Pressurization and heat absorption transcritical cycle hot dry rock geothermal power generation model based on CO2 mixed working medium

A technology of mixed working fluid and geothermal power generation, which is applied in geothermal power generation, collectors using groundwater as working fluid, geothermal energy, etc. To achieve the effect of reducing the irreversibility of heat transfer, saving pump work and improving cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

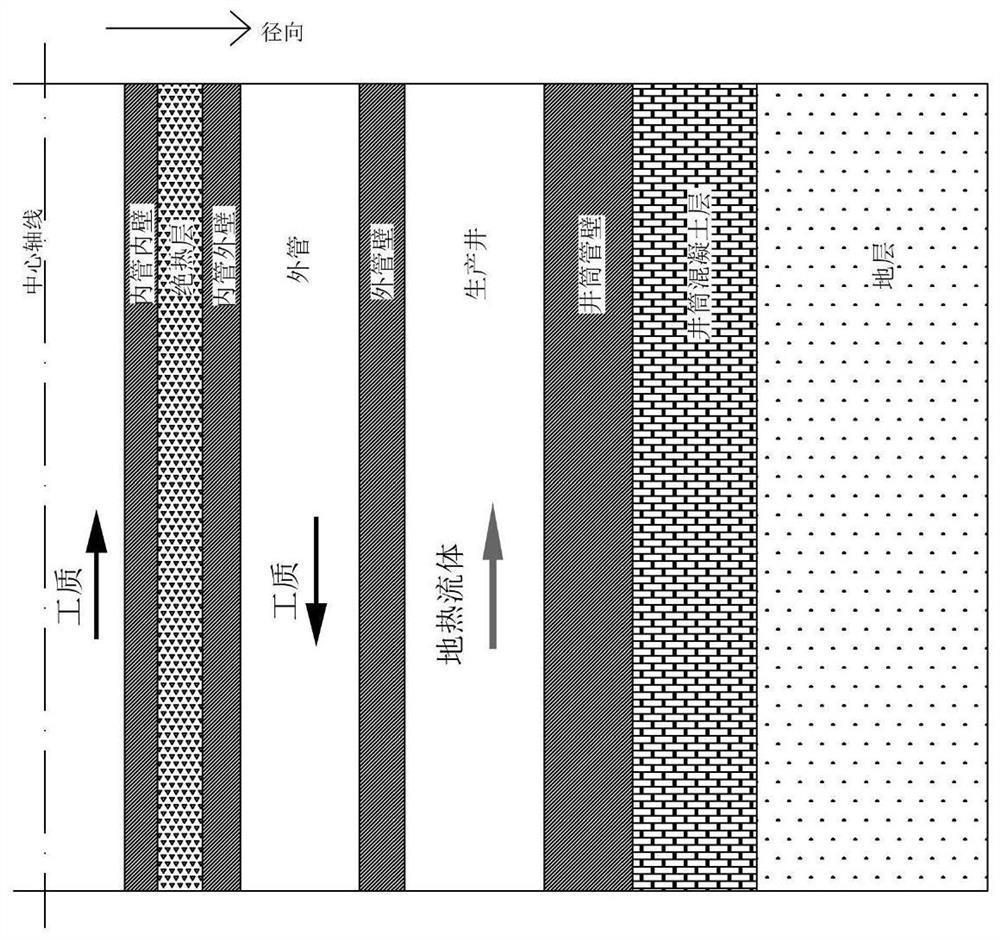

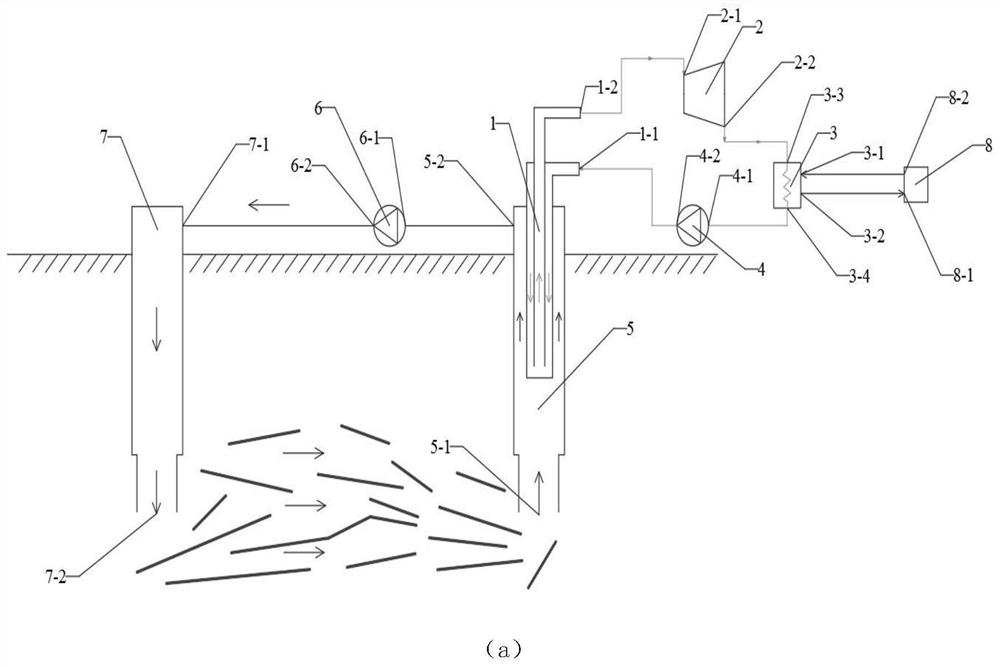

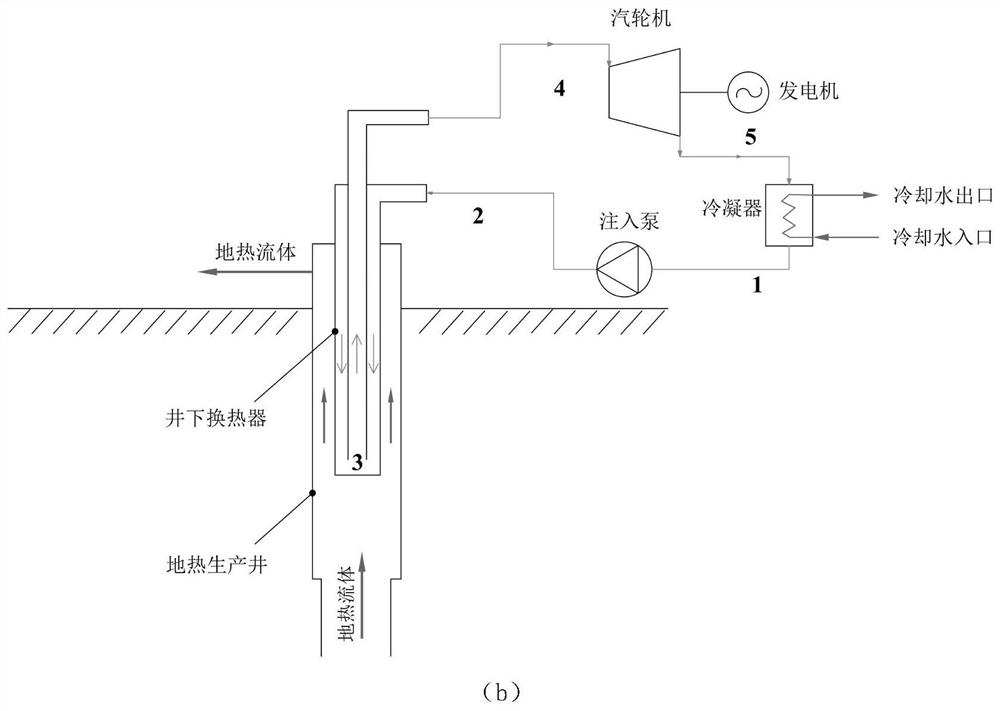

Method used

Image

Examples

specific Embodiment

[0134] The simulation of the present invention adopts the patternsearch algorithm for optimization calculation, and the output work of the geothermal fluid per unit mass (hereinafter referred to as the specific output work) is used as the objective function, and the mixing ratio of the mixed working medium, the working medium injection pressure of the downhole heat exchanger and the working medium flow as an independent variable. In the simulation, the mixing ratio range of the mixed working fluid is 0.1-0.9, the injection pressure range of the working fluid is 10MPa-18MPa, and the mass flow range of the working fluid is 1kg / s-10kg / s. The simulation considers two cases where the geothermal fluid temperature is 120°C and 180°C, and the calculation results are shown in Table 3 and Table 4.

[0135] In addition, the influence of in-situ hot water flow rate, downhole heat exchanger length and operating fluid type on the thermal performance of the system was also calculated and ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com