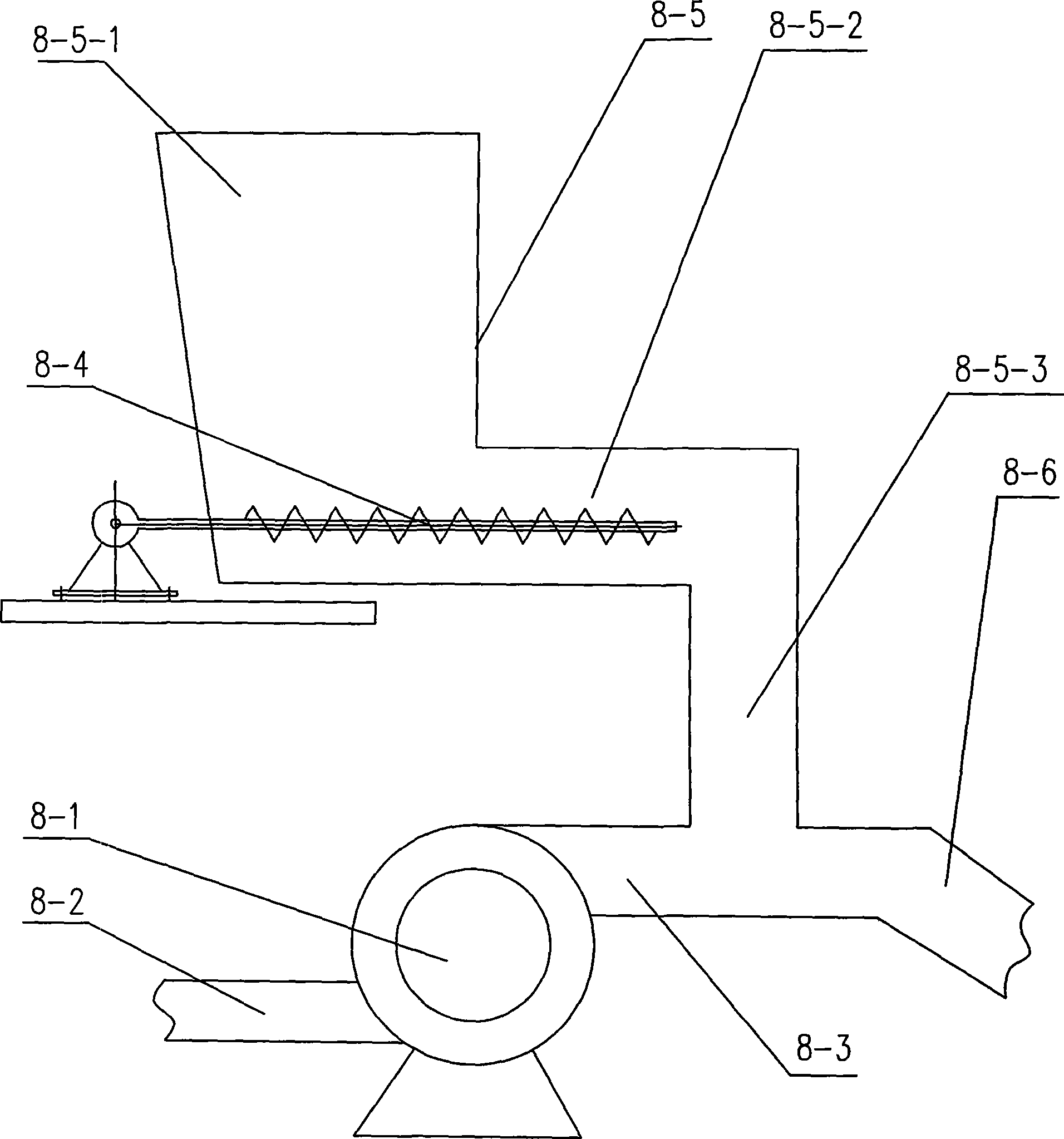

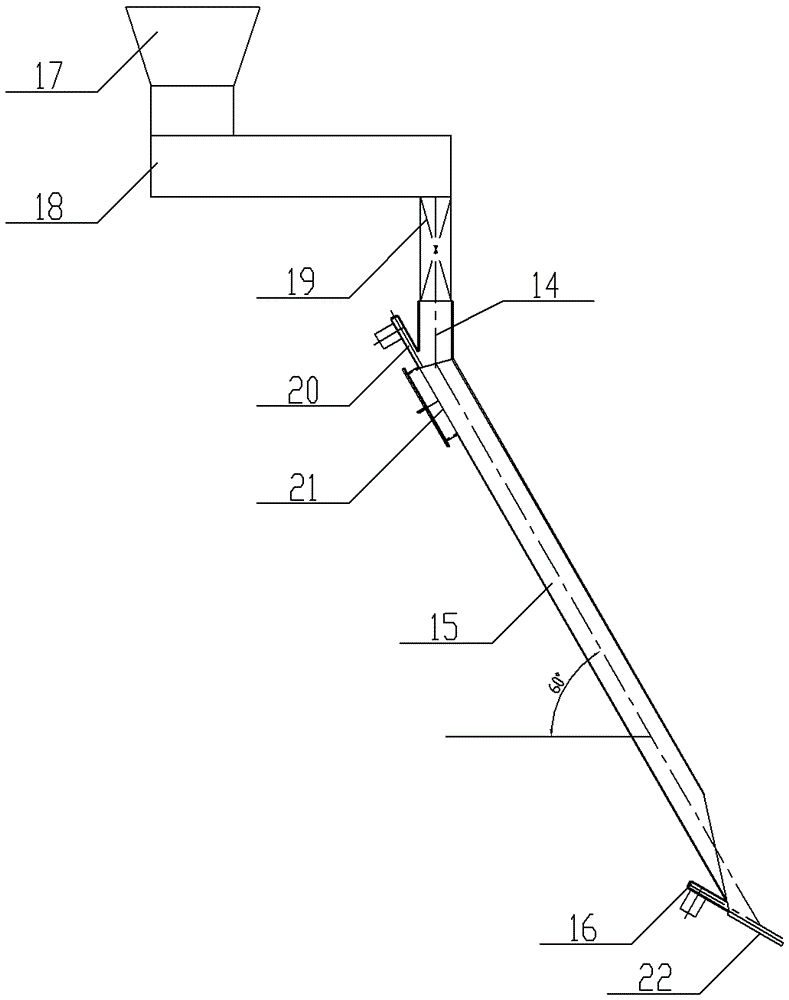

Chain boiler plant for burning multi-biomass fuels

InactiveCN101363618AEvenly loadedStrong seasonalitySolid fuel combustionNon-combustible gases/liquids supplyAir volumeBoiler plant

A chain-grate boiler device for burning a plurality of biomass fuels relates to a chain-grate boiler device. The chain-grate boiler solves the problems of unstable chain-grate boiler load and being difficult in adjusting the boiler load when the existing chain-grate boilers burn biomass. In the device, a biomass nozzle device (8) on an arch is obliquely arranged on a front arch (7) and is communicated with a hearth (3), a secondary air nozzle (10) on the arch is positioned at the slanting upper part of the biomass nozzle device (8) on the arch, the secondary air nozzle (10) on the arch is arranged on the front arch (7) and is communicated with the hearth (3), and the secondary air nozzle (10) on the arch is provided with an airflow regulating valve (16). The chain-grate boiler device adopts a combined feeding device composed of a biomass blanking hopper, the biomass nozzle device on the arch and the secondary air nozzle on the arch, thus causing the load of the chain-grate boiler for burning the biomass fuels to be stable and being convenient for adjusting the boiler load.

Owner:HARBIN INST OF TECH

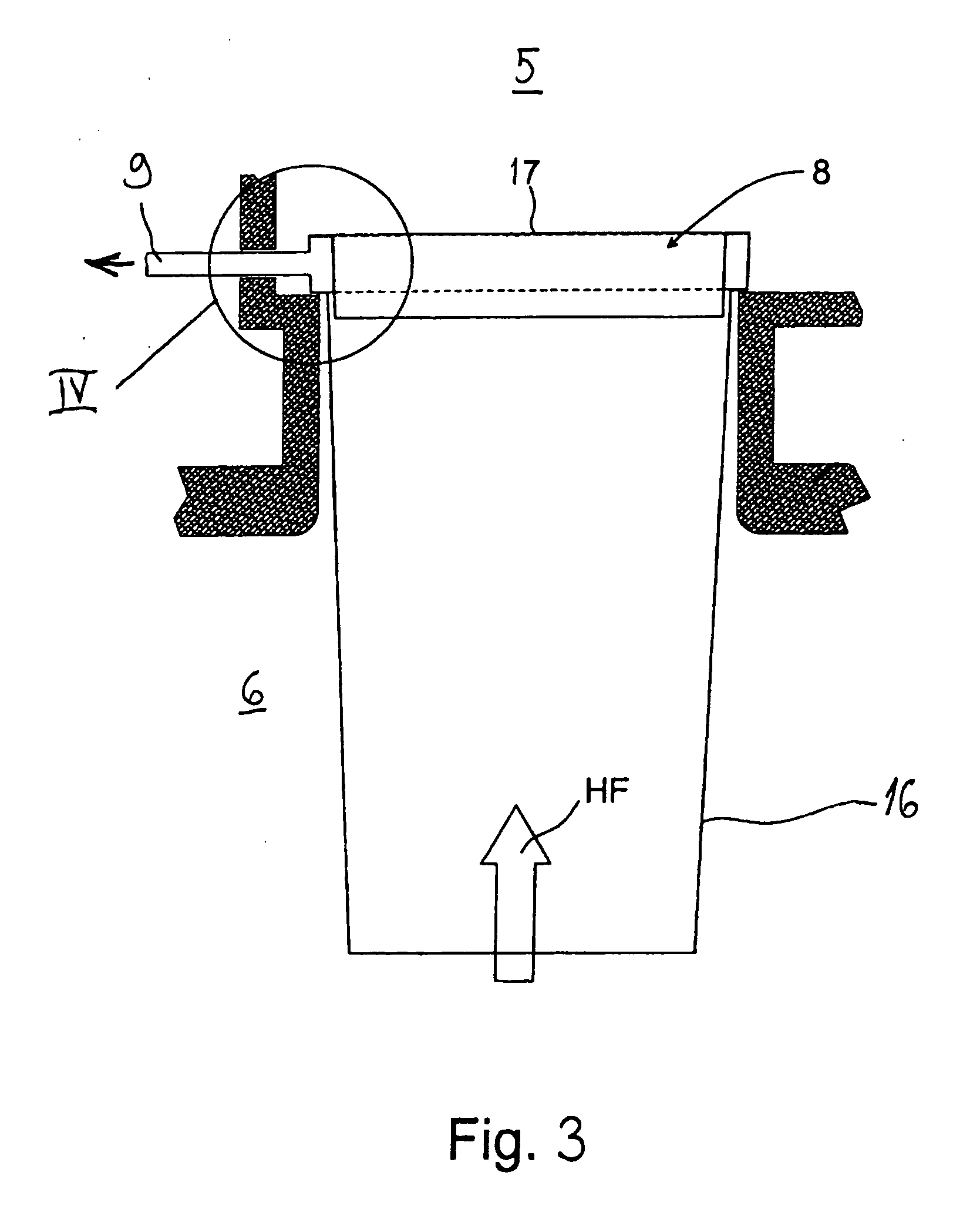

Oxyfuel Combustion Boiler Plant

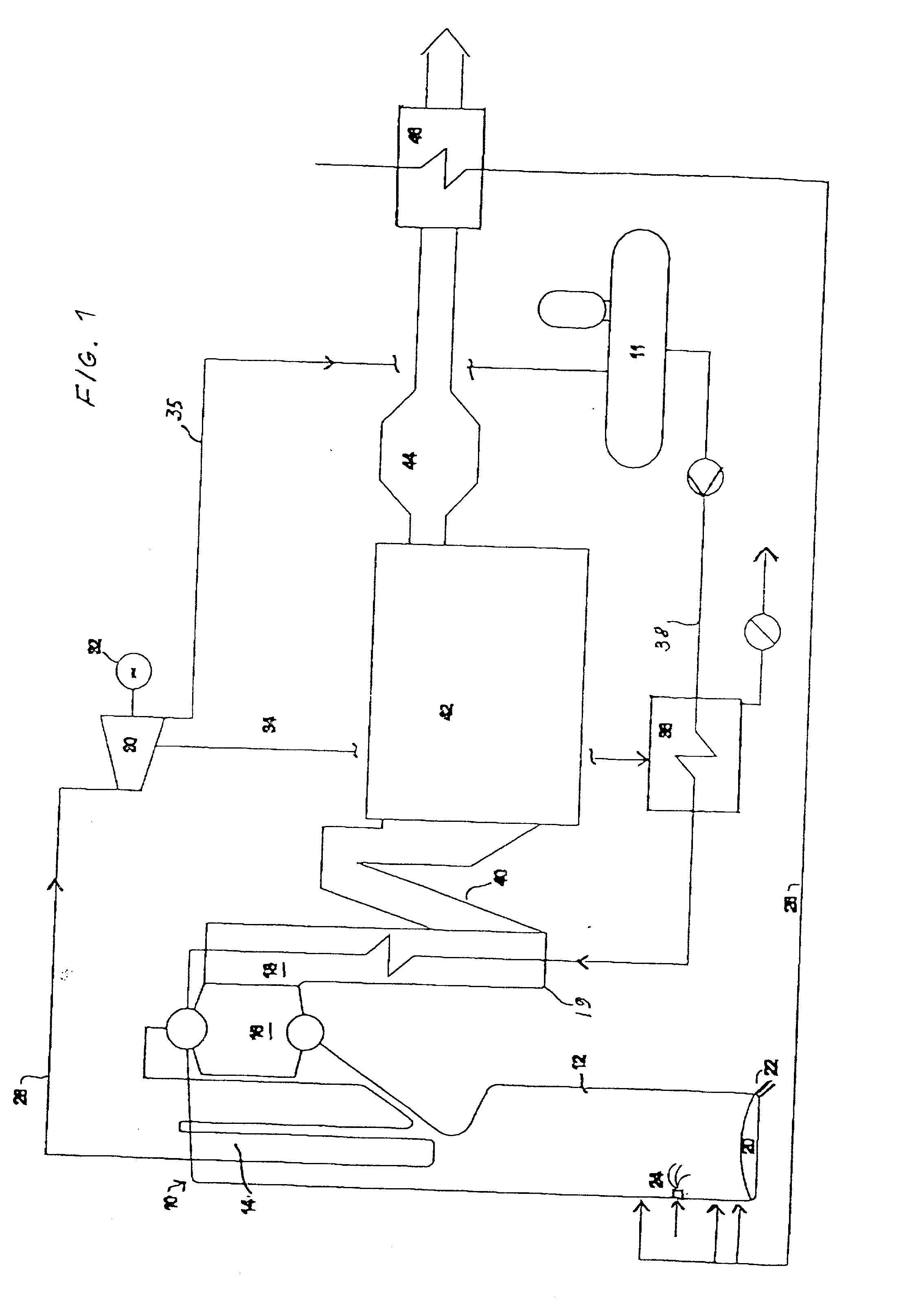

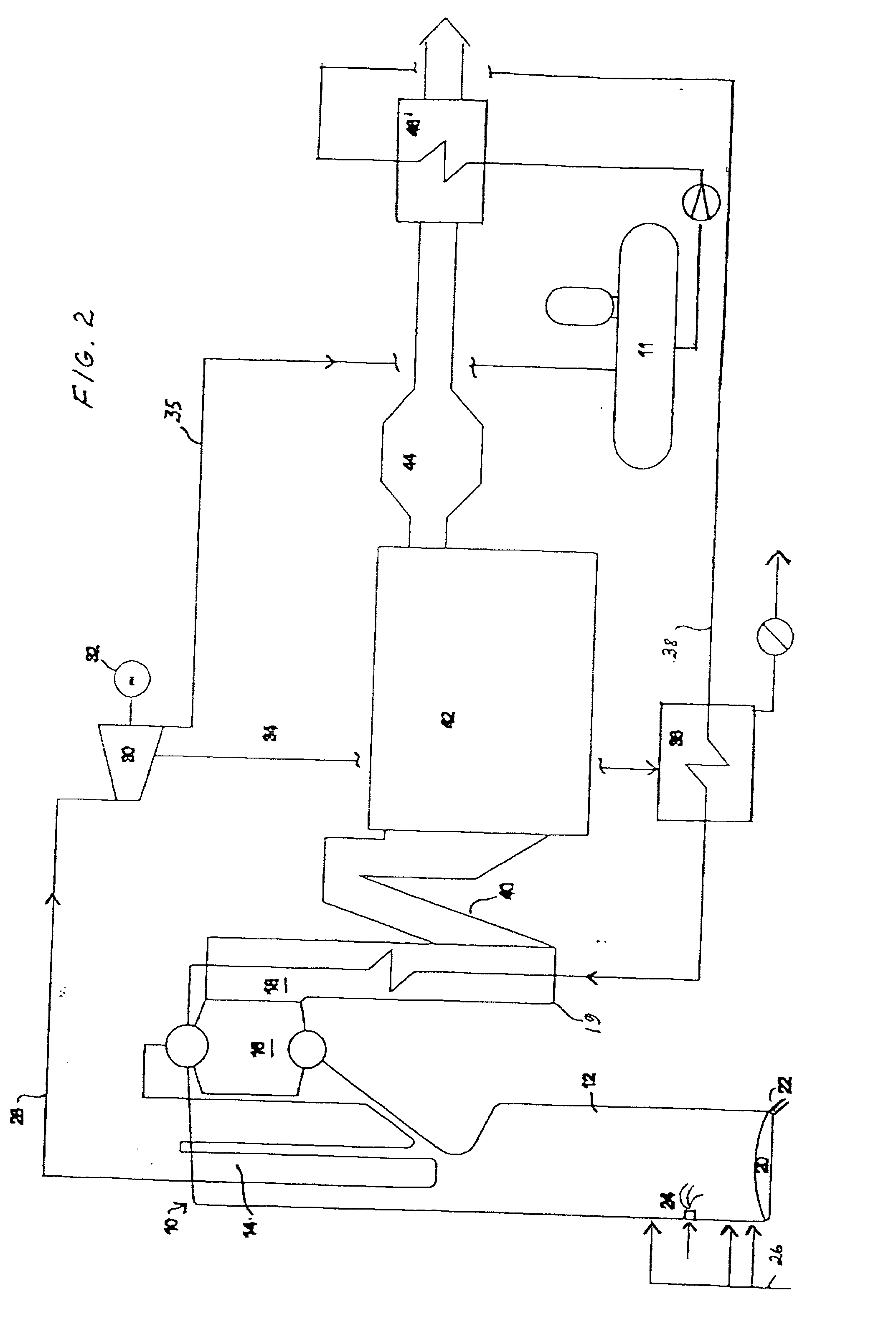

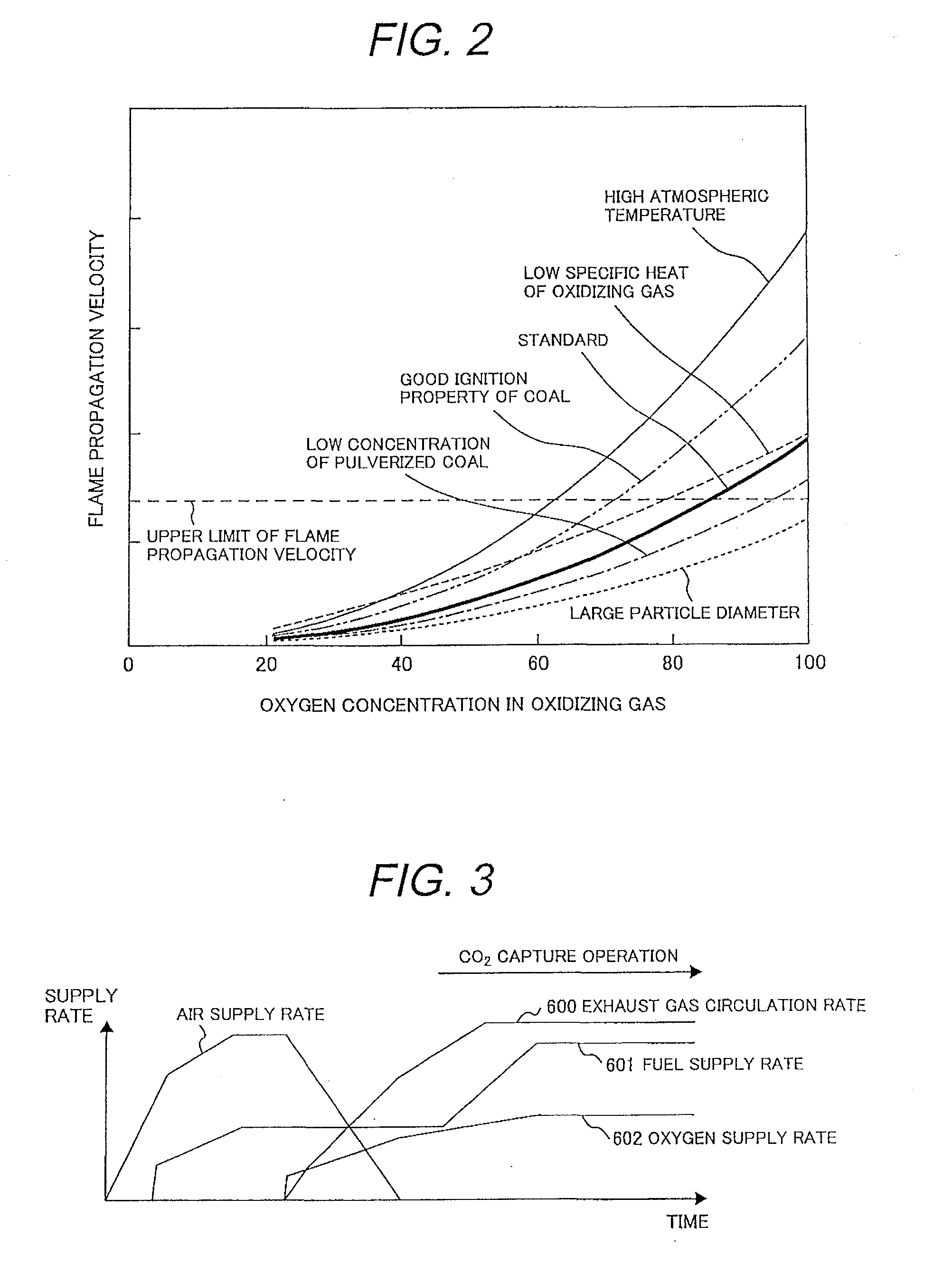

ActiveUS20110073020A1Improve ignition performanceDifficulty occurEmission preventionFluegas recirculationCombustorBoiler plant

An oxyfuel combustion boiler plant comprising: an air separation unit for manufacturing oxygen by separating nitrogen from air, a boiler having a burner for burning the oxygen supplied from the air separation unit and pulverized coal, and a primary system pipe for supplying the pulverized coal to the burner, an exhaust gas recirculation system pipe for supplying combustion exhaust gas discharged from the boiler to the primary system pipe, and a carbon dioxide capture unit for capturing carbon dioxide in the exhaust gas discharged from the boiler, the oxyfuel combustion boiler plant is further comprising: an oxygen supply pipe for supplying the oxygen manufactured by the air separation unit to the primary system pipe in the burner, and a pipe for supplying the combustion exhaust gas discharged from the boiler to the oxygen supply pipe, wherein an injection port of the oxygen supply pipe is disposed on an upstream side of an injection portion of the burner.

Owner:MITSUBISHI POWER LTD

Method and arrangement for producing electrical energy at a pulp mill

InactiveUS20020194849A1Improve power production efficiencyElectrical efficiencyPulp liquors combustionSteam generation using steam absorptionSuperheaterEconomizer

The invention relates to a method and an arrangement in the production of electric energy in a boiler plant of a pulp mill. Black liquor having a dry solids content of more than 80% and combustion air are fed into a furnace of a recovery boiler for combusting black liquor and recovering chemicals contained therein. The flue gases generated in the combustion are led into an economizer of the recovery boiler, in which economizer the feed water for the boiler is heated, and after the economizer to gas cleaning. The feed water is led from the economizer onto the steam-generating bank at a temperature below the saturation temperature and further into a superheater to produce steam having a pressure of more than 80 bar. The steam is led from the recovery boiler to a steam turbine to produce electricity. The temperature of the feed water being led into the economizer is regulated by means of bleed steam of the turbine so that the flue gases exit the economizer at a temperature of more than 250° C. and that after the economizer the flue gases are cleaned in at least a hot electrostatic precipitator and the cleaned flue gases are cooled by the combustion air or the feed water.

Owner:ANDRIZ OY

Heavy Oil Fuel

InactiveUS20080073247A1Low viscosityImprove stabilityHydrocarbon purification/separationLiquid carbonaceous fuelsBoiler plantTar

This invention relates to oil refining, more particularly to a composition of a heavy fuel oil for use in marine power units and boiler plants. The fuel comprises, in percent by weight: an extract from the selective extraction of gas oil—(3-5), heavy catalytic cracking gas oil—(3-10), vacuum gas oil—(5-10), tar or topped residuum—(3-10), straight-run black oil—(10-20), viscosity breaking residue of heavy oil fractions—the rest. The selected combination of the components and their ratio may for example, result in a stable heavy fuel oil having improved viscosity properties. The inclusion of the above components into the fuel composition may also make it possible to expand the production of heavy fuel oils produced.

Owner:OILTREID LIABILITIES

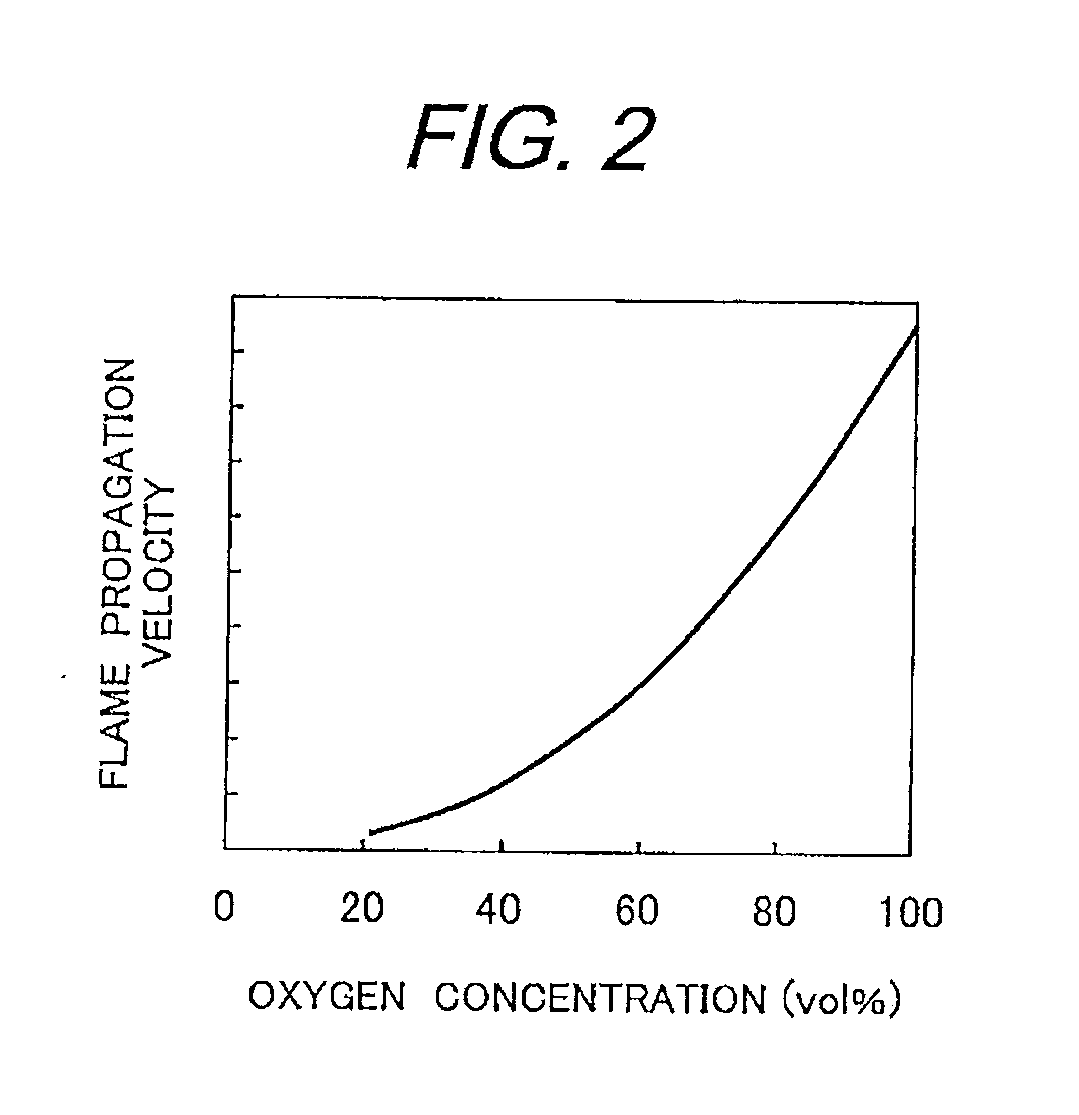

Oxyfuel Combustion Boiler Plant and Operation Method of Oxyfuel Combustion Boiler Plant

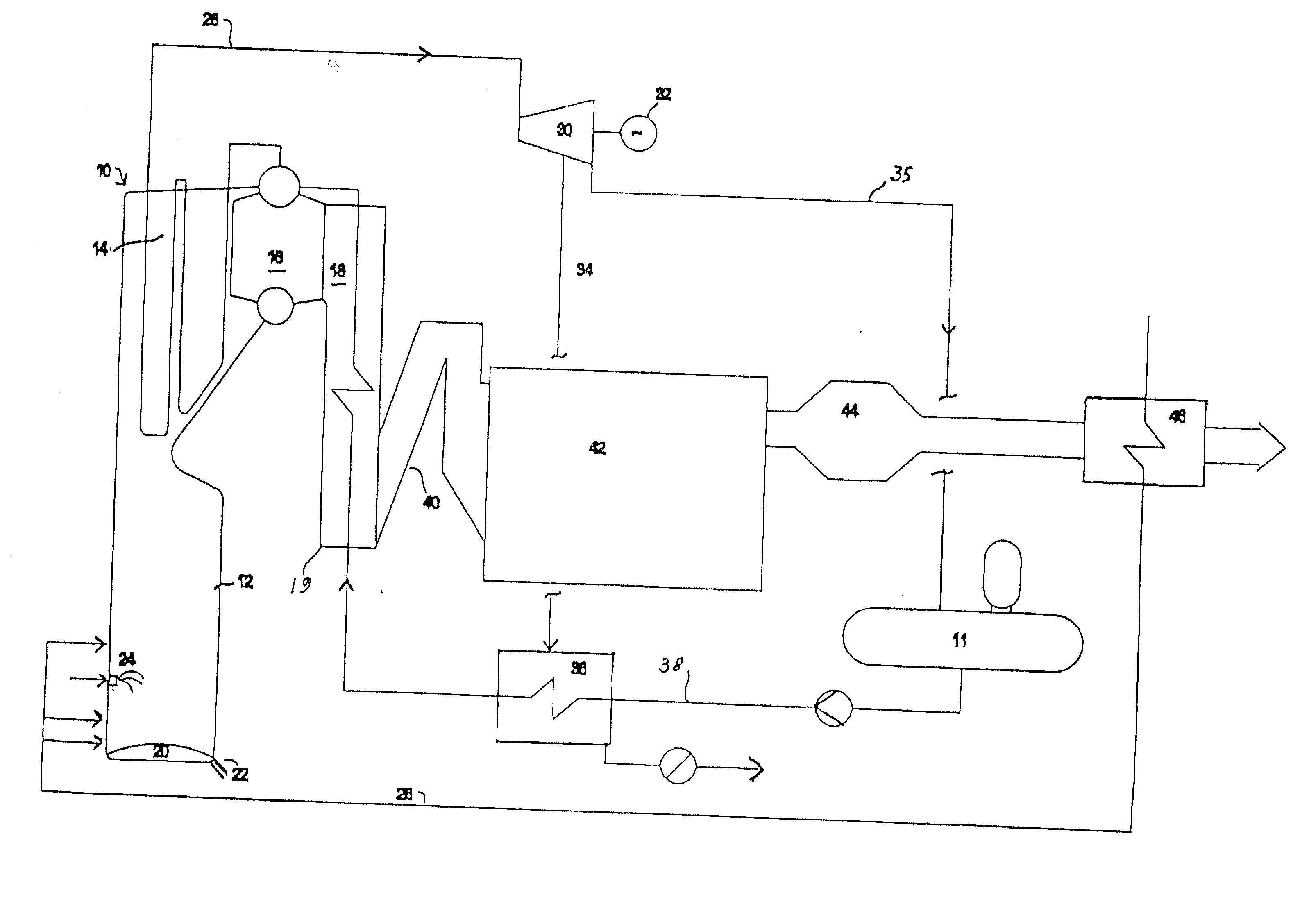

ActiveUS20110073051A1Avoid abnormal combustionIncrease oxygen concentrationFluidized bed combustionSolidificationCombustorBuffer tank

An oxyfuel combustion boiler plant comprising:a boiler having an air separation unit for manufacturing oxygen by separating nitrogen from air, a burner for burning the oxygen supplied from the air separation unit and pulverized coal, and a primary system pipe for supplying the pulverized coal to the burner, exhaust gas recirculation system pipe for supplying combustion exhaust gas discharged from the boiler to the primary system pipe, a carbon dioxide capture unit for capturing carbon dioxide in the exhaust gas discharged from the boiler, the oxyfuel combustion boiler plant is further comprising: an oxygen buffer tank disposed on a downstream side of the air separation unit; an oxygen supply pipe for supplying oxygen to the primary system pipe of the burner from the oxygen buffer tank; and a nitrogen supply pipe for supplying a part of nitrogen generated from the air separation unit or an air supply pipe for supplying air from outside which is connected to the oxygen supply pipe on a downstream side of the oxygen buffer tank and on an upstream side of a junction of the primary system pipe.

Owner:MITSUBISHI POWER LTD

Oxyfuel Combustion Boiler Plant and Operating Method for the Same

ActiveUS20100212555A1Emission reductionCarbon compoundsFluegas recirculationHigh concentrationCombustor

An oxyfuel combustion boiler plant having a first boiler and a second boiler for injecting gas including oxygen in higher concentration than that in the air, gas including carbon dioxide in higher concentration than that in the air, and fuel from a burner and generating steam by combustion gas in a furnace, respectively, comprising:an exhaust gas supply pipe for supplying exhaust gas discharged from the first boiler to a burner of the second boiler, and a gas flow rate control apparatus for controlling a flow rate of exhaust gas flowing through the exhaust gas supply pipe.

Owner:MITSUBISHI POWER LTD

Optimizing multiple boiler plant systems with mixed condensing and non-condensing boilers

A system is provided to optimize multiple boiler plant systems having mixed condensing and non-condensing boiler groups. The system advantageously employs the independent groups of boilers depending on preset conditions under control of a system control unit. The preset conditions are checked against operating conditions of the boiler plant, and a system control unit controls which of the groups of boilers is the lead and which is secondary. In some instances, both groups of boilers may be utilized under heavy load. Further, effective switching between groups and within groups is also provided to minimize unnecessary repetitive boiler operation.

Owner:HEAT TIMER

Boiler plant, a support structure and a method for supporting the walls of a steam boiler of a boiler plant

A boiler plant, which comprises a boiler (2) and a frame (1) of a boiler house surrounding the boiler. In addition, the boiler plant comprises support structures (3), by which the walls of the boiler (2) are supported laterally to the frame (1) of the boiler house. In addition, the invention relates to a support structure (3) and a method for supporting the walls of a boiler (2) of a boiler plant.

Owner:METSO POWER OY

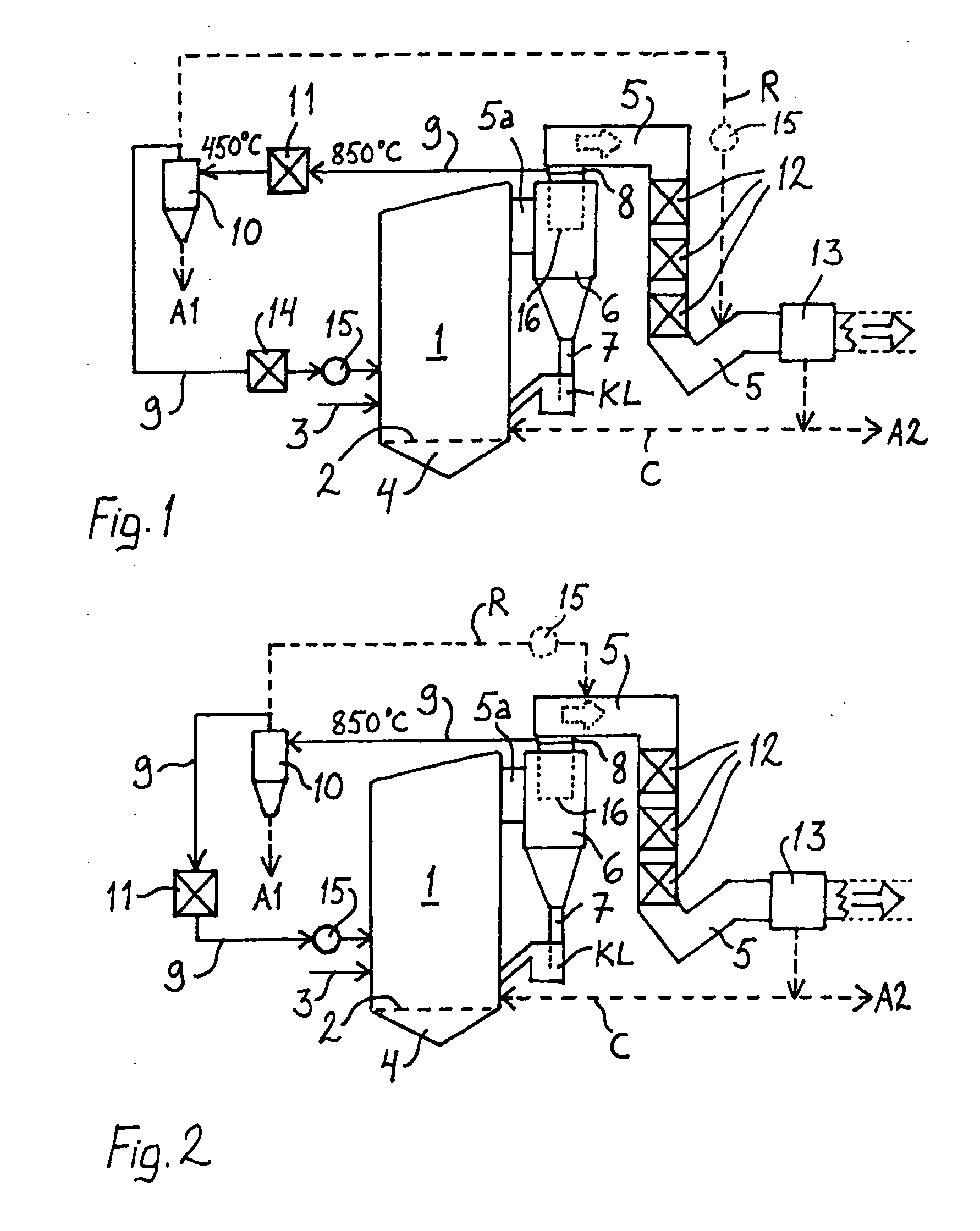

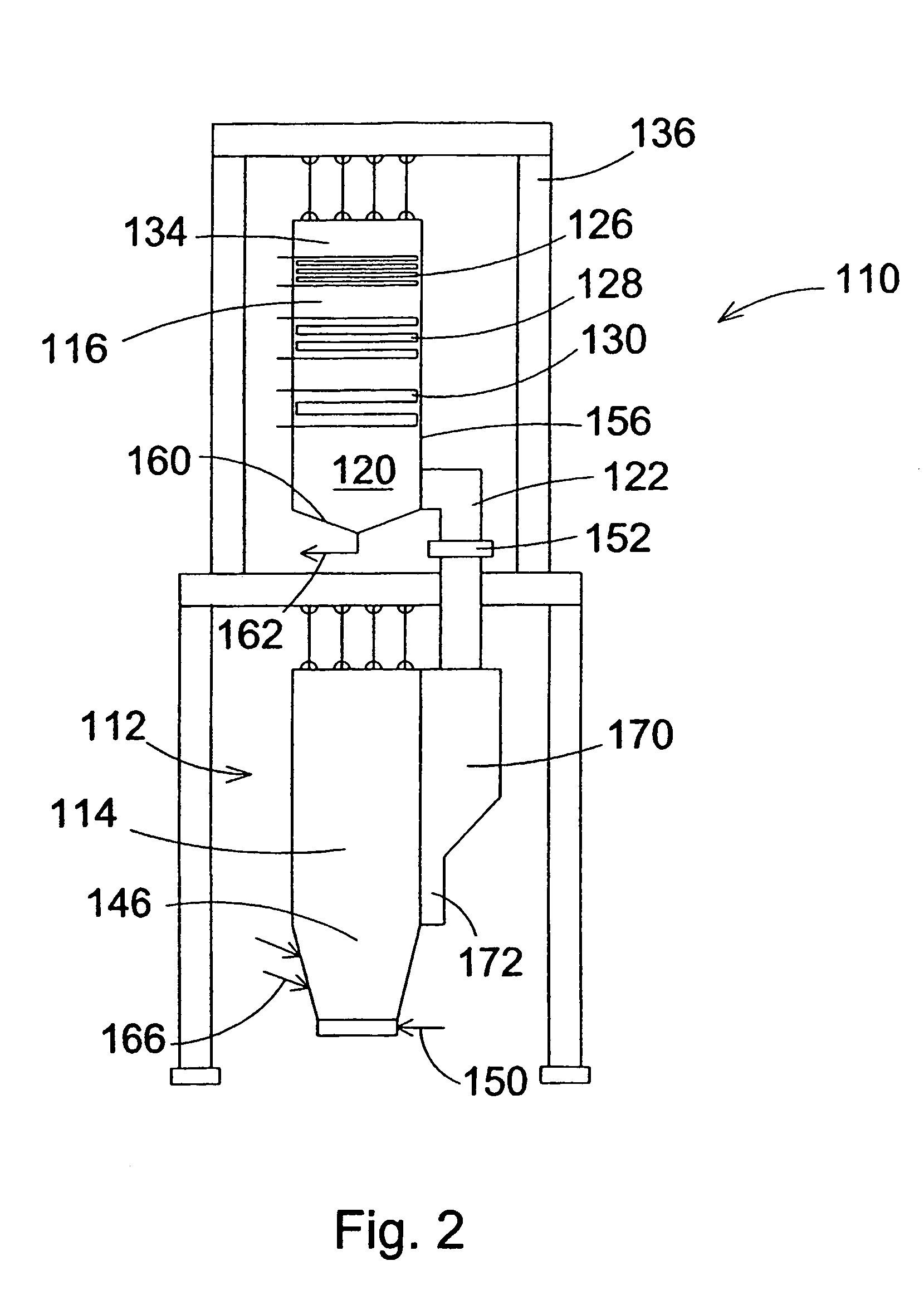

Method for treating fly ash in a fluidized bed boiler and boiler plant

InactiveUS20060140832A1Quantity minimizationHigh solid contentFluidized bed combustionDispersed particle filtrationBottom ashFlue gas

A boiler plant comprises a fluidized bed boiler having a furnace (1), a flue gas duct (5) exiting the furnace, and a sorting device (8) which is arranged to separate a first fraction from the fly ash entering the flue gas duct, as well as a side duct (9) for leading the first fraction away from the sorting device (8). The boiler plant comprises a separator (10) for separating a first fly ash fraction from the flue gases flowing in the side duct (9). The sorting device (8) is arranged to separate into the side duct (9) the flue gases from a flow entering the flue gas duct (5). The flow in the side duct is more concentrated with respect to the fly ash and has a smaller gas volume than a flow that remains in the flue gas duct (5) after the sorting device (8). As to its hazard classification, the first fraction of fly ash obtained by the separator (10) corresponds to bottom ash.

Owner:METSO POWER OY

Tower boiler including a stationary supporting structure

InactiveUS7240640B2Reduce time consumptionShort timeBoiler supporting/setting arrangementsFuel injection apparatusCombustionBoiler plant

A boiler plant, including a combustion section, a heat exchange section including heat exchange surfaces, arranged above the combustion section and having a flow direction from the bottom upwards, and a stationary supporting structure. The combustion section and the heat exchange section are separate chambers, flexibly joined with each other, and the chambers are each separately hung from their upper part to the stationary supporting structure.

Owner:FOSTER WHEELER ENERGIA OY

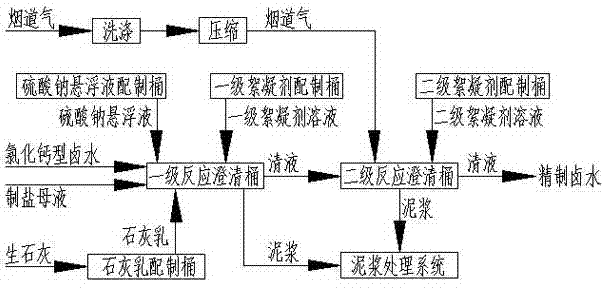

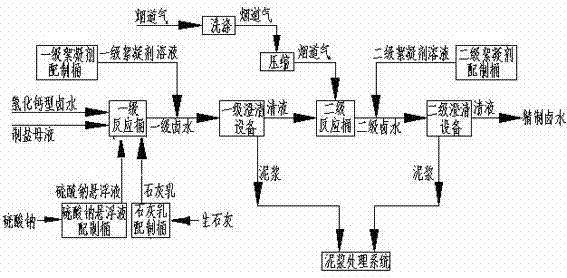

Lime-sodium sulfate-carbon dioxide method used for purifying calcium chloride type bittern

ActiveCN103482655AAccelerated settlementEmission reductionAlkali metal chloridesFlue gasBoiler plant

The invention discloses a lime-sodium sulfate-carbon dioxide method used for purifying calcium chloride type bittern. The lime-sodium sulfate-carbon dioxide method comprises following steps: (A) preparation of lime milk; (B) preparation of sodium sulfate suspension; (C) preparation of a first order flocculating agent solution; (D) first-order reaction; (E) preparation of carbon dioxide; (F) preparation of a second order flocculating agent solution; and (G) second-order reaction. According to the lime-sodium sulfate-carbon dioxide method, quicklime and carbon dioxide in flue gas are used for removing Ca<2+> and Mg <2-> in calcium chloride type bittern, so as to reduce purification cost of enterprises producing calcium chloride type bittern, reduce carbon dioxide discharge capacity of thermal power plants or boiler plants, and provide novel technological methods for purification of calcium chloride type bittern.

Owner:CHINA CEC ENG

A boiler plant, a support structure, and a method for supporting the walls of a steam boiler of a boiler plant

InactiveCN101303121AReduce in quantityShorten the lengthBoiler supporting/setting arrangementsSteam boilersThermodynamicsBoiler plant

A boiler plant, which comprises a boiler (2) and a frame (1) of a boiler house surrounding the boiler. In addition, the boiler plant comprises support structures (3), by which the walls of the boiler (2) are supported laterally to the frame (1) of the boiler house. In addition, the invention relates to a support structure (3) and a method for supporting the walls of a boiler (2) of a boiler plant.

Owner:METSO POWER OY

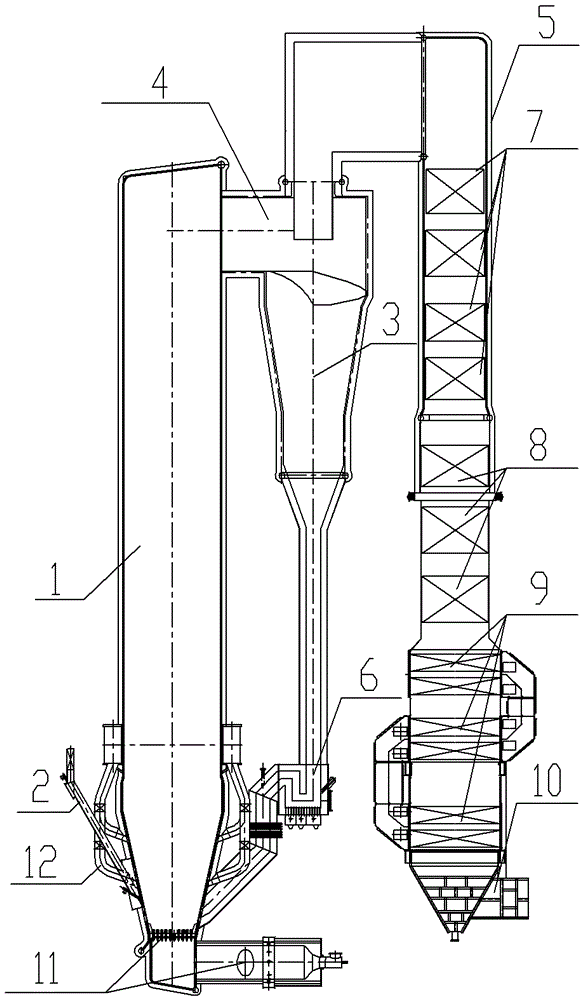

Low-nitrogen efficient energy-saving high temperature and high pressure circulating fluidized bed boiler

PendingCN106838892AStrong reducing atmosphereReduce air volumeFluidized bed combustionApparatus for fluidised bed combustionSuperheaterHearth

The invention belongs to the field of boiler plant and specifically relates to a low-nitrogen efficient energy-saving high temperature and high pressure circulating fluidized bed boiler. The boiler can effectively reduce the generating volume of pollutant gas, can reduce the energy consumption, can increase the boiler efficiency and is stable and reliable in running. A coal feeding system and a first-secondary air system are arranged at the lower end of a hearth; a separation system is communicated with the upper end of the hearth; the separation system comprises a separator inlet flue and a cyclone separator; an in-furnace ammonia spraying denitration system is arranged between the hearth and the cyclone separator; the separator inlet flue is communicated with the hearth; a tail flue is communicated with an upper end inlet of the cyclone separator; a feedback system is arranged between the lower outlet of the cyclone separator and the lower end of the hearth; a super-heater unit, a coal economizer and a pre-heater are arranged in the tail flue; an outlet flue is connected with the tail flue; the first-secondary air system comprises a first air system and a secondary air system; the first air system comprises a first air feeding structure and a zone air distributing structure; the first-secondary air system has a double-layer structure of upper layer and lower layer; the ratio of first air to secondary air is 1:1.

Owner:WUXI HUAGUANG BOILER

Method and arrangement for producing electrical energy at a pulp mill

InactiveUS6647726B2Improve efficiencyEffective recoveryPulp liquors combustionSteam generation using steam absorptionSuperheaterEconomizer

The invention relates to a method and an arrangement in the production of electric energy in a boiler plant of a pulp mill. Black liquor having a dry solids content of more than 80% and combustion air are fed into a furnace of a recovery boiler for combusting black liquor and recovering chemicals contained therein. The flue gases generated in the combustion are led into an economizer of the recovery boiler, in which economizer the feed water for the boiler is heated, and after the economizer to gas cleaning. The feed water is led from the economizer onto the steam-generating bank at a temperature below the saturation temperature and further into a superheater to produce steam having a pressure of more than 80 bar. The steam is led from the recovery boiler to a steam turbine to produce electricity. The temperature of the feed water being led into the economizer is regulated by means of bleed steam of the turbine so that the flue gases exit the economizer at a temperature of more than 250° C. and that after the economizer the flue gases are cleaned in at least a hot electrostatic precipitator and the cleaned flue gases are cooled by the combustion air or the feed water.

Owner:ANDRIZ OY

Oil-gas organic heat transfer furnace

The invention discloses an oil-gas organic heat transfer furnace, which comprises a barrel body and a coiled pipe; the barrel body is a box body with a quadrate cross section; and the coiled pipe is a quadrate box shaped coiled pipe which is formed by connecting a plurality of linear single pipes and is provided a quadrate cross section in whole. According to the oil-gas organic heat transfer furnace disclosed by the invention, a radiating section of a combustion chamber adopts a structure of the quadrate box shaped coiled pipe and is formed by welding and assembling bent steel pipes, thus, requirements for the equipment is low, the production can be convenient to carry out, and common medium and small-sized boiler plants can produce large-scale organic heat transfer furnaces; moreover, a convection section has the structure formed by a plurality sections of snake-shaped convection pipes; the oil-gas organic heat transfer furnace has the effects of gas sweeping and heat exchange superior to the coiled pipe clearance sweeping; and an air preheater is integrated into the boiler body, thus, little loss is generated in heat dissipation, the structure is simple, and lower resistance is brought by the gas and the air.

Owner:TAIJUNE BOILER IND KUSN

Automatic control method for saturated steam heating rate in startup temperature-rise period of thermal power generating unit

ActiveCN103453509AReduce startup timeImprove securitySuperheating controlBoiler controlCombustorAutomatic control

The invention discloses an automatic control method for the saturated steam heating rate in the startup temperature-rise period of a thermal power generating unit. The method comprises the following steps: (1) putting into a burner; (2) setting up a program about waiting for 1 min; (3) judging whether the unit startup temperature-rise period is finished or not; (4) judging the saturated steam heating rate. By virtue of the method, the thermal power generating unit can automatically control the saturated steam heating rate in the startup period to be close to the upper limit value but not exceed the upper limit value. The judgment can be performed by automatically monitoring change of the saturated steam heating rate in real time as follows: if the heating rate is slow, the burner is put into the unit in time to shorten the startup time; if the heating rate is too fast, the burner is taken out in time to ensure the safety of a boiler plant. Therefore, the labor intensity of operators can be reduced; the unit startup time can be shortened; the security and the economic efficiency in the startup temperature-rise period of the thermal power generating unit can be improved.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

Fluidized bed boiler plant and method of combusting sulfurous fuel in a fluidized bed boiler plant

InactiveUS8382470B2Readily put to end storageReduce water treatment costsBurnersFluidized bed combustionCombustionFlue gas

A fluidized bed boiler plant and a method of combusting sulfurous fuel in the fluidized bed boiler plant, a furnace of which plant is provided with a fluidized bed of particles. Sulfurous fuel, CaCO3-containing sulphur-binding agent and combusting air are introduced to the bed of particles, whereby fuel burns and generates flue gases and the sulphur-binding agent calcinates to CaO and binds SO2 generated in the combustion. Energy is recovered to a heat exchange medium circulating in heat exchange tubes of a condensing heat exchanger arranged in a flue gas channel, and a water solution of acid condensing on outer surfaces is neutralized by mixing it in a mixing vessel to a CaO-containing ash from a plant, preferably, fly ash collected by a dust separator.

Owner:FOSTER WHEELER ENERGIA OY

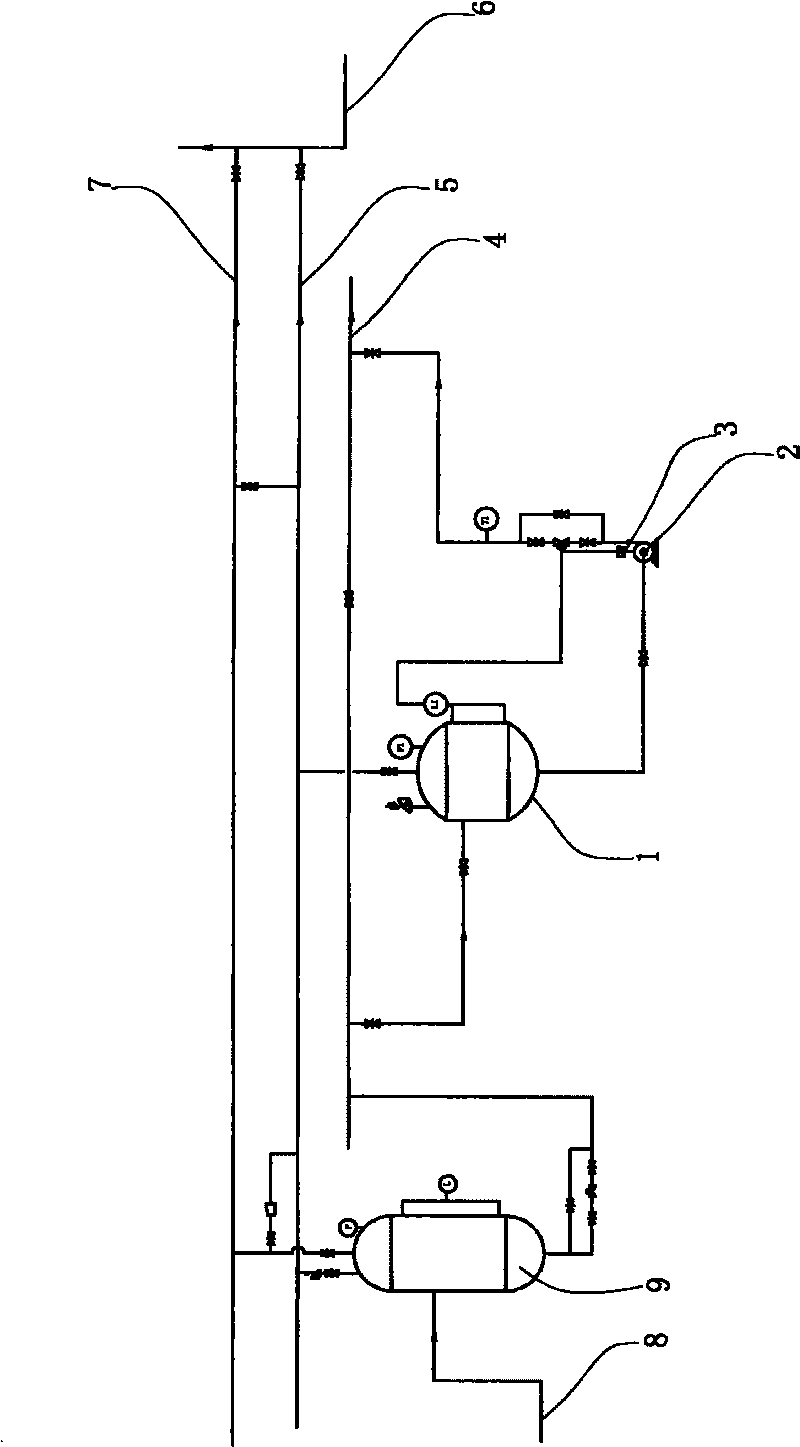

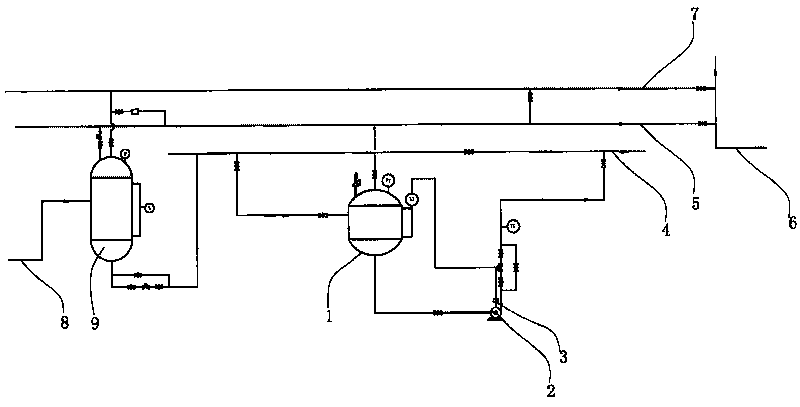

Method and device for recovering waste heat of steam condensate of calcination plant

InactiveCN101761913ATake advantage ofSave energyEnergy inputSteam generationSodium bicarbonateBoiler plant

The invention discloses a method for recovering waste heat of steam condensate of a calcination plant, which comprises the following steps: carrying out secondary flashing on the steam condensate from a secondary flashing tank in the sodium bicarbonate calcination process for preparing calcined soda by an ammonia-soda process; recovering and reutilizing the flashed steam; and adopting a device for recovering the steam condensate of the calcination plant. The device comprises a condensate backflow liquid collection tank, one side of the condensate backflow liquid collection tank is connected with the secondary flashing tank, the top end of the condensate backflow liquid collection tank is connected with a secondary flashing second steam pipe, the top end of the secondary flashing tank is connected with a secondary flashing first steam pipe, one side of the secondary flashing tank is connected with a primary flashing steam condensate inlet pipe, the secondary flashing second steam pipe and the secondary flashing first steam pipe are connected in parallel with the a distillation steam main pipe, the bottom end of the condensate backflow liquid collection tank is connected with a condensate pump, and the secondary flashing tank, the condensate backflow liquid collection tank and the condensate pump are simultaneously connected to a condensate pipe of a condensate heat removal electric boiler plant. Thus, the steam is fully utilized, and the energy sources are saved.

Owner:山东海天生物化工有限公司

Method and system for removing coal-fired boiler pollutants by utilizing solar energy

InactiveCN103223294AReduce steam extractionAdjust utilization structureDispersed particle separationSteam useEngineeringPollution

The invention relates to a method and system for removing coal-fired boiler pollutants by utilizing solar energy. The method is characterized in that a solar heat collection device is introduced into a denitrification and ammonia decarbonization regeneration device of a coal power generation system, a first evaporator and a first heat exchanging pipe both of which the heat source is sourced from the solar heat collection device as well as a second evaporator and a second heat exchanging pipe both of which the heat source is sourced from the steam bleeding of a steam turbine are arranged in the denitrification and ammonia decarbonization regeneration device, and a working medium heated by the solar heat collection device exchanges the heat with the first evaporator and a pyrolysis regeneration tower so as to supply the heat source to the vaporization of a denitrification catalytic reducing agent and the regeneration of an absorbing agent for the ammonia decarbonization and to substitute all or partial heat generated during the steam bleeding on the steam turbine side and released in the evaporator and the pyrolysis regeneration tower. The invention also provides a system for implementing the method. By utilizing advantages such as abundance and no pollution, of the solar energy, the energy utilization structure is adjusted, under the situation that the unit generating capacity is maintained constant, the coal consumption is remarkably reduced, and the benefit of a power plant is increased while the emission of the nitrogen oxides of the coal power plant is effectively reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Thermal Energy Usage Metering System for Steam-Heated Multiple Unit Building

ActiveUS20180181150A1Defective operationMechanical apparatusSpace heating and ventilation safety systemsThermal energyBoiler plant

A system for determining the relative space heating energy contribution of different tenant spaces in a multiple tenant building that is heated via a central steam piping distribution system. A steam piping distribution system is connected to a central heat source such as a steam boiler plant or a local utility district steam service. The steam distribution system includes terminal units located throughout the building which deliver heat to different spaces. Data collected at regular intervals from sensors located throughout the building are analyzed by a computer in order to calculate the fraction of the overall building's steam use that is delivered to particular tenant spaces over a given interval in time.

Owner:STEVEN WINTER ASSOCS

Cogeneration system configured to be installed into an existing boiler plant/ emergency generator installation and process for cogeneration

ActiveUS20160301344A1Creates heatInternal combustion piston enginesExhaust apparatusElectricityBoiler plant

At least one embodiment relates to a cogeneration system configured to be coupled to an electrical input of a building and configured to be coupled to a heating or cooling system of a building. The cogeneration system can comprise a generator configured to generate electrical energy. There can be also a fluid output and a fluid input that passes through the generator and configured to absorb heat from the generator. There can also be an electrical output coupled to the electrical input of the building wherein when the generator is operational, the engine creates both heat and electricity. There can also be a processor in communication with the generator, wherein the processor controls when the generator turns on and off based upon the amount of heat or cooling needed, the cost of fuel and the existing electrical rates. These costs can be obtained using communication with real time rates over the internet.

Owner:PAC

Method for treating fly ash in a fluidized bed boiler and boiler plant

InactiveUS7758835B2Quantity minimizationHigh solid contentFluidized bed combustionDispersed particle filtrationBoiler plantFluidized bed

A method for treating fly ash of flue gas exiting a furnace of a fluidized bed boiler. A side flow conveying a first fraction of fly ash is separated from a flow conveying a second fraction of fly ash. After the separation, the side flow conveying the first fraction has a higher solids content than the flow conveying the second fraction. The first fraction of fly ash is separated from the side flow at a separation temperature of at least 400° C., whereafter the first fraction of fly ash is discharged from the process.

Owner:METSO POWER OY

Responsibility division method for turbine island and boiler island in performance acceptance of single-shaft combined cycle generating unit

The invention discloses a responsibility division method for a turbine island and a boiler island in performance acceptance of a single-shaft combined cycle generating unit. By building performance models of triple-pressure, reheat and un-fired waste heat boilers and a performance model of a steam turbine free of a middle steam extraction function, the influence of boundary conditions of the waste heat boilers on outputs of the waste heat boilers is simulated, the influence of the boundary conditions on the power and heat consumption rate of the steam turbine is simulated, and correction curves of the waste heat boilers and a correction curve of the steam turbine are provided, so that the outputs of the waste heat boilers can be corrected and the power and heat consumption rate of the steam turbine also can be corrected; and in combination with a correction curve of a gas turbine provided by a manufacturer, all sub-devices of combined cycle and external characteristics of the whole combined cycle can be obtained. By utilizing the obtained correction curves, the performance deviation responsibilities of the turbine island and the boiler island are scientifically divided.

Owner:XIAN THERMAL POWER RES INST CO LTD

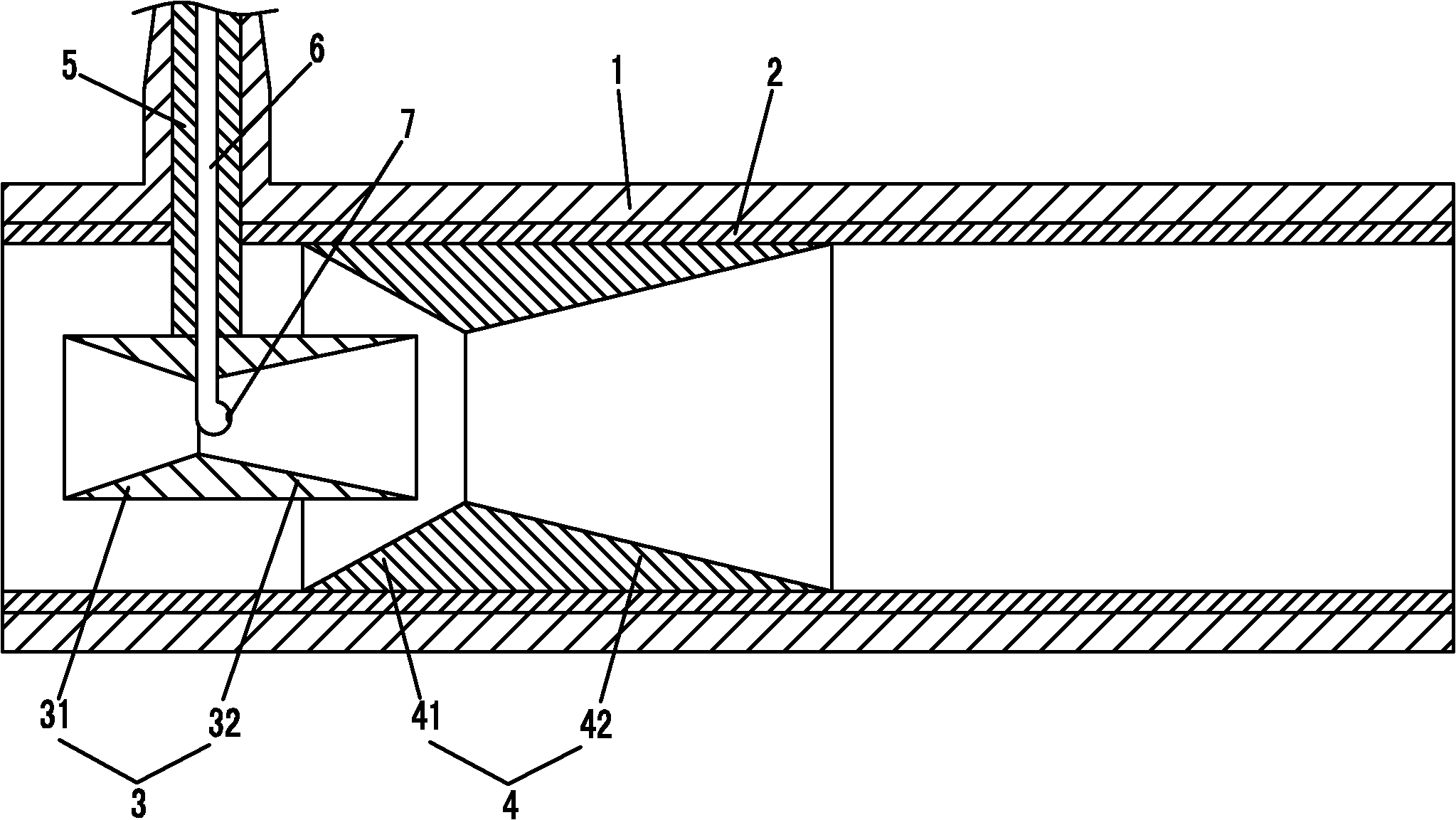

Spray desuperheater

InactiveCN101979918AImprove heat transfer efficiencyImprove spraying effectSuperheating controlBoiler plantEngineering

The invention discloses a spray desuperheater, which belongs to the field of boiler plants. The spray desuperheater comprises a tubular desuperheater header and the like. An inner sleeve is sleeved to a cavity of the desuperheater header. A primary venturi tube and a secondary venturi tube are arranged in the cavity of the inner sleeve, wherein the flared section of the primary venturi tube enters the cavity at the throat of the secondary venturi tube from the left end of the secondary venturi tube. A cooling water pipe vertically runs through the desuperheater header and the inner sleeve; the lower end of the cooling water pipe is connected with an upper end at the throat of the primary venturi tube; and the cavity of the cooling water pipe is communicated with that of the primary venturi tube. The lower end of a centrifugal nozzle runs through the cooling water pipe and then is extended into the cavity of the primary venturi tube; and the spray directions of spray orifices at the lower end of the centrifugal nozzle are dead against the secondary venturi tube. Due to the combination of the centrifugal nozzle and the primary and secondary venturi tubes, the spray desuperheater solves the problem of small atomization range and poor heat exchange effect of desuperheating water, is simple to machine, and can highly-efficiently atomize the desuperheating water in large scale to further effectively improve the heat exchange performance of the desuperheater.

Owner:FEICHENG BAIZHUANG COAL MINE +2

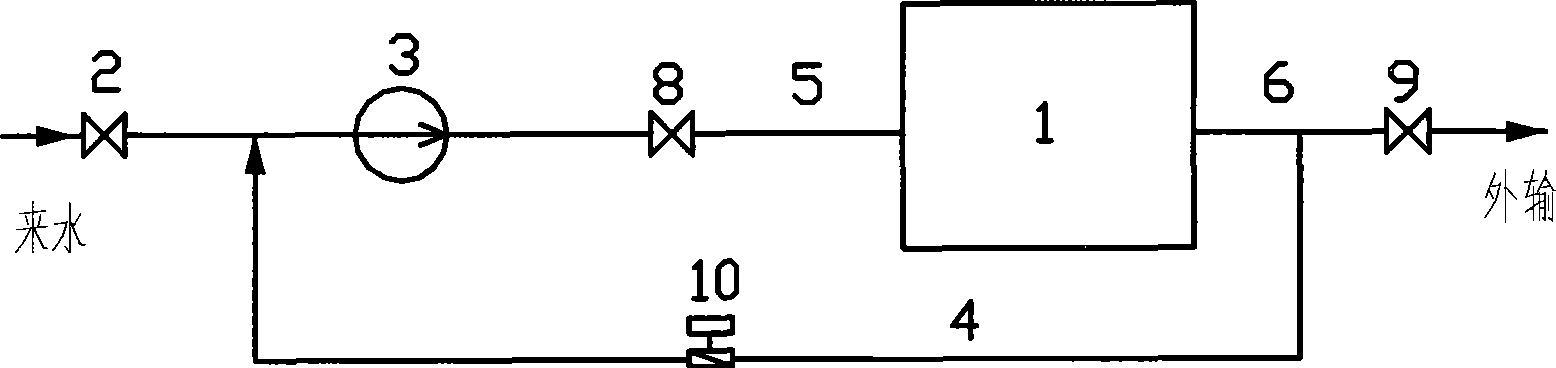

Method and apparatus for retarding scale formation of water heating boiler by utilizing reflux dilution turbulence

InactiveCN101430174ASmall footprintLess investmentCorrosion preventionHeat exchange apparatusBoiler plantWater flow

A method for diluting disturbance and slowing down scaling of a hot water boiler by using refluence and a device thereof belong to the field of boiler plants. The device comprises a hot water boiler (1), a booster water pump (3), a refluence by-pass pipe (4), and a water circulating pump (7). The invention is characterized in that the invention is realized by the mode that part boiler outlet water circulates, reflows in a back-flow by-pass pipe, and then blends with new boiler inlet water to be transported to the hot water boiler: (1) scaling ion concentration of the boiler inlet water is reduced; (2)water flow velocity in a heat exchange tube of the boiler is increased; the scouring and peeling on scaling layers of tube walls is strengthen; (3) inlet temperature is increased; scaling reacts ahead of time; scaling deposition shifts to the inlet of the heat exchange tube; scaling intensity of the back end of the heat exchange tube is reduced; homogenizing distribution of the scaling layers can effectively prolong about 30% to 60% of formation time of blockage caused by pipeline scaling, the effect of which can greatly surpass effect generated by flow velocity increment and ion concentration reduction. The superimposing of the three effects causes that formation time of blockage caused by pipeline scaling is greatly prolonged; the period of cleaning and contaminant separation is prolonged more than 50 %.

Owner:UNIV OF SCI & TECH BEIJING

Liquid environment-friendly heating water anti-theft agent and preparation method thereof

InactiveCN101538069APrevent unauthorized theftLower heating costsLighting and heating apparatusScale removal and water softeningWater useThiol

The invention relates to a liquid environment-friendly heating water anti-theft agent and a preparation method thereof. The heating water anti-theft agent comprises the components based on the weight ratio: 65-94.4% of diallyl disulfide, 0.3-15% of diallyl trisulfide, 0.1-10% of propene thiol, 2-3% of boiler corrosion inhibitor, 3-5% of boiler scale inhibitor and 0.2-2% of amidosulphuric acid; the components are weighed according to the mixture ratio and evenly mixed together. The invention is beneficial to preventing residents from illegally stealing the water used for heating, so as to effectively reduce the heating cost of heating enterprises, ensure the boiler plant to have safe operation, and be beneficial to prolonging the service life of the boiler.

Owner:刘占省

Boiler waste heat gradient utilization and deep water heat recovery system based on absorption heat pump

ActiveCN113007921AIncrease heating capacityImprove utilization efficiencyMechanical apparatusHeat pumpsFlue gasBoiler plant

The invention discloses a boiler waste heat gradient utilization and deep water heat recovery system based on an absorption heat pump. The embedded absorption heat pump is used for deeply recycling waste heat and water of a low-temperature flue gas with a high moisture content, the recycled flue gas waste heat is used for heating heat supply network return water to supply heat, the recycled water resource is used for supplementing heat supply network pipe water and boiler feed water, and therefore deep recycling of the low-temperature flue gas waste heat and the water resource is achieved. The problems of metal corrosion, low-temperature cold source preparation and the like in the field of flue gas waste heat recovery can be effectively solved, and water resources are effectively saved. In the heating season, the flue gas waste heat can be used for gradient heating of the heat supply network return water, the heat supply capacity of the boiler is effectively enhanced, energy consumption is reduced, the energy utilization efficiency is improved, the environmental influence of a boiler plant is reduced, and considerable economic benefits and environmental benefits are achieved.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Boiler arrangement

InactiveCN101044356AGood air supplyConstant penetration distancePulp liquors combustionCasings/liningsBoiler plantChemical recovery

The present invention relates to an arrangement and a method for enlarging a boiler, especially a chemical recovery boiler, and in that way for optimizing and simplifying a capacity increase. An object of the present invention is to provide for a boiler plant, which is easily adaptable to increasing boiler loading without decreasing the efficiency of the combustion process, but facilitating its optimal control. In accordance with the invention, the option of enlarging the boiler is taken into account by reserving space in connection with the boiler so that a side wall (3) may be moved, thus increasing the length of the front wall (2) and the rear wall (4). After the enlargement, the distance between the front and rear walls is essentially the same as before the enlargement.

Owner:ANDRITZ AG

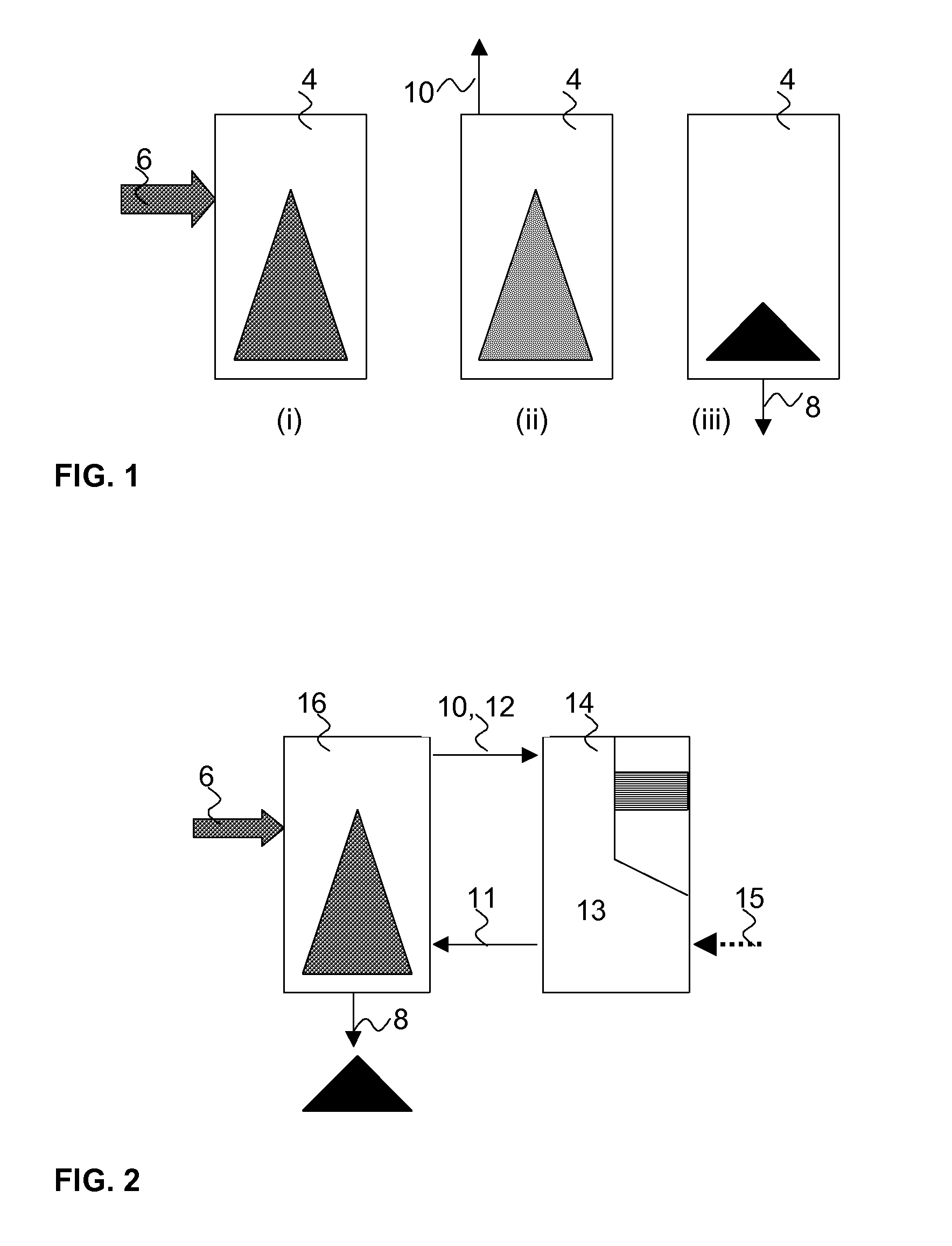

Method for the thermal treatment of biomass in connection with a boiler plant

ActiveUS20120060412A1Reduce frictionImproving fuel-propertiesProductsReagentsDecompositionBoiler plant

The invention relates to the improvement of the fuel-properties of biomass in an integrated manner to facilitate storage, shipping and applicability thereof. In the process, biomass (6) is thermally treated within a combustion process to cause partial torrefaction of the organic matter present in biomass, thus yielding components inert to biological decomposition processes. Constituents (10) separated in gaseous form are utilized as fuel, while the thermally treated biomass (8) remaining in the solid form is utilized in a separate process.

Owner:VALMET POWER OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com