Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about "Steam generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydraulic-compression power cogeneration system and method

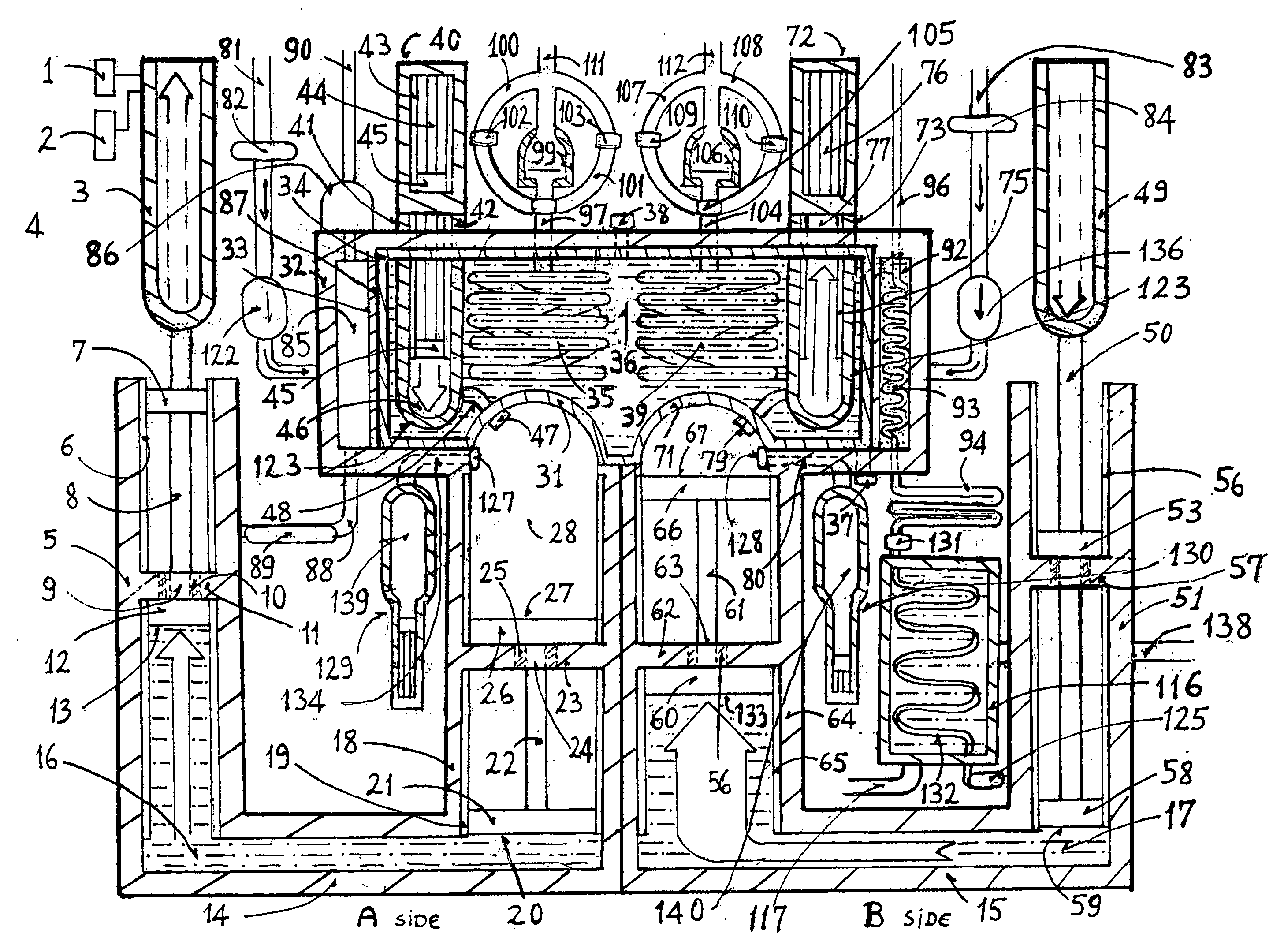

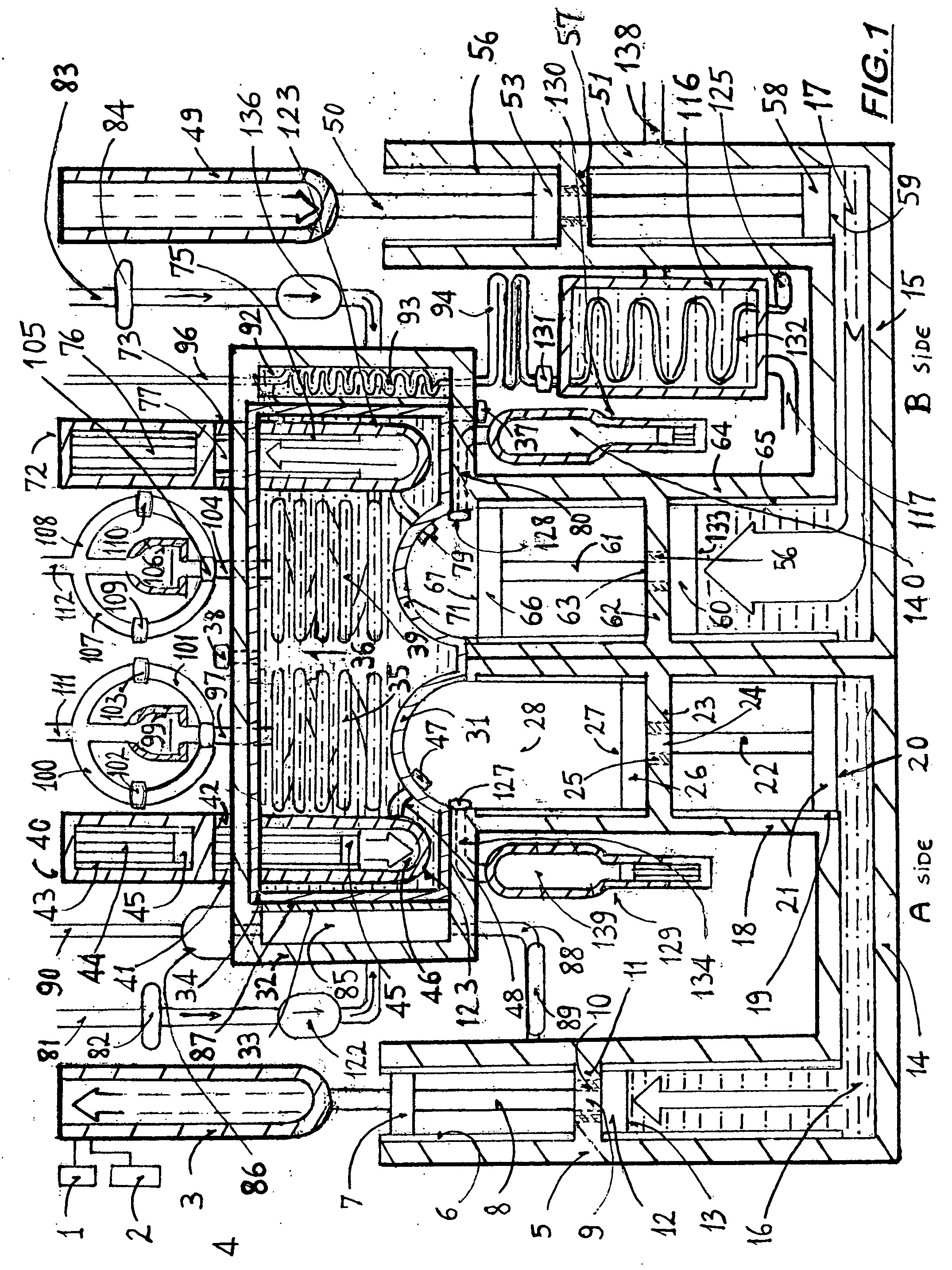

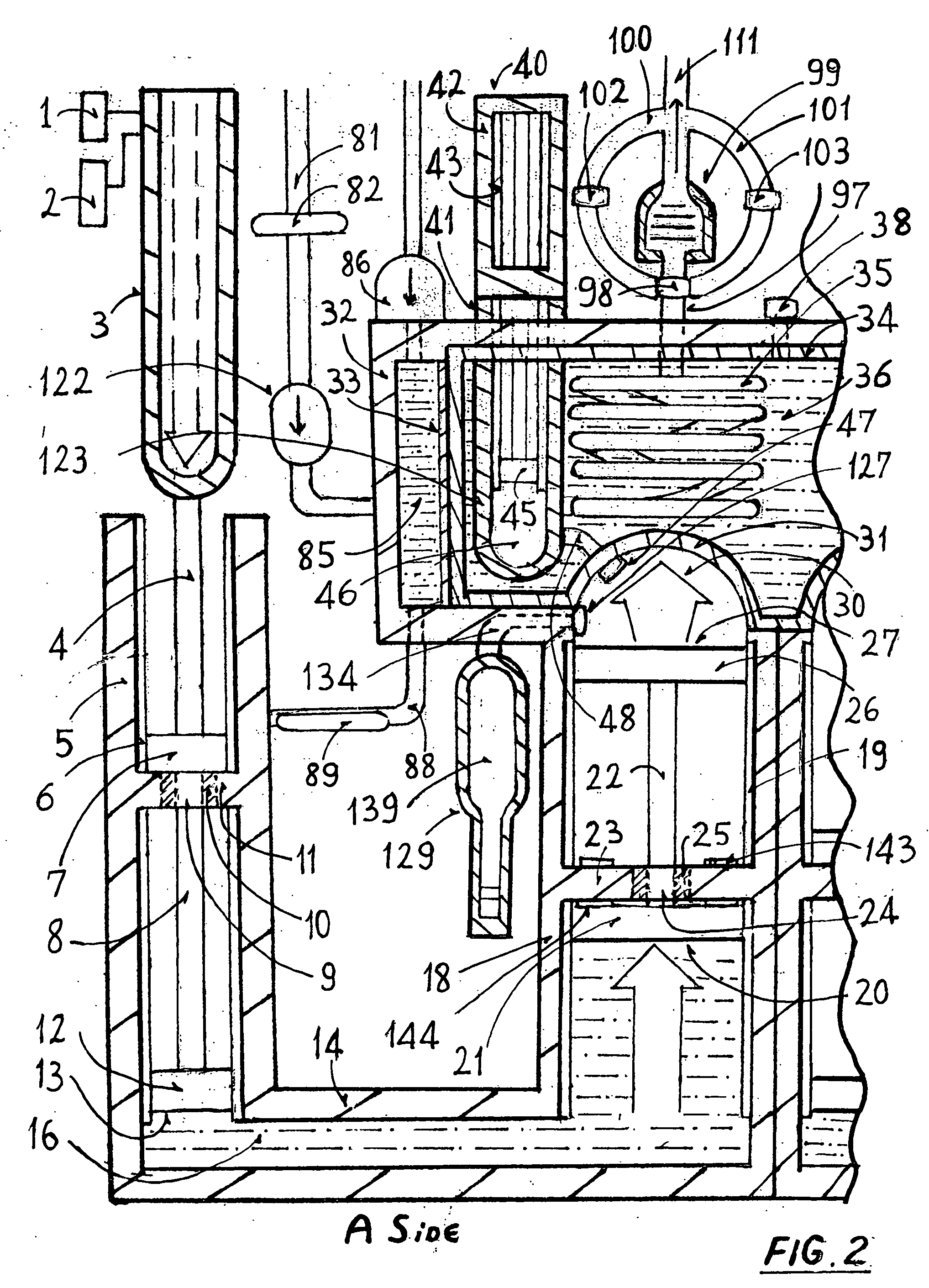

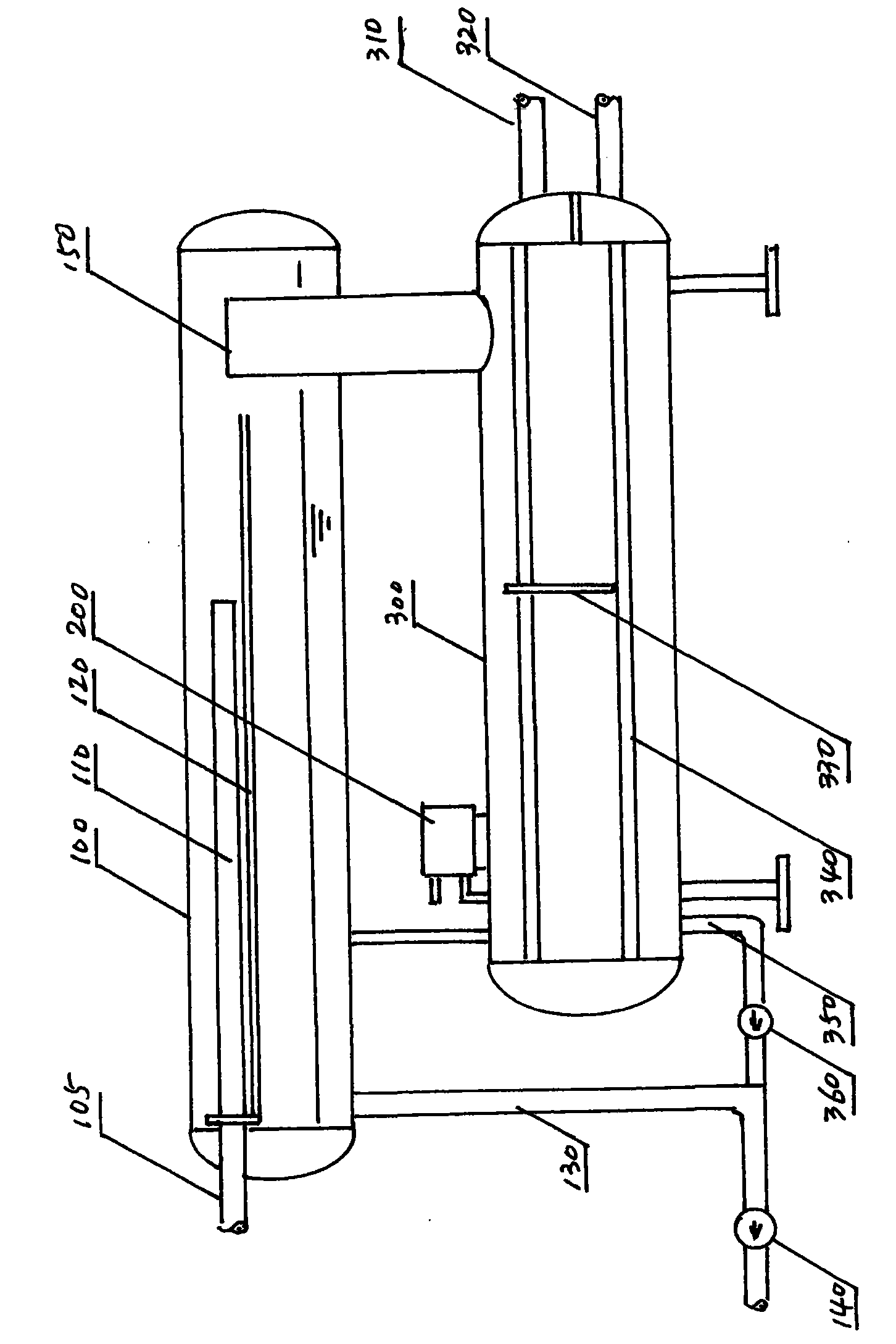

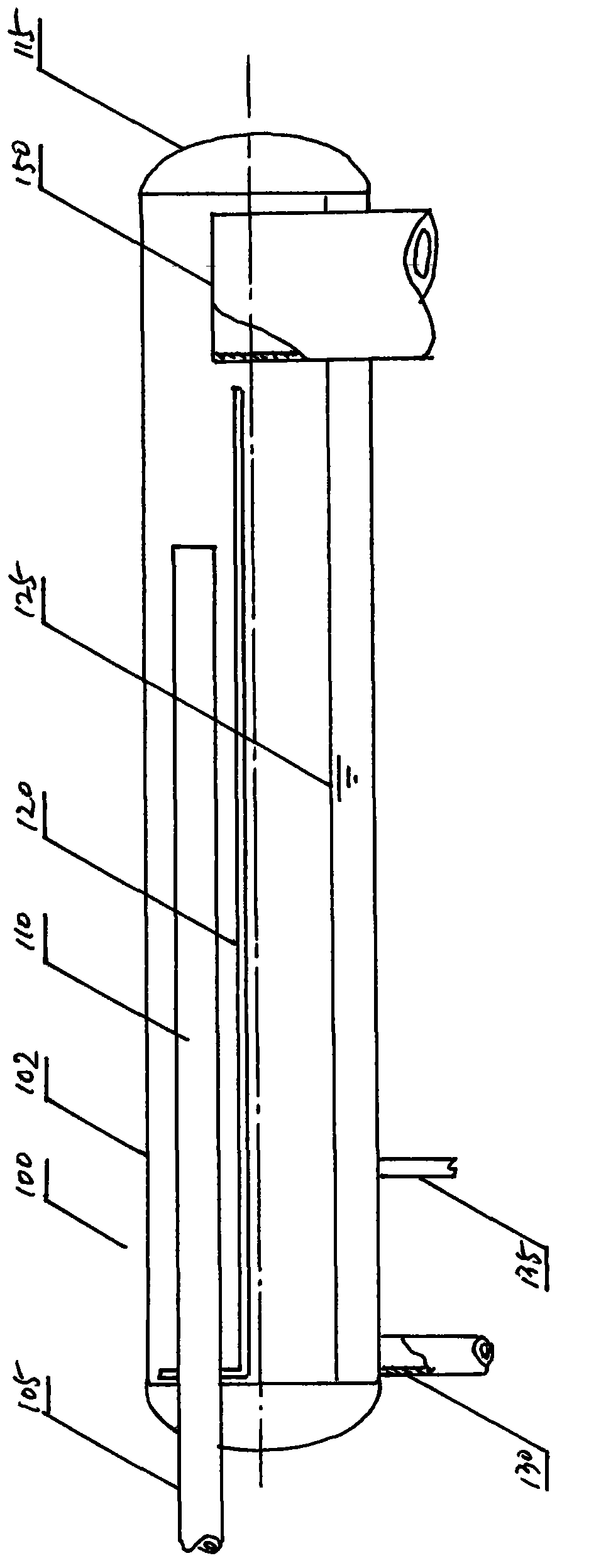

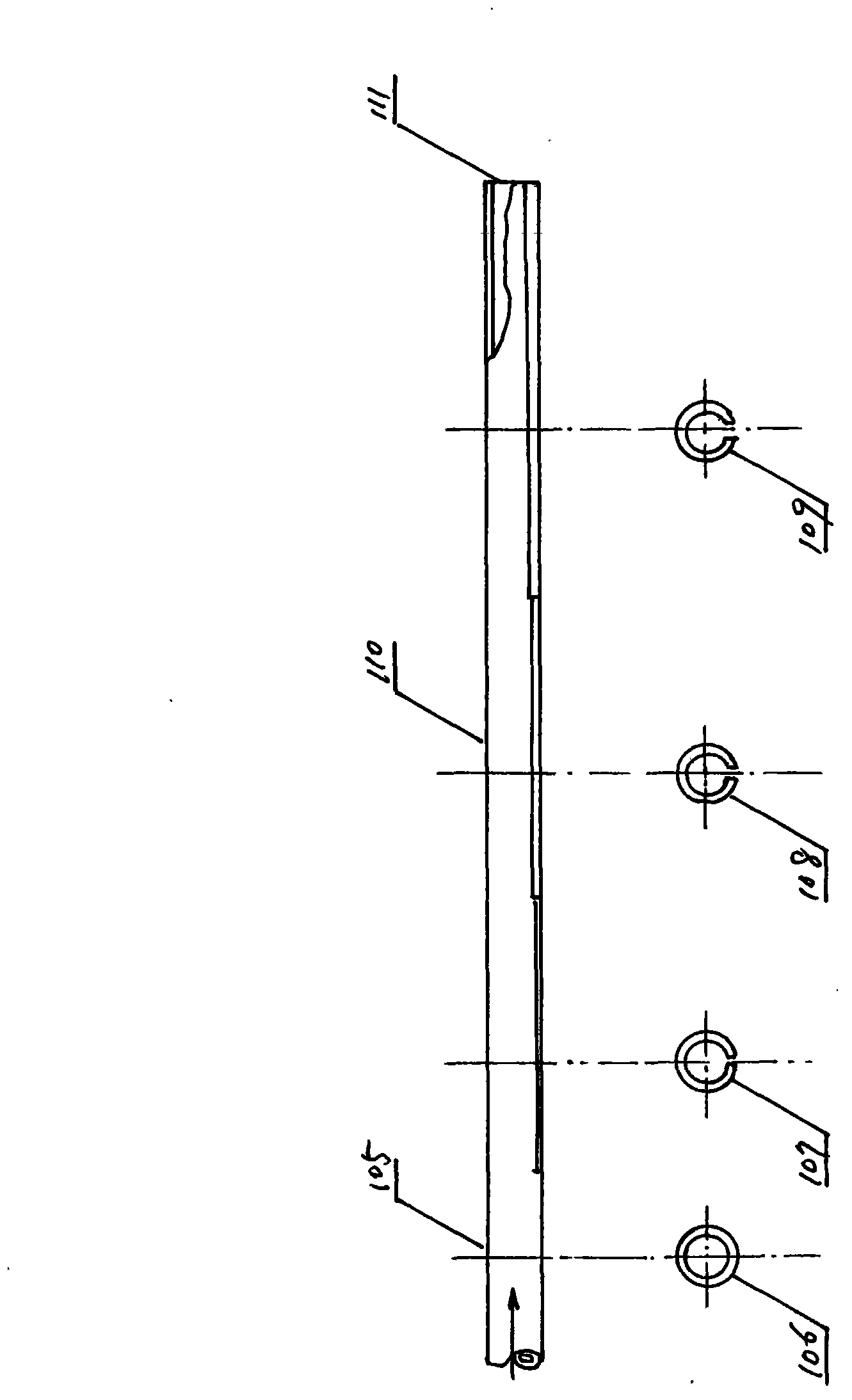

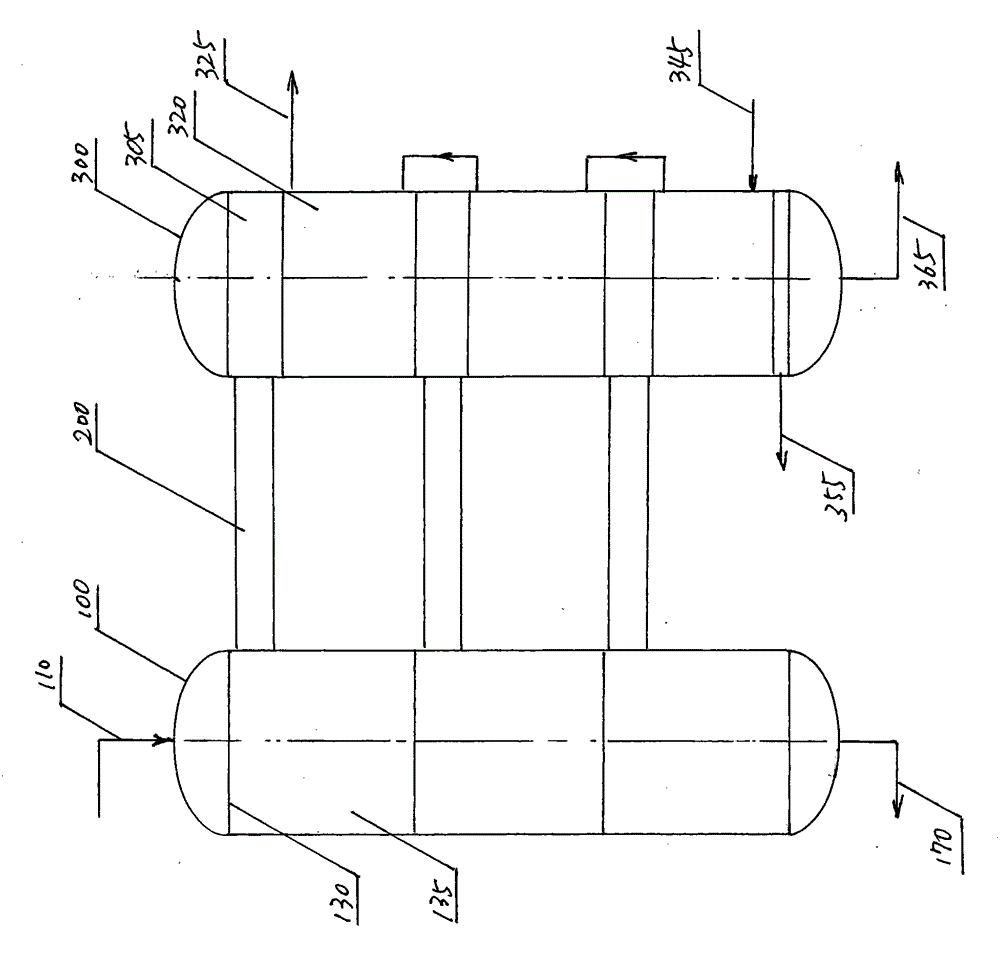

A system and method for converting kinetic energy into useable thermal energy by means of a gas compression based cogeneration. Kinetic forces applied, that are coupled to kinetic components of electro-mechanic thrusters 3, 49-input side, and upper small area pistons 7, 53-receiving side transmitted by shafts 4 and 50 get multiplied through Pascal hydraulic oil links 16 and 17, that are between the lower side small area pistons 12, 58 and lower side large area pistons 21, 60. At least two compression chambers are used to compress gas therein repeatedly to increase the pressure and temperature of the same. Auxiliary compressors 41, 73 help to increase temperature of compressed gas further. Said heat generated is conducted into a single liquid sodium thermal storage volume 36 that facilitates a highly stable thermal storage volume and contains working gas spiral sections 35, 39 circulating within. Steam 113 generated within spiral sections 35, 39 generates power in turbines 99, 106 and then heat residential and / or commercial buildings 115. Service hot-water is provided utilizing a water tank 85 and refrigerant coil circulation oil volume 92, both utilize thermal storage volume 36 waste heat by conduction for a triple integrated system. The system may also be combined with other power generation systems. In second embodiment 121 with more than two units of compression chambers and higher capacity, low cost electric power generated enables efficient hydrogen mass production. A thermo-physical cogeneration system with central heating means, and a cogeneration power plant 121 with hydrogen mass production and hydrogen storage capabilities; are presented as what are new in the art.

Owner:ZABTCIOGLU FIKRET M

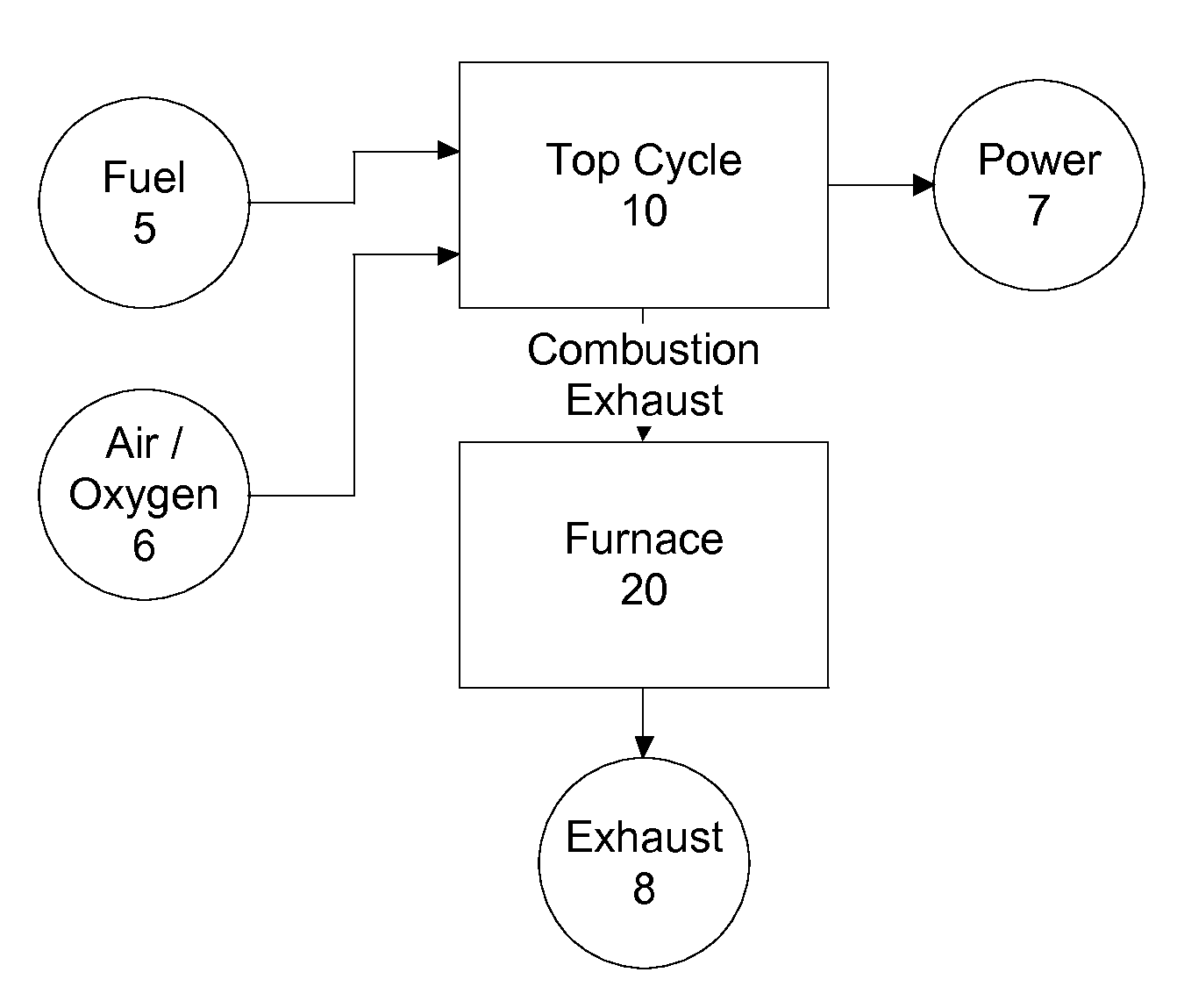

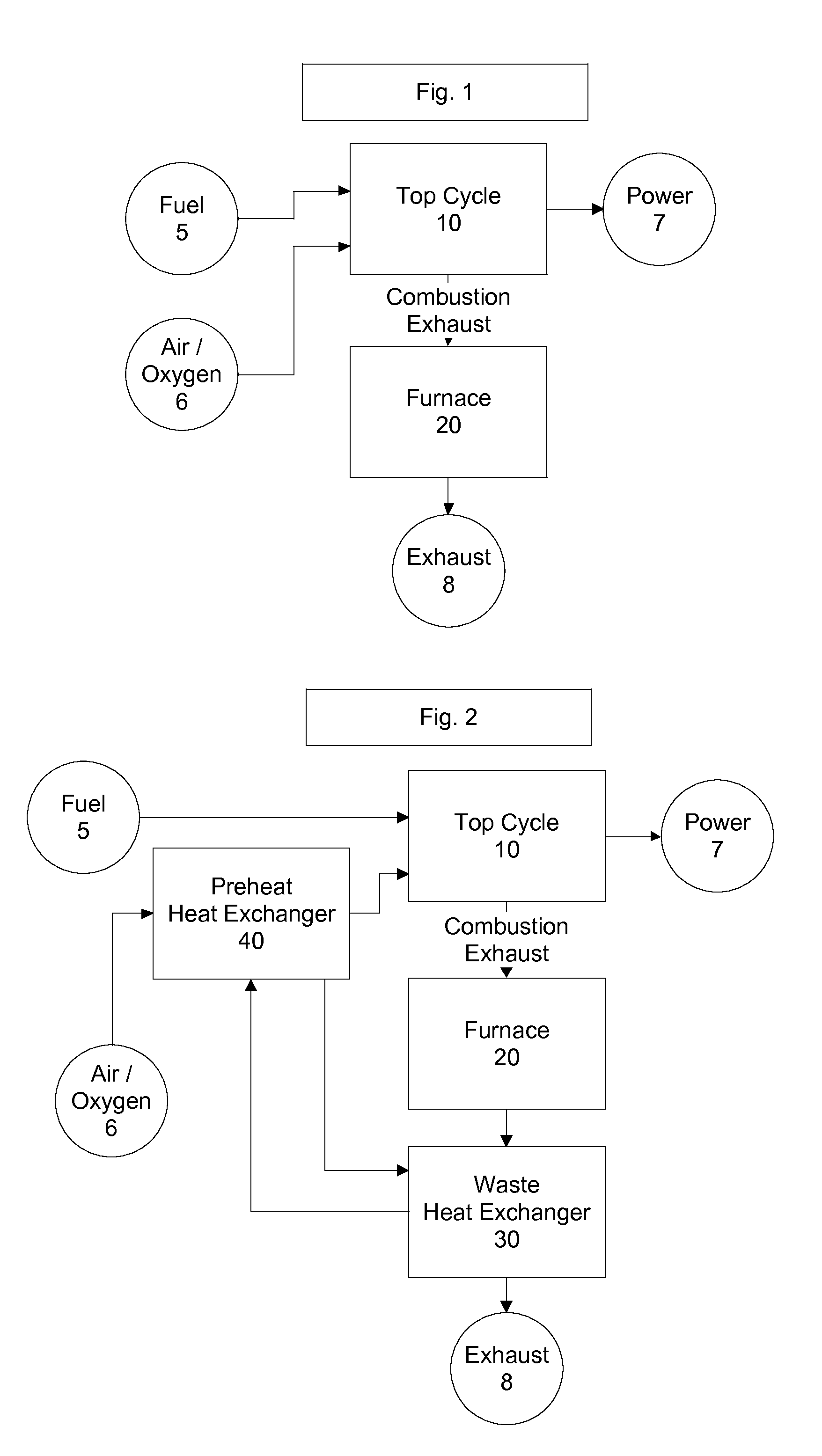

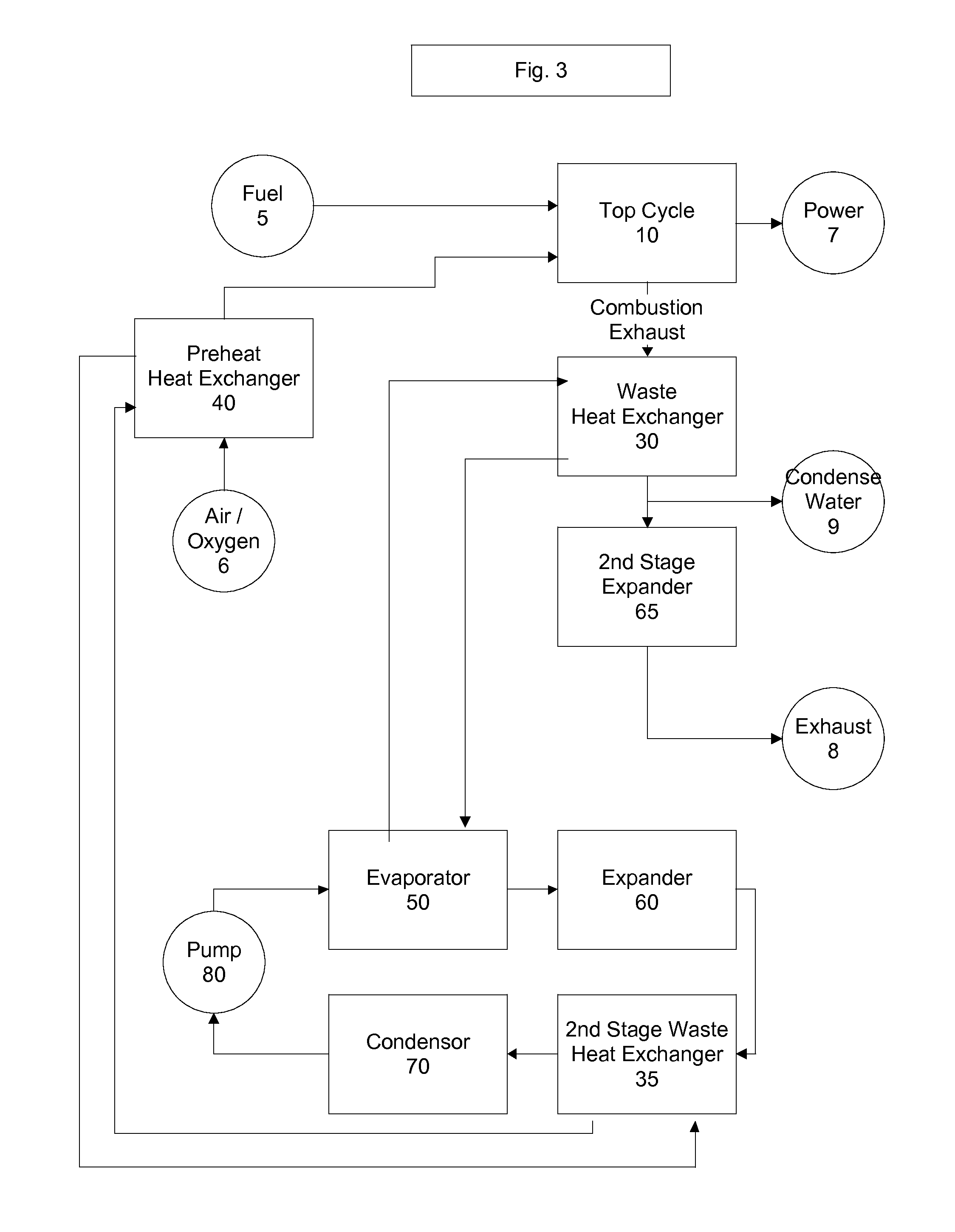

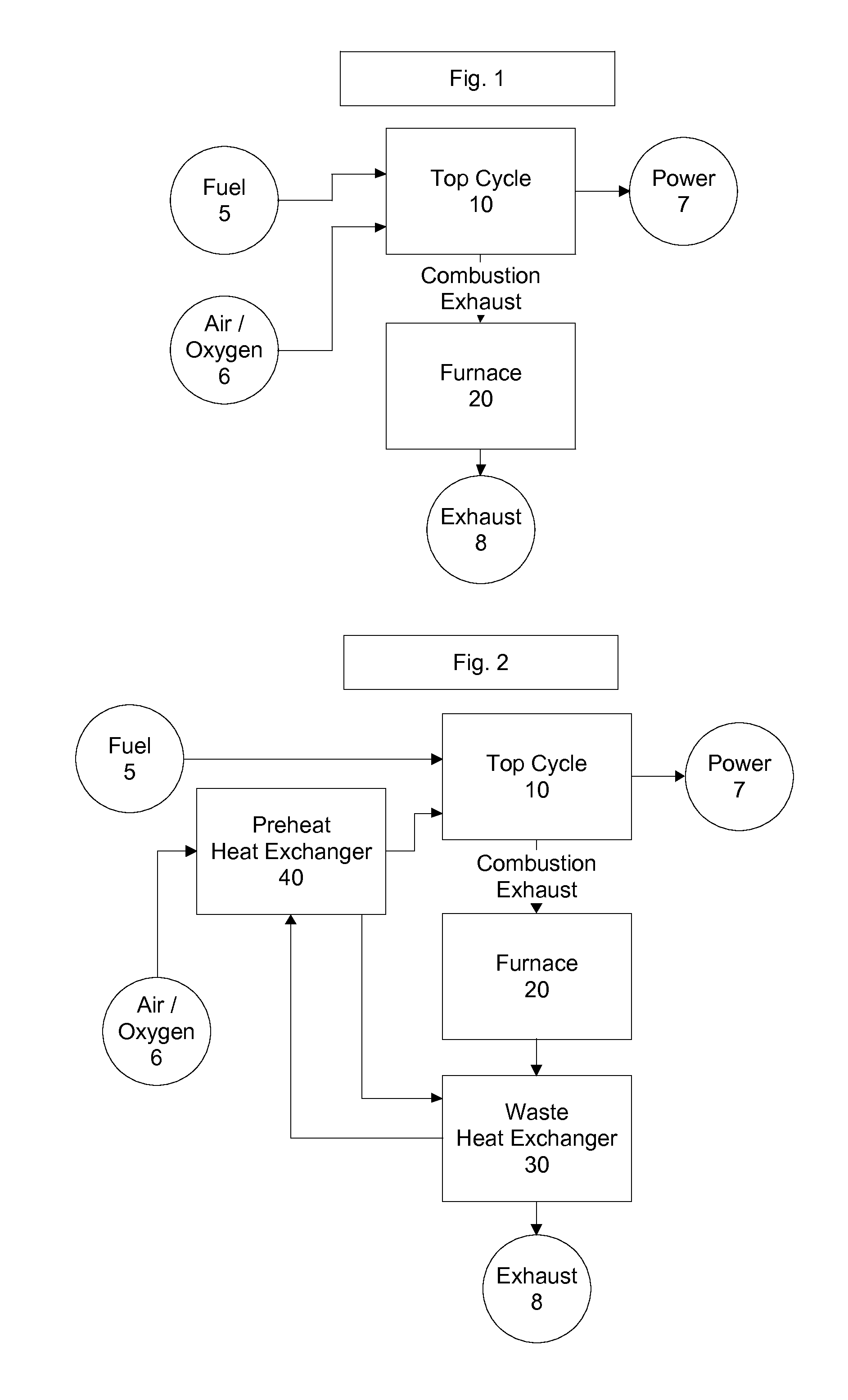

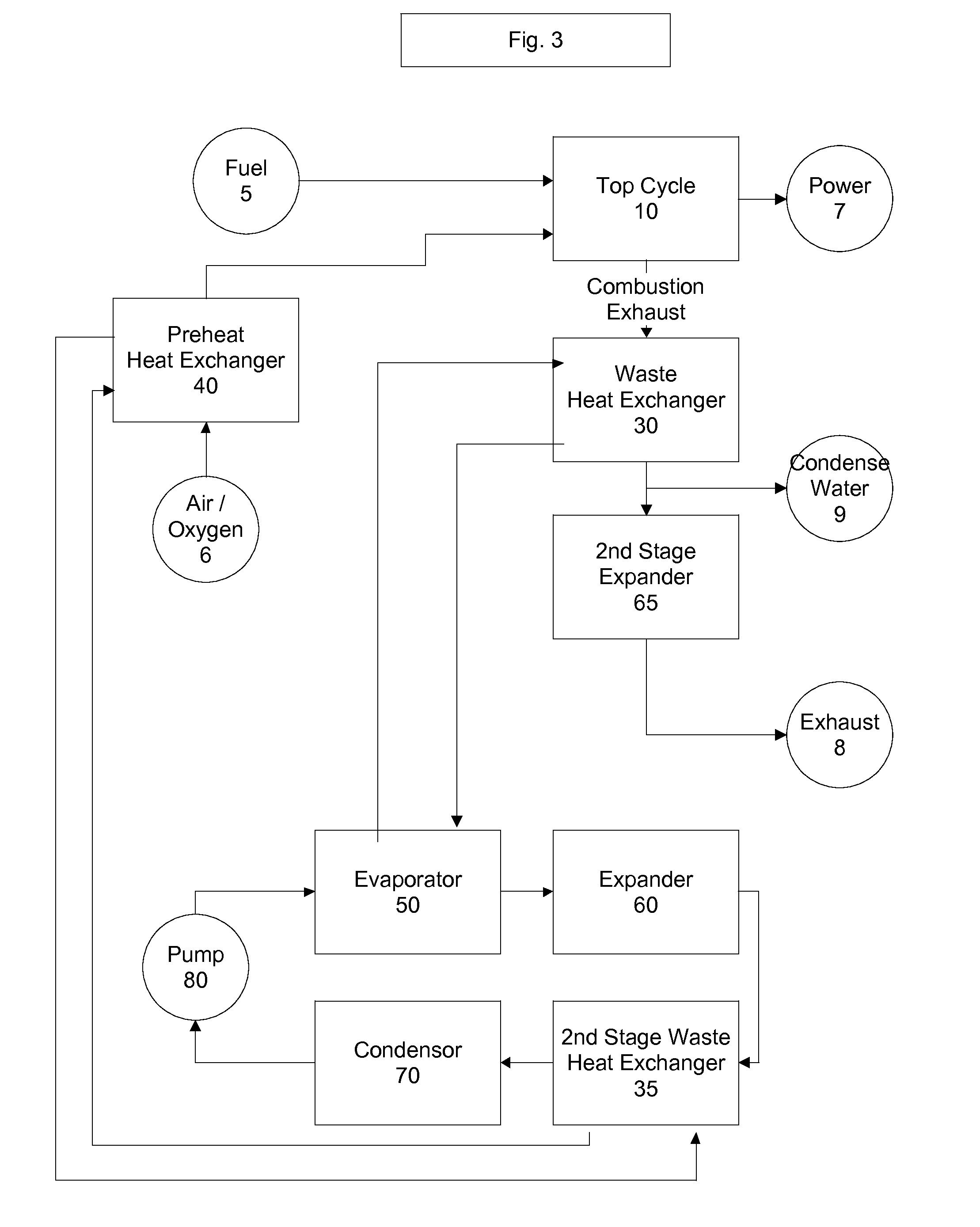

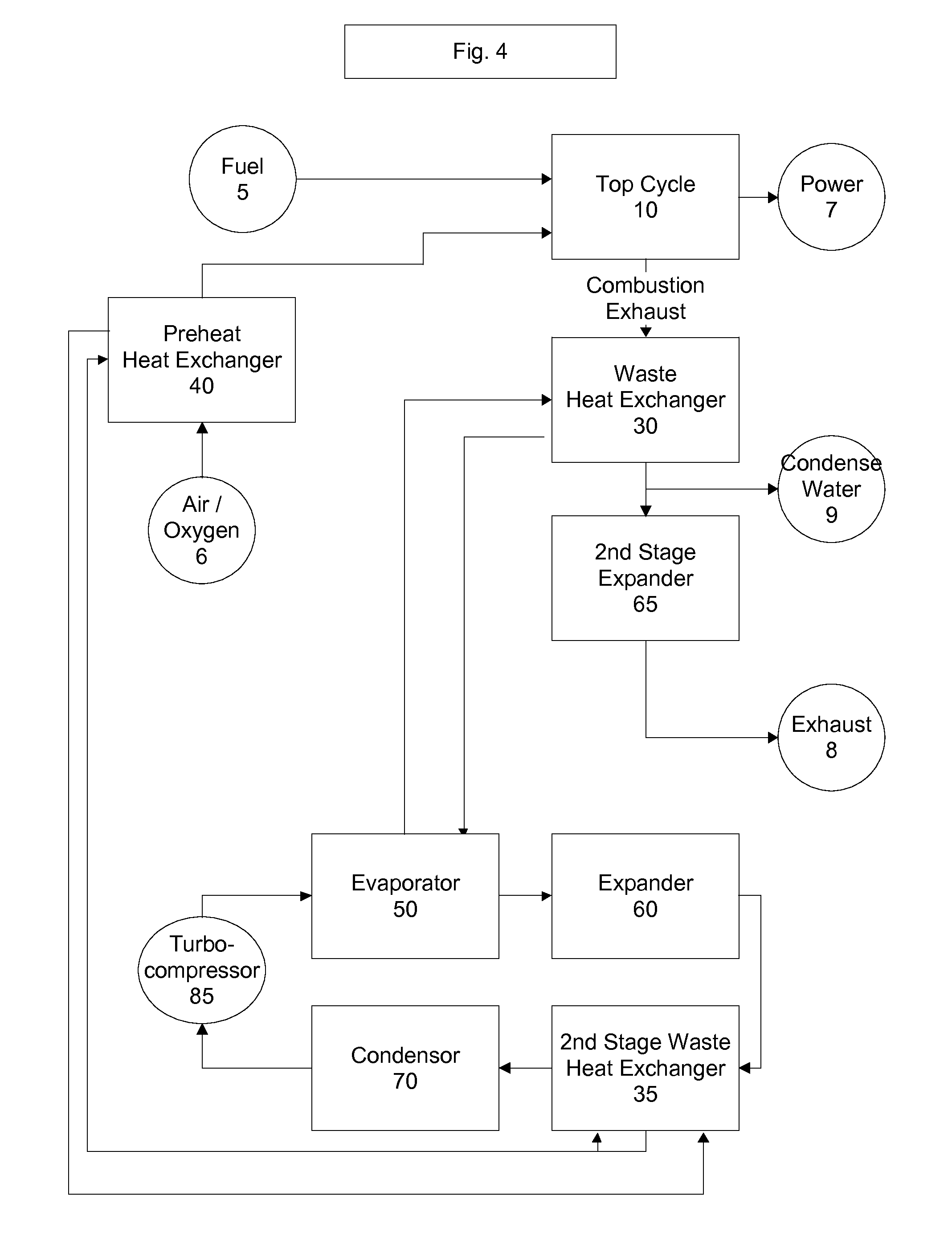

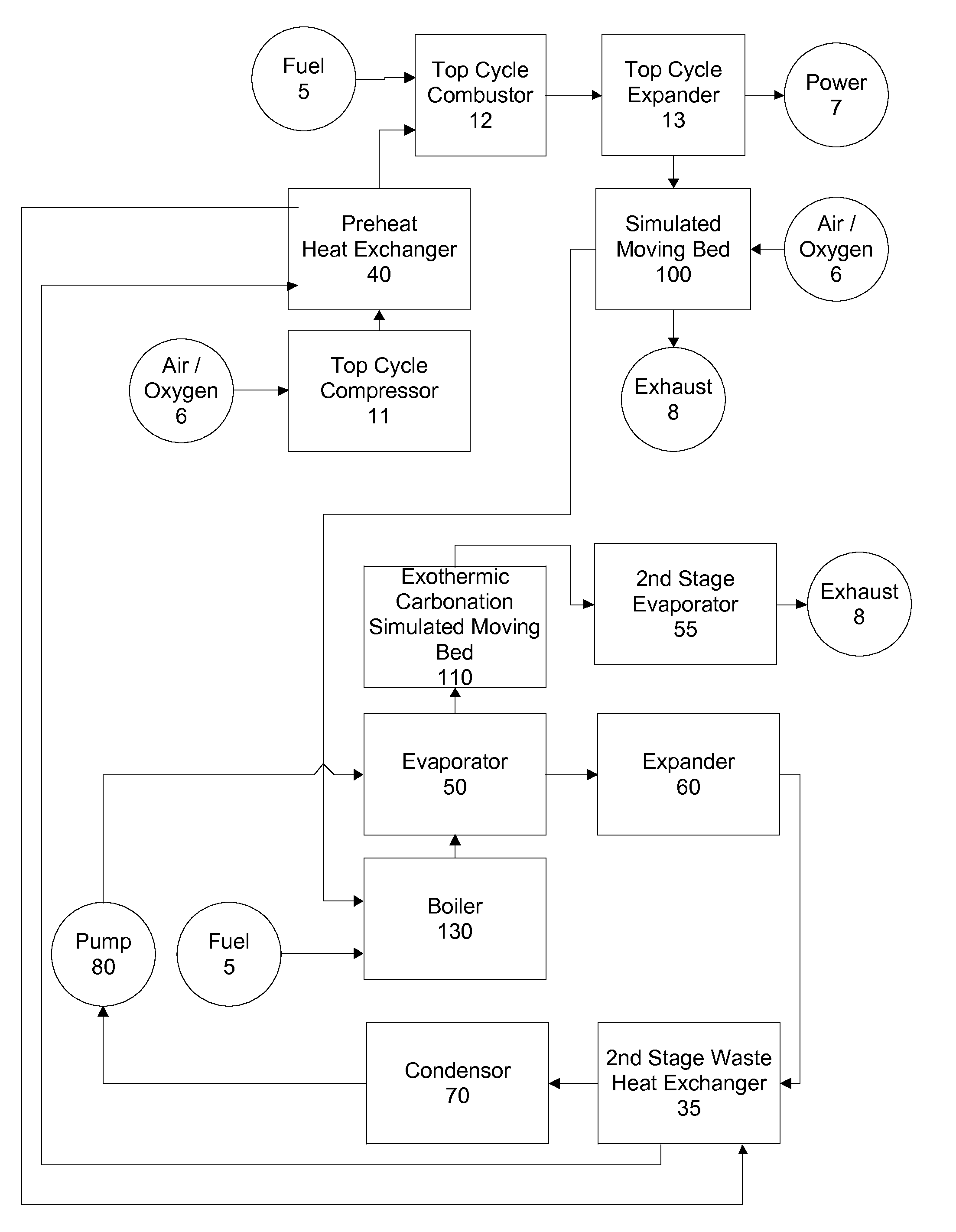

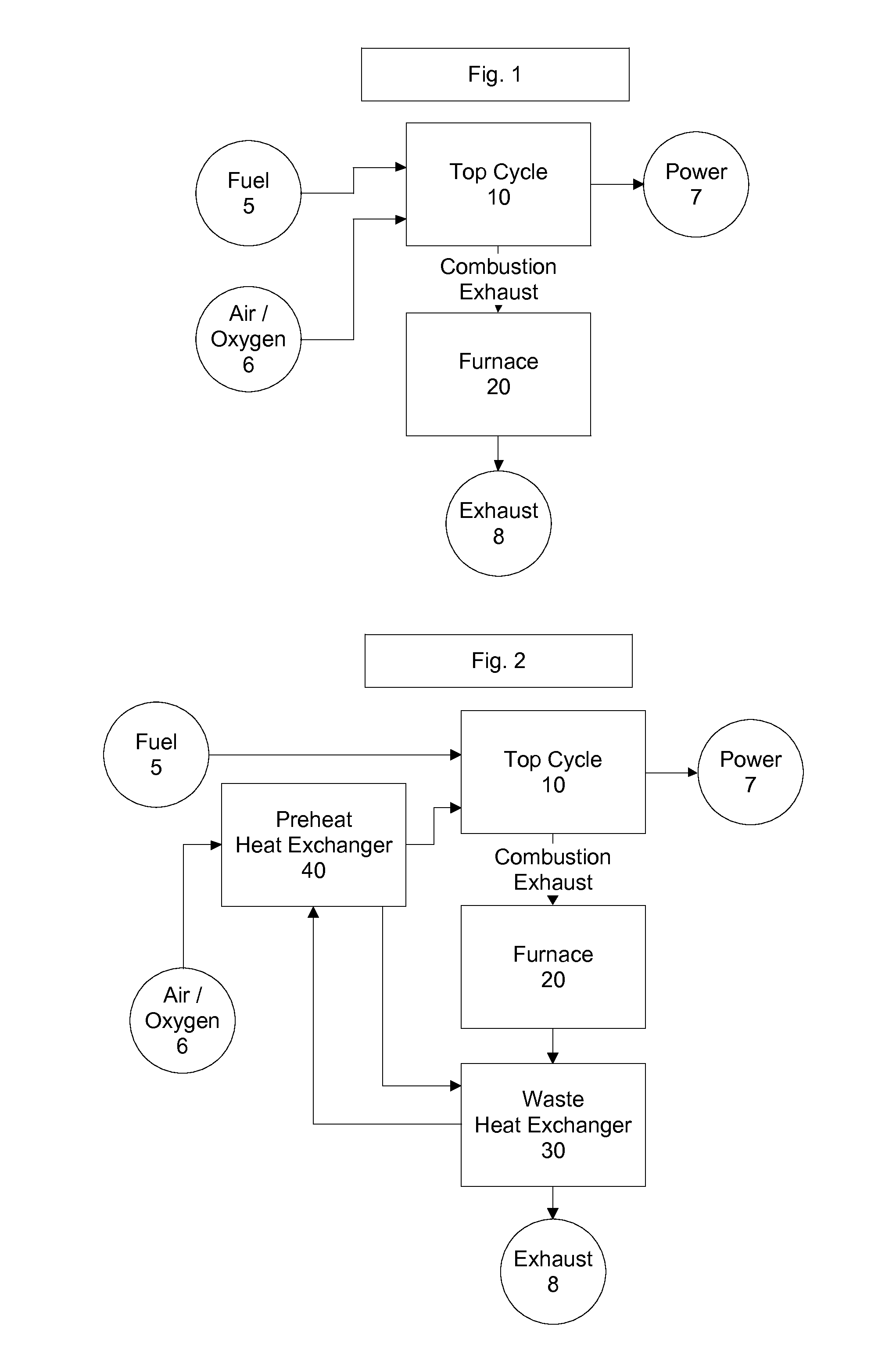

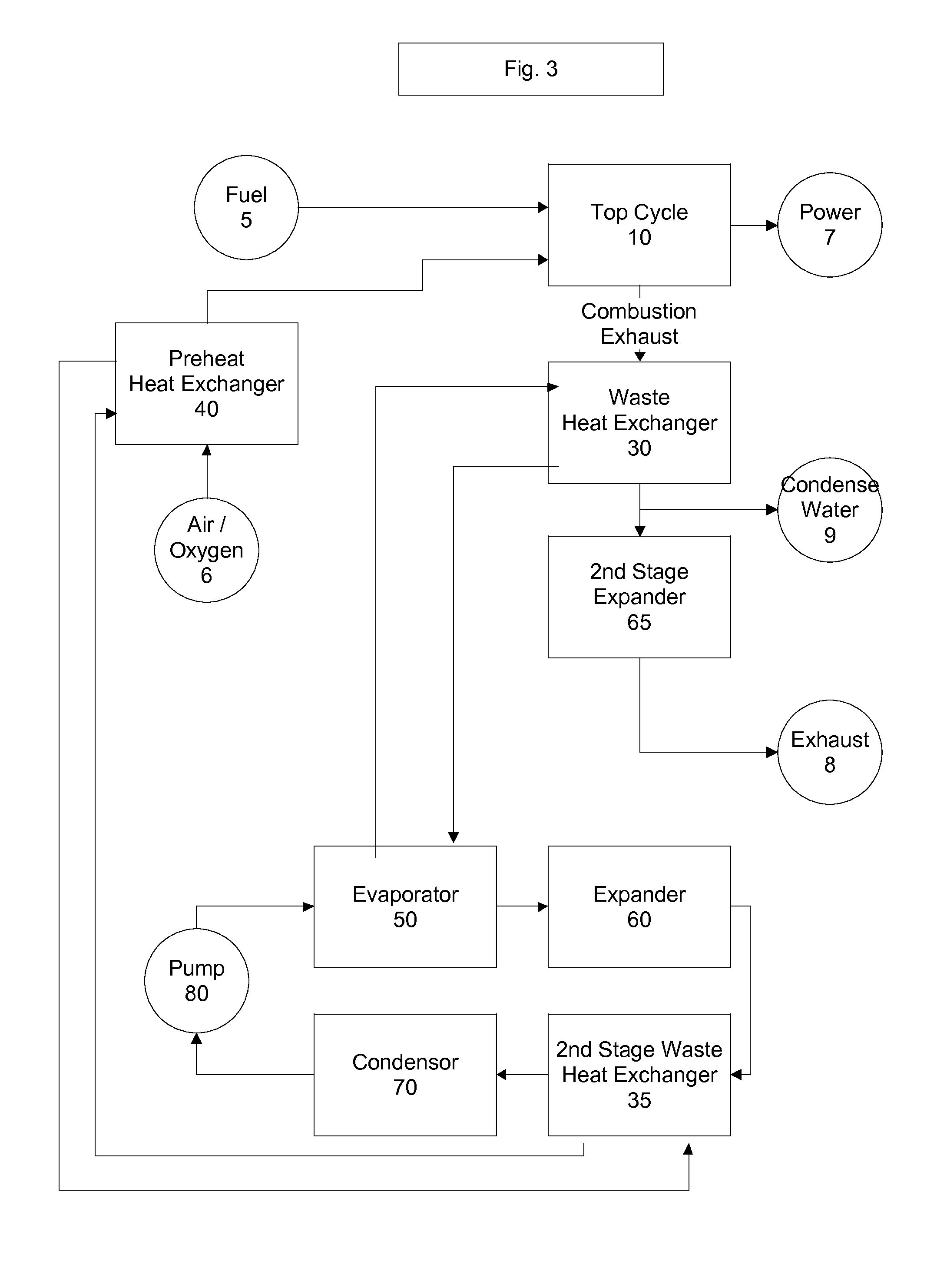

Top cycle power generation with high radiant and emissivity exhaust

The present invention generally relates to power generation methods and secondary processes requiring high radiant and emissivity homogeneous combustion to maximize production output. In one embodiment, the present invention relates to a top cycle power generator with combustion exhaust modified to have radiant flux in excess of 500 kW per square meter and emissivity greater than 0.90, and supercritical CO2 power generating cycle to maximize exergy efficiency.

Owner:GURIN MICHAEL

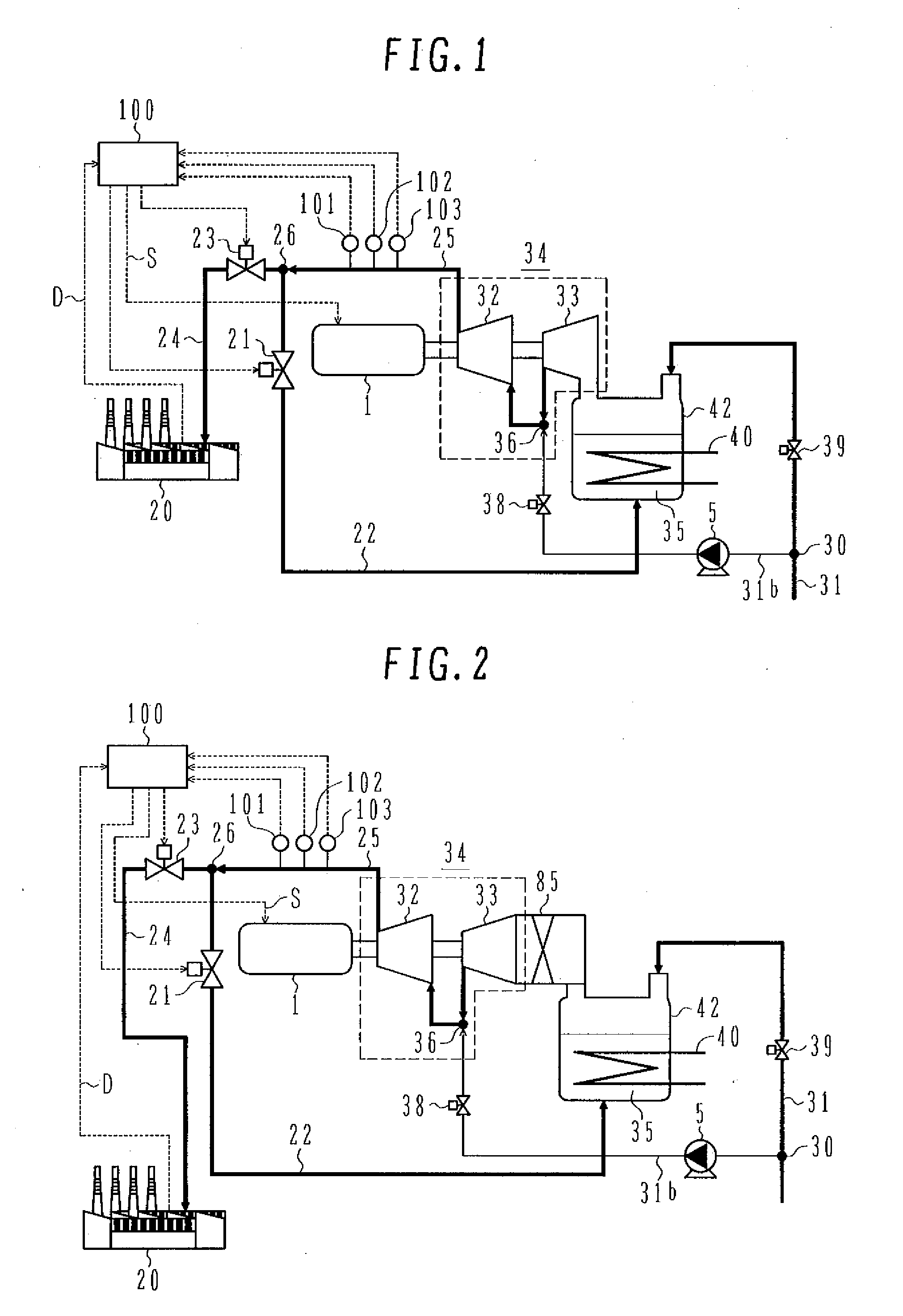

Heat pump system and heat pump operation method

InactiveUS20090126377A1Prevent surgeCompression machines with non-reversible cycleGas turbine plantsLiquid waterEngineering

A compact heat pump system and a heat pump operation method, which can avoid the occurrence of surging in a compressor at startup of a heat pump and can directly supply vapor of a working medium produced by the compressor to an external heat-utilizing facility. The heat pump system comprises an evaporator for recovering heat of an external heat source to a working medium supplied as liquid water from the exterior via a water feed channel, thereby evaporating the working medium, a compressor for compressing the working medium evaporated in the evaporator and increasing temperature of the evaporated working medium, and a driving unit for giving motive power to drive the compressor. The heat pump system further comprises a supply channel for supplying, as a heat source, vapor of the working medium having temperature increased by the compressor to an external heat-utilizing facility, and a return channel branched from the supply channel and introducing the working medium discharged from the compressor to the evaporator.

Owner:HITACHI LTD

Top cycle power generation with high radiant and emissivity exhaust

The present invention generally relates to power generation methods and secondary processes requiring high radiant and emissivity homogeneous combustion to maximize production output. In one embodiment, the present invention relates to a top cycle power generator with combustion exhaust modified to have radiant flux in excess of 500 kW per square meter and emissivity greater than 0.90, and supercritical CO2 power generating cycle to maximize energy efficiency.

Owner:GURIN MICHAEL

Top cycle power generation with high radiant and emissivity exhaust

The present invention generally relates to power generation methods and secondary processes requiring high radiant and emissivity homogeneous combustion to maximize production output. In one embodiment, the present invention relates to a top cycle power generator with combustion exhaust modified to have radiant flux in excess of 500 kW per square meter and emissivity greater than 0.90, and supercritical CO2 power generating cycle to maximize exergy efficiency.

Owner:GURIN MICHAEL

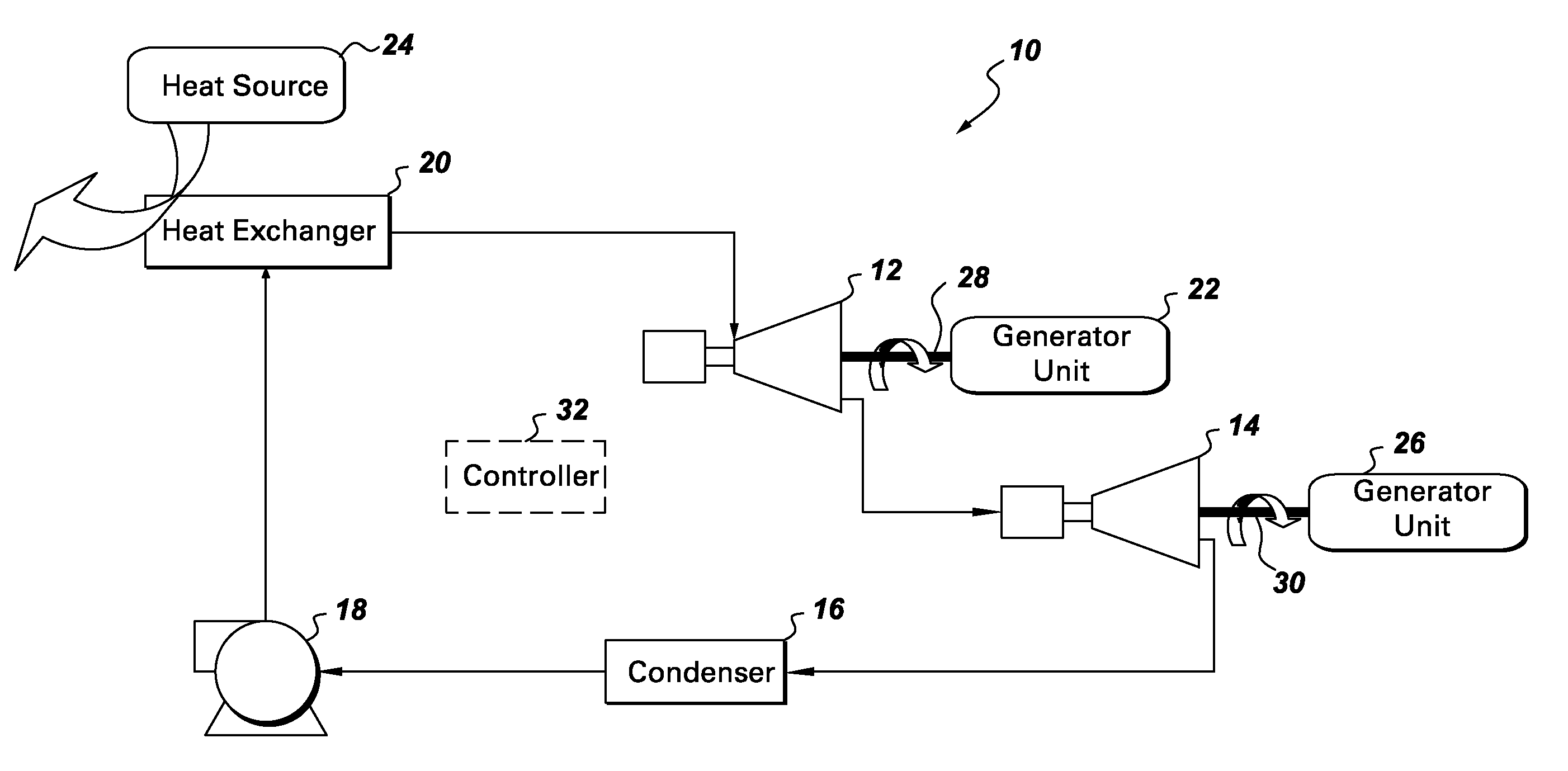

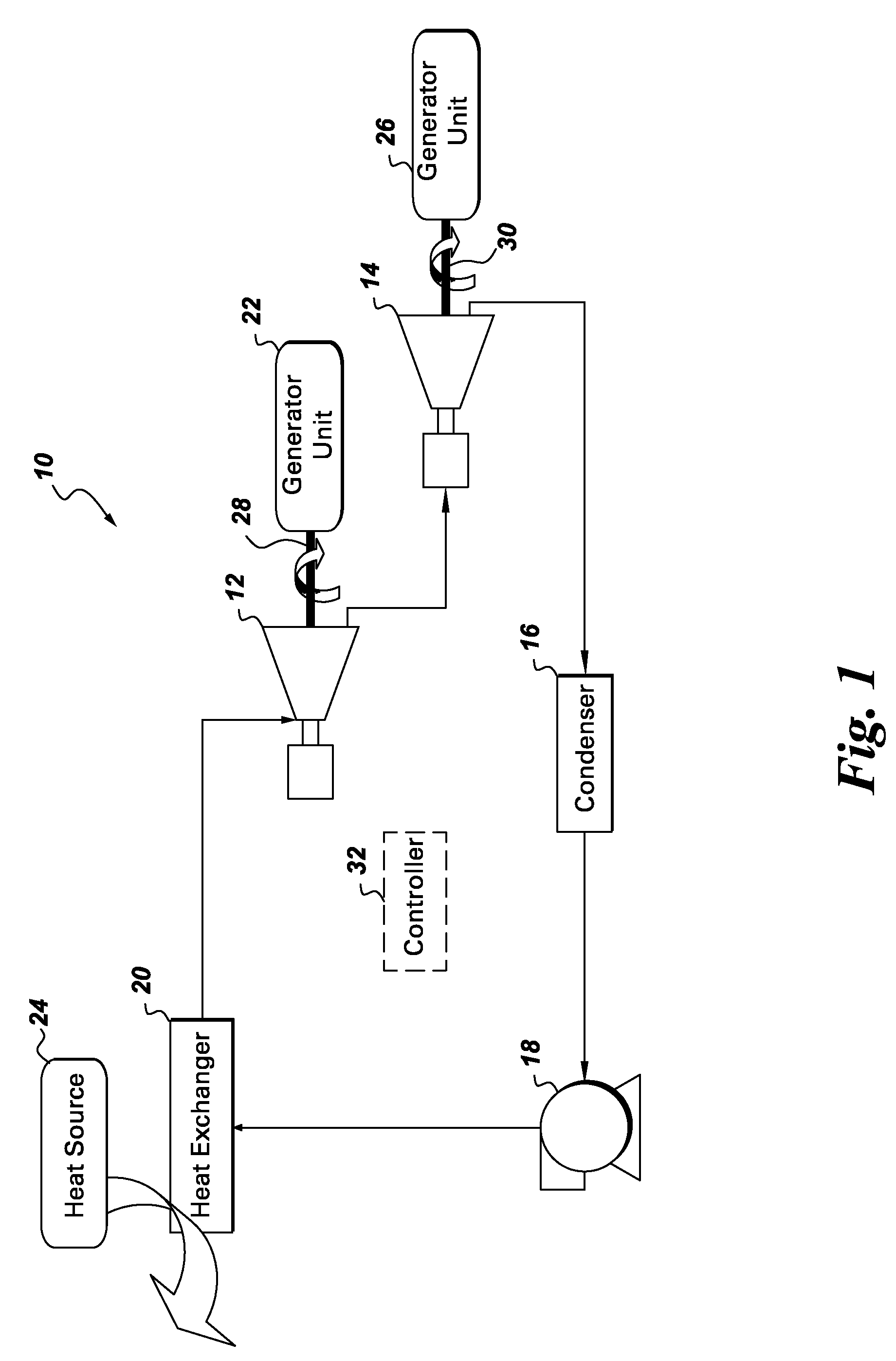

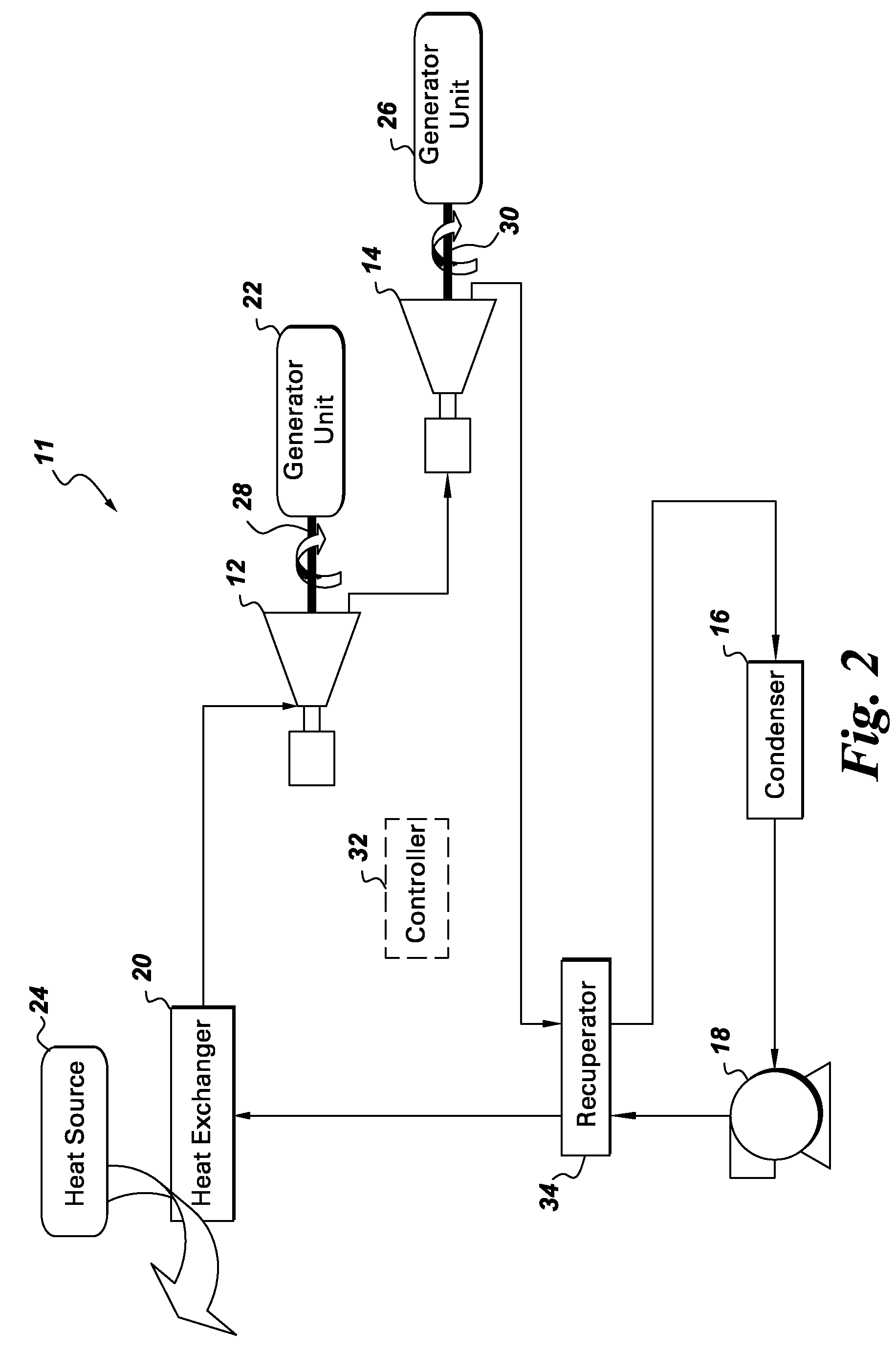

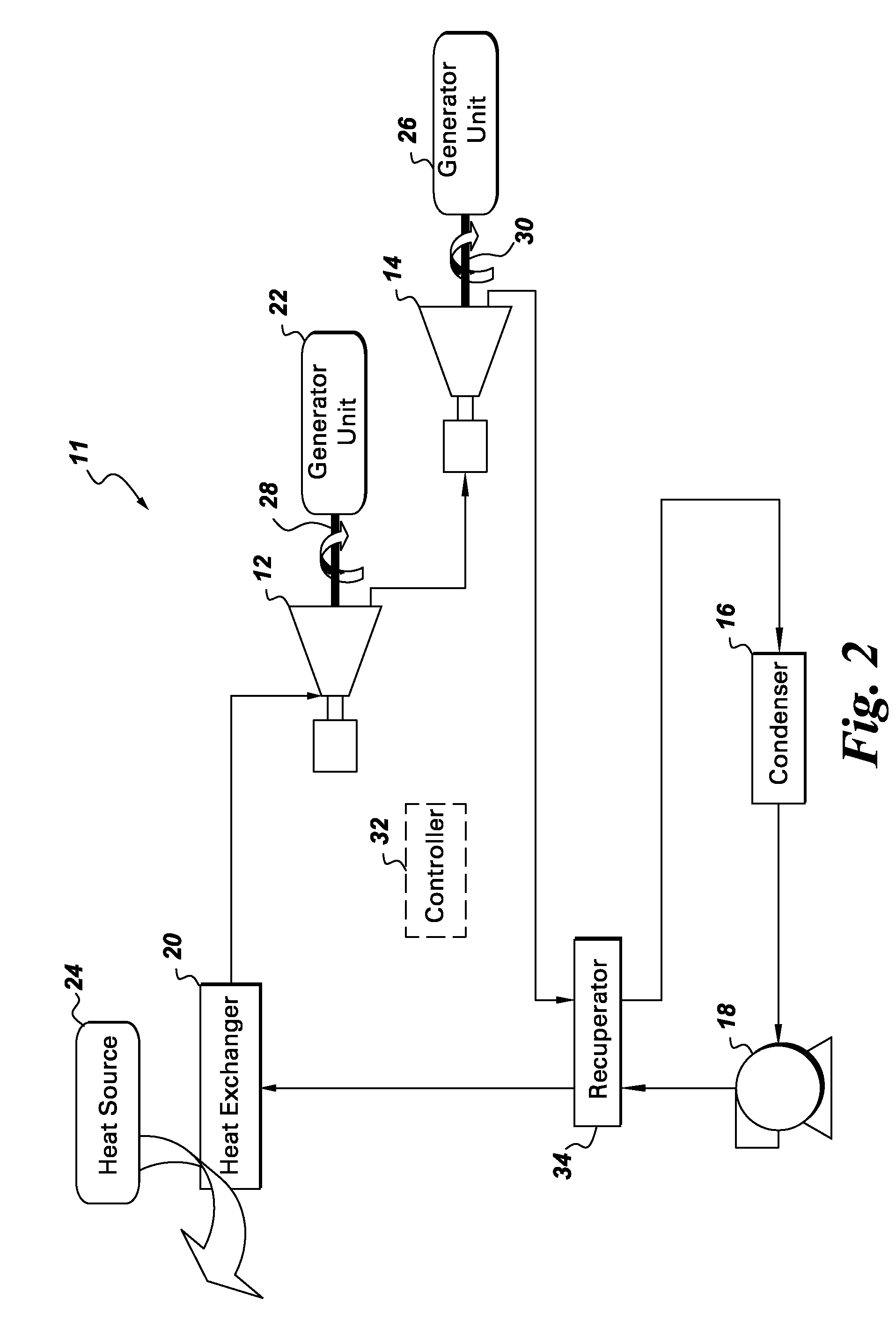

Two-phase expansion system and method for energy recovery

A closed loop expansion system for energy recovery includes a heat exchanger for using heat from a heat source to heat a working fluid of the closed loop expansion system to a temperature below the vaporization point of the working fluid; a radial inflow expander for receiving the working fluid from the heat exchanger and for expanding and partially vaporizing the working fluid; a screw expander for receiving the working fluid from the radial inflow turbine and for further expanding and vaporizing the working fluid; and a condenser for receiving the working fluid from the screw expander and for liquefying the working fluid.

Owner:AI ALPINE US BIDCO INC

Start-up method with circulating-stove-water pump monotube boiler near steam heating boilers

ActiveCN101135433AShorten oiling timeReduce fuel consumptionSteam generationEngineeringHigh pressure

This invention declares a starting process of once-through boiler with by neighboring steam heating in which the high pressure heater is connected by the pipeline receiving exogenous heating steam. The mentioned process includes: heating the water in the unit boiler with the exogenous steam through the high pressure heater, heating the heat delivery surface of the boiler indirectly when starting up at cold, warm or hot status, starting the boiler water circulating pump and air-gas system when the temperature is close to the saturation temperature of the exogenous steam, ignition of the boiler, increasing the thermal load with bypass system after the is started, switching off the fuel when the thermal load of the coal exceeds the minimum oil-break thermal load and switching to the general starting process; when starting at the extreme hot status, ignition of the boiler after purging, after the coal pulverizing system is started, switching off the fuel when the thermal load of the coal exceeds the minimum oil-break thermal load and switching to the general starting process. The starting process will shorten the starting duration, and save fuel, coal and water.

Owner:冯伟忠

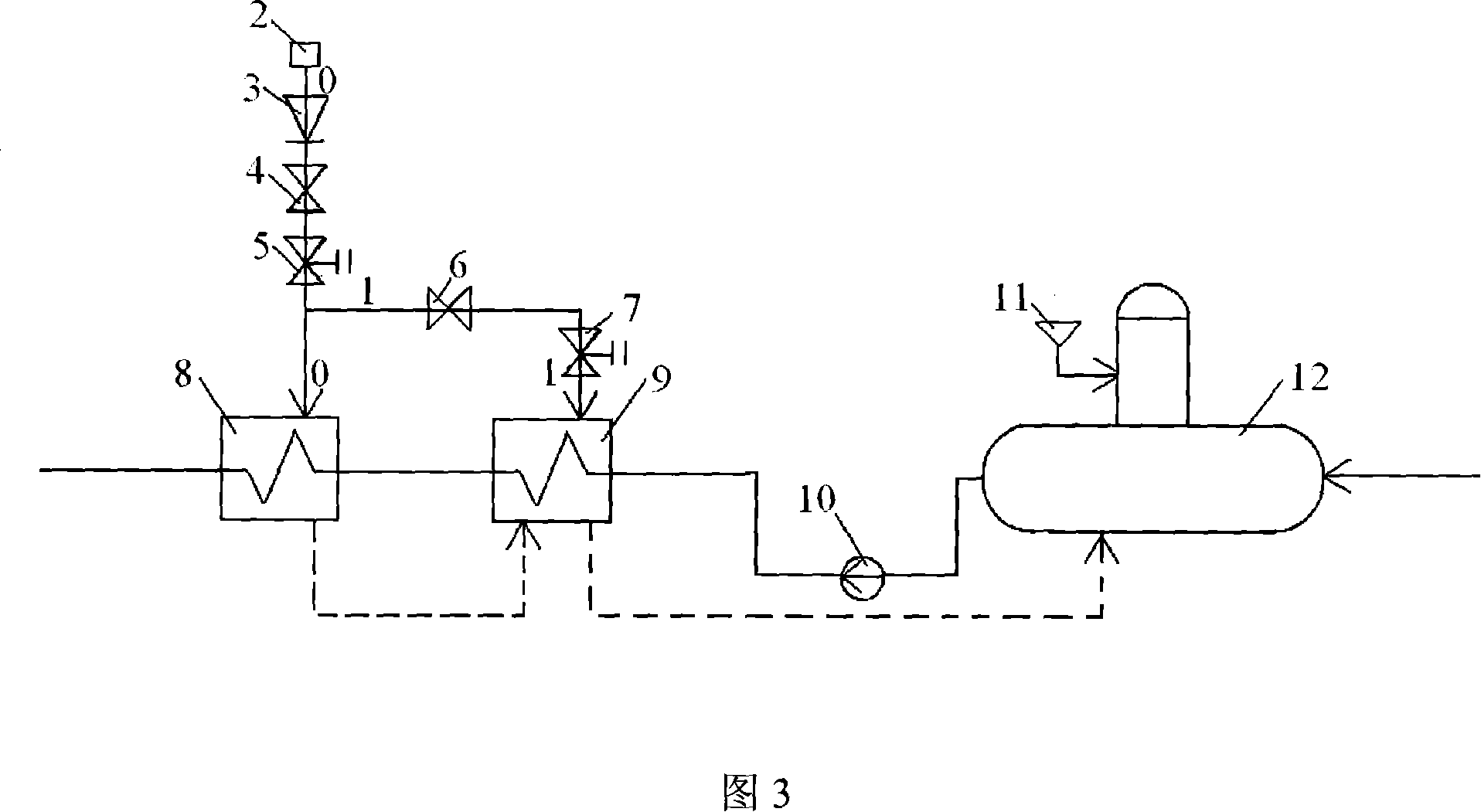

Combined cooling, heating and power supply system

The invention discloses a combined cooling, heating and power supply system. The combined cooling, heating and power supply system is characterized by being formed through treating a SOFC / GT hybrid power generation system as a reference system and introducing CO2 circulation, ORC circulation and a LNG cold energy utilization system. According to the combined cooling, heating and power supply system, a SOFC / GT serves as a prime mover, high-temperature waste heat, medium-temperature waste heat and low-temperature waste heat of a recovery system of the CO2 circulation and the ORC circulation areutilized correspondingly, and an LNG is used as a cold source for the CO2 circulation and the ORC circulation, and therefore, external cooling (air conditioning and refrigeration), external heating, external power supply, external natural gas supply and external supply of ice and dry ice can be achieved; and the low-carbon emission of the system is realized by condensing and separating CO2 in a flue gas, the available energy loss of the combined supply system can be effectively reduced, gradient and efficient utilization of energy is achieved, and the good energy-saving and emission-reducing effects are achieved.

Owner:SHANDONG UNIV

Heat pump system and heat pump operation method

InactiveUS20070000267A1Prevent surgeEnergy recuperation in distillationSteam generationLiquid waterEngineering

A compact heat pump system and a heat pump operation method employs an evaporator for recovering heat of an external heat source to a working medium supplied as liquid water from the exterior via a water feed channel, thereby evaporating the working medium, a compressor for compressing the working medium evaporated in the evaporator and increasing temperature of the evaporated working medium, and a driving unit for giving motive power to drive the compressor. The heat pump system further includes a supply channel for supplying, as a heat source, vapor of the working medium having a temperature increased by the compressor to an external heat-utilizing facility, and a return channel branched from the supply channel and introducing the working medium discharged from the compressor to the evaporator.

Owner:HITACHI LTD

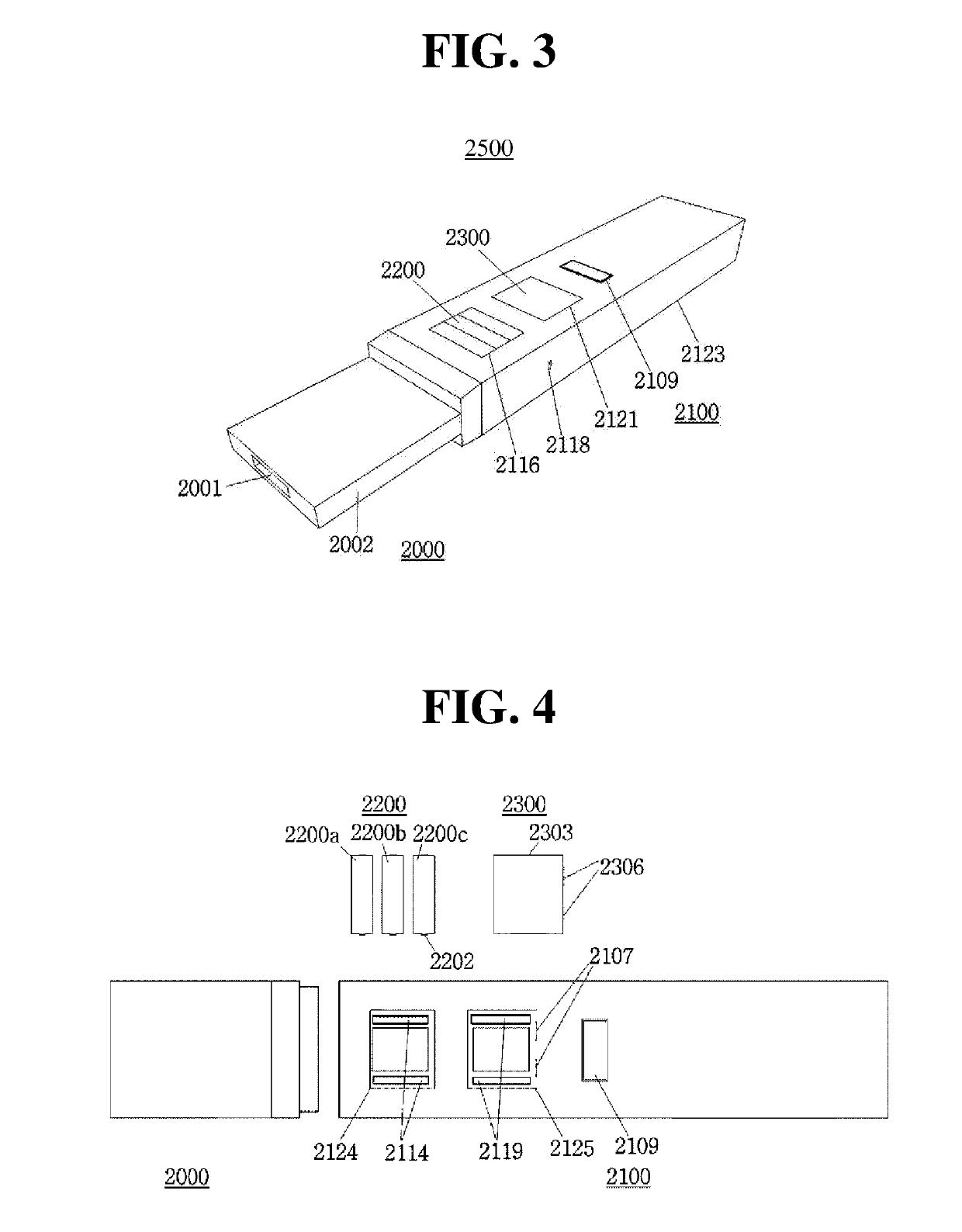

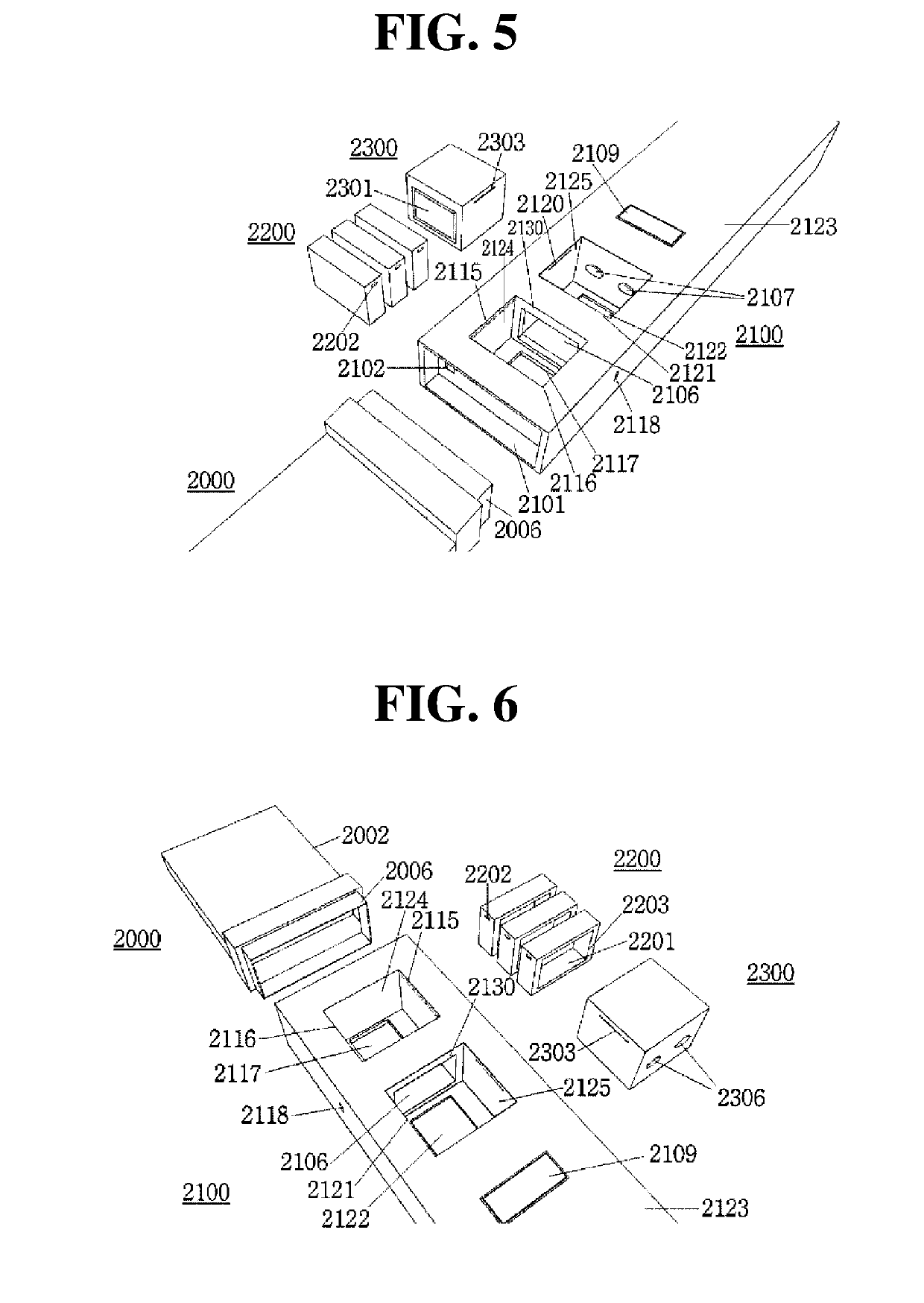

Modularized vaporizer

PendingUS20190142071A1Suppress generationAvoid inconvenienceTobacco treatmentCigar manufactureComputer moduleLight beam

The present invention relates to a modularized vaporizer, which enables a fuel module, a heating module, or a vaporizing module to be coupled and separated, in a drawer manner, to and from a body portion housing since a fuel module chamber, a heating module chamber, or a vaporizing module chamber is provided in the body portion housing. The modularized vaporizer reduces the carbonization of fuel or an absorbent member since the fuel or a surface of the absorbent member is uniformly heated (irradiation) by heating energy (light, beam, or heat) emitted (irradiation) from a heating member of the heating module.

Owner:LV LAB

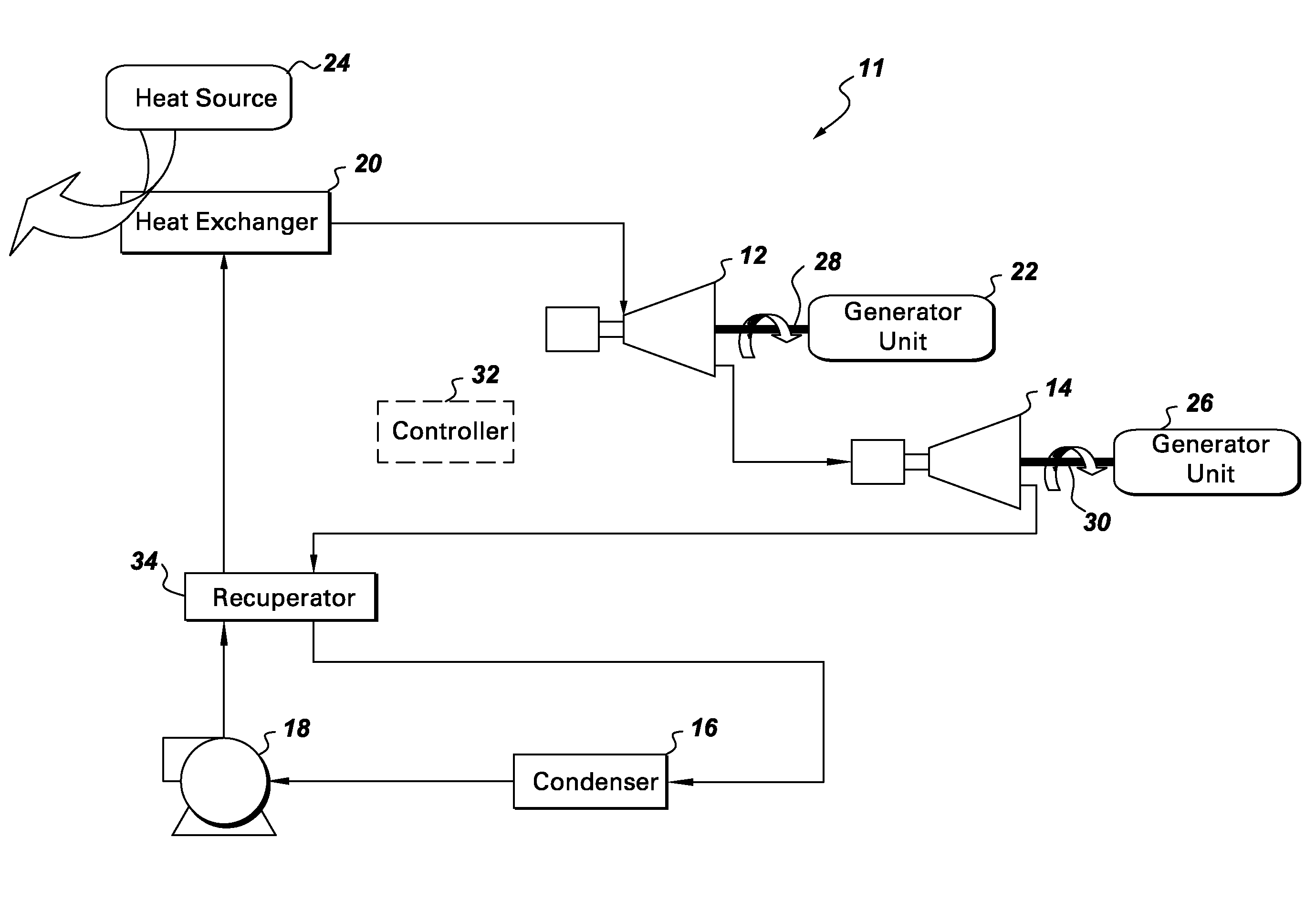

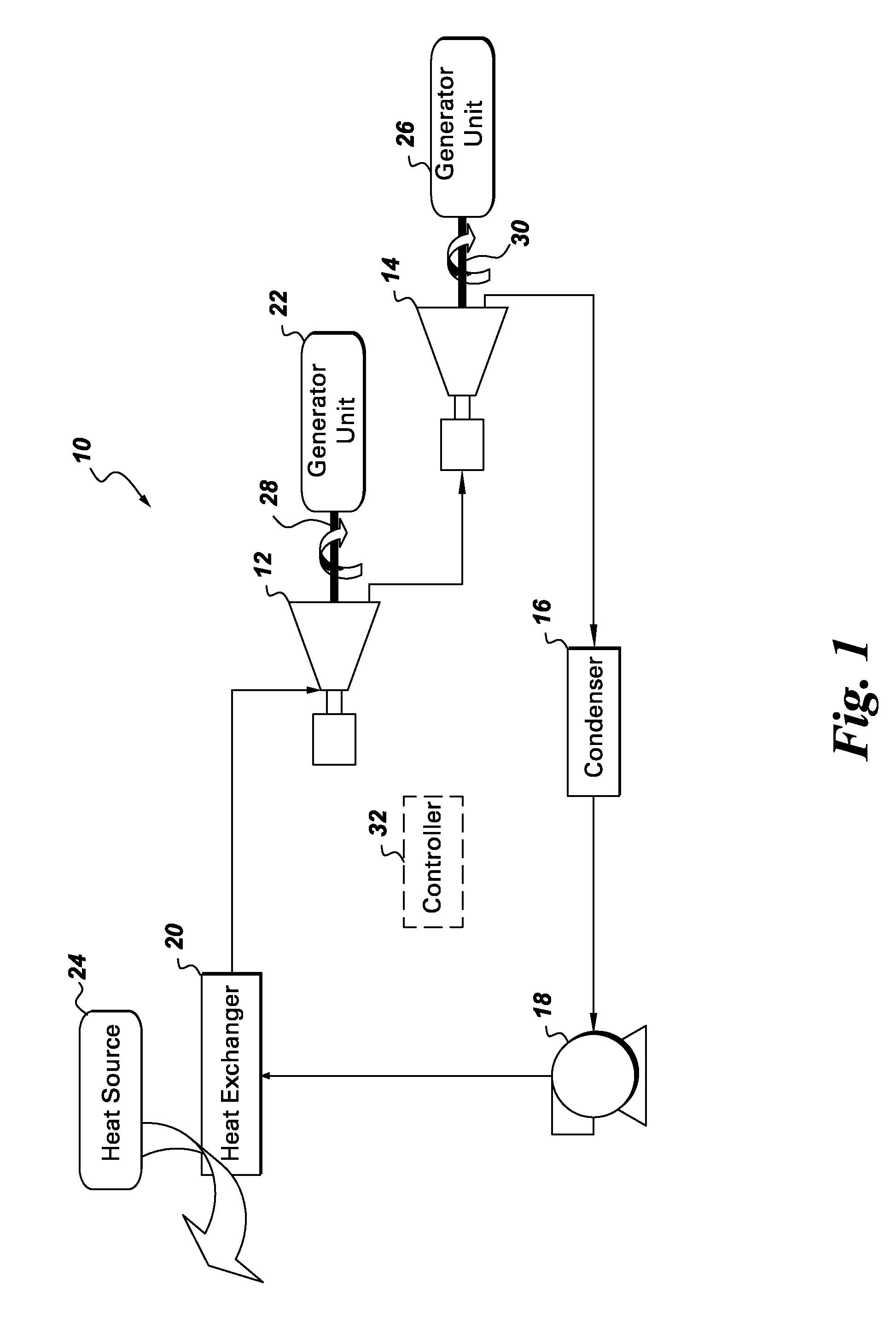

Two-phase expansion system and method for energy recovery

A closed loop expansion system for energy recovery includes a heat exchanger for using heat from a heat source to heat a working fluid of the closed loop expansion system to a temperature below the vaporization point of the working fluid; a radial inflow expander for receiving the working fluid from the heat exchanger and for expanding and partially vaporizing the working fluid; a screw expander for receiving the working fluid from the radial inflow turbine and for further expanding and vaporizing the working fluid; and a condenser for receiving the working fluid from the screw expander and for liquefying the working fluid.

Owner:AI ALPINE US BIDCO INC

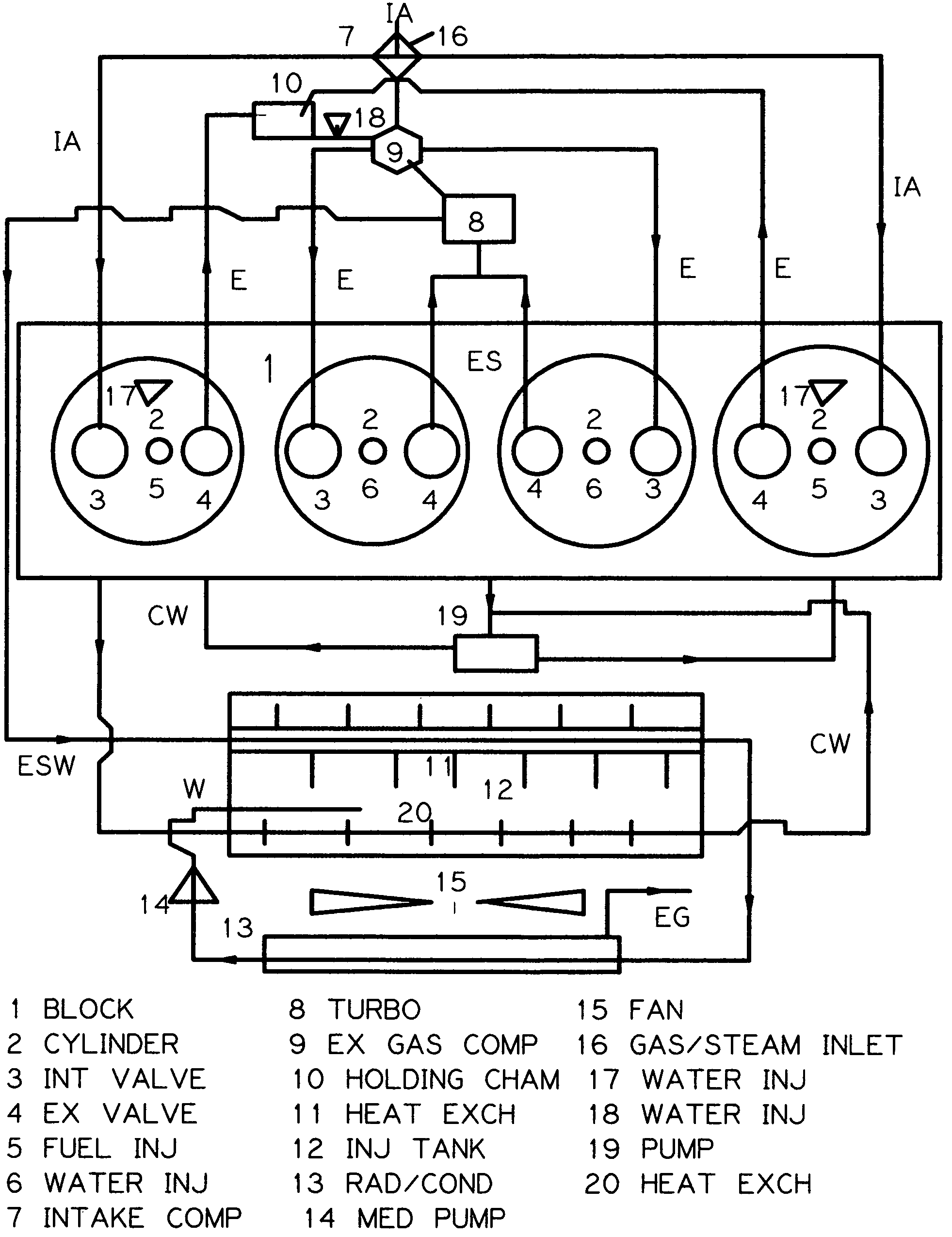

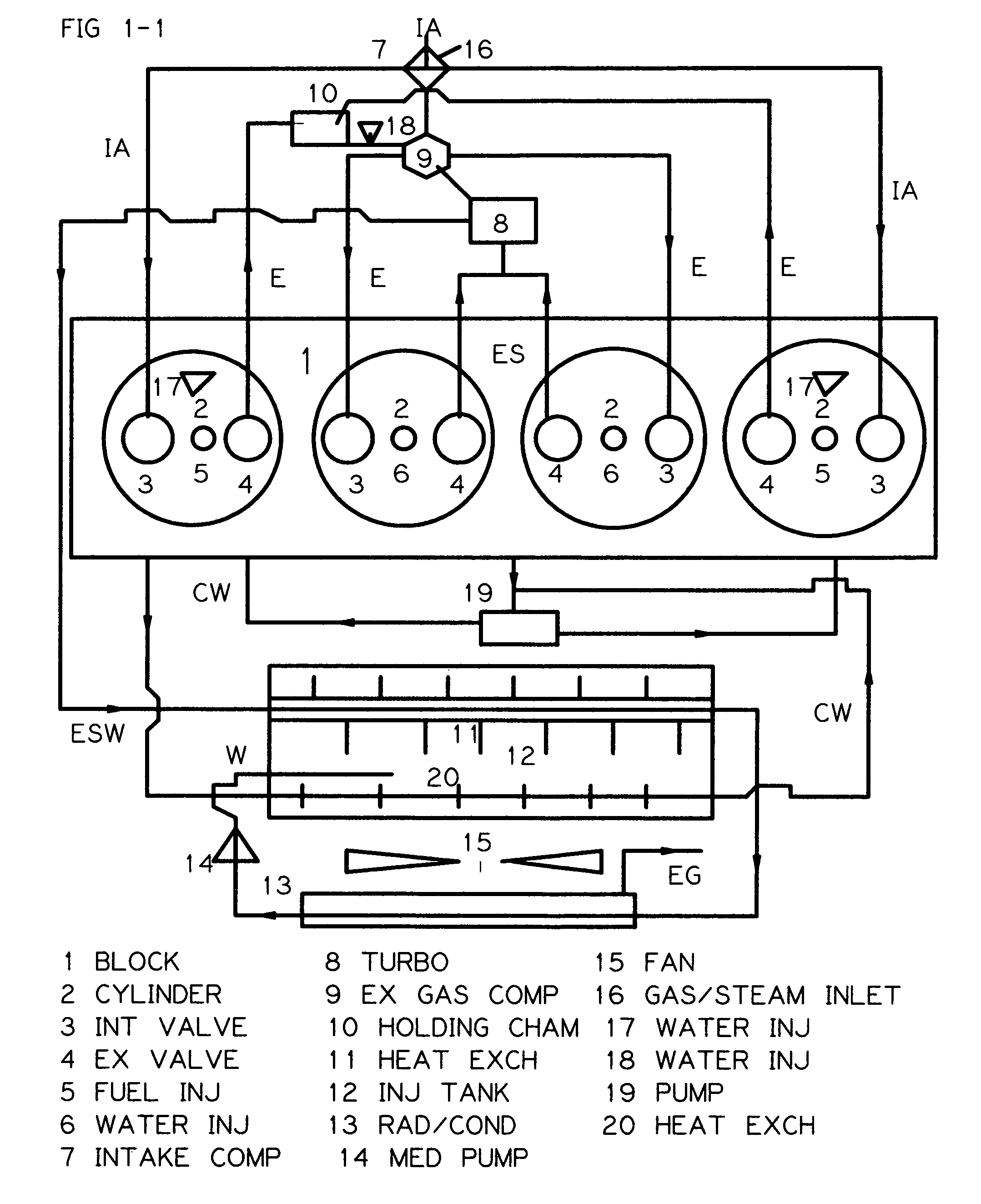

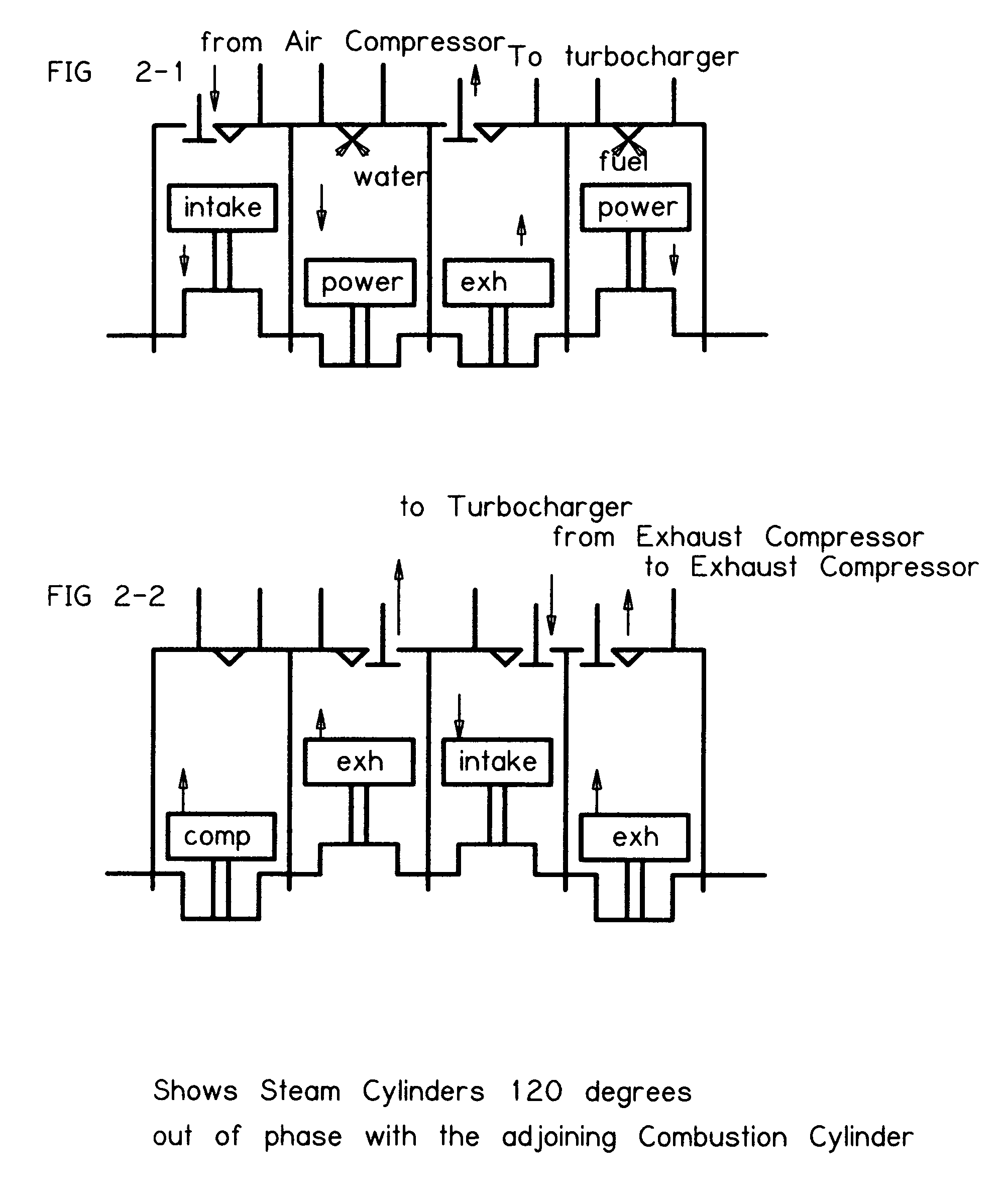

Turbocharged internal combustion/steam hybrid engine

InactiveUS7793493B1Reduce pumpingReduce friction lossNon-fuel substance addition to fuelInternal combustion piston enginesCombustionTop dead center

An engine (FIG. 1-1) comprising of multiple cylinders designated (2-5) combustion cylinders and (2-6) for heat recovery steam cylinders, each cylinder having a piston connected to a common crankshaft. The combustion cylinders operate on a four stroke cycle and the heat recovery steam cylinders operate on a two stroke cycle. The exhaust gas from the combustion cylinders is pressurized by a compressor, driven by a turbine, before entry into the heat recovery steam cylinders. This happens during the intake / power stroke of the heat recovery steam cylinders, as the intake valve closes, after top dead center, heated pressurized water is injected into the cylinder and spontaneously turns to steam driving the receding piston down. This heated exhaust gas and steam is expelled from the heat recovery steam cylinders to drive the turbine which in turn drives two compressors, one to compress the exhaust gas and one to compress the intake air.

Owner:MCILROY ROBERT

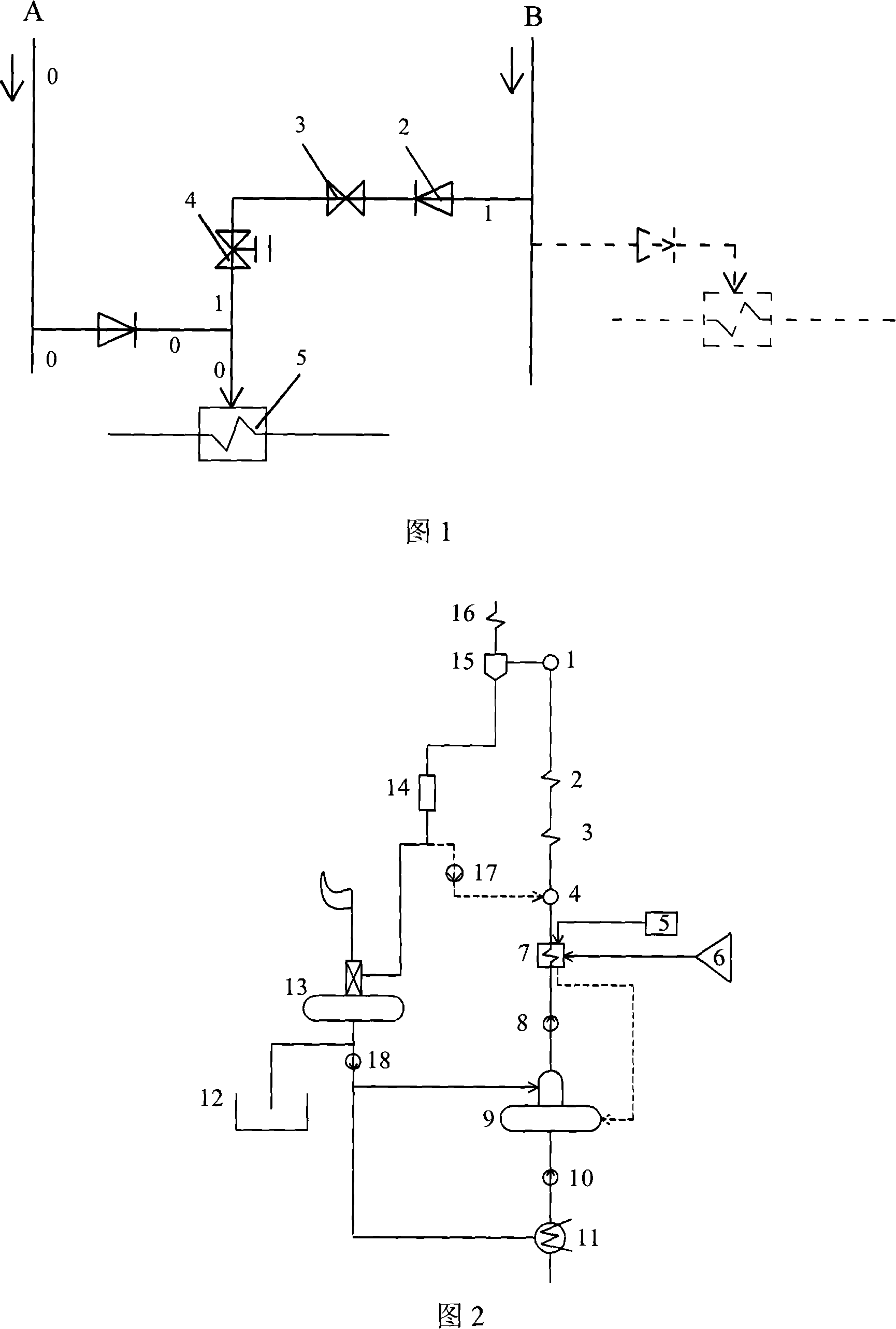

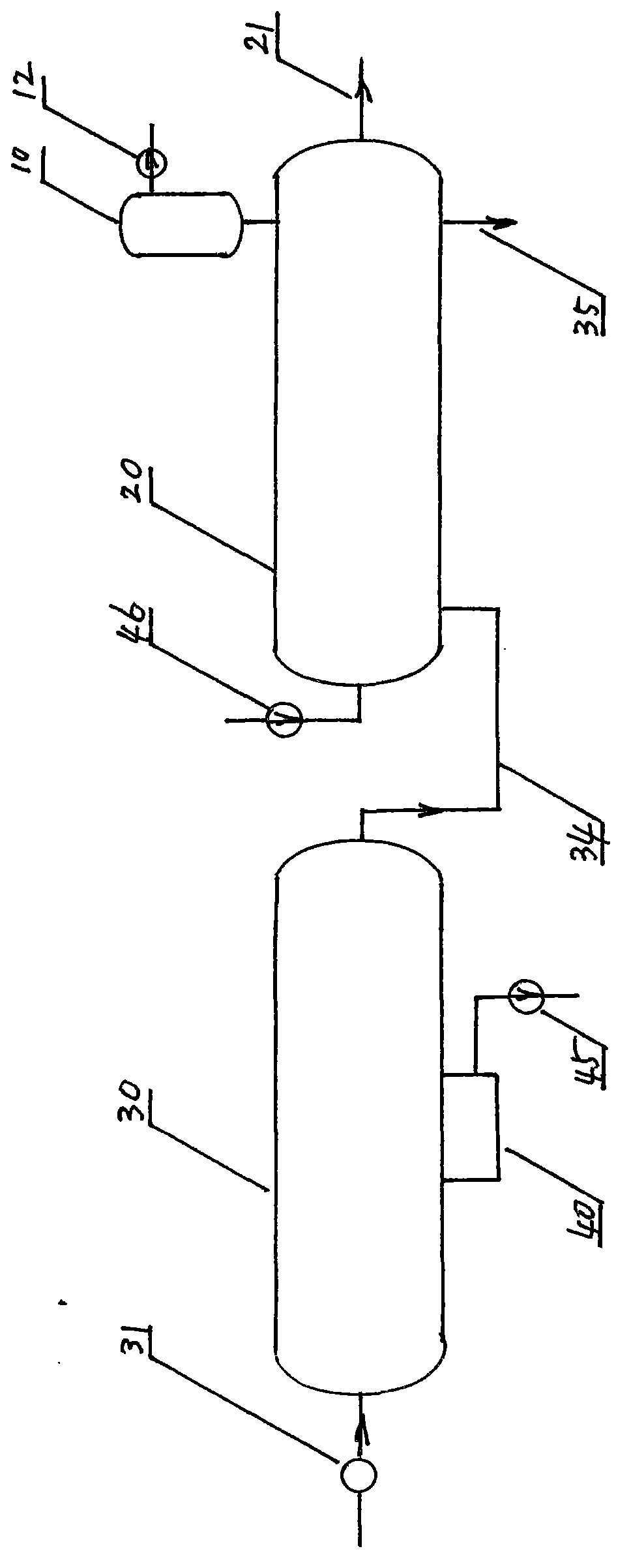

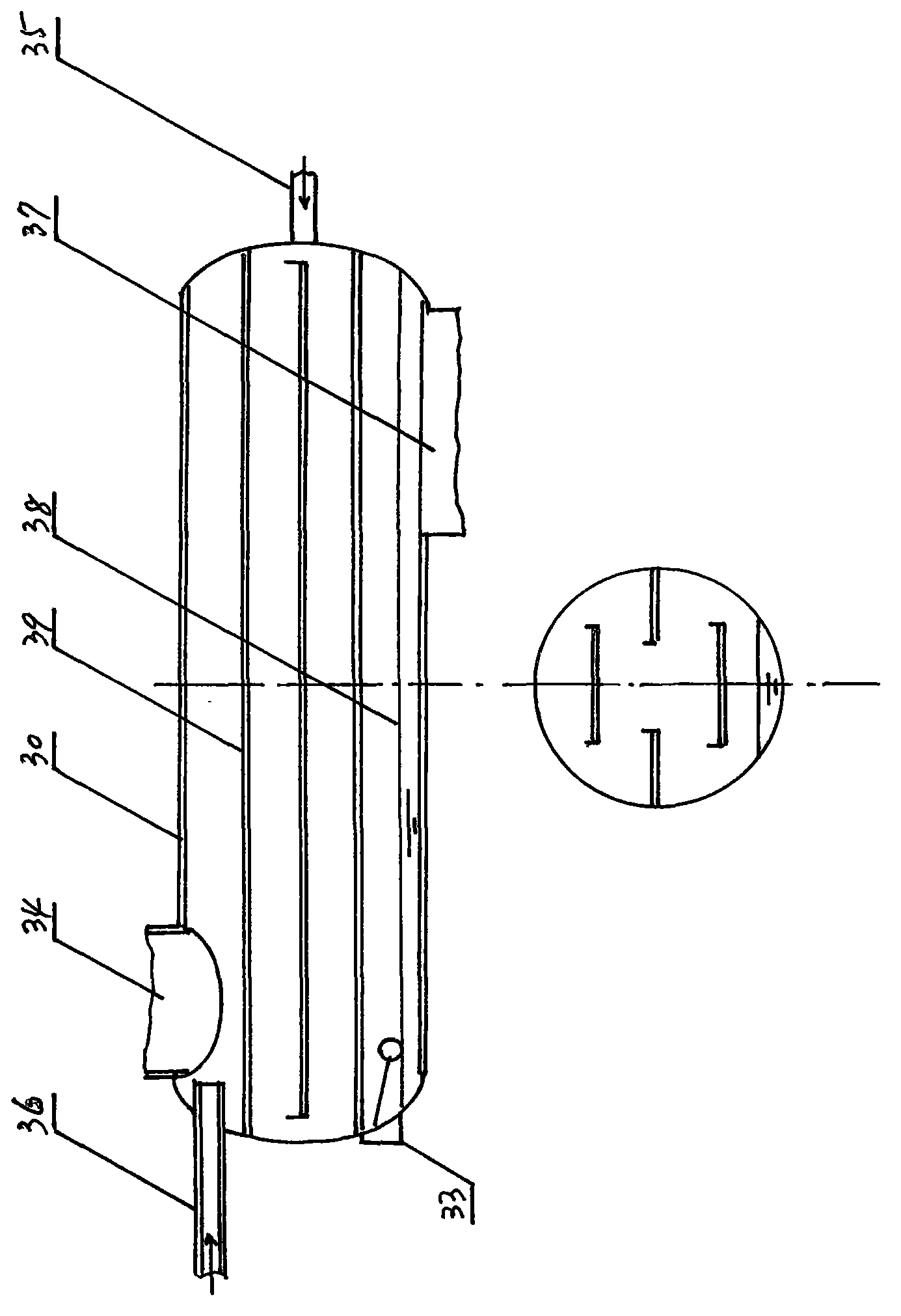

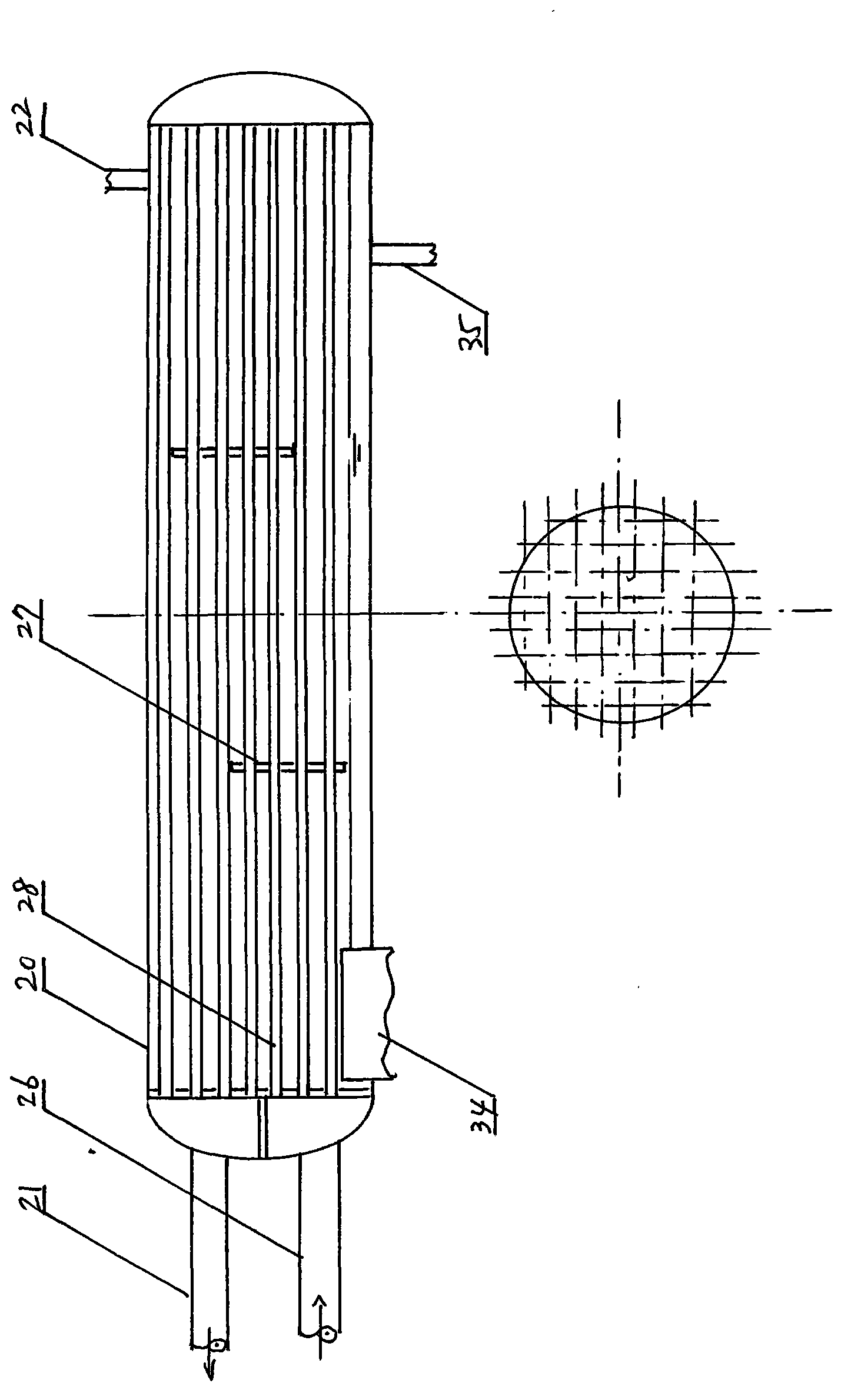

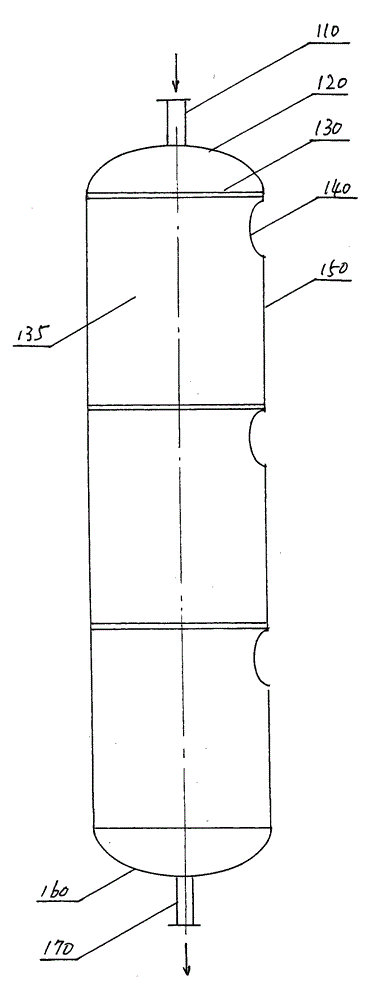

Device for recovering waste heat and supplying steam through multistage dilatation flashing

ActiveCN103123107AIncrease the number of unitsTake advantage ofEnergy industrySteam generationEngineeringThermal water

The invention provides a device for recovering waste heat and supplying steam through multistage dilatation flashing. Hot water (or low-pressure steam or steam-water mixture two-phase flow) is used as a circulatory medium to absorb the high-temperature waste heat in the device; the high-temperature waste heat is changed into the steam with a pressure energy level, capable of being used by the device, through flashing, the dilatation flashing and steam jet type heat pump pressurization; and the steam is changed into condensate and returned to the system after being used, the steam and the low-temperature hot water after the dilatation flashing are delivered into the device to absorb high-temperature waste heat, and closed recirculation is formed. According to the device for recovering the waste heat and supplying the steam through the multistage dilatation flashing, energy can be fully absorbed and delivered in a long distance to heat using sites according to needs, the heat can be stably supplied, and the device can be suitable for waste heat recovery and steam supply of heat using units with used heat changed.

Owner:NINGBO JINHAI CHENGUANG CHEM +1

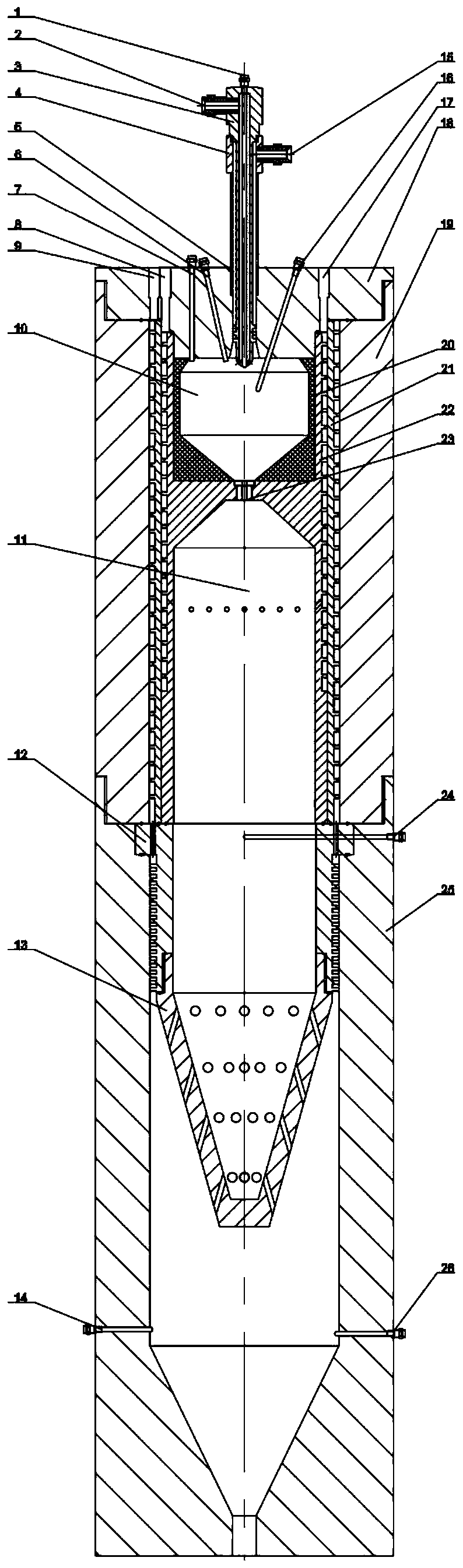

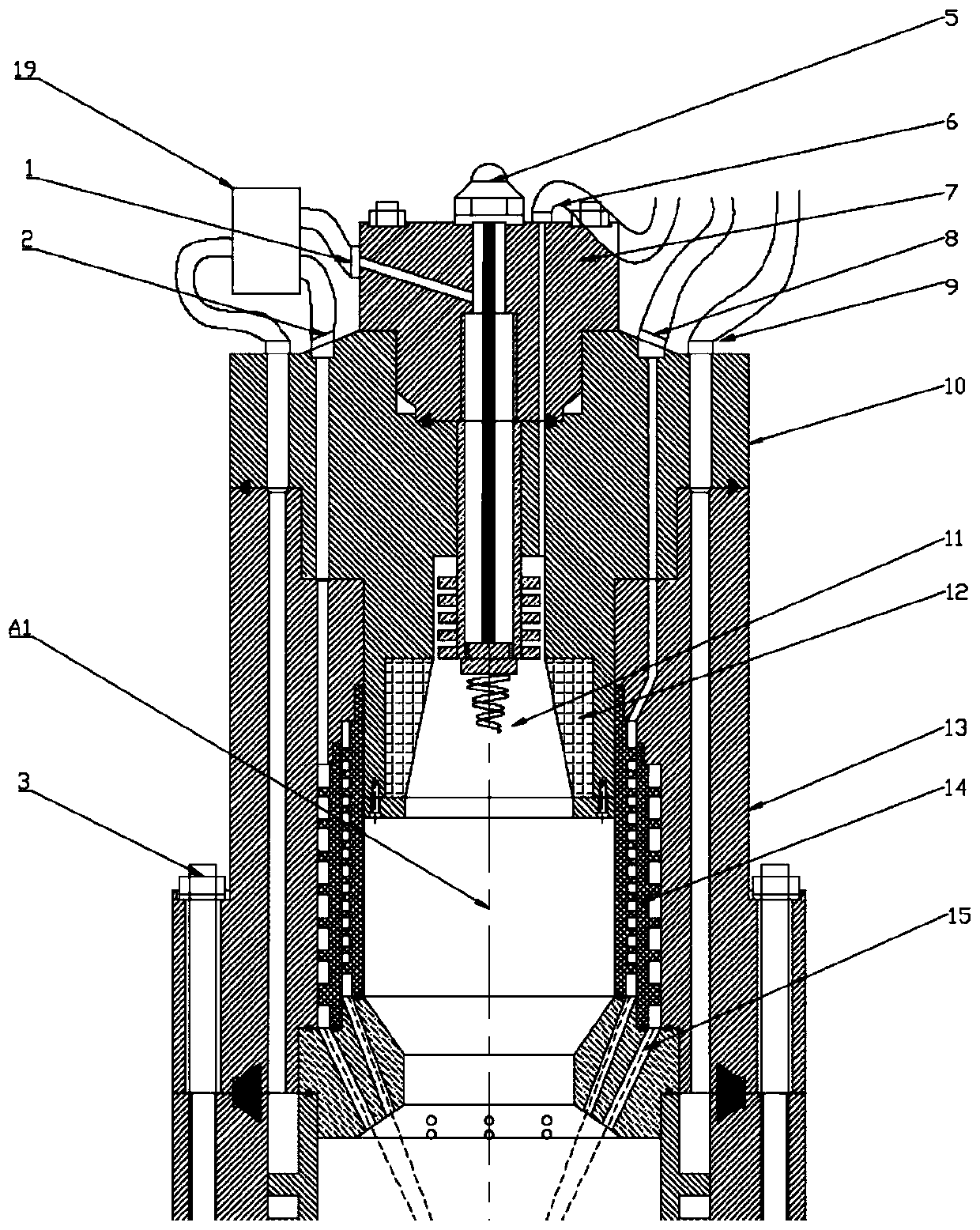

Supercritical hydrothermal combustion type steam generator for thermal recovery of heavy oil in ultra-deep well

PendingCN110617466AAvoid heat lossHigh thermal efficiencyInsulationFluid removalCombustion chamberEngineering

The invention discloses a supercritical hydrothermal combustion type steam generator for thermal recovery of heavy oil in an ultra-deep well. The supercritical hydrothermal combustion type steam generator comprises three parts, namely a generator head, a generator upper part and a generator lower part, an electric heating rod for ensuring the occurrence of the supercritical hydrothermal combustionreaction is arranged on the generator head, the generator upper part comprises a primary combustion chamber and a secondary combustion chamber to ensure sufficient supercritical hydrothermal combustion reaction of fuel and an oxidant, a spray head and reducing ports of the generator lower part ensure that the parameters of reaction products meet the requirements of oil field thick oil recovery, and cooling water in the generator is used for ensuring that the generator is not overtemperature so as to protect safe operation of the generator. According to the supercritical hydrothermal combustion type steam generator, the heavy oil recovery cost is lowered, the heat utilization efficiency is improved, pollutants are prevented from being discharged, and efficient recovery of deep and offshoreoil reservoirs is realized.

Owner:XI AN JIAOTONG UNIV

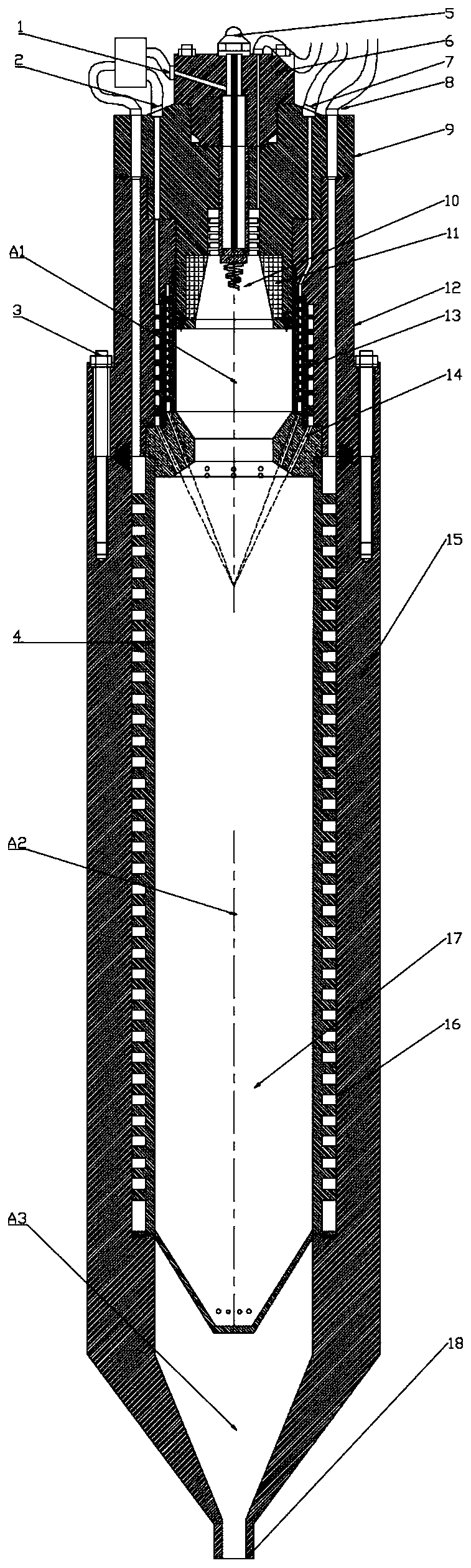

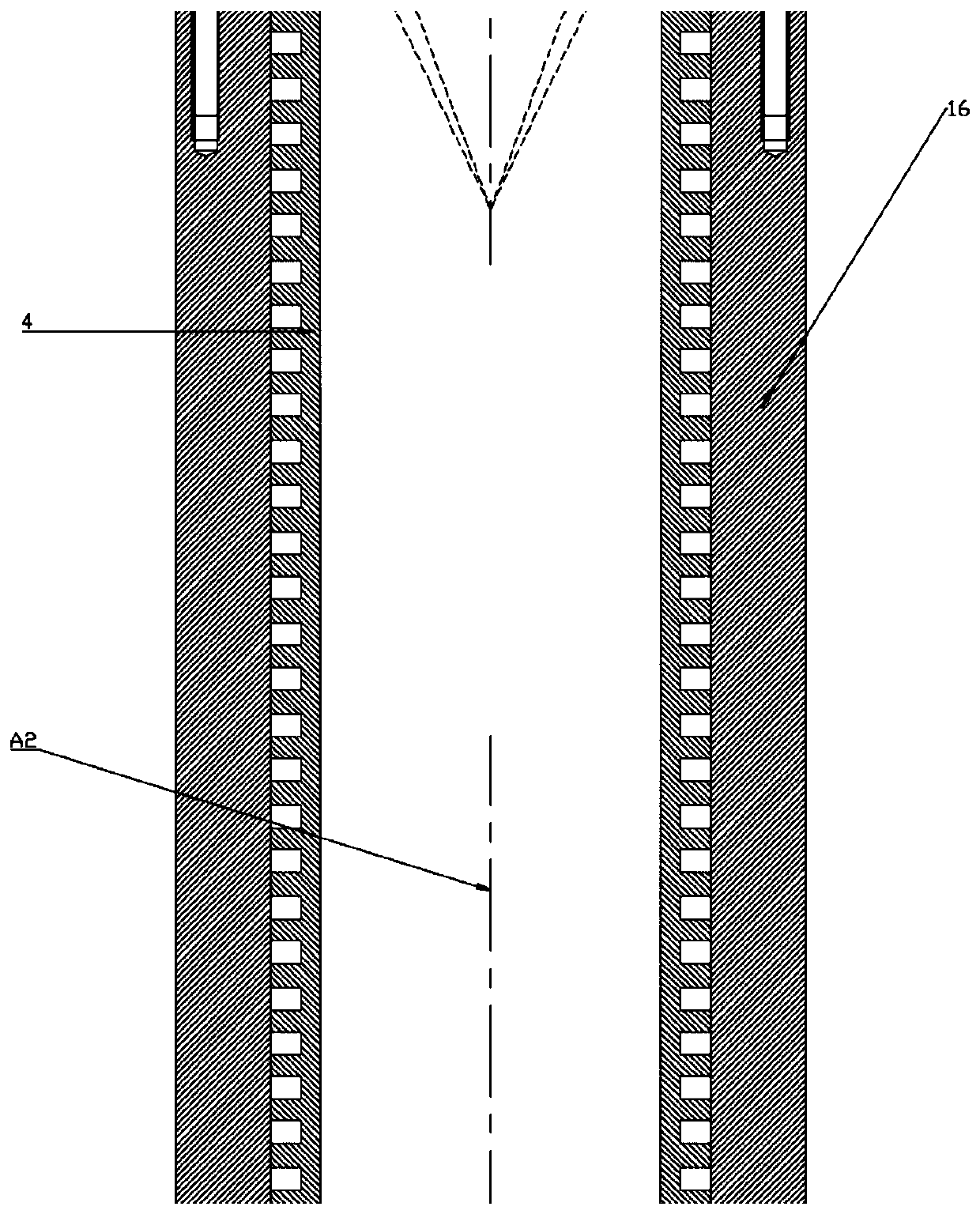

Supercritical hydrothermal combustion device suitable for high-viscosity fuel

PendingCN110645555AAvoid lostImprove heat utilizationFluid removalSteam generationThermodynamicsCombustion chamber

The invention provides a supercritical hydrothermal combustion device suitable for high-viscosity fuel. The supercritical hydrothermal combustion device suitable for the high-viscosity fuel is mainlycomposed of an upper end cover, a middle end cover, a first combustion stabilization chamber body and a second combustion chamber body which are sequentially connected and assembled. The upper end cover is provided with a first-grade fuel inlet, a high-energy heating rod and a first-grade oxidizing agent inlet. The middle end cover is provided with a second-grade fuel inlet, a second-grade oxidizing agent inlet and a reactant first-grade spray nozzle. The reactant first-grade spray nozzle communicates with the first-grade fuel inlet. The inner wall of the first combustion stabilization chamberbody is a double-layer-spiral wall, the bottom end of the first combustion stabilization chamber body is provided with a second-grade spray nozzle communicating with the second-grade fuel inlet and the second-grade oxidizing agent inlet. The inner wall of the second combustion chamber main body is a double-spiral cooling wall, and the bottom end of the second combustion chamber main body is provided with an outlet hole group. Finally, a combustion stabilization chamber is formed between the first-grade spray nozzle and the second-grade spray nozzle. A combustion chamber is formed between thesecond-grade spray nozzle and the outlet hole group. A mixing chamber is formed between the outlet hole group and a bottom outlet of a reactor. The supercritical hydrothermal combustion device suitable for the high-viscosity fuel directly generates steam in an oil layer, so that the problems of high energy consumption and heavy pollution caused in the steam injection process of a heavy oil thermalrecovery ground boiler are solved.

Owner:XI AN JIAOTONG UNIV

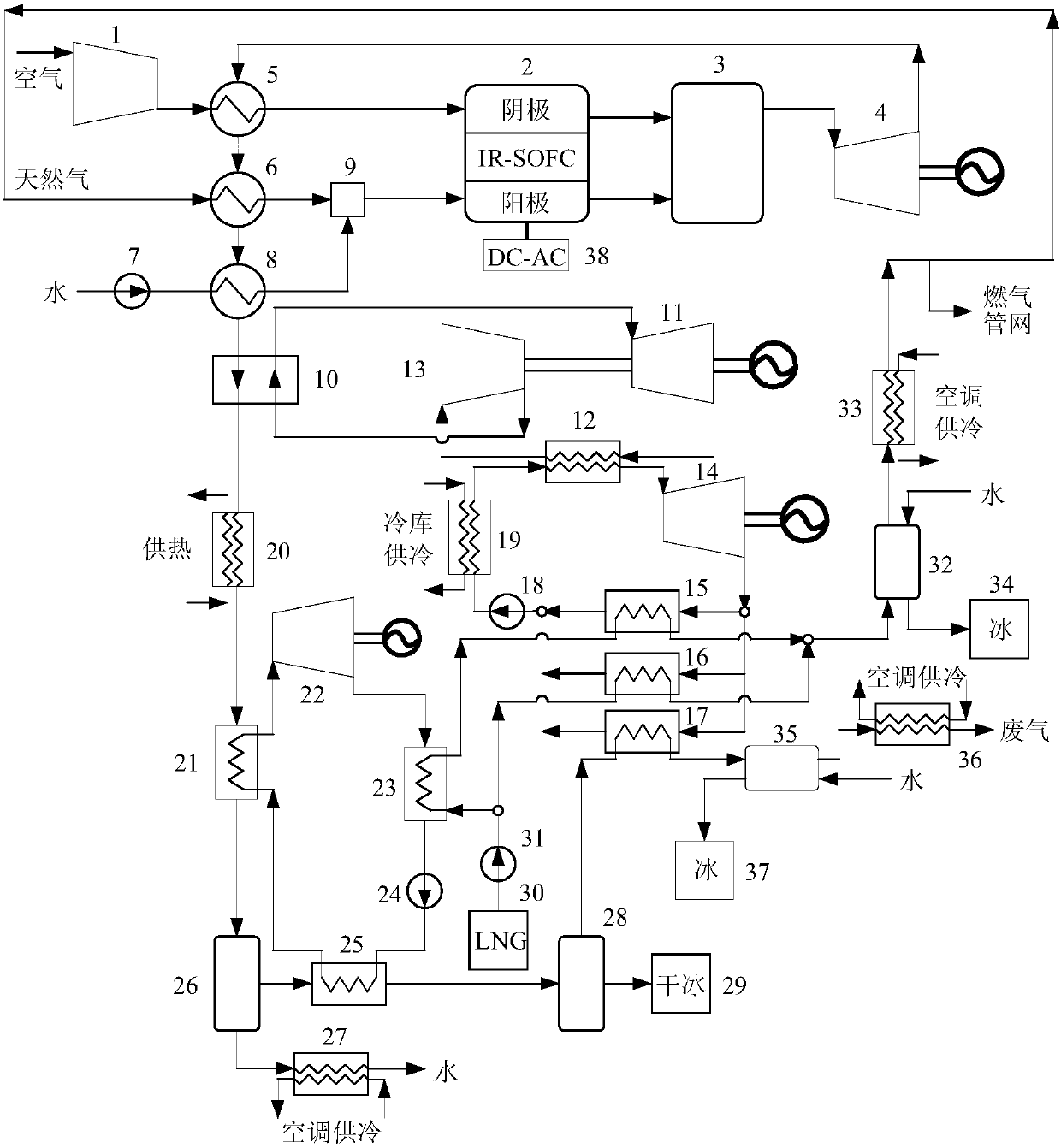

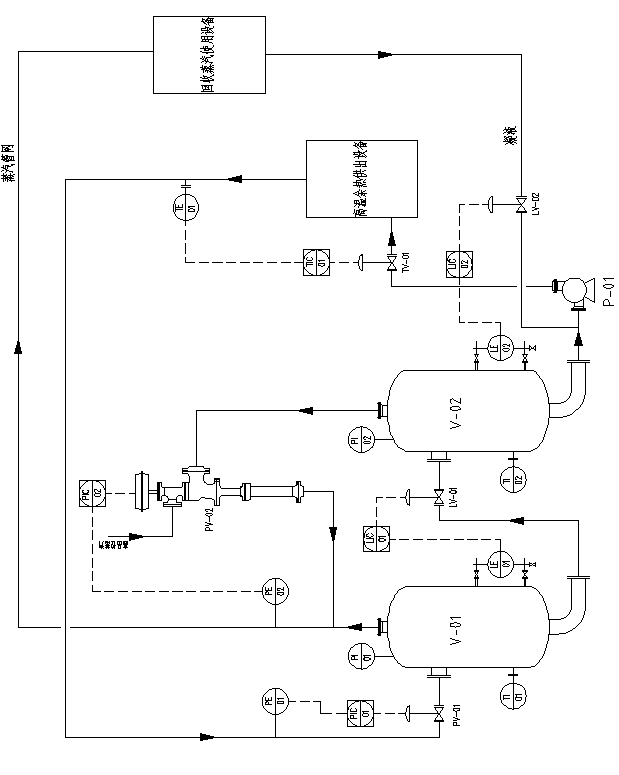

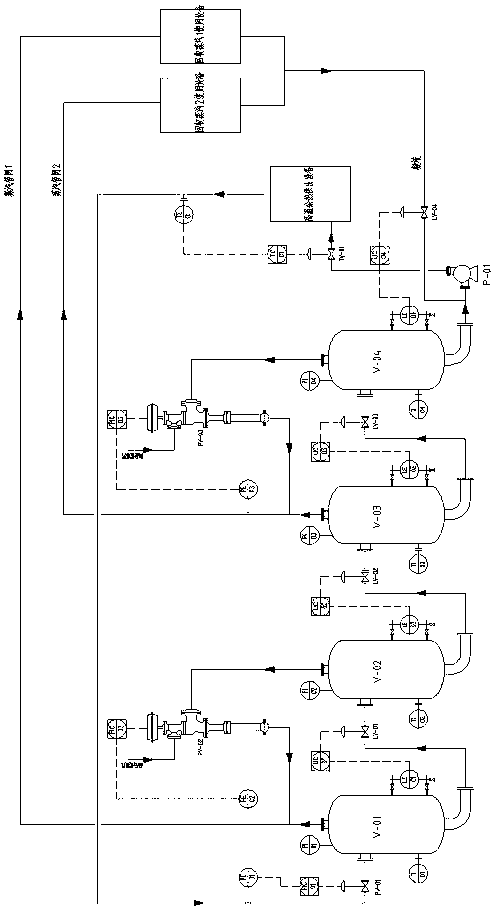

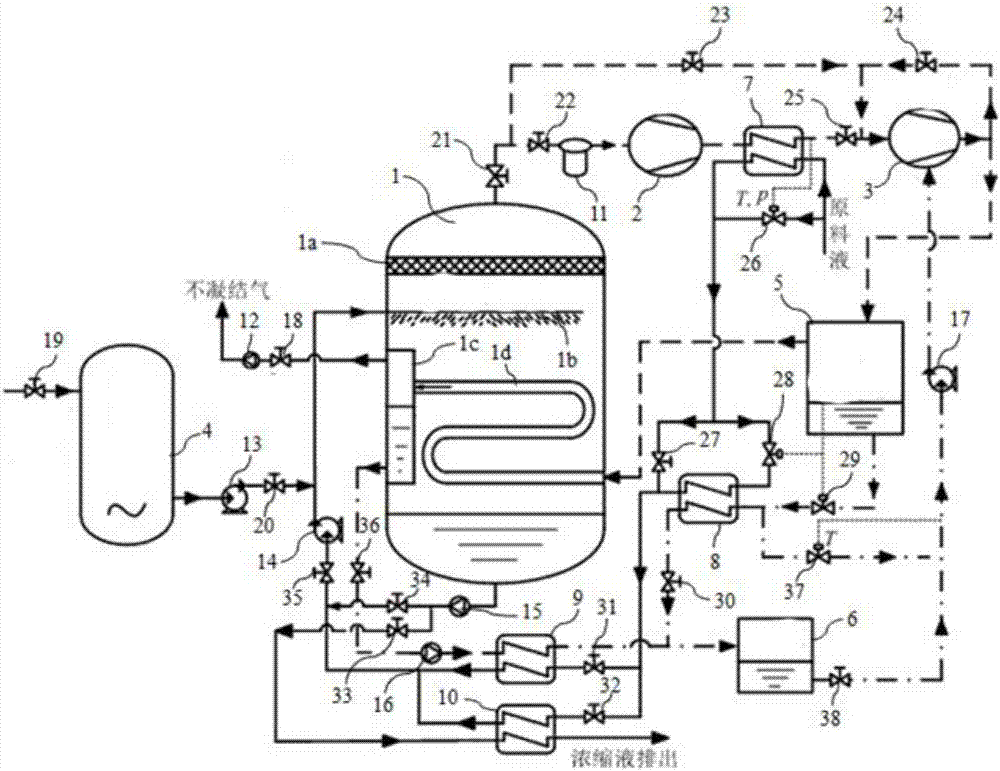

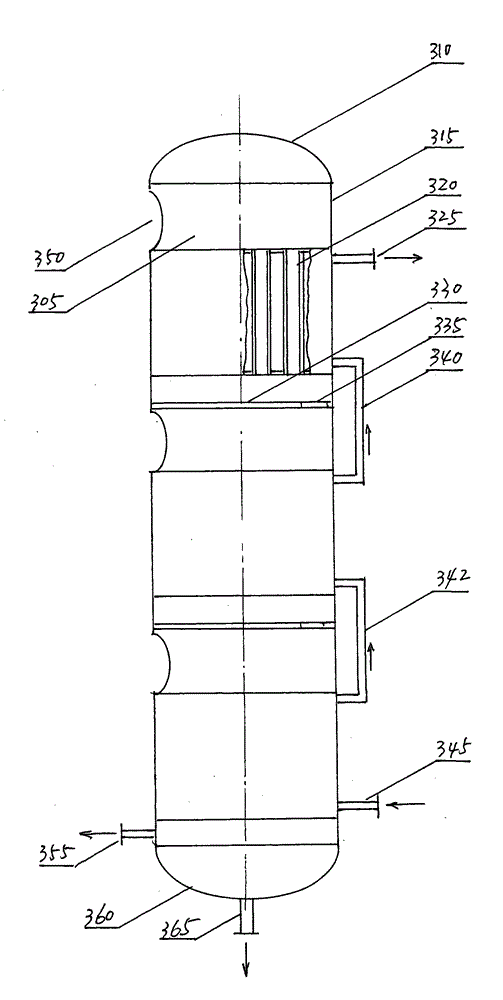

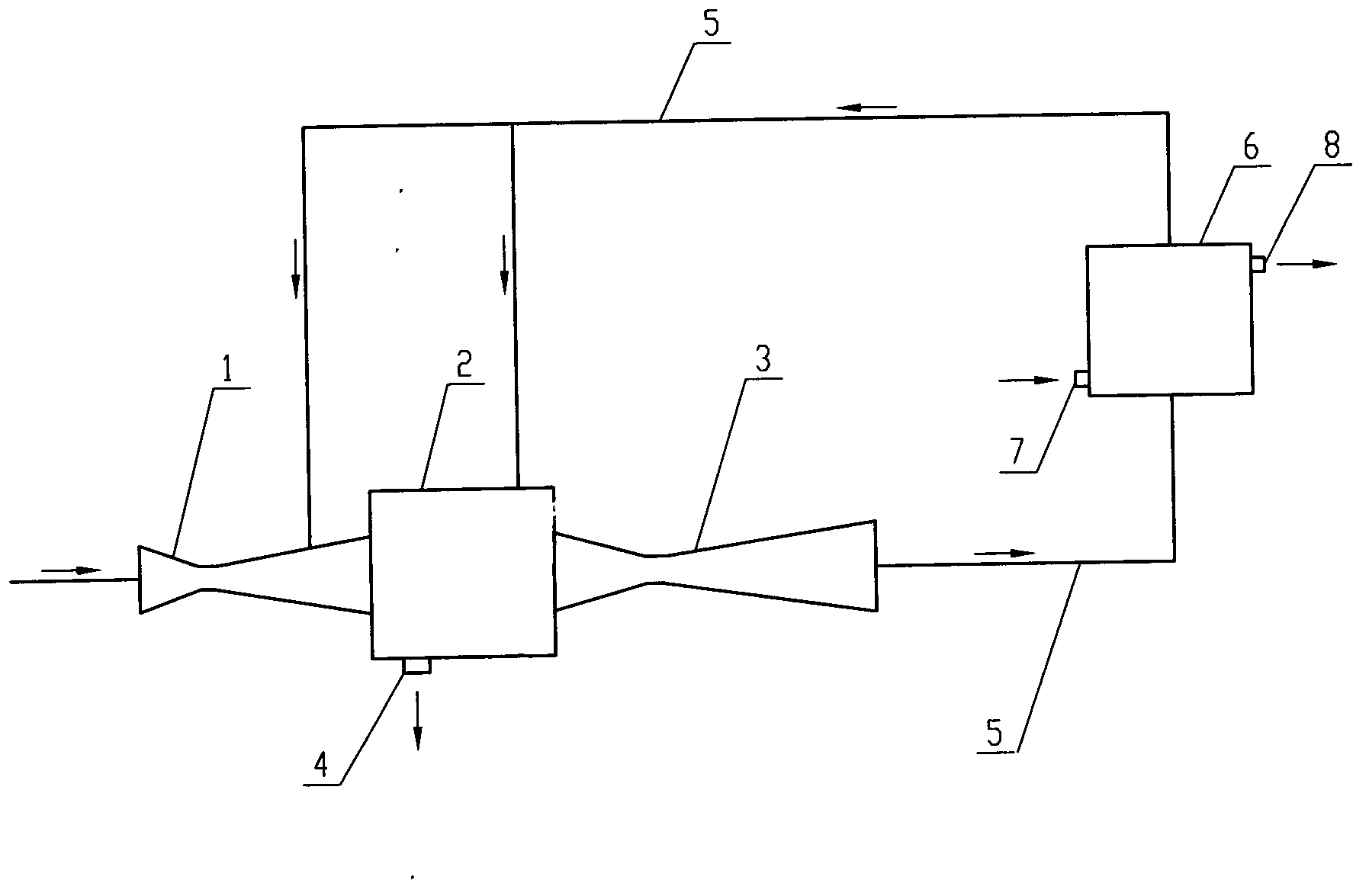

Mechanical steam recompression system and control method

ActiveCN107213659AImprove energy efficiencyImprove performanceDistillation regulation/controlEvaporator accessoriesVapor–liquid separatorHigh energy

The invention provides a mechanical steam recompression system comprising an evaporative condenser, a centrifugal compressor, a screw compressor, an electric water heater, a vapor-liquid separator and a fresh water box. The evaporative condenser communicates with the centrifugal compressor and the screw compressor; a first valve and a drain separator are arranged between the evaporative condenser and the centrifugal compressor; a second valve is arranged between the evaporative condenser and the screw compressor; the centrifugal compressor communicates with the screw compressor; an outlet of the screw compressor communicates with the an inlet of the screw compressor; and the screw compressor communicates with a condensing tube of the evaporative condenser through the vapor-liquid separator. The mechanical steam recompressing system provided by the invention is a mechanical steam recompressing system which has no need to start heat-source steam, can realize a high vapor pressure ratio (Saturated temperature rise of compressed steam) and high vapor flow, and has higher energy efficiency. In addition the mechanical steam recompression system has functions of expanding the application range of conventional mechanical steam recompression systems and realizing industrial energy conservation.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

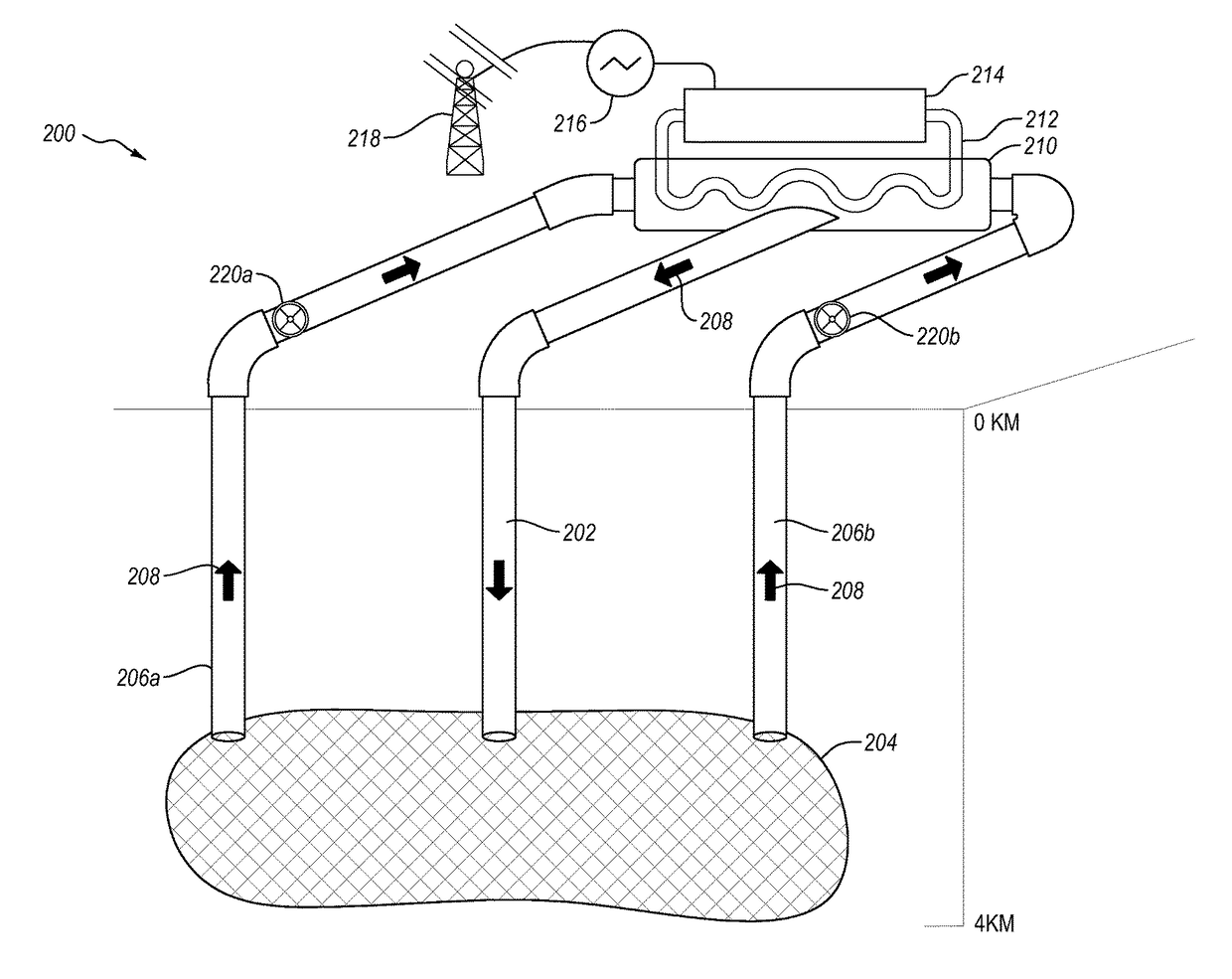

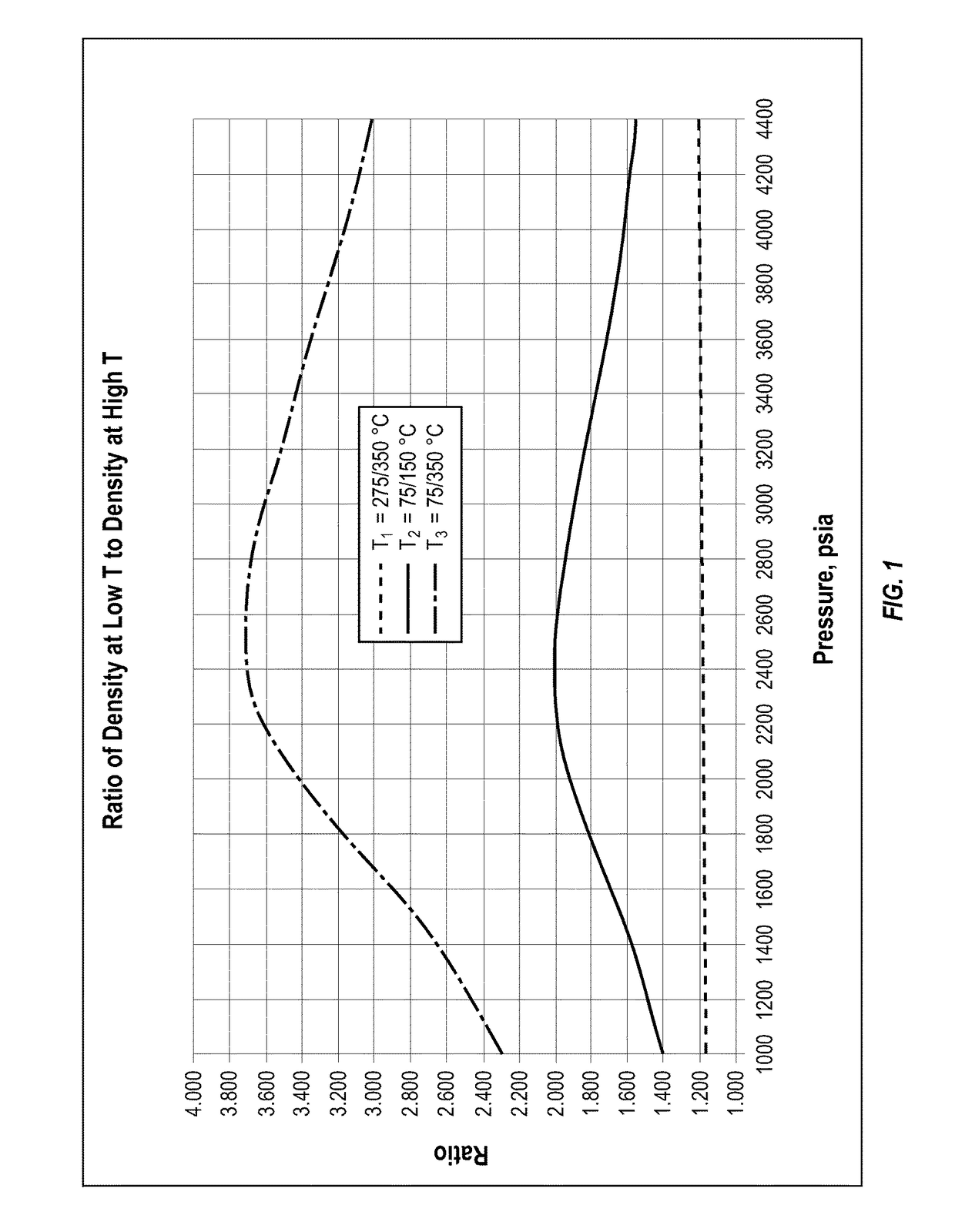

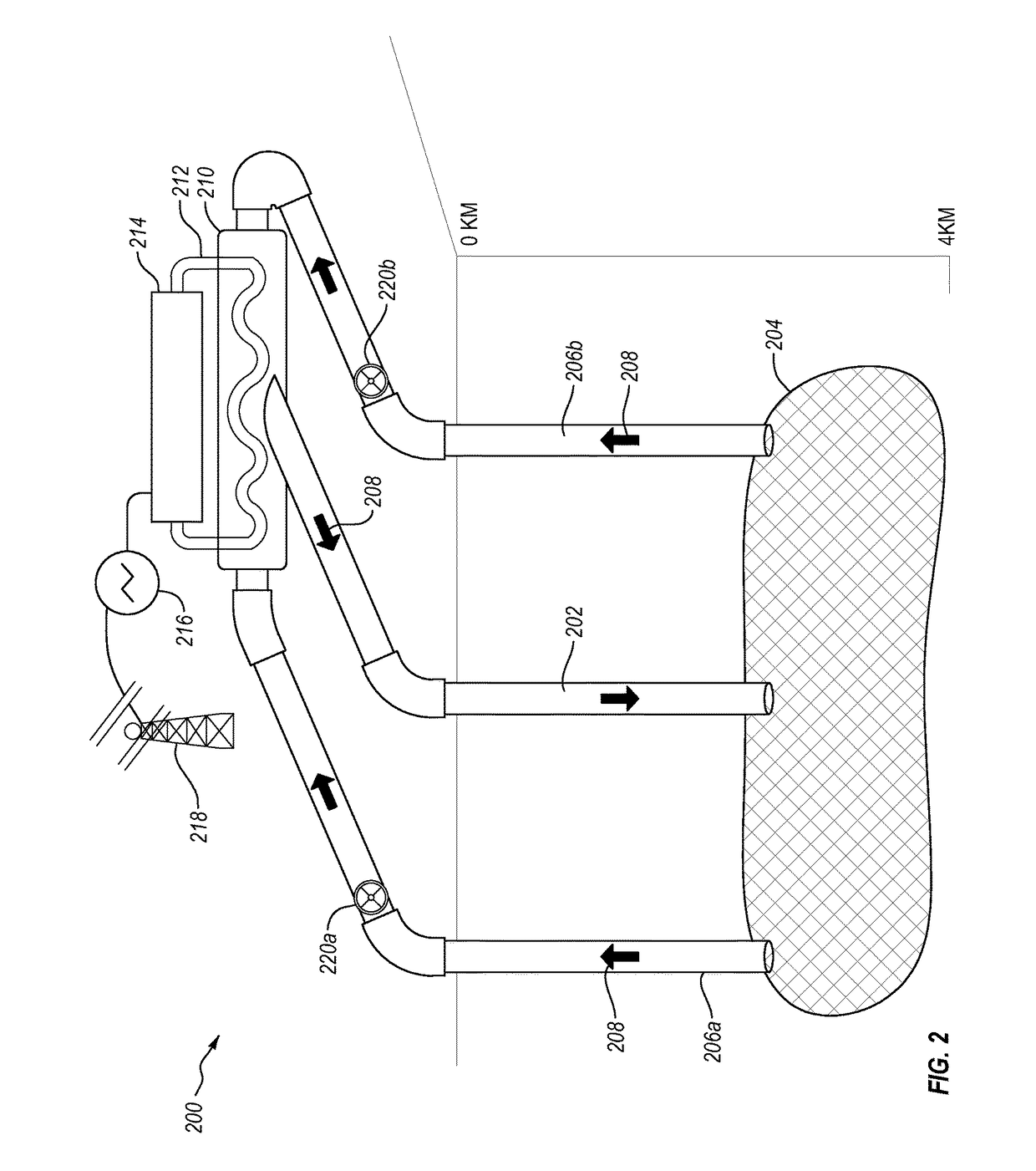

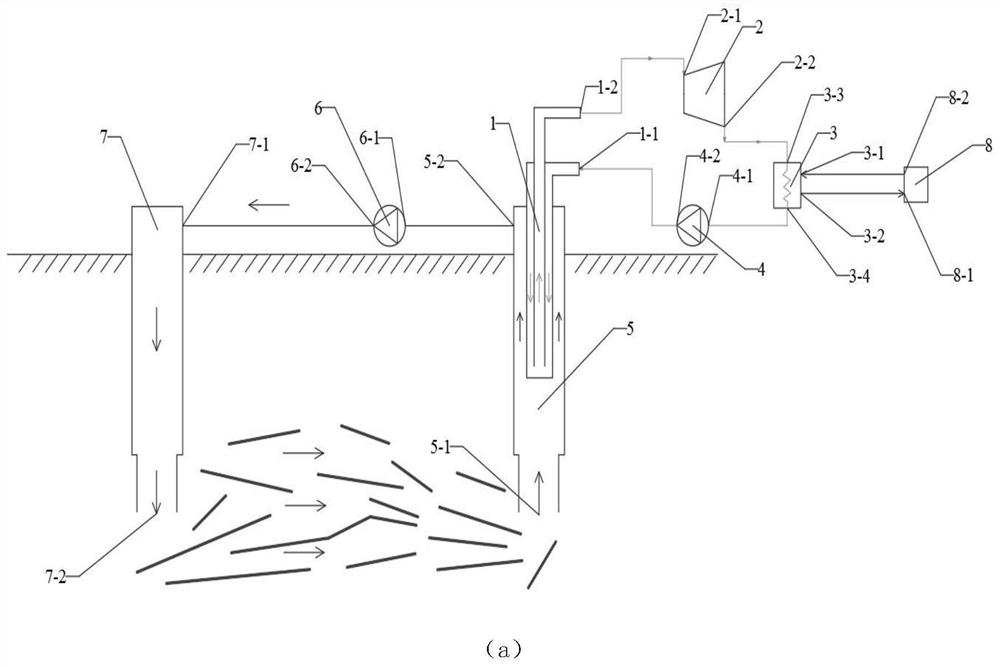

Thermosiphoning supercritical CO2 in geothermal energy production

ActiveUS9803626B1Minimize and eliminate needThermosiphoning is maximizedOther heat production devicesGeothermal energy generationInjection wellGeothermal energy

Methods for thermalsiphoning supercritical CO2 within a geothermal formation includes providing a geothermal energy system that includes an underground hot rock reservoir, a production well, and an injection well that together form a fluid path suitable for circulating supercritical CO2. The supercritical CO2 flows by thermosiphoning. Thermosiphoning is maximized by maintaining a pressure between 1400-4000 psia, an injection temperature in a range from 50-200 C and a production temperature in a range from 150-600 where injection temperature and the production temperature differ by at least 50° C.

Owner:GREENFIRE ENERGY

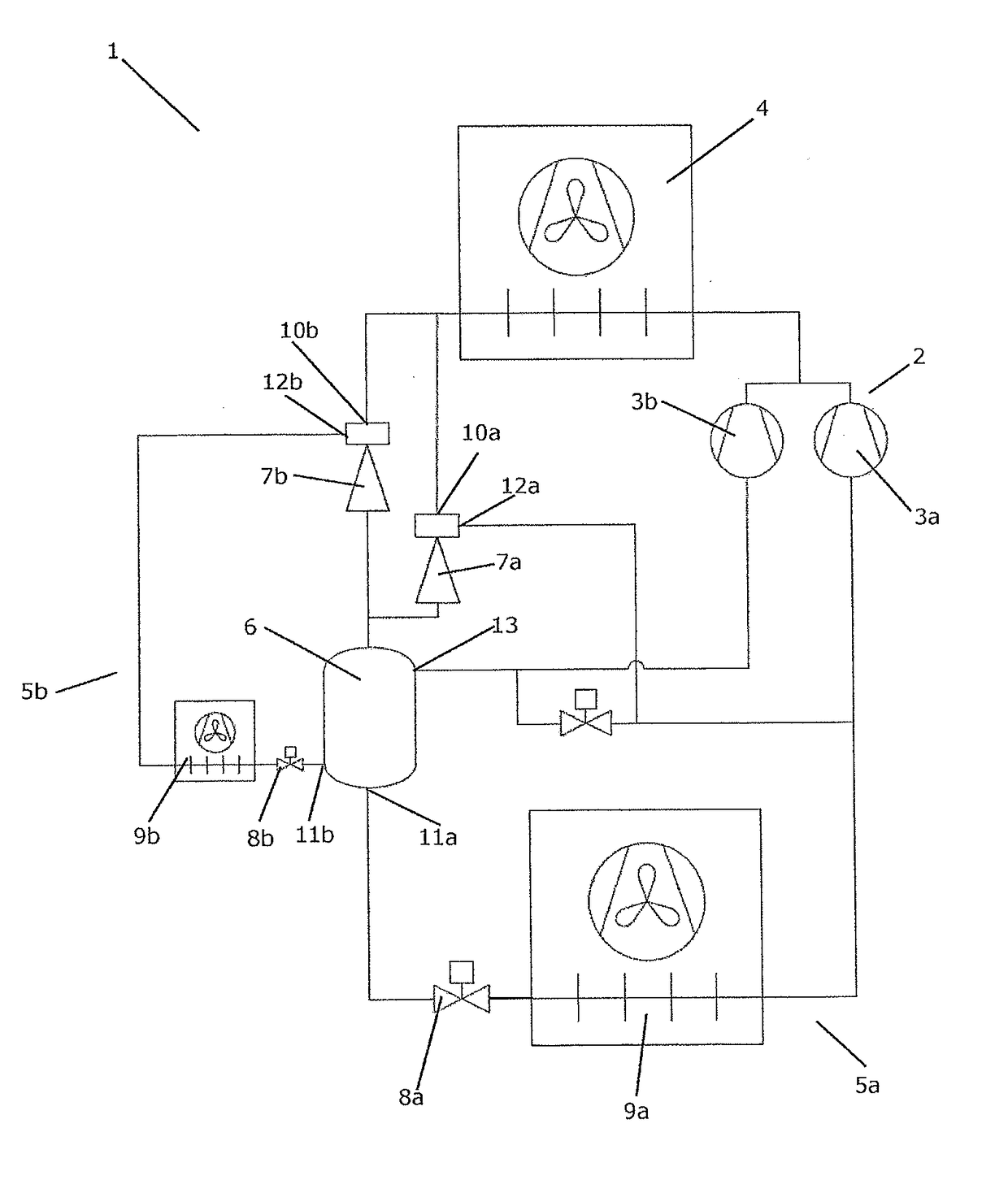

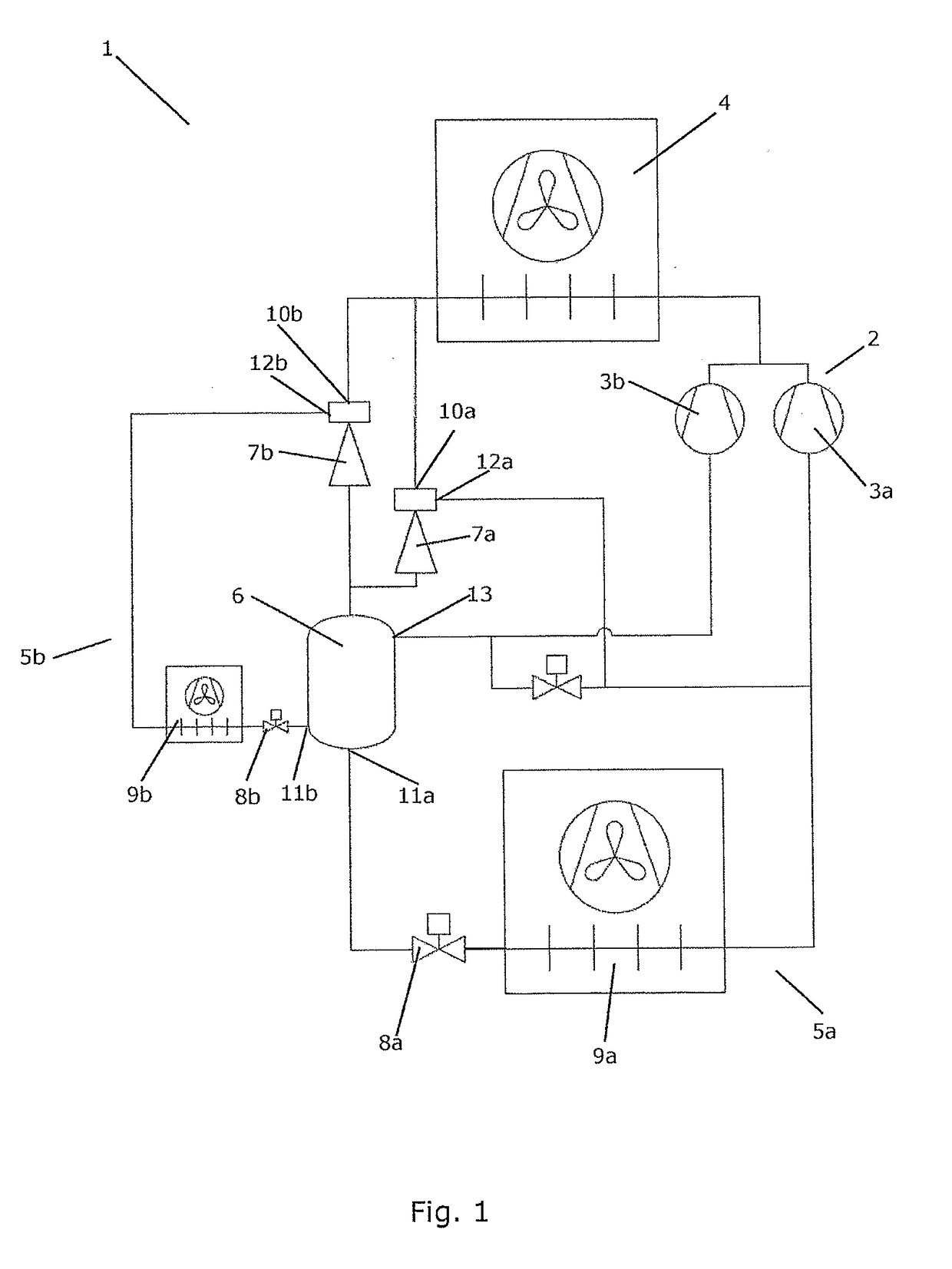

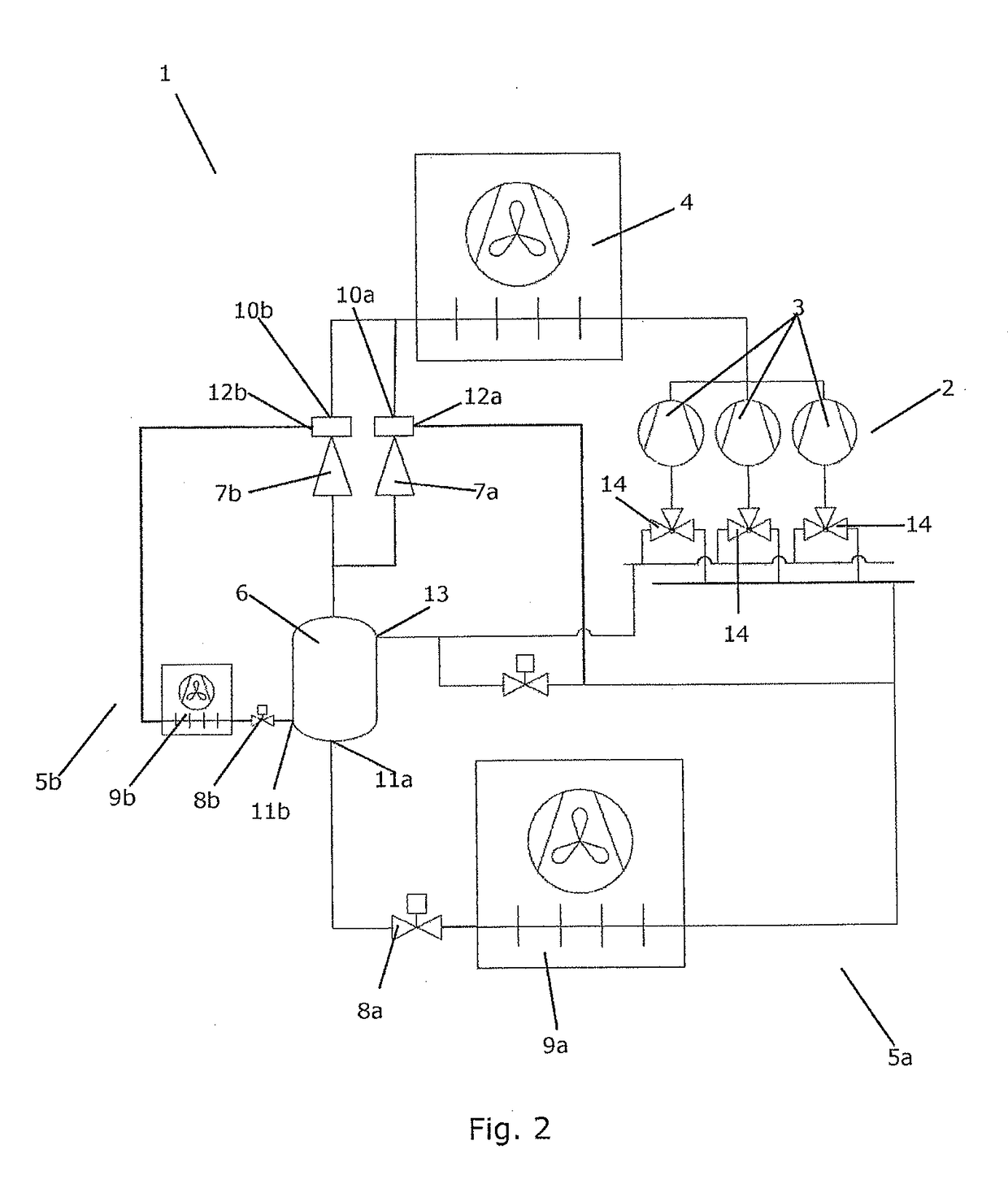

Vapour compression system with at least two evaporator groups

ActiveUS20180231284A1Improve energy efficiencyMechanical apparatusCompression machines with several evaporatorsAgricultural engineeringRefrigerant

A vapour compression system (1) comprising at least two evaporator groups (5a, 5b, 5c), each evaporator group (5a, 5b, 5c) comprising an ejector unit (7a, 7b, 7c), at least one evaporator (9a, 9b, 9c) and a flow control device (8a, 8b, 8c) controlling a flow of refrigerant to the at least one evaporator (9a, 9b, 9c). For each evaporator group (5a, 5b, 5c) the outlet of the evaporator (9a, 9b, 9c) is connected to a secondary inlet (12a, 12b, 12c) of the corresponding ejector unit (7a, 7b, 7c). The vapour compression system (1) can be controlled in an energy efficient and stable manner. A method for controlling the vapour compression system (1) is also disclosed.

Owner:DANFOSS AS

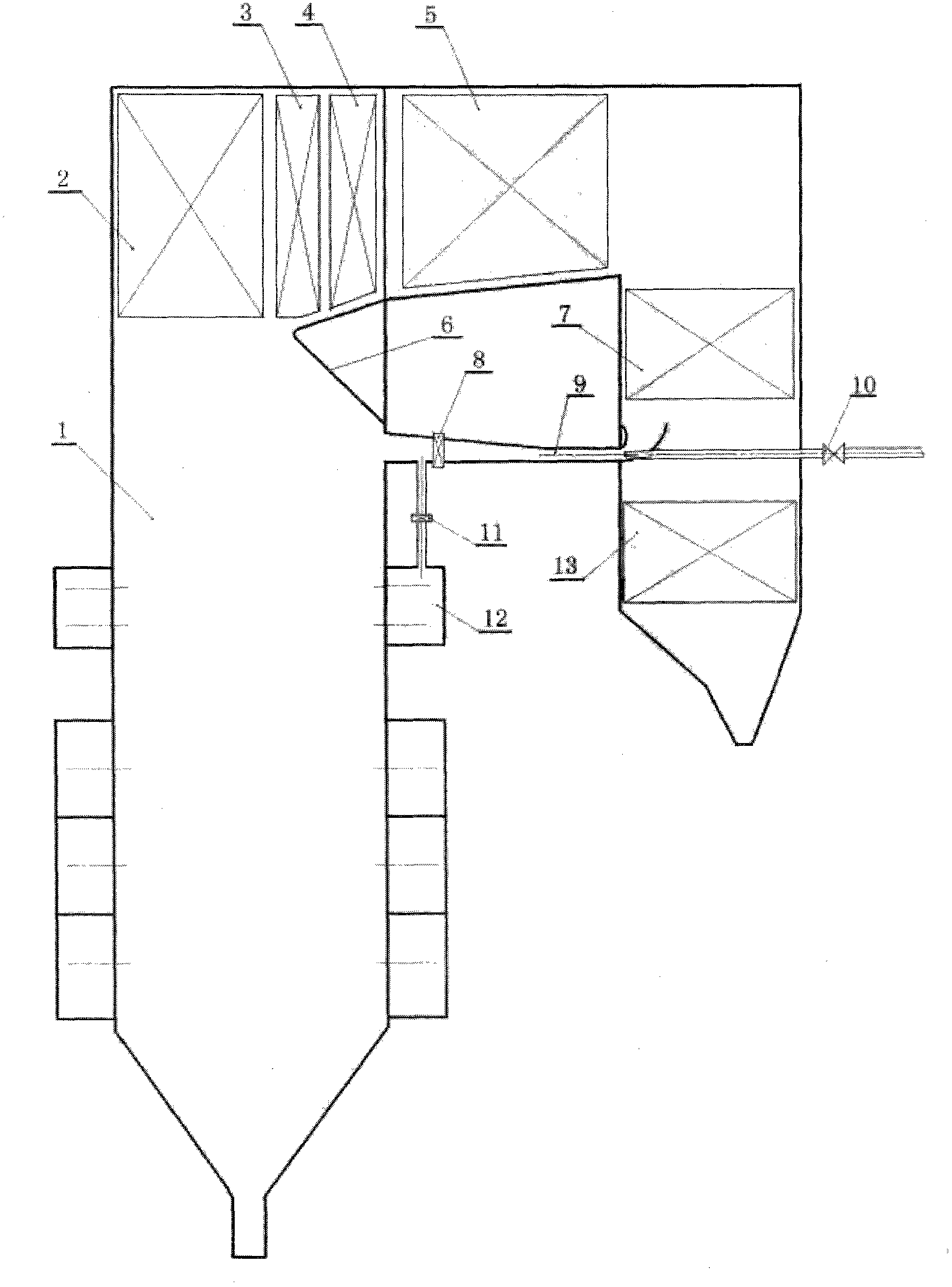

Supercritical once-through boiler capable of firing eastern Junggar coal

ActiveCN103486563ASave huge investmentSolve the serious problem of slaggingSteam generationCombustorEngineering

The invention discloses a supercritical once-through boiler capable of firing eastern Junggar coal, and relates to a supercritical once-through boiler which can be used by a thermal power station and is capable of safely and completely firing eastern Junggar coal for a long time. The supercritical once-through boiler comprises a hearth, a combustor, a divider screen superheater, a screen-type superheater, a high-temperature superheater, a high-temperature reheater, a flue deflection corner, a low-temperature reheater, an air-flue ejector shutoff barrier, a temperature regulating air-flue ejector, an ejector hot primary air regulating barrier, an ejector disable protection cooling air barrier, a separation secondary air bellow and a coal economizer. The ejector hot primary air regulating barrier is started when low and medium loads of the boiler and / or fouling factors of the reheaters are increased, so that the weight flow of temperature regulating flue and air mixtures can be adjusted between 0% and 30% of BMCR (boiler maximum continuous rating) flue gas weight flow. The supercritical once-through boiler has the advantages that the problem of severe slagging of an existing hearth in a eastern Junggar coal co-combustion procedure in the prior art can be solved; problems of fouling blockage corrosion of flue sides of high-temperature convection heating surfaces, increase of flue gas temperature, decrease of loading capacity and incapability of safely and completely combusting the eastern Junggar coal for a long time can be solved.

Owner:章礼道

Directly heating machine

The invention provides a directly heating machine which structurally comprises an evaporator, a condenser, a deaeration device and an anti-cavitation device. Medium-high temperature wastewater is flashed in the evaporator to produce steam; a steam passage is arranged between the evaporator and the condenser; and steam condenses to give out heat in the condenser. The deaeration device is connected to a part above the condenser, and the anti-cavitation device is connected to a water outlet below the evaporator. The evaporator is a horizontal pressure vessel; and the condenser is a horizontal shell and tube exchanger. The deaeration device structurally comprises an air collector and a vacuum pump. The anti-cavitation device structurally comprises a water suction pump, a water jet pump, a nozzle and a diffuser pipe. Residual saturated wastewater after flashing in the evaporator flows into a pressurizer; the nozzle in the pressurizer is connected with a water jet pipe and the water jet pump; and the diffuser pipe in the pressurizer is connected with a water outlet pipe and the air suction pump. The nozzle in the pressurizer jets at a high speed, and jet waterflow and saturated wastewater are mixed and flow together into the diffuser pipe to be subjected to deceleration and pressurizing to be changed into unsaturated water to be drained by the water suction pump.

Owner:HIT HARBIN INST OF TECH KINT TECH

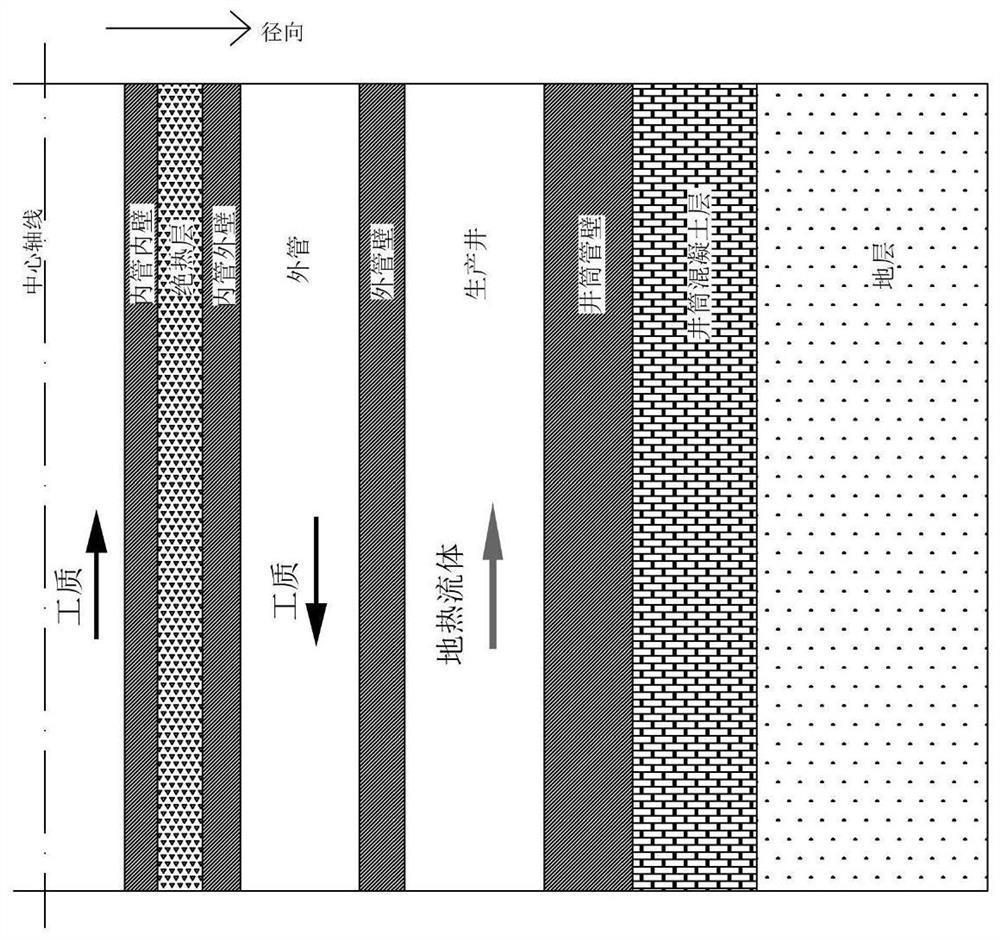

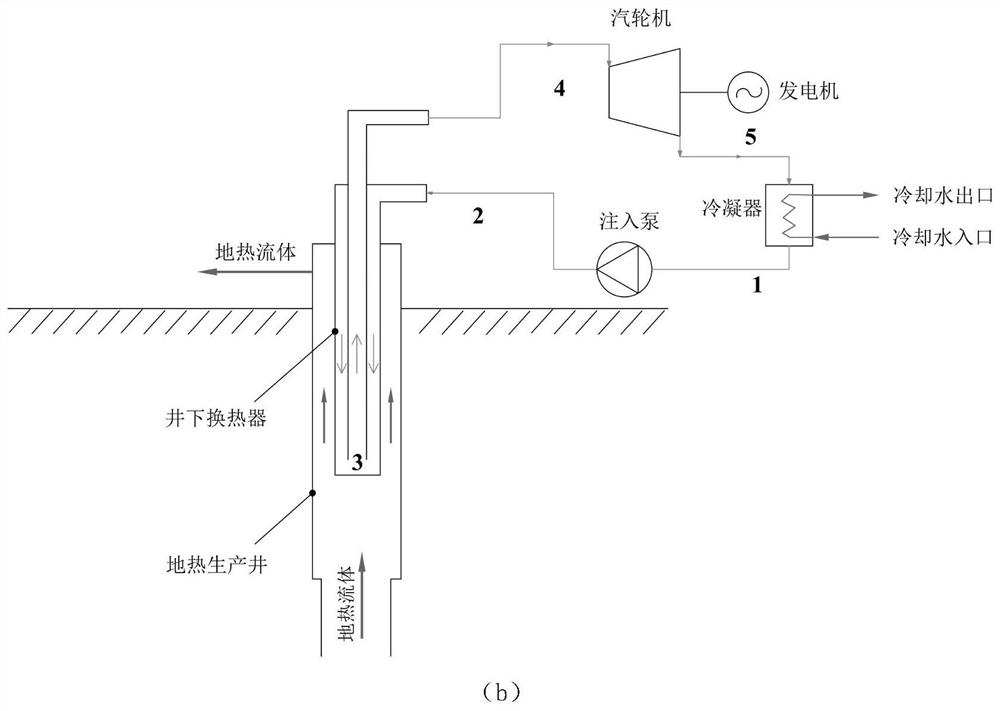

Pressurization and heat absorption transcritical cycle hot dry rock geothermal power generation model based on CO2 mixed working medium

InactiveCN112065521AConsider thermal propertiesTaking into account stabilityGeothermal energy generationSteam generationTranscritical cycleBinary cycle

The invention relates to a pressurization and heat absorption transcritical cycle hot dry rock geothermal power generation model based on a CO2 mixed working medium, which comprises a geothermal watercycle, a mixed working medium cycle and a cooling water cycle; and an underground coaxial sleeve heat exchanger is arranged in the mixed working medium cycle. The innovation is reflected in that a pressurization and heat absorption process is realized by utilizing a gravity field, so that the cycle heat absorption capacity is increased, and the cycle power generation is increased. A binary mixedworking medium composed of CO2 and an organic working medium is adopted; and therefore, a transcritical cycle with pressurization heat absorption and temperature reduction heat release can be achieved, irreversibility of heat exchange of a heat source and a cold source can be effectively reduced, and the cycle efficiency is improved. The mixed working medium adopted by the cycle comprises (but notlimited to) CO2 / R32, CO2 / R161, CO2 / R1270, CO2 / R1234yf, CO2 / R134a, CO2 / R152a and CO2 / R1234ze. The pressurization and heat absorption transcritical circulation hot dry rock geothermal power generationmodel based on the CO2 mixed working medium mainly aims at hot dry rock geothermal resources, but is not limited to the hot dry rock geothermal resources; and the power generation system is also suitable for application occasions of other binary cycle geothermal power generation systems.

Owner:TIANJIN UNIV

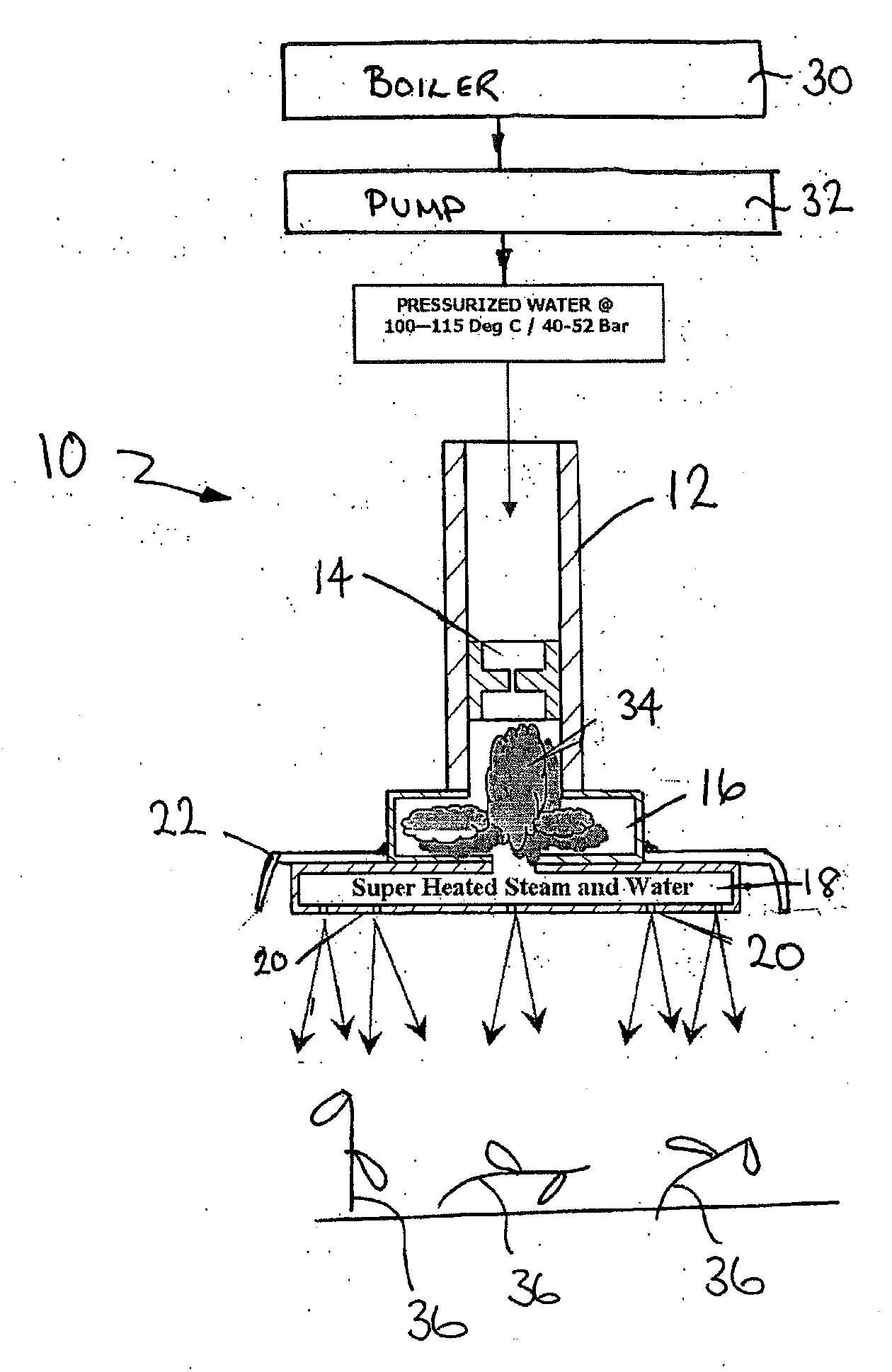

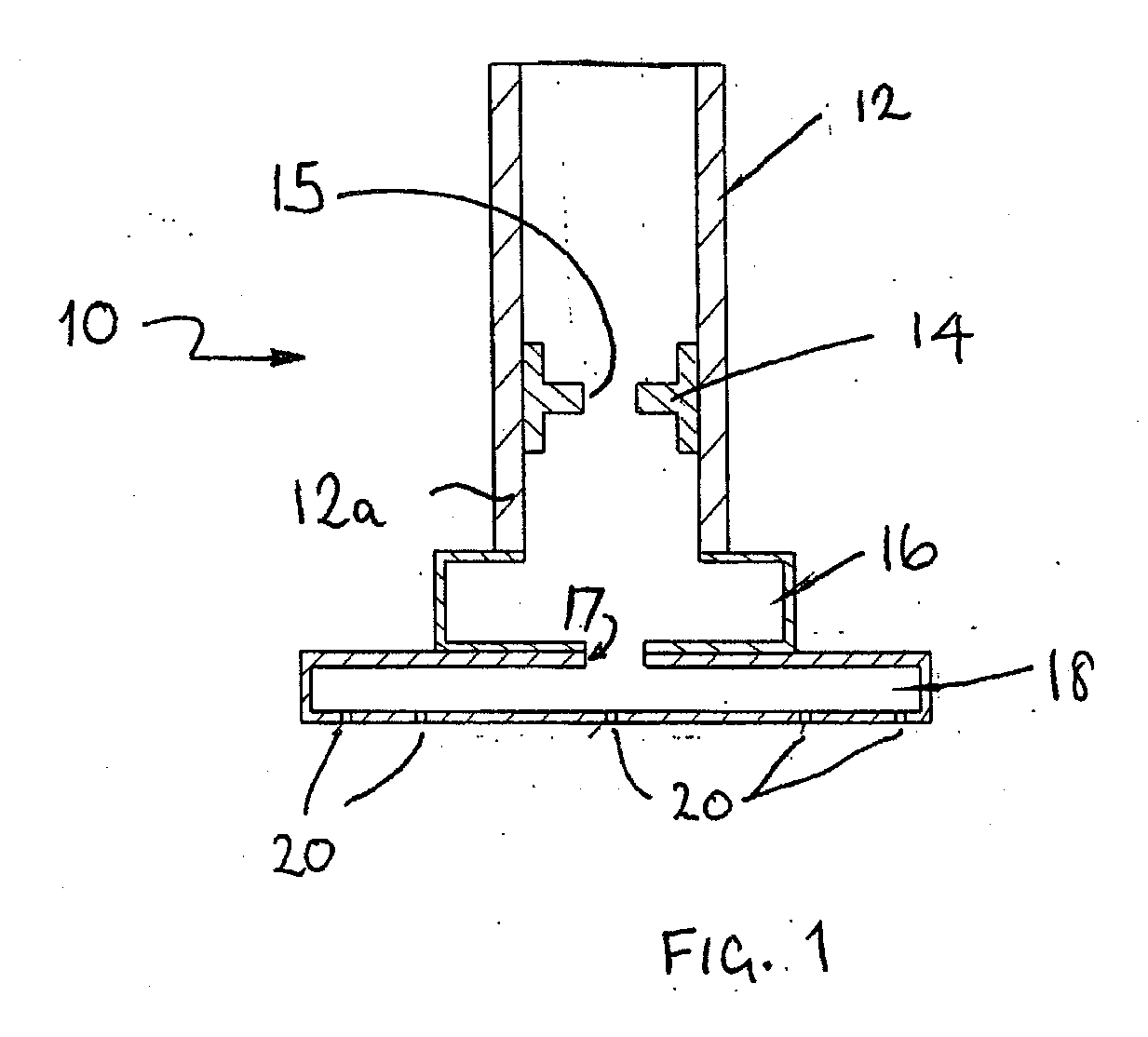

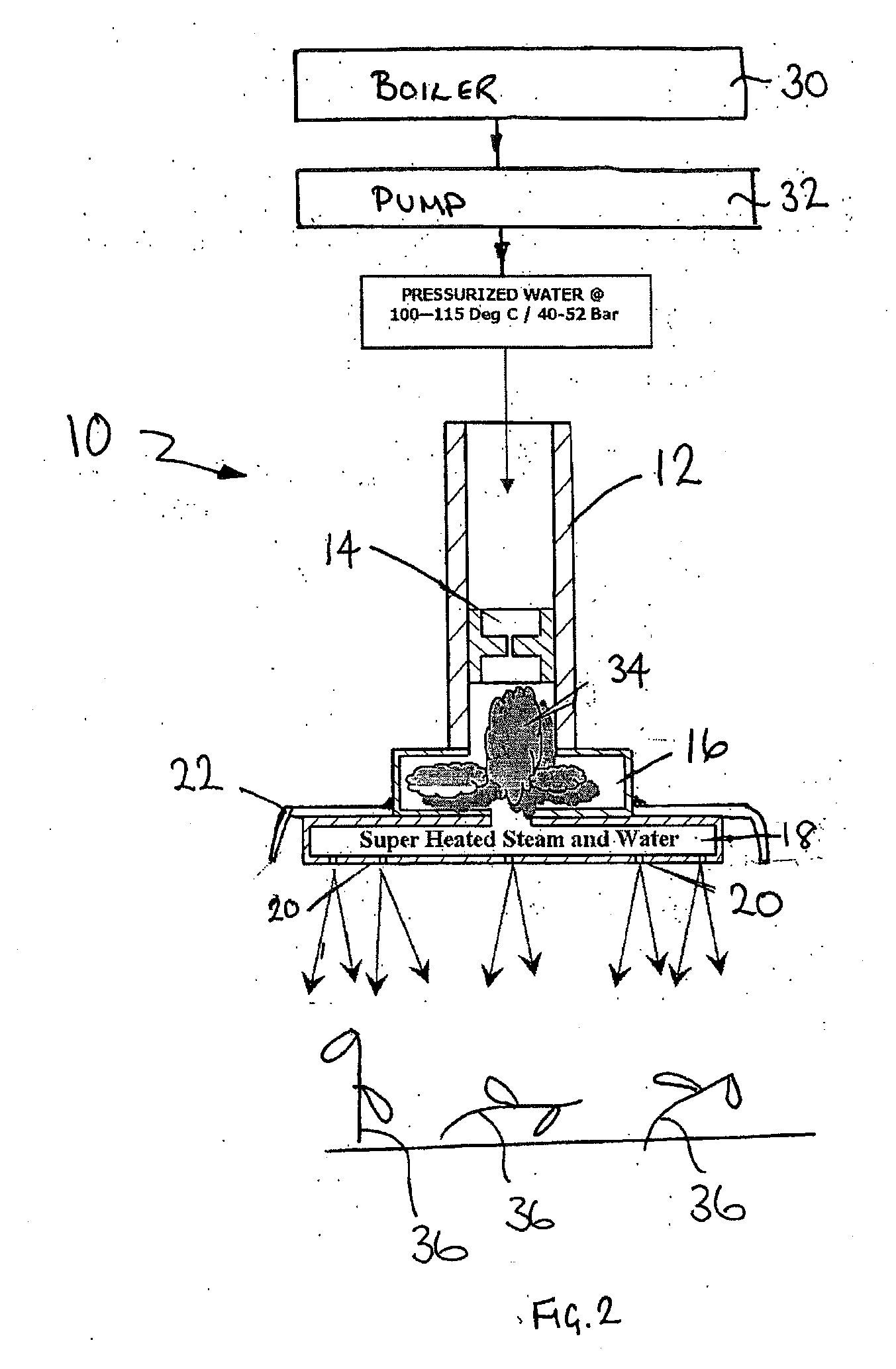

Apparatus producing superheated water and /or steam for weed killing and other applications

Apparatus producing superheated water and / or steam for weed (36) killing, etc. has diesel fired boiler (30), which, via pump (32), generates hot water at a pressure of 40-52 bar and temperature of 90-115° C. This passes down tube (12) and encounters the constriction provided by nozzle (14). Passing through nozzle (14) into depressurisation chamber (16), which is at atmospheric pressure, the water boils. When the super heated water exits ports (20) of distribution pipe (18) it encounters ambient temperature and is transformed into high temperature water vapour and / or water droplets. The apparatus controls or kill weeds (36) using a smaller volume of water and less energy.

Owner:STEAMWAND INT

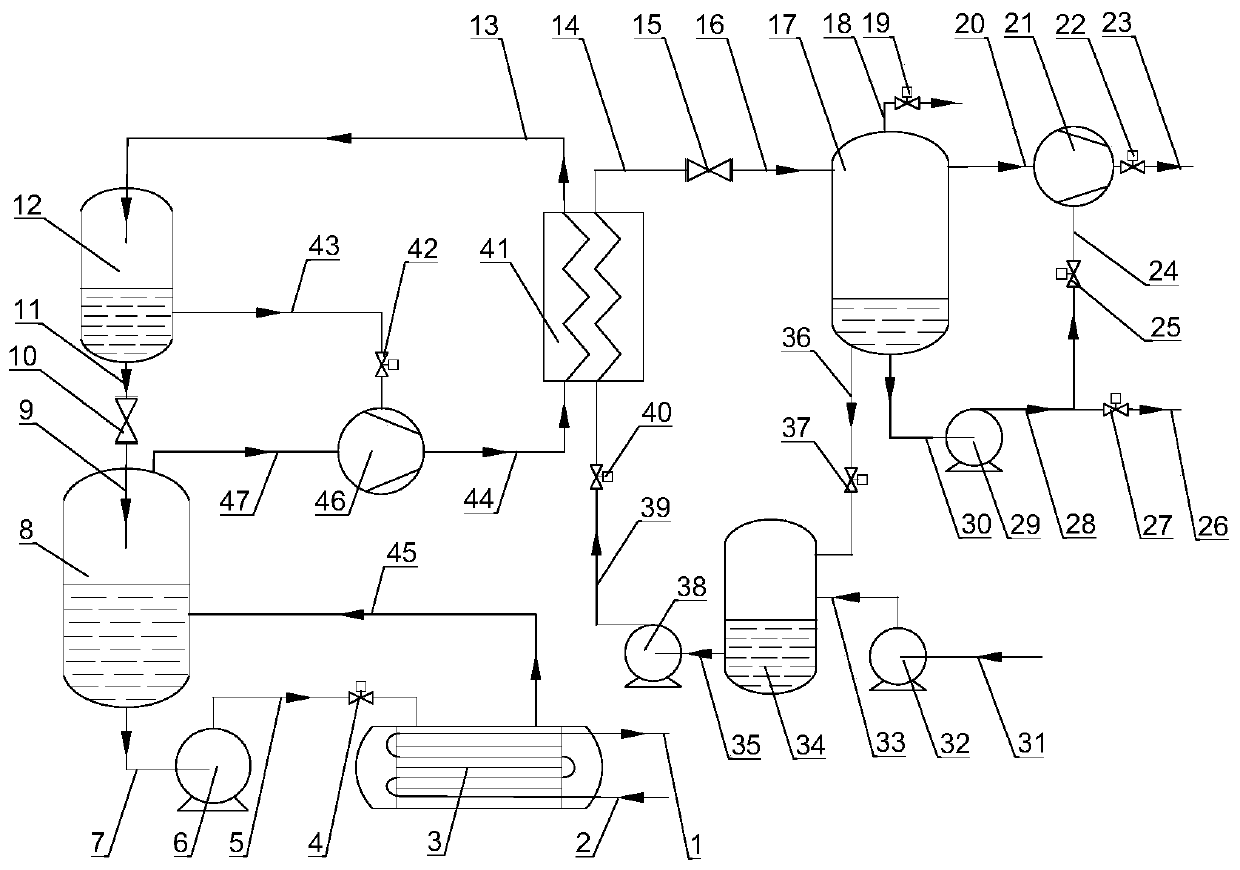

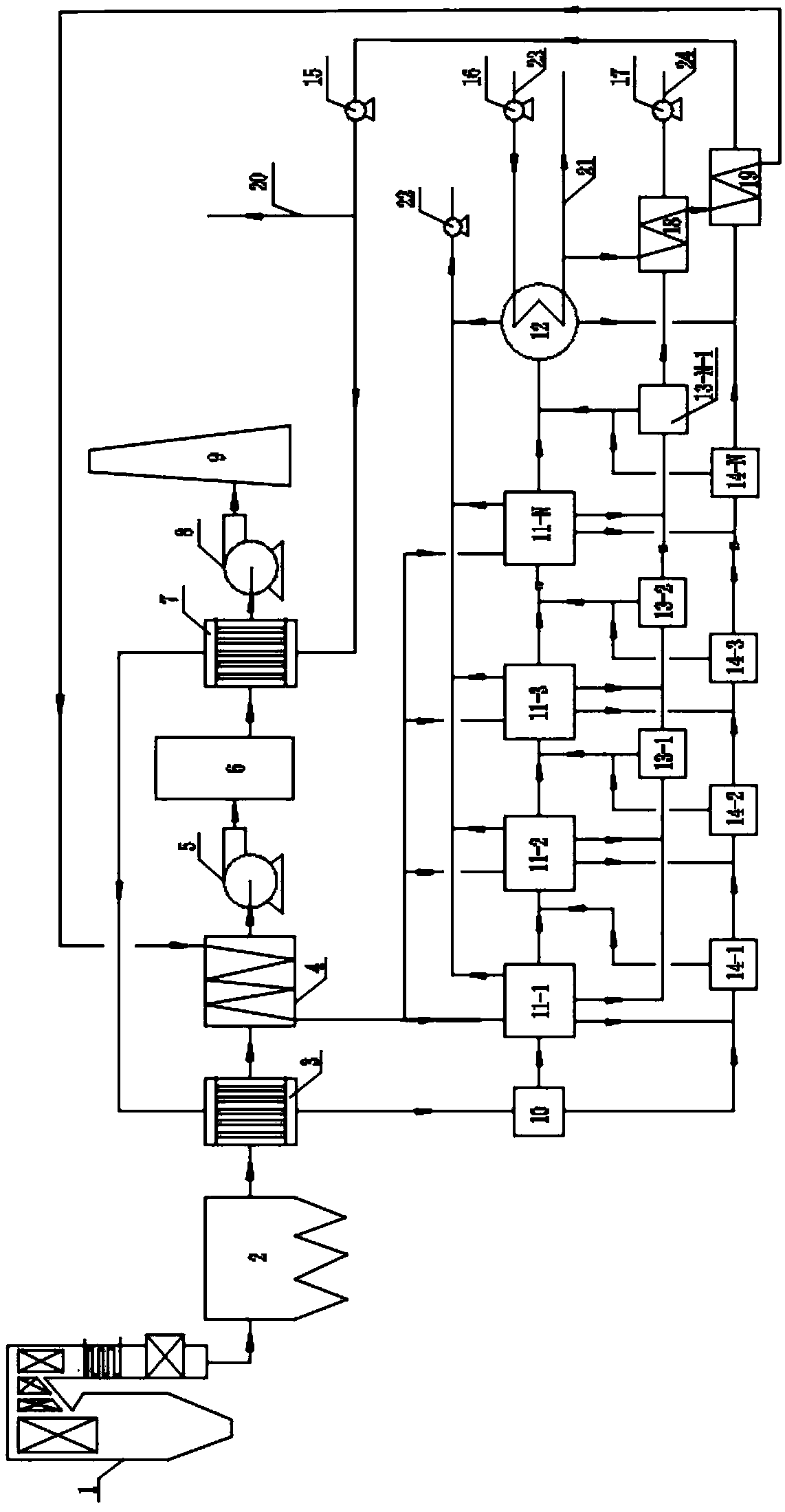

Low-pressure steam, high-pressure steam and high-temperature hot water triple-supply water actuating medium heat pump system

ActiveCN110186219AReduce usageLow costHeat pumpsEnergy efficient heating/coolingOzone layerAtmospheric air

The invention provides a low-pressure steam, high-pressure steam and high-temperature hot water triple-supply water actuating medium heat pump system. The system comprises a low-grade waste heat recovery heat pump subsystem and a steam hot water triple supply subsystem, wherein the low-grade waste heat recovery heat pump subsystem and the steam hot water triple supply subsystem both adopt a wateractuating medium, and the low-grade waste heat recovery heat pump subsystem is connected with the steam hot water triple supply subsystem through a condenser. According to the system, the natural water actuating medium is used as a working medium of the whole heat pump system, the water actuating medium has no damage effect on atmospheric ozone, the greenhouse effect is not generated basically, the use of an artificial synthetic actuating medium with high damage to an ozone layer and high greenhouse effect is avoided, and the environment is effectively protected.

Owner:SHANGHAI JIAO TONG UNIV +1

Low-position straight heating machine

The invention provides a low-position straight heating machine. The structure of the low-position straight heating machine comprises an evaporator, a condenser and a deaeration device, wherein the evaporator and the condenser are arranged up and down; the evaporator is a horizontal type pressure container, waste water at the middle and high temperature enters the evaporator through a water inlet pipe, is sprayed out downward from a long and narrow nozzle of a spray pipe, flows along a surface of a water spraying tray and downward from the edge of the water spraying tray, and simultaneously is evaporated through flash vaporization; generated vapors enter the condenser through a vapor channel, and residual waste water after the flash vaporization is discharged through a water suction pump; the condenser is a shell tubular heat exchanger, heating circulating water enters a hot water pipe of the condenser, performs heat exchange with vapors outside the pipe through the pipe wall, after the heating circulating water is heated through a few of processes, the heating circulating water flows out from a water outlet pipe; the vapors entering from the vapor channel bypass a baffle plate and flow curvedly and condensate for heat release; and condensation water accumulated at the bottom of the condenser flows out through a condensation water pipe. Besides, an exhaust pipe is arranged above the tail end of the condenser and connected with a vacuum pump, so that non-condensable gas in the condenser is sucked out.

Owner:HIT HARBIN INST OF TECH KINT TECH

Direct heater

The invention discloses a direct heater. The direct heater mainly structurally comprises an evaporator, a condenser and steam channels. The evaporator and the condenser are arranged left and right, and the steam channels are arranged between the evaporator and the condenser. Medium-temperature waste water and high-temperature waste water evaporate in the evaporator to generate steam, and the steam of the evaporator enters the condenser for condensation and heat release through the steam channels. The direct heater is characterized in that the condenser is formed by vertically connecting three dividing wall type heat exchangers in series; the steam channels structurally comprise barrels and fans on the barrels; the barrels are round steam pipelines and are connected between steam outlets of evaporation chambers of the evaporator and steam inlets of condensation chambers of the condenser through flange plates; and the fans on the barrels comprise motors, drive belts, drive shafts and impellers, the impellers are driven by the motors to rotate in the barrels through the drive belts and the drive shafts, and the steam is pushed to flow and flows to the condenser from the evaporator.

Owner:HIT HARBIN INST OF TECH KINT TECH

Sea water desalination system based on steam trapping and waste heat recovery for flue gas from power plant

ActiveCN109160563AReduce water consumptionReduce water vapor contentGeneral water supply conservationSeawater treatmentWater desalinationTrapping

The invention discloses a sea water desalination system based on steam trapping and waste heat recovery for flue gas from a power plant. A boiler is connected with a dust catcher, shell pass of a first steam absorber, shell pass of a flue gas waste heat recoverer, an induced draft fan, a desulfurizer, shell pass of a second steam absorber, a booster fan and a chimney through a pipeline; low-temperature fresh water is heated by the second steam absorber and the first steam absorber, enters a flash evaporator and flashes in the flash evaporator to produce steam which serves as heating steam of afirst-effect evaporator of the sea water desalination device; part of cooling drained water of a condenser passes through a concentrated water heat recoverer, a fresh water heat recoverer and a fluegas waste heat recoverer, after heat recovery, the water serves as a fed material to enter multiple effect evaporators. The sea water desalination system has the advantages that steam in the flue gascan be trapped, flue gas corrosion can be reduced, water consumption of the desulfurizer can be reduced, and sea water desalination can be realized by waste heat.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Subcritical damp steam generating system by petroleum sludge innoxious energy-gathering treatment

The invention discloses a technological device system which aims at harmless treatment and resource energizing utilization of petroleum mud residue waste produced in process of petroleum production and refining. The system components comprise a petroleum mud residue pretreatment system, a pyrolytic incineration system, an exhaust treatment system, an energizing utilization system, and an automatic monitoring system. A technological process that petroleum mud residue pretreatment->pyrolytic incineration->energizing utilization->exhaust acid and dust removal->discharge while reaching environmental protection standard. Oilfield wet vapor of subcritical super high pressure produced by energizing treatment after the pyrolytic incineration of the petroleum mud residue is applied to steam injection in oilfield and oil well. The petroleum mud after efficient utilization no longer contains petroleum or other harmful components, thus meeting environmental protection requirements and realizing aim of minimizing, harmless treatment and resource utilization of dangerous waste treatment.

Owner:张俊林

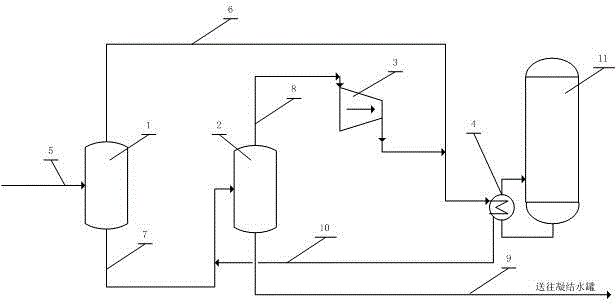

Condensate heat recovery method using double flashing and pressurizing

The invention relates to a condensate heat recovery method using double flashing and pressurizing and aims to solve the problem that in the traditional techniques, condensate heat is greatly wasted. By introducing a two-stage flashing technique and a vapor compression technique, heat in condensate can be recycled in the form of low-pressure vapor; the method is suitable for recovering the heat of vapor condensate at the temperature lower than 190 DEG C and under the pressure lower than 1.0 MPaG. The method includes the steps of primary flashing of condensate, secondary flashing and pressurizing, and returning and reusing of condensate occurring after flash steam heats medium. The method has the advantages that energy recovery rate is high and vapor value is high.

Owner:张高博

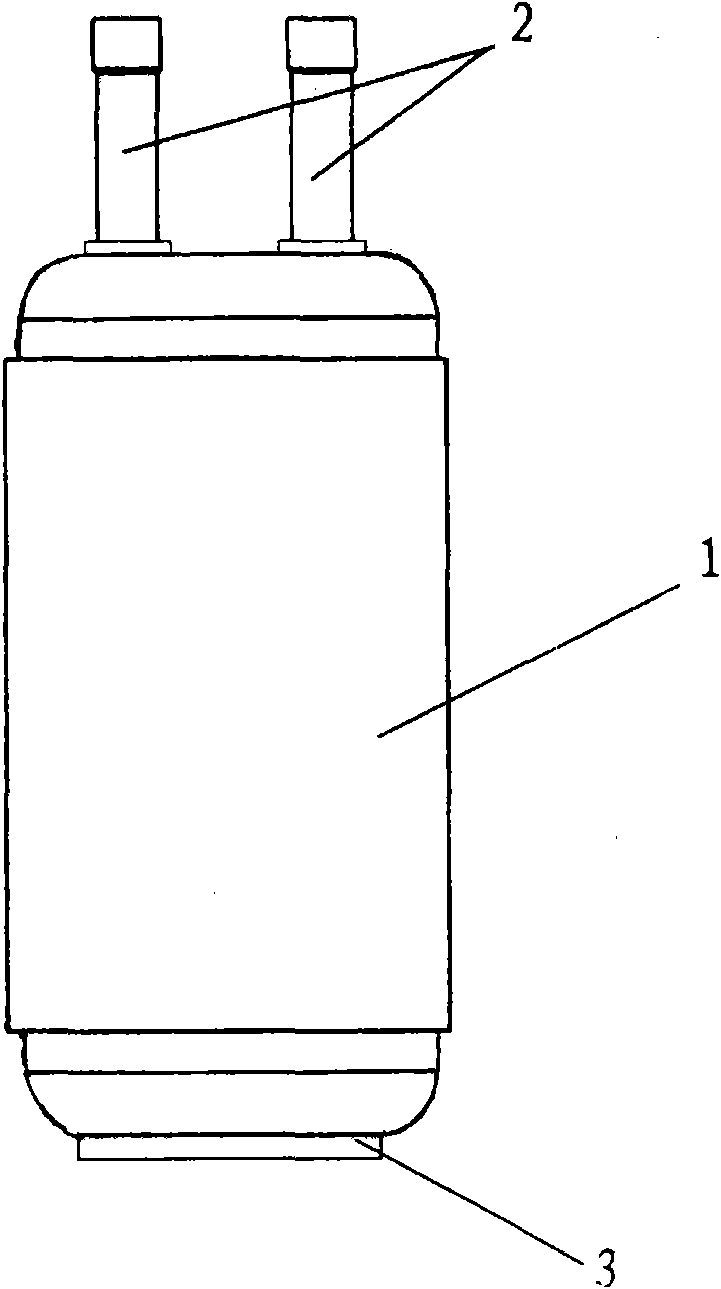

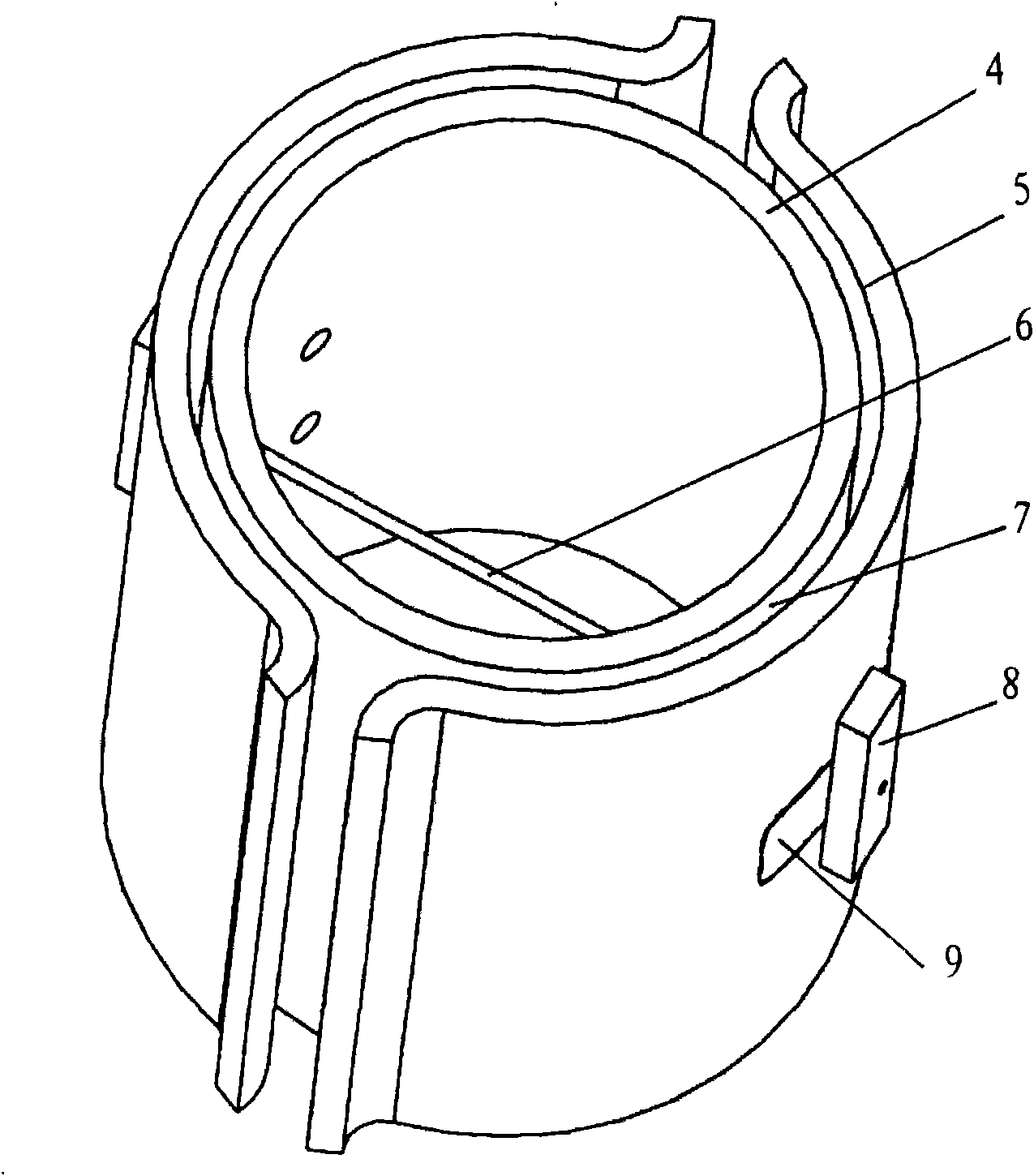

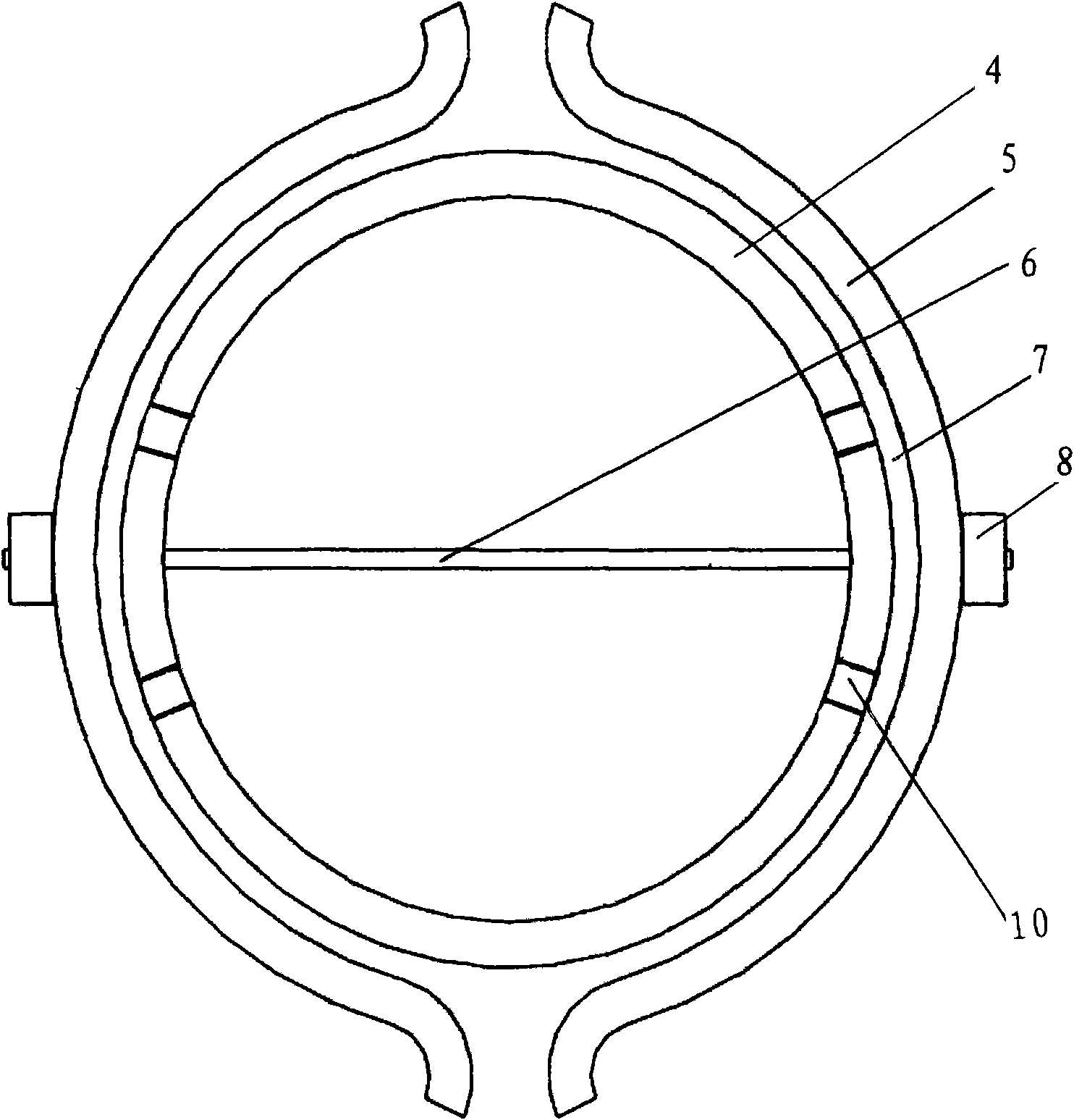

Manufacturing clamp for induction electric heater of liquid collection tank of gas-liquid separator

InactiveCN101644513AHeating evenly and efficientlyIncrease contact areaSteam generationRefrigeration componentsElectricityElectrical resistance and conductance

The invention relates to a manufacturing clamp for induction electric heater, which consists of a cylindrical internal cylinder and curved surface shells. Two pieces of symmetrical curved surface shells are fixed on the outer side of the internal cylinder by a metal threaded rod, and arc-shaped gaps are reserved between the internal cylinder and the curved surface shells. A winding core of the electric heater is formed by winding a resistance wire in the gaps between the internal cylinder and the curved surface shells along the outer wall of the internal cylinder, and the wall of the internalcylinder is provided with four symmetrical threading holes used for selecting the starting position of winding the resistance wire randomly. A locking piece arranged outside the curved surface shellscan rotate at the end of the metal threaded rod, and the locking piece is rotated to separate the curved surface shells from the metal threaded, and to take the manufactured induction electric heaterdown. The induction electric heater consists of double-cambered-surface winding cores of the electric heater, is fixed on the outer side of a liquid collection tank through a clamp, and is suitable for the liquid collection tanks of all gas-liquid separators; besides, by enlarging the contact area of the electric heater and the liquid collection tank, the electric heater heats the gas-liquid separators more evenly and effectively; moreover, the electric heater is very convenient to mount, maintain and replace, and the reliability of an air container is improved.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Method for obtaining high-pressure steam through absorbing heat from low-pressure steam

InactiveCN102937286AIncrease usageTake advantage ofEnergy industrySteam generationComing outEngineering

The invention relates to a method for obtaining high-pressure steam through absorbing heat from low-pressure steam, which is capable of improving the utilization rate of waste-heat steam and achieving an obvious energy-saving effect. A device for implementing the method is mainly composed of an expansion pipe, a heat exchanger, a diffuser pipe, a condensed water outlet, a steam pipeline, a high-pressure steam generator, a high-pressure feedwater inlet and a high-pressure steam outlet. According to the invention, the waste-heat steam enters the expansion pipe to be mixed with a part of steam coming out form the high-pressure steam generator, then flows out from the expansion pipe at a high flow speed, successively enters the heat exchanger to indirectly exchange heat with the other part of the steam coming out form the high-pressure steam generator and finally enters the diffuser pipe to be diffused and heated to obtain the high-pressure steam; the other part of the steam coming out form the high-pressure steam generator gives out heat to be turned into condensed water which is discharged; the high-pressure steam discharged from the diffuser pipe is used for heating high-pressure feedwater in the high-pressure steam generator, then is discharged from the high-pressure steam generator after being cooled and finally enters the expansion pipe and the heat exchanger respectively; and the high-pressure feedwater is discharged after being heated to the high-pressure steam by the high-temperature steam in the high-pressure steam generator.

Owner:尹华勤

Popular searches

Combined combustion mitigation Closed-cycle gas positive displacement engine plant Steam engine plants Semiconductor devices Hot gas positive displacement engine plants Liquid degasification arrangements Continuous jet plants Ram jet engines Turbine/propulsion fuel heating Direct carbon-dioxide mitigation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com